sustainability

2022 has been a year of great challenges for Laminazione Sottile Group: despite the complexities and uncertainty of the global economic landscape, aluminium demand has shown an ongoing upward trend in several key sectors. Our Group has continued to evolve to meet these needs. We invested in production capacity, sustainability and, above all, in the development of human resources: the true heart of our companies.

Massimo Moschini PRESIDENT AND CEO LAMINAZINE SOTTILE S.P.A.

We made new strategic investments, aimed at improving both productivity and environmental impact of our operations along the entire integrated supply chain. We are increasing the use of renewable energy and carrying out the optimization of each process step.

We equipped our plants with state-of-the-art technologies to reduce CO2 emissions and increase the energy efficiency: as an example, the new coating line featuring an innovative Volatile Organic Compounds (VOC) abatement system, which can recover the produced heat and significantly limit the natural gas consumption.

The focus is not only on environmental impacts: our development plan promotes an all-round sustainability ethic.

In the difficult socio-economic context we are currently experiencing, the implementation of projects aimed at mitigating the impact of energy price increments allowed us to gain greater financial stability for the companies, thus safeguarding our employees jobs. However, what we are most proud of is the investment we make every day on people, focusing on their training and growth within Laminazione Sottile Group.

People are the true wealth of an organisation and, therefore, we do our best to ensure a positive and stimulating working environment, starting from the onboarding phase of new employees. We want to make resources and tools available to our employees to support their development and professional well-being. The employee must if fact increasingly be the centre, the engine of the international growth process that our Group continues to pursue.

We strongly believe in internal training: it is a determining factor in the development of our human capital and in maintaining the excellence of our processes. In 2022, we inaugurated the headquarter of the Guido Moschini Academy, expanding our training offer and delivering almost 18,000 hours of education over the year, organised in over 180 technical and soft skill learning paths for the various areas and functions, and an additional focus on the updates in the field of safety in the workplace.

An approach intended for the internationalisation, but also a great attention to local communities which make us very proud: in 2022 we supported cultural and social initiatives and promoted projects against food waste. In addition, we supplied thousands of aluminium food containers to public canteens and soup kitchen, sharing the social mission they have embraced.

We are getting closer to 100 years of activity: it will be a great milestone that will tell the story of where we started and where we want to go. We will continue on our path marked by sustainability, innovation and the resilience shown in recent years, always preserving our historical roots. This Sustainability Report try to describe the enormous and remarkable work that every single person, in each company of Laminazione Sottile Group, carries out with passion and professionalism. I have read with pride the numbers, results and activities recounted in these pages.

Like aluminium, we will continue to transform ourselves while preserving our unique properties: we will look towards the future, ready to face new challenges but aware of all we have built. Since 1923.

Sustainability report 2022

9 SITES

1,249 CORPORATE POPULATION

18,532 HOURS OF TRAINING PROVIDED

70 COUNTRIES TO WHICH THE GROUP EXPORTS

SALES REVENUES

€ 938,205,734

+6.8%

ORGANIC GROWTH COMPARED TO THE PREVIOUS YEAR

€ 103,906,878

80% PRODUCTION SITES WITH ISO 14001 CERTIFICATION

65% PRODUCTION SITES WITH ISO 45001 CERTIFICATION

Sustainability report 2022

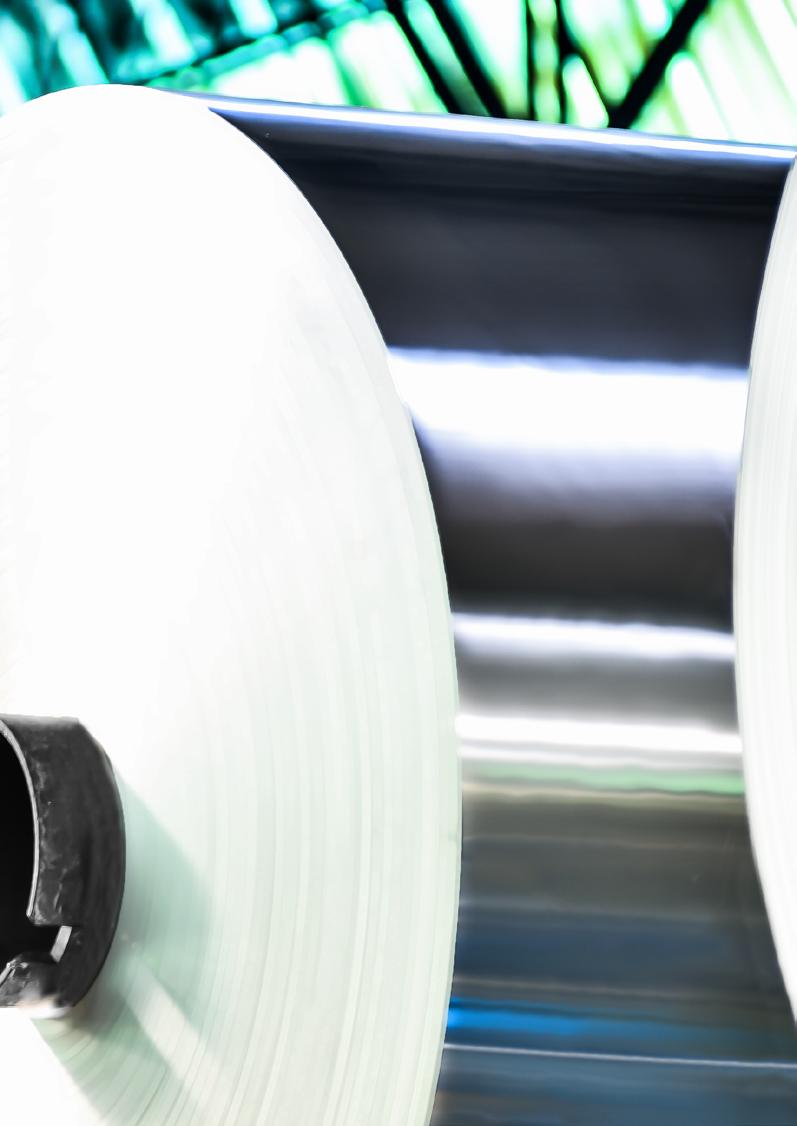

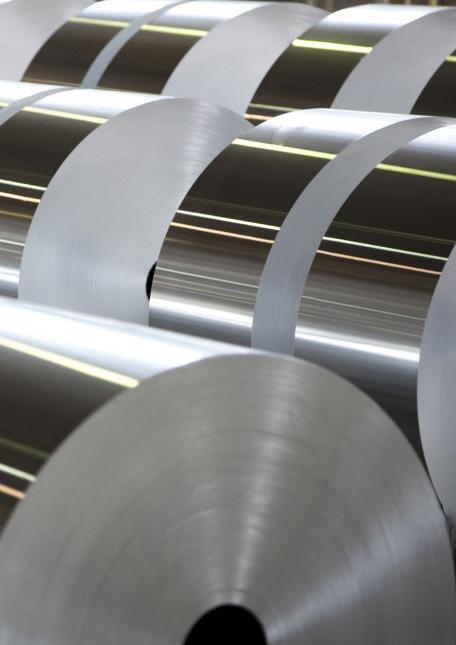

Il The Laminazione Sottile Group evolved from the company of the same name, founded in Naples in 1923 and specialised in the manufacture of semi-finished aluminium products. After an initial period that focused on the production of closures and tubes for toothpaste, a process of industrial development began, based on diversifying the product range and aiming at new markets, while simultaneously investing in human resources, machinery and technology.

In the 1960s, the plant was transferred to a 200,000 m2 site in the industrial zone of San Marco Evangelista (CE), which is still in operation today and produces aluminium rolls.

Production has grown year after year, and in 2016 broke the threshold of 100,000 tonnes per year. The company is one of Europe's biggest manufacturers of rolled aluminium, with exports representing over 65% of total production. In 1991 the company embarked on an expansion strategy through the creation of other companies.

