SHAPING TOMORROW TOGETHER

Research Bulletin No.7 April 2023 Research Bulletin No.7-April 2023

EDINBURGH DUBAI MALAYSIA

Wellbeing Sustainability Performance and Productivity HEC Rating 2022 5

Editorial

Dr Mustafa Batikha

Topic of Focus: The Road to (and beyond) COP28

Prof. Lynne Jack

3D Concrete Printing: Bus Station Case Study

Olivier Cremens, Apoorva Doctor and Mikhail Samoilov

3D Concrete Printing at Dubai Municipality: Achievements, Responsibilities, and Future Agenda

Waleed Mosad Abdulghafar, Abdellatif Badr Masoud and Marwan Aljanaahi

How To Make Cement Greener: Misconceptions and the Reality

Prof. Karen Scrivener and Jeremy Packham

Materials & Waste Management for Decarbonisation of the Cement Industry in the UAE

Dr Mustafa Batikha, Warren McKenzie, and Dr Olisanwendu Ogwuda

How Artificial Intelligence is Improving Safety on Construction Sites

Dr Rodaina Aboul Hosn

Major Design Challenges for Improving the Transportation Networks in UAE

Islam Badawi and Dr Noor Zainab Habib

Cooling Systems in the Arab Gulf Region Using Energy Geostructures

Prof. Lyesse Lalou, Dr Elena Ravera, Dr Ahmed Badr Mabrouk, Dr Alessandro Rotta Loria, and Sofie Elaine Ten Bosch

Metal Additive Manufacturing in Construction: Review of Current State, Challenges and Opportunities

Dr George Vasdravellis

Accelerating System Solutions for a Just Transition to Net-Zero

Prof. Mercedes Maroto-Valer and Dr Phil Renforth

Counting Down To COP 28: As construction emissions continue to rise, what’s preventing meaningful change in the industry?

Prof. Gabriela Medero

The Impact of Urban Heat Island (UHI) on Health and Well-being of Urban Residents

Dr Ashley Hong and Ying Jia Low

History of Bridges and How It Influenced Human Mobility

Prof. Sabih G Khisaf

Table of contents Research Bulletin No.7 April 2023

54 2 3 5 18 27 33 23 31 15 7 11 40 43

News & Events, Partner News

46 49

About us

About Us

Centre of Excellence in Smart Construction (CESC)

Heriot-Watt University’s Centre of Excellence in Smart Construction (CESC) is committed to advancing industry-led innovations in construction that will revolutionise the way we develop, manage and operate smarter cities.CESC partners with like-minded organisations and government entities to lead the transformation of the Built Environment and development of next generation professionals for the benefit of the economy. CESC is a global hub for disruptive thinking, a platform for collaborative research and a model for solutions development and stakeholder engagement. More details about CESC can be found in the following link: https://www.hw.ac.uk/dubai/research/centre-excellence-smart-construction.htm

CESC non-executive board

CESC’s non-executive board, chaired by His Excellency Dr Abdullah Belhaif Al Nuaimi, Former UAE Minister of Climate Change & Environment, brings together a group of expert opinions and leading voices across academia, industry and government.

Profiles of each CESC board member can be found using the following link: https://www.hw.ac.uk/dubai/research/cesc/non-executive-board.htm

CESC core team

Prof. Lynne Jack, Interim Director

Dr Olisanwendu Ogwuda, Manager

Charlotte Turner, Strategic Marketing Manager

Judy Aneiny, Executive Assistant

CESC committee (Heriot-Watt)

Dr. Hassam Chaudhry, Director of Studies Representative

Linsey Thomson, Academic Lead for Student Engagement

Matthew Smith, EGIS Representative

Dr. Mustafa Batikha, Academic Lead for Publications

Dr. Karima Hamani, Academic Lead for Knowledge Exchange

Dr. Yasemin Nielsen, EngD Programme Leader

Dr. Taha Elhag. Academic Lead for Proposals

CESC Industy Partners

How to become a CESC partner

Would your organisation like to become an esteemed industry partner of CESC? We work with our partners with the shared goal of transforming the future of construction by driving research and innovation in the sector.

Sharing information, skills and knowledge is key to advancing industry adoption of innovative solutions. Collaboration between industry and academia offer the opportunity to shape the challenges facing the Built Environment and preparing the next generation of construction professionals with the skills and knowledge to make a step change.

For more information about partnership benefits and working collaboratively with The Centre of Excellence in Smart Construction please contact S.Bushnell@hw.ac.uk

Research Bulletin No.7 April 2023

About Us 2

Bulletin Editor & Contact

Mustafa Batikha E-mail: m.batikha@hw.ac.uk Contact Us E-mail: cescdubai@hw.ac.uk

Media:

Dr

Social

Editorial

Dr Mustafa Batikha Associate Director of Research

School of Energy, Geoscience, Infrastructure and Society

Heriot-Watt University-Dubai Campus Dubai, UAE m.batikha@hw.ac.uk

School of Energy, Geoscience, Infrastructure and Society

Heriot-Watt University-Dubai Campus Dubai, UAE m.batikha@hw.ac.uk

The seventh issue of the CESC Research Bulletin “Topic of Focus” article by Professor Lynne Jack, Associate Principal (International Research) Director, Institute of Sustainable Built Environment and Interim Director of CESC, confirms how the CESC is committed to encouraging innovative solutions for meeting the UAE sustainability agenda. Jack also brings the long journey of sustainable challenges, which requires continuous progress beyond COP28 in December 2023. For faster achievements, the “Topic of Focus” asks for working collaboratively, such as the aim that the CESC exists to form knowledge partnerships among the academia, industry and government.

This seventh issue also presents the worthy experience of well-practised authors toward the CESC core themes: Performance &Productivity, Sustainability and Wellbeing.

The editorial highlights in brief twelve new topics as follows:

Performance and Productivity

Under this theme, Lyesse Laloui, Elena Ravera, Ahmed Badr Mabrouk, Alessandro Rotta Loria and Sofie Elaine Ten Bosch discuss how the CO2 emissions per capita have doubled in the Gulf region because of a significant increase in energy consumption due to population rise, development and construction growth. Since AC cooling contributes 60% to 85% of the total energy consumption, the authors propose geothermal energy as an alternative to achieve the Net-Zero Energy (NZE) target. It is to use the ground’s natural energy to heat and cool the structures, producing hot water. The proposed system proved environmentally friendly, covering about 40% of a building’s cooling with significant financial feasibility. In the article, the installation of the geostructure system is explored. Also, a case study in Dubai is discussed as an efficient application of such a system in an arid climate.

The second article is by Olivier Cremens, Apoorva Doctor and Mikhail Samoilov from BESIX, the well-respected 3D concrete printing company in Dubai. The authors present full technical, construction process and structural analysis details for a 3D-printed bus station project. The article highlights some lessons learned from this project to make 3DCP technology successful such as discussion between all the stakeholders from the early beginning. Also, the paper points out that although 3DCP is a powerful, flexible tool, it still has some limitations, such as the absence of standardised codes. Thus, it depends on the engineering judgement during the execution process.

George Vasdravellis, in the third article, explores 3D metal printing and its advantages in reducing material waste, making complex shapes such as connections at low cost and on-site implementation. The author discusses two metal printing methods with each technique’s advantages and disadvantages. Vasdravellis encourages going with hybrid construction because the cost is high when full-scale elements are printed. Therefore, the steel connections can only be printed. Some examples showed that printing nodes reduced their weight by 75%. However, the paper addresses that the current use of 3D metal printing may harm sustainability as it is an energy-intensive process. Its future spread depends on using clean electrical energy.

