FANUC

Can UK manufacturing raise robotics uptake by learning from Europe?

ACG

ACG Becomes the world’s first capsule manufacturing factory to join the Global Lighthouse Network Community 202324

BURCKHARDT

WEARIN

IoT and AI to enhance safety on operations

KHS HASYTEC

KHS HASYTEC Dynamic Biofilm Protection

OPTIMAL INDUSTRIAL AUTOMATION

Vision systems advance quality control capabilities

INTRALOGISTEX

Intralogistex expansion ensures 2024’s show is set to be biggest and best yet

EK ROBOTICS

Europe’s No. 1 for home fitness automates new central warehouse

PRIMEVISIONS

Consistently meeting fluctuating demand in logistics

The leading source for innovators in Technology, Manufacturing and Maintenance within the Engineering & Processing industry worldwide.

Published bimonthly, a subscription to PECM magazine is essential for Process Engineers, Chemical Engineers, Instrumentation Engineers, Mechanical Engineers, Plant Engineers, Precision Engineers, Environmental Engineers & General Engineers, Companies and Organizations in the Food, Dairy, Beverage, Brewing, Semiconductor, Pharmaceutical, Biotechnology, Chemical, Oil & Gas, as well as all UK's major manufacturing units.

Every issue of the magazine contains the latest news, in-depth features, together with product innovations and case studies showing how process engineers are implementing new technologies to reduce costs and impact on the environment.

With over 140,000 readers worldwide the publication is widely read, recognized, and well respected within the Process, Engineering & maintenance industries.

A subscription to PECM magazine is the industry's 'must have' publication.

SUBSCRIBE TO 6 BIMONTHLY ISSUES OF PECM FOR JUST £27

• The magazine gets delivered directly to your door once every issue is published

• The quality of the hard copy enhances the reading experience

To Subscribe please call 01304 806039

SUBSCRIBE TO OUR DIGITAL EDITION COMPLETELY FREE OF CHARGE

Designed for the digital age, the magazine has been created for easy viewing on all electronic devices.

All our issues stored in one place: get unlimited access to our previous and future issues.

To Subscribe please visit www.pecm.co.uk/subscribe

EDITOR IN CHIEF

Antony Holter editor@mhmagazine.co.uk

BUSINESS MANAGER

Josh Holmes josh@mhmagazine.co.uk

SALES DIRECTOR

Jake Page jake@pecm.co.uk

Tel: 01227 937174

SALES MANAGER

Martin Richardson martin@pecm.co.uk

Tel: 01304 086039

DIGITAL MANAGER

Jamie Bullock jamie@mhmagazine.co.uk

Tel: 01227 936971

EDITOR

Elizabeth Hutton elizabeth@pecm.co.uk

STUDIO DESIGNER

Richard Bland richard@mhmagazine.co.uk

ACCOUNTS DEPT

Alison Holmes accounts@pecm.co.uk

Tel: 01227 936976

PUBLISHING DIRECTOR

Martin Holmes martin@mhmagazine.co.uk

Tel: 01304 806039

DIGITAL ASSISTANT

Stacey Goodwood

Tel: 01227 936971

www.pecm.co.uk

Despite punching well above our weight as a manufacturing powerhouse, the UK is in danger of slipping down the international rankings unless we increase our levels of automation. Now sitting at 25th in the global robotics league table , we are the only G7 nation outside the top 20 and have been eclipsed by most of our European counterparts in terms of numbers of robots per 10,00 workers, including Italy, Belgium, Switzerland and the Czech Republic. Here, factory automation leader FANUC, which has subsidiaries across the world, examines the potential reasons behind the UK’s reluctance to automate – and asks what we can learn from our continental cousins…

The benefits to UK manufacturing of robotics and automation technology are greater than ever, helping us to meet net zero targets, boost productivity and underpin our key industries. And with an estimated 70,000 vacancies in manufacturing, robots are also alleviating the longstanding labour shortages which have only worsened since Brexit and COVID.

In regard to automation uptake, it is certainly an improving picture. Led by the automotive sector, UK robot installations were up by 3% in 2022, with operational stock growing by 7%. But at just 98 robots per 10,000 workers we are still well behind European leaders Germany (415).

UK: Focused on short-term ROI

Among the many potential explanations for this are a focus on short-term payback rather than longer-term total cost of ownership (TCO); a fear of change; outdated

Led by the automotive sector, UK robot installations were up by 3% in 2022, with operational stock growing by 7%.

perceptions of engineering as a career; a lack of government incentives; our reliance on cheap manual labour; and no long-term national manufacturing strategy. While some of these are beginning to change – the government recently announced a £4.5bn package of support for British manufacturing, for example – should we also be looking to our European neighbours for some automation inspiration?

Germany: Prioritising precision and innovation

Dr Bob Struijk certainly thinks so. As the Vice President of FANUC

Europe, Dr Struijk has overseen automation installations across numerous countries, and believes there are a variety of reasons why certain nations are further ahead of the UK on their automation journey.

“Germany is the clear European automation powerhouse and owes a large part of its success to a profound respect for engineering and manufacturing,” he explains. “The German model emphasises the meticulous craftsmanship of products, fostering a culture that places a premium on precision and innovation. Catapulted by the automotive industry, robotics and automation have been at the forefront of bringing Germany to its position today as a manufacturing leader.”

In addition, bridging the gap between industry and academia has helped to boost German innovation. “In Germany, collaborative efforts between industry and academia contribute to a continuous cycle of research, development and implementation, creating an ecosystem that thrives on technological advancement. The German apprenticeship system also provides a seamless flow of skilled labour into industry, at low cost. The UK can learn from this by cultivating a similar synergy between its educational institutions and industrial sector to breed a culture of continuous improvement.”

In this regard, FANUC UK is working hard to help develop a pipeline of manufacturing talent through a range of different initiatives. The company’s Training Academy at its Coventry HQ offers accredited

courses that feed into educational programmes, giving students hands-on robotics experience; it recently held its first ever Work Experience Week, for young people aged 16-18; and the 2023 FANUC UK Open House played host to the finals of the WorldSkills UK Industrial Robotics competition.

However, for a nation built on SMEs, Dr Struijk is also clear that UK government support is critical to future success: “The penetration of robotics and automation in the UK is especially low among small and medium sized enterprises. Government tax breaks or accelerated depreciation of robots could certainly help to change this.”

At sixth place in the global automation league table, Sweden boasts an impressive 343 robots for

Above, Catapulted by the automotive industry, robotics and automation have been at the forefront of bringing Germany to its position today as a manufacturing leader.

Left, By investing in automation and robotics, UK manufacturers can help to futureproof their business and ensure we continue to compete on the international stage in the years to come.

every 10,000 workers. Neighbours Denmark have 274, Finland has 168 and Norway has 103 – all sit higher than the UK.

“With their realistic approach towards return on investment (ROI), the Nordic countries have successfully integrated automation into their industries,” outlines Dr Struijk. “By focusing on the longterm benefits, these nations have cultivated a business environment that encourages companies to invest in automation technologies.”

By looking at TCO rather than just ROI – considering indirect cost savings such as reduced energy bills, less waste, higher productivity and increased production capacity – investing in automation could be a far more attractive proposition to UK manufacturers than it is today. But again, the importance of government support cannot be overlooked, explains Dr Struijk:

“While the UK could draw inspiration from the Nordic model by fostering an environment where companies can confidently invest in automation, this must also be backed by supportive government policies and incentives,” he states. “In the Nordic countries, robust government initiatives have provided financial support and created favourable conditions for the adoption of automated solutions. For example, in the city of Odense, the government has stimulated the set-up of a ‘Robot Valley’ – a cluster of private companies, start-ups and academic institutions – that is helping to drive the Danish robotics market forward.”

Finally, Eastern European countries such as Slovakia, Hungary and the Czech Republic have embraced automation as a means of prioritising worker welfare.

“By automating dull, dirty and dangerous tasks, these nations have not only increased their manufacturing efficiency but have also enhanced the overall wellbeing of their workforce,” states Dr Struijk.