Registered offices: S. Marco Evangelista (CE)

- Italy

Established: 1923

Activity: Manufacture of aluminium coils and sheets for industrial applications

Registered offices: Pignataro Maggiore (CE)

- Italy

Established: 1991

Activity: Manufacture of containers, trays and plates in bare and lacquered aluminium; aluminium foil, clingfilm and baking paper; PET containers

Registered offices: Pignataro Maggiore (CE)

- Italy

Established: 1993

Activity: Manufacture of lacquered aluminium coils and sheets for industrial applications

Registered offices: Telford (Birmingham)United Kingdom

Acquired: 2009

Activity: Production of bare and lacquered aluminium containers for food use

Registered offices: Sachsenheim (Stuttgart)Germany

Acquired: 2018

Activity: Distribution of bare and lacquered aluminium coils and sheets

Registered offices: Alessandria (AL) - Italy

Acquired: 2015

Activity: Manufacture of converted aluminium foil for packaging applications

Registered offices: Çerkezköy / TekirdağTurkey

Established: 2019

Activity: Production of aluminium containers and rolls for food use

Registered offices: Seoul - South Korea

Established: 2016

Activity: Distribution of aluminium containers for food use

Registered offices: Richmond (Virginia) - USA

Established: 2020

Activity: Distribution of aluminium containers for food use

In 2019, the Laminazione Sottile Group joined the ASI (Aluminium Stewardship Initiative) consortium, an international non-profit organisation which defines the environmental and social standards for aluminium production.

In January 2021 it concluded the Performance Standard certification process for 3 plants: Laminazione Sottile, Italcoat and IPS.

ISO 9001:2015; ISO 14001:2015; ISO 45001:2018; SA 8000:2014; EMAS; AEO-F; IATF 16949:2016; ECOVADIS GOLD RATING; ASI PERFORMANCE STANDARD

ISO 9001:2015; ISO 14001:2015; ISO 45001:2018; EMAS; AEO-F; ECOVADIS GOLD RATING; ASI PERFORMANCE STANDARD

ISO 9001:2015; ISO 14001:2015; ISO 45001:2018;BRCGS AA; EMAS; ECOVADIS GOLD RATING; ASI PERFORMANCE STANDARD

ISO 9001:2015

BRCGS GRADE AA; ISO 14001:2015; FSC CHAIN OF CUSTODY; SEDEX

BRCGS GRADE AA; ISO 9001:2015; ISO 14001:2015; ISO 45001:2018; EMAS BRCGS GRADE AA

In 2021, the Laminazione Sottile, Italcoat and IPS plants obtained the ASI Performance Standard Certification. Issued by the Aluminium Stewardship Initiative Consortium, the Certification is specific to the aluminium supply chain and aligns with other certification schemes such as ISO 14001:2015, ISO 45001:2018 and SA 8000:2014. The ASI Performance Standard scheme applies a set of criteria to assess the Health and Safety, Environment, Social Responsibility, Governance and Sustainability aspects of the supply chain.

In particular, the Laminazione Sottile Group adopts a management system that is consistent with the requirements of the ASI, respecting the 11 cardinal principles of the Standard.

Business Integrity

Policy and Management

Transparency

Sustainable management of materials

Greenhouse gas emissions

Emissions, discharges and waste

Water Management

Biodiversity

Human Rights

Workers’ Rights

Occupational health and safety

Laminazione Sottile adopts and applies a Corporate Social Responsibility system aligned with the international standard SA 8000, which aims to certify certain aspects of corporate management in the field of Corporate Social Responsibility, and shares this system with Group companies.

The system considers the following aspects:

respect for human rights

respect for employment rights

protection against child labour

guarantee of a safe and hygienic working environment

The company constantly monitors these topics, ensuring continuous compliance with the policies and procedures adopted and providing specific training to all new hires.

In order to guarantee the ethical nature of the management system, the Social Performance Team (SPT) was established to implement and ensure the correct application of the SA 8000 standard.

Furthermore, in line with the provisions of the Group Code Of Ethics, Laminazione Sottile has adopted the SA 8000 Policy as further confirmation of the Group's corporate commitment to achieve the highest standards of ethics and sustainable business development.

The management works to establish all the measures and provide the necessary resources to pursue these objectives and general principles, in line with the focus on continuous improvement in the company's social performance.

The SA 8000 management system is audited by a third-party certification body every six months.

The two audits conducted in 2022 on the management system were concluded positively.

(GRI 2-23)

A COMPANY SHAPED ON ALUMINIUM: INNOVATIVE AND RELIABLE, DYNAMIC AND SUSTAINABLE

OUR MISSION IS TO GENERATE VALUE:

becoming a trusted partner to our customers and supporting their growth;

expressing a corporate culture based on responsibility, shared values, communication and results.

The Group's vision and mission are shared with all employees and collaborators when they join the company and are backed up by regular internal communication activities and initiatives that actively engage employees (working groups, sporting and music events). Through this approach, the guidelines on which the Group bases its future development become a collective heritage and an integral part of the company experience.

The Laminazione Sottile Group is founded on a set of values that characterise all of the companies belonging to the Group. The values guide corporate decisions and are a point of reference for all employees and collaborators.

We pursue results with respect for collaborators, customers and suppliers, creating value and spreading the culture of work in the territory in which we operate.

We are committed to reducing the impact of our activities on the environment, optimising resources according to a model of sustainable growth.

We take care of employees and their safety.

We value people who express passion in their work, ethics, integrity and fairness.

We want to live up to our past, projecting our Group into the future, guaranteeing continuity and development while respecting tradition.

(GRI 2-6)

The Group's companies are structured into three Business Units:

ROLLING

Production of aluminium coils

CONVERTING

Surface treatment and lacquering of aluminum strips

The

Production of aluminium containers, tubs and rolls

In addition to these Units, the Group also operates three companies that manage the distribution of the manufactured products in specific geographical areas.

The semi-finished products manufactured by Laminazione Sottile (bare aluminium), Italcoat and IPS (lacquered and printed aluminium) are aimed at a broad range of market applications.

variety of possible uses of aluminium, combined with the diversification of products and end markets, is one of the strengths of the Group, which can thus adapt its business strategies in relation to the constant evolution of the market

The main sectors of application of rolled aluminium are:

RIGID PACKAGING

pharmaceutical closures

bottle closures (wine, mineral water, oil)

boxes and lids for food or cosmetic use

SEMI-RIGID PACKAGING

containers and trays

containers for candles

FLEXIBLE PACKAGING

bottle caps

chocolates

yoghurts and creams

mini cheeses

blisters and coldforms

INDUSTRIAL APPLICATIONS

adhesive tapes

cables

multilayer pipes

honeycomb panels

light bulbs, neon tubes

insulating panels

CONSTRUCTION/INTERIOR DESIGN

roofs, panels, suspended ceilings, roof capping

roller shutters, shutters

raised floors

HVAC-R

fins for radiators, evaporators

heat exchangers

cooling panels

hoses

AEROSPACE

structural components

non-structural components

AUTOMOTIVE

thermal and acoustic shields

batteries

structural components

non-structural components

The primary market of the Containers Business Unit, which manufactures finished products, is the food sector. The companies operate in the B2B sector, with a limited range of products aimed at the B2C market.

Direct customers include:

food industries;

distributors;

Cash&Carry, wholesalers;

mass distribution (private label and Contital brand);

packers.

Certain products are aimed at other target markets such as the beauty and floriculture sectors.

(GRI 2-6)

The Laminazione Sottile Group adopts the following strategic guidelines:

investing in the growth and internationalisation of its business, both in terms of internal product ranges and acquisitions;

promoting the use of aluminium, pursuing the idea that aluminium products are a winning choice. This is due both to the qualities of the metal itself and to its limited environmental impact, thanks to its infinite recyclability. Furthermore the Group continues to research solutions using rolled aluminium to manufacture increasingly lightweight, high performance and aesthetically superior products;

respecting and protecting the environment through investments in technologies to reduce the environmental impact of its production activities through the reduction of emissions (including greenhouse gases) and water use, the use of renewable energy, energy recovery during combustion processes, and the reduction of solid waste directed to landfill;

promoting the well-being and enhancement of each employee through a policy aimed at training and developing skills both with classroom and on-the-job activities.