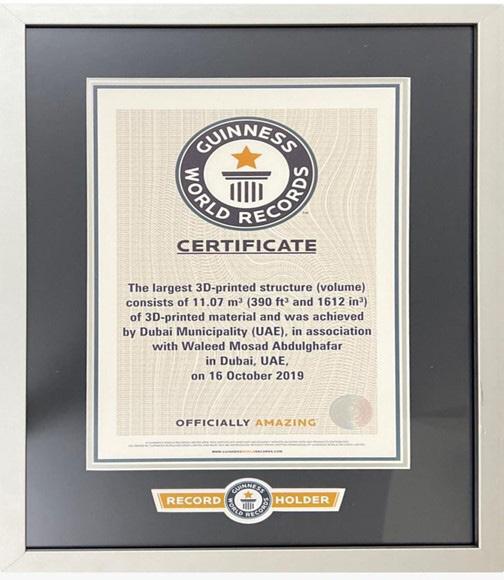

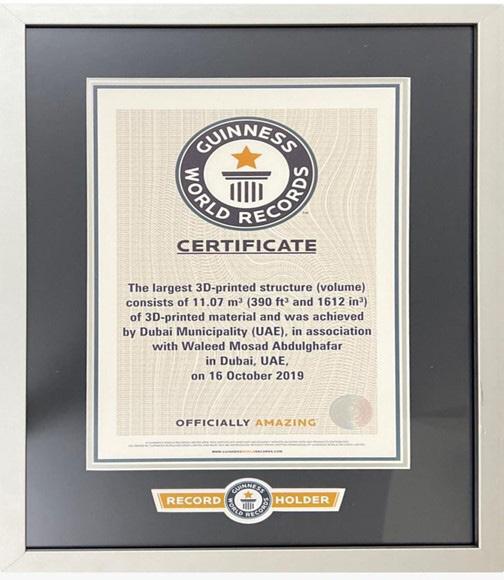

The fourth paper by Waleed Mosad Abdulghafar, Abdellatif Badr Masoud and Marwan Aljanaahi from Dubai Municipality (DM) presents the vital role the DM plays in monitoring the building process according to rules and regulations. Later, the authors introduce 3D Concrete Printing (3DCP). Then, they went through the process of building the largest printed building worldwide through massive lab trials, which reached 200 to confirm the 3DCP buildability, especially in the hot weather of the UAE. The article pointed out that DM aims to make Dubai an international hub for 3D printing activities, which pushes a lot of responsibilities on the DM to achieve this aim and put the 3DCP on the right track.

Sustainability

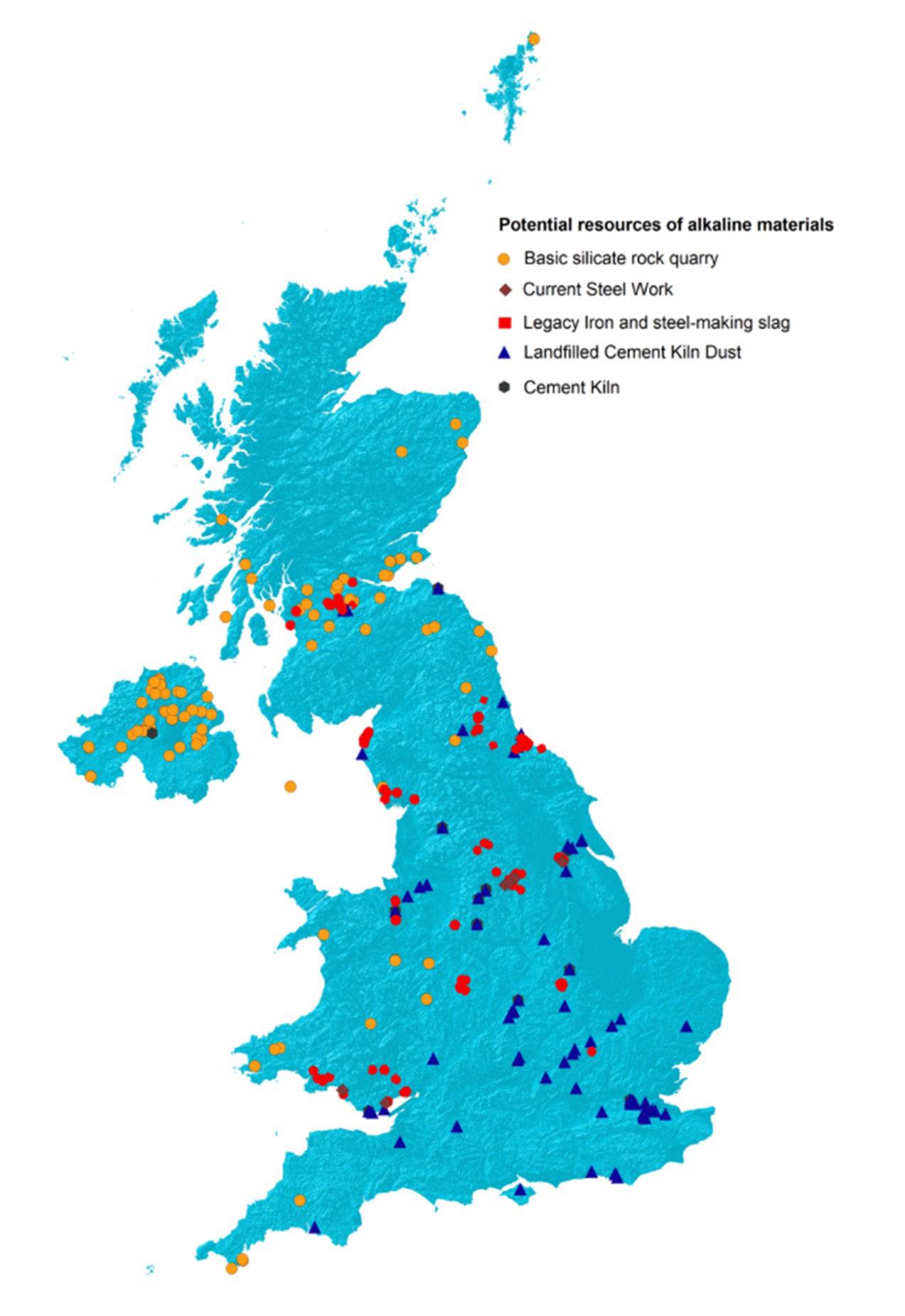

In the first paper under this theme, Mercedes Maroto-Valer and Phil Renforth introduce the UK Industrial Decarbonisation Research and Innovation Centre (IDRIC) as a centre to accelerate the green industrial revolution via the collaboration of 250 partners from academia, industry, policymakers and society representatives with a fund of up to £261 million from the industry. The IDRIC supports 63 projects about the challenges facing industrial decarbonisation to find cost-efficient green solutions for the industrial sectors, which contribute to 50% of CO2 emissions. The article focuses on the role of the cities, which produce 70% of humaninduced greenhouse gas emissions because of population growth, such as the UAE example. However, it is encouraging that the article records that the UAE is the first Arab country to set voluntary clean energy targets. For instance, DEWA launched the Dubai Green Fund of $27bn to support clean energy. Also, the Dubai Master plan 2040 will double the green area of Dubai, besides using sustainable technology in the construction, green building facades, and launching the region’s first green hydrogen plant.

