PROFITABLE PRODUCTION STRATEGIES www.cottonfarming.com ONE GROWER PUBLISHING, LLC AUGUST 2023 North Carolina Educator Informing The Public On Agricultural Practices Transforming Cotton From A Perennial To An Annual Mid-South Soil Health Study Underway AGVOCATES IN THEIR FIELDS

AUGUST 2023 PROFITABLE PRODUCTION STRATEGIES

www.cottonfarming.com

FEATURES

6 FROM PERENNIAL TO ANNUAL

Clemson researchers are determining how to develop higher-yielding, better-quality cotton by altering plant growth habit and form.

12 SOIL HEALTH STUDY BEGINS

A comprehensive three-year study by the Arkansas Agricultural Experiment Station will evaluate the impact of conservation practices in the Mid-South.

14 PLANT GROWTH REGULATORS

Cotton experts discuss why PGRs are a tool to consider in cotton production and how to interpret the factors that are involved.

20 GINNERS MARKETPLACE

Informing The Public

Krista Huss, who farms with her husband, Matt, near Lincolnton, North Carolina, never expected she would be sharing the story of agriculture to all who would listen. Huss said the inspiration to include her thoughts on social media was simply friends who loved her content and wanted to see more. Huss says one of the major pros for social media is the amount of people she is able to reach.

DEPARTMENTS & COLUMNS

4 Editor’s

7

ON THE COVER: A scenic shot of a white cotton field at sunset. Cover photo by Wirestock/Dreamstime.

problems

the official publication of the ginning industry TCGA interns, Josiah Keck and Riley Gryder, report on their “real-world experience” while working with member gins this summer.

LAST CALL: 2023 CCOY NOMINATIONS

To nominate a deserving candidate for the 2023 Cotton Consultant of the Year Award, co-sponsored by Cotton Farming and Syngenta, fill out the form online at cottonfarming.com/ccoy. Deadline for nominations is Aug. 15.

WEB EXCLUSIVE

Award-winning law blogger, Ti any Dowell Lashmet, is an associate professor and Extension specialist in agricultural law in the Department of Agricultural Economics at Texas A&M University. Read her comments on a neighbor-to-neighbor farm sale that leads to lawsuits and how the case broadly applies to any situation involving a written agreement. Go to www.cottonfarming.com for this Web Exclusive report.

TWITTER: @COTTONFARMING AUGUST 2023 COTTON FARMING 3

COTTON FARMING (ISSN 0746-8385) is published monthly January through December by One Grower Publishing LLC, 875 W. Poplar Ave., Suite 23, Box 305, Collierville, TN 38017. Periodicals postage paid at Memphis, Tennessee, and at additional mailing o ices. POSTMASTER: Send address changes to Omeda Communications, Customer Service Department, P.O. Box 1388, Northbrook, IL 60065-1388 (Phone: 847-559-7578) (Fax: 847-564-9453). Annual subscriptions are $40. International rates are $55 in Canada/Mexico, $90 in all other countries for air-speeded delivery. Surface delivery not available due to

in reliability.

Vol. 67 No. 8

10

Note

5 Cotton’s Agenda

Research & Promotion 13 Industry News 16 Specialists Speaking 22 My Turn

CCOY NOMINATION Sponsored Cotton (CCOY) Award four decades. The recognizes consultant who contributions to through outstanding relations, leadership honors consultant these requirements Syngenta and Cotton magazine — CCOY sponsors your help in selecting recipient, who will be celebration Friday, at the Peabody Tennessee. consultant and the nominates the winner two-night hotel stay and airfare The 2023 CCOY recipient featured in four-page the February 2024 Farming Submit nominations by Aug. 15, 2023. Mail: csmith@onegrower.com version located www.cottonfarming.com. online: cottonfarming.com/ccoy Cotton Consultant of theYear2023 If you would nominate consultant of this outstanding recognition, moment to following form. Consultant’s Company your own you are nominating for the Cotton Award. Additional emailed or attached nomination form. Background: Biographical/Industry Involvement Background. well as support attached form. Name: Mailing separate page for biographical/professional information. recommendations or emails consultants members encouraged to provide nominee.

Editor’s Note

Carroll Smith

Anticipating ‘First Light’

Duck hunting is a revered tradition and rite of passage in the Mississippi Delta. My son grew up listening to his dad and his friends talk about everything involved with “the hunt.” Although you may not realize it, kids sit quietly at times and soak up every morsel of your conversations.

He learned they got together during hunting season to go to breakfast at the local diner while it was still dark. The restaurant always opened early during the season to accommodate the hunters’ schedule. Then they gathered back at the house to collect all the equipment they needed to head out to the duck hole before first shooting light. At seven-years-old, our son had not yet been invited to join the men’s excursion, but he always woke up early to hear them carrying out their rituals.

One pre-dawn morning, after the guys left for breakfast, he climbed the short stairway up to the attic. After rummaging around, he found several pieces of camouflage netting and began to meticulously tape it around his tennis shoes. Not duct tape, but the scotch tape I kept in the kitchen junk drawer. Once his handiwork was complete, he went out to the back steps to wait for his dad to return from breakfast with his buddies. When they saw the young boy sitting there in his homemade “duck-hunting” gear, how could they say no to him tagging along?

As it turned out, he shot his first duck that day and named him “Fred.”

First light is a special time in the morning that occurs about 30 minutes before sunrise. It’s always filled with anticipation about what the day will bring. Agriculture is filled with anticipation as well. As we draw closer to harvest season, everyone in the cotton industry is hoping for a bountiful crop.

Several field days that cover cotton also are offered in August and September. They are good “first light” barometers of what is to come in the pipeline. Check the calendar at cottonfarming.com, strap on your cotton farming gear and make plans to attend.

Who knows? If this season is a success, you may decide to name your 2023 crop “Fred.”

EDITORIAL/PRODUCTION

Editor Carroll Smith csmith@onegrower.com

Southeast Editor Amanda Huber ahuber@onegrower.com

Associate Editor Cassidy Nemec cnemec@onegrower.com

Digital Content Editor Katie Guthrie

Art Director Ashley Kumpe

ADMINISTRATION

Publisher/Vice President Lia Guthrie (901) 497-3689 lguthrie@onegrower.com

Associate Publisher/Editor-In-Chief

Carroll Smith (901) 326-4443

Associate Publisher/Sales

Scott Emerson (386) 462-1532 semerson@onegrower.com

Production Manager David Boyd dboyd@onegrower.com

Audience Services

Kate Thomas (847) 559-7514

For subscription changes or change of address, call (847) 559-7578 or email cottonfarming@omeda.com

EDITORIAL ADVISORY BOARD

David Burns – North Carolina

David Lynch – South Carolina

Bob McLendon – Georgia

Larkin Martin – Alabama

Mike Sturdivant Jr. – Mississippi

Charles Parker – Missouri

Jimmy Hargett – Tennessee

Allen Helms – Arkansas

Jay Hardwick – Louisiana

Ronnie Hopper – Texas

Ron Rayner – Arizona

John Pucheu – California

ONE GROWER

PUBLISHING, LLC

Mike Lamensdorf President/treasurer Lia Guthrie Publisher/Vice President

ACKNOWLEDGEMENT OF COOPERATION: Cooperating with COTTON FARMING are various cotton producer organizations across the Cotton Belt. Many representatives of producer organizations serve on COTTON FARMING’s editorial advisory board. Opinions expressed and conclusions reached by contributors are not necessarily those of the cooperating organizations or the editors. All statements, including product claims, are those of the person or organization making the statement or claim. The publisher does not adopt any such statement or claims as its own and any such statement or claim does not necessarily reflect the opinion of the publisher.

Copyright 2023 ©

ASSOCIATED PUBLICATIONS – One Grower Publishing, LLC also publishes RICE FARMING, THE PEANUT GROWER, SOYBEAN SOUTH and CORN SOUTH.

If you have comments, please send them to: Cotton Farming Magazine, 7201 Eastern Ave., Germantown, TN 38138.

One Grower Publishing, LLC 875 W. Poplar Ave., Suite 23, Box 305 Collierville, TN 38017

4 COTTON FARMING AUGUST 2023 COTTONFARMING.COM

Carroll

Cotton’s Agenda

Gary Adams

The Next Step

The National Cotton Council reminds its producer members that September 1, 2023, is the deadline for both enrolling this season’s cotton crop in the U.S. Cotton Trust Protocol and applying for the new U.S. Climate Smart Cotton Program.