The main objectives include: focus on internationalisation and on promotion of the aluminium made by the companies of the Group. A product that combines quality and sustainability

communication

(GRI 2-1, 2-7, 2-9, 205-1, 205-3, 206-1, 401-1, 405-1, 418-1)

The Laminazione Sottile Group adopts a traditional management and control model, whose main corporate bodies are the Shareholders’ Meeting, the Board of Directors and the Board of Statutory Auditors.

The Board of Directors of the Parent Company Laminazione Sottile S.p.A. is responsible for defining and managing the strategic guidelines and issues related to sustainability, as well as the periodic verification of the adequacy and effective functioning of the risk management system. The Board of Directors approves the Sustainability Report, which represents the main document through which the Group describes its environmental and social impacts and identifies the relative risks and opportunities. The Board of Directors of Laminazione Sottile S.p.A. is also responsible for managing and coordinating the activities of the Group's investee companies and subsidiaries pursuant to art. 2497 et seq. of the Italian Civil Code and for monitoring their development.

BOARD OF DIRECTORS

Chair and CEO: M. Moschini

CEO: L. Moschini

CEO: P. Moschini

Board Directors: Gottfried B. Giulini T. E. Muntoni A. A.

BOARD OF STATUTORY AUDITORS

Chair: F. Parisio

Standing auditors: Migliardi C. Tardini M.

Alternate auditors: Smith M. Pessina M.

(GRI 2-7, 401-1, 405-1)

Composition of the administrative bodies of the Laminazione Sottile Group companies by gender and age group

The ordinary and extraordinary management of the company falls to the Board of Directors, which is responsible for defining and managing the strategic guidelines, the periodic verification of the adequacy and effective functioning of the risk management system, as well as the guidelines of the corporate sustainability strategy and the definition of objectives.

BoD: 5 members

Board of Statutory Auditors: 3 members

Ips

BoD: 5 members

Board of Statutory Auditors: 1 member

Pllana

Sole Administrator Advisory Board

BoD: 3 members

Board of Statutory Auditors: 3 members

BoD: 3 members

BoD: 5 members

BoD: 3 members

I2r

BoD: 3 members

(GRI 2-25, 205-1, 205-3, 206-1)

Businesses in Italy adopt Management and Control Models that define a set of principles, rules of conduct and operating procedures aimed at preventing the commission of unlawful conduct and guaranteeing ethical practices by all those who operate on behalf of the company, respecting the principles of lawfulness, integrity and transparency. The Models are approved by the BoD and contain general principles and specific rules. They are divided into a “general section” and “special sections” aimed at integrating the content in relation to certain categories of offence for which corporate responsibility applies, and are supported by administrative, organisational and technical procedures.

To ensure the effective and constant application of the Organisation, Management and Control Models, and pursuant to article 6 of Italian Legislative Decree 231/01, a Supervisory Body vested with autonomous powers of initiative and control is established for each company, which is responsible for monitoring the correct implementation of the Organisation and Management model and providing for its relative update. As at 31 December 2022, four Supervisory Bodies (SB) are operational within the Group structure, specifically at the companies Laminazione Sottile SpA, Italcoat Srl, Contital Srl and IPS Srl.

The SB is a collegiate body composed of three members, of which one is appointed Chair. The Supervisory Body is an executive body and reports directly to the Board of Directors, to which it refers any breaches of the Model. The Supervisory Body responds to the eligibility criteria provided for under Italian Legislative Decree 231/2001 and specified in the Organisation, Management and Control Model: integrity, autonomy and independence, and competence.

The Models are based on the adoption of a Code of Ethics, which represents the principles, values and rules of conduct of the Companies of the Laminazione Sottile Group.

The duties, powers and responsibilities of the Supervisory Body are defined by a specific regulation. In conducting its control activities, the Supervisory Body is supported by various corporate departments - the Internal Audit department in particular - which in 2022 conducted audits on major corporate processes and the main areas identified within the Model as “sensitive”. The Code of Ethics expresses the ethical commitments and responsibilities of the company in the context of its activities towards its customers and in the context of its internal activities with regard to all stakeholders including shareholders, employees and collaborators.

The Code is therefore a set of principle that must be respected by all of its recipients in order to ensure the proper functioning, competent management and image of the Laminazione Sottile Group. The Code provides for anonymous and protected communication methods to report breaches of the rules and principles contained therein, which guarantee the secrecy of the identity of the whistleblower and are addressed to the Supervisory Bodies of the Group companies.

The Code of Ethics can be consulted on the company websites and a notice on the adoption of the Code is given to all new hires; regarding suppliers, in order to be admitted for inclusion on the Supplier Register, all suppliers must acknowledge and accept the Code. In 2022 there were no identified or reported cases of corruption or anti-competitive conduct.

Specifically, anti-corruption is governed by the 231 Model of each Company which considers, among the relevant offences, those referred to in arts. 24 and 25 of the Decree, which refer to corruption in the Public Administration, and in art. 25-ter, which includes private sector corruption and incitement to private sector corruption. To date, the Companies of the Laminazione Sottile Group have not deemed it necessary to adopt a specific anti-corruption policy.

During 2023, an update of the Models of the Group companies is planned in order to adapt to the recent regulatory changes relating to the introduction of new predicate crimes

The Group pays close attention to the management of sensitive information, not only with respect to regulatory compliance but also with regard to security and business priorities. The European Regulation on the protection of personal data (GDPR - General Data Protection Regulation), since 2018 one of the points of reference for a renewed commitment to the protection of personal data, represents one of the cornerstones of the approach adopted.

The Group is constantly committed to updating tools such as the data processing register, company policies, information, internal appointments, External Manager appointments, System Administrator appointments and regular updates, etc.

The regulations relating to the containment measures of the Covid 19 contagion made it necessary also in 2022 to manage confidential information relating to employees, collaborators and external companies. This has led to a careful structuring of the data acquisition and storage processes and of adequate protection tools against breaches by third parties or against any improper use, guaranteeing an information flow in which the intended use of the data is always clear.

It should be noted that in 2022 there were no breaches of privacy or loss of data relating to customers, employees or users of corporate mailing lists.

GENERAL DATA

PROTECTION REGULATION

(GRI 2-23, 2-27, 3-3, 201-4, 301-1, 301-2, 302-1, 302-3, 302-4, 303-1, 303-2, 303-3, 303-4, 303-5,305-2, 305-5, 305-7, 306-2, 306-3)

For many years the Laminazione Sottile Group has adopted an environmental impact policy based on an approach to manufacturing that integrates long-term environmental sustainability targets, mainly aimed at reducing atmospheric emissions, improving energy efficiency, reducing industrial water consumption and the relative effluents, and reducing the amount of waste produced and the quantity of ancillary materials used in the production process.

All of this has been made possible thanks to a substantial investment plan and continuous research into ever less impactful products, processes and technologies.

The “Integrated Policy for Quality, Safety and the Environment” clarifies, for each company, the strategy of the Laminazione Sottile Group, in terms of the values, vision and mission, and the commitment to adopt the principles of sustainable development, guaranteeing continuous improvements in environmental performance through the adoption of specific KPIs that precisely indicate the most effective areas for improvement. In particular, the Group aims to reduce the risks of pollution, polluting emissions and waste and to optimise resources.

The Laminazione Sottile Group is strongly committed to recovering scrap aluminium from industrial processes. The semi-finished products are supplied to customers that transform the material into finished products. The swarf is returned to the factory, where it is reused and transformed into rolled aluminium in a genuinely sustainable process that aligns perfectly with the principles of the circular economy.

The Group is also committed to maximising the reuse of production waste.

In 2022 no significant fines or sanctions were given to Group companies for non-compliance with environmental regulations.

Aluminium is 100% recyclable for an infinite number of times without losing any of its properties.

The possibility of recycling metal represents an important advantage for the environment as primary production (from mines) requires a considerable expenditure of energy (approximately 16 kWh/Kg);

instead, energy consumption is reduced by 95% due to the melting of recycled material (around 0.4 kWh/Kg).

