6 minute read

RAPID + TCT PREVIEW

Next Article

RAPID + TCT celebrates its 30th year on 13-15th September in Chicago. Here, we take a look at what you can expect from North America’s largest AM event.

After two years, two rescheduled dates and too many Zoom calls and online conferences to count, RAPID + TCT returns in-person this September to celebrate three decades of additive manufacturing (AM) innovation, promising much-needed face-to-face connections and everything you need to know about the latest 3D technologies, all under one roof.

Much like TCT 3Sixty in the UK, RAPID + TCT will provide a first opportunity for the AM community in North America to see first-hand the new technologies launched over the last year. From producing PPE and nasal swabs to major acquisitions and new machines, the technology breakthroughs have kept coming and, as always, there are plenty of launches expected to take place across the three days at McCormick Place.

THE SHOW FLOOR

More than 250 exhibitors are gearing up to bring their latest machines, software, materials and applications, with over 125 new products expected to be showcased at the event. AM software developer Dyndrite (E7219) will be offering demos of its AM tools and APIs tuned for serial production, while nTopology (E6901), building on a collaboration with Stratasys announced last year, will be taking feedback on various parts it has been working on through the partnership. It will no doubt be a busy show for Stratasys (E8201) too which has had an exciting 12 months of launches, including its Selective Laser Absorption process and acquisition of Origin’s P3 technology.

Large-format AM specialist Massivit (E7249) will be exhibiting its Massivit 5000 machine. Based on its Gel Dispensing Printing (GDP) technology, the machine leverages an advanced thermoset photopolymer gel that cures on-the-fly to enable large parts to be produced within hours. For even more large-scale printing, BigRep (E8228) will be demonstrating the capabilities of its BigRep PRO with examples from automotive interior parts to jigs and fixtures and even a mold for a humansized drone.

Fresh off the back of its 500+ machine install milestone, industrial laser powder bed fusion system manufacturer Farsoon Technologies (E7222) will be showcasing its flagship plastic production machine the Flight HT403P, as well as large-formatmetal industrial solutions.

Digital manufacturing provider Fast Radius (E8901) will be showcasing the power of its Cloud Manufacturing Platform through end-use applications including recent 3D printed lattice inserts which are being manufactured at scale for Rawlings’ next-generation REV1X baseball glove.

Having first introduced the technology back in April, Essentium, Inc. (E7625)

LAURA’S PRESENTATION PICKS

13th September | 09:00-10:00

MAIN STAGE

Keynote: How AM is Disrupting the Aerospace Industry: Opportunities and Challenges on the Road Ahead Melissa Orme, PhD | Boeing 14th September | 13:30-14:45

MAIN STAGE

Panel: Hospital-Based 3D Printing: Better Patient Care Through InHouse Manufacturing? Andy Christensen, FSME | University of Cincinnati Jonathan Morris, MD | Mayo Clinic Peter Liacouras, PhD | Walter Reed National Military Medical Center Beth Ripley, MD, PhD | VA Puget Sound Health Care System Nicole Wake, PhD | Montefiore Medical Center

15th September | 12:30-13:30

SME ZONE THEATER

Career Development Forum: Career Pathways of AM – A Panel Discussion Jennifer Coyne | The Barnes Global Advisors Ellen Lee, PhD | Ford

AT THE FOREFRONT OF TECHNOLOGY

FIERCELY CUSTOMER FOCUSED

Experience Matters.

Dinsmore Inc. has over 20 years of expertise in 3D Printing, which means we know how to bring your project from prototype to production as efficiently as possible. Our customer experience is second to none— we focus on digging deep to find out what you need for your design to be successful. With multiple technologies under one roof, Dinsmore is committed to matching our clients with the best technology for their projects.