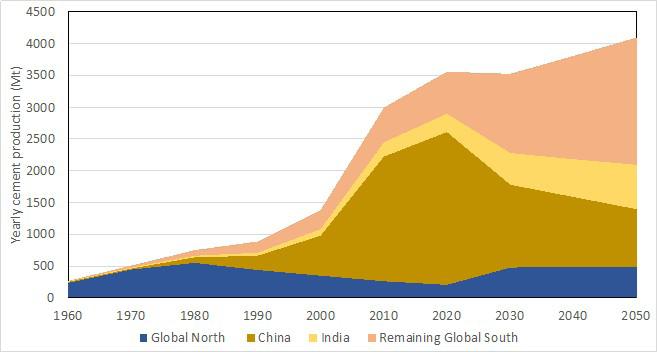

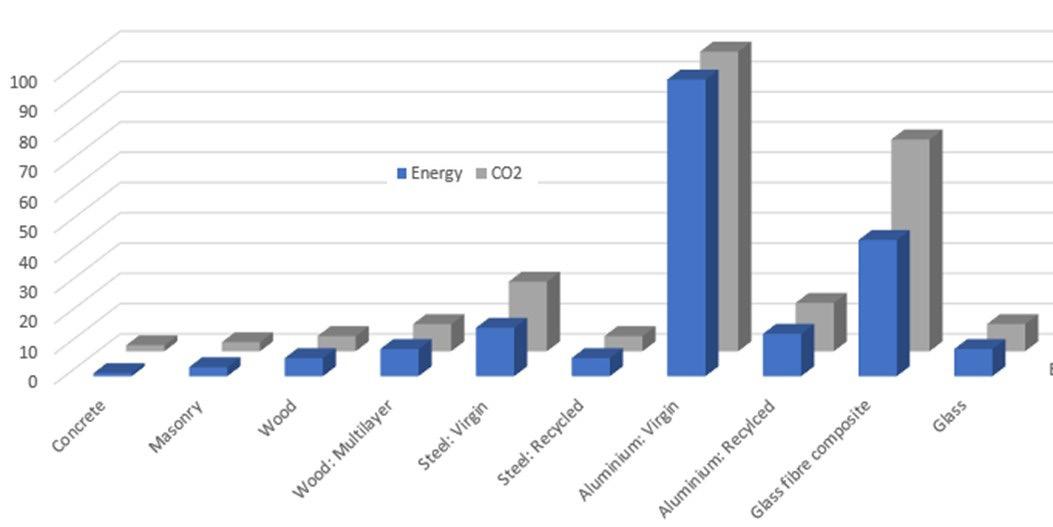

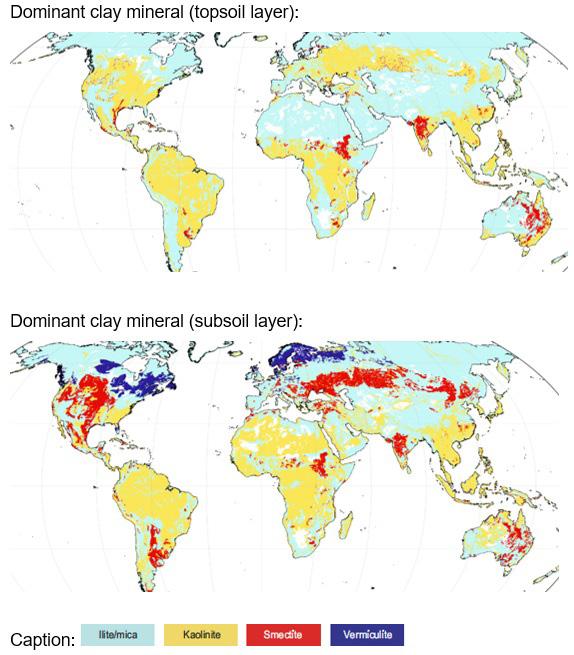

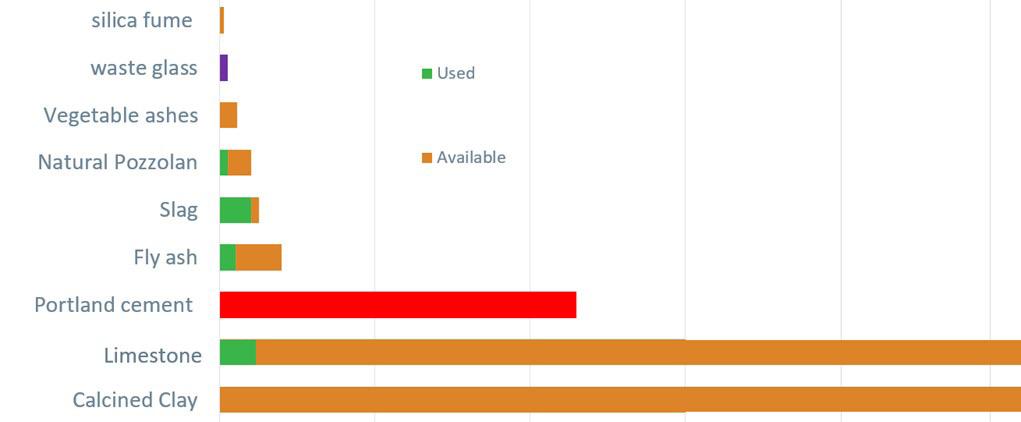

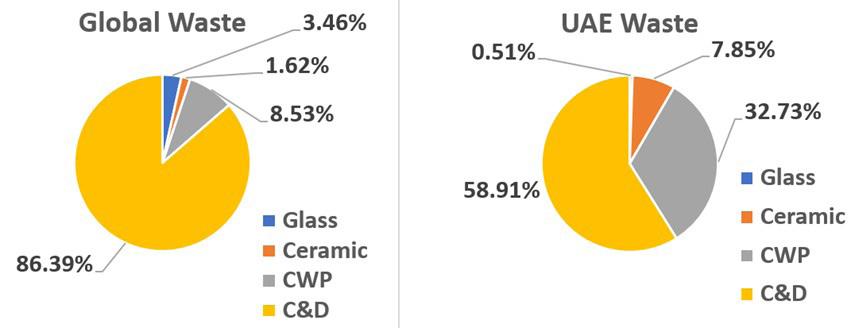

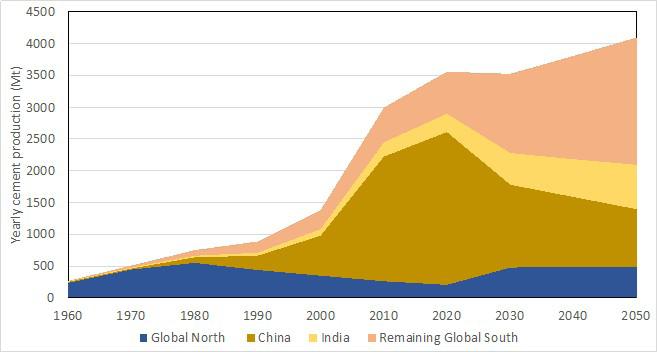

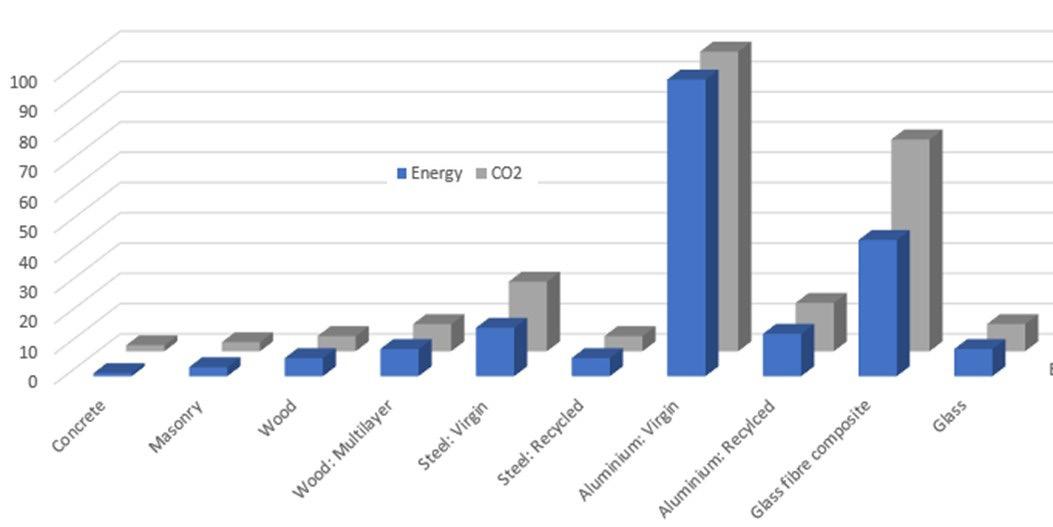

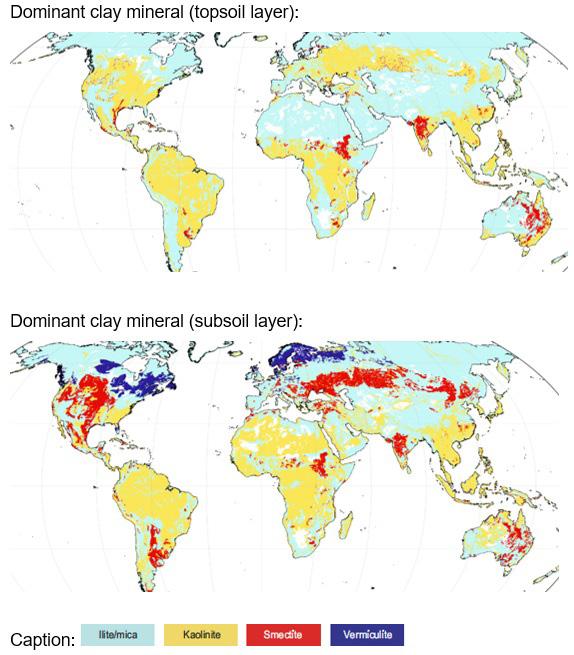

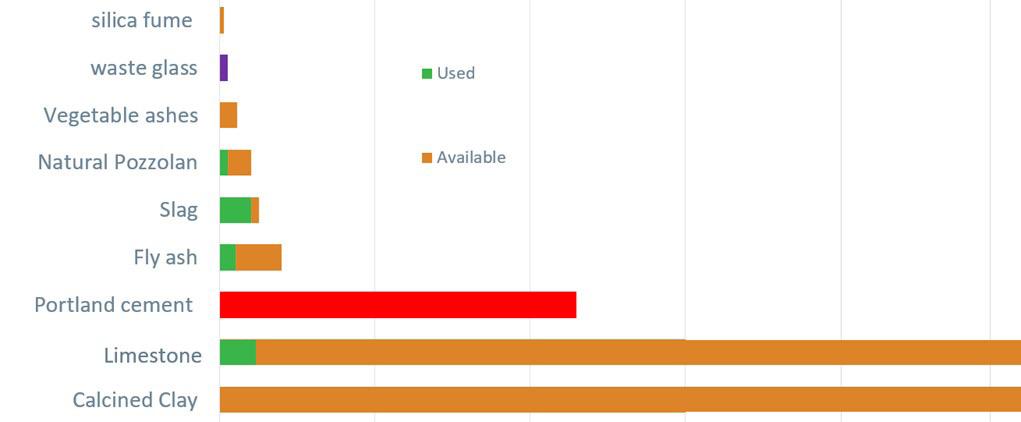

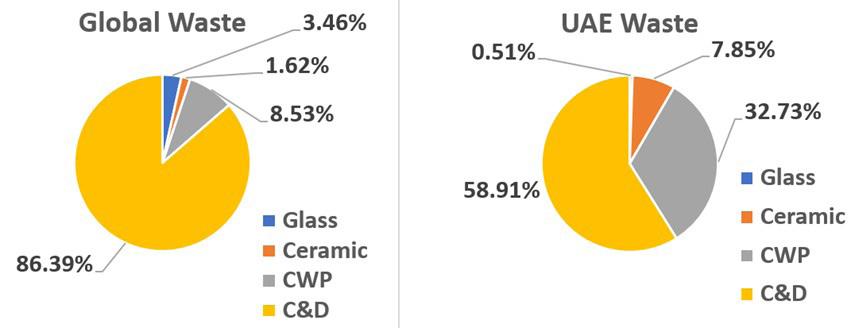

The second paper is by Karen Scrivener and Jeremy Packham, who start with the fact that, due to the growth of construction because of the increase in the population, we can’t reduce cement production but reduce GHG emissions that come from it. The article describes cement as a miracle material that its use can’t be simply avoided because the cement components are similar to the earth’s geological composition of limestone. Any other materials to replace limestone are very limited or much more expensive. Instead, the authors suggest using Limestone Calcined Clay Cement (LC3) which is much available in the Global South and requires little changes to existing cement plants. The article confirms

Research Bulletin No.7 April 2023

Editorial 3