Environmental Protection, energy efficiency and the rational use of resources are the main objectives of the Laminazione Sottile Group

The Group's companies are certified according to Standard UNI EN ISO 14001:2015, which emphasises resource optimisation, context analysis, stakeholder engagement, continuous improvements in performance and compliance with all applicable regulations.

Various three-yearly audits have been completed, confirming the achievement of all of the Group's sustainability objectives.

As part of its commitment to continuous improvement, the Group has voluntarily adopted Regulation (EC) 1221/2009 (EMAS III) and defined an environmental management programme that aligns with the Environmental Policy which is reviewed by Company Management and audited and approved once a year by a third-party certification body.

The implementation of this programme has triggered the development of a culture of Environmental Sustainability within Group companies and formalised the assumption of responsibility and the commitment to internal and external transparency. To date, various three-yearly audits have been completed, confirming that all of the targets defined in the various Environmental Declarations have been achieved and that the Laminazione Sottile Group complies with all applicable legislation.

Specific internal communication campaigns aimed at all company employees and collaborators aim to raise awareness of the certifications obtained and the importance of recycling and promote the adoption of effective waste separation practices.

Several triennial verifications were completed which confirmed full achievement of all the Group's sustainable objectives

Some plants of the Group, specifically Laminazione Sottile S.p.A., Italcoat S.r.l. and IPS S.r.l., are subject to the issuing of the Integral Environmental Authorisation (AIA), i.e. the provision which focuses on the prevention and reduction of pollution deriving from the IPPC activities referred to in Annex VIII of Italian Legislative Decree 152/06 and subsequent amendments and which provides for measures aimed at avoiding or reducing emissions into the air, water and soil, including those relating to waste, to achieve a high level of environmental protection and to implement continuous monitoring.

The Authorisations were issued after a preliminary phase during which the following actions were carried out:

collection, sharing and analysis of information relating to the systems and production organisation

verification of compliance with all the environmental regulatory limits and the use of the best available technologies

identification of any actions aimed at continuous improvement

definition of a monitoring and control plan

In 2021, following the IEA review process, Laminazione Sottile was awarded a new authorisation decree which considered the various environmental improvement projects implemented, such as the installation of a new fume extraction system in the aluminium foundry which channels the emissions from all of the smelters into four abatement systems, optimising system performance and reducing pollutant emissions. At the same time, new systems were authorised to increase production capacity, some of which entered into operation in 2022.

The company Contital S.r.l., which does not fall under the scope of the IPPC directive, holds the Sole Environmental Permit (in Italian ”AUA”) introduced under Italian Presidential Decree 59 of 2013 which amalgamates all existing environmental procedures set forth in industry regulations.

(GRI 301-1, 306-2, 306-3)

For many years the Laminazione Sottile Group has been committed to increasing its use of the best available technologies aimed at:

waste reduction

waste re-use

waste recovery

Waste management plays a major role in the definition of an effective environmental sustainability strategy. In this context, Laminazione Sottile has set itself the objective of preventing and reducing its environmental impact and pursuing the overall improvement of the “humanenvironment” system. The reduction of waste production and its dangerousness is a fundamental element of the integrated policy which promotes its recycling and recovery.

The complexity of the problems connected to waste management and the pursuit of objectives of continuous improvement of the economic-environmental efficiency of the management cycles translate into a very wide differentiation of the technologies put in place.

The plants of the Laminazione Sottile Group produce special (industrial) waste and municipal solid waste. Municipal solid waste is collected and managed by the council. Industrial waste (such as foundry slag, dusts removed from foundry fumes, sludge deriving from the waste water treatment process, depleted refractories, etc.) is delivered to specific external disposal companies, selected on the basis of reliability criteria and authorised according to the current legislation.

Waste management plays a major role in the definition of an effective environmental sustainability strategy.

In this context, Laminazione Sottile has set itself the objective of preventing and reducing its environmental impact and pursuing the overall improvement of the “human-environment” system

At the same time, the Group implements strategies and actions aimed at minimising the portion destined for disposal and increasing that for recovery. Laminazione Sottile pays attention to the destination of waste, an aspect with a significant impact in terms of sustainability and circular economy: over 90% of the total waste produced is classified as non-hazardous.

Furthermore, over 90% of the waste is intended for recovery, while less than 10% is destined for disposal through suitable external disposal companies. In 2022, the amount of waste intended for disposal was reduced by 18% compared to the previous year, while the waste destined for recovery increased by 6%.

For municipal solid waste, the Group promotes effective waste separation practices through internal communication campaigns aimed at all those who work at its plants (employees, collaborators, third-party firms), in order to optimise waste collection and reduce the amount of mixed waste.

>90%

The chemical surface treatment of rolled aluminium increases the adhesion of polymer films and improves resistance to corrosion.

Traditionally, surface treatments involve dipping the rolled aluminium in chemical baths at controlled temperatures and concentrations before rinsing with demineralised water. In these processes, the products must be rinsed to remove any excess chemicals deposited on the surface of the metal. The water used to rinse the products is directed into a chemical-physical waste water treatment plant which generates sludge that must be disposed of as “special non-hazardous waste”.

Laminazione Sottile has invested in the design and development of no-rinse treatment plants. This process generates a significantly lower quantity of waste water and a lower volume of sludge. Through the installation of a system with "No Rinse" technology, in 2022 a 60% reduction was achieved in the sludge produced compared to the previous year, avoiding the production of over 337 tons of sludge.

In order to pursue our constant commitment to environmental sustainability, we installed an innovative plant to dry the filter media used to treat the lubrorefrigerant fluids in cold rolling plants. In 2022, this system made it possible to reduce the production of used media for disposal by 10%, for a total of 20 tons of waste less than the previous year

The goal to reduce the dust and waste generated by foundry slag and dross has been tackled by piloting the use of a waste cooling plant in order to improve the plant's environmental performance in line with the relative BAT-C for the non-ferrous metals sector. The cooling system treats all types of foundry waste through the indirect application of water followed by a sieving process to separate the aluminium from the waste oxides. The system also guarantees a higher metal content of the treated waste, reducing the overall amount generated. Combined with the more rigorous management of the slagging process, this new system allows:

1. the reduction of diffuse dust emissions generated during the transport, storage, handling and loading of waste onto vehicles

2. the reduction of disposed waste

3. the recovery of aluminium to be reintroduced into the production cycle

For the Laminazione Sottile Group, the use of technologies aimed at reducing, sustainably managing and recovering waste is increasingly important

(GRI 302-1, 302-3, 302-4)

Considering the type of production and the size of the companies belonging to the Laminazione Sottile Group, electricity and natural gas consumption represents a major aspect of the Group's environmental impact, and consequently optimising the use of resources is a indispensable tool to achieving its sustainability targets. For this reason, for several years the Group has been implementing a series of actions aimed at monitoring energy performance and quantifying energy use and consumption. The analysis of the main performance indicators has made it possible to launch important projects aimed at optimising consumption per unit of product, both through management improvement and through system efficiency. Over the years the Group has succeeded in significantly reducing its energy intensity per tonne of product, as demonstrated by some of its major projects in this field:

The installation of a heat recovery system for flue gases emitted from furnaces, reducing the consumption of natural gas to heat process fluids and saving some 2,300,000 kWh, 600,000 standard cubic metres of natural gas and 2,200 tonnes of CO2 per year

The general installation of recuperative burners for all plate heating furnaces and foil heat treatment plants; in 2022, these systems enabled a reduction in natural gas consumption of about 1,700,000 standard cubic metres per year, reducing CO2 emissions by about 3,500 tonnes per year

The general installation of regenerative burners for all smelting furnaces, which in 2022 enabled a reduction in natural gas consumption of about 7,600,000 standard cubic metres per year and reduced CO2 emissions by approximately 15,500 tonnes per year

The installation of LED lights in the interior and exterior areas of the Group's Italian plants, saving approximately 950,000 kWh of electricity per year and reducing CO2 emissions by some 400 tonnes per year

The installation of photovoltaic plants with a total output of 3,300 kW, saving around 4,125,000 kWh and around 1,800 tonnes of CO2 per year

The installation of inverters on fan and pump motors enabled savings of around 2,400,000 kWh and 1,000 tonnes of CO2 per year