What is the Climate Smart Cotton Program?

■ This five-year initiative is one of USDA’s Partnership for Climate-Smart Commodities pilot projects. The Trust Protocol is leading the program which will measure and improve the carbon footprint of the U.S. cotton industry. Its $90 million grant is an historic investment that will be used to assist participating producers who will receive technical and financial support as well as other benefits that can enhance their operations, profitability, and environmental stewardship.

Along with the technical and financial assistance, the Climate Smart Cotton Program specifically aims to:

1) advance adoption of Climate Smart Agriculture (CSA) practices such as no-till, cover crops, and nutrient management on 1.2 million U.S. cotton acres; 2) produce 4.2 million bales of Climate Smart Cotton™ over five years; 3) enroll 1,650 U.S. cotton producers, including 330 producers from historically underserved communities; and 4) reduce CO2e emissions by 1.14 million metric tons. The program’s partners include Cotton Council International, Cotton Incorporated, the Soil Health Institute, Texas A&M AgriLife Research, Agricenter International, Alabama A&M University and North Carolina A&T State University.

How can producers apply?

■ To be eligible, producers must be enrolled in

the Trust Protocol by September 1, 2023. All data entered in the voluntary Trust Protocol is secure and confidential, only being used in aggregate form. Crop consultants may be authorized to enter information on the producer’s behalf. September 1 also is the deadline for Trust Protocol producers to apply for the Climate Smart Cotton Program. Applications will be approved on a first-come, firstserved basis and applicants must agree to upload their 2023 bales by March 1, 2024. Trust Protocol enrollment can be completed at https://members. trustuscotton.org/register/step/role and Climate Smart Cotton Program application at https://trustuscotton.org/u-s-cotton-growers-can-now-applyfor-the-climate-smart-cotton-program/. A step-bystep video on how to apply is at www.youtube.com/ watch?v=htWaXmE0gHY. Email info@trustuscotton.org with questions or for assistance.

Why is participation important?

■ U.S. cotton has long focused on continuous improvement. The industry’s Trust Protocol launch in 2020 allowed greater transparency by affirming and measuring its sustainability outcomes. These are reductions in greenhouse gas emissions, soil loss and water/energy use, while increasing land efficiency and soil carbon.

Now, the Climate Smart Cotton Program is taking our industry to the next step by 1) utilizing the Trust Protocol’s foundational reputation and our program partners’ expertise so producers can learn, grow and explore new opportunities for reducing climate impacts and 2) providing implementation resources. Among economic benefits participating producers will realize are a reduction in input costs, potential yield improvements, and added revenue from carbon insets. These benefits — all generated by CSA practices — will incentivize long-term commitment to management change and accelerate growth in adoption beyond this five-year pilot.

TWITTER: @COTTONFARMING AUGUST 2023 COTTON FARMING 5

Gary Adams serves as president/CEO of the National Cotton Council of America and as president of the U.S. Cotton Trust Protocol.

Producers are encouraged to apply for the Climate Smart Cotton Program before the September 1, 2023, deadline.

Annual-Type Cotton Plants

Clemson Researchers Tweak Cotton Genes To Improve Productivity

BY A. DENISE ATTAWAY, PH.D. CLEMSON UNIVERSITY

Clemson University researchers are determining how to develop a higher-yielding, better-quality cotton by altering plant growth habit and form. Led by molecular biologist Sachin Rustgi, they are looking at how regulating certain genes can transform cotton from a perennial plant to an annual, as well as genes that control the number of bracts — small leaf-like structures that protect the plant’s floral buds, or squares, against bollworms and other pests.

“Right now, cotton is planted and grown as an annual plant, but it is really a perennial plant,” said Rustgi, a scientist in the Advanced Plant Technology Program at Clemson’s Pee Dee Research and Education Center near Florence, South Carolina. “If we can develop an annual variety for cotton, we believe South Carolina farmers will benefit by seeing a higher-yielding cotton with higher-quality fiber.”

The United States is the world’s leading cotton exporter, providing about 35% of global cotton exports in recent years. Figures from the U.S. Department of Agriculture show almost 18 million bales of cotton were produced in the United States in 2021. In addition to South Carolina, other major cotton-producing states are Alabama, Arizona, Arkansas, California, Georgia, Louisiana, Mississippi, Missouri, New Mexico, North Carolina, Oklahoma, Tennessee, Texas, Florida, Kansas and Virginia. Cotton takes from 130 to 160 days to grow. During this time, the plants go through several stages — planting to emergence, emergence to first square (bud), square to flower, flower to open boll and harvest.

“The cotton plant growth habit and structure determine its productivity and influence management strategies for production,” said Salman Naveed, a Clemson doctoral student working with Rustgi.

The researchers are looking at how plants use environmental and hormonal cues to transition from vegetative growth to reproduction. Reproductive development begins four to five weeks after planting when squares form. During this stage, bracts surround the squares.

Tobacco Rattle Virus

Typical cotton plants include three bracts. A fourth bract can form on some cultivars under certain conditions. The extra bract is undesirable because it can provide openings and allow thrips and other pests access to the squares. During this study, researchers injected tobacco rattle virus into cotton plants to finetune the balance between vegetative and reproductive growth. The virus was used to manipulate a cotton gene associated with bract development to help prevent a fourth bract.

“When injected into a cotton plant, the tobacco rattle virus ‘knocks down’ the gene associated with the fourth bract and just three bracts are produced,” Rustgi said. “Compactly packed bracts make it more difficult for insects to attack the bolls.”

The tobacco rattle virus also was used to manipulate a cotton

gene associated with plant growth.

Cotton’s Growth Habit

Perennial crops usually grow in environments that may have limitations such as short growing seasons or dry climates, or where plants’ ability to access resources may be limited. Perennial plants store reserves such as carbohydrates, fats and proteins to use for regrowth. In many plant species, this process produces root and shoot buds that can grow into new plants. This is called “vegetative reproduction.”

Because of its growth habit, cotton continues to add vegetative growth at the same time as reproductive development, diverting the plant’s energy away from lint and seed production. The researchers believe an annual cotton variety will help cotton plants use more energy to produce higher-quality lint resulting in more profits for growers. The hope is for the results of this study to lead to breeding methods to develop annual-type cotton plants. Upland cotton cultivars used in the study are Coker 201, CABD3CABCH-1-89, ARKOT 8102, HOPI MOENCOPI, SPNXCHGLBH-1-94, CAHUGLBBCS-1-88, TAMCOT SP-23 and GSA 74.

In addition to Naveed, other researchers collaborating with Rustgi on this project include Clemson graduate student Seyi Toyinbo and Clemson technicians Nitant Gandhi and Sarah Rawlins. Mike Jones, Clemson Extension cotton specialist, and Todd Campbell, USDA-Agricultural Research Service research geneticist, also are involved.

This research is supported by the South Carolina Cotton Board and Cotton Incorporated.

6 COTTON FARMING AUGUST 2023 COTTONFARMING.COM

Denise Attaway, Ph.D., is a writer/editor with Clemson University.

Clemson researchers are looking at how regulating certain genes may result in a higher-yielding cotton with higher-quality fiber.

Cotton In The Classroom

Back-to-School Resources For Educators

As teachers and students alike get ready for back-to-school season, Cotton Incorporated has once again partnered with Young Minds Inspired (YMI), an educational site geared toward educators, to provide free cotton-themed curriculum and resources meant to engage students with hands-on classroom lessons and activities about cotton, cotton science and cotton sustainability.

The curriculum focuses on STEM — Environmental Sciences and Math. Cotton Incorporated and YMI created the resources to help elementary and middle school students learn about and evaluate the properties and benefits of cotton. There are teaching kits for students ranging from second grade to eighth grade. The free curriculum includes downloadable teacher guides, activity sheets, posters and an online whiteboard activity.

“Today’s students become tomorrow’s consumers,” said Anne David, director of advertising for Cotton Incorporated. “We want to ensure we educate the next generation of consumers about all the amazing things cotton can do.”

Updated Materials

Cotton Incorporated’s advertising department has worked with YMI for the past four years to bring hands-on classroom lessons and activities about cotton science to students and educators nationwide. This year, Cotton Incorporated and YMI refreshed all the materials with updated numbers and statistics. They also launched a new 360-degree virtual field trip video series showcasing cotton’s journey from dirt to shirt.