“They have benefitted from their close proximity to the German automotive market and used a combination of skilled labour and investment in robots to take a large share of the tier 1 market, as well as a host of greenfield investments by major European and Asian automakers. The UK could benefit by adopting a similar mindset; using automation to alleviate workers from monotonous and hazardous tasks, thereby improving job satisfaction and increasing overall productivity.”

There is no doubt that manufacturing is already one of the UK’s greatest success stories. By investing in automation and robotics, UK manufacturers can help to futureproof their business and ensure we continue to compete on the international stage in the years to come

For further information, please visit www.fanuc.eu/uk/en

ACG, the world’s largest integrated supplier and service provider to pharmaceutical industry celebrated the inclusion of its capsule manufacturing facility in Pithampur, India, into the esteemed Global Lighthouse Network (GLN) by the World Economic Forum at the 54th Annual Davos Summit.

The World Economic Forum’s Global Lighthouse Network has acknowledged the exemplary integration of Fourth Industrial Revolution (4IR) technologies, including artificial intelligence and big data analytics, by select factories globally. These facilities have been distinguished for their commitment to enhancing efficiency, fostering sustainable development, and simultaneously advancing their workforce’s skills and safeguarding the environment.

Upon receiving the award, Mr. Karan Singh, Managing Director, said: “I am delighted to receive this recognition on behalf of my team. For me the most unforgettable part of our journey wasn’t any technology or efficiency milestone, but the incredible team that made it all possible. Just ordinary people, united towards one goal, bringing about innovative collaborations to push boundaries of what is possible.”

He added: “One of the stand-out features of our application was the Gen-AI integration. Something that was done in the less than two weeks. In between all the debate on what Gen-AI can do to humans it is a beautiful reminder that ‘technology

One of the standout features of our application was the Gen-AI integration.

is brilliant, but humans drive the change’. Let’s remember

that!”

ACG operates across 138 countries in six continents and has positioned itself as a leader in the pharmaceutical sector by focusing on high-quality capsule production, increasing responsiveness, improving production yields, and boosting workforce efficiency.

The company produces billions of capsules annually and has implemented over 25 innovative applications of 4IR technologies, including the industrial internet of things (IIoT), machine learning (ML), deep learning (DL), digital twins, extended reality, and generative AI.

Selwyn Noronha, CEO, ACG Capsules, added: “We are extremely proud of our first factory lighthouse. From its inception the facility has pioneered in its field, but this latest honour recognises the excellence in adopting AI at speed and scale.

“Our continued future-focused approach sets new benchmarks in quality and innovation, with the aim of ensuring maximum benefit for customers, regulators and the entire pharmaceutical ecosystem.”

For further information, please visit www.acg-world.com

An intelligent, digital electro-pneumatic positioner in two-wire technology used to control pneumatically operated process valves.

• ATEX / IECEx certified explosion protection for gas environments.

• Two-wire connection technology.

• Bluetooth communication for remote app access and configuration.

• Fast commissioning using well-balanced reconfiguration.

• Economical, almost no air consumption when idle.

• Low maintenance replaceable solenoid / filter cartridge.

www.gemu.co.uk

To avoid electrostatic discharge, plastics used in explosive fume extraction systems that move air, or are situated in an area where potentially hazardous fume are present, must be electrically conductive or static dissipative. The most effective way of dissipating electrostatic discharge is to add conductive carbon black to the polymer matrix.

For the context of this article, we’ll consider how polypropylene corrosion resistant fans which are the preferred construction material used to handle toxic and hazardous fumes in fume extraction systems, are modified to enhance the ATEX suitability for zone 2 potentially explosive environments. These ATEX certified polypropylene fans are manufactured from polymers that have special branched carbons with a structure that can transport the flow of electrons and dissipate electrostatic charge.

In potentially explosive environments, if the conditions call for it, such as the build-up of IIC hydrogen gas in large quantities, the presence of static discharge can be enough to ignite and cause an explosion. The concept of ensuring a product is ATEX certified ensures that the fan component in our case, is not itself, a risk or an ignition source. ATEX fans reduce the risks of creating sparks from friction, static electricity or from arcs in motor malfunctions for example. In ATEX product labelling, Ex h markings signify that the nonelectrical fan component (excluding the motor) has been constructed sufficiently to be used as intended

in an explosive environment. In short, precautions during the manufacturing process have reduced this risk.

By nature, without additives or fillers, commercial plastics are electrical insulators. Charges deposited on the polymer surface are living therefore a long time, and the longer the lifetime, the more likely the possibility of an electrostatic discharge event such as static discharge. The rate of charge dissipation is known as the charge decay time, this considers the electric resistivity which tells us how strongly a material opposes the flow of electric current, and the dielectric permittivity, which characterises the ability of the material of storing an electrical charge when subjected to an applied voltage.

For static dissipation, we must reduce the decay time of the charge, by enhancing conductivity and reducing permittivity. The loading of polymers with conducting additives reduces the resistivity of polymers.

Due to the presence of static charges, polymers must be

turned into materials capable of draining these charges and protect the devices from static discharges. Therefore be able to conduct electricity to some extent. Commercial polymers are natural electrical insulators, so they need to be engineered to become antistatic dissipative or conductive. This is realised either through chemical treatment or through the addition of conductive agents during the processing.

One of those fillers is known as carbon black, a relatively inexpensive and processible filler material, formed by burning hydrocarbons in a limited oxygen environment. These are used extensively in packaging but also used, as shown in our ATEX corrosion resistant range, for CB filled high density and low-density polypropylene.

Simply put, carbon loading is a process in which carbon black particles or fibres are incorporated into the polypropylene during manufacturing. This addition of carbon enhances the conductivity allowing it to dissipate accumulated static charge more effectively, minimising the risk of ESD. Where airflow passes through fan blades, friction can generate static charges on the fan surfaces, and in environments with combustible materials, static charges can ignite or trigger an explosion

So, in a nutshell, that’s how we ensure that our ATEX polypropylene fans are manufactured in line with the ATEX directive, making them suitable for their intended use.

For further information, please visit www.axair-fans.co,uk

Containment of chemicals is one of the key activities in fume extraction processes, and at the core of these systems, when maintaining the required pressure and airflow to extract fumes effectively, the responsibility rests with the industrial fan.

This makes correct fan selection one of the most important system specifications. Enter our comprehensive specifier white paper: The Ultimate Guide to Fan Selection in Fume Extraction Systems.

One of the UK’s leading strategic manufacturing outsourcing specialists has set its sights on breaking the £40m sales revenue barrier in 2024.

PP Control & Automation, which works with over 20 of the world’s most successful machinery builders in a wide range of markets including energy, packaging, food processing, printing, material handling and high technology sectors, has seen sales rise from £24m to £36m over the last twelve months.

It is now looking to add a further £4m of orders by investing in more automation at its West Midlands factory, starting with the £250,000 integration of a new Komax Zeta 640 harness machine fitted with twister, ferrule station and 2-off crimp press.

Utilising improved crimp force monitoring and enhanced quality software validation, this technology can group cables together to simplify build orders, feed cables at up to 22mph and deliver automatic changeover capability, so that 36 cables can be loaded and ink colour changed from black to white when required.

Ian Knight, Chief Information Officer, commented: “We are massive advocates of combining investment in automation with investment in people and this blended approach seems to be paying off with a record year in 2023 and strong growth prospects for the next twelve months.

“The Komax investment brings the latest crimping technology to our

state-of-the-art facility and will provide the business with greater capacity, greater speed and the ability to eliminate human error that can prove so costly.”

He went on to add: “It will also give us improved inkjet marking

capability when it comes to quality, fonts and different sizes.”

Record sales wasn’t the only thing PP Control & Automation was celebrating in 2023, with apprentice Sophie Young and Chief Executive Tony Hague securing a

string of awards for their personal performances throughout the year.

The latter is excited about the future, especially now that global supply chains have begun to settle and lead times on materials have started to reduce, giving the company greater stability to plan for growth.

Exciting new opportunities in clean energy and the circular economy are at the top of the ‘potentials’ list, along with the launch of a new service that will foster innovation and encourage commercialisation in the UK.

Tony went on to add: “Despite all the pressures we’ve faced, the country has remained unbelievably resilient and there’s a real desire to buy British.

