PROCESS AND PACKAGING BEVERAGE & PACKAGING it. MAGAZINE n° 7-2023 یندیشون و ییاذغ عیانص ی هلجم

AsiaWorld-Expo , Hong Kong 6-8 September 2023 10.00-17.00 hrs Save up to 40% www.asiafruitlogistica.com

Technology

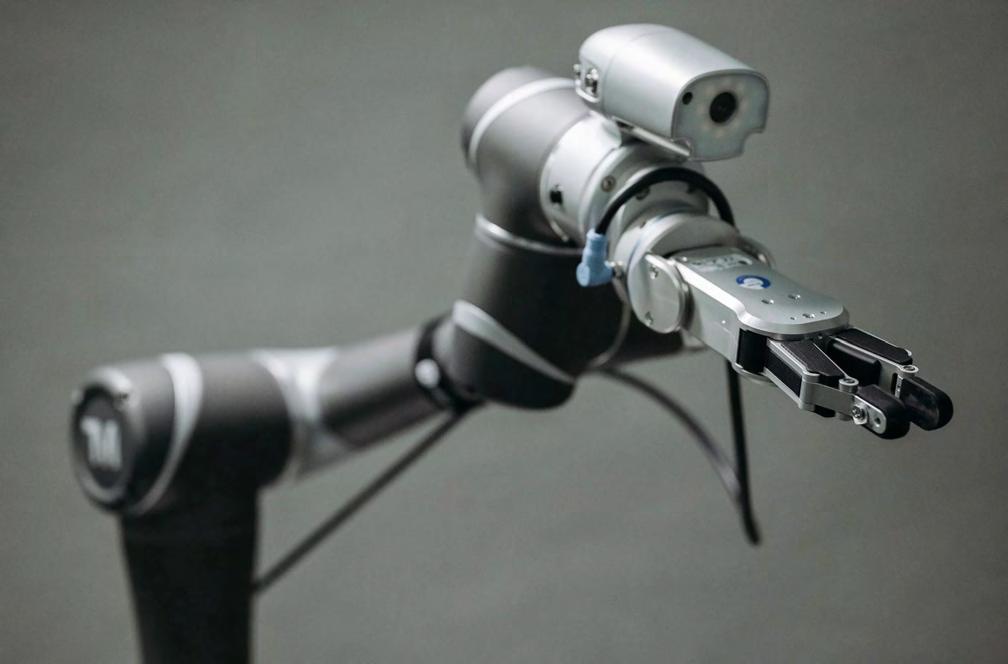

Cama Group is a leading supplier of advanced technology secondary packaging systems continuously investing in innovative solutions. www.camagroup.com sales@camagroup.com

inspired by human talent

editorial management and registered office: Editrice Zeus Srl: Via Cesare Cantù, 16 20831 Seregno (MB) - Italy

Tel. +39 0362 244182 / +39 0362 244186

web site: www.editricezeus.com

e-mail: redazione@editricezeus.com

portal: www.itfoodonline.com

skypeTM: editricezeus

Editrice Zeus:

Machineries, plants and equipment for food and beverage industry year XXXIII - issue n. 7 - June 2022

managing editor Enrico Maffizzoni direzione@editricezeus.com

editorial manager S.V. Maffizzoni redazione@editricezeus.com

editorial production Sonia Bennati bennati@editricezeus.com

account dep. manager Elena Costanzo amministrazione@editricezeus.com

project and layout design

ZEUS Agency grafica@editricezeus.com

creative dep

ZEUS Agency grafica@editricezeus.com

translations Leomilla Translation

in partnership with: Thai-Italian Chamber of Commerce info@thaitch.org

printing

ZEUS Agency

Italian Magazine Food Processing Europe: single issue: Euro 25

Annual (six issues): Euro 120

Outside Europe: single issue: US$ 30

Annual (six issues): US$ 170

Subscription payment can be made in the name of Editrice Zeus sas, by bank money transfer or cheque.

Italian Magazine Food Processing

An outline of the suppliers of machines, plants, products and equipment for the food industry. Published: monthly.

Registration: Court of Monza no.10 of 05.09.2018.

Shipment by air mail art.2 comma 20/b law 662/96 Milan.

Panorama dei fornitori di macchine, impianti, prodotti e attrezzature per l’industria alimentare

Periodicità: mensile. Autorizzazione del Tribunale di Monza, n.10 del 05.09.2018

Spedizione in a. p. 45% art. 2 comma 20/b legge 662/96 Filiale di Milano

The reproduction of the articles and/or pictures published by this magazine is reserved (the manuscripts and/or photos sent to the Publisher will not be returned). The Editor declines all responsibilities for any mistake of photocomposition contained in the published papers of any magazine by EDITRICE ZEUS Srl.EDITRICE ZEUS. SAP ITALIA SRL 57 ﯽﻧﺪﯿﻣﺎﺷآ و ﯽﯾاﺬﻏ ﻊﯾﺎﻨﺻ یاﺮﺑ تﺎﺴﯿﺳﺎﺗ و ﻞﺣ هار ،هﺪﯾا NAVATTA GROUP FOOD PROCESSING SRL 63 ،NAVATTA هوﺮﮔ تﺎﺠﯾﺰﺒﺳ و هﻮﯿﻣ ﺪﯿﻟﻮﺗ و شزادﺮﭘ طﻮﻄﺧ ﯽﻧﺪﯿﺷﻮﻧ و ﯽﯾاﺬﻏ ﻊﯾﺎﻨﺻ ی هلﺠﻣ ROCKWELL AUTOMATION SRL 84/86 و رﺎﮐدﻮﺧ ﻼﻣﺎﮐ ﮏﺸﺧﺮﯿﺷ تﺎﺴﯿﺳﺎﺗ و هﻧﺎﺧرﺎﮐ DAIRY FOODS VREUGDENHIL ی هﺪﺷ لﱰﻨﮐ

هﺻﻼﺧ 84-96 تﺎعﯾﺎﻣ یﺪﻨﺑ هتﺴﺑ 62-83 )یزﺎﺳوسرﻨﮐ( ﯽطﻮق یﺪﻨﺑ هتﺴﺑ DOWNLOAD THE MAGAZINE www.editricezeus.com 34-47 ﺎتﺳﺎﭘ 1-33 یﺪﻨﺑ هتﺴﺑ 48-61 رﺎﺒﺧا CAMA GROUP 4/6 ﺎﺑ هﻧﺎﯿﻣروﺎﺧ رد ﯽﻨﯾﺮﯿﺷ ﺪﯿﻟﻮﺗ هﻧﺎﺧرﺎﮐ نﯾﺮﺗگرﺰﺑ رد ﺪﯿﻟﻮﺗ طﺧ نﯾﺪﻨچ ﺪﻨﻨﮐﯽﻣ هدﺎفتﺳا ﺎهیﺪﻨﺑهتﺴﺑ نﯾﱰهﺑ زا CAMA یروﺎﻨف دﻮجو ESCHER MIXERS SRL 34-35 ﻻﺎﺑ رﺎﯿﺴﺑ ﺖﯿفﯿﮐ ﺎﺑ ﯽتعﻨﺻ یﺎه سرﮑﯿﻣ

یندیشون و ییاذغ عیانص ی هلجم .دنک هدافتسا شا یدنبهتسب و دیلوت همه رد هیوناث یدنبهتسب یارــب اما تکشر یژولونکت زا اهنت شدیلوت طوطخ تکشر چیه و دنکیم هدافتسا Cama یگدترسگ زا حطس نیا یرگید یدیلوت .درادــن ار هناخراک نــیا رد یرواــنــف هاگتسد 24 دیلوت طخ شش رد لک رد ام« طخ کی .تشاد میهاوخ راک لاح رد طخ ود ،کچوک یاهکیک یارب دیلوت تییوکسیب یارب طخ ود ،رفیو یارب رکارک یارب رخآ دیلوت طخ و ،یچیودناس هدافتسا دروم یاههاگتسد همه و .تسا Breakthrough لدم زا ام هناخراک رد ».دنتسه )BTG( Generation یاهیگژیو یاراد Cama BTG یسر یاهدرادناتسا هک تسا یتایلمع و یحارط نییعت ار هیوناث یدنبهتسب رد زاین دروم ،هچراپکی یاه مرف .دنکیم میظنت و یحارط اب یترشم زاین اب قابطنا تیلباق یتشادهب یاه درادناتسا ساــسا ربو نردم نویساموتا اب ییاذغ داوم تعنص یشخرچ هتفشریپ یروانف لماش دیدج و یاه تابر اب یمکحم دنویپ هک یطخ و و یریذپفاطعنا و دنراد نیشام لخاد یارب یتایح رایسب و زاین دروم یراگزاس مهارف ار نردم یدنبهتسب یاهدرکلمع تلاآنیشام زا فیط نــیا .دننکیم یلاتیجید مرفتلپ رب ینتبم نینچمه بلاقنا لماک یاهتیلباق زا هک دنتسه زا )4.0 Industry( مراهچ یتعنص شزوــمآ ،شــیاــمزآ و VR ،AR هلمج .دننکیم ینابیتشپ یزاجم درکلمع و لماش هچراپکی یاههاگتسد رــکا« لوصحم یراذگراب ، نتراک یهد لکش ماکرز هناخراک رد هک نتراک تنسب و دنریگیم رارق هدافتسا دروم )Zarkam( متسیس و کیتابر عماج یاهمتسیس زا یراذگیاج و تشادرب یارب یمشچ لترنک دیلوت طخ هب هتسب هک دنتسه دنمهرهب نودب ای یدنبهتسب اب تلاوصحم یارب نینچمه .دــنراد دربراک یدنبهتسب نتراک نداد رارق یارب گنینوتراک هاگتسد دنچره .تسا دوجوم زین هبعج لخاد رد )Zarkam( ماکرز هناخراک رد هک لاتیجید

یارب

رد

.تسا

هناخراک نیا رد هدنیآ میت کی ،یبرتعم هژورــپ نینچ یارــب« یناریا صصختم و یاهفرح ینابیتشپ Zar یارب روما ریاس ماجنا و بصن یارب Zar Group .میتفرگ رظن رد Group و تلاکشم هب تبسن ینارگن نودــب یارب نامز و ازیو هیهت ،ینابز عناوم هس اب ناــمز ره رد دنناوتیم رفس ساتم Cama یلحم تقوماتم سدنهم یدنب هتسب 4

یاهتیفرظ ماتم زا ضراح لاح

مرفتلپ اما ،دوشینم هدافتسا ام

اه یژولونکت نیا زا یاههدافتسا

دوجوم

یندیشون و ییاذغ عیانص ی هلجم و نیرتگرزب زا یکی Zar Group رد ییاذغ یاــهتــکشر نیرتعونتم شیب اب هورــگ نــیا .تــسا هنایمرواخ هن ، هقطنم نیا رد هقباس لاس 30 زا اتساپ دیلوت هعومجم نیرتگرزب اهنت ریخا یاهیراذگهیامسر هکلب ،دراد ار یحارط ببس نآ یراــک شترسگ و هعومجم نــیرــتگرزــب تــخاــس و .تسا هدش زین هقطنم نیا یزپینیریش ییاهاذغ هـــئارا تــکشر نــیا فدــه و بسانم یتمیق اب ،عیسر ،تمیقنازرا تسا هعماج رد دارفا همه یارب هیهت لباق تاقیقحت ،هاگیاج نیا هب ندیسر یارب و یاتسار رد ار یاهدترسگ یاهتفشریپ و یاهیروانف و دیدج تکشر یاهدرکلمع یاهدمع شخب .تسا هتشاد نآ ییارجا هراــبرد یسررب لماش قیقحت نیا زا زاتشیپ یناهج یاهدنرب ریاس تیلاعف تخاس سپس و ییاذغ داوم دیلوت رد هک تسا ناریا رد دیلوت هعومجم کی زارتمه یاهتکشر نیترهب حطس رد درکلمع ،تیفیک رظن زا ناهج رد دوخ .دشاب یدنبهتسب تیفیک و ،ییارجا یاهنیترهب درکلمع تنفرگ رظن رد اب و یارب یدنب هتسب یاهراکهار ،یناهج رازاب لح هار لماش یعیبط روطهب طخ یاهتنا رترب دنرب فرط زا لماک و عماج ییاه .تسا هدوب Cama Group یناهج و شورف یسدنهم ریدم ،مرکم نیشفا Zar« :دیوگیم Cama Group رد 2016 لاس زا تفرگ میمصت Group نیا« .»دوــش یزپینیریش رازاــب دراو تفشریپ یعون راــک رازاـــب شترسگ داوم ًلابق تکشر نیا اریز دوب یعیبط تعنص زاین دروم هک ار یرایسب ماخ ».دوب هدرک دیلوت ار تسا یزپینیریش دیدج دنرب یارب دیدج هناخراک تخاس عوشر 2018 لاس زا )ماکرز( Zarkam رد ار شهاگتسد نیلوا Cama و دش داد لیوحت تکشر نیا هب 2019 لاس دیووک یرمایب شترسگ رطاخ هب اما ، تعسر و دش داجیا ههام 18 یاهفقو لاس رد اددجم هچرگ .دــش مک راــک لاح ردو ،درک زاغآ ار شتیلاعف 2021 یکی هعومجم نیا دیلوت طوطخضراح ییاهن یزادنا هار لاح رد یرگید زا سپ .دنشاب یم رازاــب هب لوصحم دورو و فلاخرب هک تسا نیا هجوت لباق هتکن« رد رگید یاــه هعومجم زا یرایسب یصصخت روطهب هک ناهج سراــتسر نیا ،دننکیم دیلوت ار لوصحم کی تلاوصحم زا یناوارف فیط هعومجم ،رفیو ،کیک هلمجزا ، یزپینیریش ار رکارک و ،یچیودناس تییوکسیب نیا .دنکیم دیلوت دحاو ناکم کی رد نیا هک تسا ینعم نیا هب دیلوت عونت یعونتم یاهیروانف زا دیاب هعومجم شخب ره یارــب هناگادج تروــص هب اب هنایمرواخ رد ینیریش دیلوت هناخراک نیرتگرزب رد دیلوت طخ نیدنچ .دننکیم هدافتسا اهیدنبهتسب نیترهب زا CAMA یروانف دوجو یارب یروانف هچ زا رترب یاهدنرب دنیبب هک تسا نیا یوجتسج رد یناهج یهاگن اب PUORG RAZ .تسا هدش متخ PUORG AMAC مان هب اهراب و اهراب وجتسج نیا و دننکیم هدافتسا یدنبهتسب یدنب هتسب 5