The installation of air handling units (AHU) to provide air conditioning in the electrical control rooms of the plants, saving some 2,700,000 kWh per year and enabling a reduction in around 1,100 tonnes of CO2 per year

The installation of incinerators for solvents produced by the finishing lines with RTO (Regenerative Thermal Oxidizer) technology which, along with the introduction of the CTR2, enabled average monthly natural gas consumption to be reduced by around 77,000 standard cubic metres, resulting in an annual saving of 850,000 Sm³ of natural gas and around 1,700 tonnes of CO2

The installation of a post-combustion fume heat recovery system that enabled savings of around 100,000 Sm³ of natural gas and some 200 tonnes of CO2

A new painting line has been launched featuring a system that reduces VOCs through the oxidation of solvents and, by recovering the heat produced, supports the oven at the same time and significantly reduces the consumption of natural gas and the consequent CO2 emissions

Installation of a further 1,800 kW of photovoltaic panels that will provide savings of 2,250,000 kWh per year and avoid the emission of a further 950 tonnes of CO2

Optimisation of the hot rolling line with a new section that will enable hot rolling at lower thicknesses. This will enable considerable savings due to the lower amount of energy required for hot rolling compared to cold rolling.

The foundry department will be expanded with the addition of an innovative melting furnace dedicated to the recovery of waste: this will make it possible to reduce consumption by exploiting the calorific value of the pollutants present, while ensuring the complete elimination of harmful substances in the exhaust fumes.

The use of water resources is mainly linked to the cooling operations necessary for the various production activities and, to a lesser extent, for process water. All the companies in the Group use underground water drawn from owned wells duly authorised by provincial decrees. The total quantity of water drawn from the 4 Italian plants of the Laminazione Sottile Group in 2022 was 770,000 m3, with a reduction in consumption of a further 1,400 m3 compared to the previous year.

Almost all of the cooling water used at the plants is recovered within a closed system and reused, while process water is also treated and reused. In 2022, this enabled savings of 5,500,000 m3 of water, in line with the current IPPC regulations. Water used in cooling processes is recovered continuously thanks to a cooling tower system.

Consequently, the amount of water withdrawn from the wells is limited to the amount necessary for the reintegration of evaporation water and the minimum overflow level required to maintain the characteristics of the recirculating water.

For cooling processes, all of the Group's companies use groundwater withdrawn from the Group's wells. Water resources are recovered within a closed system and reused.

The management of atmospheric emissions is stringently monitored and subject to Italian and European legislation that requires the Group's companies to perform increasingly rigorous controls. Protecting the environment requires major investments which, over the years, have led the Laminazione Sottile Group to apply some of the leading emission-reducing solutions.

Over the years, the companies of the Group have achieved important results, as shown by the data from monitoring emissions into the atmosphere in terms of concentrations of pollutants, which are always far below the authorised legal limits. This has been made possible by the adoption of advanced technologies aimed at continuous improvement and maintaining plant efficiency through advanced maintenance programmes.

Moreover, for many years Laminazione Sottile has been committed to reducing greenhouse gas emissions (GHG): this commitment to improve our direct (Scope 1) emissions, which mainly derive from the combustion of natural gas, is pursued by improving our energy efficiency. In addition, the plant is part of the European Emission Trading System, which requires the company to obtain permits that cover the amount of CO2 released. This mechanism is a further incentive to reduce the direct impact of greenhouse gas emissions.

The Group has reduced direct and indirect CO2 emissions, always remaining well below the authorised legal limits

In 2022, the Group decreased its direct CO2 emissions by 1,000 tonnes, compared to the previous year.

Indirect (Scope 2) emissions are largely attributable to electricity consumption from the grid. In addition to the energy efficiency of processes through targeted plant and procedural improvement projects, Laminazione Sottile is continuously increasing the share of energy produced from renewable sources, with the installation of photovoltaic production systems in various plants.

In 2022, the Group decreased indirect CO2 emissions by 139 tonnes compared to the previous year.

External (Scope 3) emissions depend on a number of factors which cannot be directly controlled but which the company is able to influence. To reduce the environmental impact of its business, Laminazione Sottile is committed to:

Increasing the amount of scrap and waste used as raw materials in the production process, reducing the general impact of primary aluminium manufacture from bauxite, which produces around 6 tonnes of CO2 per tonne of aluminium produced. The quantity of secondary aluminium in the form of scrap used in 2022 increased by more than 2,000 tonnes compared to 2021, corresponding to 14,000 tonnes of CO2 avoided.

Where it is not possible to replace the primary aluminium with scrap or waste, the company aims to procure the raw materials from suppliers that only use renewable energy.

-50%

VOC emissions, relating to cold rolling mill fume extraction systems, have also decreased by 50% since 2014, thanks to the careful optimisation of extraction processes

As part of the research activity, in 2022 the companies of the Laminazione Sottile Group benefited from the "Research and Development Tax Credit" envisaged by Italian legislation as well as enjoying the benefits of hyper-depreciation for equipment acquired in Industry 4.0

The Research & Development department, which is centralised at Group level, is responsible for promoting product innovation and finding solutions to meet customers’ needs.

The development of the projects is also performed in collaboration with external partners and is sometimes co-financed by regional (Regional tenders on competitiveness and innovation), national (MIMIT, tax credit) and European institutions.

The company has a laboratory with state-of-the-art instrumentation, which allows very detailed analyses to be performed to support the study and creation of innovative materials and products.

201-4, 301-2)R&D supports the specific production and process areas of the individual plants on various focuses:

Developing and increasing the procurement and use of scrap aluminium to develop projects aimed at different applications, reducing the use of primary aluminium and offering customers the option to transform their production waste into rolled or sheet aluminium, respecting the principles of the circular economy

Developing aluminium and coating systems for food use, focusing on recyclability and sustainability

Investing in LCA (Life Cycle Assessment) training, mapping each phase of the process in order to determine the environmental impact of the finished products and the various types of rolled aluminium

Promoting the central role of aluminium to support environmental sustainability

Supporting customers in the development of high performance products with a lower environmental impact.

The projects undertaken in 2021-2022 pursued various objectives aimed at sustainability:

Development of antimicrobial or anti-mould coatings for the production of air purification systems, for the reduction of cleaning interventions and the related environmental impacts

Production of foil, containers and lids with 100% recycled post-industrial raw materials

Development of aluminium/coating systems for the HVAC-R sector, aimed at reducing water consumption or promoting energy recovery

Use of PVC-free technologies that reduce the dioxin production risk during the heat treatment of production waste.

Study and development of coatings made from resins of natural origin

The R&D department also coordinates the publication of scientific articles written in collaboration with various universities, as well as the participation in scientific or educational events. It also manages projects relating to internships and undergraduate and post-graduate theses in manufacturing or research fields.

The R&D department also coordinates the publication of scientific articles written in collaboration with various universities, as well as the participation in scientific or educational events.

It also manages projects relating to internships and undergraduate and post-graduate theses in manufacturing or research fields.

Among the publications of 2022, an article published by the Journal of Applied Polymer Sciences on lacquered aluminium laminates for packaging capable of extending the shelf life of food products is of particular relevance.

At the heart of the Group's human capital are the selection process, the constant updating of the Onboarding and Induction processes, the improvement of the employee experience and the engagement of new hires

Laminazione Sottile believes in the value of People who contribute to the company's growth every day with professionalism, passion, a sense of belonging and collaboration.

For this reason, during 2022 the Group continued to invest in processes and tools to promote the wellbeing of People and to support the dissemination of sustainability values.

We support our new employees with customised onboarding programmes, enhancing promising candidates and young people through individual development plans and programmes designed to enhance their potential and reflect their personal motivation.

We recognise their merit and value through a Performance Management system that annually evaluates their conduct, performance and the achievement of certain targets against our Skills Model.

The development of technical and soft skills is further promoted through the continuous training provided by our Academy which, in just two years since its foundation, now boasts a skilled team of internal trainers as well as several important partnerships with schools and training institutions

(GRI 2-30, 3-3, 202-2, 401-1, 401-3, 404-1, 404-3)

We also take part in careers events with college students, undergraduates and graduates at various specialist technical colleges and universities. Moreover, we work with a number of business schools, proposing project work relevant to our business and welcoming the ideas and suggestions provided by the young participants.