that using LC3 can save up to 40% of CO2 emissions. It is most interesting that the paper argues six current misconceptions about reducing the CO2 emissions from cement production.

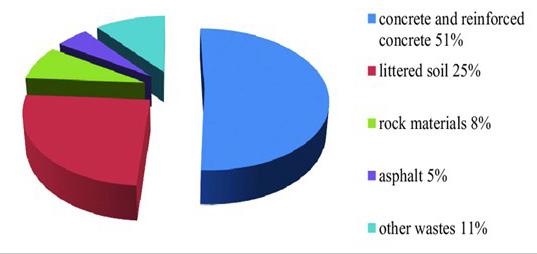

Gabriela Medero, in the third article, requests the urgent need for an action plan to start meaningful change through COP 28. Medero confirms that, via COP 28, she will push for recycling the vast quantities of construction and demolition waste for reuse. It is the only way to save our natural earth. The author brings bricks as an example, where the UK alone used more than 2.6 billion bricks in 2019. Making bricks requires an incredible amount of energy, with a burning temperature reaching 1,300 degrees Celsius adding further pollution to our atmosphere. Therefore, the author and her team have acted to produce a unique brick called K-Briq from 90% demolition and construction waste. Moreover, no firing and cement are required to bind the ingredients, resulting in less than 10% of the energy used with traditional bricks. More about the properties of the K-Briq product are detailed in the article. It is so interesting that the author shares the story of how her research has been taken from the lab to the market by forming a company (Kenoteq).

