Zero Outsourced Engineering and Service

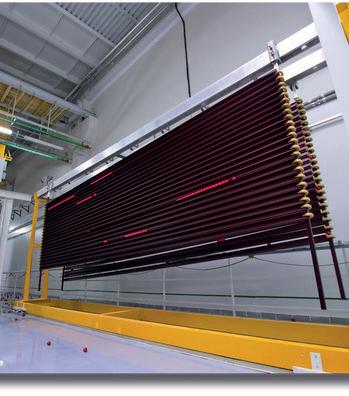

From concept to completion, all mechanical and controls engineering is completed in-house. Our trained service engineers and technicians use the most advanced tools to keep your equipment performing at peak efficiencies.

100% USA Engineered & Manufactured

All Granco Clark equipment comes from our 92,000 square foot modern Michigan facility providing the industry’s most innovative custom equipment built with the exceptional quality you come to expect from Granco Clark. Our repeat customers attest to that.

All-inclusive Turn-key System Supplier.

Granco Clark is your all-inclusive turn-key system supplier. Expect superior performance, industry knowledge, unmatched and proven solutions, onsite commissioning, support, and responsive service technicians.

Our industry knowledge and experience are superior and proven, with our custom-engineered equipment delivering the solutions and performance you expect from Granco Clark.

Being a full-service company means we are with you from the initial planning phase of the project through the start of production and beyond. You will have access to unmatched industry service, support and parts. Our global team of trained service technicians are available to keep your production facility always running smoothly and provide on-site service (in most cases, within 24 hours).

100% Employee-owned Contact us to discuss your next project. +1-800-918-2600 | www.grancoclark.com We are 100% customer focused. Engineering. Manufacturing. Global Support. Excellence is our standard.

Editorial

Editor: Nadine Bloxsome

Tel: +44 (0) 1737 855115 nadinebloxsome@quartzltd.com

Assistant Editor: Zahra Awan

Tel: +44 (0) 1737 855038 zahraawan@quartzltd.com

Production Editor: Annie Baker

Sales

Commercial Sales Director: Nathan Jupp nathanjupp@quartzltd.com Tel: +44 (0)1737 855027

Sales Director: Ken Clark kenclark@quartzltd.com

Tel: +44 (0)1737 855117

Advertisement Production

Production Executive: Carol Baird

Managing Director: Tony Crinion CEO: Steve Diprose

Circulation/subscriptions

Jack Homewood

Tel +44 (0) 1737 855028

Fax +44 (0) 1737 855034 email subscriptions@quartzltd.com

Annual subscription: UK £270, all other countries £292. For two year subscription: UK £510, all other countries £527. Airmail prices on request. Single copies £50

ALUMINIUM INTERNATIONAL TODAY is published six times a year by Quartz Business Media Ltd, Quartz House, 20 Clarendon Road, Redhill, Surrey, RH1 1QX, UK. Tel: +44 (0) 1737 855000 Fax: +44 (0) 1737 855034

Email: aluminium@quartzltd.com

Aluminium International Today (USO No; 022-344) is published bi-monthly by Quartz Business Ltd and distributed in the US by DSW, 75 Aberdeen Road, Emigsville, PA 17318-0437. Periodicals postage paid at Emigsville, PA. POSTMASTER: send address changes to Aluminium International c/o PO Box 437, Emigsville, PA 17318-0437. Printed in the UK by: Stephens and George Ltd, Goat Mill Road, Dowlais, Merthyr Tydfil, CF48 3TD. Tel: +44 (0)1685 352063 www.stephensandgeorge.co.uk

Quartz

7 Creative use of aluminium weatherbreak

UPDATE

US Aluminium Outlook 2024

DECARBONISATION

16 India’s Vedanta Aluminium - leading the charge towards a sustainable future 20 Reshoring, recycling and efficiency pave the way 23 Aluminium industry decarbonisationA turning point? 25 Engineered aluminium’s role in decarbonisation

AEROSPACE

COATINGS

Explore the recent trends impacting aerospace coatings

Schelling Group

Expansion into Istanbul

INDUSTRIAL AI

Enhancing manufacturing systems with industrial AI

Dystopia or Utopia: November 2022

AUTOMATION

The rise of autonomous mobile robots

ROLLING

Meeting the demand for a stronger, lighter and more secure future

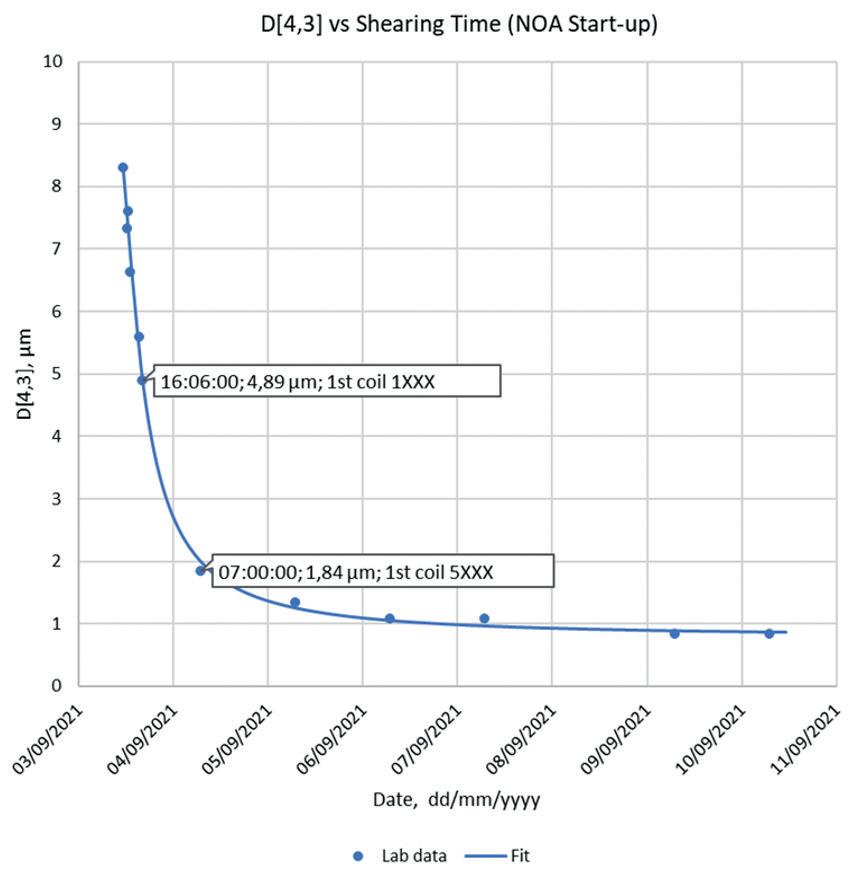

NOA hot rolling premium coolant technology

PARTNERSHIP

60 Mytilineos’ game-changing investment in Ghana

CONTENTS 1 www.aluminiumtoday.com Aluminium International Today May/June 2024 2 LEADER 2 NEWS Volume 37 No. 3 – May/June 2024 COVER Cover picture courtesy of GILLESPIE & POWERS, INC.

©

Business Media Ltd 2024 ISSN1475-455X Supporters of Aluminium International Today SEARCH FOR ALUMINIUM INTERNATIONAL TODAY 31 16 35 42 14 THE ALUMINA

GLOBAL

CHRONICLES

14

IMA

31

INTERVIEW:

35

40

42

49

57

53

It’s nearly that time of year again when the cobwebs are dusted off and the industry gets to meet at a host of industry events across the globe. May seems to be awash with conferences and exhibitions, all aimed at showcasing the latest technologies and developments across the sector.

As we gear up for our very own Future Aluminium Forum in Istanbul from the 21st - 23rd May, this issue offers a detailed look at enhancing aluminium manufacturing with AI and the rise of autonomous mobile robots (which isn’t as scary as it sounds!)

This is just a sneak peek into some of the topics we will be covering at the Forum and of course, where there is new technology, there is a focus on how this can support, or work hand in hand with decarbonisation efforts.

In a detailed focus report, Pernelle Nunez, Deputy Secretary General at the International Aluminium Institute, considers if we are at a turning point and where there are still significant efforts required with emission reduction in the sector.

We also hear from Vedanta’s CEO, John Slaven, about how he is leading the company in its sustainability efforts.

There is also all of the usual news, regional updates and an exclusive interview with Maximilian Lehner, CEO at IMA SCHELLING GROUP about the company’s latest opening of a new subsidiary in Istanbul.