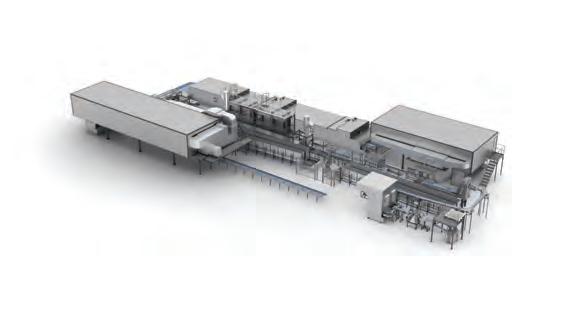

MULTIPLE LINES IN THE MIDDLE EAST’S BIGGEST CONFECTIONARY PLANT END WITH PACKAGING PERFECTION THANKS TO CAMA TECHNOLOGY

The Zar Group is one of the Middle East’s biggest diversified food companies. Serving the region for over 30 years, it not only owns and operates the region’s largest pasta production site, but recent investment following a portfolio enlargement has led to the design and build of the region’s largest confectionary plant too.

With a mission to make inexpensive food available to everyone in society, by offering it quickly and at a reasonable price, the company undertook significant research and development in regard to its new factory’s operations and the technology it would deploy. A large portion of this research involved ascertaining what other leading global food brands were using, and then creating a production facility in Iran that was on a

level with the best in the world – in terms of product quality, operational throughput and packaging excellence.

And with the best in the world in mind, the end-of-line packaging operations naturally included fully integrated solutions from global leader Cama Group.

“Zar Group made the decision to enter the confectionery market in 2016,” explains Afshin Mokaram, Sales Engineer Manager, at Cama Group. “This portfolio expansion was a natural progression, as the company already handled and processed many of the raw materials.”

Construction of the new plant for

یندیشون و ییاذغ عیانص ی هلجم

یدنب هتسب 6

Zar Group looks globally to see what leading blue-chip brands are using for end-of-line packaging, and Cama Group’s name comes up again and again.

یندیشون و ییاذغ عیانص ی هلجم رازگساپس رایسب رظن نیا زا هک دنریگب هیلوا لحارم رد نینچمه ام .دنتسه ارچ میتشاد یراکمه رواشم ناونعهب تعنص زا یــناوارــف شــناد اــهنآ هک ساسا رب ام .دنتشادن یزپینیریش و عیانص ریاس زا هک یناوارف شــناد رد ،میتشاد ناهج سراتسر زا تامادقا ،داوم باختنا ،یدنبهتسب یحارط هنیمز تلاوصحم یزادناهار و اههاگتسد لحم هشیمه ام .مــیدرــک کمک اــهنآ هب میهدیم حیضوت نانمایترشم یارــب ام ،میتسین هدننکدیلوت طقف ام هک میوشیم لاحشوخ هک میتسه یکیشر زا نانیمطا یارب ار نماشناد و اهتراهم .میراذگب کاترشا هب نارگید اب تیقفوم عوشر نامز زا« :دیوگیم نایاپ رد مرکم هقطنم رد رگید یاهتکشر هژورپ نیا یاهتکشر نونکا .دناهتفرگ ساتم ام اب Zar Group دننام هقطنم رد یرگید دوخ ییاپورا یاتمه یاهتکشر زا هک قشمسر یروانف و تلاآنیشام هنیمز رد Zar Group زا دنهاوخیم دناهتفرگ راک هب ار یروانف نیترهب و دننک یوریپ هاگیاج و ینابیتشپ میت دوجو اب و .دنریگب یارب ار هاگیاج نیترهب ام ، یلعف مکحم ».میراد زین نایترشم نیا هب تامدخ هئارا هعومجم لماع ریدم ینیما نسحم ترکد ناهج رد هکنیا یارب« :دیوگیم ماکرز رد اهنیترهب زا دیاب ،میشاب نیترهب یاکشر دوب مزلا سپ ،مینک هدافتسا ناهج کمک ام هب هک مینک باختنا ار یروانف تلاآنیشام .میسرب نمافادها هب دننک رترب یاهدنرب زا یرایسب رد Cama رارق هدافتسا دروم ناهج رد یزپینیریش تلاصا مان نیا هک مینادیم سپ ،دنریگیم لاتیجید تخاسریز .دراد ار شدوــخ یگچراپکی تــسا هدــش ثعاب اــهنآ رد ربراک طبار و ،دوش داجیا رتتحار ،تسا هباشم Cama یاههاگتسد همه یریگدای هب زاین اهروتارپا هجیتن رد و تیماح .دــنراد یترمک دیدج تاکن زا دعب و لبق ،بصن نامز رد ینابیتشپ هطوبرم یاهیگنهماه نینچمه و نآ ».دوشیم ماجنا لکش نیترهب هب

www.camagroup.com یدنب هتسب 7

Mr. Mohsen Amini CEO at Zarkam

the newly formed Zarkam brand began in 2018 and Cama delivered its first machine in 2019, but work was subsequently stalled and put on hold for 18 months, due to the Covid pandemic. However, it started back up again in 2021 and step by step all the production lines of this company are getting ready and they are launching their products in the market..

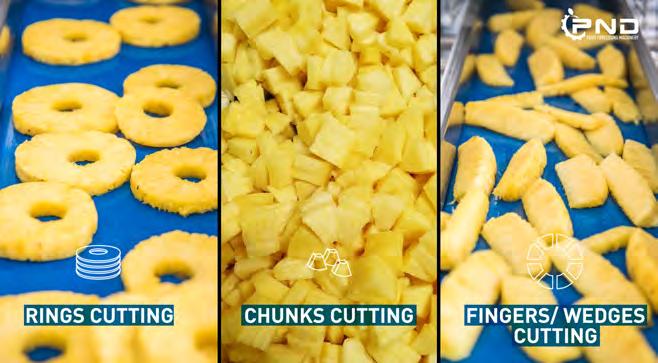

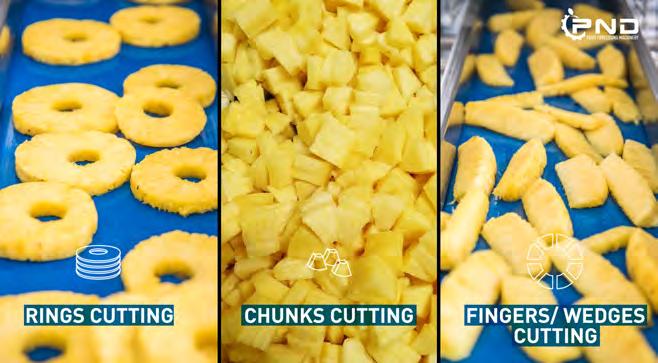

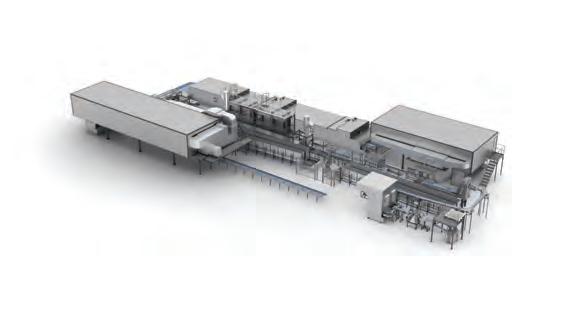

“Interestingly, unlike many other plants around the world that specialise in single product types, this plant produces a huge variety of confectionery from a single site, including cakes, wafers, sandwich biscuits and crackers. This product variety means that the plant has to deploy a wide range of technology solutions for every element of the individual processing and packaging steps. But Cama is the only company handling secondary packaging across all the lines, no other machine supplier has this depth of technology in the plant. “We will eventually have a total of 24 machines in operation across six lines. One line is for mini cakes, two are for wafers, two are for sandwich biscuits and the final line is for crackers. And all the machines we are supplying are from our Breakthrough Generation (BTG).”

Cama’s BTG Series has design and operational features that are setting the standard in secondary packaging. Their modular, scalable and hygienically designed frameworks house contemporary automation solutions – including advanced rotary and linear servo technology – which can be tightly coupled to in-housedeveloped robotics, to deliver the allimportant flexibility and adaptability required by modern packaging operations. The machine range is also based on a digital platform that supports full Industry 4.0 capabilities, including AR, VR and virtual testing, training and operation.

“Most of the monoblack forming, loading and closing machines we are supplying Zarkam deploy tightly inte-

grated robotic and vision systems for pick-and-place operations – for both nude and flow-packed products, depending on the product line. There are also case packers to place the cartons into boxes. Although Zarkam is not currently leveraging the full

digital capabilities of our solutions, the platform is there for them to use in future enhancements. “For such a prestigious project, we deployed a dedicated Iranian support team for the Zar Group for installation and commissioning. Zar Group can

یندیشون و ییاذغ عیانص ی هلجم یدنب هتسب 8

call up on three full-time local Cama engineers, without worrying about language barriers, visas and travel times, something for which they are very appreciative.

We also acted as a consultant in the early stages, as they did not have deep knowledge of the confectionery industry. We helped them with packaging design, material selection, machine locations and product launches, based on our in-depth knowledge from other industries and

applications around the world. We always explain to our customers that we are not just a supplier, we are a partner that is happy to share skills and knowledge to ensure success.

“Since the commencement of this project,” Mokaram concludes, “we

have been approached by other companies within the region. Much like the Zar Group emulating its European counterparts in terms of machines and technologies, other companies in the region now want to learn from the Zar Group and deploy best-in-class technology. And with our foothold and support team in place, we are ideally placed to serve these customers too.”

A spokesperson at Zarkham explains: “To be the best in the world, you have to use the best in the world, so it was essential that we chose technology partners that could help us achieve our aims. Cama’s machines are used by many of the world’s leading confectionery brands, so we know there is an established pedigree behind the name. Their digital infrastructure makes integration easier, and the user interface is the same across all the Cama machines, so there is less to learn for the operators. The support before, during and after installation and commissioning has been excellent.”

Mr. Mohsen Amini CEO at Zarkam

www.camagroup.com

یندیشون و ییاذغ عیانص ی هلجم یدنب هتسب 9

IMA STRATEGICPARTNERFOR CONFECTIONERYCOMPANIES

Thanks to its wide technological offer, ranging from processing to primary, secondary and end of line packaging solutions, IMA is a strategic partner for confectionery companies, able to design and manufacture complete and customized lines. A knowhow recognized around the globe, which is enriched today by new solutions, ensuring higher sustainability, easy to use and production flexibility. We deepened this topic with Daria Lolli and Fabio Tozzi, who follow sales respectively at IMA Active division, processing side, and at IMA GIMA division, packaging side.

The world of technologies is constantly evolving. According to your experience, which are the new must in this sector?