Exciting new opportunities in clean energy and the circular economy are at the top of the ‘potentials’ list, along with the launch of a new service that will foster innovation and encourage commercialisation in the UK.

“We must capitalise on this by working together to bring manufacturing back home through design, innovation and by adding value. These are our strengths and

now is the time to make the most of them.

“At PP C&A we have already started to benefit by working with international customers to help them launch new technologies in green energy, as well as developing a whole host of new innovations that will hopefully accelerate the move to cleaner transport.”

He concluded: “Two major international countries for us in 2024 will be the Netherlands and Denmark - I can see real growth potential in these territories.”

PP Control & Automation is also a proud member of the Manufacturing Assembly Network (MAN), a unique collective of six sub-contract manufacturers and a special engineering design agency.

ViSWIR Hyper APO Features:

• Capable of fully corrected focus shift in visible and SWIR range (400nm - 1700nm)

• Achieves spectral imaging with a single sensor camera by simply syncing the lighting Floating design adjusts focus for different wavelengths 8mm, 12mm, 16mm, 25mm, 35mm* and 50mm* (*2023)

ViSWIR Lite Features:

High transmittance at whole wavelength of 400nm - 1700nm by adopting hyper wideband AR coat

• Outstanding cost-performance for single-wavelength lighting & narrow-band imaging Compact design 5mm, 8mm, 12mm, 16mm, 25mm, 35mm, 50mm

computar-global.com

What is a Huck® BOM® fastener?

The BOM® (Blind, Oversized Mechanically-locked) heavyduty fastener stands out as a structural blind fastener with superior strength and tamper resistance. BOM® not only delivers high tensile and shear strength typically associated with Lockbolts, but also introduces the flexibility of single-sided installation. This makes it especially well-suited for use in areas with limited access.

The versatility of BOM® structural makes them suitable for diverse range of projects.

Huck® BOM® fasteners are commonly used in industrial and construction applications. Here are some general applications: -

Heavy Machinery and Equipment:

These fasteners are often employed in the assembly and construction of heavy machinery and equipment. Their oversized design and structural integrity make them suitable for handling significant loads and vibrations.

Transportation Industry: In the transportation sector, particularly in the assembly of commercial vehicles, trucks, buses, and other large vehicles, Huck® BOM® are used to provide robust and reliable connections and maintain strength and structural integrity for the life of the joint.

Infrastructure and Construction:

For large-scale construction projects, such as bridges, buildings, and other infrastructure, these fasteners can be used to join structural elements securely.

Rail and Aerospace Applications:

The rail and aerospace industries often require fasteners that can withstand high levels of stress and

1. Insert the fastener into the hole and slip the installation tool over the pintail.

2. Press the trigger to initiate pulling action. As the tool pulls on the pintail, the unique collar design “stands off” the swaging action until the maximum allowable bulb is formed on the backside.

3. Continued pulling on the pintail draws the work pieces together and the swaging anvil overcomes the standoff and moves down the length of the collar, securely locking the collar to the pin.

ensure the structural integrity of components.

Energy Sector: In power plants, oil and gas facilities, or renewable energy projects, these fasteners are utilised for assembling components that need to endure harsh environmental conditions.

Often used as a replacement for welding, the Huck® BOM® fastener is so strong, one BOM® fastener can do the work of several conventional fasteners. Huck® BOM® fasteners have been proven to withstand years of service in high-stress, highvibration environments without weakening

Key Benefits of the Huck® BOM®

• Offers Lockbolt® level performance.

• Very high tensile and shear strength.

• Exceptional quick, consistent and

4. Once the collar is swaged, the pin breaks leaving a high strength, vibration resistant secured joint.

repeatable installation.

• Excellent vibration resistance.

• High grip capability

• Tamper-resistant features.

• A wide variety of diameters are available.

High strength/diameter ratio: BOM® is used in demanding structural applications as an alternative to threaded fasteners as it has high joint tightness when compared to conventional blind fasteners.

Huck® BOM® fastener vs Welding

The choice of fastening methods plays a key role in determining the success of any project. Whether Huck® fasteners are a superior fastening method than welding depends on the specific application, requirements, and constraints of the project.

Both methods have their advantages and disadvantages, and the choice between them should be made considering various factors. Here are some situations where the Huck® BOM® fastener might be considered preferable to welding:

Speed and Ease of Installation: Huck® fasteners are generally quicker to install than welding as producing a welded joint involves a more intricate process, demanding additional time for preparation, execution, and cooling. If time is a critical factor in a project, Huck® fasteners can offer a faster assembly process.

No Heat Generation: Welding involves the application of heat to melt and fuse materials which can lead to thermal distortion, potentially leading to weakened structural integrity. Huck® fasteners do not generate heat during installation, making them suitable for heat-sensitive materials or applications where heat distortion is a concern. As welded joints are more susceptible to vibrational stresses impacting long-term

The choice of fastening methods plays a key role in determining the success of any project.

structural stability, they may require higher maintenance needs over time. Once correctly installed, the Huck® BOM® fastener needs no further checking.

Corrosion Resistance: The corrosion resistance of fasteners is a critical aspect in any project, where durability and longevity are paramount. Ensuring the corrosion resistance of fasteners not only preserves the structural integrity of the components but also extends the lifespan of the entire assembly.

No Specialised Training Required: Installing Huck® BOM® blind fasteners requires less specialised training compared to welding. The simple installation procedure requires just basic training, which in turn reduces the labour costs associated with installation and assembly, ultimately optimising the workflow.

Enhanced Structural Integrity: The BOM® fastener creates a robust mechanical link, enhancing structural integrity. Its large bearing area on both sides of the workpiece ensures a permanent, tamper resistant joint.

Vibration Resistance: The collared flange is locked to the pin through a swaging process, creating a high

vibration resistant connection, crucial in maintaining structural stability.

Repair, Dismantling and Recycling: Welded joints may require cutting and additional processing for recycling. Huck® BOM® fasteners are generally easier to remove than welded joints. This can be crucial in situations where components need to be disassembled / recycled, repaired, or replaced.

Versatility: Huck® fasteners can be used in various materials. They offer versatility in terms of material compatibility and can be a practical choice for projects involving differing materials.

It’s important to note that although Huck® fasteners have advantages in certain scenarios, welding also has its own strengths, after all, welding has long been utilised in applications that requires a secure joint. However, today’s manufacturers have an alternative fastening method which offers several compelling reasons to consider installing Huck® BOM® maintenance-free structural blind fasteners as a proven alternative to welding.

In summary, the choice between installing Huck® fasteners and welding depends on the specific requirements of the application, including the materials being joined, the desired strength of the joint, time constraints, and the need for reversibility or repairability. Each method has its own set of advantages and limitations and the best solution depends on the unique circumstances of each application.

For more information call us on +44(0)115 932 4939 or email sales@starfasteners.co.uk

Automated processes and production lines are an integral part of modern production plants and are therefore indispensable in the sense of rapid technological development. For the successful use of complex machines and automated technologies, no compromises in safety and speed must be made within the framework of the respective production and operating processes. Safety at the highest level is an important prerequisite for the modernisation of production plants in industry.

For a safe and efficient working environment, it is first and foremost important to comply with the existing safety regulations and at the same time optimally position a business for future technical developments. In addition, there is the constantly increasing demand to optimally increase operating speed and efficiency. That’s why we’ve developed the new ASSA ABLOY RP400 – a more powerful new generation machine protection door that offers a new level of safety, quality and reliability for your operation.

In order to meet the growing demands of the industry in the long term, the ASSA ABLOY RP400 offers even more protection at high speed, smaller space requirements and maximum operating time. With this new combination of our most innovative technologies in one door solution, this new generation of machine protection door achieves maximum functionality and

efficiency. Designed with a range of built-in and optional safety features, this powerful high-speed door is our most advanced machine protection door ever.

The innovative door solution for production plants enables short cycle times due to a high opening and closing speed of up to five cycles per minute. In combination with the high reliability of the robust door and the minimised service requirements of the design, the ASSA ABLOY RP400 delivers long-term functionality at the highest level. Of course, this new, forward-looking door solution also meets the applicable standards and guidelines in terms of machine safety and is certified in accordance with the current EN-ISO requirements. The versatile safety functions packed in a typically elegant design characterise the new machine protection door from ASSA ABLOY Entrance Systems.