Hopefully you have picked this issue up either at the CRU World Aluminium Conference, the Future Aluminium Forum or NorCast and you will get to see some of these articles and their topics brought to life in presentation form!

nadinebloxsome@quartzltd.com

Century Aluminum Company was selected by the U.S. Department of Energy (“DOE”) Office of Clean Energy Demonstrations to begin award negotiations for up to $500 million in Bipartisan Infrastructure Law and Inflation Reduction Act funding to build a new aluminum smelter as part of the Industrial Demonstrations Program (“IDP”).

Century’s Green Aluminum Smelter Project is one of 33 projects across more than 20 states to receive funding designed to demonstrate commercial-scale decarbonization solutions needed to

move energy-intensive industries toward net-zero while strengthening local economies, creating, and maintaining high-quality jobs, and slashing greenhouse gas emissions.

With the help of this funding, Century plans to build the first new U.S. primary aluminum smelter in 45 years. Upon completion, the smelter would double the size of the current U.S. primary aluminum industry.

This historic investment represents a major capital injection for the U.S. primary aluminum indus-

Century Aluminum to receive $500 million green aluminium smelter investment

try. The Project will strengthen domestic supply chains for materials critical for the green energy transition, including electric vehicles, renewable-energy production and storage, building and construction, and sustainable packaging.

“We are extremely proud that the DOE has selected Century’s Green Aluminum Smelter Project to receive such significant support, and we are excited to continue moving this transformational project forward,” remarked Century CEO, Jesse Gary.

Alcoa enters into binding agreement to acquire Alumina Limited

Alcoa have announced that it has entered into a binding Scheme Implementation Deed (the “Agreement”) with Alumina Limited (ASX: AWC), under which Alcoa will acquire Alumina Limited in an all-scrip, or all-stock, transaction. The Agreement terms are consistent with the previously agreed and announced transaction process deed (“Process Deed”).

Consistent with the Process Deed, the Alumina Limited Board of Directors has recommended that Alumina Limited shareholders vote in favor of the Agreement in the absence of a superior proposal and subject to an independent expert concluding (and continuing

to conclude) that the transaction is in the best interests of Alumina Limited shareholders. The Inde-

pendent Directors of Alumina Limited, and its Managing Director and Chief Executive Officer intend to vote all shares of Alumina Limited held or controlled by them in favor of the Agreement.

“Entering into the Scheme Implementation Deed to acquire Alumina Limited is a milestone on our path to deliver value for both Alcoa and Alumina shareholders,” said William F. Oplinger, Alcoa’s President and CEO.

“This transaction provides enhanced opportunities for value creation, including strengthening Alcoa’s position as one of the world’s largest bauxite and alumina producers.

Eivind Kallevik appointed CEO of Hydro

Eivind Kallevik has been appointed President and CEO of Norwegian aluminium and renewable energy company Norsk Hydro ASA. Kallevik succeeds Hilde Merete Aasheim, who has decided to step down after five years. The appointment will be effective May 13, 2024.

“I am pleased to announce that Eivind Kallevik has accepted the job as President and CEO of Hydro. Throughout his more than 30 years of experience from Nor-

wegian and international finance and industry, Eivind has a strong track record of developing the business, capturing opportunities,

and maneuvering the industrial landscape and markets. I am confident Eivind has what it takes to lead Hydro towards 2030 and beyond,” says Dag Mejdell, chairperson of Hydro’s Board of Directors. Kallevik is currently Executive Vice President and Head of Hydro’s Aluminium Metal business area, a position he has held since 2019. From 2013 to 2019 he held the position as CFO in Hydro. Prior to this, Kallevik held several senior management positions in Hydro.

COMMENT 2

May/June 2024 Aluminium International Today TOP STORIES

THE INDUSTRY GATHERS

EGA upgrades to SAP software

Emirates Global Aluminium have signed a deal with SAP to transform its core enterprise resource planning solution to SAP’s latest S/4HANA software.

EGA uses SAP software solutions to manage functions such as marketing & sales, supply chain, finance, human capital, production planning & scheduling, and plant maintenance across its global business. Currently, EGA processes more than 150,000 business transactions every month. Up-

grading to S/4 HANA will increase data processing speeds by 30x, future-proofing computing for EGA’s functions and unlocking potential for digital capabilities such as artificial intelligence and advanced real-time data analytics.

EGA’s new SAP S/4HANA will be hosted in a private cloud in Microsoft Azure and will benefit from continuous updates as SAP technologies evolve. The migration to the new system will be through SAP RISE.

EGA launched its much-wider digital transformation in 2021, aiming to enhance every aspect of its operations and business, while upgrading customer and employee experience and ultimately creating new revenue streams.

Abdulnasser Bin Kalban, Chief Executive Officer of Emirates Global Aluminium, said: “Our digital transformation is a core part of achieving EGA’s bold aspiration to innovate the future of aluminium production.”

Alba and EGA sign technology service agreement for Line 6

Aluminium Bahrain B.S.C. (Alba) and Emirates Global Aluminium (EGA) have announced they have recently inked a Technology Services Agreement for Alba’s Reduction Line 6.

The Agreement was signed between Alba’s CEO Ali Al Baqali and EGA’s CEO Abdulnasser Bin Kalban in the presence of top officials from both companies.

This Agreement encompasses both onsite and remote assistance

wherein EGA will provide Alba’s Reduction Line 6 with technical support services, monitoring services as well as operational consultation. The agreement also covers operational and process audits, technical training workshops, as well as hands-on operation support among others.

Commenting on this occasion, Alba’s CEO Ali Al Baqali stated:

“Alba’s Reduction Line 6 is a success story built upon the foun-

dation of our exceptional local talent and bolstered by EGA’s DX+ Ultra technology playing a role in it.

We are excited to build on our partnership with EGA through this technical services agreement as it will enable our human talent to continuously benefit from EGA’s DX+ Ultra advancements and achieve our sustainability objectives.”

Women With Metal – the ALUMINIUM Awards announced

The organiser of the ALUMINIUM World Trade Fair, RX, have announced the “Women With Metal – ALUMINIUM Awards”, which will be presented for the first time as part of this year’s fair. The awards ceremony will be organised and hosted in cooperation with Women With Metal, the UK Aluminium Federation (ALFED) and Aluminium International Today on the second day of the trade fair, October 9th.

The awards intend to promote equality and diversity in the aluminium industry, recognise outstanding achievements by women and strengthen their position within the sector. They will also ac-

knowledge the efforts of male colleagues who have demonstrated extraordinary support for their female counterparts, serving as allies in the pursuit of gender equality.

“The ALUMINIUM World Trade Fair is not just a platform for the entire aluminium industry, it is a place for the world and a place for everyone – which is why we also want to provide more support and

visibility for women in the industry and thus created the ‘Women With Metal – ALUMINIUM Awards’ together with our partners,” explains Yasmin Ouiriemmi, Product Manager of ALUMINIUM at the organiser RX.

The Awards aim not only to honour women in the industry but also to encourage other women to assert themselves confidently.

RHI Magnesita announces intention to acquire Resco Group

RHI Magnesita announces its intention to acquire Resco Group, a US based producer of alumina monolithics and wide range of basic and non-basic refractories, for an enterprise value of up to $430 million.

Novel recycling technologies for European Aluminium

In a pioneering initiative that was recently officially launched in Vienna, the RecAL (Recycling technologies for circular ALuminium) project aims to develop innovative recycling technologies and a digital platform for a circular aluminium economy.

Industry and Norwegian government agree on the CO2 compensation scheme

The Norwegian government, industry associations and trade unions have reached an agreement on the future of the Norwegian CO2 compensation scheme, valid from 2024 until 2030.

“The CO2 compensation scheme is essential for maintaining competitive frame conditions for industries in Norway. This agreement will provide predictability, while accelerating decarbonization and green investments,” says President and CEO, Hilde Merete Aasheim.

Rio Tinto to invest in the world’s best technology startups

Rio Tinto is teaming up with a leading global venture studio and start-up investor to back the development and commercialisation of breakthrough technologies in the mining industry, to find better ways to provide the materials the world needs.

3 NEWS IN BRIEF May/June 2024 NEWS Aluminium International Today

www.aluminiumtoday.com

Hydro Årdal opens new recycling unitwith 25,000 tonnes capability

As part of its efforts to meet the demand for low-carbon aluminium in European markets, aluminium and renewable energy company, Hydro, has invested NOK 100 million in recycling technology in

the casthouse at the Årdal primary aluminium plant in Norway.