Fabio: Without any doubts, sustainability is becoming a central factor; and, in some cases, even influential in purchasing decisions. Today consumers are more and more informed and aware: they select products whose packaging is easily disposable. This leads manufacturing companies to look for solutions able to reply to this new requirement, while preserving the quality of their products.

Daria: Not only is this trend valid for the packaging: also the product itself must respect the environment. Let’s think about chewing gums case. The downward sales trend recorded in the last few years may be due to the fact that the raw material, they are made of, requires almost 5 years to biodegrade. Nevertheless, some confectionery producers have found a solution to overcome this: they have replaced synthetic rubber with organic one, which makes the chewing gums 100% biodegradable in

a few months. Besides protecting the environment, another central topic for this sector is the personal well-being. Just think about the increasing use of food supplements. Confectionery products, when enriched with functional ingredients, like vitamins, minerals, ginseng or hyaluronic acid, become an alternative way to take these elements in a shape different

from pharmaceutical tablets and capsules.

Which packaging solutions do you offer to customers looking for more eco-friendly technologies?

Fabio: IMA GIMA has always worked with their customers in the design of specific packaging, finding the right combination of marketing and

LABELLING

یدنب هتسب 10

applicability on technologies. In collaboration with manufacturing companies, our technicians test each new material on the machines, identifying those that best adapt to the different technologies. In this way, we assist our customers with our experience, to help them in creating sustainable packaging made with recycled, recyclable or biodegradable material.

Can you make us a few examples?

Fabio: As far as primary packaging is concerned, we propose containers with different shapes and functionalities made of carton, PET or hybrid materials, all of them achievable on our vertical platforms. These types of packaging help in renovating the image of the product on the shelf or in replacing injection molded containers, significantly reducing packaging ecological impact. IMA GIMA range of vertical fillers includes several models able to reach a speed of up to 500 ppm.

According to the product to be handled (dragées, candies, mints, liquorices, jellies, dried fruit, chocolate, chewing gums and others), our machines can be equipped with dedicated feeders such as mechanical or electric counting systems, volumetric dosing systems and multi-head scales. News also in the difficult field of over wrapping.

A pack of chewing gum, candies, dried fruit or other, needs to be over wrapped for protection, preservation of the aroma and/or for multi pack. On the basis of the level of the barrier effect that we want to reach, different types of material can be used. We have already tested successfully on our over wrapping machines alternative materials like biopolimer, compostable transparent material, paper based material which can be recycled together with paper, and mono-material easily recyclable.

Going back to chewing gums, which are the new processing

technologies proposed by IMA Active division?

Daria: Chewing gums are traditionally produced by preparing a dought, which is then extruded or flattened with rollers, cut in single units, cooled and eventually coated. Such an equipment needs space and it may require a huge investment for who is willing to start from zero. Besides, a lot of functional ingredients, which more and more often are added to recipes, are vulnerable to thermomechanical stresses: their beneficial effects risk to fade away before the product reaches the mouth of the consumer. Therefore, IMA Active

proposes an alternative solution for the manufacturing of these new generation of chewing gums, which is cheaper, more compact and flexible: PREXIMA tablet presses, for the direct compression of powders.

How does PREXIMA work?

Daria: The different ingredients, after being mixed, are fed into the PREXIMA, where the direct compression occurs. The process is quick and the mechanical stress of the product is minimal, so that the effect of functional ingredients is not activated unless it is the right moment, that is while chewing.

Also ingredients which are vulnerable to high temperatures are safely treated, thanks to PREXIMA high yield motorization. The ventilation system alone is enough to keep under control the motors temperature and heat is not transferred to the process area.

Which level of flexibility does this tablet press ensure?

Daria: Huge flexibility. The shape of the final product depends on the shape of the punches tip and of the die hole. It can be simple, round or rectangular, but it can become more complex, like the shape of the heart or of the teddy bear face, just to mention a few. It is easy and fast for the operator to change the tooling on PREXIMA.

Furthermore, it is possible to obtain bilayer chewing gums with PREXIMA 800, using powders with different colors and consistency, each one with its own specific function. A technology which ensures maximum reliability, process repeatability and minimal waste of raw material and energies.

Very innovative technologies. Are they also easy to use?

Daria: “High” innovation does not

mean “more complicated”. In fact, our machines aim to be simple to use and quick to clean. Without forgetting that we have a laboratory with technologists expert on processes and raw materials, and equipment available to carry out tests with our clients: we are ready to support them in the development of new products or in the optimization of current processes.

It is not rare to see customers willing to proceed with a technology transfer, making some manual phases of the manufacturing process automatic.

I think Fabio agrees with me, our experts in processing and packaging are looking forward to having the chance to work side by side with our clients to make their dreams come true.

ima.it

LABELLING

یندیشون و ییاذغ عیانص ی هلجم یدنب هتسب 12

BUSINESS OPPORTUNITIES START HERE

Thai-Italian Chamber of Commerce (TICC) main aim is to enhance business cooperation between Europe and Thailand.

We are strategically situated in Bangkok, Thailand which is a Business Hub for South East Asia.

The main purposes of all TICC activities are:

•To assist Italian companies and other professional bodies who are either already established and/or planning to do business in Thailand or within the ASEAN region.

•To provide insights and advices on matters of trade, investment, finance and industry between Italy and Thailand or within South East Asia.

•To organize bilateral events/trade shows periodically, in the form of seminars, talks, missions, round table or business dinners, in order to promote interaction between subjects.

•To keep close contact with the Thai authorities, pressing issues when necessary.

•To support, represent, and protect the interests of the Members, both in Italy and Thailand.

Interested companies may write to us for exploring the market and business in Thailand or for browsing potential business opportunities.

Thai-Italian Chamber of Commerce 1126/2 Vanit Building II, 16th Fl., 1601B, New Petchburi Rd., Makkasan, Rajdhevee, Bangkok 10400 GET IN TOUCH

2 255 8695 info@thaitch.org Thai - Italian Chamber of Commerce (TICC) www.thaitch.org Thai-Italian Chamber of Commerce TICC thaitch

+66

PACKAGING LABELLING - WEIGHING یدنب هتسب تــفاظن و یرادــهگن اــب ،تدــم یــنلاوط نیمضت ار درــکلمع رــکادح هــک تــسا ناــسآ .دــنک یم لاــس نــیدنچ زا یــتتئود یدــنب هتــسب و یندیــشون تــعنص رد هژــیو هــب شاهــبرجت راــبتعا اــب ، دــنکیم هدافتــسا یزاــس ورــنک یاهســس ،بآ ،هوــیم بآ ،هباــشون ،رد یوــق ریاــس و هــکسر/نغور رد تاجیزبــس ،هداــمآ .دراوــم یدیلک تاــلک داــتعا و یراکــمه ،هرواــشم اهنآ ساــسا رــب تکشر تــیقفوم هــک دنتــسه یکی شورــف زا ســپ تاــمدخ .تــسا راوتــسا .دــشابیم تــکشر یــلصا توــق طاــقن زا هراوــمه ،موادــم و رمتــسم هعــسوت و دــشر قــیقد یــبایرازاب یزــیر هــمانرب و دــیلوت اــب هــک ،تــسا هدوــب هارــمه هنافاکــشوم و زا یــکی ناوــنع هــب داد هزاــجا یــتتئود هــب دوجوم یاــه تــکشر نــیرتروآون و نــیرتایوپ یــساسا طشر نآ هــک ،دــشاب لاــعفرازاب رد هدــش هتخانــش زا یکی هب ندــش لــیدبت یارــب .دــشابیم اکشر نــیرت و دــیلوت تــیفیک زا ناــنیمطا یارــب اــب قــباطم یــتتئود یدــنب هتــسب ، تاــمدخ )4.0 Industry( 4.0 تــعنص یاهدرادناتــسا 9001 ISO هــمانیهاوگ یاراد و دــنکیم لمع .تــسا www.duettipackaging.com )یدنب هتسب( ندرک چیپرود کشخ ریش یاهیطوق یاهبعج )multiple( یدنب هتسب 14

PACKAGING LABELLING - WEIGHING یدنب هتسب رد 2008 لاس رد یتتئود یدنب هتسب و یــحارط فدــه اــب ناــیاپرد یدــنب هتــسب یاهمتــسیس تخاــس .دــش سیــسات دــیلوت طــخ شورف هکبــش قیرط زا یــتتئود یدــنب هتــسب موادــم و جــیردت هــب دوــخ یاهــفرح و ناوــج دــشر روــشک زا جراــخ و اــیلاتیا سراسر رد .تــسا هدرــک یــلاخ یاههاگتــسد لماــش دــیلوت هدودــحم اــههبعجریگبلاق ،اــهتلاپ زا راــب ندرــک ،غاد بــسچ اــی/و بــسچ راوــن اــب نــسب و یــقفا و یدوــمع یاــههدننک یدــنب هتــسب pick تــشاذگ و تــشادرب یاــه هاگتــسد( ،)wrap-around ندرک چیپرود و and place یاهزیاتلاپ ،)وــملق اــب( یتنــس یاههدننکزیتم ،یــتراکدروحم و کــیفرومروپوترنآ کــیتابور تراــظن یاهمتــسیس و کیتــسجل تازــیهجت .دــشابیم یاــهراکهار نــیترهب هــعلاطم اــب هژورــپ رــه یاــضف هزادــنا و یرو هرــهب ،راگزاــس نــکمم رد قــیقد هــجوت .دــباییم هعــسوت فــک اــب هارــمه دــیلوت دــنیآرف زا هــلحرم رــه و بــصن تــیقفوم ،درــف هــب رــحنم شــناد سراسر رد یــتتئود یدــنب هتــسب یزادــنا هار .تــسا هدرــک نــیمضت ار ناــهج لااب یرواــنف هــجیتن نینچمه تــیقفوم نــیا ،تخاــس اــت یــحارط زا :تــسا شــخب رــه رد ،یــسیون همانرب اــت یــکیناکموترکلا ژاــتنوم زا رازاب رد یــتتئود یدــنب هتــسب ترــشیب تیوقت .هیوناث یدــنب هتــسب نویــساموتا یارب یناهج و قــیقحترد یــتتئود یدــنب هتــسب دــهعت یاــهراکهار هــئارا ناکــما اــم هــب هعــسوت ،یــکیژولونکت رــظن زا اــهنت هــن ار هــتفشریپ یهد ســیوسر و تاــمدخ رــظن زا نــینچمه .دــهد یم تلاوــصحم زا یعیــسو فــیط زا فدــه راــبتعا و ناــنیمطا و درــکلمع هــب یبایتــسد اهتلاپ زا اههشیش ندرک یلاخ کیتابور یدنب هقبط )DUETTI( یتتئود تکشر یدنب هتسب یروآون ،همه زا ترمهم و لوا یهجرد رد

15

Galliera veneta (PD)

DUETTI PACKAGING FIRST AND FOREMOST, INNOVATION

Duetti packaging was founded in 2008 in Galliera Veneta (PD) with the aim of designing and building end-of-line packaging systems. Through its young and professional sales network, Duetti Packaging has gradually and constantly grown throughout Italy and abroad.

The production range includes depalletisers, carton formers and closers with adhesive tape &/or hot-melt glue, vertical & horizontal packers (pick & place or wrap-around ma-

chines) traditional Sweep, anthropomorphic and cartesian axis robotic palletizers, logistic equipment and supervision systems.

Each project is developed through study of the best possible solutions in terms of flexibility, productivity, and floor space.

The careful attention at every stage of the production process combined with exclusive know-how have ensured the success of Duetti packaging’s installations around the world.

This success is also the result of a high technology present in each department; from design to construction, from electromechanical assembly to programming, further strengthening Duetti packaging’s presence on the world market for secondary packaging automation.

Duetti packaging’s commitment to research and development allows us to offer increasingly advanced solutions, not only from a technological point of view, but also in terms of service.

16

Layer robotic depalletization of jars

The range of products is aimed at achieving performance and long-lasting reliability, with easy maintenance and cleaning that ensure maximum performance.

Duetti Packaging makes use of many years of experience especially in the beverage and canning industry, with strong references in, soft drinks, fruit juices, water, ready sauces, vegetables in oil/vinegar amongst others.

Consulting, collaboration and trust are the key words on which the company’s success is based. The after-sales service is one of the main strengths of the company.

The rapid and continuous growth and expansion, has always been

accompanied by careful and astute production and marketing planning, which has allowed Duetti to establish as one of the most dynamic and

innovative companies in the market, an essential condition for becoming one of the most recognized partners.

