FULL CIRCLE: FRANKI'S JOURNEY BACK TO PAARDEN EILAND 04 MATHE GROUP’S RECYCLED RUBBER HITS THE ROAD 42 APRIL 2024 | No 1180 28 CONCRETE MASTERY TRANSFORMS WATERFALL CITY SKYLINE SOUTH AFRICA collaboration WITH PROGRAMME DIRECTOR: Vikashnee Harbhajan T IM E ACTIVITY SPEAKERS

South African Builder is the official journal of Master Builders South Africa, established in 1923. The opinions expressed by contributors are not necessarily those of Master Builders South Africa. SA Builder is a registered trademark of Master Builders South Africa. Any use of this trademark without the express and written approval of Master Builders South Africa is prohibited. No material contained herein may be reproduced in whole or in part without the prior written permission of the publisher. SA Builder © 2024. All rights reserved.

02 From the president’s desk

COVER

04 Full circle: Franki's journey back to Paarden Eiland

MBA NEWS

07 MBA North emphasises benefits of safety as regional safety rompetition closes

10 How construction firms shjould prepare for extortion

INDUSTRY NEWS

13 Five stars for Vodacom and WSP

14 Peikko SA launches an online shop

16 Building a future for young pupils

17 Concor builds momentum with fasttrack projects

BUSINESS

19 2024 earnings threshold announced FEATURES

21 Standard established for Precast concrete grandstands

24 Peri’s brand-new team tailored solutions for formwork requirements

HEALTH AND SAFETY

26 Atlas Copco’s new wellness programme for children’s mental well-being

PUBLISHER

Isikhova Media (Pty) Ltd 10th Floor, Metal Box, 25 Owl Street, Milpark, Johannesburg, South Africa

Tel: +27 11 883 4627 www.sabuilder.co.za www.isikhova.co.za

CONTRIBUTIONS

Master Builders South Africa

Tel: +27 11 205 9000

PRODUCTS

28 Mathe Group’s recycled rubber hits the road

30 A logical solution

31 Bobcat showcases new material handling line-up at LogiMAT 2024

32 Eva-last: the benefits of composite decking

SKILLS AND TRAINING

34 Upcoming events

TRENDS

38 The role of the private sector in affordable housing

PROJECTS

40 Honouring a legend

42 Concrete mastery transforms Waterfall city skyline

GLOBAL VIEW

44 Nigeria’s new Knowledge Zone

CAPTAINS OF CONSTRUCTION

46 Kagiso Maleka

E-mail: editor@sabuilder.co.za www.masterbuilders.org.za

Managing director: Imraan Mahomed E-mail: imraan@isikhova.co.za

Creative director: Phumi Vilakazi E-mail: phumi@isikhova.co.za

Sales director: Thuli Majola E-mail: thuli@isikhova.co.za

Copy editor: Anne Phillips

Advertising

APRIL 2024 SOUTH AFRICAN BUILDER 01 CONTENTS

CONTENTS

+27 11 883 4627 Mobile: 072 383 3203/083 450 6052 17 31 24 42

download available on:

Twitter: @Builders_SA | Facebook: @SouthAfricanBuilder

sales: Tel:

Free

www.sabuilder.co.za

savvy thinkers smart doers together people

STORY

MESSAGE FROM THE PRESIDENT

The stability and strength of the construction industry are gradually improving, although growth is very slow.

Despite rocky years in the industry, forecasts are generally positive. The SA Construction Market Report overview projects that the industry will achieve an average annual growth rate of more than 3% from 2024-2027. Nevertheless, there are challenges ahead for it this year, including ongoing load-shedding, increases in material and labour costs, construction site invasions, labour shortages, lack of access to funding, slow technology uptake and the slow turn-around time on building plans.

In January this year, building approvals nationally declined for the seventh consecutive month, with a 13% decrease year-on-year. The Free State saw a significant

EDITOR'S NOTE

increase, while other regions like Limpopo and KwaZulu-Natal showed modest improvements. However, overall national trends show lower approval rates than last year.

Gauteng and the Western Cape led in approved square metres, but the Western Cape experienced the strongest decline year-on-year. Affordability issues persist, especially in provinces like the Western Cape, where house prices are high. The Free State was an exception, with increased demand, mainly in retail, industrial and housing sectors.

Despite the market decline, there are opportunities in smaller provinces and specific market segments. Rising inflation and increased bond repayments are putting pressure on consumers. The 2024 budget reflected adjustments in energy and

One quarter of the way into the year, the construction industry – like all other sectors – is contending with a myriad of challenges, including continuing service delivery issues, an ever-weakening rand and high unemployment.

In its feature, How Construction Firms Should Prepare for Extortion, in this issue, MBA North also discusses the persistent scourge of the “construction mafia”, offering crucial guidelines for companies to protect themselves and their workforces.

On a more positive note, we highlight the full circle Franki has come, from and back to Paarden Eiland. We also feature two outstanding initiatives – Atlas Copco’s wellness programme for mental health

water, but social infrastructure funding was reduced, impacting sectors like health, education and housing.

As MBSA, we urge government and private investors to invest in the infrastructure of our country. It must be noted that the role of the construction sector in the economy is vital due to its direct and in indirect impact on development. The industry plays a key role in capital accumulation, as well as the creation of jobs and income to households, and it has the potential to bridge inequality in the economy.

Musa Shangase, MBSA president

among children and the long-overdue renovation of former President Nelson Mandela’s residence in Houghton, Johannesburg, at last honouring the great man’s legacy in the home where he lived and died.

We also focus on Corestruc’s remarkable track record of erecting concrete structures in double-quick time, without compromising on the impeccable quality which makes the company a leader in its field.

Like the rest of the country, SA Builder waits with bated breath for what is likely to be the most significant election we have had since the advent of democracy. We remain optimistic that whatever changes it heralds will augur well for our industry, as a key driver of South Africa’s economy and growth.

SOUTH AFRICAN BUILDER APRIL 2024 2

YOUR PRECAST

PRODUCTS

Storm Water

Electrical

Markers

Water Reticulation

Outdoor & Building

Polymer Products

Mining Solutions

Kerb Inlet & Road Products

Custom Products

SERVICES Moulds

Drawings

always the last piece in a puzzle that goes missing!

‘cause we’ ve got it!

It’s

That’s

CONCRETE SPECIALIST TWINSTAR PRECAST solves those diffi cult, one-off jobs that make civil engineering & construction challenging. Address: Unit 21, Hunky Dor y Business Park, 9 Goedehoop Avenue (M57), Olifantsfontein Telephone: (012) 670 9083 E-mail: info@twinstar.co.za

FULL CIRCLE: FRANKI'S JOURNEY BACK TO PAARDEN EILAND

By Roger Feldmann, business development manager: Keller Geotechnics SA

Arial photography by Byron Strydom (Ruwacon).

In the vibrant tapestry of South Africa's construction history, Franki stands as a stalwart pioneer, shaping the landscape with innovative foundation solutions since 1946. Established by Wally

Rowland, Frankipile in South Africa began as a subsidiary of Frankipile International, a renowned Belgian-based piling company. As we continue to write our story, our recent project, a multi-franchise vehicle dealership in Paarden Eiland, serves as a poignant reminder of our rich heritage and ongoing commitment to excellence in the specialised geotechnical engineering sector.

THE BIRTH OF FRANKI: A LEGACY BEGINS FOR CLIENT AND CONTRACTOR IN PAARDEN EILAND

In 1946, Franki made its mark in South Africa as a pioneering force in piled foundation technology. The first office in Cape Town marked the beginning of a remarkable journey rooted in the traditional “Franki” pile, backed up with expertise from abroad. From the fledgling start of the first contract – the installation of eight piles for a small building in Paarden Eiland – Franki has demonstrated the capability and capacity to handle large and complex geotechnical projects across Sub-Saharan Africa and the Indian Ocean Islands

Paarden Eiland was declared an industrial area in 1935 and was heavily developed after World War II, which ties up with the early records of Frankipile‘s activity in this area. This new industrial suburb boasted one of the country’s first motor assembly plants which, to this day, is still a popular location for the motor industry.

The historic suburb of Paarden Eiland thus witnessed the birth of Franki that would shape the future of geotechnical construction in South Africa. Paarden Eiland means “island of horses” in Afrikaans. It was given this name in

SOUTH AFRICAN BUILDER APRIL 2024 04 COVER STORY

(Below): Ruwacon towers over Paarden Eiland.

honour of the wild horses or zebras which roamed the area in the days of Jan van Riebeeck.

PIONEERING PILED FOUNDATIONS: A TRADITION OF EXCELLENCE

Franki's expertise in piled foundations has certainly contributed to the local construction industry, enabling the development of many iconic structures and major infrastructure projects across South Africa. Through decades of experience, Franki has earned a reputation for offering “design and construct” service for specialised foundation solutions, with unparalleled quality and unwavering resilience to the typical cyclical construction industry in South Africa. Piled foundations have since become synonymous with stability, durability and efficiency, thanks to Franki’s pioneering spirit.

FROM FRANKI TO KELLER: CONTINUING THE TRADITION OF EXCELLENCE

In 2013, Franki was bought by Keller, a global leader in geotechnical solutions. While the company is now known as Keller, the original name of Franki remains a household name for the construction industry and geotechnical contractors in South Africa. This transition further strengthened Franki's capabilities and expanded its reach, while preserving its legacy of excellence.

RETURNING TO ITS ROOTS: FRANKI'S JOURNEY BACK TO PAARDEN EILAND

Coincidentally, Franki finds itself back in Paarden Eiland, near the

“THE FORD MOTUS CAR DEALERSHIP PROJECT SHOWCASES KELLER'S ABILITY TO BLEND CUTTING-EDGE TECHNOLOGY WITH TIME-TESTED TECHNIQUES, ENSURING SUPERIOR FOUNDATION RESULTS.”

site of its inaugural project, to undertake the piling for the new multi-franchise vehicle dealership.