Image above: Årdal Recycling opened on April 10 by Mayor of Årdal Christian Sønstlien, Minister of Trade and Industry Jan Christian Vestre and Plant Manager Anveig Bjordal Halkjelsvik. (Photo: Jens Christian Boysen/Hydro)

“The demand for low-carbon aluminium is increasing, particularly in the automotive industry. Thanks to the cutting edge technology and know how utilized by our team in Årdal, customers can reduce the carbon footprint in their value chain and get closer to achieving their climate targets,” says Eivind Kallevik, Executive Vice President of Hydro Aluminium

Metal.

The upgraded casting line in Årdal will mix primary aluminium made with renewable hydropower with up to 30 percent post-consumer aluminium scrap. This is resulting in a record low-carbon footprint that helps some of the most advanced customers in Europe cut the embedded greenhouse gas emissions of their products.

The recycling unit in Årdal had its official opening on April 10. Hydro Årdal is now able to deliver REDUXA 3.0 aluminium with a carbon footprint of below 3.0 kg CO2e/kg aluminium.

This is approximately 80 percent lower than the world average.

Constellium Ravenswood: $75 million low carbon technology investment

Constellium have announced that its facility located in Ravenswood, West Virginia, was selected by the U.S. Department of Energy (DOE) Office of Clean Energy Demonstrations to begin award negotiations for up to $75 million in Bipartisan Infrastructure Law and Inflation Reduction Act funding as part of the Industrial Demonstrations Program (IDP). This investment will help fund the implementation of breakthrough low-to-no emissions technologies in Constellium’s Ravenswood facility, supporting the decarbonization of the casthouses, the plant’s most energy inten-

sive operation.

This investment will support

the installation of low-emissions

SmartMelt furnaces that can operate using a range of fuels, in-

cluding clean hydrogen, paving the way towards a zero carbon casthouse. In addition to reducing carbon emissions, the project is expected to help maximize recycled scrap intake, and to improve worker safety with the introduction of a hands-free casting process.

The project will also contribute to the local communities around Ravenswood with a dedicated budget to build a new training and wellness center for all employees and an onsite childcare, and to provide financial and technical resources for local education.

Aluminium industry reports decline in greenhouse gas emissions

New data from the International Aluminium Institute (IAI) reveals that, for the first time, total greenhouse gas emissions from the global aluminium sector did not grow, even though aluminium production grew.

The 2022 data, the latest available, shows aluminium production grew by 3.9% from 104.1 million tonnes to 108.2 million

tonnes. However, greenhouse gas emissions from the industry showed a slight decline from 1.13 giga-tonnes CO2e to 1.11 giga-tonnes CO2e, and the GHG emissions intensity of primary aluminium production (the average quantity of emissions from the production of a tonne of primary aluminium) has been declining since 2019. In 2022, intensity de-

2024 DIARY

MAY

14th - 16th

CRU: 30th World Aluminium Conference

The 30th World Aluminium Conference will return to the St Pancras Renaissance Hotel, London, co-hosted by the International Aluminium Institute (IAI) and the Aluminium Stewardship Initiative (ASI). www.events.crugroup. com/aluminium/home

21st - 23rd

Future Aluminium Forum

The Future Aluminium Forum was originally developed to explore the transformational impact of digital technologies in the aluminium manufacturing processes. By hosting this next edition in Istanbul, we will be looking to uncover the potential to revolutionise the industry in Turkey and the surrounding regions.

www. futurealuminiumforum. com/turkey/

29th - 31st

NorCast

NorCast presents highprofile executive leaders as Distinguished Guest Speakers, along with an international line-up of presenters, to cover important aspects of the aluminium industry. Held in Arendal, Norway www.norcast-seminar.com

JULY

3rd - 5th

ALUMINIUM CHINA

clined by 4.4% from 15.8 tonnes CO2e per tonne to 15.1 tonnes CO2e per tonne.

IAI Secretary General Miles Prosser said: “Our challenge is to reduce emissions while growing production. Aluminium demand is expected to grow significantly over the decades ahead, because of its role in decarbonisation economy-wide.”

ALUMINIUM CHINA brings together high-quality resources from the aluminium industry and end-use applications at home and abroad to comprehensively display innovative technologies and products.

Held in Shanghai www.aluminiumchina.com

For a full listing visit www.aluminiumtoday.com/ events

Aluminium International

Today

4

May/June 2024 GREEN NEWS

TotalEnergies 552 006 454 RCS Nanterre - France. Photos: 123RF - Design: ms.industry@totalenergies.com lubricants.totalenergies.com TotalEnergies Industry Solutions Aluminum processing fluids Hot & cold rolling mills Expertise and technical support for all applications

Creative use of aluminium weatherbreak

The Summer of 2023 highlighted how business, educational, and civic leaders in the United State of America, Canada, and Norway worked together to showcase how aluminium was used to protect people from extreme weather more than 70 years ago and how the metal could be further utilised to face some of the challenges of today.

Factory workers in Indiana and Kentucky as well as academic leaders and students in the District of Columbia and Missouri were just some of the people involved in these collaborative activities.

“Reconstructing ‘Weatherbreak’: Geodesic Domes in an Age of Extreme Weather” was a joint exhibit of the School of Architecture and Planning at The Catholic University of America (Catholic University) and the National Museum of American History (NMAH) of the Smithsonian Institution.

Weatherbreak was “…North America’s first large-span, self-supporting geodesic dome, illustrating the significance of dome architecture in an age of extreme weather,” according to a news statement from Catholic University on 5 July 2023. “By the nature of their geometry, geodesic domes can support more load and have higher wind resistance than any other shelters of comparable size and weight.”

The original Weatherbreak – officially called “Weatherbreak 8C270” – was built in 1950 in what is known today as BaieD’Urfé, Québec, Canada. This community is located in suburban Montréal.

“Decades later, the nation and planet are focused on sustainability as it relates to climate change,” stated Dr. Abeer Saha, Merrill Family Secretarial Scholar and Curator in the Division of Work and Industry at the NMAH. “This living exhibition adds to such urgent dialogue by reconstructing and contextualizing the dome for contemporary audiences in an age of extreme weather.”

Aluminium was the key element used to build the original Weatherbreak as well as the critical backbone for the reconstruction of the structure.

By Richard McDonough*

This geodesic dome was rebuilt within the NMAH during a three-day period from 5 to 7 July of 2023. The dome rose 25 feet high and was 49 feet wide (7.62 meters high and 14.94 meters wide); it covered approximately 2,000 square feet (185.81 square meters).

The exhibit was on display for much of July of 2023.

Dr. Peter Kilpatrick, President of Catholic University, expressed strong support for the joint efforts with the NMAH. In the news statement issued on 5 July 2023, he noted that the collaboration not only showcased the expertise of the students at the School of Architecture and Planning, but also encouraged “…a critical conversation about the utility of geodesic

domes in the face of extreme weather challenges.”

This exhibit was on display in the Flag Hall at the NMAH, explained Melinda Machado Director of the Office of Communications and Marketing at the NMAH, “…the busiest crossroads and at the entrance where two-thirds of our visitors enter.”

Dr. Saha indicated that more than 180,000 visitors saw the Weatherbreak exhibit during its display at the NMAH.

The National Museum of American History describes its collections, its research activities, and its public outreach as ways for people to explore “… the infinite richness and complexity of American history. The museum helps

Do you have questions about the aluminium industry? Governmental regulations? Company operations? Your questions may be used in a future news column. Contact Richard McDonough at aluminachronicles@gmail.com. © 2024 Richard McDonough

THE ALUMINA CHRONICLES 7 Aluminium International Today May/June 2024

Weatherbreak was reconstructed by the School of Architecture and Planning at The Catholic University of America in partnership with the National Museum of American History of the Smithsonian Institution. (The photograph was provided courtesy of the National Museum of American History, July of 2023.)

to describe his pioneering effort to develop affordable, energy-efficient, and environmentally-conscientious housing,” according to a statement dated 27 March 2023 from Catholic University.

The concept of a geodesic dome, though, predated the writings of Mr. Fuller.

According to a number of reports, the first geodesic dome was the Zeiss Planetarium in Jena, Germany. It officially opened to the public in 1926. Three years earlier, in 1923, a dome was built on the roof of Carl Zeiss Optical Works in Jena to test the planetarium, according to a statement from the ZEISS Group.