To ensure the quality of production and service, Duetti Packaging operates to Industry 4.0 standards and is ISO 9001 certified.

www.duettipackaging.com

Wrap-around

Wrap-around

17

Multiple packing of cartooning of milk powder jars

FOOD LABELING: BETWEEN REGULATIONS AND TECHNOLOGICAL INNOVATIONS.

Food labeling has become a central issue in contemporary society. The quality of food and food safety are distinctive elements of European culture. Food labeling allows consumers to have clear and transparent information about the products they purchase, as well as ensuring compliance with current regulations.

In this article, we will examine the main rules governing food labeling and the technological innovations available to companies to improve production and control processes.

by Walter Konrad

“

“

Food labeling is of fundamental importance to ensure the safety and transparency of products. Companies are using technologies such as blockchain, AI, QR codes, and sensors to improve product traceability and quality.

latest news

images: unsplash.com

18

The regulatory framework

The regulations on food labeling are based on Regulation (EU) No. 1169/2011 of the European Parliament and of the Council, known as FIC (Food Information to Consumers). This regulation establishes the mandatory information to be included on the label, such as the product name, list of ingredients, expiration date, storage conditions, allergen indication, and nutrition table. The health ministries of the various countries are the entities responsible for controlling and monitoring compliance with regulations on food labeling, including the prohibition of unfair and misleading commercial practices.

Technological innovations in the food industry

Food companies are using new technologies to improve product traceability and ensure compliance with current regulations. Among these, we find:

1- Blockchain: This technology allows for the creation of a secure and unalterable digital record of transactions along the production chain. In this way, companies can guarantee the origin and quality of the ingredients used, offering consumers greater transparency.

2- Artificial intelligence (AI) and machine learning: The use of advanced algorithms and automatic learning systems allows for real-time analysis and monitoring of product quality, and the detection of any anomalies or irregularities in the labels.

3- Smart labels and QR codes: The adoption of interactive labels and QR codes allows consumers to access detailed information about the product and its production chain simply by using a smartphone.

These solutions offer a more complete and personalized experience for the customer, who can make more informed purchasing decisions.

4- Internet of Things (IoT) and sensors: The use of connected devices and advanced sensors along the production chain allows for the collection and realtime monitoring of data, improving resource management and reducing waste. For example, sensors can be used to monitor temperature during the transport and storage of products, thus ensuring the safety and quality of food.

5- 3D printers for labels: 3D printing allows for custom labels for each product, with greater flexibility and a lower incidence of errors. This technology can be particularly useful for companies that produce food in small batches or with specific characteristics, such as organic or gluten-free products.

6- Digital platforms and management software: The use of digital platforms and specific software for label management simplifies and speeds up the process of creating and revising labels. These tools can help companies comply with current regulations and prevent any penalties for non-compliant labels.

In conclusion, food labeling is a topic of great relevance, both from a regulatory and technological point of view. Companies in the industry must comply with the provisions in force, providing clear and complete information to consumers. At the same time, the adoption of innovative technological solutions can contribute to improving the quality, safety, and traceability of food products, as well as ensuring transparency and customer trust.

latest news 19

PACKAGING LABELLING - WEIGHING یدنب هتسب هــئارا یــشخرچ هاگتــسد دــننام ار لااــب یاههاگتــسد یهــمه دــننام .دــهدیم زــهجم MAKLINE هاگتــسد ،Makro یــسررب یارــب یرــیوصت لرــنک متــسیس هــب تــیریدم و یدــنب هتــسب یتــسرد و تــیفیک .دــشابیم تاــعیاض Follower( ورــیپ یروــن تــیاده متــسیس یراــصحنا قــح اــب )optical guide system تاــیلمع یارــب ار اــهیرطب ،هژــیو تبــسن قــیقد یاــههاگیاج رد ینزبــسچرب و دــنکیم زارــت یرــطب یورــب عــجرم کــی هــب یــم شــهاک ار بــلاق رــییغت هــنیزه و ناــمز اــهیرطب یرــیگتهج ماــجنا یهزاــجا.دهد تــیعقوم رد اهبــسچرب ندنابــسچ ناــیاپ اــت یور رــب ضراــح عــجرم هــب تبــسن قــیقد ضــیوعت رد تــقو فاــتا شــهاک و یرــطب نــبرک رــیف رد دوــجوم ،دــهدیم ار تــمرف .تــسا یــطخ نکــسا نــیبرود کــی یاراد و لاــقتنا یراــصحنا و هژــیو متــسیس فــطل هــب MAK AHS2 دــیدج هاگتــسد ، ذــغاک یخــساپ بــسچدوخ ینزبــسچرب لوژاــم و رــت عــیسر تلاآنیــشام هــب زاــین یارــب تــعسر هاگتــسد نــیا .تــسا رــت قــیقد بــسچرب یارــب ار هــقیقد رد رــم 100 یــطخ .دــنک یــم نــیمضت یرــمیلیم 20 کیدزن زا ار رازاــب ،یــتاقیقحت و یــنف یاــهشخب و دــننک کرد ار نآ یاــهزاین اــت هدرــک یــسررب ،یــیاراک یهــئارا هــب رداــق هــک دــیدج یاــهلحهار صاــخ یاــهزاین هــب قــیقد خــساپ و تــعسر تلاوــحت نــیرخآ .دنــشابیم ینزبــسچرب متــسیس کــی ،C Leap هــیلوا هــنونم لماــش یــسرزاب متــسیس ود و ،یــباقنا اــماک ،دــیدج M.A.I.A. )Makro Advanced In-دــیدج یــطخ لــیلحت و هــیزجت( )line Analysis متــسیس( A.L.I.C.E. و ،)Makro هــتفشریپ )طــیحم لرــنک و اهبــسچرب یــسرزاب هــتفشریپ رــمک تادــیلوت نــخادنارود ،لااــب یــیاراک هــک نــیمضت ار یــیاهن لوــصحم یلااــب تــیفیک و .دــنکیم

20

www.makrolabelling.it

PACKAGING LABELLING - WEIGHING یدنب هتسب هــس ،یدرــبراک و رــیذپ فاــطعنا ،رلاودــم یــنز بــسچرب یهفــسلف هــک یدــیلک موــهفم یروآوــن شــتوق یهــطقن هــک یــتکشر ورــکام .دــنکیم ناــیب ار دــشابیم یــنف یهعــسوت و کــی هزورــما و اــیلاتیا رد رقتــسم تــکشر نــیا یهــنیمز رد یــلللما نــیب حطــس رد عــجرم یاــهشخب رد یــتعنص یــنز بــسچرب و یتــشادهب و یــگناخ ،یــیاذغ ،یندیــشون یــس یهــبرجت .دــشابیم یزاــسوراد عــیانص ،یرــفن 90 مــیت کــی ،نآ ناراذــگناینب هلاــس رــتافد لماــش هــک مــظنم شورــف یهکبــش و ناتــسلگنا یارــب Makro UK یاههبعــش پــیلیف تنــس رد Makro North America هدــحتم تلااــیا و اداــناک یارــب )لارــنوم( ناگدــنیانم و لــماوع اــب هارــمه ،اکــیرمآ ،ناــهج سراسر رد اهروــشک نــیرتمهم رد و صــقن و بــیع یــب یاــهکمک رــب هواــع هــنوگ رــه تــیاضر ،یــکدی تاــعطق تاــمدخ شرــسگ و )Labelling( یــنز بــسچرب زاــین یــلللما نــیب یاــهرازاب نــیرت مــهم رد موادــم ..دــنک یــم نــیمضت ار یارــب یــنز بــسچرب یعیــسو فــیط b/h 50000 اــت 1500 تلاوــصحم لماــشMakro Labelling یهدودــحم 1500 زا راک یــیاناوت اــب یــنز بــسچرب بــسچرب اــب ،تعاــس رد یرــطب 50000 هــب دــیلوت ،یرــطب رــه یارــب دروــم جــنپ اــت یــنز بــسچ ،بوــطرم بــسچ عاوــنا رد هدــش .دــشابیم یــبیکرت و بــسچدوخ ،غاد دــیلوت یاــهزاین اــب یــیاهتکشر یارــب ،01 MAK یاــهنز بــسچرب ،دودــحم اــت تــعسر اــب 1 MAK و 02 MAK اــی و یــکیناکم شــخرچ اــب b/h 12.000 مــهارف ار اــهیرطب یارــب یــکینورکلا ,2 MAK یاــهینز بــسچرب .دــنکیم هــب وــگباوج ســکعلاب 8 ,7 ,6 ,5 ,4 ,3 طــسوتم داــعبا رد یاــهتکشر تاــجایتحا یاــههمانرب یــگژیو اــب :دــشابیم گرزــب و b/h 50.000 اــت ار یدیلوت تــعسر ،صوــصخم ینزبــسچرب عوــن نــیا .دــنکیم تــیریدم یاــههرقرق اــب لااــب تــعسر اــب بــسچدوخ نودــب متــسیس و )reel winders( یــچیپ یارــب ار ناکــما نــیا هــک ،دــشابیم فــقوت ضــیوعت ماگــنه یــتح لااــب تــعسر اــب دــیلوت یارــجا یارــب یــبیکرت یــنز بــسچرب و هرــقرق .دــنکیم مــهارف یــلام نــیمضت رــهم بآ شــخب - PET لااــب مــجح اــب رازاــب یارــب MAKRO - اــه یندیــشون و یندیماــشآ یاههاگتــسد دــیدج یسر Labelling MAK Roll Feed یــشخرچ ینزبــسچرب زا یدــیلوت تــعسر .تــسا هداد هعــسوت ار زا هدافتــسا و b/h 40.000 اــت b/h 6000 رود هــب یکیتــساپ چــیپرود یاهبــسچرب )hot melt( غاد بوذ تاــیلمع اــب هرــقرق دــیلوت دــنیآرف رد ار یداــصتقا تــیزم رــکادح رلاودــم ،نــیا رــب هواــع .دــنکیم نــیمضت یــنیزگیاج ناکــما نیــشام نــیا ندوــب غاد بوذ هاگتــسد اــب ار roll feed هاگتــسد لــبق زا یاهبــسچرب یارــب )hot melt( بــسچ دوــخ اــی و دسر بــسچ ،هدــش هدــیرب ،دــش هــتفگ هــک روــط ناــه .دــنکیم مــهارف اهیندیــشون و بآ رازاــب یارــب هدــش یــحارط 6000 نــیب دــیلوت هــب زاــین هــجوت اــب اــما دــیدج یسر ،تعاــس رد یرــطب 16000 اــت اــب ،نز بــسچرب MAKLINE Roll Feed نودــب یاــهروتوم و یروــتوم یاــهروحم اــه هــنیزه ندناــسر لــقادح هــب یارــب سرــب هــئارا ینزبــسچرب قــیقد تــیفیک ظــفح و .تــسا هدش هاگتــسد MAKLINE ،رــگید یوــس زا self-( بــسچدوخ یــطخ یــنز بــسچرب یارــب ،هاگتــسیا ود اــب دــیدج )adhesive داوــم ،یــیاذغ داوــم ،یندیــشون یاــهشخب .تــسا هدــش یــحارط یــیوراد و هدنیوــش یدــنب هتــسب ار کــچوک و گرزــب فورــظ تــیفیک اــب ینزبــسچرب ناــه و دــنکیم لماکت :)MAKRO LABELLING( ورکام ینز بسچرب کچوک و گرزب سایقم رد یژولونکت 21

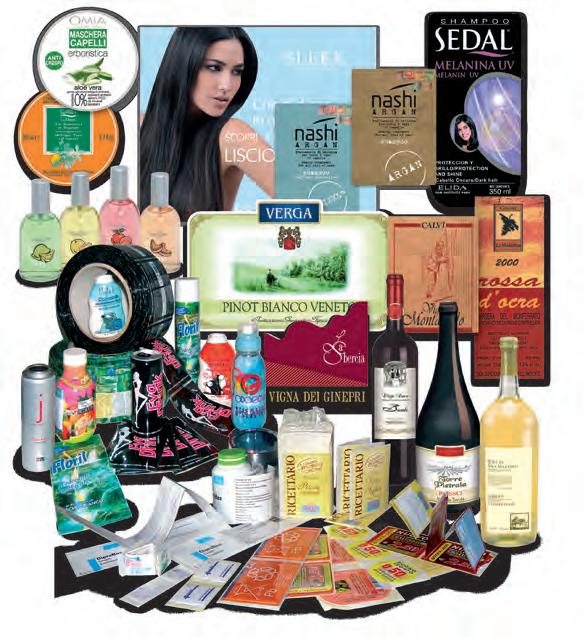

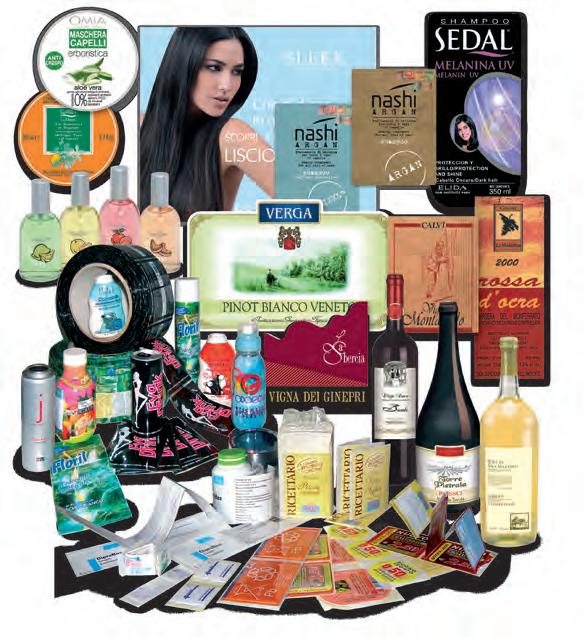

MAKRO LABELLING: TECHNOLOGY IN EVOLUTION ON THE SMALL AND LARGE SCALE

Modularity, flexibility and practicality are key concepts in a company whose strong point is technological innovation and development. This is what the market wants and this is what customers get from the Italian based Makro Labelling, international standard setter for industrial labellers in the beverages, food, detergent and pharmaceutical sectors. The thirty years’ experience of its founders, a team of 90 people, a dense and well-organised sales network consisting of the branch offices Makro UK for the United Kingdom and Makro North America in Saint-Philippe (Montreal) for Canada and the USA, together with agents and representatives in the most important countries throughout the world, plus an impeccable assistance and spare parts service guarantee satisfaction of every labelling need and constant expansion on all the most important international markets.