The new video series, geared toward

BY STACEY GORMAN WARREN, ARKANSAS

second through fourth graders, includes five short videos explaining cotton planting, cotton harvest, cotton ginning, cotton at the spinning mill and making cotton into fabric. Each video allows the user to click and drag around the screen to get a unique, 360-degree view of each step in the process.

“These new videos allow students to take a surprising journey to the farm to

see where it all begins,” said David. “By following the process all the way from dirt to shirt, these future consumers are learning to connect the dots between fashion and the farm.”

Tremendous Response

Between March and April 2023, the program targeted 240,000 2nd-4th grade educators with e-blasts about the materials, and in just those two months, Cotton Incorporated saw 14.5 million impressions and 44,600 downloads by educators.

If you, or a teacher you know, is interested in the cotton curriculum or the Dirt to Shirt 360-degree videos, visit https:// ymiclassroom.com/lesson-plans/cotton/. As always, Cotton Incorporated is proud to offer these downloadable materials free of charge.

Stacey Gorman is The Cotton Board’s director of communications. Contact her at sgorman@cottonboard.org.

ACKNOWLEDGMENTS: The “Dirt to Shirt” video program would not have been possible without the support of the Schniers family-Texas, the Leggett family-North Carolina, the Wall Co-Op GinTexas, John Maness of Gildan, North Carolina, and both Cotton Incorporated and The Cotton Board.

TWITTER: @COTTONFARMING AUGUST 2023 COTTON FARMING 7

RESEARCH & PROMOTION

The Big Picture

An Industry That Never Stops Spinning

Sometimes it’s easy to lose sight of the forest because all the trees are getting in the way. The same could be said for the complexity of the journey of a cottonseed from pre-emergence to the point where someone actually picks out a shirt in a store, bags it up, hauls it home, sticks their arms through the sleeves and eventually walks out the door to start their day.

The 2023 season grows ever closer to conclusion. Texas has already harvested their first bale of cotton – a fact that is always semi-annoying to growers from California to North Carolina. It’s even semi-annoying to other Texas growers who might as well live and operate their machinery a planet away from the Rio Grande Valley.

In reality, nothing stops when the deer blind starts. Far from the field, the process keeps spinning. Literally.

Data Driving Decisions

Technology continues to influence the entire industry with novel developments from field to fabric. Sometimes it’s all about the data. A new tool for spinning mills was recently launched at International Textile Machinery Association 2023 that allows mills to evaluate their performance in comparison with other cotton mills. The COTTON USA Mill Performance Index™ is designed to highlight how mills compare to their direct competition and how purchasing U.S. cotton increases productivity

and provides higher yields.

ITMA is the world’s largest international textile and garment technology exhibition that showcases new technologies and developments in the industry. Although seemingly far removed from the day-to-day challenges of growing a cotton crop, it’s still part of the big picture that ultimately makes the difference.

“The benchmarking capability of this tool from Cotton Council International (CCI) has the potential to transform a mill’s performance,” said CCI Executive Director Bruce Atherley. “The COTTON USA Mill Performance Index™ shows how mills compare to their direct competition and how sourcing U.S. cotton ultimately increases productivity and provides higher yields.”

The COTTON USA Mill Performance Index anonymously collects data from participating spinning mills and gives performance measurements across five key cost drivers: material yield, machine productivity, labor productivity, efficiency management and energy management. Data security is a top priority, and anonymity is guaranteed.

The launch of this tool at ITMA 2023, the world’s largest international textile and garment technology exhibition, follows a pilot program of the COTTON USA Mill Performance Index™ involving 47 mills across 13 countries. The program showed that U.S. cotton increased labor productivity and lead to better running conditions/less ends down, higher yield in combed and

8 COTTON FARMING AUGUST 2023 COTTONFARMING.COM

From the eld to ginning and spinning, cotton travels a very complex process.

carded yarns, higher machine productivity and higher spindle speed, according to CCI.

The COTTON USA Mill Performance Index™ is an invitation-only program available to spinning mills that are members of the U.S. Cotton Trust Protocol®. To qualify, mills must process at least 10,000 bales of U.S. Upland and Supima cotton.

Marketing Madness

After the spinning, the spin begins. Or perhaps it never ends. Marketing programs across the Cotton Belt touch all facets of the industry. What begins locally in the field very often has a global impact.

Supima Reaches Out

The 69th Supima annual meeting schedule will kick off in California on August 29 in Coalinga, California, and continue for the next few days on a whirlwind tour through Arizona, New Mexico and Texas. Details can be accessed online at https://supima.com/industry-news/save-the-date.

Long recognized as a leading liaison between growers and the textile industry, Supima is one of the leading innovators in cotton promotion – domestically and globally. The upcoming grower meetings will showcase the organization’s marketing efforts regarding traceability, transparency authentication as well as other programs.

CI Celebrates 50

While marketing is by its nature constantly evolving, some visuals are just plain noteworthy.

Cotton Incorporated recently celebrated the 50th anniversary of the Seal of Cotton trademark, an iconic logo that transformed cotton from an agricultural commodity into a globally recognized symbol of natural comfort, trust and sustainability.

The Seal of Cotton was introduced in 1973 as a symbol of trust, quality, sustainability and reliability to consumers, retail-

ers and textile brands. It was designed in 1973 by Susan Landor Keegin, daughter of Walter Landor who founded branding giant Landor Associates.

Landor Keegin was inspired by seeing the cotton plant growing in the field. The Seal of Cotton was born, allowing for easy recognition of the fiber and differentiation from synthetic fibers.

“The assignment was to find a way to stand up against synthetics,” recalls Susan Landor Keegin. “I was going to see relatives who lived in the area and saw cotton growing in the fields with the bolls puffed up. Something about seeing it in person, the rigidity of the stem and the softness of the boll, I had never seen that.”

Today, the Seal of Cotton is used by over 950 brands in nearly 70 countries, becoming a global symbol associated with fashion, durability, quality and sustainability. Nearly eight in 10 consumers (78%) have awareness for the Seal, according to Cotton Incorporated’s 2023 Seal of Cotton Consumer Research.

“The 50th anniversary of the Seal of Cotton is a celebration of a highly recognizable icon that brings consumers a sense of emotional and physical comfort and familiarity,” said Kim Kitchings, senior vice president, consumer marketing for Cotton Incorporated.

2023 In Retrospect

The books haven’t quite closed on the current season from a grower’s perspective except for maybe a few places far to the south in the Belt. Whether it’s the deer or duck blind, the beach or some other form of relaxation, it’s nice to know the rest of the industry is still ginning and spinning long after that last boll hits the hopper.

Brenda Carol, a freelance writer based in San Luis Obispo, California, compiled the information for this article. Contact her at brenda@carolcommunications.com.

TWITTER: @COTTONFARMING AUGUST 2023 COTTON FARMING 9

Data from CCI’s Cotton USA Mill Performance Index can help spinning mills improve their operations to compete more e ectively within the global industry.

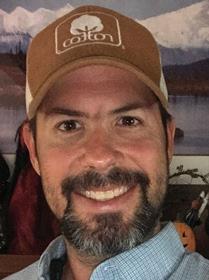

A North Carolina Educator

Relentlessly Informing The Public On Agricultural Practices

BY CASSIDY NEMEC ASSOCIATE EDITOR

Krista Huss never expected she would be sharing the story of agriculture to all who would listen. Upon marrying a fourth-generation farmer, Matt Huss, that would all soon change.

The Husses farm cotton, corn, soybeans and wheat and raise goats as well. The main farm was established in 1921, and they have been in the area of Lincolnton, North Carolina, they are in now for almost 40 years.

From Detest To Devotion

Krista recounted her journey from being skeptical of the industry to now wanting to share the goodness it brings to everyone she can.

“I started out on the farm with no role whatsoever and hating agriculture, but my heart just softened over the years,” Huss said. “Now I do everything from picking up spare parts, bringing meals, running equipment and taking care of the goats.”

She said during harvest, she will often be over at the module builder and following behind everyone from field to field.

“You have to be flexible because, with what I’m doing, it could change in five minutes.”

The Social Media Impact

Huss said her inspiration for sharing on social media was simply friends who loved her content and wanted to see more. She mainly uses Instagram to bring agriculture to the forefront and admires people like Meredith Bernard, Kelly Griggs and Natalie Kovarick who also all work to tell their stories and make their mark on the industry.

“About the time I started getting serious with Instagram two years ago was when reels became popular, so I thought reels would be a good way to combine comedy and education together and make it something fun that could reach a lot of people,” she said.