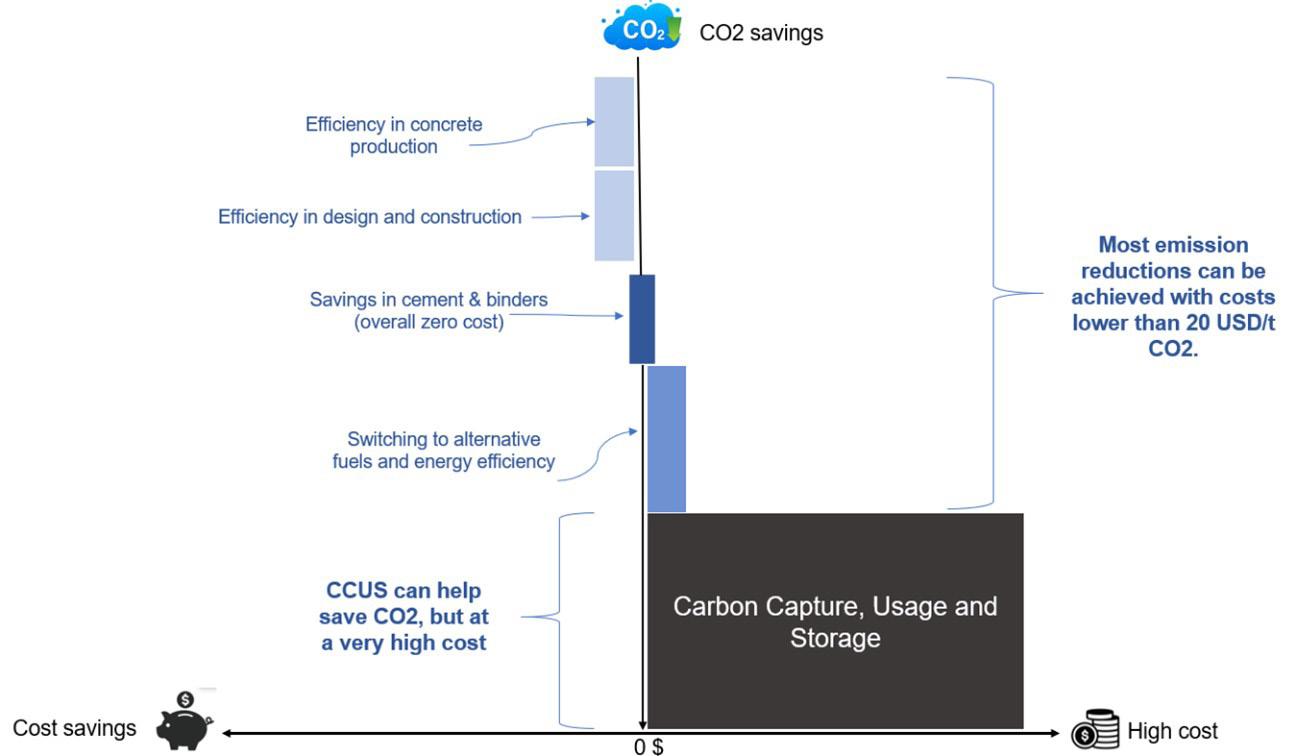

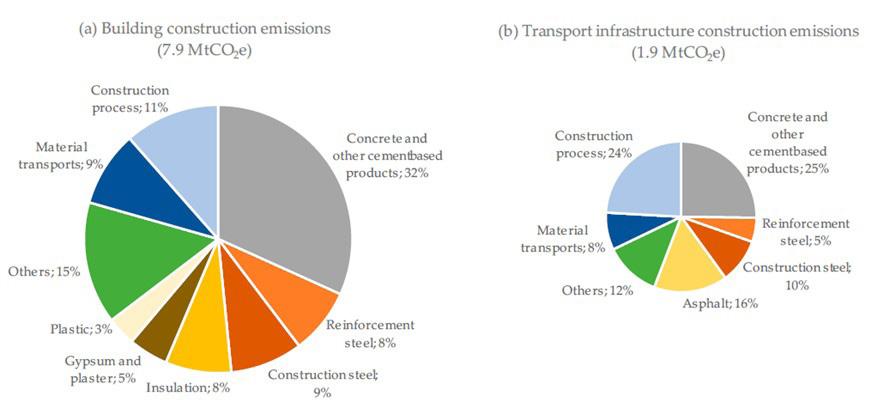

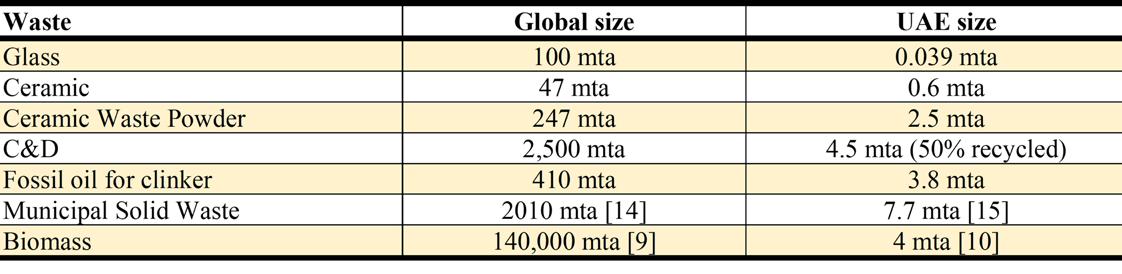

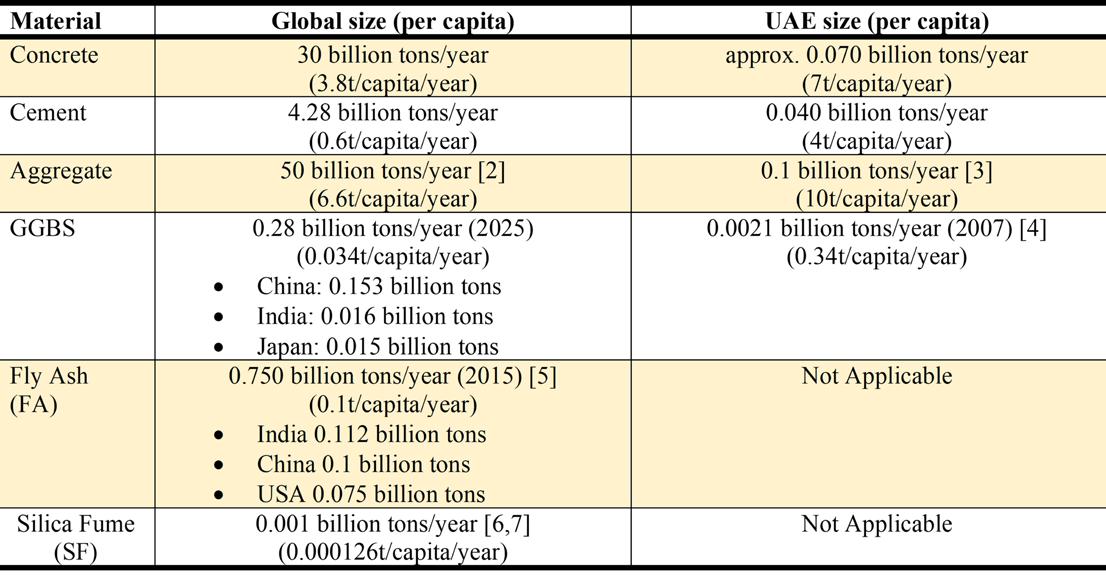

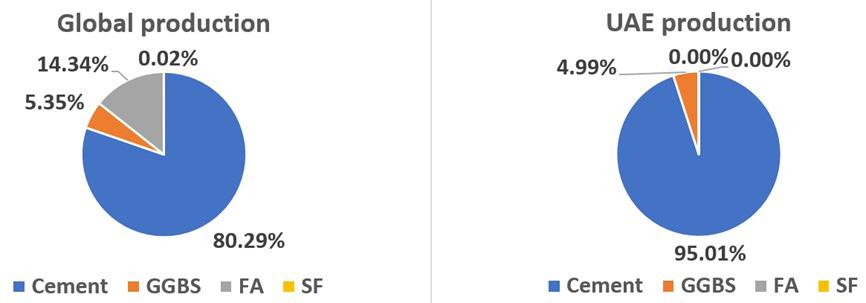

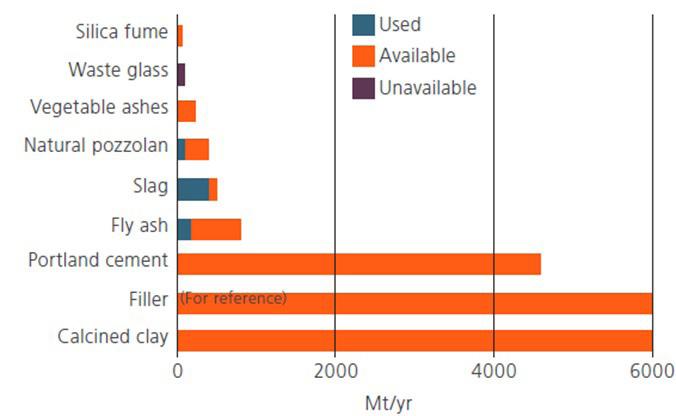

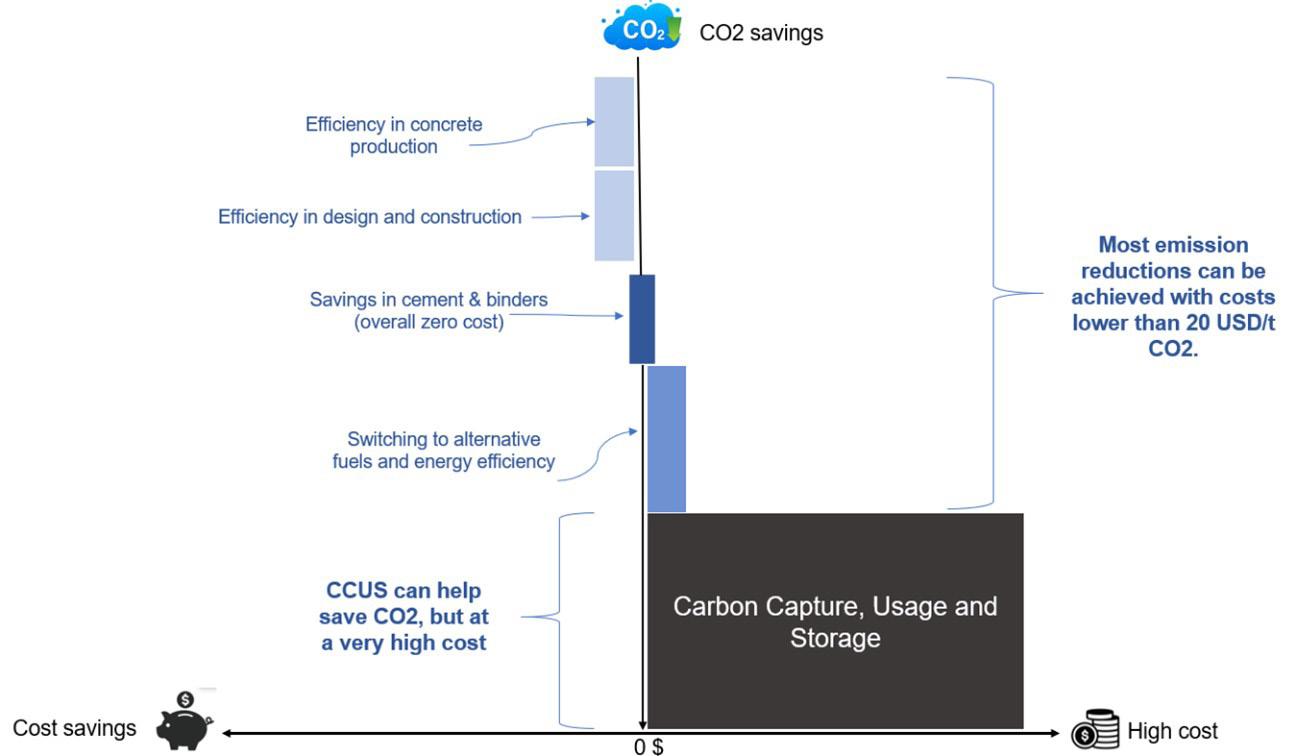

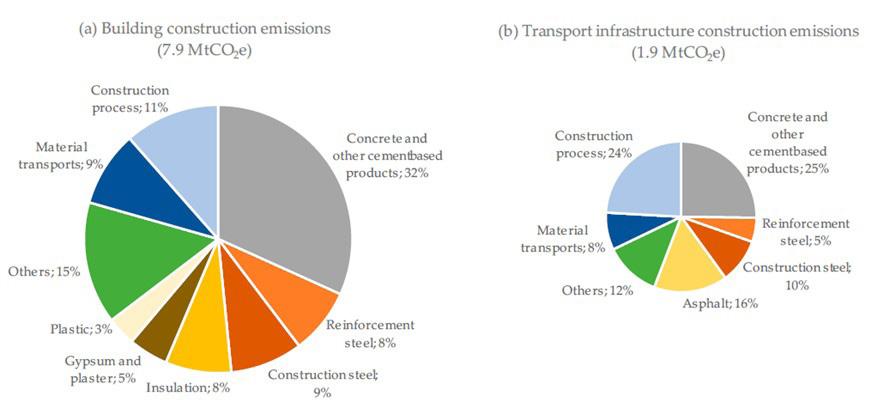

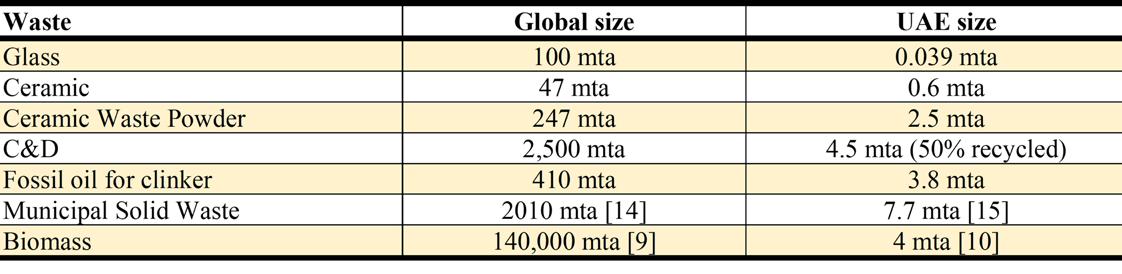

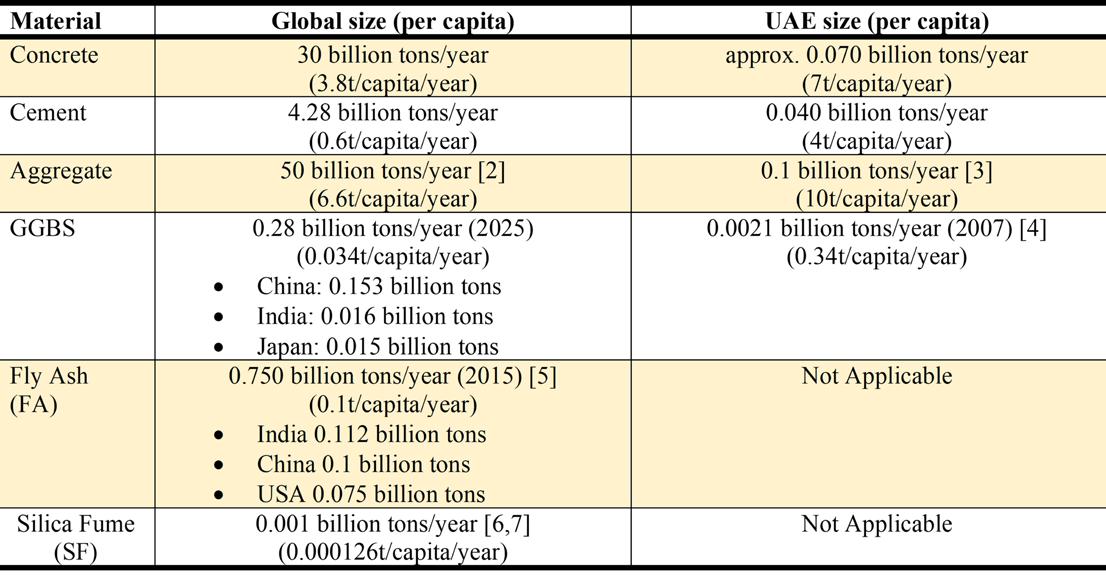

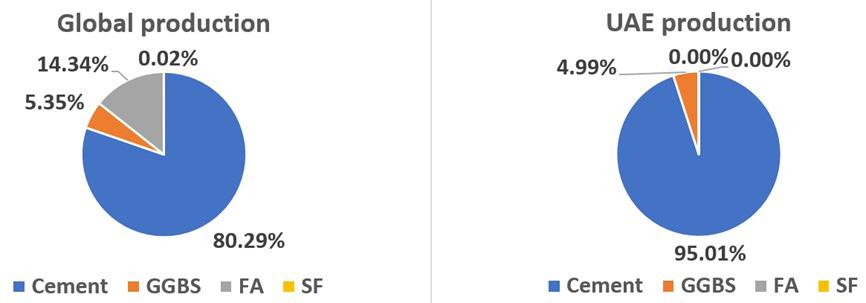