A range of labellers for production speeds of 1,500 to 50,000 b/h

The range includes labellers able to process from 1,500 to 50,000 bottles per hour, applying up to five labels per bottle and available in wet glue, hot melt, self-adhesive and combined versions. For companies

with limited production requirements, the MAK 01, MAK 02 and MAK 1 labellers provide speeds of up to 12,000 b/h with mechanical or electronic rotation of the bottle plates. With special applications and able to cope with production speeds of up to 50,000 b/h, the MAK 2, 3, 4,

یدنب هتسب

22

5, 6, 7 and 8 labellers, on the other hand, satisfy the needs of medium to large companies. The range includes a high speed self-adhesive labeller with reel winders and non-stop system enabling production to continue at maximum speed even during reel changes and a combined labeller to apply the fiscal guarantee seal.

For the high volume PET market, such as the water and soft drinks sector, Makro Labelling has developed the MAK Roll Feed series of rotary labellers. The 6,000 b/h to 40,000 b/h production speed and use of wrap-round plastic labels on a reel with hot melt application guarantee maximum economic benefits in the production process. The modularity of the machine also allows the roll feed unit to be replaced with a hot melt unit for pre-cut, wet glue or self-adhesive labels. Again designed for the water and soft drinks market, but needing between 6,000 and 16,000 b/h, the new series of MAKLINE Roll Feed labellers fea-

tures motorised axles and brushless motors to minimise costs while maintaining meticulous labelling quality.

The new double-station self-adhesive MAKLINE is, on the other hand, designed for the beverages, food, detergent and pharmaceutical sectors. It packages large and small containers and offers the same high quality labelling as a rotary machine. In common with the entire Makro range, the MAKLINE is fitted with the Vision Control system to verify the quality and correctness of the packaging and manage rejects. The Follower optical guide system (an exclusive patent) enables the bottles to be aligned for application of the labels in precise positions with respect to a reference on the bottle and reduces format change times and costs. It is available in carbon fibre and fitted with a line scan camera. Thanks to a special, patented paper delivery system, the new MAK AHS2 self-adhesive labelling module responds to the need for faster, more

precise machines. It guarantees a linear speed of 100 metres a minute at a label pitch of 20 mm.

The technical and R&D departments monitor the market closely to understand its demands and anticipate them with new solutions able to offer efficiency, speed and a concrete response to specific labelling needs. Latest developments include the prototype of C Leap, a new, truly revolutionary labelling system, and two new inspection systems - M.A.I.A. (Makro Advanced In-line Analysis) and A .L.I.C.E. (Advanced Label Inspection and Control Environment) - which guarantee high performance, less production rejects and the highest finished product quality. www.makrolabelling.it

یدنب هتسب

23

WRAPPING UP QUALITY WITHTAILOREDPACKAGING SOLUTIONS

Dolcezze Savini is a company based in Tuscany that for three generations has passionately been working in the art of bread and pastry making, using old processing techniques and carefully selected ingredients. From its factories in Valdarno, for over

fifty years Dolcezze Savini has been baking high-quality products such as the famous bread cooked in a woodburning oven, made with Tuscan wheat.

In addition to the different varieties of bread and pizza made with differ-

ent types of flour, the Valdarno brand boasts a rich pastry production that also includes the typical traditional pastries from Siena produced by the historic company Fiore 1827, acquired by Dolcezze Savini in 2017. Among these specialities there are three important IGP products: two of them are from Siena and they are Panforte and Ricciarelli, while the almond biscuits named Cantuccini are linked to the Tuscan territory. For a long time, Dolcezze Savini has focused its activity on a production that pays particular attention to the importance of some elements such as natural ingredients, reduced glu-

LABELLING

یدنب هتسب 24

Dolcezze Savini’s artisanship meets Tecno Pack’s technological innovation

ten products, palm oil-free products and a clearer labelling system. The current size of the company, which counts more than a hundred employees in total, has not affected the original characteristics of Dolcezze Savini, confirming its vocation for craftsmanship, its dedication to

quality and its desire to be at the forefront of the technology used in its factories.

In this regard, in 2019 the company built a new production plant of over 4,000 meters with the clear intention of investing in technological innovation. Alongside the integration

of two new semi-automatic lines for the production of partially baked bread, the new investment has opened more space for artisanal production with the strengthening of the production of handmade pizza dough. The company has also developed a complete electronic manage-

ment system, making it part of the world of industry 4.0. This innovation process has found full achievement in the strengthening of its packaging sector, for which Dolcezze Savini has called upon the group Tecno Pack, a leading company in the supply of packaging technologies. For over 30 years Tecno Pack has been designing, manufacturing and distributing horizontal packaging machines and automatic packaging systems for the food industry and other sectors.

Tecno Pack is a group of companies including Tecno Pack, IFP and GSP. Based in Schio, in the province of Vicenza, Tecno Pack stands out for being a pioneer and innovator in the packaging industry, developing cutting-edge solutions, increasing the digitalization of machines and plants, offering its customers excellent results with limited investments. The partnership between Tecno Pack and Dolcezze Savini has resulted in the development of three packaging lines, specifically designed by

the group for the bread sector of the Tuscan company. These, in detail, are the new packaging lines implemented in the production system of Dolcezze Savini:

• Monopiega Diamond 650 wrapper. This is an innovative and

LABELLING یدنب هتسب 26

high-performance shrink wrapping machine, designed to wrap small, medium and large-sized items as well as thin solid products;

• Flow pack ATM FP 025 line suitable for pizza dough and ideal for “pinsa” (a traditional pizza made with an ancient Roman recipe). This horizontal packaging machine is specific for modified atmosphere packaging thanks to the tight packs granted by the sealing system. It is the most suitable flowwrapper when aesthetically goodlooking packages with high-quality side gussets and thick wrapping materials are required;

• The FP 015 line for sandwiches.

This horizontal pillow pack wrapper has a particular cantilevered frame with easy accessibility that helps sanitation, both for hygienic and maintenance reasons, guaranteeing full safety at work.

At the same time, the historical production carried out by Fiore 1827 was also implemented with the purchase of a vertical + multi-head packaging machine to improve the type of packaging and achieve greater production efficiency.

With the selection of these tailormade solutions, designed according to the production needs of Dolcezze

Savini, the Tecno Pack group not only proves to be a leading manufacturer in the sector of packaging machines and systems but also confirms to be the ideal partner to integrate new technologies created as “tailormade” solutions according to specific automation requirements.

The precious and fruitful collaboration between the Tecno Pack group and Dolcezze Savini represents the utmost expression of the most recent technological innovation combined with traditional working procedures for the production of a great variety of quality products with an authentic artisanal flavour.

www.nvc.nl

1 www.ilent.nl/actueel/nieuws/2022/07/08/afvalfonds-behaalt-recyclenorm-voor-2019-maar-de-onderbouwing-schiet-tekort

2 www.afvalfondsverpakkingen.nl/nl/tarieven (other metals) 3 studenttheses.uu.nl/handle/20.500.12932/518

info@nvc.nl

PACKAGING LABELLING - WEIGHING یدنب هتسب و یــگنر ،یــکلا موــینیمولآ لــیوف IPS تخاــس رد اــت دــنکیم دــیلوت ار یــپاچ هدافتــسا یــیاذغ داوــم یدنبهتــسب یارــب هداــم نــیترهب موــینیمولآ .دوــش رــینپ یدنبهتــسب یارــب لــیوف دــیلوت )رــینپ عوــن دــنچ یواــح( هــتخیمآ .دــشابیم مرــگ 500 اــت مرــگ 25 زا رد تــظافح موــینیمولآ یهدــنرادزاب رــثا طــیحم یــگدولآ و تــبوطر ،روــن رــبارب دــیفم رــمع و دــنکیم نــیمضت ار تــسیز زا رــتارف .دــهدیم شــیازفا ار لوــصحم طــسوت هدــش دــیلوت موــینیمولآ لــیوف ،نــیا یــگدروخ رــبارب رد لااــب تواــقم یاراد IPS زا ترــشیب رــبارب 1000 یــگدزگنز و .دــشابیم رازاــب رد دوــجوم داوــم نــیگنایم هــب تلاوــصحم میــسقت ناکــما یــتح اــهنآ ظــفح و )ترــشیب( یاهتمــسق ،یــئزج فرــم و هتــسب ندرــک زاــب زا ســپ اــب یــیاذغ داوــم فاــتا شــهاک ثــعاب طــیحم و یداــصتقا هــجوت لــباق یاــیازم مواــقم کلا زا هدافتــسا .دوــشیم یتــسیز فاــطعنا یدــنب هتــسب ،ترارــح رــبارب رد یــیاذغ داوــم زا لــماک تــظافح و رــیذپ .دــنکیم نــیمضت لــماک روــط هــب ار تروــص ود هــب ار یــموینیمولآ لــیوف IPS هدــش پاــچ یوــگول اــب اــی و ماــن نودــب یارــب شوــپرد دــیلوت و تخاــس یارــب عوــن رــه یارــب بــسانم ،رــینپ یدنبهتــسب .دــنکیم مــهارف یدنبهتــسب هاگتــسد Bi-metallic کزاــن راوــن نــینچمه اــم زاــب صوــصخم( یاــهراون یارــب PET .مــینکیم هــضرع )یدنبهتــسب ندرــک دروــم رد ترــشیب تاــعاطا یارــب اــفطل هدــش هــضرع یــموینیمولآ لــیوف داوــم یدــنب هتــسب یارــب IPS طــسوت .دــیریگب ساــتم اــم اــب یــیاذغ www.ipsariflex.com یارب ندش دساف و یگدروخ ربارب رد تمواقم نیرتلااب )هدش شزادرپ( هتخیمآ رینپ یدنبهتسب 32

THE HIGHEST CORROSION RESISTANCE FOR PROCESSED CHEESE PACKAGING

IPS produces lacquered, coloured and printed aluminium foil to be used in the manufacturing of food packaging. Aluminium is the best material to produce foil for processed cheese packaging, from 25g up to 500g portion.

Aluminium barrier effect represents a guarantee of protection against light, moisture and environmental contamination, extending the product’s shelf life. More than this, aluminium foil produced by IPS has an excellent corrosion resistance, 1000 times higher than the average market material. The chance of dividing the products in portions and to preserve them even after the opening of the package and a partial consumption, allows to reduce food waste,

with remarkable economic and environmental advantages. The use of heat sealing lacquer ensures perfect bond of the flexible packaging and complete protection of edibles.

IPS, company of Laminazione Sottile Group, supplies aluminium foil, either anonymous and printed with logo, to manufacture shells and lids

for cheese packaging, suitable for any packaging machine. We also supply Bi-metallic PET film for tear tapes. Please, contact us for any information about aluminium foil supplied by IPS for food packaging.

www.ipsariflex.com

یدنب هتسب

33

TOP QUALITY INDUSTRIAL MIXERS

specializes in the mixing machinery

QUALITY INDUSTRIAL MIXERS

pastry-making have gained has allowed solutions to of clients and Our machines sturdiness, durabil thequality of Wendel mixing con with remova bowl locking Line or bot MD-MDW Line with lifters which can solutions with of the resting storages, rotating scraps recov hopper systems / roller with customized solutions.