Huss said one of the major pros for social media is the amount of people she is able to reach. “I have so many friends from non-cotton-growing states who just love learning all they can about cotton, so I’m able to educate friends.”

She added the ease of it as being convenient so she can post whenever and wherever. Relationships are a big plus for Huss

when it comes to social media as she has been able to meet many people and make one of her closest friends through Instagram.

Feeling overwhelmed and pressured when people may mean well and want to know what is happening all the time are a couple of cons she discussed. “It’s sweet, but it can be overwhelming to feel the pressure and expectations.”

On the flip side, Huss enjoys the everyday interactions she gets to have with others through her platform. “I try to do my best to respond to all messages. I feel like direct messaging is a way to interact one-on-one with somebody, and sometimes I’ll even do

10 COTTON FARMING | AUGUST 2023 COTTONFARMING.COM

AGVOCATES IN THEIR FIELDS

the voice memo if I have a lot to say — somebody from a different part of the state or country loves listening to my accent.”

She said it is all a chance to make a connection and educate.

As with most social media cons comes the sour side of putting yourself out there for everyone to see.

“Because you expose yourself to so many people, not all of them are going to be welcoming. There is going to be negativity, which I can handle — if you have a different opinion than me, that’s fine — but you don’t have to degrade me and attack me.”

Goals In Education

Huss has goals for herself in sharing more about agriculture. She is currently working to obtain her Bachelor of Science degree in Agriculture Business and getting certified to teach in North Carolina while she continues to work. She has seen firsthand the need for education in this field.

“People who aren’t in ag have no idea of all that goes on,” Huss said. “I love to educate. My heart is in education.”

She recounted some of her recent experiences speaking to fourth and fifth graders about cotton at some local schools.

“I was absolutely blown away at the lack of knowledge these kids had. I actually brought in a stalk of cotton and gave some of the cotton picked out of the bolls to some of the kids. One of the first kids looked at it, picked it up and popped it in his mouth. He thought because it grew in a field, that meant it was food,” she said.

“That just really opened my eyes to the lack of knowledge

there is, and we as farmers in this generation — if we don’t take the time to educate this next generation, who’s going to do it?”

Huss emphasized the role misinformation plays in abundance throughout society.

“Kids nowadays hear stuff from parents or on the news — lies about ag — and if we don’t get out there as farmers and one, defend ourselves, but two, share our knowledge and educate them, then it’s just going to get worse.”

She said she encourages farmers to share, even if it means just going to a local town hall meeting to share with other locals. “I don’t think people realize how important sharing our story in ag is because people don’t know.”

Huss said she wants to bring honesty to the agricultural industry in this realm.

“There’s so much that goes on in agriculture that people have wrong beliefs about, and I hope through honestly sharing my life — the good, the bad, the ugly — to use that honesty to educate people and share our life and the way we do what we do.”

Huss finds it important to share the education farmers have as well. “People think, ‘Oh, just dumb farmers pouring a bunch of chemicals,’ but it’s not. We know what crop this can go on, we know whether it’s going to kill your bees, we actually keep track of bee registries around here, and the public doesn’t realize that we are educated and not out to harm them.”

She said she believes not necessarily in changing people’s minds but rather in providing them with all the information before they make a decision. She emphasized that her goals are not in the followers.

“I don’t do it for the numbers. I do it because my heart is in it and because there’s just a lack of knowledge from the general public,” she said. “If I have the chance to educate five people, that’s fabulous.”

Overall, Huss wants to be transparent and informative when it comes to the industry. “I want to use my honest life experience to share our little part of agriculture to a community who isn’t fully aware of all ag has to offer.”

“AGvocates In Their Fields” features those providing a voice for American agriculture through their platforms. If you know of an “agvocate” or group of agricultural advocates you would like to see featured, contact Cassidy Nemec at cnemec@onegrower.com.

TWITTER: @COTTONFARMING AUGUST 2023 | COTTON FARMING 11

AGVOCATES IN THEIR FIELDS @HussFamilyFarms

VICTORIA WILLIS PHOTOGRAPHY

Mid-South Soil Health Study

Seeking Links Between Tillage, Carbon Sinks, Yield Potential

BY JOHN LOVETT UNIVERSITY OF ARKANSAS SYSTEM DIVISION OF AGRICULTURE

As much as the Mississippi Delta has been farmed, the impact that agronomic practices such as cover crops, carbon sequestration, reduced tillage and nutrient management have on Delta soil quality has not been heavily investigated.

A comprehensive three-year study by the Arkansas Agricultural Experiment Station, the research arm of the University of Arkansas System Division of Agriculture, will change that by evaluating the impact of conservation practices from short- and long-term field trials in the unique environment of the Mid-South.

With support from a nearly $750,000 grant from the U.S. Department of Agriculture’s National Institute of Food and Agriculture, the study seeks to better understand how soil conservation and nutrient management practices affect soil health indicators in Mid-South irrigated crop production systems. The study will measure soils on 34 selected soil health measurements including pH, soil organic matter, water infiltration and total carbon.

Mid-South crop production is unique because most crop production is irrigated, the soils are poorly drained, have low organic matter by nature, are usually heavily tilled and mild winter temperatures allow soil microbes to work overtime to decompose crop residues, which makes it difficult to build up soil organic matter.

Comprehensive Assessment

Gerson Drescher, assistant professor of soil fertility for the experiment station, is the principal investigator of the study. Studies oftentimes report a lack of relationship between soil health scores, soil management practices and crop yield, he said.

“Ultimately, that is what a producer wants to know,” Drescher said. “If they adopt certain soil conservation practices, such as cover crops or no-tillage, what is changing?”

Soil health assessments from commercial and public entities have become more popular in recent years, Drescher said, but there is still limited research focused on a comprehensive soil health assessment, integrating chemical, physical and biological soil properties. And there is even less research on the matter in the Delta, where most of Arkansas’ row-crop farming takes place.

“We have research done with different crop production systems, either with no-tillage, different cover crop species, cash crops or nutrient management, that has been going for four, 10, 15 and even 22 years across Arkansas,” Drescher said. “We have now a unique opportunity to look at soil health indicators in those long-term experiments to see what is changing and how certain management practices impact soil health, carbon sequestration and crop production resilience.”

Farmer Participation

Soil data for the research will also be collected in collaboration with producers participating in the Arkansas Discovery Farms Program. The program is supported by a host of sponsors and industry stakeholders focusing on soil and water quality research. Currently, there are 15 active Discovery Farms across the state representing both row-crop and livestock production.

Looking at data from many short- and long-term field trails, Drescher and his team will see what soil properties are changing and if there is a connection between them that translates to more yield, increased water-use efficiency and less need for fertilization. It will help identify practices that have the biggest impact on soil health and yield potential for silt loam soils in the Mississippi River Delta regions of Arkansas and be representative for soils in the Delta regions of Louisiana, Mississippi and Missouri, Drescher said.

Co-principal investigators on the project include Kristofor Brye, university professor of applied soil physics and pedology for the experiment station; Mike Daniels, soil and water conservation specialist for the Cooperative Extension Service; and Trent Roberts, associate professor of soil fertility and soil testing for the experiment station, and endowed chair in soil fertility research.

To learn more about Division of Agriculture research, visit the Arkansas Agricultural Experiment Station website: https://aaes. uada.edu. Follow on Twitter at @ArkAgResearch. To learn more about the Division of Agriculture, visit https://uada.edu/. Follow us on Twitter at @AgInArk. To learn about Extension programs in Arkansas, contact your local Cooperative Extension Service agent or visit www.uaex.uada.edu.

12 COTTON FARMING | AUGUST 2023 COTTONFARMING.COM

Kristofor Brye, university professor of applied soil physics and pedology, uses a slide hammer and core chamber to collect a soil sample in a soybean plot.

FRED MILLER/U OF A

Members Of NCC’s 2023 Emerging Leaders Program Receive Training

Twelve U.S. cotton industry members were chosen for the National Cotton Council’s 2023 Emerging Leaders Program.

Representing many of the industry’s segments were: PRODUCERS – Trey Beyer, Portland, Texas; Ryan Johnson, Wilmot, Arkansas; Nick Marshall, Baker, Florida; John Newby, Athens, Alabama; Ross Rayner, Goodyear, Arizona; Will Sanford, Prattville, Alabama; and Blake Wilbur, Tulare, California.