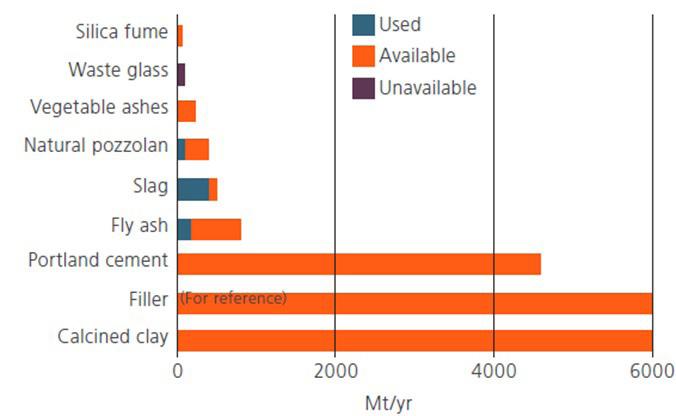

The final article under this theme is by Mustafa Batikha, Warren McKenzie and Olisanwendu Ogwuda, who present a report submitted during a workshop held by The Centre of Excellence in Smart Construction (CESC) at Heriot-Watt University to decarbonise the cement industry in the UAE. Through discussing valuable collected data, the report brings conclusions and recommendations as a roadmap for decarbonising the cement industry.