Building upon the known and trusted benefits of our RP door range, the ASSA ABLOY RP400 comes with several safety and design features.

· Safety light curtain: integrated into the door’s side frame, covering the full width and height of the door to better protect workers and equipment

· Advanced safety limit switch: more precisely prevents machine hazards with a higher stopping accuracy

· Flat-bottom profile: no protruding edges and a smoother front profile to reduce the risk of serious injury during the upward movement of the door

Easy installation choices: door can be wall mounted or freestanding to optimise floor space, while its highly robust and stable frame construction leads to less vibrations during activity

· Premium design: rounded edges and a better embedded motor to ensure a smoother, more flush profile

So, for one of the safest, most reliable, and highest-quality machine protection doors available today, look no further than the new ASSA ABLOY RP400.

For further information, please visit www.assaabloyentrance.com/uk

Work safer with the new ASSA ABLOY RP400

Work safer with the new ASSA ABLOY RP400

Advantages of the door

Advantages of the door

• Rapid opening and closing ensures short cycle times up to 5 cycles per minute

• Rapid opening and closing ensures short cycle times up to 5 cycles per minute

• High reliability even after years of high numbers of cycles

• High reliability even after years of high numbers of cycles

• Safety limit switches according to EN ISO 13849-1 and EN 62061

• Safety limit switches according to EN ISO 13849-1 and EN 62061

• Doors conform to EN ISO 12100 and EN ISO 14119

• Doors conform to EN ISO 12100 and EN ISO 14119

• Versions conforming to various factory standards are possible

• Versions conforming to various factory standards are possible

• Type tested machine protection door with fabric door blade

• Type tested machine protection door with fabric door blade

Energy usage causes up to 95% of the total life cycle costs of pumping equipment. Therefore, improving energy efficiency pays off quickly. Sulzer’s energy audit is a consulting service that aims at improving the energy efficiency of a pumping system.

“The concept relies on Sulzer’s expertise on pumping equipment and process knowledge, while supporting the environmental sustainability goals mutually important for both our clients and us.” Pekka Salmi Head Business Development CSS at Sulzer Flow Equipment.

The audit offers actionable insights into what to do to reduce the operational energy consumption and costs. All too often, unnecessary energy costs are a result of an oversized pump or equipment operated outside its optimal point. Changes in processes, planned capacity, or in the rest of the process line might lead to a pump operating off its best efficiency point.

An energy audit supports companies in the modernization of their equipment base. It has proven to be especially valuable for operators with a large number of aged equipment. Alternatively, the audit

can be used for the final optimization of equipment that is efficient to begin with.

Companies can leverage the results of energy audits in meeting emissionrelated standards, or when seeking environmental declarations and certificates. The audit can be used to assess and minimize environmental emissions by reducing energy consumption without decreasing the number of equipment or capacity.

How the audit proceeds

Sulzer experts work in cooperation with the customer to review available data sources and define

the scope of the audit. The selected scope may contain all equipment at a certain site or process. At large sites, the audits can be done step by step on a predefined selection of equipment.

The audit may cover only equipment with performance issues or a selection that is expected to have the biggest energy saving potential. Typically, the focus is narrowed down to pumps running less than optimally, leaving out the ones with variable frequency drives, low annual running time, and pumps that already operate close to their optimal point.

The pumps with the biggest improvement potential are identified and reviewed with the customer. “It is not uncommon that the customer is already satisfied with the audit at this phase, even though the most valuable part is yet to come,” says Pekka Salmi, Head Business Development CSS at Sulzer.

Following the analysis, the customer receives a comprehensive report that contains the current energy usage, identified savings potential, and a detailed list of recommended actions for decreasing energy consumption. To assure usability and easy adoption, the recommendations are completed with cost estimates and payback times for the equipment and site work.

The recommended actions are tailored to the customer’s needs and

An energy audit supports companies in the modernization of their equipment base.

preferences. Usually, they consist of replacement and upgrading opportunities for pumping and mixing equipment. In addition to the hydraulic performance improvement a broader installation audit offers ways to improve the entire installation by modernizing and optimizing the construction of the equipment. Moreover, environmental sustainability is always considered.

The report lists detailed actions to be carried out on the equipment base, enabling reduced energy consumption. The suitable product range, adequate dimensioning, materials of construction, and accessories are specified according to the applications.

“The concept relies on Sulzer’s expertise on pumping equipment and process knowledge, while supporting the environmental sustainability goals mutually important for both our clients and us,” Pekka Salmi summarizes.

Improved energy savings in pumps, agitators, and turbocompressors

As a full-line supplier, Sulzer’s

portfolio offers a range of equipment and efficiency-enhancing accessories to decrease energy usage. “We constantly develop our portfolio to reduce energy consumption. We also aim at maximizing the lifespan and recyclable alternatives,” says Saku Vanhala, Head of Product Management at Sulzer.

Retrofitting is often the most costeffective method to improve the performance of larger pumps. This involves modifying the impellers to optimize the hydraulic

performance or changing the entire hydraulic kit, enabling the pump to operate at the best efficiency point. For smaller pumps, it may be more cost-effective to replace the equipment with more efficient and reliable equivalents.

Agitators can also be retrofitted for better energy efficiency. As the selection of Sulzer’s agitators is continuously developed, their performance is improved with each new generation. Most agitators can be upgraded by changing into a newer and more efficient propeller.

In addition to pumping and mixing processes, savings can be found also in compressed air applications. Usually, the best way to drive business performance and sustainability goals of turbocompressors is to upgrade them into more modern and efficient models. Sulzer’s oil-free high-speed turbocompressors provide significant energy savings over conventional compressors. Additionally, with nonwear magnetic bearing units, they offer considerable long-term costsavings with reduced maintenance.

To take the entire array of circular economy into account, the customer might prefer a preowned replacement pump. Sulzer refurbishes and repurposes usable pumping equipment. In addition to smaller environmental impacts, the customers benefit from reduced investment costs and faster lead times. The concept extends equipment life cycle while at the same time offering reduced disposal costs and increased CAPEX savings.

For more information, visit www.sulzer.com

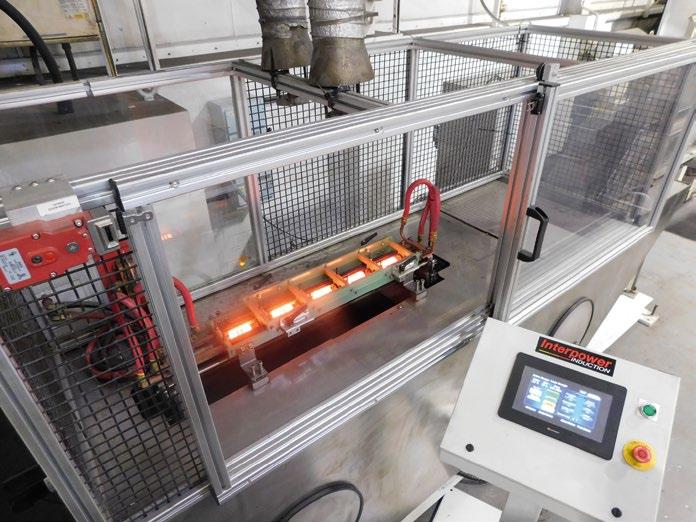

Melling Performance Springs, Lytham St Annes, Lancashire adds specialist induction heat treatment equipment to aid technical advancements for the most demanding applications.

Melling Performance Springs has recently invested in specialist induction heat treatment equipment giving increased design and manufacturing capabilities for the most demanding compression spring applications.

Induction heat treatment is a highly efficient and precise method of hardening springs made from strategically selected materials. This technology is key for very demanding spring applications. The MPS machine operates with a 50 Kilowatt solid state insulated gate bi-polar transistorised power supply.