This convergence of past and present symbolises Franki’s enduring commitment to South Africa's challenging construction environment and its continuous quest for excellence. The new project not only highlights Franki’s resilience over the past 78 years, but also reaffirms its historical ties to Paarden Eiland, where it all began.

HONOURING TRADITION, EMBRACING INNOVATION

While rooted in tradition, Keller still installs the original “Franki”-type pile with the unique bulbous base and loa- carrying capacity, while

embracing innovation to meet the ever-evolving needs of the construction industry. A large portion of Paarden Eiland is built on reclaimed land, which is quite variable in nature and certainly not conducive to founding new structures such as the proposed dealership. The imported fill material used in land reclamation can contain rubble and refuse, and is typically highly variable in its compressibility. These conditions are ideal for the “Franki”-type pile, often referred to as the “silver bullet” of pile types because of its ability to deal with a myriad of different soil conditions, with a load-carrying capacity of up to 2 200kN on a 610mm-diameter “super-heavy” pile. The project showcases Keller’s ability to blend cuttingedge technology with time-tested

APRIL 2024 SOUTH AFRICAN BUILDER

05 COVER STORY

(Below): Franki Rig No SA 1084 installing the time-tested “Franki”- type pile.

techniques, ensuring superior foundation results.

CO-ORDINATED CONSTRUCTION: ORCHESTRATING THE EVOLUTION OF THE NEW MULTI-FRANCHISE VEHICLE DEALERSHIP

Navigating through the intricacies of the new multi-franchise vehicle dealership project entails a meticulously planned twophase approach, emphasising collaboration between Franki, Ruwacon and the client. Phase 1 involves the strategic demolition of half of the existing building, making way for the construction of the new dealership premises. Upon completion, the client will transition into the newly erected structure, marking the commencement of Phase 2. In this subsequent phase, the remaining portion of the building

will be constructed to finalise the dealership’s expansive layout. The orchestrated sequence of phases ensures minimal disruption to the client’s operations, while allowing for the continuous evolution of the dealership’s facilities. This intricate construction challenge demands careful co-ordination and synchronisation among all stakeholders, exemplifying the dedication to precision and efficiency characteristic of the project’s collaborative approach.

In the collaborative effort to bring the new multi-franchise vehicle dealership to life, Ruwacon serves as the main contractor overseeing the project’s execution. Leveraging its expertise and experience, Ruwacon has meticulously planned the construction process, ensuring seamless co-ordination among various stakeholders. After a rigorous and vibrant

tendering process, Ruwacon was awarded the main contract and subsequently awarded the piling contract to Keller, recognising its unmatched proficiency in geotechnical solutions. As a toptier South African construction firm founded in 1999 by the current MD, Pieter Ruthven, Ruwacon boasts over 24 years of success in the industry. Its commitment to excellence and dedication to delivering exceptional results have solidified its reputation as a trusted partner in the construction sector. With Ruwacon at the helm, alongside Keller’s specialised expertise in piling, the project stands poised for success, embodying the synergy of industry leaders coming together to achieve a common goal.

LOOKING TOWARDS THE FUTURE: KELLER'S CONTINUING LEGACY

As Keller forges ahead into the future, Franki’s rich history remains an integral part of Keller and the construction industry in South Africa, including its indelible identity and reputation. With a commitment to sustainability, integrity and excellence, Keller continues to uphold the legacy of Franki, while driving progress and innovation in the construction sector. The journey that began in Paarden Eiland in 1946 is far from over, as Keller – with Franki’s legacy at its core – continues to shape the landscape and build the foundations for a brighter tomorrow.

SOUTH AFRICAN BUILDER APRIL 2024

(Above): Phase 1 of the new Motus dealership nearing completion in the foreground.

06

COVER STORY

MBA NORTH EMPHASISES BENEFITS OF SAFETY AS REGIONAL SAFETY COMPETITION CLOSES

Entries for this year’s Master Builders Association North Regional Safety Competition have now closed and the adjudication or auditing phase has begun. Gerhard Roets, construction health and safety manager at MBA North, says the annual competition highlights the importance of safety in an intrinsically dangerous industry like construction.

“Ultimately, any business is only as good as its people and the same is true of industries. Our people are the core of our success and protecting our human capital makes sense on every level,” he says.

Statistics collected by the Federated Employers Mutual Assurance Company (FEM) over

the years show which areas of the construction business cause the most fatalities. Motor vehicle accidents cause the most deaths (six in 2023), followed by the “Struck by” category (four) and “Falling from different levels” (two). In terms of the overall number of accidents, “Struck by” leads the pack, with 857 accidents.

Aside from the human cost of accidents on site, FEM’s statistics indicate the financial cost involved. The average cost per incident for motor vehicle accidents is R112 446, while “Struck by” incidents cost on average R57 815. “Falling from different levels” incidents cost an average of R99 189 each. High costs like these can impact a company’s bottom line significantly, especially given

the industry’s low margins.

“Improved safety reduces the costs and downtime caused by accidents. It also lessens ongoing costs for medical insurance, worker compensation claims and so on,” says Roets. “A better safety record also impacts the firm’s legal position as regards compliance with safety regulations and, above all, enhances its reputation with clients and employees.”

Previous award-winner, VIVA Group, commented on the benefits of winning an award. “Our core scope, temporary works, is in one of the highest risk categories, which means we need to take additional care to ensure the safety of our people and the project. Placing or winning in a category is

APRIL 2024 SOUTH AFRICAN BUILDER MBA NORTH

07

MBA NORTH

a badge we at VIVA wear with great pride,” says VIVA Group director Thor van Eunen. “It shows our trusted customers that we’re going the extra mile in ensuring their project is delivered to the highest possible safety and compliance standard.

“Entering the competition allows us to accurately gauge how we as VIVA compare with the rest of the industry – and we’re starting to see more of our competitors enter the competition with MBA North, which is great. The construction industry, specifically in the formwork and scaffolding sector, is full of guys trying to take shortcuts that don’t meet the minimum requirements to be compliant on site. The competition highlights those in the industry who’re looking to improve their safety and compliance, as opposed to hiding away from it. It's all part of making our industry a safer place to work.”

Lester Stubbs, safety manager at WBHO, agrees, saying that MBA North’s safety awards is a significant milestone. “It’s not just a check on our safety standards; it's a chance to see how well we’re doing in our jobs compared with others. Importantly, the results aren’t just about recognition; they directly benefit all of us working on site.

“The real motivation comes from being in a room filled with likeminded individuals. This shared space encourages every company to step up their compliance game, ultimately contributing to a safer industry and better working conditions for everyone,” he says.

This year’s entrants dropped to 67, with a higher total project value of R13,3 billion, compared with 78 entries with a total project value of R10,6 billion in 2023. Roets says this is likely a sign of the tough economic conditions prevailing in the industry, with many wellestablished companies having gone bankrupt or in business rescue.

The audit process ends on 30 May. Roets says there were three auditors, each of whom handled all the audits in a category. “That’s very important in ensuring we get a consistent rating across the category,” he says.

Category winners of the regional competition will go forward into the national awards programme, which will be adjudicated during June and July. However, MBA North’s Regional Competition category award-winners will only be announced publicly at a function in August, with the national award ceremony scheduled for September.

MBA North’s focus on safety is not restricted to the awards programme. It runs regular safety and compliance workshops for members, making it possible for smaller, less well-resourced firms to improve their safety posture.

is playing a part in driving the safety message home,” says Roets. “These awards, along with our regular workshops, have also driven higher levels of compliance with the Department of Employment and Labour’s health and safety guidelines.”

“Over the years, FEM’s statistics show that our safety record as an industry is improving and we can assume that this safety competition, which we’ve been running for more than 40 years,

SOUTH AFRICAN BUILDER APRIL 2024 8

One Day OHS Compliance Seminar: REPUTATIONAL DAMAGE IN THE CONSTRUCTION INDUSTRY 16 April 2024 11:30 – 15:00 17 April 2024 08:30 – 13:00 VENUE: CMA OFFICE PARK, NO. 1-2ND ROAD, HALFWAY HOUSE, MIDRAND PROGRAMME – ––– ––– ––– – –– –– –––PROGRAMME – ––– –––– – –– –– –––R 695,00 – MBA North members & FEM policy holders R 895,00 – Non-members RSVP by 12 April 2024

HOW CONSTRUCTION FIRMS SHOULD PREPARE FOR EXTORTION

Extortion in the construction sector has reached worryingly high levels, derailing and delaying projects worth billions of rands. With no signs of this trend reversing, construction firms should build extortion preparation and best practices into their planning ahead of every project.

This is the advice of Roelof Viljoen, national project manager at Business Against Crime SA (BACSA), which is the primary point of contact for business interaction with government on crime and corruption through government structures, including the National Priority Committee on Extortion and Violence at Economic Sites – a body in which MBA North also participates.

Viljoen explains that extortion requires two factors: the demand for a benefit such as money, work or a contract, as well as a threat of damage or harm to individuals should the demand not be met. Business forums, or so-called “construction mafias”, put pressure on developers and contractors to pay them or risk lock-outs, strike action or violence.

“Some of these syndicates are highly organised and linked to legitimate businesses or even highly connected individuals in

the community,” he says. This, he notes, could make local law enforcement slow to react to complaints.