Dr. Walther Bauersfeld was the chief engineer at Carl Zeiss Optical Works and is credited with the design of the geodesic dome. The dome itself was fabricated by Dyckerhoff and Widmann Aktiengesellschaft.

The structure received international attention and praise.

Aktiengesellschaft, then of Berlin, Germany, were awarded the Edward Longstreth Medal by The Franklin Institute of Philadelphia, Pennsylvania, in 1938.

In a news statement issued on 15 March 2023, Catholic University noted that whilst Mr. Fuller was not the original inventor of the structure, he was credited with popularising the geodesic dome.

A team led by Jeffrey Lindsay, a Canadian architect, inspired by the theories of Mr. Fuller “…designed Weatherbreak as a lightweight, stable structure that could resist extreme environmental impacts,” according to a news statement from Catholic University on 5 July 2023.

The geodesic dome, this news statement indicated, “…was designed to withstand snow and winds up to 200 miles per hour.”

people understand the past in order to make sense of the present and shape a more humane future.”

This museum is one of the 21 museums that form the Smithsonian Institution. Among the missions of the Smithsonian is the “…shaping the future by preserving heritage, discovering new knowledge, and sharing our resources with the world. The Institution was founded in 1846 with funds from the Englishman James Smithson (1765–1829) according to his wishes ‘under the name of the Smithsonian Institution, an establishment for the increase and diffusion of knowledge.’”

Historical Significance

“Famed American architect R. Buckminster Fuller coined the term ‘geodesic dome’

“Large Dome Erected in Germany Which Permits Visitors to See Planetary System” was the headline of a news article in The Enquirer And Evening News of Battle Creek, Michigan, on 3 March 1926.

The Capital Times of Madison, Wisconsin, reported in its edition dated 27 February 1926 that “the dome itself is simple to build – just a thin shelled concrete layer on a wire net, about 50 feet in diameter with a capacity for about 250 spectators.”

Several newspapers in the United Kingdom also detailed aspects of this structure and the planetarium. The Observer of London, England, reported that the “dome [was] built of concrete thinner than an eggshell” in a report dated 28 November 1926.

In recognition of the engineering marvel of “concrete shell type of roof construction,” Carl Zeiss, Inc. as well as Dyckerhoff and Widmann

“This project has the potential to convey that historical artifacts can inform our search for sustainable solutions in an age of climate change,” Dr. Saha stated in the news statement dated 15 March 2023. “Weatherbreak represents a visionary approach to building quick, affordable and sustainable shelters; one worth revisiting at a time when more than 24 million people are displaced by extreme weather events worldwide each year.”

The initial Weatherbreak – there were several structures that bore the name “Weatherbreak” – was disassembled in Canada and later reconstructed in California as a private residence in the late 1950s, according to a statement from the NMAH. In the early 1970s, Weatherbreak was again disassembled and the components of this geodesic dome were donated to the National Museum of History and Technology (now known as the “National Museum of American History”) of the Smithsonian Institution. The pieces of the initial Weatherbreak remained in storage at the NMAH until the exhibit at the museum in 2023.

Aluminium International Today May/June 2024 THE ALUMINA CHRONICLES 8

A design pattern and some of the aluminium pieces that were used in a test build of Weatherbreak on the campus of The Catholic University of America.

(The photograph was provided courtesy of Norsk Hydro, 25 April 2023.)

Some of the aluminium pieces utilised in a test build of Weatherbreak on the campus of The Catholic University of America. (The photograph was provided courtesy of Norsk Hydro, 25 April 2023.)

The School of Architecture and Planning at The Catholic University of America conducted a test build of Weatherbreak prior to the formal reconstruction at the National Museum of American History.

(The photograph was provided courtesy of Norsk Hydro, 25 April 2023.)

Wagstaff is a trusted leader in the aluminum industry, known for our commitment to superior quality and customer satisfaction. Our equipment is designed to last, ensuring longevity for both the products and the partnerships we form. With a legacy of progress and a dedication to professionalism, Wagstaff is a partner you can rely on for all your aluminum casting needs. EXPERIENCE THE SERVICE, LOYALTY, AND DEDICATION TO YOUR SUCCESS THAT ONLY WAGSTAFF CAN PROVIDE. 1.509.922.1404 www.wagstaff.com Leaders in Aluminum Direct Chill Casting Solutions AirSlip® NuMax® ARC™ APEX™ LHC™ ShurCast™ AutoCast™ VariMold® Epsilon™ and more

Reconstruction

“Students developed models, worked on the fabrication of missing parts, planned the reconstruction, and undertook two test builds on campus in preparation for the live build,” according to a news statement dated 5 July 2023 from Catholic University.

A news statement from the NMAH issued on 3 July 2023 indicated that the project team “…had to build models and work with partners to reconstruct missing or damaged parts to reassemble Weatherbreak.”

More than 1,000 struts and sprits were utilised to reconstruct Weatherbreak.

In a news statement issued on 15 March 2023, Catholic University noted that there was no instruction booklet to reconstruct the geodesic dome, “…only a single page of colour-coded strut lengths – leaving a mystery for the students to figure out. An initial surprise was discovering the pieces, or rods, came in 16 different lengths.”

According to the news statement from the NMAH issued on 3 July 2023, sections of Weatherbreak, including the bottom support rungs and the top of the dome, were reconstructed using replica parts.

Dr. Saha explained that “…the ratio of original to replica used for the exhibition was closer to 50:50, not because 50% of the original pieces are damaged or unusable, but because we didn’t want the museum visitors to touch the original historical object, and thus built the last two rings with the replica struts.”

Educational Experience

Students working “…on this once-ina-lifetime, hands-on project to study, fabricate and rebuild the dome” were part of an architecture studies class under the direction of Tonya Ohnstad, Associate Dean of Graduate Studies and Assistant Professor at the School of Architecture and Planning at Catholic University, and faculty member Lorenzo Cardim DeAlmeida, according to a news statement from the NMAH issued on 3 July 2023.

The Catholic University of America describes itself as “….the national university of the Catholic Church and the only higher education institution founded by the U S bishops. Established in 1887 as a papally-chartered graduate and research centre, the University comprises 12 schools and 31 research facilities and is home to 5,000 undergraduate and graduate students.”

Ms. Ohnstad noted in a news statement from Norsk Hydro (Hydro) on 4 May 2023 that this project was “…a great learning experience for our students and the use of varied materials is an integrated part of their architecture education.”

Aluminium International Today May/June 2024 10

Pictures 1, 2 and 3. Day One of the reconstruction of Weatherbreak at the National Museum of American History.

(The photograph was produced by Patrick Ryan and provided courtesy of The Catholic University of America, 5 July 2023.)

Day Two of the reconstruction of Weatherbreak at the National Museum of American History.

1 2 3

(The photograph was produced by Patrick Ryan and provided courtesy of The Catholic University of America, 6 July 2023.)

Dr. Saha provided additional information from Ms. Ohnstad in which she explained that “Architects continue to solve issues of material efficiency, structural integrity, and constructability that were central in the original making of Weatherbreak… Weatherbreak can easily withstand hurricane forces, what does that mean for structures in most environments where climate is shifting?”

“Understanding Weatherbreak as a prototype was translated from an idea to assembly is an everlasting issue in projects today,” she continued. “Working in this way reveals much more than the object but the socio-cultural moment, dreams of the designer, and places the students into the minds of the creators. This project elucidates the transition between the design, a pure mathematical form, and reality that is handcrafted. Reality is not as straightforward as we are led to believe.”

Ms. Ohnstad added that “All architecture relies on the joinery of the elements. In this project, the joinery is part of a flexible system that is expressed with clarity, not obfuscated. Funny enough, the full joinery is still the most difficult for us to decode and re-fabricate. The answer to massive and multiple crisis is not likely embedded singularly in this work, but learning from this work is central. We can certainly expand on Weatherbreak using new tools, better alloys, wider information networks to improve on the original drive.”

Industry Support

A number of entities worked with Catholic University and the NMAH to make this exhibit possible.

In a news statement dated 5 July 2023 from Catholic University, leaders detailed “…the support and in-kind contributions of faculty and students of Washington University in St. Louis under the leadership of Professor Wyly Brown; Architectural Systems Inc., which fabricated missing components; Norsk Hydro, which donated the material for the parts; DSI Spaceframes; and Consigli Construction Co. Inc.”

The items donated by Hydro included extruded aluminium structural members made from Hydro CIRCAL. The company noted that Hydro CIRCAL contains “…at least 75 percent recycled, post-consumer scrap…[and] offers the lowest carbon footprint of any aluminium products manufactured in the world today.”