TECHNOLOGIES:

MJF • FDM/FFF • DMLS • SLS • POLYJET CARBON DLS • DLP • SLA/FRSLA

MATERIALS:

NYLON 12 PA ABS-M30I NYLON SIL 30 AGILUS30 MPU 100 BIOCLEAR SI 60 RPU 70 ULTEM 9085 ULTEM 1010 EPX 82 PC ASA CE 221 UMA 90 VEROWHITE PC-ABS PERFORM + MORE

Constantly Expanding Our Capabilities and Technologies

Carbon L1

Large frame Carbon DLS printer for product designers, engineers and manufacturers. Dinsmore is the first service bureau on the West Coast to offer this solution.

Stratasys Digital Anatomy J850

Creates human anatomy that mimics bone and tissue.

Stratasys Neo 800

Large frame SLA that builds highquality parts with superior surface quality, accuracy and detail.

Post Pro 3D

Automated chemical vapor smoothing system for MJF, FDM and FFF parts.

dinsmoreinc.com

SAM'S PRESENTATION PICKS

13th September | 10.30-11.45

MAIN STAGE

Breakthrough to Manufacturing with AM - What you need to know Jerone Anderson | General Motors Nic Sabo | GE Additive Callie Zawaski, PhD | Virginia Tech Todd A. Grimm | T.A. Grimm & Associates

14th September | 9.00-10.00

MAIN STAGE

An industry 30+ years in the making Terry Wohlers | Wohlers Associates 15th September | 13.00-13.30

AM CLASSROOM A

3D printing emissions and their impact on health and indoor air quality Qian Zhang, PhD | Underwriters Laboratories