2022 was a year full of new projects for the Human Resources area, particularly for the Development area: the Academy is supported by the use of a SAP ERP management software module, whose name (eHuReka) was chosen following a competition involving employees of the Group's Italian companies.

The identification of a pool of Young Talent has launched the planning of development projects and career paths. The eHuReka suite has been enhanced with the implementation of the Digital module of the Recruiting Process, the extension of the Career Site and the Employee Central UK.

A structured calendar has been defined for the various employer branding activities. At the same time, the foundations were laid for new projects in 2023.

Implementation of the tool to make viewing of the Group's organisational structure functional

Creation of an Employee Portal

Start up of the new onboarding and performance process

Specific projects on employee experience, talent retention, equal opportunities and welfare

Harmonisation and implementation of processes from a Global perspective

Everything is aimed at improving the satisfaction of our People, who have always represented a strategic component in the pursuit of the company's growth and continuous improvement objectives.

(GRI 2-7, 202-2, 401-1)

Regarding the selection process, whose task it is to constantly enhance the human capital of the Group in line with the needs of the business and with the principles of fairness and equal opportunities, the constant updating of the Onboarding process remains central, differentiated according to the category and area of responsibility of the new employee, aimed at improving employee experience and engagement

The data refer to employees of the Laminazione Sottile Group, excluding contracted workers. The data do not include the i2r UK, i2r Korea and i2r Inc personnel.

The data refer to employees of the Laminazione Sottile Group, excluding contracted workers.

The data refer only to the Italian companies of the Laminazione Sottile Group

The Laminazione Sottile Group prohibits any type of discrimination against those who work for various reasons in the companies or who apply for job positions. In particular, forms of discrimination based on differences in gender, age, state of health, nationality or ethnic group, political or religious opinions are not tolerated. The adoption of an Organisational Model pursuant to Italian Legislative Decree 231/2001 and of a confidential and anonymous reporting system represent - for all those who collaborate with the Group companies - a tool for communicating any offences and breaches to the dedicated Supervisory Body. In 2022, no cases of discrimination were recorded.

Over the years the Laminazione Sottile Group has also been increasing the number of women operating in the company, not only in clerical roles but also in those historically male-dominated technical fields.

In 2021 a project was launched to promote the recruitment of women to manual roles.

The option to take maternity or paternity leave is a key indicator, reducing the risk of parents not returning to work after the birth of a child. Both the rate of return after maternity/paternity leave, as well as the number of employees remaining in post a year after returning demonstrate that almost all employees who took parental leave both returned to work and remained in the workforce.

100% OF EMPLOYEES ARE ENTITLED TO PARENTAL LEAVE

(GRI 404-1, 404-3)

The Guido Moschini Academy was founded in 2021 with the mission of developing the company's heritage of people and knowledge. Its objectives are to:

Develop the professional and social skills of Laminazione Sottile Group employees

Share the technical and manufacturing knowledge present within the Group

Optimise people's ability to work together by promoting effective interaction and organisational procedures in line with the Company's values.

Training programmes can be divided into two main development categories:

Our range of courses is constantly evolving and currently includes 140 classroom courses and 40 MOOCs (Massive Online Open Courses).

The physical headquarters of the Academy were inaugurated in 2022: in this way face-to-face training has been made even more effective, and an adequate location is available for organising or hosting events and conferences including of an international scope. The office is also intended to welcome university or secondary school students, on the occasion of training visits to the Laminazione Sottile plant.

NUMBER OF EMPLOYEES WHO RECEIVE AN ASSESSMENT WITH THE NEW EHUREKA PERFORMANCE SYSTEM, BY GENDER

OF TRAINING BY GENDER - EMPLOYEES

The Group believes that to improve production performance, the quality of work and products, workers must be involved as an active part in the processes, intervening, operating and expressing their opinions: the latter are considered of equal level, importance and dignity with respect to those expressed by the company managers. For this reason, together with the RSU, the creation of working groups was established aimed at improving the individual production areas, processes and technical-organisational systems. Furthermore, the Group is activating communication campaigns (workshops, focus groups, interactive seminars) to inform employees about innovation projects active in the company and about organisational changes (Circular no. 5/E/2018 art. 4 of the Revenue Agency) .

The Group undertakes to plan and activate, for the three-year period 2023-2025, 24 hours of training coinciding with the contractual working hours or in any case according to comparable methods: the training is aimed at guaranteeing and generating polyvalence and multi-functionality processes between workers and at increasing individual skills, both technical and cross-cutting. The courses can be activated according to the delivery methods established by Fondimpresa. The companies in the Campania region have signed an agreement with the RSU/RSA relating to the performance bonus for the year 2022. This agreement is aimed at significantly rewarding the achievement and exceeding of the objectives. On the basis of the provisions of law no.28/2015 and subsequent amendments, the worker may choose to use all or part of the amount of the individual performance bonus due in works and services with socially relevant purposes, paid directly or in the form of reimbursement of expenses or through additional contributions to the supplementary pension scheme and/or to the Supplementary Assistance Fund.

Hours worked

(GRI 3-3, 403-1, 403-2, 403-3, 403-4, 403-5, 403-6, 403-7, 403-8, 403-9, 403-10)

The Laminazione Sottile Group has voluntarily adopted an Occupational Health and Safety Management System (OHSMS) with a view to ensuring continuous improvement and engagement among workers. The OHSMS is certified by an independent third party in compliance with the UNI ISO 45001:2018 standard and is applied to all employees and non-employee workers whose work and/or workplace is controlled by the organisation. In 2022, the Group companies successfully passed the surveillance audit. The responsibility of the OHSMS lies with the Prevention and Protection Service, consisting of a team of resources which annually, with the support and continuous involvement of Management, trade union representatives and all workers, defines health and safety tangible and measurable improvement objectives, at the same time defining the performance indicators that allow constant monitoring.

On the basis of regulatory requirements, within the context of the OHSMS and with a logic inspired by the PDCA (Plan-Do-Check-Act) cycle, each company in the Group analyses, measures and defines the risks by task and develops the related prevention and protection measures; the results of the investigations, the measures adopted and the improvement plans are reported in the Risk Assessment Documents of the individual companies in compliance with Italian Legislative Decree 81/08. Furthermore, the management system provides, periodically and following each relevant report and/or event relating to health and safety aspects, or in any case following changes potentially impacting the place and work organisation, the analysis of the activities work and hazard identification. Consequently, by encouraging the involvement of all stakeholders and with the support also of external experts, appropriate preventive and protective measures are defined, mainly oriented towards eliminating the danger/ risk, in accordance with the objectives of the OHSMS.

HAZARD IDENTIFICATION, RISK ASSESSMENT, AND INCIDENT INVESTIGATION

Particular attention is given to the participation of workers, who are involved in the continuous assessment and mitigation of health and safety risks in the workplace. To identify potential sources of risk, the Laminazione Sottile Group has equipped the supervisors with near miss, unsafe act and unsafe condition detection and analysis systems. The team analysis and development of these reports allows the company to integrate the risk assessment and to continuously develop new improvement actions.

The development and progress of the action plans are discussed in monthly meetings in which the main actors of prevention take part, for each department.

With a view to improving the culture of safety at all company levels, periodic discussion sessions are envisaged, also defined and organised within the context of the OHSMS and in accordance with Italian Legislative Decree 81/08, between the Plant Management, the Human Resources Management, the Prevention and Protection Service and the Workers' Safety Representatives (RLS). During the discussion sessions, the HSE results obtained are shared, the trends of the monitored indicators are analysed and the new objectives and actions to be implemented for the improvement of health and safety in the workplace are defined.