“Some construction firms simply pay the extortionists so they can get on with business. However, if the extortionists are paid off, it might work as a short-term solution, but you may have created a precedent and they’re likely to come back,” he adds. “Giving in to the demands of extortion encompasses corruption, which implies that the company’s guilty. Industry isn’t opposing development, but can’t contribute to someone’s wealth without a return on investment. Alleged slow transformation can’t be a valid reason for crime.”

Viljoen says developers and contractors should prepare for possible extortion at every site, training staff and building awareness of the correct procedures to follow should anyone attempt to extort money.

“In principle, it’s about being aware of who’s allowed on site and what the procedures are if extortionists do venture onto it,” he explains. “As part of briefings for new staff, you need to outline the procedures for managing extortion. The site manager or another senior person should also be made responsible for handling these occurrences. You might also need to have external or internal negotiators who manage extortion situations.”

SOUTH AFRICAN BUILDER APRIL 2024 10 MBA NORTH

Images by Freepik

Viljoen adds that some developers now also appoint legal representatives to liaise with the local police, notifying them that construction is about to begin and stating the expected police response time, should extortionists threaten or delay the project.

“It’s important to be prepared,” he says. “The key is to identify a possible incident before it starts escalating. Even if you get a threatening phone call or a threat on WhatsApp, don’t just shrug your shoulders. If you, as an individual, feel threatened, it qualifies as a risk. Make a note of it and report it to senior management. If you have on-site security, report it to them too – they’ll also have procedures and reporting structures in place.”

BACSA’S GUIDELINES INCLUDE:

• Outline and document a set of safety procedures that must be followed if there is an extortion attempt.

• If the project is a private project/development, place a notice at the entrance stating that preferential procurement regulations do not apply.

• If it is a public project, place a notice stating that preferential procurement regulations have already been complied with.

• Hold documentation on hand on site to confirm this.

• Seek local sub-contractors to include the local communities

“GIVING IN TO THE DEMANDS OF EXTORTION ENCOMPASSES CORRUPTION, WHICH IMPLIES THAT THE COMPANY’S GUILTY. INDUSTRY ISN’T OPPOSING DEVELOPMENT, BUT CAN’T CONTRIBUTE TO SOMEONE’S WEALTH WITHOUT A RETURN ON INVESTMENT. ALLEGED SLOW TRANSFORMATION CAN’T BE A VALID REASON FOR CRIME.”

MBA NORTH

7075 A.Shak Constr SA BUILDER 1/2pg APRIL’24 Use Quality Formulated Products, including Application-specific Release Oils, to enhance your construction efforts from routine to PROFESSIONAL: • Tel: + 27 11 822 2320 • Fax: + 27 11 822 2354 • e-mail: cindy@ashak.co.za • Bonding Agents • Chemical Anchors • Concrete Bonding • Concrete Crack Repairs • Concrete Release Agents • Concrete Repair Mortars • Curing Compounds • Epoxy Adhesives • Epoxy Grout • Joint Sealants • Non Shrink Grouts • Pre Cast Repairs • Water Proofing build with confidence!

MBA NORTH

before being approached by a business forum.

• Do not allow business forums on site to discuss preferential procurement options.

• Explain that on-site personnel are not empowered to make decisions about the allocation of work.

• Explain that it is illegal to sub-contract without a bidding and tender process.

• Create a safe area for employees on site. This could prove challenging on new sites, but could be an area as far as possible from entrances.

• Ensure there is an alternative exit, if necessary.

• Install CCTV recording

equipment, if possible. Record any irregular (unarranged) interaction with a cellphone, if necessary, to capture evidence of a situation that may develop into extortion.

• For operational response, log any extortion incidents with BACSA and the police. The most efficient method is to involve a service provider participating in the Eyes and Ears Initiative (E2), an official joint crime-fighting initiative between the police, BACSA and the private security industry (PSI). E2 records all reported incidents and has direct communication with operational police.

• Every extortion incident must be recorded as a crime to the police. A case is not required to be reported at the station in whose area the crime

occurred. Once a crime is reported (and a case number generated), the investigation will be allocated to the appropriate investigating officer.

• Follow the procedures and guidelines by BACSA for successfully prosecuting a case of extortion in court.

Mohau Mphomela, executive director at MBA North, says it is cause for serious concern that extortion has become so widespread that construction firms now view it as yet another routine challenge. “This form of crime increases the costs of doing business for our members and puts companies and jobs at risk. We commend BACSA for coming up with these guidelines and we urge all members to heed them when preparing to deal with construction extortion,” he says.

12 SOUTH AFRICAN BUILDER APRIL 2024

FIVE STARS FOR VODACOM AND WSP

Following an extensive collaboration between Vodacom and WSP in Africa to drive sustainability and green building design at the telcom provider’s Business and Corporate Parks at its headquarters campus in Midrand, the Green Building Council of SA (GBCSA) awarded both buildings five-star Existing Building Performance (EPB) certifications.

Vodacom is a long-standing client of WSP in Africa, with both companies sharing a commitment to environmental stewardship and sustainable innovation. The certifications, underpinned by the sustainability consulting services provided by the WSP Built Ecology team, are a testament to the implementation of sustainable design principles at both buildings.

This achievement is underpinned by WSP’s comprehensive sustainability services, including building performance benchmarking, energy modelling and the development of bestpractice guidelines. WSP in Africa has been involved in over 50 diverse sustainability projects across industry sectors to provide the company with a strong foundation. This experience enabled WSP to implement cutting-edge sustainability

solutions at Vodacom’s buildings. These included advanced energyefficiency measures, water conservation strategies and the integration of renewable energy systems.

Vodacom Business Park is a two-storey office building that spans 4 900m². The reception enters into a double-volume atrium. Virtually all of the lights at the building are LED. The remaining 1% of traditional lights are due for replacement in the next maintenance cycle. The north façade of the building is characterised by double-glazed strip windows. For its part, Vodacom Corporate Park is a fourstorey building spanning more than 15 830m².

In awarding the certification,

the GBCSA considered several factors that included resource-efficiency, particularly in energy, water and waste management. “The success of Vodacom's certification reflects WSP’s impact on the local built environment. Through its expertise in sustainable building, we’ve assisted Vodacom in enhancing its corporate sustainability profile and setting a new benchmark for environmental responsibility in the telecommunications industry. This collaboration shows how strategic partnerships, underpinned by a commitment to sustainability, can achieve remarkable outcomes for the planet and the community,” says Alison Groves, regional director of WSP in Africa.

APRIL 2024 SOUTH AFRICAN BUILDER INDUSTRY NEWS

13

(Above): The Vodacom team receiving the certification

PEIKKO SA LAUNCHES AN ONLINE SHOP

In what is a first on the African continent, Peikko SA – supplier of a large selection of concrete connections and composite beams for both precast and cast-in-situ construction solutions, for a wide variety of project applications – has launched an online shop.

“Peikko’s innovative solutions have always made the construction process faster, safer and more sustainable” says Daniel Petrov, Peikko SA’s MD, “and now the online shop will make the process even easier not only for companies, but also for individuals.”

He says the platform is now live, so that anyone can browse and shop from Peikko SA’s wide range of products.

The Peikko online shop will be available in more than 20

countries throughout Africa and works in exactly the same way as any other online shopping platform, where the propective purchaser registers, logs on and then is able to browse and purchase not only products, but the company’s technical and design services too. Goods can be collected or delivered to one’s door.

“The online shop will make our products more visible and easily available to end-users, while also enabling them to purchase in smaller quantities – a major advantage over conventional construction material retailers.

Having our product lineup available at the touch of a button is a much more convenient and time-saving way of purchasing requirements, which – these days – is essential in the construction industry,” says Peikov.

“The platform’s targeted at precasters, builders, constructors, developers, flooring specialists, machine manufacturers, power plant designers, architects and structural designers.”

Peikko SA is part of the Peikko Group Corporation, a leading global supplier of slim floor structures and connection technology for precast and cast-in-situ applications. To access the online store, visit: https://www.peiko.co.za.

SOUTH AFRICAN BUILDER APRIL 2024 INDUSTRY NEWS

Daniel Petrov, MD of Peikko SA.

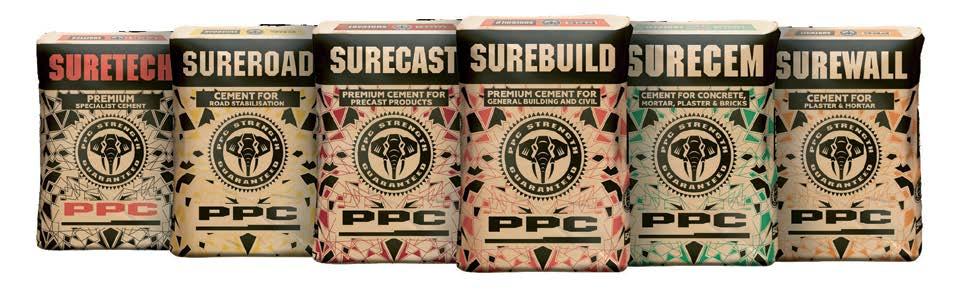

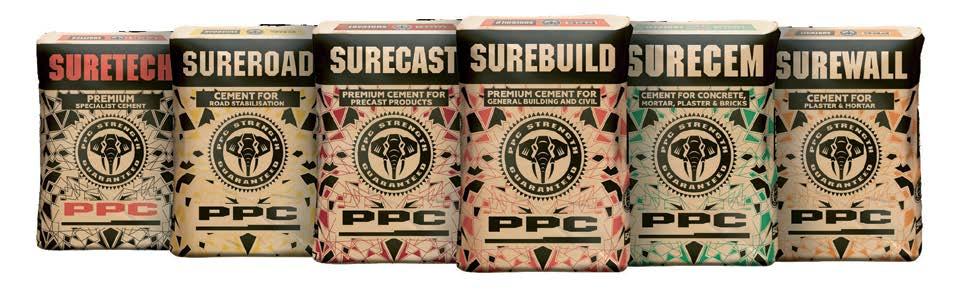

Build with proven quality

For 131 years we’ve cemented our legacy as a reliable and supportive Pan-African industry partner, with a range of hard working, 100% LOCAL, 100% PREMIUM QUALITY PRODUCTS.