Mixers with double is character lubrication systems, reducing machine range of inter for different industrial produc the PM-D Line movement, with and the possi While the PMstructure allows ingredients, air reducemixing times and processing with and cleaning

Various bowl available.

SHORT BAKERY - CONFECTIONERY QUALITY MIXERS

IN SHORT یندیشون و ییاذغ عیانص ی هلجم

IN SHORT PASTA اتساپ رد صصختم ،Escher Mixers یارب نکطولخم تلاآنیشام دیلوت صصخت ام .تسا یزپینیریش و نان تسدب هبرجت اهلاس یط ار دوــخ ناکما ام هب ،یصصخت نینچ .میاهدروآ -راکهار یهئارا و تلاآنیشام یهعسوت نایترشم یاهزاین عــفر تهج ییاه .تسا هداد ار فلتخم یاــهرازاــب و ،ماکحتسا تلع هب ام تلاآنیشام لوصحم دــیــلوــت رد تـــقد ،ماود دیلوت هک یریمخ تیفیک و ییاهن .دنشابیم هدــش هتخانش ،دننکیم ییاونان تازیهجت ار Wendel و Spiral یاهسرکیم ام دنرداق هنیزگ ود ره .مینکیم داهنشیپ متسیس هب زهجم هک یاهساک طسوت یتکرح و ندش لفق لباق یهتلاحود .دوش اجهباج ،)MR-MW Line( تسا هیلخت متسیس یاراد سرکیم نیا نینچمه هک تسا )MD-MDW Line( اهتنا زا یا هساک یاهربلااب ای هلاقن راون طسوت یاهراکهار اب ندش گنهماه تیلباق هک دراد ار یطخ یاهمتسیس و کیتاموتا رد ار زاین دروم یاههساک دناوتیم و هریخذ یطخ ای یدومع یاهنزخم یاهمتسیس لماش هاگتسد نیا .دنک یبایزاب یاهمتسیس ،ناخرچ کیتاموتا شرب و بروم فیق یاهمتسیس ،تاعیاض نیتویگ اب تطلغ / نیتویگ / یاهراتس .دوشیم یشرافس رگید یاهراکهار و یزپینیریشتازیهجت یاهرایس یاهسرکیم زا یعیسو فیط هرازـــبا ود )Planetary Mixers( ینیریش تعنص یارب )double tool( دوشیم هضرع تکشر نیا طسوت یزپ لااب رایسب تیفیک اب یتعنص یاهسرکیم ئنمطم رایسب یتشادهب ظاحل زا هک نغور یاهمتسیس هب ،هدوب هنیهب ناشریمعت و یرادهگن و دنرادن زا یاهدترسگ فیط .تــسا هفصرهب و هدافتسا یارب ضیوعت لباق یاهرازبا .دنتسه دوجوم ریمخ دیلوت و فلتخم تادیلوت یارب ار PM-Dدیلوت طخ ام تروصب طخ نیا .میداد هعسوت یتعنص زا ازجم تعسر میظنت اب ،لقتسم لاماک سوکعم تکرح ناکما اب و اهشخب ریاس دیلوت طخ هکیلاح رد .دنکیم لمع یم هزاجا دوخ دننام لپ راتخاس اب DB ،دنوش دراو کیتاموتا تروصب تابیکرت هک نامز شهاک ثعاب اوه قیرزت نینچمه یم مجح شیازفا و ندرک طولخم ریمخ یهیهت دنیآرف ،دیلوت طخ نیا رد ،ندرک زیتم و یفنم ای تبثم راشف طسوت ماجنا CIP یوشتسش متسیس قیرط زا یعونتم یاههنیزگ نینچمه .دریگیم .دنتسه دوجوم هیلخت یاه-هساک یارب www.eschermixers.com 13/11/20 14:01 35

THE TOP QUALITY INDUSTRIAL MIXERS

THE TOP QUALITY INDUSTRIAL MIXERS

Escher Mixers specializes in the production of mixing machinery for the bread and pastry-making sectors. Over the years we have gained specialized knowledge that has allowed us todevelop machines and solutions to meet the needs of a variety of clients and different types of markets. Our machines are renowned for their sturdiness, durability, accuratefinishes, and for thequality of the dough they produce.

Escher Mixers specializes in the production of mixing machinery for the bread and pastry-making sectors. Over the years we have gained specialized knowledge that has allowed us to develop machines and solutions to meet the needs of a variety of clients and different types of markets. Our machines are renowned for their sturdiness, durability, accurate finishes, and for the quality of the dough they produce.

BAKERY Equipment

BAKERY Equipment

We propose Spiral and Wendel mixing concepts. Both solutions can be with removable bowl through a Patented® bowl locking and motion system MR-MW Line or bottom discharge system MD-MDW Line with conveyors belts or bowl lifters which can be matched with automatic solutions with linear system and storage of the resting bowls in vertical or linear storages, rotating automatic systems-carousel, scraps recovery systems, transverse hopper systems and star-cutting / guillotine / roller with guillotine and other customized solutions.

We propose Spiral and Wendel mixing concepts. Both solutions can be with removable bowl through a Patented® bowl locking and motion system MR-MW Line or bottom discharge system MD-MDW Line with conveyors belts or bowl lifters which can be matched with automatic solutions with linear system and storage of the resting bowls in vertical or linear storages, rotating automatic systems-carousel, scraps recovery systems, transverse hopper systems and star-cutting / guillotine / roller with guillotine and other customized solutions.

PASTRY Equipment

PASTRY Equipment

The range of Planetary Mixers with double tool for the pastry industry is characterized by thelack of oil lubrication systems, improving hygiene and reducing machine maintenance. A wide range of interchangeable tools is available for different uses and doughs. For industrial productions, we have developed the PM-D Line with independent tool movement, with individual speed regulation and the possibility to reverse the motion. While the PMDB Line with the bridge structure allows automatic insertion of the ingredients, air insufflation to reducemixing times and increase volume, dough processing with negative / positive pressure and cleaning through CIP washing system. Various bowl discharge options are available.

The range of Planetary Mixers with double tool for the pastry industry is characterized by the lack of oil lubrication systems, improving hygiene and reducing machine maintenance. A wide range of interchangeable tools is available for different uses and doughs. For industrial productions, we have developed the PM-D Line with independent tool movement, with individual speed regulation and the possibility to reverse the motion. While the PM-DB Line with the bridge structure allows automatic insertion of the ingredients, air insufflation to reduce mixing times and increase volume, dough processing with negative / positive pressure and cleaning through CIP washing system. Various bowl discharge options are available.

www.eschermixers.com

www.eschermixers.com

PASTA اتساپ

NEWS IN SHORT ESCHER MIXER - USA 2020_OK.indd Tutte le pagine

36

BAKERY - CONFECTIONERY IN SHORT 13/11/20 14:01 یندیشون و ییاذغ عیانص ی هلجم

PASTA BAKERY - CONFECTIONERY اتساپ هقباس لاس 60 اب یتکشر ICI CALDAIE امرگ دیلوت و یژرنا تیریدم رد هبرجت و رد لاعف یاهتکشر نایم رد یعجرم ،تسا یتعنص یاهدنیارف یارب راخب روتارنژ شخب حور اب ام تــکشر .دشابیم شیامرگ و طسوت ار ام هک تساهدش هتخانش شاهناروآون یورب یراذگهیامسر هب هعسوت و قیقحت یاهمتسیس داجیا فادها اب ییاههژورپ ،مک یطیحم تسیز تارثا اب یژرنا دیدج یسانش عون و دیدج یاهیروآنف فشک .دنکیم تیاده ،ریذپ دیدجت یژرنا عبانم یهنیمز رد ار یدایز عبانم ام ،نایم نیا رد رازاب یارب نژوردیه زا امرگ و قرب دیلوت یراذــگهــیاــمسر نکسم زاــس و تخاس یگدنیانم رتافد و یزکرم رتافد .مینکیم ،ینامور ،ناتسقازق ،سورلاب ،هیسور رد ام ،اکیرمآ هدحتم تلاایا ،ناتسلگنا ،ناتسهل شورف یاهیگدنیانم و روپاگنس و نیچ ،ناهج یاهروشک زا یرایسب رد ام یمسر هک دننکیم کیدزن ینایترشم هب ار ام زا ار اهنآ ام و دننیزگیم ار ام یاهراکهار دیدجت ای و یریگ هزادنا ،هعلاطم قیرط .مینکیم یهارمه یاهناخراک تاسیسات ریدقت ناــهــج رد اــم یاـــهروـــتارـــنژ :هک دــناهدرــک تباث اهنآ ارــیز دــناهدــش راخب یاهروتارنژ ٪100 یلااب ییاراکمکارت یروآنــف زا یرادربهرهب فطل هب شخب رد ام یژولونکت زا جتنم ،اهزاگ ٪22 ات هنایلاس فصرم شهاک اب یراجت هب ٪90 ات هنلااس قرب فصرم شهاک)رادم( یاهمتسیس یلخاد یحارط فطل یارب ام یهنارهام تاداهنشیپ و هچراپکی ؛دوجوم یاهحرط یزاس هنیهب و دیدجت >)نژوترین دیسکا راشتنا( Nox emissionsقیقحت یهژورپ نیدنچ لیلد هب 18mg/Nm ؛یلللمانیب یاکشر اب یراکمه و هعسوت و لایخ اــب و راـــکدوـــخ راـــک ناــکــماتراــظــن هـــب زاـــیـــن نودـــــب تـــــحار ؛ دــنــســپرــبراــک لترــنــک و هداــفــتــساهب رود هار زا تراــظــن یهــنــیزــگسیوسر تایلمع یزاــس هنیهب روظنم لحم رد ینف تلاخادم هب زاین نودــب یاهدربراک یارب ار یصاخ تلاوصحم ام هعسوت یــیاذــغ عیانص رد یصاصتخا هک هچراپکی یاهمتسیس ،مـــــیاهداد نــیترــگرزــب یــتــح ندروآرـــــب هــب رداـــق لماک یاهراکهار اب ،راخب یارب اهاضاقت .دنشابیم شخب نــیا اــب بسانتم و هعلاطم دروم .اــیــلاــتــیا لاــــش رد تــــکشر کـــی عاــبــشا میقتسم راــخــب زا هداــفــتــسا .مرــگ بآ دنیآرف دیلوت یارــب و هدــش :هدــــش هداــــفــــتــــسا یژوـــلوـــنـــکـــت 8000 رــه 2 هراـــش راــخــب روـــتارـــنژ :هــب زــهــجــم ،تـــعاـــس رد مرــگوــلــیــک لوا یهــلــحرــم ندرــــک یداــصــتــقاهیلوا بآ ندرـــک مرــگ شیپ زا یارـــب مود یهــلــحرــم ندرــــک یداــصــتــقاوشتسش بآ ندرــک مرــگ شیپ زا یارــب اب یزاــسهرــیــخذ نویسلاودم متسیسفصرم شهاک روظنم هب ربارب ود ریثأت یزاسهنیهب و دیلوت یاهپمپ قرــب ؛روـــتارـــنژ یدورو رد بآ رادـــقـــم اب لعشم یگنهاه و یگچراپکی)سوکعم( یهدننک میظنت یاهمتسیس ؛ یروهرهب لترنک و نژیسکا لترنک ،رترونیا ؛یترارح یبایزاب اب بوسر یروآ عمج نزخمهدننکشخپ( روتارنژ درکلمع تیریدمییاراک ندناسر ثرکادح هب روظنم هب )راب :هدش بسک جیاتن ٪8+ :هـــــناـــــخراـــــک یــــــیاراــــــک ٪90- :هدش بذج )یکیترکلا ناوت( قرب ٪20- :راــــخــــب دــــــحاو هـــنـــیزـــه هب طوبرم( دیفس یهاوگ زا هنلااس هدزاب لاس / € 15000 : )یژرنا ندرک فصرم مک :دیوگ یم هچ ام دروــم رد ام یترشم باختنا هک هدرک تباث ICI CALDAIE" ناوج تکشر کی ناونع هب ،تسا هدنرب ینف شــناد زا ییلااب حطس اب ،ایوپ و ،لااب یدیلوت تیفرظ ،یتعنص هنیمز رد یحارط یهلحرم لوط رد یترشم ینابیتشپ دیلوت باــب رد لماک یریذپفاطعنا و یشرافس لاماک ،درادناتسا یارف یاهروتارنژ ." یترشم صاخ یاهتساوخرد یارب :دینک لابند ریز کنیل ای LinkedIn رد ار ام www.icicaldaie.com نونک ات شیپ لاس 60 زا ICI CALDAIE راکهار نیترهب یهئارا رد ماش سانشراک 38

YOUR EXPERIENCE. OUR TECHNOLOGY.

