When it comes to the treatment of marine sewage, HAMANN’s systems are unparalleled. After successfully doubling its turnover in the last eight years, the company is now on a mission for growth. CEO Felix von Bredow explained more, in an exclusive interview. Report by Imogen Ward.

With expansion in mind, HAMANN is on a quest to conquer the cruising industry.

“Our advanced treatment systems can handle cruise vessels carrying several thousand people,” said CEO Felix von Bredow. “We see a positive future in this industry and hope to gain a bigger portion of the market.”

HAMANN was founded by Knud Hamann in 1972, as a family-run business. From the get-go, the company pioneered the industry with its equipment.

“We were actually one of the first companies to develop sewage treatment systems in the maritime industry,” Mr von Bredow explained. “We were also one of the first to manufacture this equipment for ships compliant with IMO MEPC.2(6).”

In 1998, the company broke barriers again, when it launched the Super Mini sewage treatment plant. This super compact system was designed for smaller boats within the superyacht sector.

Inspiration struck again in 2014 (ten years after HAMANN moved to its own purpose-built facility in Hollenstedt), when the first generation of sewage treatment plants compliant with IMO MEPC.227(64) were launched.

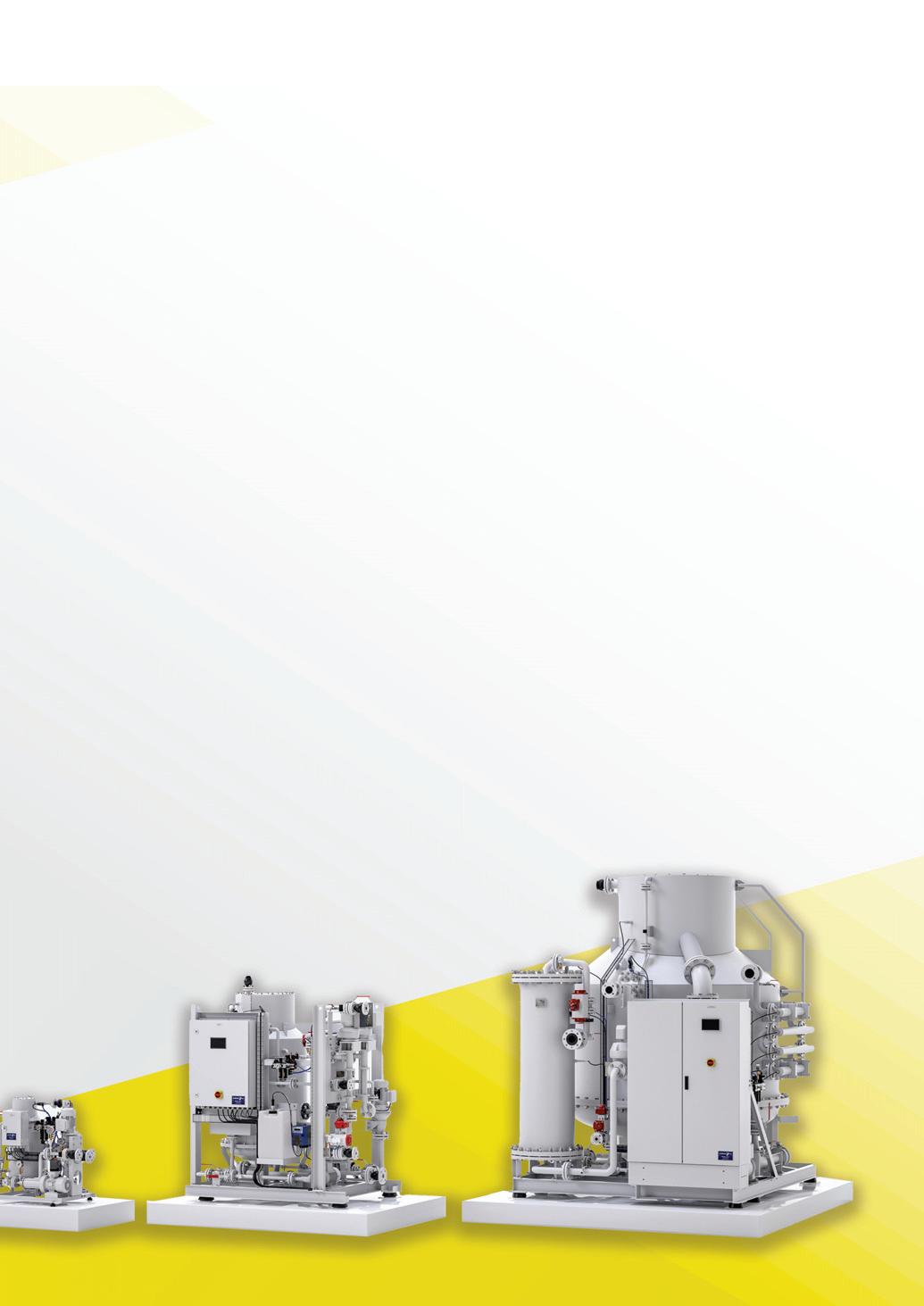

That same ingenuity can be seen in the models on offer today. Currently, HAMANN has a portfolio dedicated to two distinct product lines. The first, dedicated to standard sewage treatment plants, is applicable to most marine applications, including superyachts, yachts, ferries, passenger vessels, cruise ships and naval vessels.