THE ALUMINA CHRONICLES 11 Aluminium International Today May/June 2024

Pictures 1 and 2. Day Three of the reconstruction of Weatherbreak at the National Museum of American History. (The photograph was produced by Patrick Ryan and provided courtesy of The Catholic University of America, 7 July 2023.)

1

Hydro Aluminium Metals USA produced the Hydro CIRCAL utilised in the Weatherbreak exhibit at the National Museum of American History. This aluminium product was manufactured from recycled, post-consumer scrap aluminium at the company’s recycling facility in Henderson, Kentucky. (The photograph was provided courtesy of Norsk Hydro.)

2

Norsk Hydro is headquartered in Oslo, Norway; the firm has operations in more than 140 locations and 40 countries.

“The unique properties of aluminium enable the structural design to be lightweight, strong, and highly efficient,” according to a news statement from Hydro issued on 4 May 2023. “Architects have long been advocates for the use of sustainable materials and lifecycle thinking, so it is no surprise that aluminium plays a significant role in the modern built environment.”

“Just as the student-led project seeks to conserve a unique piece of architectural history, recycling aluminium conserves resources and energy,” the news statement continued. “Unique among modern building materials, aluminium is also infinitely recyclable, so it naturally makes sense to design aluminium products in ways that are easy to disassemble and reclaim at the end of their useful life.”

Trond Gjellesvik, Business Unit President of Hydro Aluminium Metals USA, said that Hydro was “…pleased to partner with Catholic University to assist the Smithsonian in helping revive this historic structure. Much like Fuller’s vision for ‘Spaceship Earth,’ for nearly 120 years Hydro has sought to create a more viable society by developing natural resources into products and solutions in innovative and efficient ways.”

“The team at our Henderson, Kentucky, recycling plant was able to produce extrusion ingots for this historic project almost entirely from post-consumer scrap, the reuse of which is critical to improve sustainability,” stated Mr. Gjellesvik.

The company noted that the aluminium was then extruded into the needed items

at the company’s extrusion facility in Elkhart, Indiana.

“By increasing the use of post-consumer scrap and driving towards 100% recycled content, aluminium can play a vital role in decarbonizing the building industry” stated Charles Straface, Business Unit President of Hydro Extrusion North America. “By taking end-of-life aluminium scrap and transforming it back into building components, we feel this project highlights the potential of aluminium to address climate change in unique ways.”

Hydro also provided enough material for Catholic University to construct the replica dome for a traveling exhibit in the future.

As to the disposition of the replica aluminium items used for the exhibit at

the NMAH, Dr. Saha of the NMAH stated that “after deconstruction, the replica pieces were added to our permanent collections.”

In the news statement from Hydro, Ms. Ohnstad of Catholic University expressed appreciation to Hydro for the opportunity to have participated “…in the restoration of a truly historic piece of architectural history. This project is a great learning experience for our students and the use of varied materials is an integrated part of their architecture education. We are looking forward to learning more about the benefits of aluminium as a sustainable building material through the partnership with Norsk Hydro.” �

Aluminium International Today May/June 2024 12

Completion of the reconstruction of Weatherbreak at the National Museum of American History.

(The photograph was produced by Patrick Ryan and provided courtesy of The Catholic University of America, 7 July 2023.)

The aluminium used in the Weatherbreak exhibit at the National Museum of American History was extruded into the needed items by Hydro Extrusion North America at its facility in Elkhart, Indiana.

(The photograph was provided courtesy of Norsk Hydro.)

Refratechnik hybrid castables: Also suited for low temperatures.

We have optimised the technology of Sol Gel bonded castables even further, enabling us to combine the best of two worlds for you: Faster drying and high strength already at room temperature.

Your benefits with hybrid castables: Time and energy savings during production of prefabricated components and when commissioning furnaces.

Learn more: www.refra-hybrid.com/en

US Aluminium Outlook 2024

By Myra Pinkham*

While there is optimism that the US aluminium market is at the cusp of turning upward, much of the market is holding off to wait and see what happens in an attempt to decipher the mixed signals coming from the aluminium supply chain and the domestic and global economies.

There is no question that there is a lot of variation sector by sector and product by product; but largely, 2024 is being seen as a transition year. Helped, in part, by several new governmental policies, the potential for US interest rates to start inching down again, the need for lightweight materials to support the energy transition, industry observers believe that things could start trending upwards over the next year or so.

After being strong for much of 2022, with post-Covid pandemic lows, the US aluminium market has seen its demand decline over the past 20 months. Matt Aboud, senior vice president of strategy and business development for Century Aluminum noted that there has been such a prolonged downturn, especially amid a pretty strong economic backdrop over the past few years.

Recently there have been some signs that the market might be starting to turn the corner. In fact, Matt Meenan, a spokesperson for the Aluminum Association noted that the trade group’s new orders index is currently at its highest level since the summer of 2022.

“But we need to distinguish whether this is because of true organic demand from the end markets, or if it is that North American producers are gaining some share because of some overseas and geopolitical issues”, Aboud declared.

In fact, while it appears as if US

aluminium shipments are steadying, partly due to the completion of excess inventories, Matthew Abrams, CRU, said that meaningful recovery won’t be seen until the back half of this year or sometime next year.

Improvement has occurred at a mixed pace and will likely continue to be so.

Daria Efanova, head of research for Sucden Financial said that improvement in the aluminium market has been driven by several downstream aluminium consuming markets, as opposed to coming from the upstream where there are rising costs of production. This has been challenged by the high electricity prices as well as continued competition from China and other developing countries. This has resulting in North American smelter capacity to decrease in recent years.

“But while the primary aluminium market has generally been sluggish, given that it follows the downstream, we are seeing that that things are starting to turn, and we are hopeful that the second half of the year will be better,” Aboud noted.

While, in general, downstream US aluminium demand was “flattish” in the first quarter of 2024 compared with late in 2023, Duncan Pitchford, president of Hydro Aluminum Metals USA, said that it has varied sector by sector. For example, noting that while automotive demand remained up, other sectors like building and construction have seen a softer demand with the higher interest rates. If this reduction in demand continues this could be concerning given that, according to Efanova, the construction sector accounts for about a third of US aluminium demand.

*US correspondent

However, with some builders ramping up in anticipation of the spring construction season, she said this would bring some good news for aluminium. The US housing market was also starting to bounce back, but this was seen to weakened again in March due to higherthan-expected mortgage rates.

CRU’s Abrams said that aluminium rolled products seem to be faring well, with demand for can sheet really picking up at the same time as North American auto build rates, which is not only positive for aluminium flat products, but extrusions as well.

While the US can sheet market is traditionally pretty flat, Meenan noted that it has been more volatile recently as a result of the considerable post-Covid inventory built up in 2022, followed by destocking last year. “But recently can sheet demand has been moving in the right direction again,” he said. In fact, it was up about 10% year on year through February.

Meanwhile, according to head of North American aluminium analysis at CRU, Kaustabh Chandorar, there is an expectation that the North American light vehicle output will move up to 1616.5 million units for the remainder of the decade and expectations of a bump in the electric vehicle (EV) share. With this, autorelated aluminium demand is expected to increase by 5-6% this year and even more in 2025.

John Tumazos, president and metals analyst for John Tumazos Very Independent Research, pointed out that the growth in the EV share is a big contributing factor to the increase of light vehicle output

Aluminium International Today May/June 2024 GLOBAL UPDATE 14

given that they tend to contain at least 200 lbs. EVs contain more aluminium per vehicle than internal combustion engine (ICE) vehicles. Mike Stier, vice president of finance and strategy for Hydro Extrusions, noted that the higher demand for aluminium seen from EVs is due to lightweighting and the structural and battery components.

However, he observed that while there was some excitement when some new models such as light truck models launched, the increase in US EV production hasn’t been as fast as anticipated. This is largely due to the lack of infrastructure for EVs in the US in comparison to other countries. That being said, Steir commented that “once more EV infrastructure is put in place, US consumers will become more confident that EVs are reliable transportation”.

These markets are supportive of the new US flat roll and extrusion capacity coming online. This includes two greenfield rolling mills expected to come online by 2026 –marking the first new rolling mills built in the US since 1980.

Novelis is building an integrated aluminium manufacturing facility in Bay Minette, AL, which will include hot rolling, recycling, casting and finishing capacity. Also, the newly formed Aluminum Dynamics unit of Steel Dynamics have announced that they are building a lowcarbon recycled aluminium rolling mill in Columbus, MS, this will be supported by two satellite recycled aluminium slab centres.