Today, our products remain as proudly South African and unshakeable, as the people who invest in them.

Provider of Premium Quality Building Materials.

0800 236 368 | www.ppc.africa @PPC_Africa PPC Ltd

Scan for more product info

BUILDING A FUTURE FOR YOUNG PUPILS

Leading construction material company AfriSam has collaborated with the Northern Cape Department of Education to complete a community development initiative aimed at improving educational infrastructure in the region. As part of this initiative, AfriSam constructed two Grade R classrooms at the GN Pressley Intermediate School, providing a conducive learning environment for 60 young pupils. Each classroom can accommodate up to 30 children, allowing for smaller class sizes and personalised attention.

The collaboration between AfriSam and the department underscores their shared commitment to investing in the future of South Africa’s youth.

“We’re proud to partner with the Northern Cape Department of Education in this community development project,” says Lerato Masiu, AfriSam community development specialist.

“Education is the cornerstone of a prosperous society and we believe that by investing in quality infrastructure, we can create a positive impact on the lives of young pupils.”

The spacious and well-lit classrooms at GN Pressley Intermediate School are equipped

with age-appropriate furniture and educational materials provided by the department.

“This initiative has significantly improved the learning experience of our Grade R pupils. The modern facilities and resources have created an environment that inspires curiosity and supports their holistic development,” says Ralph Langeveldt, the principal of the school.

The community development initiative by AfriSam and the Northern Cape Department of Education aligns with the

UN Sustainable Development Goals, particularly Goal 4: Quality Education. By investing in education infrastructure, the partners aim to contribute to the achievement of equitable and inclusive education for all.

“Former president Nelson Mandela once said that the true character of society is revealed by the way it treats its children. As AfriSam, we’re extremely proud and grateful to make a contribution towards the development of our children,” says Nathi Shoba, general manager of AfriSam’s Ulco Operation.

INDUSTRY NEWS SOUTH AFRICAN BUILDER APRIL 2024 16

CONCOR BUILDS MOMENTUM WITH FAST-TRACK PROJECTS

Concor has remained active in the building sector, with the company having successfully completed several major fast-track projects in 2023. These include the Trevenna Super Basement project in Pretoria, 5 Parks Boulevard in the Oxford Parts Precinct, the Eastgate Sustainability Project and tenant reconfigurations at Westgate Shopping Centre.

Martin Muller, contract manager at Concor, says the new year also started on a positive note with projects spread across new builds, refurbishment and repurposing of existing facilities, all of which are on tight construction programmes.

“Our multi-disciplinary teams are agile and have the requisite skills sets to deliver quality on these projects, despite the varying scopes and the fast-track nature of all of them,” he says.

Commenting on current projects, he says work is underway in the Oxford Parks Precinct with a project to construct two office buildings with a common basement and podium. “What’s exciting on this project is that Concor will be piloting Green Star V2. Our team’s experienced in constructing to Green Star requirements, as this was a feature of many of the structures within the

Oxford Park Precinct, so we’re well positioned for the challenge,” he says.

“Implementing and executing V2 will result in some learning curves for sub-contractors, but the Concor team has the skills set to guide the process and we’ll work closely with the professional team to ensure we meet the requisite new benchmark.”

Another interest project is the refurbishment of an existing office building in Pretoria, which dates back to the late 1970s. The project will transform it into an A-grade office facility.

INDUSTRY NEWS APRIL 2024 SOUTH AFRICAN BUILDER 17

INDUSTRY NEWS

Concor has an established track record undertaking this type of work and apart from the challenges of working within the confines of the inner city, Muller says this is a straightforward 14-month contract.

Extensions to and the refurbishment of an existing shopping centre in Pretoria is another of the contracts secured by Concor this year. It understands the demands of working in live shopping centre environments and has successfully completed numerous such projects safely. This is also on a tight timeline of five months.

Also in Pretoria, the company is constructing a taxi holding facility

which will provide a much safer environment for daily commuters in this area. This project started in February this year and is scheduled for completion this month (April).

Muller says that an important aspect on all projects is the inclusion of sub-contractors from the surrounding areas. “With competent core teams in place, we use the services of SMMEs and emerging contractors who can offer appropriate services such as wet trades and some finishes.”

This is aligned with Concor’s ongoing commitment to uplift local communities in the area in

which it undertakes projects. Muller explains that awarding sub-contracts is not where this ends and ongoing support and mentorship are provided to these companies to ensure their sustainability over the long term.

“An example where this has paid off is within the Oxford Parks Precinct, where Concor’s been building for more than five years. Over that period, we’ve assisted in developing a number of sub-contractors to competency levels that have seen them continuing to work with the company and with other players in the market,” he says.

NHI:

Dr. Aquina Thulare Technical Advisor: National Health Insurance

Mrs. Roseanne Harris Health Policy Actuary: Discovery Health

Mr. Luyanda Njilo Research Analyst: Nedbank

Mr. Musa Shangase President:

APRIL 2024 SOUTH AFRICAN BUILDER 18

MASTER BUILDERS SOUTH AFRICA IN collaboration WITH THE IMPLICATIONS OF NHI ON THE CONSTRUCTION INDUSTRY PROGRAMME DIRECTOR: Vikashnee Harbhajan TIM E 09:00 – 09:05 09:05 – 09:10 ACTIVITY Welcome & Opening Message of support by stakeholders SPEAKERS

09:10 – 09:55 10:00 – 10:45 10:45 – 11:00 11:00 – 11:45 11:55 – 12:00

on Construction Sector. What employers need to know

Aid

of NHI on Medical Aid

Mr. Roy Mnisi Executive Director: Master Builders South Africa Prof S Kgalamono Executive Director: National Institute for Occupational Health

NHI Implications

Medical

Schemes: Effects

COMFORT BREAK

The Investor's Point of View Closing Remarks

Thank You

Builders

OR Scan To Register 17 APRIL 2024 CLICK HERE TO REGISTER

Master

South Africa

2024 EARNINGS THRESHOLD

ANNOUNCED

The earnings threshold will increase to R254 371,67 with effect from 1 April 2024, entitling employees falling below the threshold to stricter protections in terms of labour legislation.

It is the fourth consecutive annual increase to the threshold (following a period of seven years without any adjustment) and sees the threshold increase by R13 261,08 from the current earnings threshold of R241 110,59. The earnings

threshold, a determination in terms of section 6(3) of the Basic Conditions of Employment Act (BCEA), impacts the applicability of certain of the provisions of the BCEA, the Labour Relations Act (LRA) and the Employment Equity Act (EEA). Employees who earn above the threshold are not entitled to certain of the protections afforded to those employees earning below the threshold.

Sections of the BCEA regulating ordinary hours of work, overtime, meal intervals, daily and weekly rest periods, Sunday pay, pay for night work and pay for work on public holidays only apply to employees earning below the threshold.

Employees earning above the threshold are not subject to the deeming provisions that apply to temporary employment

BUSINESS

APRIL 2024 SOUTH AFRICAN BUILDER 19

services (labour brokers) and fixedterm employment provisions under the LRA.

Employees earning above the threshold are not permitted to refer disputes relating to unfair discrimination under the EEA to the CCMA for arbitration unless it is related to sexual harassment or all parties agree to arbitration. Such disputes must proceed to the Labour Court for adjudication.

The determination explains what is included in the definition of “earnings” for the purposes of calculating whether an employee falls above or below the earnings threshold and understanding this is essential in seeking to minimise

“EMPLOYEES EARNING ABOVE THE THRESHOLD ARE NOT PERMITTED TO REFER DISPUTES RELATING TO UNFAIR DISCRIMINATION UNDER THE EEA TO THE CCMA FOR ARBITRATION UNLESS IT IS RELATED TO SEXUAL HARASSMENT OR ALL PARTIES AGREE TO ARBITRATION. SUCH DISPUTES MUST PROCEED TO THE LABOUR COURT FOR ADJUDICATION.”

the risk of non-compliance with the BCEA. Importantly, “earnings” in this context must be differentiated from what is otherwise included in “remuneration”, in terms of the Ministerial Determination regulating the Calculation of Employees’ Remuneration in terms of section 35(5) of the BCEA.

The increase to the earnings threshold may result in an increase or decrease in the number of employees who are entitled to the stricter protections afforded to such employees in labour legislation, such as overtime

is in the remuneration review cycle. This may, in turn, have financial consequences for employers. It is appropriate that employers review their remuneration structures in order to account for the change and the associated costs. Equally, employers that make use of atypical employment arrangements must review such arrangements (or require a review by any temporary employment service facilitating such arrangements) in order to ensure ongoing compliance with the BCEA and, where necessary,

SOUTH AFRICAN BUILDER APRIL 2024 BUSINESS

20

STANDARD ESTABLISHED FOR PRECAST CONCRETE GRANDSTANDS

Over the past 12 years, Corestruc has constructed many precast concrete grandstands of various sizes for municipal recreational sports complexes. These have established the benchmark in the construction of prefabricated concrete grandstands and serve as sound examples of the many inherent benefits of precast concrete technology.

“Our precast concrete system has become the preferred method of building grandstands for municipal sports and recreational

centres. This is considering the speed at which they can be constructed and the savings they provide municipalities, both in terms of construction and operating costs over their long usable life,” says Willie de Jager, MD of Corestruc.