The induction heat treatment process improves the mechanical and physical properties of the spring material. During induction heat treatment, an alternating current is passed through a set of parallel copper coils, creating a rapidly alternating magnetic field. When a spring is placed within these induction coils, the magnetic field induces eddy currents within the spring material, generating heat due to resistance. This localised heating allows for precise control over the heating process, resulting in uniform and consistent heating. Once heated to an exact temperature, and held for a specific time, parts are then rapidly cooled using an exact concentration of a specialised polymer-based coolant at a controlled temperature. These quench parameters are critical to avoid steam pockets, material cracking and decarburisation. The machine is equipped with precise equipment to control the heating, holding time and quenching parameters that allows for a consistent and repeatable method of achieving specific metallurgical properties - giving improved and optimised performance.

Induction heat treatment offers several advantages over traditional heating

methods, The rapid heating, and cooling cycles, allow for a highly efficient process that is more economical and environmentally friendly, resulting in reduced cycle times, lower energy consumption, and increased productivity, leading to overall cost savings. The rapid heating from the induction coils coupled with the machines electronic and mechanical control technology allows the springs to heat uniformly in a matter of seconds which dramatically reduces decarburisation levels, maintaining the materials surface quality and wear resistance. This eliminates the need for an atmospheric heat treatment process that would require open flames or hazardous chemicals and gasses.

Induction heat treatment plays a pivotal role in tailoring the microstructure of materials, leading to enhanced mechanical properties and performance. During induction heat treatment, the raw material undergoes various phase transformations, such as austenitization, followed by precisely controlled quenching to achieve the desired microstructure. These changes in microstructure directly impact the mechanical properties of the material, including hardness, tensile strength, toughness, and wear resistance. The increased hardness coupled with

optimised methods of shot peening, allows Melling Performance Springs to increase the levels of compressive residual stress induced into the material. These improved levels of compressive residual stress enhance the material and provides a beneficial counterbalance to the tensile residual stress, therefore exhibiting superior performance and reliability, enabling Melling Performance Springs to manufacture higher stressed parts that allow for reduced weight/ active mass, improved natural frequency giving superior harmonics, improve fatigue performance, wear and relaxation resistance and reducing the chance of premature failure.

Melling Performance Springs, is based in Lytham St Annes, Lancashire and manufactures, high performance, precision compression springs for its global customers. We aim to provide solutions to our customers problems. MPS holds IATF 16949:2016, ISO 9001:2015 & ISO 14001:2015 accreditations. The company was originally founded in 1996 and purchased by Melling in 2020. Our parent company, Melling Engine Parts is headquartered in Jackson, Michigan, USA.

Further information can be found at www.mellingperformancesprings.com or contact springsales@melling.com

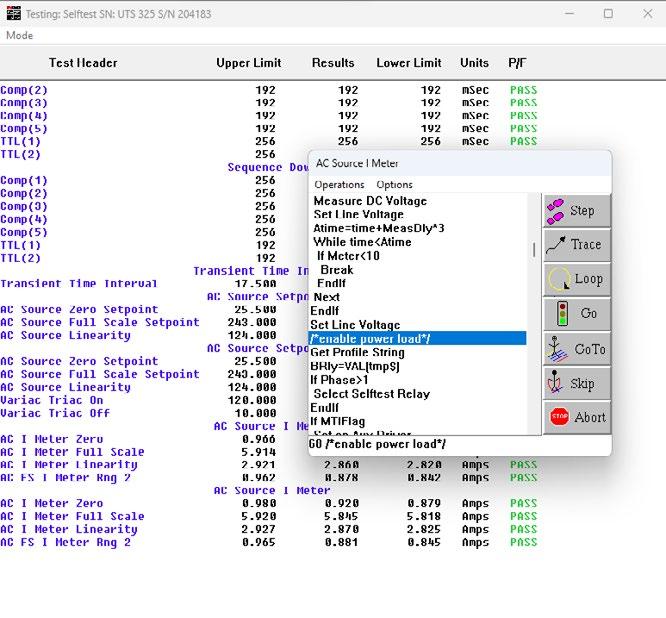

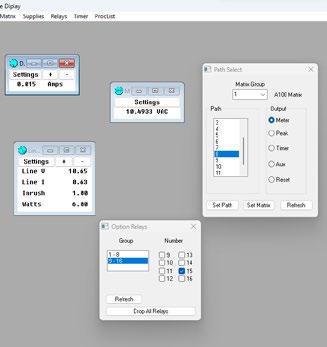

In 1977 Mr. Robert Cox set out to build a test and measurement platform based upon some simple tenants. He produced the best automated test platform that could be designed. He knew the needs of the market based on his time at several companies that were struggling to automate testing on the manufacturing/production floor. He wanted to take advantage of the nascent personal computer business that was just starting to take hold. Mr. Cox knew if he could incorporate a microcomputer with a robust automated test platform, he would have a winner. With the help of his brother and father, Autotest was born. While the market has changed significantly over those 45 years the company has survived the dot.com bust, the offshoring of technology, the throw away switching power supply boom and in 2000 the telecom bust.

45+ years later Autotest is still providing our customers automated testing platforms that now keeps our nation’s defense, healthcare, and consumer products up and running by testing them in high reliability test suites custom built for the customers we serve.

Over the years we have built systems for nearly every industry and niche, recently our business has been focused in two areas of high reliability power supply testing in aerospace and medical. We are proud to say we have shipped over 900 ATE Systems worldwide and can boast that some of the machines we continue to maintain have been in the field over 25 years and are still being upgraded, and test parts daily. We are extremely

proud and would like to share our successes in three areas.

APG testing software suite is a very user-friendly interface for building test procedures and recording the results. The program is now in its 35th year having started in DOS and moving into the Windows® environment at the time Windows®

was initially introduced. After all those years, our intention is to keep it Easy-to-Use so routines can be built using simple blocks like user functions and modules to build extremely complex routines that interface with today’s new instruments. We continue to improve APG in a 32-bit environment and now onto the 64-bit with the latest supporting Windows 11, just recently released to the field. APG allows for the use of OLDER hardware and/ or add new hardware along with the latest peripherals without the need to completely re-write custom routines our customers have written for use on the floor. This saves our customers tens of thousands of dollars at upgrade time in porting time for the latest software.

We had built custom interface boards with extremely tight voltage and noise requirements due to the extreme environment we needed to test products in. Autotest was able to build test interface boards with included custom tests programs that best allow for testing voltages in the 1-3V range while having resolution precision measurements at 0.2% at extremely low noise. Autotest was able to harness expertise from its engineering staff experience in the semiconductor testing and using on board instrumentation built onto the interface boards keeping traces and wiring to an absolute minimum and shortest length so as not to introduce noise. Those signals were then passed onto the legacy ATE test suite for recording and reporting to the QC & Production departments, along with engineering.

Finally, we entered a partnership with a large aerospace company that involves a long-term commitment to support. Autotest has built and updated our customers’ systems annually along with adding at least one new system to increase this customer’s

Over the years we have built systems for nearly every industry and niche, recently our business has been focused in two areas of high reliability power supply testing in aerospace and medical.

throughput, service, and support to their end customers. This machine has become an Autotest staple over the past 6 years, and we believe it will take beyond the middle of the 2020’s and perhaps into 2030’s.

In 2027, Autotest will CELEBRATE 50 years in business. Not many businesses can claim that milestone. Autotest commitment to long term support for our customers and their bespoke ATE systems built over the years which we believe speaks volumes to Mr.

Cox’s original vision and we know we will be there another 45 years with the add-ons of new young engineers eager to continue Mr. Cox’s vision.

For further information, please visit www.autotest.com

Modern industrial machinery is already benefitting from Industry 4.0 and digitalization with predictive maintenance solutions that can identify potential issues before they develop into unplanned downtime. The next step is providing live, expert technical support from a remote location using virtual and augmented reality, enabling local technicians to recreate their machinery virtually and receive step-by-step instructions for troubleshooting and maintenance operations.

Greg Griggs, Sales Engineer for Burckhardt Compression, looks at how the industrial metaverse is bringing a host of benefits to operators in challenging locations.