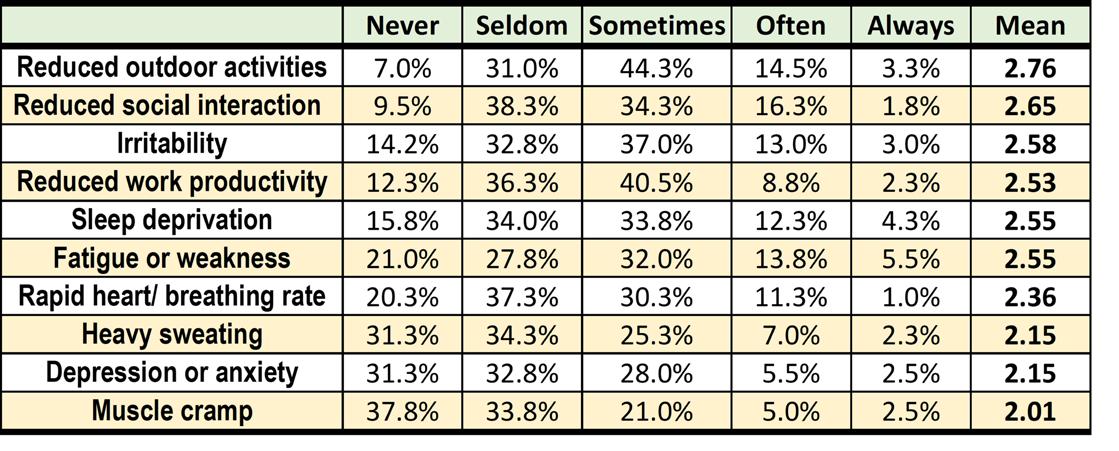

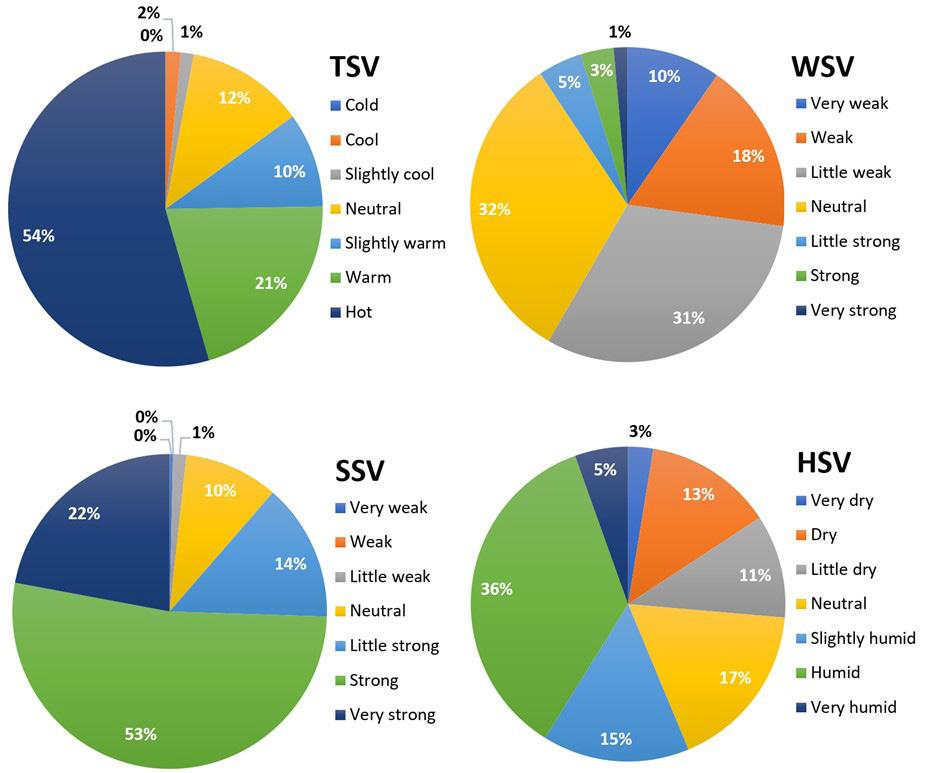

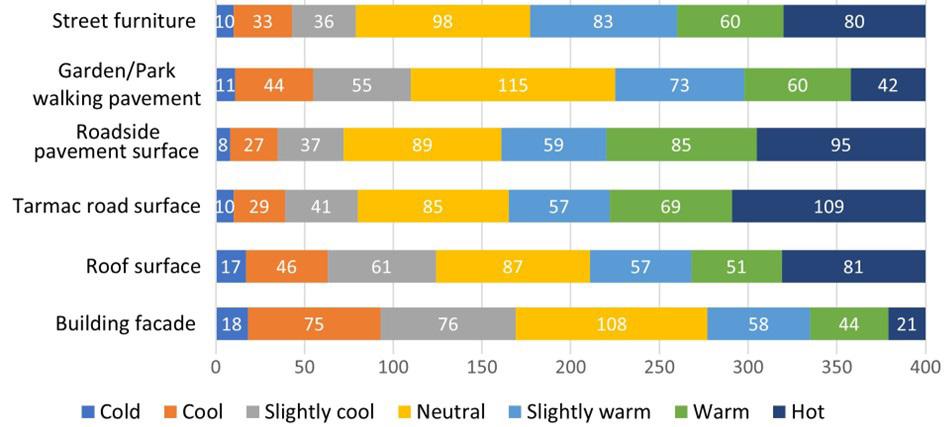

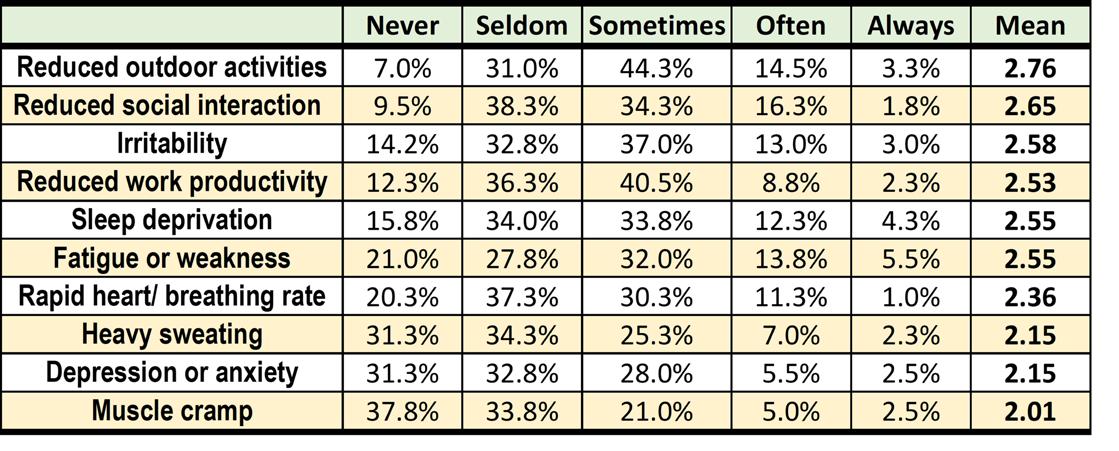

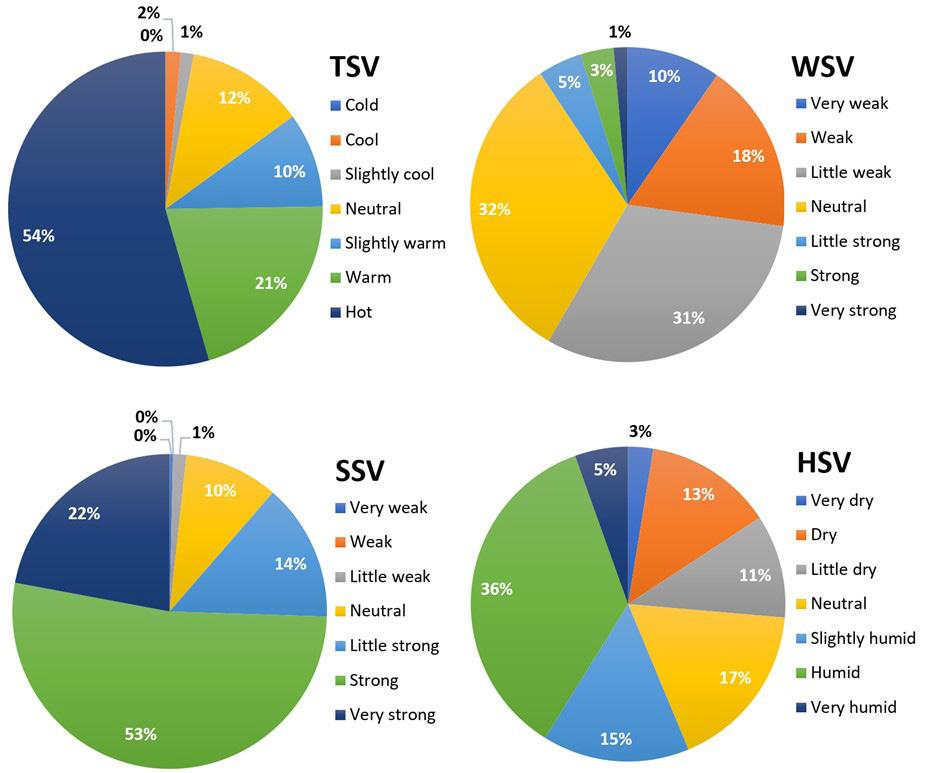

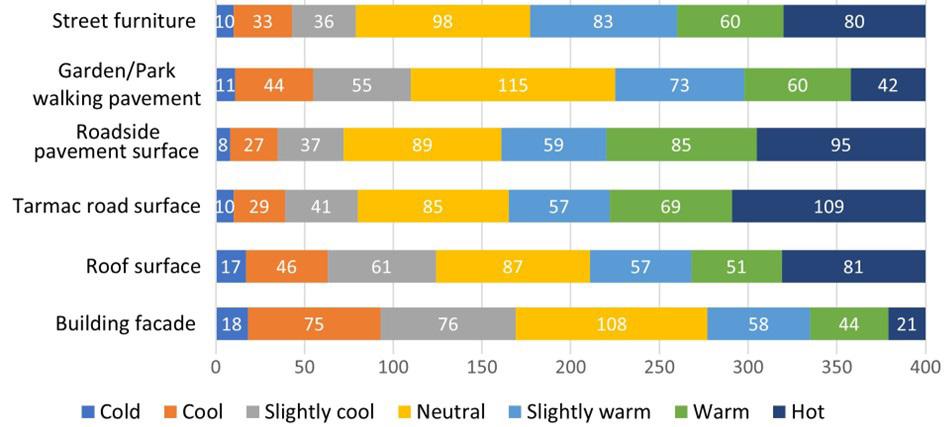

Wellbeing

Under this theme, Ashley Hong and Ying Jia Low address the increase in the urban outdoor temperature because of population growth, which influences human activities and causes more climate problems by making people stay indoors, releasing more non-renewable energy into the atmosphere through massive uses of the AC, besides the injuries and deaths coming