The most recent grandstand Corestruc constructed was for the upgraded Richards Bay Football Club in KwaZulu-Natal. Consisting of more than 800 precast concrete elements and 22 grids, the prefabricated concrete structure

is 14,9m in height at the back columns and 121m in length.

Impressively, it was constructed in only four months after the in-situ footings were completed. Piling commenced in March and was completed in May. However, due to persistent heavy rain through to July, progress was delayed, with actual integration of the precast concrete elements only commencing that month.

The rapid rate at which the company can construct these

APRIL 2024 SOUTH AFRICAN BUILDER 21 FEATURE

(Above): Construction of the precast concrete grandstand was completed in only four months after earthworks .and site terracing, as well as the construction of the in-situ foundation.

FEATURE structures has been facilitated by a unique design which has been perfected over many years. Corestruc’s standardised system can be quickly and efficiently modified to suit most municipal requirements during the design phases. This enables the manufacture of the system to commence as early as possible. In this way, the various precast concrete elements that make up the system are ready to be dispatched to site as and when they are required, once the earthworks and site terracing have been completed.

Moreover, Corestruc’s design facilitates quick and efficient integration of the precast concrete grandstands. What took the company only a few months to construct would have taken a year, had traditional cast-in-place concrete methods been used to build the large grandstand in Senwabarwana.

Time spent on site has been significantly reduced by standardising and minimising the number of precast concrete elements that make up the grandstand. Curved columns and rakers, benches and side panels also facilitate quick and efficient installation. To further streamline construction, the manner in which the various precast concrete elements are connected has been simplified. The columns are connected to the in-situ bases by components that have been cast into the precastconcrete elements. They are then secured using hold-down bolts in the bases. The raker beams,

“ DESIGNED TO CONTINUE ADDING VALUE FOR AT LEAST 100 YEARS WITH MINIMAL MAINTENANCE, OUR PRECAST CONCRETE GRANDSTANDS ARE OF AN EXCEPTIONALLY HIGH QUALITY. ”

seating benches and side panels are secured with strategically positioned dowels. They fit seamlessly into the sleeves that have been cast into the various precast concrete elements and into which the grout is then poured.

The high accuracies achieved when designing the grandstands and executing these in the precast concrete factories during the manufacture of the different concrete elements also streamline construction. Corestruc’s engineers use sophisticated commercial software for structural analysis and design. Building information management (BIM) systems are deployed to model the structures and each precast concrete element. BIM improves quality control by enabling seamless tracking and tracing of every precast concrete element from its design phase through to integration on site. It also facilitates quick and efficient communication between all stakeholders, including clients and their implementing agents, consulting engineers, principal contractors and the specialist precast concrete sub-contractor, as well as its engineers, who lend additional technical support.

To further ensure accurate manufacture of the precast

concrete elements, forms have been manufactured from steel that has been cut with laser-cutting machines. Since quick turnaround time is important to avoid delays, they have also been designed to facilitate the accurate placement of the various cast-in components. Moreover, computerised batching plants facilitate optimised curing processes to further reduce lead times.

In addition to those deployed in the precast concrete factories, quality control checks are conducted after transportation of the prefabricated concrete elements to site. This is another important component of the precast concrete value chain over which Corestruc has complete control. The precast concrete elements are carefully loaded onto and affixed to the company’s triaxle flatbed trailers. Although they have had enough time to harden fully, extreme caution must still be exercised to avoid damaging them. As an additional precautionary measure, quality control is also undertaken during the various phases of construction.

Considering the precise design and manufacturing processes deployed, Corestruc’s riggers achieve tolerances of 5mm when connecting the columns to the foundations and 5mm

SOUTH AFRICAN BUILDER APRIL 2024 22

when integrating the other components of the system.

The middle columns are the first to be placed. They are set out with co-ordinates to confirm the plumb and position. The front raker beams are then aligned with the top and bottom bolts of the columns and fastened in place. Corestruc then places the rear columns and braces them with structural steel. This provides the necessary stability at this stage of construction, considering the slenderness of the columns. The top raker beams are then installed in the same way that the front elements are placed. Afterwards, they are braced horizontally in a similar sequence to that used for the back columns. This is followed by the placement of the seating

benches. They are lined up with the raker beams and then grouted into position, forming a single monolithic structure. Thereafter, the side panels and steps are installed. The roofs of the structures vary from one sports and recreational centre to the next, but are predominantly constructed using structural steel with sheet metal as the cover.

Corestruc’s system is also up to 40% more cost-effective than in-situ construction, since it eliminates the need to manufacture bespoke shutters and operating a tower crane for almost 12 months on site, among other preliminary and general costs associated with such a project.

Moreover, by standardising the system, Corestruc can fix construction costs. This facilitates

accurate budgeting and avoids cost overruns.

Precast concrete also addresses the delicate cost concerns associated with scheduling a typical cast-in-place construction project. By eliminating logistical concerns, scheduling becomes easier which, in turn, helps ensure that unexpected costs do not accrue.

“Designed to continue adding value for at least 100 years with minimal maintenance, our precast concrete grandstands are of an exceptionally high quality. This reduces maintenance costs for municipalities. Fewer construction materials are required to maintain these structures over their long usable life, which also reduces the already lower carbon footprint of our unique grandstands,” says De Jager.

FEATURE APRIL 2024 SOUTH AFRICAN BUILDER 23

The in-situ foundations were constructed by the principal contractor ahead of Corestruc mobilising to site

PERI’S BRAND-NEW TEAM TAILORED SOLUTIONS FOR FORMWORK REQUIREMENTS

As one of the world’s largest manufacturers and suppliers of formwork and scaffolding systems, Peri already occupies an unassailable niche in the construction industry. Established in 1969, it is the world’s largest manufacturer of formwork and scaffolding. In addition to the parent plant and headquarters in Weissenhorn near Ulm, Germany, it has over 60 subsidiaries and 120 logistics centres. The global company employs over 9 100 employees and generated a turnover of €1,846 million in 2022.

Peri South Africa upholds the same commitment to excellence in all its offerings. Its products span a wide range of construction essentials, including wall formwork (which it both sells or rents) with tie technology which can be operated on one or both sides to circular and façade formwork, slab formwork (with craneable columns, circular steel columns or girder column framework, as well as the necessary safety technology and push-pull props), climbing formwork (including work platforms, rail climbing

systems, self-climbing systems, single-sided climbing systems and climbing protection walls) and special formwork created for clients’ specific project requirements. The company also offers advice and help in CNC cutting and formwork assembly.

Peri’s many years of experience in the scaffolding business make it an innovation leader in the industry. In its modern scaffolding plant in Günzburg, Germany, it produces scaffolding according to the highest quality standards. The

SOUTH AFRICAN BUILDER APRIL 2024 24 FEATURE

(Above): The Peri SA management team.

processes defined there are then transferred to the Peri production and logistics network all over the world.

The company’s scaffolding solutions are equally diverse, including infrastructure solutions (plywood and timber), while its construction accessories include panel products (plywood and timber).

Besides its range of products, Peri offers a bouquet of on-site and off-site services designed to help and advise construction teams, such as logistics support (from the start of construction right through to the last return delivery), 3D planning, building information modelling, training in formwork and scaffolding, and technical services (customised free-form formwork for the construction of complex, multi-curved reinforced concrete components. Based on a 3D building model with “free-form surfaces”, the formwork units are individually produced in the Peri formwork assembly facilities.

A BRAND-NEW TEAM

To reinvigorate the company and uphold its commitment to making construction more efficient, safer and faster for all its clients, Peri SA has appointed a new team of directors, headed by MD Jaco Vermeulen (whose career spans three decades in the construction industry), sales director Etienne Ecksteen, technical director Van Reenen Coetzee, financial director Jan Hugo van der Merwe, operations director Dirk Lubbe

“ THE GLOBAL COMPANY EMPLOYS OVER 9 100 EMPLOYEES AND GENERATED A TURNOVER OF €1,846 MILLION IN 2022.”

and head of human resources

Terry Adams, whose visionary leadership plays an integral

part in creating an environment of excellence, diversity and inclusiveness.

FEATURE APRIL 2024 SOUTH AFRICAN BUILDER 25

(Below): Terry Adams, head of human resources: Peri SA.

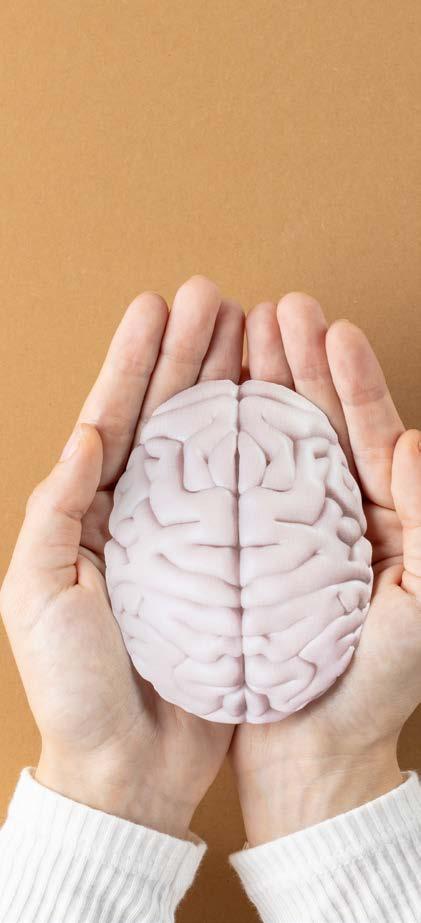

ATLAS COPCO’S NEW WELLNESS PROGRAMME FOR CHILDREN’S MENTAL WELL-BEING

South Africa’s struggling economy is pushing more and more communities into poverty. Children and the youth are particularly vulnerable, facing hunger and homelessness. Studies show that they are also at greater risk of developing mental health issues.