For new US extrusion capacity, in midMarch Century Aluminum formed a joint venture with Metal Exchange to build a billet remelting facility. As well as this, Hydro’s Cassopolis, MI, recycling based

remaining 25% production at Mt. Holly, as it is an operating plant.”

cast house came online at the end of last year and is expected to reach full capacity in June. Hydro have also upgraded the recycling capabilities at its Cressona, PA, extrusions plant is to be completed by midyear. CRU’s Abrams said that 30-40 new extrusion presses are expected to would be added in the US over the next few years.

Meanwhile, going counter to the trend in the US primary aluminium market, it looks like Century Aluminum could be poised to eventually build a new smelter, which would be the first primary aluminium smelter built in the US in about 45 years. Tumazos noted that Century, which idled its Hawesville, KY, smelter in 2022, mostly has smaller assets that it acquired from other producers.

Aboud pointed out that the January closure of the Magnitude 7 New Madrid, MO, smelter reduced domestic primary aluminium output by about 30% with only four smelters now operating.

However, Alcoa has announced that it will be restarting one production line at its Warrick, IN, smelter, KC Chang. A senior associate with S&P Global Market Intelligence said that the restart of a smelter with 54,000 tonnes of production capacity cannot offset New Madrid’s closure. “And now buyers needing to satisfy “Buy America” requirements have one less supplier option.” This is assuming there aren’t any other restarts. “We haven’t closed Hawesville indefinitely,” Aboud said, noting that Century continues to maintain the smelter to allow it to eventually be restarted if the conditions are right to do so. “We would need to have a sustained period of low energy costs and higher LME prices,” he explained. “Also, our first priority is to bring back the

Joe Quinn, director of the Center for Strategic Industrial Materials and vice president of SAFE Foundation, pointed out that the four smelters currently operating isa number down from 23 smelters in 1993. He said his group believes that domestically produced primary aluminium is important for both defense application and to support the green energy transition.

Century Aluminum’s plans for a new green primary aluminium smelter is part of the new US Department of Energy Office of Clean Energy Demonstrations’ Industrial Demonstrations Program, which includes a total of $6 billion in grants funded by the IIJA bipartisan infrastructure law and the Inflation Reduction Act.

In late March Century Aluminum’s Green Aluminum Smelter Project was one of 33 US projects named to demonstrate commercial-scale decarbonisation solutions needed to move energyintensive industries toward being net zero. This is now entering negotiations to be awarded $500 million, the maximum for any single project.

“We are confident that will be successful,” Aboud said, and that the company will then be able to go through an engineering and site selection process. “It is still many years away from being a reality,” he noted, “But once it is we believe that it will approximately double the volume of primary aluminium produced in the US today.”

Quinn described Century’s plan for a new smelter as “phenomenal,” especially given that it plans to secure carbon free energy for the facility. “But one question is where that energy will come from. That isn’t known yet.”

The impact of certain trade related factors is also another unknown. That includes the pending extrusions trade case and recently passed restrictions by the US and the UK on Russian-origin aluminium. �

GLOBAL UPDATE 15 Aluminium International Today May/June 2024

India’s Vedanta Aluminium - leading the charge towards a sustainable future

By John Slaven*

Our world today has a clear mandate. If we are to secure a habitable future for human life on Earth, we must act swiftly and collectively to halve all greenhouse gas emissions by the mid-2030s. This will enable us to limit the rise in global temperature to under 1.5°C above preindustrial levels. Achieving this goal will require a rapid transition to a low carbon global economy.

Of the myriad of materials needed to facilitate this transition, aluminium is undoubtedly among the most critical. Aluminium’s inherent versatility and recyclability - a relatively unique combination of essential characteristics –has placed it at the forefront of the push to decarbonise key industries, lending it the sobriquet of ‘The Metal of the Future.’

The metal stands out due to its superlative properties such as a high strength-to-weight ratio, high corrosion resistance, and superior ductility and conductivity. The sustainable nature of modern bauxite mining, which is the ore from which aluminium is produced, further cements its pivotal role in shaping a sustainable world. The metal also holds strategic significance for national security and economic progress, with widespread applications in key sectors like aerospace, space exploration, defence, construction, transportation, automotive, electrical distribution, and packaging.

The aluminium sector in India shines bright as an opportunity for significant growth and investment, against a global backdrop of geopolitical instability and industry headwinds. India is the world’s second-largest producer and third-largest consumer of aluminium, and is poised for a doubling in domestic demand over the next five years. Much like China, India too is set to exponentially escalate its metals consumption.

However, if it is to indeed realise its stated goal of creating “One Earth, One Family, One Future”, India must closely

This versatility and broad application is spurring an unprecedented demand for aluminium, with global demand set to soar by nearly 40% by 2030, according to a recent study conducted by analysts at CRU International. Few countries understand the immense potential of this opportunity better than the emerging economic superpower of India.

*CEO, Vedanta Aluminium

Aluminium International Today May/June 2024 DECARBONISATION 16

Aerial view of Vedanta Aluminium Smelter at Jharsuguda

pursue this aluminium opportunity as part of its larger goal of undertaking the energy transition – in a way that is not only environmentally-responsible but also supports the achievement of a more sustainable world through efforts aligned with the United Nations’ 17 Sustainable Development Goals.

Despite being home to 18% of the global population, India produces less than 4% of the world’s emissions. Its economy has thus set the standard for economic growth and development without the accompanying increase in emissions usually experienced by other advanced economies. India’s Nationally Determined Contribution (NDC) to the UN

Framework includes an emissions-intensity target of 45% below the 2005 level and an achievement of 50% cumulative electric power installed capacity from non-fossil fuel-based energy resources, both by 2030.

Embedding the principles of sustainability into both the mining and downstream beneficiation of aluminium will be absolutely pivotal in fostering economic growth while achieving NDC targets and decarbonising large swathes of the industrial landscape.

Vedanta has fully embraced this ethos, not just in support of its host country’s responsible economic growth objectives, but from a deep understanding of the

urgent need to move towards more sustainable production and consumption practices.

Over the past few years, we have been making systematic efforts to fully embed principles of environmentally and socially responsible production across our entire business, which has included committing US$5 billion over the next decade to accelerate our transition to Net Zero before 2050. Such has been the success of these efforts that Vedanta Aluminium is now the world’s most sustainable aluminium producer, as per the esteemed S&P Global Corporate Sustainability Assessment 2023.

Vedanta Aluminium operates a two million-tonne-per-year (mtpa) capacity alumina refinery in Lanjigarh, Odisha, set up in 2007, and an associated 75 MW captive power plant. The refinery feeds our massive aluminium smelters at Jharsuguda, in Odisha, and Bharat Aluminium Company Limited (BALCO), in Chhattisgarh. In fact, Vedanta Jharsuguda is the world’s largest singlelocation aluminium plant, with a 1.8 MTPA aluminium smelting capacity. We are keenly focused on 100% vertical integration, and have recently expanded the 2 mtpa capacity at the Lanjigarh refinery to 3.5 mtpa, en route to becoming a 5 mtpa producer of premium smelter grade alumina (SGA).

As one of the world’s top producers catering to customers in nearly 60 countries across the Americas, Europe, Asia, Middle East, and Africa, the wider impact of our efforts towards a decarbonised, sustainable future on the global supply chain are profound. In fiscal year 2024 alone, Vedanta Aluminium produced more than half of India’s aluminium at 2.37 million tonnes. We have also entered into long-term power distribution agreements to source 1335 MW of renewable energy towards decarbonising our operations and creating a steady source of green power for production of our low-carbon ‘green’ aluminium.

Embracing new technologies and decarbonisation also brings opportunities for greater growth and operational efficiencies. For example, Vedanta Aluminium hosts India’s largest fleet of electric lithium-ion forklifts. These offer a potential reduction in greenhouse gas emissions by approximately 1,600 tonnes of CO2 equivalent annually, while also saving on diesel costs. We are also committed to electrifying 100% of our entire Light Motor Vehicle fleet by 2030 and 75% of our mining fleet by 2035. Such changes reduce direct emissions, but they also contribute to lower operating costs. McKinsey estimates that

DECARBONISATION 17 Aluminium International Today May/June 2024

John Slaven, CEO, Vedanta Aluminium

electric vehicle ownership can be around 20% cheaper than traditional combustion engine vehicles too. Despite this, only around 0.5% of mining operations globally use them. In addition to this, Vedanta Aluminium is exploring the usage of biodiesel across its operations, as a part of a wider strategy to decarbonise its operations. Already, we have successfully conducted trial runs of using biodiesel as a ‘green’ fuel alternative for our fleet of commercial vehicles.