Other members of the program include: GINNER – David Hardin, Yuma, Arizona; and Steve Sterling, Tuscumbia, Alabama; MERCHANT – Paula Price, Cordova, Tennessee; WAREHOUSER – Randy Squires, Hobart, Oklahoma; COOPERATIVE – Kevin Madding, Bakersfield, California.

Supported by a grant to The Cotton Foundation from Bayer, the Emerging Leaders Program provides participants with a better understanding of how the NCC carries out its mission of ensuring the U.S. cotton industry can compete effectively and profitably in the raw cotton, oilseed and U.S.-manufactured product markets at home and abroad.

Specifically, participants get an in-depth look at the U.S. cotton industry infrastructure and the issues affecting the industry’s economic well-being; the U.S. political process and the NCC’s programs as well as its policy development and implementation process.

They also learn about Cotton Council International’s activities aimed at developing and maintaining export markets for U.S. cotton, manufactured cotton products and cottonseed products and the role that Cotton Foundation members play in fostering a healthy U.S. cotton industry.

The Emerging Leaders Program, now in its eleventh year, provides participants with professional development and communications training such as presentation and business etiquette instruction for engaging with the news media and utilizing social media tools and tactics.

The 2023 program members participated in sessions from June 18-22, in Memphis and St. Louis. They received an orientation to the NCC, media training, communication skills training and an agribusiness briefing.

Remaining Opportunities For Texas Ginning Safety Seminars

Texas Cotton Ginners’ Association is entering the final

stretch of its safety seminar schedule. It’s a little different than last year, so pick the meeting that works best for you and your gin crew.

The organization will provide a seminar in Canyon, Texas, on Sept. 19. It will be followed by a Sept. 20 meeting in Childress. The safety meetings wrap up Sept. 21 in Lubbock.

The seminars will run from 8:30 a.m. to 4:30 p.m. with a catered lunch. Please note all seminars will begin at 8:30 a.m. sharp. There will be two identical sessions conducted. The morning session runs from 8:30 a.m. to noon and will be presented in English while the afternoon session will be the same in content but will be presented in Spanish.

Those attending the afternoon session are encouraged to show up at 11:45 a.m. to eat lunch. The morning session attendees will eat once their session concludes and will be free to go after lunch.

The Texas Cotton Ginners’ Trust manager session begins at 1 p.m. Remember, TCGT staff conducts manager meetings following each TCGA district meeting as well. The Texas Cotton Ginners’ Trust is the sole sponsor of the 2023 safety seminars.

The goal of the seminars is to go through the ginning process from picking up the module to hauling the finished bale off the yard. Throughout the entire presentation, participants will hear about some of the different accidents that happened during the past ginning season.

If you have questions about the upcoming safety seminars, please contact Aaron Nelsen at aaron@tcga.org or 512-476-8388 at the TCGA office.

Congratulations To The 2023 First Bale Of Cotton

Wesley Vanderpool (right) harvested this year’s first bale of cotton — a Stoneville 4990B3XFvariety — near Alamo, Texas. Pictured alongside Wesley is his partner, Verne Vanderpool.

Alamo, Texas, is once again home to the first bale of the 2023 cotton season. Wesley Vanderpool, who also had the first bale in 2022, harvested on Tuesday, June 20, after planting Stoneville variety 4990B3XF Feb. 7. Vanderpool’s harvested bale was then ginned at Willacy Co-Op Gin in Sebastian, Texas.

For the past 10 years, first harvest bales have come from BASF cottonseed varieties. This bale will be auctioned off at the annual First Bale of Cotton Auction and Scholarship Fundraiser happening on Sept. 14 in Harlingen, Texas.

TWITTER: @COTTONFARMING AUGUST 2023 | COTTON FARMING 13 Industry News

Plant Growth Regulators

Mepiquat Provides Crop Management Benefits To Cotton Farmers

Since the 1980s, plant growth regulators — PGRs — have played an important role in achieving a successful, efficient and more profitable cotton crop. Cotton experts from different areas of the Cotton Belt discuss why PGRs are a tool to consider in cotton production and how to interpret the factors that are involved.

BRIAN PIERALISI, Mississippi Extension Cotton Specialist

The key purpose of plant growth regulators is to manage cotton internode length for a more efficient plant to improve production. Varietal growth habit and vegetative potential are paramount in making PGR decisions. Vegetative potential is the ability to produce abundant vegetative biomass.

Cotton varieties differ widely in terms of height and responsiveness to PGRs. The main goal is to monitor the length between the fourth and fifth nodes down from the terminal and strive to maintain an optimal distance of 2–3 inches.

Cotton growth varies greatly across fields and even within fields. Variable-rate PGR applications help improve crop response because you can treat highly vegetative zones more aggressively and vice versa. As cotton enters the reproductive growth stages, a solid PGR strategy will limit plant height, improve air circulation through the canopy, increase defoliation efficiency and enhance harvest efficiency.

Crop growth depends on calendar date, temperatures and other environmental factors that are often unpredictable. In

some situations, high fruit retention and boll load may act as a natural plant growth regulator. In this situation, excessive PGR applications can halt growth, greatly reducing plant stature. Using a conservative strategy and closely monitoring the internodal distance four to five nodes down from terminal may help avoid this problem. In fields with extreme vegetative variability, base your decisions on the most productive and predominant zones in the field. For example, if 75% of the field has high vegetation and is typically very productive, base your management primarily on this zone.

PGR management must evolve with both varieties and environmental conditions. Therefore, management strategies may vary drastically from year to year and can change during the growing season. Ultimately, the goal is to use plant growth regulators to manage internodal distances and produce a more efficient plant.

SETH BYRD, Former Oklahoma Extension Cotton Specialist

The need for a plant growth regulator often is based on current visual observations of crop growth or conditions, i.e. if the plants look too tall, then a PGR should be applied. Unfortunately, this method sometimes results in an application occurring too late for optimum growth regulation. Since PGRs only impact new growth, it is critical to base this decision upon the potential for excessive growth to occur. This means that while the size of the plant may dictate use rate (higher rates on larger plants, lower

14 COTTON FARMING | AUGUST 2023 COTTONFARMING.COM

Internode distances greater than 3 inches in cotton without a PGR application.

Optimal internode distance of 2–3 inches following a PGR application. Internode distances lower in the canopy exceeded optimal distance before application.

PHOTOS COURTESY OF JIM SAYLE, DESOTO COUNTY, MISSISSIPPI

Table 1: Plant Growth Regulator Use Factor Consideration

Variety Generally, early maturing varieties require a less aggressive PGR strategy than late-maturing varieties. However, the actual approach will be governed by many factors listed below. Most seed companies offer PGR guidelines for all their variety offerings.

Fruit Retention

Weather Forecast

Irrigation

Whether squares or bolls, fruit retention is the most effective plant growth regulator for cotton. Environmental conditions or insect feeding that result in fruit shed may necessitate earlier applications or increased rates.

If conditions favoring excessive vegetative growth are forecasted, a PGR application may be required, or rates may need to be increased. The timing and rate should also consider variety and fruit retention.

Growth potential is greater in irrigated cotton, thus PGR applications to irrigated cotton are common. Applications in non-irrigated cotton are not as common but may be needed if favorable conditions (heat and moisture) persist, or if the crop experiences a large fruit shed. This is especially true for late-maturing varieties, which are commonly selected for dryland production. Rates in non-irrigated cotton are often lower to avoid premature cutout if a forecasted rain event deteriorates or precipitation totals are lower than predicted.

Nitrogen

Source: Oklahoma State University

If adequate or excessive fertility levels are present, whether residual or applied in-season, a more aggressive PGR approach may be required. Excessive nitrogen can result in rank vegetative growth, slow the initiation of fruiting and delay maturity. Excessive nitrogen in combination with optimum moisture conditions and warm temperatures can result in particularly vigorous vegetative growth.

more aggressive.

Calendar date? For late crop, tend towards an aggressive approach if favorable growing conditions exist.

Irrigated? Recent rainfall?

If good-to-excellent rainfall and moderate temperatures (highs <90 degrees F) are forecast, be aggressive unless growth is well in check. If high temperatures, little to no rain is expected and there is minimal or no irrigation, be conservative or passive.

KEITH EDMISTEN AND GUY COLLINS, North Carolina Extension Cotton Specialists

This field shows cotton plant height reduction associated with PGR application — no PGR (left) and PGR application (right).

rates on smaller plants to achieve the same level of growth regulation), PGRs have no effect on growth that has already occurred. In addition to taking into consideration the current growth stage and size of plants, the factors shown in Table 1 also should be used to guide PGR decisions.