The Laminazione Sottile Group is particularly attentive to monitoring and analysing accidents in order to take immediate action aimed at managing and mitigating risks to occupational health and safety. Monitoring is conducted constantly through the use of accident indices, specifically the Frequency Rate (IF) and Severity Rate (IG). When defining the indices, the Group considers contracted workers as employees as there can be no distinction in the attention given to any health and safety incident. Analysing the root cause of the incidents is a particularly important step: many injuries relating to bruises are caused by carelessness. For this reason, the Laminazione Sottile Group invests every year in education and training programs to increase awareness and information with respect to occupational safety issues.

According to the analyses and inspections conducted by the Prevention and Protection Service, the main risk factors leading to injuries are as follows:

presence of handling means

use of lifting equipment

cast aluminium machining

the use of acidic substances for degreasing activities

None of these risks caused injuries with serious consequences during the reporting period, thanks to the considerable and continuous attention and investments made by the Laminazione Sottile Group for health and safety.

As noted in the reports issued by the Company Physicians, no cases of work-related ill health were recorded. This result is the fruit of the numerous structural and monitoring interventions performed progressively. More specifically:

Revamping and periodic maintenance of the systems

Continuous research and adoption of less dangerous chemicals with an impact on the health of workers

Adoption of mechanical lifting and handling devices to reduce the manual handling of loads

Periodic renewal of handling equipment and periodic maintenance of flooring to reduce vibrations

Regular monitoring of airborne chemicals released into working environment and individual checkups to monitoring inhaled substances

Periodic mapping of the noise level in the plants and installation, where necessary, of soundproofing structures

Upgrading of systems to capture and reduce diffuse emissions

Investments in new systems, preferring highly performing prevention systems

Continuous research and experimentation of systems and processes with reduced impact on health and safety

No notifications were received of work-related ill health among workers that are not employed by the Group but whose work and/or place or work is controlled by the organisation.

The Laminazione Sottile Group is strongly committed to ensuring the adoption of controls and the appointment and presence of suitably trained personnel to manage emergencies. There are also many simulations and exercises to test the readiness of emergency workers and to prepare them to face any eventuality.

In particular, the Group's workforce includes:

74 first aiders

no. 26 BLSD defibrillator operators

no. 128 fire prevention officers

All of the Group's Italian plants have appointed a qualified Company Physician who meets the requirements defined in art. 38 of Italian Legislative Decree 81/08. Each year the physician draws up a health monitoring plan and organises regular and preventive medical appointments. The Group encourages participation in periodic medical checkups, ensuring that they are performed at the workplace and during working hours. The physician is also involved in the process to identify the sources of occupational health and safety risks through the annual inspections conducted on work premises, the meeting held pursuant to art. 35, and active participation in the production of the Risk Assessment Document. As well as presenting the anonymous collective data, the physician is also involved in analysing the status and effectiveness of the actions taken to mitigate occupational health and safety risk over the years. The Laminazione Sottile Group guarantees the confidentiality of all personal data on workers’ health and safety by entrusting the processing of all data and documentation to the appointed Company Physicians.

(GRI 403-5)

The Laminazione Sottile Group considers training and continuous development among the essential elements for the correct application of high safety standards.

In line with the OHSMS, a training programme is defined each year. The training activities are defined by the Prevention and Protection Service on the basis of the evidence resulting from the analysis of Near Miss communications. Therefore, these training activities do not only concern compulsory training (according to the provisions of Italian Legislative Decree 81/08 and the State-Regions Agreement 21/12/2011), but also that relating to operating procedures and instructions. On-the-job training and education is a particular priority. The aim is to progressively increase workers’ skills to promote the more conscious and informed management of occupational health and safety risks.

Starting from 2021, the Group has set up the "Guido Moschini Academy", which has made it possible to create a catalogue of over 180 courses for over 17,000 total hours of training provided in 2022, also promoting the dissemination of the values of prevention and protection.

(GRI 403-6)

The Laminazione Sottile Group protects the health of its workers through various tools:

All employees may freely and independently access the services of the Metasalute supplementary healthcare fund for workers in the Metalworking industry

An annual flu vaccination programme is held at the Group's plants which is free to access and anonymous

To reduce the risk of contagion from COVID-19, the Group companies have redefined the organisation of work with differentiated hours and attendances and has adopted important technical and management prevention measures.

OF ON-THE-JOB TRAINING AND INFORMATION.

The absence of any cases of work-related ill health is attributable to the Group's improvement and monitoring actions aimed at:

Operation of systems

Noise reduction

Air quality

Chemicals used

Handling means

THE

AND SAFETY AREA ALONE, IN 2022, MORE THAN 3,500 HOURS OF TRAINING WERE PROVIDED BY SPECIALIST PROFESSIONALS AND MORE THAN 2,000 HOURS

(GRI 403-7)

The Laminazione Sottile Group is committed to avoiding and mitigating all occupational health and safety risks both for its employees and for all workers not employed by the Group which fall into its scope of influence. In particular, the activities conducted by third parties at their places of work are monitored through inspections conducted by the Prevention and Protection Service aimed at identifying the risks present and the dangerous actions associated with their activities. To this end, an economic system has been introduced intended to identify inappropriate behaviour and promote an increased awareness of health and safety among the suppliers that operate at the Group's sites.

The Group's attention also extends to workers who are not employees and whose work and workplace are not controlled directly by the organisation, through an initial qualification process of suppliers and the execution of Audits at their plants, during which the management of environmental and safety aspects is further explored.

In 2022, the Laminazione Sottile Group strengthened the well-established process of managing the health emergency, adopting all the precautionary containment measures to counter the COVID-19 epidemic, continuing to adapt internal procedures to the evolution of national and local regulations. From an organisational point of view, the Group has set up a Control Committee, as required by law, to discuss any countermeasures or legislative updates, and to perform site inspections to verify the effective implementation of the countermeasures adopted. The companies of the Group have ensured the daily cleaning and periodic sanitisation of the rooms, environments, workstations and communal and leisure areas, and have promoted all the recommended hygiene precautions. Regarding personal protection equipment, the Laminazione Sottile Group has provided each employee with masks on a monthly basis, this being a measure considered essential for the containment of COVID-19.

Furthermore, working hours were modified in order to avoid that overcrowding in the workplace and to prevent gatherings when entering and exiting. The Group paid particular attention to the closure of all offices for which it was possible to adopt smart working or it opted to manage attendance by limiting it to what was strictly necessary.

With the continuation of the pandemic, internal communication proved to be an essential tool to promptly and constantly inform personnel about company procedures for the management of the Covid emergency.

Through a structured system present in all Italian plants, content was disseminated to raise awareness among employees on the subject of vaccines and to update them on new local and national ordinances relating to the Green Pass obligation in private companies. The aim of this was to protect individuals and the corporate community.

From the procurement point of view, 2022 presented even more critical issues than the previous year, which had also been affected by highly unstable markets, being still in the midst of the pandemic. There were very strong tensions on the prices of all raw materials: in particular, the peculiar condition of the energy markets worldwide, also influenced by the events of the conflict that broke out in the heart of Europe, had a strong influence on a progressive and generalised increase in prices.

Therefore, the Purchasing structure of the Laminazione Sottile Group once again found itself facing an absolutely extraordinary and even worse operating condition compared to 2021, characterised by:

Continuous increase in the prices of all products and services and therefore constant worsening of the economic supply conditions;

Always latent risk of lack of raw materials from suppliers (especially in the chemical and metal sectors) which in many cases has led to delays in deliveries and consequent extraordinary actions to guarantee the continuity of the Group's production.

Despite the complex and highly challenging situation, the Group Purchasing function managed to overcome the problems encountered, always ensuring business continuity and full operation of the plants.

The results obtained confirmed the importance of the strategic choices that led the procurement process to focus on a number of key points:

CONTINUOUS SEARCH FOR THE BEST PRODUCT AND SERVICE COST/ QUALITY RATIO

GUARANTEE OF CONTINUITY OF SUPPLIES IN ALL MARKET CONDITIONS

RESEARCH AND APPROVAL OF ALTERNATIVE SUPPLIERS

DEVELOPMENT OF PARTNERSHIP RELATIONSHIPS WITH STRUCTURED SUPPLIERS

Despite the raw materials crisis, procurement performance was confirmed to be optimal in all respects.