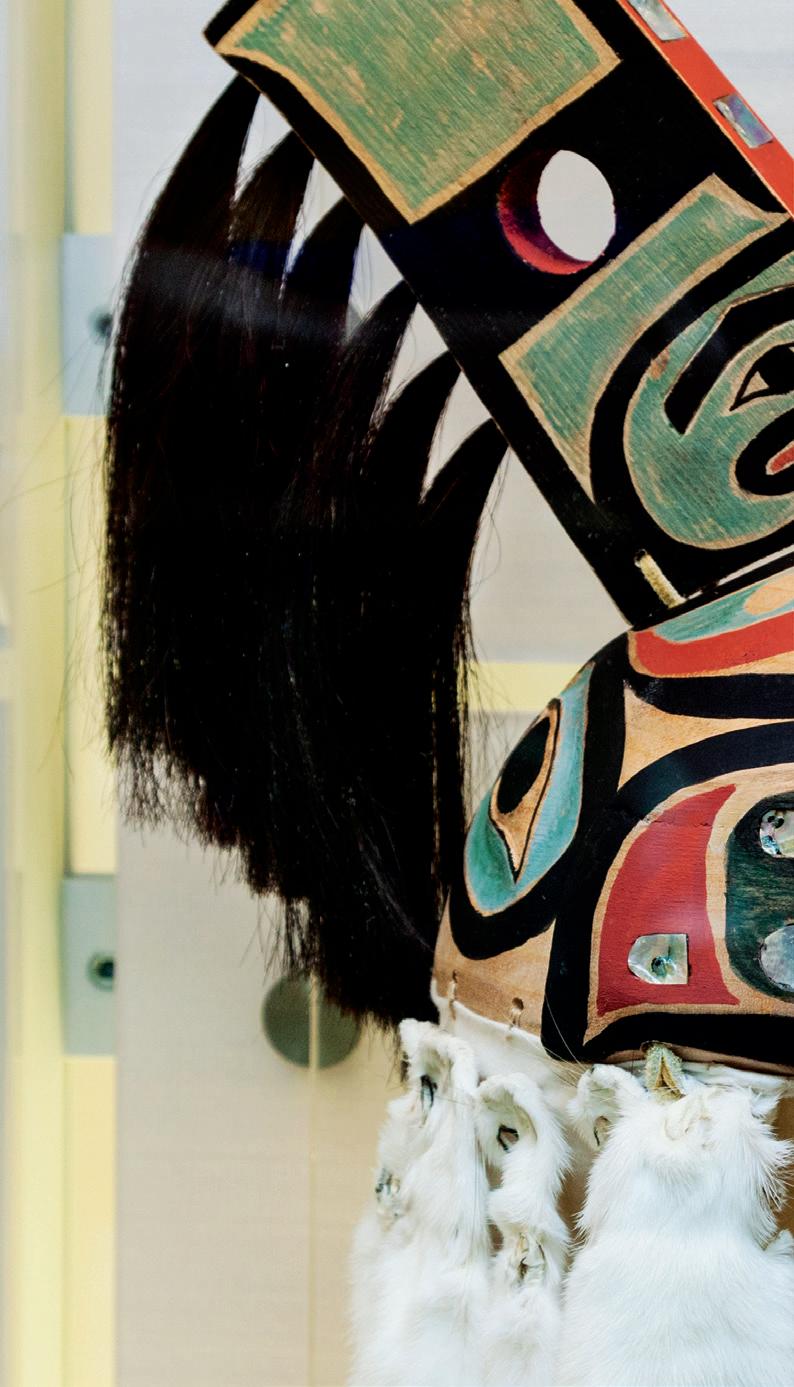

SHOWN:

THE RAPID + TCT CONFERENCE WILL FEATURE OVER 150 AM LEADERS

“The conference will focus on evaluation, adoption & optimization.”

will make the first public demonstration of its Essentium High Speed Extrusion (HSE) 280i HT 3D Printer. Equipped with an independent dual extrusion system (IDEX), the machine has been designed to meet the ‘demands of the factory floor’.

Big Metal Additive (BMA) (E8050) will be presenting prototypes made from its unique metal hybrid additive manufacturing process. The booth will have several parts on display and visitors can learn about a challenging full-scale 50” x 64” x 26” eVTOL optimized airframe component.

Visitors will have a chance to see parts printed in XJet’s (E7401) recently launched alumina ceramic material and Indo-MIM (E7652) will also be showcasing components from its metal component manufacturing services which utilizes binder jet and DMLS printing, and now ceramics.

Nexa3D (E7428) will be presenting its end-to-end validated workflow for the first time. The booth will feature the NXE400 3D printer and NXD200 dental system, alongside postprocessing equipment plus its ultrafast thermoplastic production system, the QLS350.

Bodycote (E8749) will be sharing its expertise in thermal processing services and solutions, such as hot isostatic pressing (HIP), EDM and heat treatment, and visitors can also get a look at Materialise’s (E7813) new Process Tuner software which is now being made available to U.S. customers. The company will also be running a competition that invites visitors to show why they are an “AM Champion”.

On software, AlphaSTAR (E8241) will be on hand to discuss the latest instalment of its GENOA3DP platform and its ability to model various additive manufacturing processes and materials. Meanwhile Roboze (E7231) will debut its latest Prometheus software and will also be providing live demonstrations of industrial end-use parts made from super polymers and composites like PEEK and Carbon PEEK with its ARGO 500 and Roboze One+400 Xtreme 3D printers.

CONFERENCE

Adopting a similar approach to our UK event, the RAPID + TCT Conference will focus on the three themes of Evaluation, Adoption and Optimization with over 70 presentations planned from 150+ speakers.

On the Main Stage, visitors can hear from a trio of industry-leading keynote speakers including Melissa Orme, Boeing; Terry Wohlers, Wohlers Associates; and Mark Wehde, Mayo Clinic. The Main Stage will also play host to 11 thought-leadership panels covering topics from “Breakthrough to Manufacturing with AM – What You Need to Know” to “Supply Chain Transformation”.

Across four classroom stages, attendees can take in real-life examples of AM adoption and case studies that show how the technology is transforming traditional manufacturing from design to post-processing and casting. There will also be an entire track dedicated to one of AM’s fastest growing areas of application: medical. Throughout, speakers will present on topics ranging from personalised implants to dental devices and bioprinting headlined by a keynote from Mayo Clinic on “How Technology is Changing Healthcare.”