Reciprocating compressors are working across the world in refineries, gas transfer stations and offshore installations, which makes many of them difficult to access. Rather than wait for days for support to arrive, mobile devices such as phones, tablets or virtual reality (VR) wearables will become commonplace. By scanning the local environment and recreating it in the cloud, it is possible for remote experts to assess the situation and provide live feedback and support.

The advent of the metaverse has enabled the secure exchange of huge amounts of data with greatly reduced costs. The technology has developed quickly and now it is possible to use virtual, augmented and mixed realities to deliver live expert support to technicians.

Even in areas where the local networks have low bandwidth, this technology can still be useful. The use of sophisticated data

compression techniques enables these important communication processes to reach almost any point on the globe.

There are many industrial sites that are difficult to access, even impossible at certain times of the year, and many of Burckhardt Compression’s customers operate offshore or in hard-to-reach locations. This situation can be made more challenging with the zoning of certain areas due to the possible presence of explosive atmospheres. This severely limits the tools and equipment that can be operated in these settings, adding to the complexity of delivering maintenance support.

In the past, modern communications would have stretched to phone calls, faxes or more recently video calls, each of which has their own drawbacks. On-site support for operators in challenging locations is key to continued reliability but flying specialists in by helicopter is limited

by available resources and budgets.

Delays in receiving technical support or long waits to resolve issues can have very significant consequences for a business. The advent of highspeed internet and virtual reality has led to a huge step forward in communications technology, which has the potential to drastically reduce unplanned downtime. Realtime support is the ideal solution to investigating a problem; technicians can be guided, step-by-step, with live feedback to address the findings as they appear.

It is now possible for subject matter experts (SMEs) to communicate more easily, to discuss technical issues in depth on a one-to-one basis with ability to overlay technical drawings and images to support the understanding of the subject.

The ability of two remote teams to simultaneously look at the same data, decide on the best course of action

and implement changes to prevent a reoccurrence is a step-change in modern maintenance support. Data is crucial in understanding the operating conditions of a machine and the increased analysis capabilities of modern algorithms can support predictive maintenance programs.

Digitalization and Industry 4.0 have paved the way for massive improvements in diagnostics and communications. The ability to access large amounts of data and quickly analyze it also offers benefits for planned maintenance.

For example, taking reciprocating compressors used on LNG transport vessels, there is a requirement for these ships to undergo dry-dock inspections every five years. Data analysis can be used to predict the expected service life of the equipment and highlight any components that may need attention in between planned overhauls.

As part of the Burckhardt Compression family, PROGNOST is a world leader in industrial equipment monitoring and these advances in communications technology have enabled its portfolio of solutions to be expanded. From a simple setup of a few temperature and vibration sensors connected to a PLC, to a complete sensor array providing

Digitalization and Industry 4.0 have paved the way for massive improvements in diagnostics and communications.

data to a secure monitoring site that analyses the information roundthe-clock for possible anomalies, PROGNOST is equally adept.

Now, wireless sensors are rapidly evolving, which means that a comprehensive data capture system can be installed without the need for

experienced engineers on site. These systems, wired or not, can be used for cost-effective, short-term multichannel data collection for root cause analysis as well as long-term process optimization for improved reliability and sustainability.

However, one of the major concerns of corporations, large and small, is the possibility of their data being compromised on the internet. Data security is the top priority of all providers of digital services and Burckhardt Compression holds the ISA/IEC 62443-4-1 certification for cyber security, which ensures the company’s solutions provide robust protection against recognized cyber threats.

The increased use of technology in everyday maintenance is becoming more accepted, but that is no reason to become complacent. Data security is extremely important and equipment operators should always seek assurances and evidence that the proper security protocols are in place.

The continued development of the metaverse and the tools capable of exploiting its benefits will enable expert engineers and local technicians to be in the same virtual space, looking at the same machinery and data simultaneously. Offering step-by-step guidance with immediate feedback, this technology has the potential to significantly improve machine reliability, efficiency and sustainability.

For further information, please visit www.burckhardtcompression.com

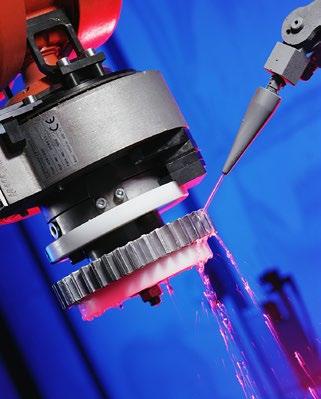

Curtiss-Wright Surface Technologies, a subsidiary of the Curtiss-Wright Corporation, boasts a global network with over 70 worldwide locations, providing material surface treatments, protective coatings, high tech processes and much more for the aerospace, automotive, oil & gas, subsea, medical, and power generation sectors. They increase the performance life of metal components by protecting them against premature failure using their high performance metal surface technology.

Offering customers a single point of contact and source solution for controlled metal surface treatments, Curtiss-Wright are specialists in metal surface treatment, and strive to improve and reduce turnaround times and costs for their clients. Indeed, their history dates back to 1929, when the Wright Brothers and Glen Curtiss founded the CurtissWright Corporation. The Metal Improvement Company was established in 1946, which was then

Among their lauded engineering coating services, Curtiss-Wright also offers thermal spray coating.

acquired by Curtiss-Wright in 1968. With nearly 90 years of history to draw upon, Curtiss-Wright Surface Technologies are unequivocal experts in their field.

Some of the practical applications and benefits of their services include controlled shot peening, which is excellent for reducing fatigue and stress corrosion cracking, shot peen forming for creating curvature in aircraft, laser peening, CASE Isotropic finishing, parylene conformal coatings and much more.

Among their lauded engineering coating services, Curtiss-Wright also offers thermal spray coating. Their thermal spray and High Velocity Oxygen Fuel spray coatings can be seen in use throughout aerospace, automotive, oil and

gas, and much more. Essentially, thermal coatings offer a costeffective and high performance alternative to hard chrome plating, providing a finish that protects metals from heat, wear, oxidation and corrosion. HVOF thermal spray coating has numerous advantages, including being able to be used with metals, alloys, ceramics and carbides. Not only that, but it also provides outstanding bond strength to withstand against extreme mechanical loads.

What’s more, their solid Film Lubricant and Liquid Component Coatings provide long lasting lubrication, and protection against friction and galling within harsh operating environments.

If you would like to find out more about Curtiss-Wright and their many specialisms, you can get in contact with the team using the details provided below. For more information and case studies on their services, be sure to head over to the website.

l Thermal Spray & HVOF Coatings

l Thermal Spray & HVOF Coatings

l Dry film lubricants - MoS2, PTFE, Graphite, WS2

l Dry film lubricants - MoS2, PTFE, Graphite, WS2

l Coatings for corrosion, chemical & environmental protection

l Coatings for corrosion, chemical & environmental protection

l Titanium anodising

l Titanium anodising

l Zinc rich coatings for corrosion protection

l Zinc rich coatings for corrosion protection

l Impingment coating processes for ultra thin solid film lubricants

l Impingment coating processes for ultra thin solid film lubricants

l Nonstick/release coatings for low coefficients of friction

l Nonstick/release coatings for low coefficients of friction

l Primers for rubber and plastics for sound absorbing and dampening materials

l Primers for rubber and plastics for sound absorbing and dampening materials

l High temperature resistant coatings

l High temperature resistant coatings

l Rare earth magnet coatings

l Rare earth magnet coatings

l Coatings for EMI/RFI shielding provide highly conductive coatings and platings to control electromagnetic interference

l Coatings for EMI/RFI shielding provide highly conductive coatings and platings to control electromagnetic interference

l Ultra thin conformal parylene coating to reduce friction and protect against contamination

l Ultra thin conformal parylene coating to reduce friction and protect against contamination

l Pre-treatments including Ti Anodising, Phosphate Conversion Coating and Chilled Iron Blasting, Aluminum Oxide Blasting and Vapour Degreasing

l Pre-treatments including Ti Anodising, Phosphate Conversion Coating and Chilled Iron Blasting, Aluminum Oxide Blasting and Vapour Degreasing

New Knowledge Hubs initiative at MACH 2024 identifies when manufacturers should adopt new technology, designed to improve productivity, efficiency and reduce costs

Reversing UK manufacturing’s poor record for adopting new technology will be tackled head on at MACH 2024 as The Manufacturing Technologies Association (MTA) launches its new Knowledge Hubs initiative, showcasing how to adopt new technology to improve productivity and efficiency in manufacturing.