“We believe that having stable and sound mental health is one of the pillars that can sustain any empowerment. The aim is to enable facilitators and counsellors at James House to make impactful changes and progress in the children and youth’s emotional well-being,” says Noluthando Zondo, communications professional: Atlas Copco Holding –Sub-Saharan Africa.

The sustainability element of what James House is doing for the community in the Hout Bay area has impressed Atlas Copco, which has supported the beneficiary for a number of years. When Cape Town was in the grips of a severe drought in 2022, James House was facing exorbitant water bills. The Atlas Copco Water For All project team sprang into action, financing boreholes, filtration systems and Jojo tanks to help irrigate the vegetable gardens that provide food.

SOUTH AFRICAN BUILDER APRIL 2024 26 HEALTH AND SAFETY

for the children who come to the centre. The vegetable gardens also generate an income for James House through the sale of the produce.

Established in 1986, James House has been doing groundbreaking work in child protection services, care and development programmes. The centre draws kids out of a life of crime and drugs, teaching them life skills. The children are supported to do well in school and develop to their full potential. Community engagement is a priority at James House and work done with community groups and stakeholders aims to influence attitudes into positive behaviours and practices. Furthermore, parents and guardians are supported to strengthen family life and, where possible, household living conditions. Families in the community are also educated about farming on a small scale, enabling them to become self-sustainable by creating their own food supply.

Atlas Copco’s over 20-year partnership with Reality Wellness Group aligns with the organisation’s employee health and wellness narrative. Wellness programmes relating to HIV/Aids, good health and well-being, mental health, sexual harassment, gender equality and Covid-19 support and education have delivered life-changing interventions for employees and their families, with a positive impact on their communities.

On 5 and 6 December 2023, a team from Atlas Copco and

Reality Wellness Group, joined by representatives from Tirisano Trust, visited James House, as well as the Hout Bay communities of Hangberg and Imizamo Yethu, where most of the children at the centre come from. Proudly founded by Atlas Copco, Tirisano Trust is a BBBEE stalwart funding organisation dedicated to transformational change and enriching communities.

During the visit, the team engaged with community members and gained an insight into their lives and community living. “We were extremely impressed with the work being done at James House and their commitment to ensuring that the children within their reach are well taken care of. With limited resources, they’ve managed to expand on what they have,” says Zondo.

She explains that the James House wellness programme aligns to Atlas Copco’s three focus areas: education, healthcare and sustainability. “The centre removes barriers that prevent any child from attending a school by, for example, ensuring that essential documents like birth certificates are available. The wellness programme equips the counsellors to effectively manage mental health and other health-related elements. Finally, the borehole water supplying the garden (part of the Water For All initiative) is a perfect example of an expanded sustainable project,” she says.

Zondo stresses that the wellness programme has broadened the view of what mental health is and

the impact it has on the community. “It’s assisted the facilitators in tackling challenges they face in both their work and personal lives, which has helped them provide better emotional and physical support to the children and families they interact with on a daily basis,” she says.

APRIL 2024 SOUTH AFRICAN BUILDER 27 HEALTH AND SAFETY

MATHE GROUP’S RECYCLED RUBBER HITS THE ROAD

The use of large amounts of recycled rubber crumb for the manufacture of road surfaces and related products is propelling South Africa towards a circular economy where waste products can be used to address key infrastructure needs, says Dr Mehran Zarrebini, CEO of Hammarsdale-based radial truck tyre recycler, Mathe Group.

Much of the production from Mathe Group factory, which recycles

approximately 1 000 radial truck tyres per day to produce 45 tons of rubber crumb, goes to bitumen product manufacturer Tosas for the manufacture of rubber-modified bitumen, a product which is used by the SA National Road Agency (SANRAL) for massive upgrades to the N1 in Gauteng and the N2/N3 leading from the port of Durban.

Tosas approached Mathe Group in 2016 for the supply of rubber

crumb. This was shortly after the group moved from a small facility in New Germany to its present location in Hammarsdale. Since then, it has increased crumb production significantly.

Deon Pagel, MD of Tosas, explains that Tosas has been operating for more than five decades and was originally jointly owned by Total and Sasol. The company became part of the JSE-listed Raubex Group

SOUTH AFRICAN BUILDER APRIL 2024 28 PRODUCTS

(Below): Ashlan Reddy, Atlas Copco Holdings controller.

and operates from seven locations: Wadeville, Bloemfontein, Worcester, East London, Durban, Gaborone in Botswana and Tsumeb in Namibia.

He says Tosas became a leading bitumen-supplying company by always keeping abreast of the latest technological developments.

The company has one of the best bitumen testing laboratories in Southern Africa and is a world leader in the development of new bitumen products.

According to Pagel, although people still refer to black-topped roads as “tarred”, the use of tar – which is extracted from coal and is carcinogenic – has been discontinued and replaced with bitumen, which is extracted from crude oil.

Bitumen, which for chipseal applications is sprayed onto the road surface at up to double the temperature of boiling water, seals the top road layerworks, protecting the foundation layers beneath and acting as a waterproofing layer. Alternatively, it can be mixed in with the asphalt and acts as a glue, strengthening the road itself.

This bitumen that exits a refinery – known as penetration-grade bitumen – is modified with the addition of a variety of different modifiers. Rubber-modified bitumen is created by mixing 20% rubber crumb with 80% bitumen and extender oils.

“This is one of the most superior

road bitumen products in the world and also offers the benefit of recycling. You take old tyres and convert them into a usable product. It’s a win-win,” says Pagel.

Bitumen rubber has now been generically specified by government and other road authorities and owners for use in the construction of roads throughout the country. Mathe Group’s role goes beyond simply producing rubber crumb to ambient grinding of radial truck tyres for Tosas, with whom it designed and developed a second plant to produce what is known as New Crumb Rubber Technology (NCRT). This involves coating the rubber crumb with aromatic oil and specialised waxes. The result is a pre-swollen rubber crumb which is bitumen rubber for asphalt mixes and spray seal applications that have greater longevity and much lower mixing temperatures.

“TOSAS

MANUFACTURES

RUBBER-MODIFIED BITUMEN, A PRODUCT WHICH IS USED BY THE SA NATIONAL ROAD AGENCY (SANRAL) FOR MASSIVE UPGRADES TO THE N1 IN GAUTENG AND THE N2/N3 LEADING FROM THE PORT OF DURBAN.”

Zarrebini, who is now looking to install a further line that will double output at Mathe Group’s Hammarsdale factory, is confident that the company can accommodate the growing need for rubber crumb for roads, as well as other applications.

“The recycling plant we’ve designed is flexible and we can manufacture different particle sizes of rubber crumb for different end uses at the same time. The specific rubber crumb size that’s used for rubber-modified bitumen is of the finer quality. The coarser grades are used as infill for artificial turf and as elastic layers for sports applications. The material that’s finer than that used in rubber-modified bitumen is utilised in non-slip paints, automotive brake pads and to manufacture new tyres,” he explains.

He adds that there is room for growing the amount of rubber crumb utilised in the roads industry, although this is largely dependent on SANRAL awarding tenders for infrastructure projects and having the available funding to follow through with them.

“From a production perspective, we have the flexibility of only manufacturing the grade of rubber crumb utilised in rubber-modified bitumen. If the demand’s lower, we can switch to manufacturing a combination of grades of rubber crumb for other industrial uses,” he says.

PRODUCTS APRIL 2024 SOUTH AFRICAN BUILDER 29

PRODUCTS

A LOGICAL SOLUTION

Schneider Electric, the leader in the digital transformation of energy management and automation, has unveiled its EasyLogic Building Management System (BMS) range, designed for basic building architectures, to the local marketplace.

Mark Freeman, offer manager: digital building for Anglophone Africa at Schneider Electric, says the system is a complete and costeffective range of field controllers and sensors that are both easy to install and scalable.

“The EasyLogic brand also delivers the reliability and robustness for which the Schneider Electric brand is known,” he says.

The EasyLogic range is designed for basic heating, ventilation and air-conditioning (HVAC)

applications and includes an integrated network of controllers, providing improved installation efficiency and energy use such as plant room and terminal units. This includes controllers for fan coil and variable air volume, as well as expansion modules. The range is also compatible with BACnet MS/ TP for network communications.

GAINING TRACTION

“Since its soft launch in the local and East and West African markets last year, the EasyLogic BMS range

“THE EASYLOGIC BRAND ALSO DELIVERS THE RELIABILITY AND ROBUSTNESS FOR WHICH THE SCHNEIDER ELECTRIC BRAND IS KNOWN.”

has steadily gained traction in the market, especially for costsensitive projects that require more affordable solutions,” says Freeman.

“While smart building technology has seen a shift towards the integration of digital building management systems, not all projects have sufficiently large budgets for state-of-the-art premium solutions. With the EasyLogic brand, we’re targeting end users who require a more affordable alternative, but still want to operate and control their buildings digitally.”

He notes that another major benefit of the EasyLogic range is that the solution can be tailored to practically any application and any size building and – once installed – will enable significant energysavings that result in a good return on investment.

“What’s more, the product comes with a hard-wired serial bus, so if a building has existing cabling and an outdated BMS that’s no longer functional, the controller can simply be replaced with an EasyLogic unit, as long as there’s an MS/TP network in place, Additionally, it comes with affordable temperature sensors that can monitor and control the temperature in a building at a very cost-effective rate,” says Freeman.

SOUTH AFRICAN BUILDER APRIL 2024 30

(Left): Mark Freeman, offer manager: digital building for Anglophone Africa at Schneider Electric.