Because PGRs inhibit gibberellic acid throughout the plant, any areas in which cells are expanding are impacted. This not only includes the main stem but leaves as well. As a result, leaf expansion is reduced following PGR application, producing smaller but thicker leaves. This results in leaves that are darker green following a PGR application when compared to plants that have not received a recent application. This is often referred to as the “Pix effect” but has no impact on crop health.

STEVE M. BROWN, Alabama Extension Cotton Specialist

Making good decisions about plant growth regulator use involves assessing current and near-term conditions. The questions below help tilt management towards being more aggressive, less so or passive altogether.

Variety – aggressive or not?

Crop growth stage, conditions?

Field conditions – fertility? growth history?

NAWF at early bloom? If 8-9, be aggressive; if 4 or 5, wait.

Current internode lengths between 4-5th leaf down from the terminal? If 3 inches or more, apply or consider being

Mepiquat can help cotton growers manage the development and maturity of their crop. Research conducted in North Carolina, as well as in other areas of the Cotton Belt, has demonstrated that mepiquat treatment can hasten maturity, reduce plant height, facilitate insect management, decrease boll rot and increase yield. These desirable features are caused by the inhibition of cell elongation in the cotton stems. Mepiquattreated plants are normally smaller and more compact. Internodes along the stem and fruiting branches are shortened. The total number of fruiting branches may also be reduced slightly. Energy is directed toward retention of bolls lower in the canopy and away from vegetative growth, due to increased light penetration to lower subtending leaves.

Mepiquat can be applied as a broadcast spray or as a banded spray. Research at North Carolina State University has shown that mepiquat also can be applied through a canvas wick applicator. The greatest advantage the wick seems to have over spray applications is that it makes it easier to apply mepiquat to tall cotton and avoid application to shorter, stressed cotton within the same field. More detailed information about using a wick can be found online on the cotton portal under Old Carolina Notes at t.ly/2VY6f and t.ly/XmfO8.

As with any management tool, the decision to use mepiquat should be based on a consideration of its usefulness in a specific situation. Your decision to apply mepiquat in any given year should be made on a field-by-field (or portion-of-a-field) basis. Certain cotton fields may require treatment every year, whereas others will rarely require treatment.

TWITTER: @COTTONFARMING AUGUST 2023 | COTTON FARMING 15

2023 Cotton Crop Update

ARIZONA Randy Norton

In last month’s comments, I had discussed how our spring and early summer had been significantly milder than in recent years. Well… that has all changed. Beginning in early July, the normal summer heat began to develop with daily high temperatures between 115 degrees Fahrenheit and 120 degrees Fahrenheit for the low deserts, with the higher desert production areas coming in with daytime highs between 110 degrees and 115 degrees.

As of this writing (first full week of July), the monsoon season has yet to begin with any significance. However, some weather forecasts are beginning to have chances of precipitation come into the longer 10-day forecasts for mid-July and into later July. We’ll see how that develops. National Weather Service, in their three-month long-term forecast, still has all of the cotton-producing regions of Arizona marked for lower-than-average precipitation and higher-than-average temperatures. However, due to the mild spring and early summer, most of the crop is approximately 200 heat units behind where we normally would be this time of year. This, coupled with the fact that a good portion of the crop was planted later than normal (approximately a week to 10 days), means most of the crop will be entering mid bloom during this heat wave.

Proper irrigation and crop water status management will be critical to avoid issues with heat-induced fruit shed. The temperatures and monsoons are not something we can manage, but we can do our best to minimize crop stress by maintaining good water relations in the crop with timely and adequate irrigation. During the next several weeks, monitor fruit retention and look for heat-stress-induced fruit shed. Be ready to manage the vegetative reproductive balance of the crop appropriately with plant growth regulators as needed.

For more information on these topics and other cotton production related topics, visit our website at extension.arizona.edu/crops-soils. rnorton@cals.arizona.edu

TEXAS Ben McKnight

As I write this in early July, the cotton crop in the Lower Rio Grande Valley and Coastal Bend regions have been struggling with the extremely warm conditions that have prevailed in the area for the past few weeks. With daytime temperatures above 100 degrees and nighttime temperatures hovering around 80 degrees, many of the dryland fields are showing drought symptoms with plants quickly approaching physiological cutout. Many of these fields are experiencing conditions that are leading to flowers and small bolls being shed from plants. Even irrigated fields are showing some signs of flower and fruit shed with the current temperature conditions. Without additional rainfall or relief from the heat, the crop is on a trajectory to progress and finish very quickly this year.

Conditions in the Upper Gulf Coast region have turned off dry and warm as well, but soil moisture conditions are more favorable than the LRGV and Coastal Bend the first week of July. Most fields in this region range from early to peak bloom, and any additional rainfall during this timeframe would help the dryland acres finish out the season strong.

Some areas of the Blackland Prairie production region are experiencing abnormally dry conditions. The cotton crop across the region ranges from second week of squaring in later plantings to late bloom in the earlier planted fields. While the crop condition in the region is mostly good

currently, potassium deficiency symptoms are beginning to show up in some fields. More timely precipitation in July and early August would help push the Blackland Prairie dryland crop across the finish line with good yields and fiber quality.

Dry conditions persist in other production regions across the state, including the West Central region and some areas within the Rolling Plains. The High Plains received heavy rainfall in early June, and in some cases, it may have been too much at once. According to the U.S. Department of Agriculture June acreage report, it appears that Texas will be down approximately 1.7 million planted acres compared to 2022 with a total of 6.1 million planted acres this growing season. bmcknight@tamu.edu

LOUISIANA Matt Foster

According to the USDA National Agricultural Statistics Service, planted acres of cotton in Louisiana are at 130,000 acres, down 65,000 acres from 2022. As I write this July 6, approximately 75% of the cotton crop is squaring and 15% is setting bolls, which is slightly below the five-year average of 78% and 23%, respectively.

It has been hot and dry in most cotton-producing areas of the state. Irrigated cotton fields have been a common sight while travelling throughout the state. Some wilting has been observed in dryland fields, but nothing too concerning. Since heat unit accumulation has been higher this year, most of the crop is progressing rapidly. Square retention was excellent as we approached first bloom. Some of the crop is weedy mainly because pre-emergent herbicides weren’t activated well with the minimal rainfall. Despite hot and dry conditions, most of the cotton crop throughout the state looks good.

For the remainder of the season, growers and consultants will focus on insect control and growth management. Insect pressure from plant bugs, aphids and spider mites has been sporadic; however, I anticipate plant bug pressure will increase in the next few weeks as our corn crop is maturing rapidly. Currently, applications of mepiquat chloride are being made to manage plant height. Hopefully, timely rains will occur through the remainder of July and August to finish out the crop. Louisiana growers are currently optimistic about the cotton crop as the end of the season approaches. mfoster@agcenter.lsu.edu

MISSISSIPPI Brian Pieralisi

As I write this July 5, overall, our crop looks good. Despite a few replanted acres, most of our cotton was planted by May 15 and is blooming or approaching bloom. In 2022, our crop was further along on this calendar date compared to the 2023 crop — primarily due to the environmental conditions we have experienced. Recent scattered showers and cloudy weather have caused some blasted squares but nothing out of the ordinary.

During mid-June, there was violent weather that ravaged crops across Mississippi. Several wind and hail events stripped cotton down to match sticks. There was cotton ranging from three to 12 nodes that was affected. Considering the date of the hail damage, there was really not a “best” option moving forward. Some growers with less severe damage opted to keep the cotton crop and see what happens. Others replanted either soybean or corn.

Continued on page 18

16 COTTON FARMING | AUGUST 2023 COTTONFARMING.COM

Specialists Speaking

Bayer Field Day Highlights O erings

BY CASSIDY NEMEC ASSOCIATE EDITOR

BY CASSIDY NEMEC ASSOCIATE EDITOR

Paul and Linda Freund Farms hosted Bayer’s 2023 Needville, Texas, field day June 13. Tour stops and discussions included Dekalb corn and sorghum products and testing information, a new technology update on VT4Pro and Smart Stax Pro for corn. Deltapine also discussed their latest cotton varieties and New Product Evaluator candidates, as well as their ThryvOn technology.