The programme showcases new technology that is readily available to UK manufacturers, helping them to understand the potential adopting such technology can bring to their operation, as well as when to adopt it and how to implement it to best effect.

The Knowledge Hubs initiative will have dedicated stands across the event, each focusing on a particular type of technology including Automation and Robotics, Sustainable Solutions, Additive Manufacturing, Consumable Tooling, and Data and Artificial Intelligence.

In recognition of the importance being placed on these hubs, each is being managed by one of the specialist centres from the High Value Manufacturing Catapult, such as the Manufacturing Technology Centre (MTC) and the Advanced Manufacturing Research Centre (AMRC).

The Catapult network is recognised for the cutting-edge research and development work being conducted at its various centres. The network collaborates with thousands of

innovative businesses across a wide range of sectors, including manufacturing, space, health, digital, energy, transport, telecoms, the urban environment and many others.

The MTA, which organises the MACH event on behalf of the engineering-based manufacturing community, has been campaigning for greater adoption of new technology for some time. It will expand upon this at MACH 2024, which opens its doors at the NEC in Birmingham on 15th April, by explaining that implementing proven, readily available techniques in manufacturing processes is the fastest way to boost the UK’s output.

James Selka DL, CEO of the MTA, said: “The MTA is part of a united front of UK manufacturing organisations, along with the Manufacturing Technology Centre (MTC) and MACH 2024 Headline Sponsor Lloyds Bank, to increase the uptake of technologies such as automation and robotics.”

“Only by embracing what the hubs are trying to achieve will the UK restore its position as a sovereign manufacturer, re-establishing itself as a major player on the global stage.”

“To have brand agnostic input from the High Value Manufacturing Catapult network, running our Knowledge Hubs, is an indication of the importance these organisations place on our initiative. Combined with the ability to see advanced technology, live and in action, in a fully working state – MACH 2024 is a must-visit for all the UK’s manufacturing community.”

The need for this approach was recently brought into sharp focus in a new report highlighting the UK’s lack of investment in technology and its poor adoption of robotics in industry. The figures, from the International Federation of Robotics, showed the UK languishing outside the top 20 developed nations in terms of the global utilisation of industrial robots in manufacturing – lagging not just behind the economic superpowers, but also the likes of Spain and Finland.

The Automation and Robotics Knowledge Hub will showcase how easily the technology can be adopted into existing manufacturing operations, automating repeatable processes, improving accuracy and consistency, and reducing repetitive and monotonous tasks.

For further information, please visit www.machexhibition.com

Lloyds

The countdown to MACH 2024, the UK’s national event for inspiring, innovating and connecting manufacturing, has reached an important landmark, with just one year to go before the doors to the National Exhibition Centre in Birmingham open for the UK’s national event for engineering-based manufacturing.

In recognition of the landmark – and reaffirming their commitment to UK manufacturing – Lloyds Bank have confirmed their headline sponsorship of MACH 2024, the sixth time they have done so. MACH is the UK’s only live, national event showcasing sustainable, innovative technologies used across the manufacturing spectrum and is the destination of choice for companies looking to adopt and invest in the digital revolution.

Commenting on the new deal, James Selka DL, Chief Executive Officer at the Manufacturing Technologies Association said; “We are delighted to again be working with Lloyds Bank –this time on the promotion of MACH 2024. Being owned by the industry, for the benefit of the industry, the MTA’s primary aim is to help and support the sector we represent to do business, boosting the UK’s manufacturing performance and enabling UK PLC to compete at a global level. Manufacturing is the heartbeat of the UK economy and growing a resilient manufacturing industry has never been more important. Lloyds Bank is an ideal partner for MACH as we share common goals and commitments.”

A key theme of MACH 2024, which takes place between 15-19th April, will be around sustainability, supporting

UK manufacturers transition to a low-carbon, sustainable business model. Dave Atkinson, UK Head of Manufacturing at Lloyds Bank commented; “Making the transition to Net Zero represents a significant growth opportunity for the UK economy, particularly for the manufacturing sector. However, we must invest in technology and skills to support such an ambitious change. Lloyds Bank are delighted to again sponsor MACH – the UK’s national showcase for the best in next-generation manufacturing technologies.”

As a full working week event, MACH exhibitors power their equipment and technology on display, demonstrating latest techniques and trends to improve productivity, reducing material resource and energy used in the process – helping to ensure a sustainable future, contributing to the drive towards Net Zero.

Attracting new talent into the engineering-based manufacturing sector is another key driver for

growth and a shared focus for both the MTA and Lloyds Bank. James Selka continues; “The MTA invests in a dedicated Education and Development Zone at MACH, successfully attracting over 3,000 students in the key age range of 1118. The zone is designed to inspire a future generation into engineering as an exciting career, helping to close the skills gap by investing in people.”

With 12 months to go before the doors open at MACH 2024, the show is already well on the way to being a sell-out. Attracting an audience of more than 26,000 people to meet and network with around 500 exhibitors, business attributed to the event in 2022 amounted to more than £180m.

Lloyds Bank’s sponsorship deal also extends to the Engineering Supply Chain Show. This three-day event, co-located alongside MACH in 2024, is where engineering and manufacturing buyers go to find world-class suppliers, exclusively in the UK engineering and manufacturing supply chain.

For further information, please visit www.machexhibition.com

In an era where precision and innovation are paramount, QFS Manufacturing Ltd emerges as the leader of metallic prototyping and turn-key solutions. Our mission is clear: to transform your visionary concepts into tangible creations with unmatched efficiency and speed. Our adaptability and flexible manufacturing capabilities ensure we meet the unique needs of our clients. We are dedicated to fostering strong, equitable partnerships and nurturing a thriving ecosystem of innovation and growth.

At QFS Manufacturing, our spectrum of services encompasses everything from adept in-house design to advanced simulation software, ensuring the seamless integration and rapid delivery of high-quality components. Specialising in metallic prototype parts and low to medium volume production.

Our technological prowess is evident in our comprehensive manufacturing capabilities. From our remarkable laser cutting facilities featuring Trumpf 5-Axis Lasers and Amada Ventis Fibre Laser to our bending, folding, and pressing capabilities, we embody precision and efficiency. Our team recently completed an impressive 72-piece Cross Car Beam assembly. This complex assembly was comprised of three sizable sub-assemblies, a mix of flat and fold components, pressed components, and a wide range of machined components.

We’ve also celebrated the successful modification of a hood hinge variant and a carryover modified Rockshield. We’ve showcased the adaptability and versatility of our production capabilities, all while working on an intricate tube fabrication project, affectionately known as “Bunny Bars.” Using bespoke aluminium extrusions and precision machined blocks, our talented team ensured the highest quality of this assembly with the help of our 5-Axis Laser and expert welding.

We invite you to experience the future of manufacturing at the MACH exhibition, where our team is in Hall 6 Stand 6-34 where we will be showcasing our cutting-edge solutions and on hand to discuss potential partnerships. Join us on this progressive journey and discover how QFS Manufacturing can bring your concepts to life.

QFS Manufacturing Ltd: Where Innovation Meets Excellence. WWW.QFSMANUFACTURING.COM

Industrial automation specialist FANUC UK will showcase a range of real-world robotic innovations at MACH 2024, including an affordable muti-axis turning and machining solution aimed at helping manufacturers in the aerospace, automotive, utilities and energy supply chains reduce cycle times, cut costs, save space and boost production efficiency.

As well as EDM wire cutting, aerospace cobot drilling and educational solutions, the centrepiece of the FANUC stand will be an advanced ROBODRILL machine, equipped with a 24k spindle and mounted with a Nikken two-axis high speed rotary table, featuring a built-in direct drive motor that achieves 1500rpm. In operation throughout the entire five days of the show, the demonstration cell will produce finished scroll compressor aluminium housings, showcasing live to visitors the costsaving and performance benefits to be gained from combining machining and turning processes.