Green metals with a low carbon footprint are rapidly growing in demand. Vedanta has been able to lead the way in India with its low-carbon ‘green’ aluminium brand, Restora, the first in the country. It represents the outcome of bringing together the company’s robust manufacturing expertise in aluminium, innovative technologies, and an unwavering commitment towards achieving Net Zero by 2050. Restora is manufactured using renewable energy and has a GHG emission intensity of four tonnes of CO2 equivalent per tonne of aluminium manufactured - the global threshold for aluminium to be considered as low-carbon.

This focus on sustainable innovations

has contributed to us receiving the Environmental Product Declaration (EPD) International verification for our wide range of products. It testifies to our advanced manufacturing practices, which are ensuring sustainability across the aluminium value chain. Our smelters at Jharsuguda and BALCO have also been awarded the Aluminium Stewardship Initiative’s (ASI) Performance Standard Certifications, reiterating our continuous commitment to responsible production practices. The ASI Certification is the only comprehensive voluntary sustainability standard for the global aluminium value chain.

Sustainability and innovation are not simply the endpoint for the mining industry, but the essence of long-term value creation too. Building a green future demands sustainable metals, and truly responsible mining practices must therefore underpin their production. The milestones we have achieved in these areas will hopefully inspire the wider industry to embrace sustainability not merely as a buzzword, but a fundamental principle that guides our collective journey towards a better, more sustainable, and equitable world. �

cutting line to cut aluminum and PVC profiles with

Flexible Minimal setup times through automatic adjustment to profile geometry. Huge cutting area, part lengths of 10-7200mm possible, as well as integration of further processing steps like measuring, marking, deburring, etc.

Fast 18,5KW saw motor, up to 180m/min positioning speed

Precise Saw module servo driven, horizontal saw blade movement, curb widening after each cut, repetition precision of +/-0, 1 mm

Aluminium International Today May/June 2024 DECARBONISATION 18

SAW LINE KS600R / KS650R

Vedanta Aluminium, largest exporter of billets

Automatic

90° cuts

pressta eisele_half page.indd 1 19/04/2024 12:10

Reshoring, recycling and efficiency pave the way

By Frederik Esterhuizen*

Aluminium’s versatility makes it a critical material across countless industries, with demand projected to soar 15% globally by 2029 [1]. From lightweight car parts to beverage cans, aluminium’s unique combination of strength, malleability and recyclability has made it a cornerstone of modern life. However, this essential metal comes at a cost – its production is highly energy-intensive, traditionally relying on a melting process that releases significant amounts of greenhouse gasses. In fact, aluminium production accounts for approximately 1.1 billion tonnes of global CO2 emissions per year [2]

The aluminium industry is undergoing a transformative shift, driven by a perfect storm of environmental concerns, geopolitical tensions, and technological advancements. Consumers increasingly demand sustainable products, while manufacturers face mounting pressure to reduce their environmental footprint. At the same time, rising geopolitical tensions are disrupting traditional supply chains, highlighting the need for more secure and reliable sources of aluminium.

These factors have converged to present an opportunity for the North American aluminium industry to reinvent itself, embracing sustainability and a regionally

focused approach. While the US is already making considerable investments to boost domestic production across the country and is making energy-efficient upgrades to existing equipment, there is still work to be done. This article explores how reshoring, recycling, and a focus on efficiency can not only improve environmental responsibility but also increase production capacity and meet the growing demand for highquality aluminium coil in North America.

The Urgency for Change

Traditionally, North America dominated the global aluminium market. However, in the last 25 years, production has dwindled, and the region has become increasingly reliant on overseas sources to meet demands. This shift, once deemed necessary as a cost-first strategy became the precedent during the globalisation era, is now facing scrutiny due to environmental concerns surrounding overseas aluminium production.

While some countries prioritise environmental regulations, others do not, creating a situation where the sustainability credentials of overseas aluminium become murky. Consequently, a global push for ecofriendly practices has led to the rise

*Global Business Line Manager for Metals, ABB

of “green aluminium” – low-carbon aluminium production that minimises environmental impact. While green aluminium surpluses currently exist, driven by a surge in production in 2023, they are not guaranteed to last forever. Businesses need long-term assurances of stable prices and a secure supply of this sustainable material. This urgency for change underscores the need to strengthen domestic aluminium production capacity in North America, ensuring access to a reliable and environmentally responsible supply.

The Reshoring Imperative

The North American aluminium industry is at a crossroads. While demand for the versatile metal is projected to surge, traditional reliance on overseas suppliers is being overshadowed by environmental supply chain vulnerability concerns. Reshoring aluminium production offers an excellent solution to this issue.

Bringing aluminium production closer to end-users strengthens domestic supply chains, minimising disruptions caused by global events. This trend, triggered by the COVID-19 pandemic and further amplified by ongoing geopolitical tensions, is gaining momentum. According to a recent survey

Aluminium International Today May/June 2024 DECARBONISATION 20

[3], a staggering 69% of U.S. manufacturers have begun reshoring their supply chains, with a remarkable 94% success rate. The Reshoring Institute [4], whose mission is to bring manufacturing jobs back to the United States, reports that 2022 saw record highs in reshoring and foreign direct investment announcements, with projections for 300,000 new jobs created in 2023 alone.

Beyond its strategic advantages, reshoring offers environmental benefits. Shorter transportation distances translate to reduced emissions and a smaller carbon footprint, contributing to a more sustainable aluminium industry. By embracing reshoring, North America can ensure a reliable supply of aluminium while minimising its environmental impact.

Recycling: Aluminium’s Renaissance Aluminium’s infinite recyclability makes it the king of the circular economy. Recycling not only preserves the metal’s properties but also offers a dramatic 95% reduction in energy consumption compared to virgin aluminium production. This solidifies aluminium as a key material for a lowcarbon future.

By integrating efficient recycling practices, North America can unlock a multitude of benefits. Recycling aluminium minimises the need for virgin materials, significantly reducing the environmental

footprint associated with mining and processing. This translates to cleaner air, water, and less land degradation. Furthermore, utilising recycled aluminium often proves more cost-effective than virgin resources, offering a financial advantage to manufacturers. Finally, a closed-loop system for aluminium creates a reliable source of materials, contributing to increased production capacity and a more secure supply chain.

North America is uniquely positioned to capitalise on this opportunity. Boasting the world’s highest Recycling Input Rate [5], with 57% of its aluminium production originating from scrap, the region possesses a strong foundation for a robust circular aluminium economy. However, to fully unlock this potential, significant investments are needed. Expanding capacity for re-smelting and refining recycled aluminium is crucial to meet future demand.

The automotive sector, a champion of circularity within its own right, presents a significant growth opportunity. As the demand for lightweight and sustainable materials for electric vehicles intensifies, readily available, high-capacity casting complexes in North America will be critical to meet this growing need.

A Collaborative Approach for Lasting Change

Realising a sustainable and efficient aluminium industry in North America requires a collective effort from every corner of the sector.

Industry leaders have the power and influence to be a driving force for change. Continued investment into cutting-edge technology that will enhance efficiency and minimise environmental impact can pave the way for the entire industry. Pioneering these initiatives will not only benefit their own operations but also serve as a model for others to follow, accelerating the industry’s collective transformation towards a sustainable future.

Of course, none of this is possible without the help of technology providers, which are the essential catalysts for efficiency throughout the aluminium production process. This includes advancements in low-carbon aluminium melting processes and technologies, like the electromagnetic stirrers (AL-EMS)

provided by ABB. ABB’s technology has proven to increase productivity by up to 25%, lower energy consumption by 10%, and reduce dross generation by 15% in more than 400 aluminium furnaces worldwide. Unsurprisingly, demand for such solutions is on the rise. Just last month, GNA alutech, aluminium furnace provider, sought to optimise efficiency, increase productivity, lower energy consumption, and help reduce operating costs, and ordered four of ABB’s electromagnetic stirrers to do just that.

In addition to the advancements mentioned previously, technology providers also play a role in developing more efficient electrical solutions within aluminium production facilities. One promising area of development is the adoption of DC (direct current) to AC (alternating current) conversion technology. While traditional aluminium smelting relies on AC power, the conversion process itself can be energy intensive. By implementing DC power supplies such as ABB’s high power rectifiers at specific stages of production, facilities can reduce energy consumption and minimise their overall carbon footprint.