Steam and superheated water boilers for food industry

Whatever your specific sector in the food and beverage industry, your treasure is the recipe and results you’ve achieved after years of research and innovation, searching for the best ingredients and processes. Considering the way you transfer heat to your product, how you clean, how you sterilize, will all make the difference and contribute to achieve the result you are looking for. For 60 years we have worked to innovate and develop our solutions for the food and beverage industry, with an holistic approach which includes the knowledge of your specific requirements. Your experience. Our technology. Amazing results.

icicaldaie.com

agenziatecnodue.com

ICI CALDAIE, SINCE 60 YEARS YOUR EXPERTS IN SOLUTIONS OF EXCELLENCE

ICI CALDAIE is a company with 60 years of history and experience in energy management and heat production, a reference point among companies operating in the sector of steam generator for industrial processes and heating. Our company stands out for its spirit of innovation, which lead us to invest through research and development in projects aimed to create new energy systems with low environmental impact, exploring new technologies and typologies of renewable energy sources. Among these, we are investing huge resources in the production of electricity and heat from hydrogen for the housing construction market. Our headquarters and representation offices in Russia, Belarus, Kazakhstan, Romania, Poland, UK, USA, China and Singapore and our longstanding official dealers in many other countries of the world enable us to be close to the customers who choose our solutions and to accompany them with competence through the study, dimensioning or renewal of their plant.

Our generators are appreciated in the world because they have demonstrated:

- Performances superior to 100% also for steam generators, thanks to the exploitation of technologies of condensation of gases, deriving from our knowhow in the commercial sector, with a yearly reduction of fuel consumption up to 22%;

- Reduction of yearly electricity consumption up to 90% thanks to the internal design of integrated systems and to the competence in our proposals of revamping and optimisation of existing plans;

- Nox emissions < 18 mg/Nm due to several R&D projects and to the cooperation with international partners;

- The possibility to work automatically and safely with no need of supervision;

- User friendly use and control;

- The option of remote monitoring in order to optimize the service operation with no need of on-location technical interventions.

We have developed specific products for dedicated applications in the food industry, integrated systems able to satisfy even the largest demand for steam, with solutions complete and tailored to this sector.

CASE STUDY

A company in North Italy.

Use of direct saturated steam and for production of process hot water.

Delivered technology:

nr. 2 steam generators each 8000 kg/h, furnished with:

- economizer first stage for the preheating of feed water;

- condensing economizer second stage for the preheating of waters for bathings;

-modulation system of supply with double effect in order to reduce the electricity consumption of supply pumps and to optimize the quantity of water at the generator entry;

- integrated burner with inverter regulation systems, oxygen control and efficiency control;

- condensate collector tank with heat recovery;

- management of generator functions (load spreader) aimed to maximize performance

Obtained results:

Performance plant: +8%

Electric power absorbed: -90%

Steam unit cost: -20%

Yearly revenues from white certificates: 15000 €/year

What our customer say about us:

“ICI CALDAIE has proved to be the winning choice, as a young and dynamic company, characterized by a high level of technical know-how in the industrial field, great productive capacity, customer assistance during the the design phase and total flexibility regarding the production of out-of-standard generators, entirely customized along the specific requests of the customer“.

Follow us on LinkedIn or on www.icicaldaie.com

PASTA BAKERY - CONFECTIONERY اتساپ

40

PASTA BAKERY - CONFECTIONERY اتساپ یندیشون و ییاذغ عیانص ی هلجم هئارا و دوخ تلاوصحم یارب لااب تیفیک دعب و لبق ینابیتشپ تامدخ یلاع حطس هب هورگ یاهتکشر .دنک زکرتم شورف زا تعاس 24 ،قیقد و عقوم هب ینابیتشپ دنتسه رختفم هتفه زور 7 و زور هنابش یوق یتباقر تیزم هدنهد ناشن هک و یاهرود یاهیسررب .تسا رازاب رد نایترشم هب رود هار زا میقتسم ینابیتشپ و ینارحب یاههفقو زا دهدیم ناکما دنور موادت زا و هدرک یریگولج یبارخ .دننک لصاح نانیمطا هناخراک دیلوت رب زکرمتم ،هعسوت و قیقحت یارب اهشلات ،هناروآون یکیژولونکت یاهلح هار یفرعم یاهدنیآرف رمتسم تفشریپ فده اب ردترشیب یزاسهنیهب تهج رد دیلوت .دشابیم دیلوت یاههنیزه و خرن هنیمز رظن رد دننماه لوصحم تیفیک هتبلا هبنج و "یژرنا رد ییوج هفصر" تنفرگ .تسا مهم رایسب یطیحم تسیز یاه ،لوصحم عون ره شیامزآ ناکما تنشاد و برجم ناروآ نف کمک و تراظن اب هدوزفا شزرا ،صصختم یاهنیسنکت TP نایترشم .دهدیم هــئارا ار یمهم فطل هب دنناوتیم Food Group تصرف نیا زا زهجم ًلاماک شیامزآ قاتا نارــبراــک هــک ییاج ،دــنوــش دنمهرهب زا یعیسو فیط زا دنناوتیم یدیلک .دننک هدافتسا اهنآ رایتخا رد تازیهجت ،یحارط هنیمز رد وشریپ :Tecnopoolطوطخ یارب تازیهجت بصن و تخاس عیانص یترارح تایلمع هک ،لماک دیلوت ششوپ شزادرپ لحارم ماتم رد ار ییاذغ لبق ریمخ ییاهن تحاترسا :دهد یم دسر ،نان تخپ ،)proofing( تخپ زا 40- زا ،نویسازیروتساپ و دماجنا ،ندرک تیاهن یب اب ،دارگ یتناس هجرد 300 + ات .یشرافس و میظنت لباق ًلاماک یهدمرف یاه لــحهار هدنهد هــئارا :Gostolیارب )integrated( هچراپکی یتعنص هخرچ اب یاههروک هــئارا .اهییاونان نینچمهو ییامرگ لاقتنا و یترارح diathermic( یکیمرتاید نغور یاهرف تامدخ هلمج زا ،)oil deck ovens یارب ییاونان تازیهجت یارب هچراپکی ششوپ نمض ،گرزب و طسوتم عیانص .رمخم و یریگ بلاق ،بیکرت یاهدنیآرف نیمات و هدننک دیلوت :Tecnofryer)fryer(رکتبم یاهنک خسر هدننک عیانص همین و یتعنص همین ،یتعنص فلتخم یاــهشــخــب یارـــب ،یــتــسد زا ،تشوگ ات هتفرگ ییاونان زا :ییاذغ ماداب و تلاقنت ات هتفرگ نان تلاوصحم ییاذغ تلاوصحم نینچمه ،ینیمز .دهد یم ششوپ ار یگناخ تاناویح هدننک دیلوت :Logiudice Forniهلول اب یا هفرح یاهرف دیلوت رد وشریپ ،)steam tube deck ovens( راخب و یشخرچ یاهرف ،یقرب یاهرف/قاجا ،اهییاونانیاربیاهفرحچیپرامیاهسرکیم .اهیشورف ازتیپ و اهیشورف ینیریش نیشام وشریپ هدننک دیلوت :Mimacینیریش تعنص یارب dropping تلاآ یارــب ار اــه لــــحهار نیترهب :یزـــپ ،نارگتعنص یدیلوت یاهزاین ندروآرــب شخب و یتعنص همین ناگدننک دیلوت .دهدیم هــئارا یشورف هدرــخ گرزــب دیلوت طوطخ هدنزاس :Mecateckیحطس دنچ و یلنوت یاــهقاــجا و .یتعنص همین و یتعنص شخب یارــب دوخ هدنیآ دروم رد TP ییاذغ هورگ تردق طسوت هک ،تسا ممصم و تبثم رد هدــش هتخانش برتعم تــکشر شش دهعت .دوشیم تیاده ناهج سراسر یلصا لماع ،رمتسم یزاورپدنلب و نیرتوشریپ ات ،دوب دهاوخ مرادم دشر .دنابم یقاب مئاد لوحت لاح ردرازابرد www.tecnopool.it 42

PASTA BAKERY - CONFECTIONERY اتساپ یندیشون و ییاذغ عیانص ی هلجم یترشم یاهزاین هب هجوت ،هناروآون هیحور یروآرف شخب رد هبرجت لاس لهچ و Tecnopool ، طیاشر نیا اب .ییاذغ داوم هعسوت ریسم رد 2015 لاس رد .S.p.A 2019 لاس رد هک تفرگ رارق دشر و TECNOPOOL لیکشت هب رجنم .دــش TP FOOD GROUP ، هتشذگ لاــس دنچ یط .تاباستکا هورگ هب اه تــکشر زا یا هعومجم Alit :دنتسویپ Tecnopool لوپنکت ،ینوولسا( Gostol ،)2015 ،ایلاتیا( و )2017 ،ایناپسا( Tecnofryer ،)2016 Logiudice Forni ، Mimac نینچمه صصخت .)2018 ،ایلاتیا( Mecateck و همه عماج شزادرپ راکهار ،هورگ یبیکرت یارب هورگ نیا .تسا هدرک لاعف ار هبناج هئارا و یروانف هعسوت موادم یریگیپ کی ، نایترشم هب لااب ییاراک اب تازیهجت :تسا هدرک نییعت ار یلصا تیرومام وشریپ هدننک نیمات کی هب ندش لیدبت لماک طوطخ و تلاآ نیشام هنیمز رد یتعنص همین ، یتعنص شزادرپ یارب دیلوت .ییاذغ داوم تعنص رد یتسد عیانص و زا شیب رد TP Food Group هزورما دیلوت ،یحارط هنیمز رد ناهج روشک 80 ،ییاذغ داوم شزادرپ تازیهجت بصن و یشرافس" یاهراکهار هب یوق شیارگ اب یلصا هدننک نیمات و رازاب وشریپ ،"یزاس رد شدرف هب صرحنم روضح اب .تسا شخب رد یلصا شقن اب ،ناهج سراسر TP Food Group ،ییاونان تلاوصحم یاهدترسگ فیط فطل هب دناوتیم ات کچوک رگتعنص ره زا ،اهقاجا زا نیترلماک ات ،یتعنص همین هاگشیامزآ ار یترشم تساوخرد ره ،یتعنص طخ :دیلوت لحارم هیلک لماش ،دنک هدروآرب .یدنب هتسب ات ریمخ یزاس هداــمآ زا عیانص ات هتفرگ کچوک یاوــناــن زا هعسوت نیا تشپ هدیا .گرزب ییاذغ اب :تسا هنازاورپدنلب و هداس ،هفقو یب اب بسانتم و لماک دیلوت طوطخ هئارا اهراکهار نیترهب ،)یشرافس( نایترشمزاین اهراتخاس .دهد هئارا اهنآ یاهزاین یارب ار ار یترشم لیخت یشرافس یاهدنیآرف و تسا لیلد نیمه هب .دنکیم دودحم اهنت TP Food Group ،رادیرخ ره یارب هک ار راــگزاــس و یشرافس یاهمتسیس یصاخ زاین ره و یزاس هدایپ و هعلاطم و قیقحت ،هبرجت .دنکیم هدروآرــب ار هب تیلاعف ههد نیدنچ یط هک ،شناد ات دهدیم هزاجا هورگ هب ،هدمآ تسد داجیا یصاصتخا و یلیلحت یدرکیور ینارحب هبنج ره یبایزرا زا سپ .دنک دناوتیم تــکشر ،یترشم اب هارمه هتفای دوبهبراکهار و هناروآون تلاوصحم .دهد هئارا دوجوم دراوم اب هسیاقم رد ار ثعاب تکشر یاهشزرا اب یوق یاهدنویپ هب یبایتسد یور هورگ هک تسا هدش یناهج یاپدر اب قفوم یراجت لدم کی :TP FOOD GROUP 43

TP FOOD GROUP: A SUCCESSFUL BUSINESS MODEL WITH A GLOBAL FOOTPRINT

IInnovative spirit, attention to customer needs and forty years of experience in the food processing sector. With these premises, Tecnopool S.p.A. embarked in 2015 on a development and growth path which, in 2019, led to the formation of TP FOOD GROUP

The acquisitions. Over the past few years, a series of companies joined Tecnopool Group: Alit (Italy, 2015), the Gostol (Slovenia, 2016), the Tecnofryer (Spain, 2017) as well as Logiudice Forni, Mimac and Mecateck (Italy, 2018). The combined expertise of the Group has enabled a well-rounded Total Processing solution offering. To constantly pursue technological development and provide customers increasingly high-performing equipment, the

group has set one main Mission: to become a global leading supplier of machinery and complete lines for industrial, semi-industrial and artisanal food processing. Today, TP Food Group is a market leader and key supplier in over 80 countries around the world, for the design, production and installation of food processing equipment, with a strong orientation towards “Tailor Made” solutions. As a unique, worldwide player, with a leading role in the Bakery Products sector, TP Food Group can satisfy every customer request, thanks to a wide range of ovens: from the small artisan to the

semi-industrial laboratory, up to the most complete industrial line, covering all manufacturing processes: from dough preparation to packaging.