Ethics

Territoriality

Continuity of supplies

Environmental sustainability of suppliers

The Group considers an ethically sound relationship with suppliers to be an essential element of the supply chain:

Transparency in relations with suppliers by all Procurement personnel;

Compliance with the principles established in the Organisational and Control Models pursuant to Italian Legislative Decree 231/2001 adopted by Group companies;

Rejection of any abuse of its dominant position in all procurement negotiations;

Monitoring of supplier compliance with the requirements of certification SA 8000 (Social Accountability);

Monitoring of compliance with contracts and working conditions by suppliers towards their own employees

The Laminazione Sottile Group aims to balance its international vocation with deep roots in its native region. Consequently, its Supply Chain is characterised by companies based in Italy and the regions local to the Group's plants. Data for 2022:

The Group has always been very attentive to the topic of sustainable procurement, as proven by:

the preferential use of marine and inter-modal transportation as opposed to road haulage. This is associated with a more efficient management of shipments and the adoption, where possible, of a combination of the transport of products made by the various Campania companies of the Group (Laminazione Sottile, Italcoat and Contital), destined for the same customer or for customers located in close geographical areas. This has made it possible to increase the saturation of means of transport, reaching 96.4% in 2022 (+1.2% compared to 2021), allowing a reduction in the number of journeys made by transport service providers, with a consequent reduction also of the environmental impacts of the related activity

research and use of suppliers who guarantee the ecocompatibility of the products sold, in all cases in which this is reconcilable with the technical requirements of the plants

strong preference for suppliers equipped to recycle post-industrial waste materials (e.g., scrap delivered directly to suppliers with appropriate transformation systems)

The Group adopts a supplier qualification and assessment procedure which regulates the initial qualification and accreditation processes, as well as defining the periodic assessment of the level of service. Suppliers are required to have a series of attestations, certifications and documents essential for their qualification and requalification.

The main requirements are identified based on the products/services offered and to ensure the correct management of quality, environment, occupational health and safety and food safety aspects. The procedure also regulates the frequency and methods of supplier audits.

Supplier certification is the responsibility of an assessment team consisting of the Procurement Manager, Category Manager/Buyer, Plant Quality, User Body and Finance Department.

In 2022 no significant changes to the supply chain of the Laminazione Sottile Group were made.

Level of HSE competence (service providers)

Full compliance with internal procedures for site access and the publication of safety documentation

Presence and adequacy of insurance policies for the Group and for the suppliers that operate in the plant

Evaluation of the production capacity and supply continuity

Existence of an “Emergency Plan” (particularly for strategic suppliers)

Presence of multiple suppliers either active or quickly activated for “non-commercial” products/services

Upstream supply chain differentiation for strategic suppliers

With regard to the final two points on the list, please see the table showing:

the percentage of supplies potentially provided by multiple suppliers

the percentage of suppliers that have different supply chains for upstream supplies

Continuous dialogue and active engagement are one way in which the Laminazione Sottile Group expresses its responsibility and commitment to the social context in which it operates. Stakeholders represent a broad range of different interests; as such, establishing and maintaining stable and long-lasting relations are a crucial element to the creation of shared, long-term value.

By understanding the specific needs and priorities of its stakeholders, Laminazione Sottile can pre-emptively manage potential issues and refine its actions to better respond to their interests. Promptly identifying stakeholders and establishing more effective channels of communication to constantly monitor their expectations, needs and opinions is the first step to establishing an effective engagement process. The Group has established dedicated departments to pursue a proactive approach to engagement with the parties with which it interacts, promoting dialogue and responding to the various needs. In fact, the Group believes that these engagement activities represent opportunities for mutual growth and enrichment

The table on the opposite page shows the following categories of identified stakeholders and the respective communication methods/expectations.

Stakeholders represent a wide range of interests: establishing and maintaining stable and lasting relationships, a crucial element for the creation of shared and longterm value

(GRI 2-29)

Employees and collaborators

Code of Ethics; Continuous dialogue; Performance evaluation process; Internal communication; Training courses; Inductions for new hires

Shareholders

Shareholders’ meeting

Trade unions

Continuous dialogue; Meetings with trade union representatives

Information on company strategies and results; clarity of objectives and bonus/incentive system; sharing and involvement; improvement of the working environment and safety; integration into corporate life

Presentation of the balance sheet and of the balance sheet report

Involvement and information activities on relevant corporate issues

Customers

Code of Ethics; Seminars, training courses; Trade fairs, events; Website, social networks and newsletters; Product documentation

Suppliers

Code of Ethics; Supplier portal; Qualification process; Periodic technical update meetings

Local communities

Participation in cultural, sports and social events and projects; Website, social networks; Meetings with representatives of associations and of local organisations

Quality, safety, punctuality; high level of after-sales service

Collaborative relationship; compliance with the contractual conditions; continuity of supply

Support for or financing of initiatives; dialogue, transparency and collaboration; mutual development

43%

of the economic value generated was retained in the company (percentage doubled compared to 2021). This reinvestment makes it possible to support production development policies and employment growth

In 2022, the Economic Value generated by the Laminazione Sottile Group amounted to 148 million Euro, with an increase of approximately 59 million, equal to +66% compared to 2021.

Generated economic value was distributed among the main stakeholders as follows:

EMPLOYEES: 74% as direct remuneration in the form of salaries and pension contributions;

LENDERS 2%;

SHAREHOLDERS 7% through distributed dividends;

PUBLIC ADMINISTRATION: 17% in payments on taxable income and social security contributions;

COMMUNITY: 0.1% in the form of donations and sponsorships.

CREATION AND DISTRIBUTION OF ECONOMIC VALUE (€)

ECONOMIC VALUE GENERATED BY THE COMPANY

ECONOMIC VALUE DISTRIBUTED BY THE COMPANY

ECONOMIC VALUE RETAINED BY THE COMPANY

PRODUCTION COSTS (€)

RAW AND ANCILLARY MATERIALS AND GOODS SERVICES

FIXED ASSETS - ACQUISITIONS FOR THE YEAR (€)

LANDS AND BUILDINGS

PLANT AND MACHINERY

INDUSTRIAL AND COMMERCIAL EQUIPMENT

OTHER ASSETS

The Laminazione Sottile Group participates in and contributes to projects and activities with social and cultural aims and believes in supporting scientific research associations.

It directs its focus specifically to the local region in which its companies operate, with the aim of promoting local development and consolidating a civil consciousness of cultural renewal.

The main initiatives in 2022 are described below.

We support Teatro San Carlo in Naples, the oldest Opera House in Europe and one of the most important cultural institutions in the world. For almost 300 years, the theatre has been devoted to promoting the art and tradition of Italy's lyrical, musical and dancing heritage.

The companies of the Group, both Italian and foreign, have supported various organisations and foundations.

In Italy we have supported: the AIRC Foundation for its research activity and for the dissemination of information on correct lifestyles to prevent disease; the Gold for Kids project of the Umberto Veronesi Foundation dedicated to childhood and adolescent cancers, to maximise the chances of recovery and to improve the quality of life of sick children and young people.

In England, the i2r subsidiary organised internal events and participated in public fund-raising events in support of Hope House Children’s Hospice, which specialises in providing assistance to families with seriously ill children, and the Alzheimer’s Society, which raises funds for research on sickness and family support services.

In Italy, as well as in Turkey and England, we have responded to requests from various soup kitchens managed by national and local charities and associations, donating thousands of aluminium containers to provide food assistance to an ever-increasing number of people who have suffered repercussions of the economic and social crisis caused by Covid.

the project -Spreco +Riciclo was developed, with the aim of promoting and enhancing the use of aluminium to combat food waste.

We supplied aluminium trays to support the soup kitchen inside the Cloister of the Monumental Complex of Santa Caterina in Naples. The activity, from the beginning of the pandemic and until the end of 2022, took place weekly in take-out mode, providing around 3,500 meals provided to 400 people in difficult situations, recovering around 2 tons of food surpluses.

A campaign aimed at disseminating the culture of food as a value, reducing its waste and increasing awareness that products made with recyclable materials, through separate collection, can return to new life with reduced environmental impact.

(GRI 2-28)

(GRI