The final piece of the puzzle is the work that governments and policymakers are doing behind the scenes, which can significantly accelerate the rate of progress. Favourable policy creates a fertile environment to capitalise on the rich industry appetite for reshoring growth and sustainable technology adoption.

North America is uniquely positioned to become a global leader in clean aluminium production. Abundant natural resources, a strong foundation in recycling, and a spirit of innovation provide a solid platform for success. By embracing reshoring, recycling, and a commitment to sustainability, the aluminium industry can not only foster environmental stewardship but also unlock significant benefits. Increased production capacity will ensure a secure and reliable supply chain. Through collaboration and innovation, all stakeholders within the industry can work together to ensure a sustainable and secure future for aluminium in North America. This will not only benefit the industry itself but also contribute to a greener and more sustainable future for the entire region. �

[1] https://www.statista.com/statistics/863681/global-aluminum-consumption/#:~:text=Projected%20aluminum%20consumption%20worldwide%20 2021-2029&text=In%202021%2C%20global%20aluminum%20consumption,some%2064.2%20million%20metric%20tons.

[2] https://www.reuters.com/business/autos-transportation/bumper-green-aluminium-output-is-good-news-carmakers-climate-2022-12-17/#:~:text=Aluminium%20is%20the%20most%20energy,tonnes%2C%20or%20about%201.2%25.

[3] http://www.medius.com/news/cid-BCE234516BD3FE66/us-manufacturers-plan-to-increase-reshoring-to-get-better-value-and-more-security/

[4] https://reshorenow.org/

[5] https://international-aluminium.org/wp-content/uploads/2021/01/wa_factsheet_final.pdf

DECARBONISATION 21 Aluminium International Today May/June 2024

Orlando, Florida

29 April-3 May 2024

Booth No. P1003

ABD Equipment Co.,Ltd have been professional manufacturers of aluminum profiles surface treatment machines for 20 years.

Since 2003, we have become an extraordinary supplier of aluminum profiles, powder coating lines, anodizing and ED lines, and PVDF lines. We supply 70% of the vertical powder coating lines in China, and supply the Top 20 biggest aluminum extrusion companies in China, all of whom are our customers. At the same time, our machine has been exported to more than 32 countries around the world, including USA, Mexico, Colombia, Dominican Republic, The Republic of Honduras, Algeria, Egypt, Ethiopia, Nigeria, Kuwait, Saudi Arabia, Qatar, Turkey, Vietnam, Thailand, Malaysia, Australia, New Zealand......

ABD

Co.,Ltd www.fsabd.com info@fsabd.com

Equipment

Visit us at:

Aluminium Industry Decarbonisation – A Turning Point?

By Pernelle Nunez*

Aluminium is a key material that has the potential to reduce GHG emissions in other sectors including transport, building & construction, and food & drink packaging. It is also an essential material for the energy transition, widely used in solar panels, energy storage and electrical cabling. As such, demand for the metal is expected to grow strongly over the coming decades. Strong demand growth provides many upsides for the sector with opportunities for both primary and recycled metal, but growing production in a world where GHG emissions are becoming increasingly constrained and stakeholder expectations are growing, means the sector faces significant challenges.

The realities [1] of the ambitious Paris climate goals of limiting global warming to well below 2 degrees and ideally, 1.5 degrees are now well understood across the sector. Producers are making significant investments and taking decisive action to reduce emissions from production and to keep global climate targets in reach but alignment with a 1.5 degrees trajectory is a major undertaking. Under this scenario, total emissions from the sector would have to be reduced from over 1 billion tonnes CO2e today to just over 50 million tonnes by 2050 – a 97% reduction.

Over the past few years, decarbonisation projects [2] have emerged across all major aluminium producing regions aligned

with the IAI’s three key decarbonisation pathways [3]. The projects are varied and widespread, from increasing zerocarbon electricity to technologies and fuel switches to eliminate direct and thermal emissions, and advances in recycling and material efficiency innovations. The latest data from IAI [4] now shows these efforts are starting to bear fruit and 2022 marks a potential turning point for the sector. For the first time, data shows total greenhouse gas emissions from the global aluminium sector did not grow, even though aluminium production grew.

Decoupling production and emissions

The latest available data shows that some progress towards that 2050 end point is being made. In 2022, aluminium production grew by 3.9% from 104.1 million tonnes to 108.2 million tonnes but total greenhouse gas emissions from the industry showed a slight decline from 1.13 billion tonnes CO2e to 1.11 billion tonnes CO2e. This noteworthy growth in production but slight decline in emissions is the first indication of a potential decoupling of historic trends. The last time the aluminium industry’s GHG emissions did not grow was in 2009, following the global financial crisis where a decline in production was the main driver.

As well as the modest reduction in total

emissions, the GHG emissions intensity of primary aluminium production (the average quantity of emissions from the production of a tonne of primary aluminium) has also continued to decline – a trend that has been emerging since 2019. Intensity of primary aluminium declined by 4.4% from 15.8 tonnes CO2e per tonne in 2021 to 15.1 tonnes CO2e per tonne in 2022.

These changes have been driven predominantly by shifts in the electricity supply used in aluminium smelting, the most significant contributor to the industry’s GHG emissions. In China, the world’s largest aluminium producer, there has been a shift towards increased hydropower electricity sources and in other regions, including the Middle East, Europe and Australia, variable renewable energy sources such as wind and solar are becoming increasingly integrated into supply chains.

The data indicates the sector could be at a critical point however it is important that this progress is not overstated at this stage; there is still much more to do, and continued progress will require implementation of new technologies, the integration of new energy sources and adoption of new ways of working at a scale and pace never before seen in the sector. To stay on track with the 1.5 degrees aligned trajectory for the sector,

DECARBONISATION 23 Aluminium International Today May/June 2024

*Pernelle Nunez is the Deputy Secretary General and Director of Sustainability at the International Aluminium Institute (IAI)

emissions over the next 10 years have to decrease annually by over 9% year-onyear.

Challenges and Opportunities

Over 60% of the sector’s emissions could be eliminated through the use of lowcarbon power but challenges remain with access to decarbonised grids and integrating ever-larger quantities of variable renewable energy power sources into a production process that requires constant, reliable electricity.

Many of the other technology pathways are well known but as yet, relatively untested at a commercial scaletechnologies such as inert anode, carbon capture and storage (CCS) and electric boilers and furnaces are still in test phases or single-site operation. There is an urgency across the sector and stakeholders that the window of opportunity to reach medium-term milestones is rapidly closing. For many, 2030 is a key check point for progress and with it just over five years away, the second half of this decade will prove to be vital for the roll out of these breakthrough technologies.

There are other opportunities though that can have an impact alongside the progress already made with the integration of low-carbon power sources. Fuel switching in alumina refining, increased aluminium recycling rates and efficiency offer opportunities for the sector to make significant strides relatively quickly. Crosssector collaboration, mobilisation of capital, and enabling policy environments remain critical to success in both the medium and long term.

It is promising to see in the data, the industry is heading in the right direction for the first time, but it also highlights

emissions reductions need to significantly accelerate to align with global climate goals. Unlike some other heavy industries, many of the decarbonisation solutions for the aluminium sector are already known, and in some cases in the process of being implemented, this provides an opportunity for the sector to engage with key partners looking to rapidly accelerate and amplify efforts in the next few vital years.

Accelerating & tracking progress

Accelerating progress on an issue that is already exceptionally challenging is not easy. As highlighted earlier, in many cases, the industry is going to need to work closely with stakeholders to instigate structural change and coordinate targeted action. These stakeholders whether they be end-use industries, the energy sector, financiers, policymakers or civil society, have varied and evolving demands of the sector and sometimes it can be difficult for them to access the information they need to make informed decisions.

This is why at COP28, the IAI launched a new Aluminium Industry GHG Initiative [5] which aims to bring much needed transparency and consistency to GHG disclosures. It commits to tracking IAI member company GHG reduction ambitions and progress over the medium and long term as well as total sector emissions - essential insights for key stakeholders. Often, this information, though publicly available, is fragmented, inconsistent and dispersed. The initiative, supported by major aluminium producers accounting for over 250 million tonnes of CO2e emissions, will consolidate this key information. It is hoped that the initiative can foster greater decarbonisation ambition across the sector as well as

bringing a new level of tracking and accountability to the sector’s reporting.