From the small baker to the large food industry. The idea behind this relentless development is simple and ambitious: to provide customers with the best solutions for their needs, by designing complete and tailor made lines. Customized structures and processes leave customer’s imagination as the only limit. That is why, for each buyer, TP Food Group studies and implements customized and flexible systems, meeting every

PASTA BAKERY - CONFECTIONERY اتساپ

یندیشون و ییاذغ عیانص ی هلجم 44

specific need. Experience, Research and the Knowledge, gained over decades of activity, allowed the group to develop an analytical and dedicated approach. After evaluating any critical aspect together with the customer, the company can offer innovative products and improved solution compared any existing one. Strong ties with company values are leading the Group to focus on meeting high quality for its products and delivering excellent level of support services before and after sales. The Group companies are proud of the timely and accurate support that can be provided 24 hours a day, 7 days a week, which represents a strong competitive advantage in the market. Periodic check-ups and direct remote support allow customers to prevent critical interruptions and downtime, ensuring continuity in the plant production process.

The Research and Development efforts, focused on introduction of innovative technological solutions, aim at continuously improving manufacturing processes to further optimize customer production rates and costs. Of course, the quality of the product is paramount as well as a considering “energy saving” and environmental aspects.

Having the possibility to test every type of product, with the supervision and assistance of experienced technologists and specialized technicians, represents an important added value.

TP Food Group customers can benefit from this opportunity, thanks to a fully equipped Test Room, where key users can take advantage from a wide range of equipment made available to them.

• Tecnopool: World leader in the design, manufacturing and installation of equipment for complete production lines, covering food industry heat treatments during all stages of processing: proofing, baking, cooling, freezing and pasteurization, from - 40 C ° to + 300 ° C, with infinite fully customizable layout configurations.

• Gostol: Provider of integrated industrial solutions for bakeries. Offering both thermal cycle and convection as well as diathermic oil deck ovens, including integrations services for the bakery equipment. Addressing medium and large industries, while covering make-up, molding and leavening processes.

• Tecnofryer: manufacturer and supplier of innovative industrial,

semi-industrial and semi-artisan fryers, for various food sectors: from bakery to meat, from breaded products to snacks and peanuts, also covering pet food products.

• Logiudice Forni: Leading manufacturer producing professional steam tube deck ovens, electric ovens, rotary ovens and professional spiral mixers for bakeries, pastry shops and pizzerias.

• Mimac: Leading manufacturer of dropping machines for the confectionary industry: he best solutions to concretely satisfy the production needs of artisan shops, semiindustrial producers and the large retail sector.

• Mecateck: builder of tunnel and multi-level lines and ovens for the industrial and semi-industrial sector.

TP Food Group is positive and determinate about its future, driven by the strength of six leading worldwide recognized companies. Constant commitment and ambition will be the leitmotif for continuous growth, to remain on the leading edge of a constantly evolving market.

PASTA BAKERY - CONFECTIONERY اتساپ

یندیشون و ییاذغ عیانص ی هلجم 45

www.tecnopool.it

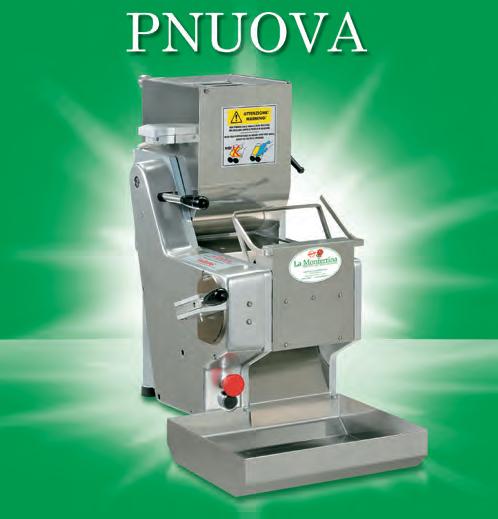

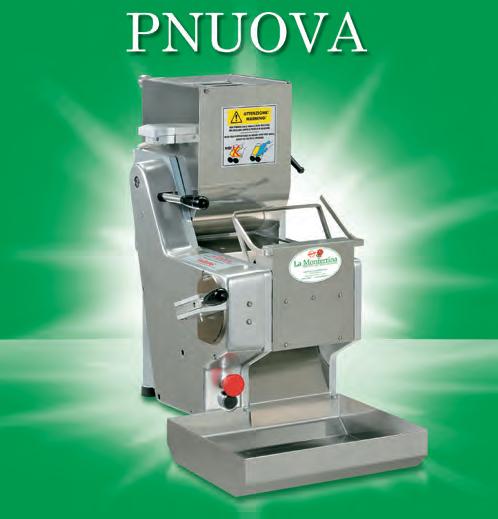

PASTA BAkery - CONFeCTIONery اتساپ انیررفنم و )Imperia( ایرپما تکشر 2010 لا��س رد )Monferrina( هک Imperia ه��ک ی��نا��مز د��ش دا��ج��یا ،دوب هد��ش یراذ��گ هیاپ 1936 لا��س رد 1978 لاس رد هک ار Monferrina ندش یکی .درک یرادیرخ ،دوب هدش سیسات یوگخساپ هک درک داجیا ار یتکشر ،ود نیا زا یعیسو فیط اب اه ت��ساو��خرد ما��تم .دشاب یم اتساپ دیلوت یار��ب تلاوصحم ،ینیلدیف ،ینیللپاک ،یلگیب - دنلب یاتساپ • ،گرزب یتگاپسا ،یتگاپسا ،یگنول یلیزوف ،ینیچنللیپسا کچوک یتگاپسا ،لشیمرو ،گرزب لشیمرو ،یلککرت یللراننت ،ارراتیک َللا یتگاپسا یلکیرفنم،لویریچ ،یللیتلااش ،هنیاوگنیل ،کچوک یتواب ،تتواب ،دلَفم ،ک��چو��ک ی هنیاوگنیل ،تتنیجر ،ک��چو��ک ی دلَفم یللپَک ،نیبراب ،نیلپیرت ،تتنرت چچوتتف ،چچوتتف ،رنولپَک ُل گند ،اینازلا ،چچاینرف ،کچوک ی ،گرزب یاینازلا ،کچوک یاینازلا ،یللتلااش ،یرککزتیپ ،للدراپپاپ ،یزتگنرت ،یزتگنتسا ،یزتگنیتسا ،ینیریلت ،ینیلویلت ،للتایلت .یتتراملااک ،اتاراملااک ،ینیتاکوب ،یللناگراگ - هاتوک یاتساپ • ،تر����ف د ک��ی��ن��م ،ی��نر��ک��ک��م ،یتتکنم ،یللچینرککم ،یچینرککم ،کچوک یندبب ،کچوک ی هننپ ی هننپ ،اتیز ی هننپ ،هننپ ،یرککپ ،یللتاچرپ ،گرزب ی هننپ ،کیراب ،ینادس ،ینتاگیر ،ینیچنتاگیر ،)ینوزلح(ینیلچایک،کچوکینادس یتیز ،یلُففوت ،ینویلیترت ،یتتیکرت ،للزناتاک ،نلالتساک ،چ��چرازا��ک ،لناپمَک ،یلیکنُک ،ینچنچ ،یتتکچ ،ی��ل��ل��تاوا��ک ،یا هناورپ ،ُل��ل��گ ید تسرک ،ینولیکنُک ،یلیج ،یللمج ،یتاکوب یلیزوف ،یلیزوف یتکوینیا ،یدراس یتکوینیا ،یکوینیا ،لدناریج ،ینوکامول ،کامول ،نتنل ،اینیمارگ ،ینامر ،کچوک کینم ،کینم ،یتتَفلم ،یتایلتلم ،یروتایدار ،یا هلول ،یلتسسپ ،یا هراوشوگ .یفرت ،یترپززتتسا ،گیپسا ،تور ،یلچچیر ،ینیلنا ،یتتلوینا – هدشرپ یاتساپ • ،نولزتم ،یللچنزَک ،یتللپپَک ،ینللنَک یللترت ،یللترت ،یلویوار ،یجریپ ،ینملپ .یچلاترت و گرز���ب ی��ل��ل��تر��ت ،ک��چو��ک .یکوینیا ،پرک – هریغ زا شیب هب تارداص یاراد تکشر عقاو رد .دشاب یم ناهج سراسر رد روشک 130 :دنراد هراشا فلتخم فده ود هب دنرب ود یاتساپ تلاآ نیشام رد صصخت یاراد ایرپما دشاب یم کچوک ی اه ناروتسر و یگناخ نیشام ی هدننک دیلوت انیررفنم هکیلاح رد اهروتاربلا ،تگرزب یاه ناروتسر یارب تلاآ انیررفنم ،تقیقح رد .دشاب یم عیانص و پرک ،یکوینیا تلاآ نیشام ی هدننک دیلوت تلاوصحم ی همه .دشاب یم یلویوار و اه .دنشاب یم ایلاتیا تخاس %100 www.imperia.com www.la-monferrina.com 1932 لاس زا اتساپ دیلوت تلاآ نیشام ی هدننک دیلوت 46

Since 1932 manufactures of paSta machineS

Imperia e Monferrina was born in 2010 when Imperia, established in 1932, bought La Monferrina established in 1978. The joint of these 2 companies created a company that answers all the requests with a range of products for pasta production.

• Long Pasta: Bigołi, Capellini, Fidelini, Fusilli lunghi, Pici, Spaghetti, Spaghettoni, Spaghettini, Spilloncini, Troccoli, Vermicelloni, Vermicelli, Spaghetti alla chitarra, Tonnarelli, Scialatielli, Ciriole, Manfricoli Bavette, Bavettine, Linguine, Linguettine, Mafalde, Mafaldine, Reginette, Trenette, Tripoline, Barbine, Capelli d’angelo, Capelvenere, Fettucce, Fettuccine, Fregnacce, Lasagne, Lasagnette, Lasagnotte, Pappardelle, Pizzoccheri, Scialatelli o Scialatielli, Stringozzi, Strangozzi, Trongozzi, Tagliatelle, Tagliolini, Taglierini, Bucatini, Calamarata, Calamaretti.

• Short Pasta: Garganelli, Maccheroni, Maniche da frate, Maccheroncini, Maccheroncelli, Manicotti, Mezze Penne, Mezzi Bombardoni, Paccheri, Penne, Penne Zita, Pennette, Pennoni, Perciatelli, Rigatoncini, Rigatoni, Sedani, Sedanini, Chiocciolini, Torchietti, Tortiglioni, Tuffoli, Ziti, Campanelle, Casarecce, Castellane, Cataneselle, Cavatelli, Cechetti, Cencioni, Conchiglie, Conchiglioni, Creste di gallo, Farfalle, Fusilli, Fusilli bucati, Gemelli, Gigli, Girandole, Gnocchi, Gnocchetti sardi, Gnocchetti romani, Gramigna, Lanterne, Lumache, Lumaconi, Maltagliati, Malfatti, Maniche, Mezze maniche, Orecchiette, Passatelli, Pipe, Radiatori, Riccioli, Ruote, Spighe, Strozzapreti, Trofie.

• Filled Pasta: Agnolotti, Anolini, Cannelloni, Cappelletti, Casoncelli,

Mezzelune, Pelmeni, Pierogi, Ravioli, Tortelli, Tortellini, Tortelloni & Tortellacci.

• Others: Crepes, Gnocchi.

Actually, the company exports in over 130 Countries worldwide.

The 2 brands referres to different targets: Imperia is specialized in home and small restaurants pasta machines, while La Monferrina produces machines for bigger restaurants, laboratories and industry.

Infact La Monferrina even produces gnocchi machines, crepes machines and ravioli machines. All products are 100% Made in Italy

www.imperia.com

www.la-monferrina.com

PASTA BAkery - CONFeCTIONery اتساپ

47