BOBCAT SHOWCASES NEW MATERIAL HANDLING LINE-UP AT LOGIMAT 2024

Bobcat chose LogiMAT 2024 as the backdrop for the international début of its material handling line-up. Having incorporated more than 200 forklifts and warehouse solutions into its portfolio over the past year, the manufacturer showcased a selection of its newly rebranded models to exhibition attendees from 19-21 March in Stuttgart, Germany.

A variety of diesel and electric forklifts, reach trucks and warehouse equipment – all sporting Bobcat’s famous white and orange signature colours –were on display at the event.

The first Bobcat-branded material handling units began rolling off production lines at the organisation’s plants in South Korea, China and Germany in January this year. The brand’s LogiMAT line-up represents the culmination of a two-year global initiative, through which the full range of forklifts and warehouse

equipment formerly produced by Doosan Industrial Vehicle (DIV) has been successfully rebranded as part of the Bobcat family.

BOBCAT’S LOGIMAT 2024 LINE-UP

The newly rebranded material handling models on display at LogiMAT 2024 included the D160S-9 10- to 16-ton 9-Series diesel forklift, the D50SC-9 4- to 5,5-ton 9-Series diesel forklift, the B25NS 2,5- to 3,5-ton 7-Series Plus electric forklift, the B20X-7 Plus 1,6- to 2-ton NXE-Series electric forklift, the B80NS 8- to 10-ton NXE-Series electric forklift, the BR16J-9 1,4- to 1,6-ton 9-Series reach truck, the BPL18S-7 1,8- to 2-ton 7-Series pedestrian pallet truck, the BPR20S-7 2-ton 7-Series ride-on pallet truck, the BDR13S-7 1,3-ton 7-Series double stacker and the LSM12N-7 1,2-ton 7-Series pedestrian stacker.

Bobcat also used LogiMAT 2024

as a platform to showcase its TL25.60 super-compact telehandler, whose optimised dimensions and superior manoeuverability allow it to operate effectively in tight spots without compromising performance.

In addition to the units on display in Stuttgart, Bobcat’s expanded line-up now includes all models previously manufactured under the DIV name. The full range of Bobcatbranded material handling solutions include the following product lines: diesel forklift trucks (lift capacities of 1,8-25 tons), liquified petroleum gas forklift trucks (lift capacities of 1,5-7 tons), electric forklift trucks (lift capacities of 1,5-10 tons) and warehouse solutions (pallet trucks, reach trucks and stackers).

For further information, visit: www.bobcat.com.

PRODUCTS APRIL 2024 SOUTH AFRICAN BUILDER 31

Some of Bobcat’s newest range of material handling equipment.

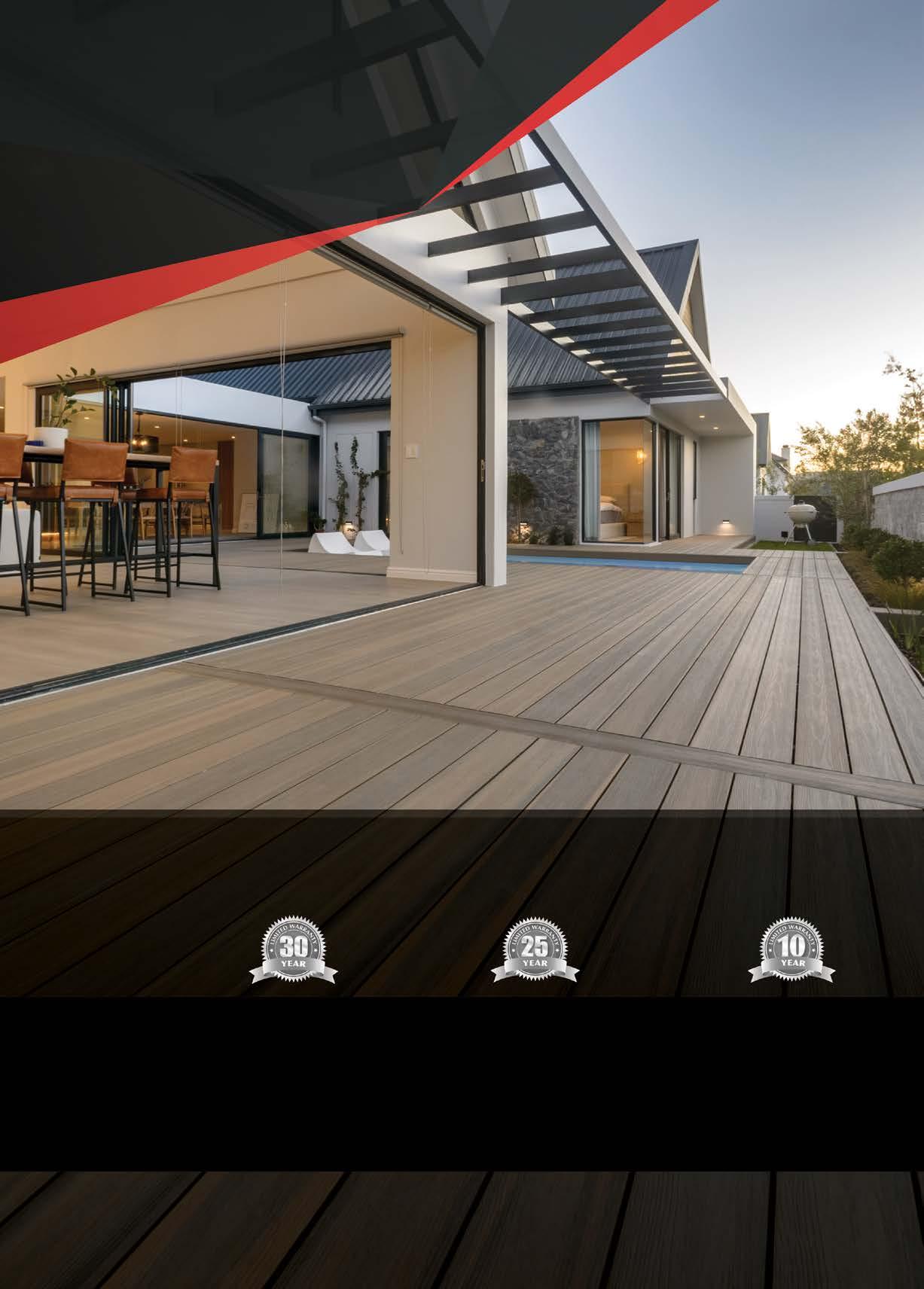

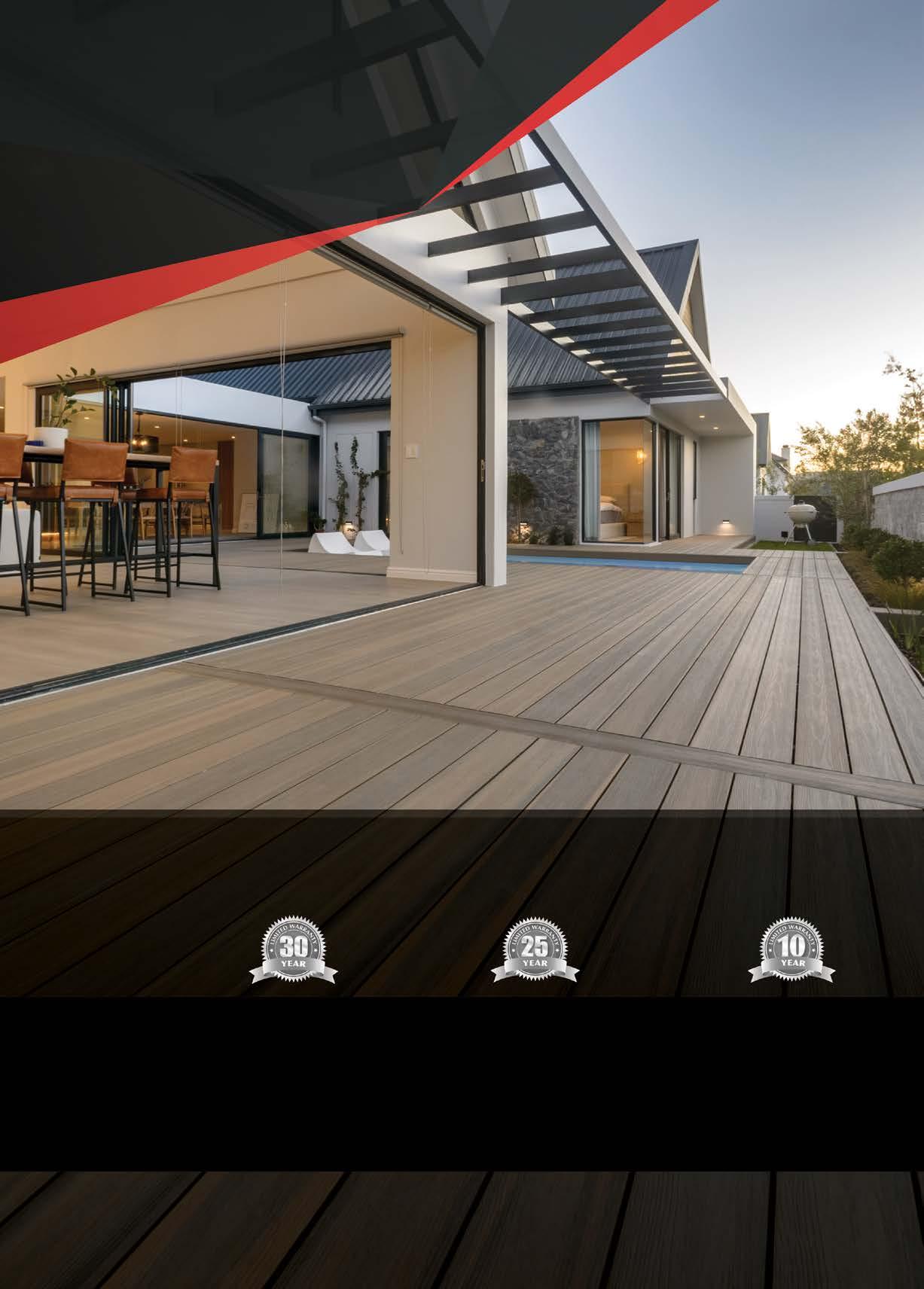

EVA-LAST: THE BENEFITS OF COMPOSITE DECKING

Build a greener future with advanced composite decking from Eva-Last, engineered to reflect the natural beauty of wood without the maintenance

Eva-Last is an expert, providing eco-friendly composite decking made from recycled plastic combined with renewable eco-friendly bamboo to over 32 countries around the world.