These systems have been designed to require minimal maintenance and, with ease of assembly and operation, are renowned for their reliability and longevity.

The second option – for those looking to invest – is a line of advanced wastewater treatment systems. Entering the market in 2018, this equipment is the perfect choice for those who want or need the highest treatment performance – be it offshore

or on inland waterways. The HL-CONT Plus OceanCruise is even compliant for operation in Alaska and the Baltic Sea.

“The advanced wastewater treatment systems meet the highest standards in sewage and greywater treatment, making them the perfect systems for vessels operating in highly protected areas,” said Mr von Bredow.

Innovative design plays a key role in HAMANN’s operations. Just last year, the company successfully designed and developed a familiar system with a twist:

“Following a request from a client, we successfully developed an advanced wastewater treatment system that can also operate as a standard sewage treatment plant,” Mr von Bredow revealed. “ This two-in-one system can change mode

during operation, which is unique to the market. Nobody has done something like this before.

“We have a very technically minded engineering team who are great at working with our customers’ requests to find a solution that works for them and is reliable.”

HAMANN’s hardworking R&D team also played a crucial role in the development of this new system. From the company’s laboratory facilities, this team runs extensive testing to ensure that every new design is up to scratch.

“We work hard to stay ahead of the regulatory requirements, incorporating new ideas and market feedback into our development,” Mr von Bredow explained. “When it comes to our technical advancement, we are years ahead of the crowd. We have already finished development of our next generation systems, and these will head to market earlier than expected.”

Mr von Bredow joined the company in 2016. Since then, HAMANN has gone from strength to strength, successfully doubling its turnover, manpower and capacity. All of this was achieved without compromising the quality and expertise that HAMANN’s systems are renowned for.

“When I started here, I had a deep look at how the organisation works,” said Mr von Bredow. “We also ran in-depth workshops with the employees to gain a better understanding of the improvements they would like to see, because their input was extremely important. We changed the organisational structure too – implementing a flatter hierarchy, with responsibility held by everyone in the company.”

HAMANN also introduced a four-day working week as well as work from home options to improve employees’ mental wellbeing. Initially concerned that productivity would decrease, Mr von Bredow was pleasantly surprised to see the exact opposite occurred.

“All our employees have given incredibly positive feedback about the changes, which have helped highlight that our workers are more than just a number to us – they are a pivotal part of the team,” Mr von Bredow continued. “Aside from that, the figures really speak for themselves, having successfully doubled our turnover, manpower and capacity. We have also introduced marketing activities, built up a strong partner network, and we are more present in the global market than ever before.”

Last year, HAMANN received the Employer of the Future Award, and Mr von Bredow has just been awarded German CEO of the Year. These accolades reinforce the success of the implemented changes at HAMANN.

As it looks to the future, HAMANN is determined to continue with its penetration of the cruise industry. Having begun implementing initial strategies four years ago, the company’s plan is well underway.

“We are determined to gain a bigger market share in the cruise industry,” Mr von Bredow explained. “This is a big challenge for us, because the projects are of a different stamina than what we are used to, and the vessels are much bigger and demand a lot more time to develop the right solution. To achieve the proposed expansion, we need to align our organisational structure and adapt our production line to separate our small and bigger plants effectively. We have several activities ongoing to achieve this, and we are maintaining a good approach where the market is concerned.”

As part of this development, the company has constructed a new production building, ready for inauguration this spring. Currently operating from 5,000 square metres, HAMANN will gain an additional 1,600 square metres of space once this building is complete.

“The new building will allow us to expand our capacity even further, whilst also

streamlining our manufacturing process,” Mr von Bredow continued. “We are very happy with this progress because it enables us to look beyond what we are currently achieving. This facility will, of course, be utilised for the manufacture of our sewage treatment systems; but it will also play an important role in our operations within the cruise industry – allowing us to react quickly and be more flexible for our clients.”

With targets set for the foreseeable, Mr von Bredow is excited to be working with everyone at HAMANN to ensure success: “We have a great team backing every move we make, and I love working with them. Everyone has a role to play in this company, and everybody has ideas on how to progress.

“Being able to watch them develop in their roles, and help the company advance, is truly special.” n