Cotton Traits, Varieties Galore

Scott Stanislav, technical agronomist for Bayer, explained the benefit of the ThryvOn technology throughout the cotton belt with the Bt trait for thrips and lygus bugs.

“We’re really looking more on the agronomic side of things. If you get thrips, you’re delaying your maturity and delaying your fruit set. Your overall plant health may be less there than with the ThryvOn technology where you have that protection.”

He suggested there may be further benefit past the typical thrips and lygus coverage as well.

“It’s key to look at the agronomic piece of it from potentially earlier fruiting to some anecdotal evidence that we may have increased root growth in the ThryvOn compared to the nonThryvOn in the presence of thrips.”

Stanislav emphasized the role these added benefits play in

Texas as well. “Especially along the Texas coast, where a lot of the time you’re racing the weather and the potential for storms, earliness can be a very key factor to whether you get the crop out of the field due to rains and potentially tropical weather.”

In addition to all of this, he noted the introduction of new varieties coming along containing the Bollgard 3 ThryvOn with the XtendFlex technology in them.

According to Stanislav, DP 2012 B3XF and DP 2020 B3XF continue to be popular varieties across the Cotton Belt. DP 2239 was originally tested on the East Coast and is now becoming a heavy contender in the Texas Gulf Coast.

TWITTER: @COTTONFARMING AUGUST 2023 | COTTON FARMING 17 DRIFT CONTROL VERY GOOD INSECTICIDE CONTACT EXCELLENT SYSTEMIC VERY GOOD FUNGICIDE CONTACT EXCELLENT SYSTEMIC VERY GOOD HERBICIDE SOIL APPLIED GOOD CONTACT EXCELLENT SYSTEMIC VERY GOOD DUAL OUTLET SPRAY TIPS THAT PROVIDE SUPERIOR LEAF COVERAGE AND CANOPY PENETRATION WHILE MAINTAINING DRIFT CONTROL. UPGRADE YOUR SPRAY TIPS FOR MORE PRECISE COVERAGE www.teejet.com DRIFT CONTROL EXCELLENT INSECTICIDE CONTACT GOOD SYSTEMIC EXCELLENT FUNGICIDE CONTACT GOOD SYSTEMIC EXCELLENT HERBICIDE SOIL APPLIED VERY GOOD CONTACT VERY GOOD SYSTEMIC EXCELLENT M AKEEVERY DROPCOUN T

Scott Stanislav (right) discusses Deltapine cotton varieties, including those from the NPE program and ryvOn technology.

On the bright side, timely rains have allowed for good growth and development. We have experienced adequate dry periods to get all management practices done in a timely fashion. Plant bug pressure has been normal with some areas having greater pressure than others. Primarily, the greatest pressure is near corn fields or ditch banks, which is to be expected. Managing growth with PGRs should be based on varietal growth habit and vegetative potential of the plant. Ideally, there should be a two-to-three inch spacing between the fourth and fifth node from the terminal. A quick-reference guide can be found at Mississippi Crop Situation website or the following link: https://www.mississippi-crops. com/wp-content/uploads/2022/06/2022_PGR_Guide.pdf.

Hopefully, August will cooperate and we will have a good crop this year! bkp4@msstate.edu

TENNESSEE Tyson Raper

Tennessee’s cotton crop is off to a relatively good start. Several in the area were able to take advantage of a very early May planting window. As we moved further into May, several large rainfall events broke up our planting window and drove replants up. June brought mild temperatures and very little rainfall.

Many consultants have been quick to share how deeply rooted our cotton crop is this year. I’ve had several ask about my concerns with lack of “heat.” On the contrary, I can’t imagine a better June for cotton. Dry conditions during June can help us drive the plant toward flowering and help naturally regulate vegetative growth. We commonly

point to optimal growth maximum and minimum temperatures of 86 degrees Fahrenheit and 55 degrees Fahrenheit, respectively; average maximum and minimum temperatures through June will likely end up falling very close to 86 degrees and 55 degrees.

Activating residuals has been challenging in many areas with the lack of rainfall, and grass control remains an issue for us. Our biggest problem in many acres has been the relatively early influx of plant bugs into this crop, which has, in some areas, driven retention down. Scattered rainfall has moved through the area in recent days (I’m writing this July 6), but the area is now in need of several good soaking rainfall events to provide adequate moisture to push us through the effective flowering window. Cotton has finally turned the corner and, again, here in the first week of July, PGR applications are beginning on a large number of acres. traper@utk.edu

NORTH CAROLINA Keith Edmisten

I am writing this July 6, and it is hard to find a bloom in the state. Most of the cotton is two to three weeks behind normal due to cooler weather. This has reduced our effective bloom period from six to seven weeks to about a four-week window. A warm, late summer and fall can help out a lot with a late crop like this, but what we need to do now is concentrate on timeliness. This is especially true of insect control. With a shortened bloom period, we cannot afford to let insects damage the crop. We have lost most of the ability of cotton to compensate from damage to pests like plant bugs and stink bugs. There will be a lot of talk about using mepiquat to help with earliness. We need to be careful there and not just automatically use it just because the crop is late. We do not want to limit the production of fruiting branches on the plant, and excessive mepiquat can reduce or slow down the production of new fruiting nodes. We need this cotton to put on nine to 10 fruiting nodes and control insects to have a shot at a two-bale or more cotton crop. Mepiquat can make the crop earlier by increasing sunlight into the lower portion of the canopy and increasing the retention of fruit lower in the canopy. keith_edmisten@ncsu.edu

GEORGIA Camp Hand

Each season is unique, and this one is no different. Thus far, we have had our fair share of challenges in Georgia. Plant bugs have been higher than ever in our state, which could result in some season-long issues if not corrected. By the time you are reading this, I hope they are out of our cotton crop.

The glaring issue to me right now is that our cotton crop is behind across the board. Although our mid-May- and early June-planted cotton seems to be growing off a little better than our early planted crop, it is still behind with respect to degree day accumulation. Compared to the past four seasons, we are 100 DD-60s behind in our early- and mid-May-planted crop. We aren’t that far behind in our June-planted cotton but still behind.

This time of year, we can normally accumulate 100 degree days in a hurry — but my worry is that we will not be able to catch up based on the current forecast. Over the same span, we have averaged right around 10 DD-60s per day in October, which puts us about 10 days behind. Compound that with the plant bug issues we have had this year, and I think it could be a bad combination. In my opinion, we should consider being more aggressive than usual with PGR strategies to encourage some earliness in this crop.

We were so glad to see everyone at the Georgia Cotton Commission Mid-Year Meeting in Statesboro, and I hope to see everyone at the field days coming up in August. Field day dates are as follows:

18 COTTON FARMING | AUGUST 2023 COTTONFARMING.COM

Specialists Speaking

Continued from page 16

Southeast Research and Education Center Field Day – Midville, GA – Aug. 9

Southwest Research and Education Center Field Day – Plains, GA – Aug. 16

Cotton and Peanut Research Field Day – Tifton, GA – Sept. 6

As always, if you ever have any questions, please don’t hesitate to reach out to your local UGA county Extension agent. They, along with your UGA specialists, are here to help! camphand@uga.edu

ALABAMA Steve M. Brown

The cool, wet spring of 2023 created a late and slow start for the Alabama crop. Very little cotton was planted in April; most went in during May, and we did hear of a planter running on May 61 (aka June 30) in the Wiregrass. Indicative of how our crop seemed to track behind, we have a block of cotton planted May 2 in Prattville. Normally, we expect first bloom to occur 50 to 60 days after planting, but at that site, we didn’t see any flowers until July 6 — 65 days after planting. From the rare field planted in April, we had one report from Selma of a bloom April 22, which marked 61 days.

The first half of June was dry enough to cause concern, but the latter half brought abundant, if not excessive, rainfall to most of Alabama. A few sites saw hail. The “oven” came on during the last week of June. Temperatures reached the mid-to-upper 90s and humidity remained high, stressing people and crops.

Early square brought unusual plant bug activity. Our entomologists Scott Graham and Ron Smith received calls from every part of the state. Dr. Smith, now in his 52nd crop as an Extension cotton entomologist, stated, “This appears to be the most widespread and highest pressure we have ever seen in Alabama.” Most years, plant bug controls are common for the Tennessee Valley, with other areas spraying sporadically. We did

observe “embedded” populations — reproducing adults with nymphs and eggs — in some fields in southwestern Alabama in 2022, and the subsequent yield losses increased the awareness and control-readiness for that region.