In line with its slogan, “Inspired by nature, designed for life”, Eva-Last’s ranges of advanced composite decking – Apex Plus, Infinity and Eva-tech –emulate the natural beauty and texture of timber, combined with the performance benefits of the latest advancements in composite technology.

Composites are manufactured materials (comprising various raw materials) that combine the technical characteristics of these materials to enhance performance properties and improve resource-efficiency, durability and sustainability.

Composites outperform traditional construction materials such as timber by far. Aside from reducing the use of limited wood supplies and deforestation, the inherent waterproof and inorganic properties of recycled plastic, combined with advanced

materials, prevent degradation or destruction by pests or environmental exposure. Extra enhancements such as glassfibre-reinforced cores (GFR) in Apex Plus, UV-stabilisers and protective polymer wear-layers are added into the composite products to deliver products with unsurpassed structural and sustainable characteristics.

Eva-Last recognised the outstanding sustainability credentials of bamboo, coupled with its superior performance characteristics, quickly switching

SOUTH AFRICAN BUILDER APRIL 2024 32 PRODUCTS

Eva-Last bamboo polymer decking is durable, resilient in all weathers – and stunningly beautiful.

from wood plastic composite (WPC) to bamboo polymer composite (BPC).

Bamboo grows 50 times faster than hardwood trees and releases 35% more oxygen, with less than 2% of waste compared with the dismal 13% utilisation of wood and addedvalue timber.

As a grass that requires no pesticides or harmful chemical fertilisers to grow, bamboo replenishes itself within three to five years. This makes it an abundant renewable resource, compared with threatened exotic species such as cedarwood, that can take up to 50 years to regrow.

Bamboo fibre’s inherent tensile strength – the resistance to

being pulled apart – is higher than that of steel and can withstand compression better than concrete. Its natural thermal properties avoid temperature extremes in either hot or cold climates, making it an ideal material for exterior installations. When polymerised with recycled plastic, bamboo composites outperform natural timber. The composites offer high impact-resistance and superior dimensional stability, limited moisture absorption, biological resistance to insect or environmental degradation, as well as added strength and extended durability. Longer lifespans mean less replacement.

The ranges are vailable in popular patterns and colours.

This, coupled with their sustainable features, make specifying Eva-Last bamboo polymer composite decking on your next green building project a must.

“EVA-LAST

RECOGNISED THE OUTSTANDING SUSTAINABILITY CREDENTIALS OF

BAMBOO,

COUPLED WITH ITS SUPERIOR PERFORMANCE CHARACTERISTICS, QUICKLY SWITCHING FROM WOOD PLASTIC COMPOSITE (WPC) TO BAMBOO POLYMER COMPOSITE (BPC).”

PRODUCTS APRIL 2024 SOUTH AFRICAN BUILDER 33

When polymerised with recycled plastic, bamboo composites outperform natural timber.

UPCOMING EVENTS

The CASI Construction Academy will be offering the following courses and events this year. Limited seats are available, so it is important to reserve places well in advance. CASI also conducts in-house training for five or more delegates at a discounted rate.

WATER NETWORK DISTRIBUTION SYSTEMS DESIGN, OPERATION AND MAINTENANCE (2 CPD)

Johannesburg/Online: 16-17 May 2024, 17-18 October 2024

Cape Town: 16-17 May 2024, 17-18 October 2024

Durban: 16-17 May 2024, 17-18 October 2024

This workshop is intended for those who require a better understanding of systems of water distribution design. You will be able to complete a water distribution system design under instructor guidance by using firstprinciple methods and/or design aids. A workshop on water CAD software will be conducted under an instructor’s supervision. After attending this workshop you will be able to:

• Understand the fundamentals of water distribution systems.

• Design new water distribution systems.

• Analyse existing systems and find out existing problems.

• Master the design software water CAD with numerous design examples and solve basic pumping system design problems, including considerations for installation, operation and maintenance.

• Select the most suitable equipment for your application and write practical specifications.

• Maximise effective operational procedures and optimise use of system controls.

• Reduce your maintenance problems and enhance system protection.

• Make condition assessment and upgrades to increase capacity.

ASSET MANAGEMENT FOR WATER AND WASTEWATER UTILITIES WITH ISO 55000: AN APPROACH TO GET BETTER OUTPUT AND LOWER TOTAL COST OF OWNERSHIP

Johannesburg/Online: 26-28 June 2024, 6-8 November 2024

Cape Town: 26-28 June 2024,

SOUTH AFRICAN BUILDER APRIL 2024 34 SKILLS AND TRAINING

6-8 November 2024

Durban: 26-28 June 2024, 6-8 November 2024

The management of physical assets for water and wastewater utilities has become significantly critical in the last decade. Due to an increasing demand for utility services, scarce resources, need for production efficiency, budget and funding limitations, increasing restrictions on output, ageing assets and climate change, there is an urgent need to manage our physical assets better, proactively and with a life-cycle view.

SA’s water and wastewater utilities face a myriad of challenges, including the breakdown of water supply systems, contamination of drinking water and the deterioration of wastewater treatment works. Asset management practices play a crucial role in addressing these challenges. By implementing good asset management practices, utilities can prolong asset life, improve decision-making about asset rehabilitation, repair and replacement, meet consumer demands with a focus on system sustainability and reduce overall costs for both operations and capital expenditures.

In SA, asset management practices have been recognised as a key component of sustainable infrastructure management. This training course will emphasise the implementation of good asset management practice that will contribute to fulfilling the corporate strategy. It will explain why asset management is and what

deliverables organisations get from it, the content and value of ISO 55000 and how to use it, as well as implementing and sustaining best asset management practices.

BEST PRACTICES IN SEWAGE EFFLUENT AND WASTEWATER TREATMENT TECHNOLOGY WORKSHOP:

Unit processes, trouble-shooting, maintenance and options in sludge treatment.

Johannesburg/Online: 24-25 June 2024, 4-5 November 2024

Cape Town: 24-25 June 2024, 4-5 November 2024

Durban: 24-25 June 2024, 4-5 November 2024

Participants will learn how to manage the effective operation and performance of wastewater treatment plants. They will gain a detailed understanding of the principles applied to the treatment of organic, inorganic or a combination of both industrial effluent types. They will also learn the legal requirements of wastewater management, the effluent parameters, unit processes and design details, maintenance requirements, trouble-shooting methods, sampling techniques and sludge treatment.

WATER

QUALITY MANAGEMENT AND RISK ASSESSMENT

Johannesburg/Online: 17-19 April 2024, 11-13 September 2024

Cape Town: 17-19 April 2024, 11-13 September 2024

Durban: 17-19 April 2024, 11-13 September 2024

This course will explain the technical and practical aspects of water and wastewater treatment, the regulatory requirements needed for Blue Drop and Green Drop status and best practices to meet the Blue Drop/Green Drop criteria, as well as management of water quality performance

BOILER CONTROLS AND MEASUREMENTS WORKSHOP

Johannesburg/Online: 23-24 May 2024, 24-25 October 2024

Cape Town: 23-24 May 2024, 24-25 October 2024

Durban: 23-24 May 2024, 24-25 October 2024

This is an instructor-led course which unpacks the principles of boiler management, maintenance, efficiency and monitoring systems. The learning blends classroom theory sessions, case studies and interactive worked examples with a series of practical, hands-on exercises. Participants will gain upto-date information and practical understanding of the basics, applications, trouble-shooting and failure diagnosis, installation and maintenance of boilers, boiler controls and measurements.

REVERSE OSMOSIS DESALINATION:

SAFEGUARDING THE SUSTAINABILITY OF YOUR WATER RESOURCES

Johannesburg/Online: 24-26 April 2024, 24-26 July 2024, 13-15 November 2024

Cape Town: 24-26 April 2024, 24-26 July 2024, 13-15 November 2024

SKILLS AND TRAINING APRIL 2024 SOUTH AFRICAN BUILDER 35

SKILLS AND TRAINING

Durban: 24-26 April 2024, 24-26 July 2024, 13-15 November 2024

This course covers a variety of RO desalination techniques, including desalinating drinking water, dialysis water, landfill leachates, ultra-pure water production for pharmaceuticals, polishing water for cosmetics and detergents. The workshop addresses the increasing need for stringent disposal rules and emphasises the irreplaceable value of water.

WATER TREATMENT PLANT DESIGN, OPERATION, MAINTENANCE AND TROUBLESHOOTING WORKSHOP

Johannesburg/Online: 13-17 May 2024, 14-18 May 2024

Cape Town: 13-17 May 2024, 14-18 May 2024

Durban: 13-17 May 2024, 14-18 May 2024

The design of water and wastewater treatment facilities requires careful planning, clear

understanding of legal implications, future expansion considerations and operation and maintenance requirements. The objectives of this extensive course are to present recent developments in the design of municipal/industrial water and wastewater treatment facilities.