Less than three metres long and a little over two metres wide, the ROBODRILL/Nikken solution is a truly lean machine with a compact footprint.

“FANUC and Nikken have worked together to create a combined machining/turning cell with an extended range of functionality, offered at a fraction of the cost of machines with similar capabilities,” says Oliver Selby, Head of UK Sales at FANUC UK.

“At the heart of the solution is our D21LiB5ADV Plus ROBODRILL,

which is a three-axis machine in its core configuration. The Nikken table adds a further two axes, allowing users to turn and machine components on the same unit,” Oliver explains. “This is a real breakthrough, which brings the functionality of million-pound machines within reach of SMEs at a significantly lower cost, helping them to become more competitive and consider undertaking work that would previously have been unavailable to them.”

Less than three metres long and a little over two metres wide, the ROBODRILL/Nikken solution is a truly lean machine with a compact footprint. It features a Nikken 5AX-201 tilting rotary table with pneumatic clamping, enabling difficult-to-hold components to be quickly mounted and changed. In addition, access from all sides means the majority of operations can be completed in one hit, optimising machine tool and operators’ time.

Cobot applications in action

Also available to visitors to the FANUC stand at MACH 2024 will be:

• An aerospace drilling cell comprising a CRX-25iA cobot, developed by FANUC partner Electroimpact. Delivering accessible and cost-effective prevalidated drilling functionality for the aerospace sector, it offers manufacturers improved reliability, repeatability and traceability compared to current manual practices.

• A FANUC C600iC ROBOCUT wire EDM.

• An automated robot machine tool loader, developed in conjunction with YMT Technologies, alongside a D21MiB5ADV Plus ROBODRILL.

Finally, as part of the company’s ongoing commitment to encouraging a pipeline of new talent into engineering, manufacturing and automation, the FANUC stand will also host a turning and milling education simulator and a new-to-market ROBOT G-code solution with a FANUC Education cell. Controlled by a proprietary FANUC CNC unit, it features all the real-world functions required to teach core robotics programming and operating skills and help inspire the next generation to realise their career ambitions.

To discover more about FANUC UK’s range of automated systems to improve manufacturers’ efficiency, visit stand 6-350 at MACH 2024, NEC Birmingham, 15-19 April 2024.

For further information, please visit www.fanuc.eu/uk/en

MACH 2024, already expected to be one of the most important exhibitions in the event’s illustrious history, is also set to the most sustainable. With challenges mounting for the UK’s engineeringbased manufacturers, MACH 2024 organiser, the Manufacturing Technologies Association is taking a proactive approach to the current situation with a show-ready ethos that promotes the green agenda while offering exhibitors costeffective solutions for attractive stands that won’t break the budget.

The approach is in keeping with recommendations from the Association of Event Organisers, which has recently published guidance for Venues, Contractor and Organisers to promote more sustainable events not just in terms of environmental impact, but true sustainability for encouraging talent and diversity, greener events and social responsibility.

James Selka DL, CEO of the MTA, said: “Let me be clear, this not a greenwashing exercise. As a not-forprofit enterprise with a strong ethos for socially responsible business decisions, the MTA is adopting the AEO guidance into its way of working as it is the right thing to do, both ethically and financially.

“We are working on a number of initiatives for the 2024 exhibition, both planned and in place, and while we are by no means fully there yet, the influence on the show will be considerable and set the tone for future events. Exhibitors and our host venue, the NEC in Birmingham, are supportive of the changes we are

making, and I thank them for their help.”

Examples of the sustainability approach include the re-use of the MTA exhibition stand from MACH 2022, the development of a ‘Green Mark’ badge of honour for exhibitors adopting re-used stands and as far as possible, a digital-only approach to marketing material to reduce unnecessary printing. Other initiatives are set to follow in the coming months, while the NEC’s own plan includes an LED light replacement programme, zero waste to landfill policy and recycling sent to a plant just seven miles from its campus to reduce unnecessary transport miles.

In keeping with this, examples of show readiness will include the use of lightweight materials so more can be stored in fewer vehicles, thereby reducing transport emissions, the encouragement of electric commercial vehicles, the re-use of show fabrics and carpets, the adoption of low-energy LED lighting, the use of solvent-free ink and where possible, the re-use or hiring of stand furniture and fittings.

This will benefit exhibitors as it helps with their own green agenda, and it also makes it easier for them to turn up of the day of the event to a good looking show stand that is all set for them to start exhibiting.

“This is the first time we will be offering this show-ready service and aside from the environmental benefits, it also means exhibitors can budget better as it enables them to fix and spread the cost of both stand space and stand build. This will also facilitate better cash flow and a lower administrational burden on their staff,” added Mr Selka.

However, one thing that will not be changing is the spirit of the event, with MACH remaining the national manufacturing show run by the industry for the industry.

This has been enhanced by developments within the MTA and its adoption of a new engineering-based manufacturing cluster containing both the Engineering Industries Association (EIA) and AMUK, the UK’s only trade association for Additive Manufacturing and 3D Printing.

Each of member of the cluster will have a strong presence at the show. The EIA will again be organising its Engineering Supply Chain Show, while AMUK is advocating through the Additive Manufacturing and 3D Printing Zone.

Co-locating the EIA with MACH 2024 also offers additional sustainability gains as it negates the need for a separate show with the costs that would entail, both commercially and environmentally.

For further information, please visit www.machexhibition.com/about-us/about-the-organisers

Quality Control Technology are a one stop solution for all your business CMM requirements, we have the largest stock of New and Refurbished CMM’s in the UK, with over 30 years’ experience of CMM service, calibration and repair.

Quality Control Technology are a one stop solution for all your business CMM requirements, we have the largest stock of New and Refurbished CMM’s in the UK, with over 30 years’ experience of CMM service, calibration and repair.

New CMMs

New CMMs

The ‘Quantum 4 CMM Range’ is built and designed at QCT’s UK works and is available in a variety of standard frame sizes, other sizes can be built on request. All CMM’s are supplied with our bespoke software and interfaces. The Quantum 4 offers outstanding build quality and cost to performance ratio.

The ‘Quantum 4 CMM Range’ is built and designed at QCT’s UK works and is available in a variety of standard frame sizes, other sizes can be built on request. All CMM’s are supplied with our bespoke software and interfaces. The Quantum 4 offers outstanding build quality and cost to performance ratio.

The ACE arm offers portable measuring capability for the largest of projects as well as the flexibility to take the measuring machine to the object. Like our Quantum range, the Ace measuring arm offers exceptional quality and is the perfect system for contact and noncontact 3D measurements with the addition of the laser scanning options.

The ACE arm offers portable measuring capability for the largest of projects as well as the flexibility to take the measuring machine to the object. Like our Quantum range, the Ace measuring arm offers exceptional quality and is the perfect system for contact and noncontact 3D measurements with the addition of the laser scanning options.

Refurbished

Refurbished CMMs

At QCT we only select high quality used machines, completely strip and overhaul them. Each used machine is rigorously tested, with all pneumatic pipes replaced, air bearings removed, cleaned, serviced & refitted. Electronics are tested & unsupported items are replaced with new. The original interface and controller are replaced with QCT’s own along with a new computer and operating system. QCT refurbished machines are supplied as a full turnkey package, fully backed with a comprehensive warranty. Re-using the frame of a pre-used CMM means that fewer resources are required to produce them, reducing their carbon footprint.

At QCT we only select high quality used machines, completely strip and overhaul them. Each used machine is rigorously tested, with all pneumatic pipes replaced, air bearings removed, cleaned, serviced & refitted. Electronics are tested & unsupported items are replaced with new. The original interface and controller are replaced with QCT’s own along with a new computer and operating system. QCT refurbished machines are supplied as a full turnkey package, fully backed with a comprehensive warranty. Re-using the frame of a pre-used CMM means that fewer resources are required to produce them, reducing their carbon footprint.

QCT also

Service and Calibration of All CMM’s

•

an ongoing calibration and service contract package to ensure your CMM is operating at its optimum.

QCT also offers an ongoing calibration and service contract package to ensure your CMM is operating at its optimum.

T:

E:

www.cmmsales.co.uk

•

•

•

•