Stink bugs typically become a common pest in late July, and they require aggressive treatment in most areas. Early observations suggested stink bug numbers might be less this year, but still, if present and untreated, they can rob a lot of cotton.

August will be the tell-tale month for our crop. Potential is there even though we’ve been a little behind. Good moisture, good insect management and favorable fall weather could mean a really good crop at the gin by Thanksgiving … or maybe into December. cottonbrown@auburn.edu

TWITTER: @COTTONFARMING AUGUST 2023 | COTTON FARMING 19

Specialists Speaking

Ginners Marketplace

COTTON FARMING IS THE OFFICIAL PUBLICATION OF THE GINNING INDUSTRY.

TCGA Interns Report On Their ‘Real-World Experience’

The Texas Cotton Ginners’ Association chose two interns to join the organization this summer and have an opportunity to experience the cotton industry. Both are with member gins throughout the summer.

Josiah Keck is a student at Texas A&M University majoring in agricultural systems management. He will graduate in 2025. Keck is originally from Iowa. His family moved to College Station in 2016. He makes and sells knives and started his own company (Keck Knives) in 2020. Keck has also worked for Texas A&M AgriLife Extension as a student worker. He is interning at Petersburg Co-op Gin and Smith Gin Co-op in Odem, Texas.

Riley Gryder is a student at Texas Tech University majoring in mechanical engineering. His expected graduation date is May 2024. Gryder is from Mertzon, Texas, (west of San Angelo) where he is the owner and financial manager of Rocker G Cattle Company (30 cow/calf) ranch. Gryder is a member of the Texas Tech Honors College and is interning at Edcot Gin in Edmonson, Texas, and Edcot Co-op Gin in Odem.

TCGA provides college students with a chance to show their value to potential employers. They will gain valuable “real-world experience” and take the next step in their careers. Below are their reports as they navigate their summer internship.

Josiah Keck

“I have been working for Myles Ramsey, manager of Petersburg Co-op Gin, for the first half of my internship. I have been learning the process of cotton ginning from Mr. Ramsey. The first week I helped take apart augers in the distributor. Next, I took apart the hangers, which are attached to the augers. I cleaned and replaced chains around the sprockets and checked for any damage around the drive shaft, sprocket and ball bearings. Later that same week, I helped one of my co-workers clean out and replace the gin stand saws.

“Mr. Ramsey also took me on several tours. We toured PYCO Industries, RAM Manufacturing and where the cotton samples go to be graded. PYCO was one of the most fascinating to me. PYCO is where the cotton seed, after being ginned, goes to be made into cottonseed oil. There I learned about the process of how a cotton seed is turned into oil. What was very fascinating to me was the lint around the cotton seed. PYCO has three cleaning processes of taking the lint o the seed, and they later turn the lint into bales. One of the coolest facts I

Cotton Ginners Marketplace 20 COTTON FARMING AUGUST 2023 COTTONFARMING.COM

COTTON

Minimize Seed Bridging 50% Larger Square Hydraulic Doors Call Jim - (972) 381-8899 / cliffgranberrycorp.com HOPPER CONVERSION KIT

has taken time

out

loading

provided a safer working environment.” Moses Gin, Inc. – Wharton, TX

“Granberry

and labor

of seed

and has

Josiah Keck

learned from the lint is that Samsung buys some of this lint to make their devices.

“During my time at Petersburg Cotton Gin, I have been asking lots of questions about the sales side of cotton. I talked to one of the Plains Cotton Cooperative Association workers and learned about the pool and grades of cotton. PCCA buys portions of cotton to add to their pool. The pool helps get more leverage in the cotton market.

“The first part of my internship was a blast! I learned a lot from Mr. Ramsey and appreciated the time he put into teaching me the ins and outs of a cotton gin. The second part of my internship will be at Smith Gin Co-op in Odem, Texas. I am very excited to get to see how gins are run during the season. Thank you, Aaron Nelsen, and the TCGA for this amazing internship.”

which has had a tough season.

Take A Hard Look At Insurance Costs And Safety Culture At The Gin

“While at the Johnson Gin, I had the opportunity to work with Kevin Williams and learn what happens inside of gins to keep them running. Pulling wires and putting in new control panels was our main focus here at Johnson Gin, as well as at Top of Texas Gin. Working under Malcom Jones, I was tasked to shadow a group of skilled electricians as we installed new module feeder and shaft monitoring control systems. While the job isn’t done, I plan to revisit Top of Texas Gin in the coming weeks, along with Adobe Walls Gin and Lonestar Gin in Pampa, Texas.

Riley

Gryder

Gryder

Distractions have become “routine” in our daily lives. Our phones go o , we get text messages and we’re bombarded by the never-ending news cycle. Everything seems to be trying to get our attention, and it’s easy to lose sight of what’s important. Things can sneak up on you, and those are the ones that will jump up and bite you.

tions have been aware of this and have brought it to the attention of our memberships. But I think many of us got distracted by the other things going on and have now been hit with the reality that it’s not getting better.

“Overall, I have had many great experiences with many people. I learned more in two weeks than most learn in a lifetime. I would like to thank Aaron Nelsen for giving me this opportunity and Phillip Kidd for organizing and allowing me to have these opportunities. I greatly appreciate the TCGA and cannot wait to learn more about cotton growing and ginning all over Texas.”

In the last year or so, we’ve seen huge increases in our costs. As I write this, we’re getting news of the highest inflation in more than a generation… maybe two.

“As my first month as a TCGA intern came to an end, I am proud to say that I have learned far more than I expected to. Assigned to Phillip Kidd at Edcot Gin in Edmonson, Texas, I have traveled around the Panhandle working alongside many great people such as Landon Kidd, Daniel Jenkins, Steven Birkenfeld and Malcom Jones. Learning the ins and outs of ginning, I have toured and worked at three Windstar gins –Edcot Gin, Johnson Gin and Top of Texas Gin.

While I’m personally seeing some of the things that increased so much ease down a bit, it’s not common for costs that have gone up this much, this fast, to come down or come down very much. We will likely have to learn to live with some of them.

The Cost Of Insurance

One of the costs that snuck up on many gins in the past year or so is the cost of insurance. Normally, this is a once-a-year expense we get hit with.

The past renewal cycle or two have been more than a bit of sticker shock for many in the ginning industry. Your associa-

“My internship began with a hands-on tour of Edcot Gin led by Landon Kidd. Throughout the week, I had the opportunity to learn about trading seed, lint and even got to tour BC Supply and MTS in Lubbock. The second week, I stayed in Turkey, Texas, with a great host and manager — Daniel Jenkins. While traveling back and forth to the Johnson Gin in Silverton, I saw how the Caprock a ects cotton growers in the area. With di erent planting dates, it looks like some farmers might have a higher yield of cotton compared to the Caprock,

TCGA provided this information.

This is a simplified explanation, but insurance companies are going to do what they need to in order to stay in business. They must make money like we do. The companies take our premium and invest it. They pay claims with it, and they expect to have some left over. If losses are low and return on investment is good, you have happy insurance companies. We get stable premiums and competition.

If they have poor investment returns and higher-than-expected cost of claims (read inflation), you have unhappy insurance companies. They may decide to pull out of the market and/or significantly increase rates. This is where we are today.

Your ginners associations and the National Cotton Ginners’ Association have been concerned about this for some time. We need healthy insurers and competition, but we really can only help one side of the insurance problem…losses. NCGA has put together a list of questions to ask yourself, so you can evaluate

Lummus Ag Technologywants to express its appreciation to our many loyal customers for their continued support and business. With the challenges we face in our industry, we are continually workingto evolve and adapt to changing market conditions and customer needs.

Lummusoffersa wide range of products and services, all geared to help your operation be efficient and profitable. Regardless of the project scope, contact Lummus to discuss your goals and needsto ensure your success.

Just a short listof items we offer:

All-new complete Gin Plants

Ginning Machinery (individual machines, stand-alone systems, presses, etc.)

Press Consoles and Main Control Consoles

Burner and Moisture Unit Gas Train/Controls upgrades

Air Monitoring and Fire Detection Kits

DGC 2020 Gin and Feeder Controls

Gin Dor-Les® and E.E. Dor-Les® Press upgrades

16” diameter Bottom Ram Conversion

Hydraulic Tramper/Pusher Conversion

Premier™ III Series Hydraulic Pumping Units

Press Rebuilds (strain rods, boxes, sills, etc.)

Quality OEM Repair Parts

UnmatchedTechnical Service