from the high temperature. Long-term exposure to hot temperatures causes a decreasing social life, lower motivation, skipping work, and depression which may lead to suicide in some cases. The high temperature more influences vulnerable groups: the elderly, children, and women. In addition, this situation will add extra medical costs for the lower income categories. To avoid that, the article emphasizes the importance of having an urban planning strategy to reduce outdoor heat by increasing green areas and proposing cooler surface materials for roads and pavement.

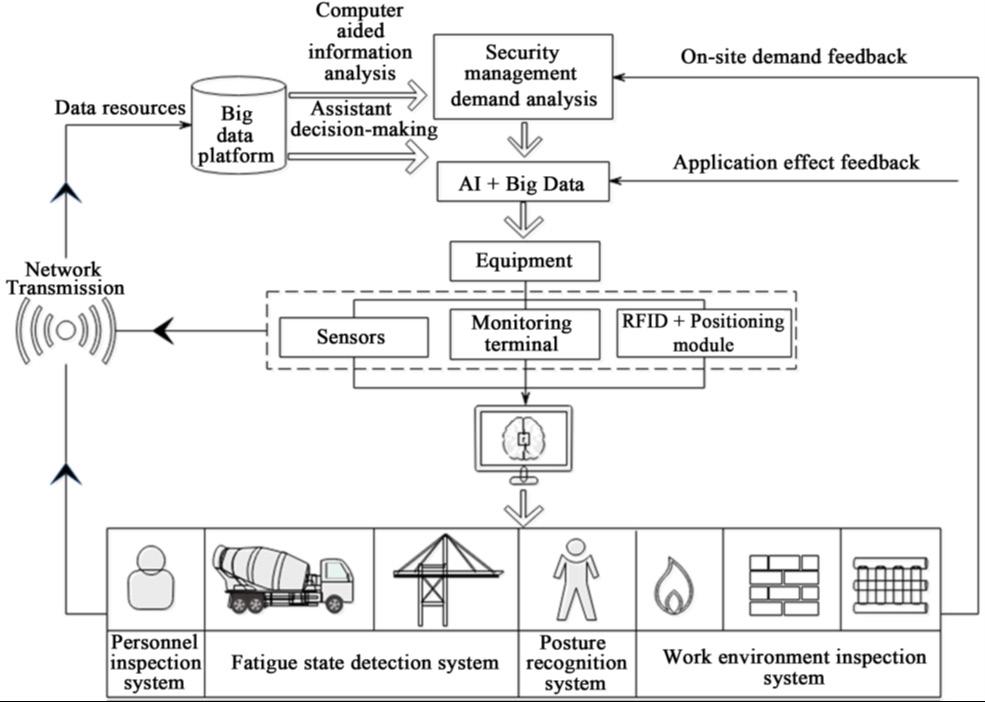

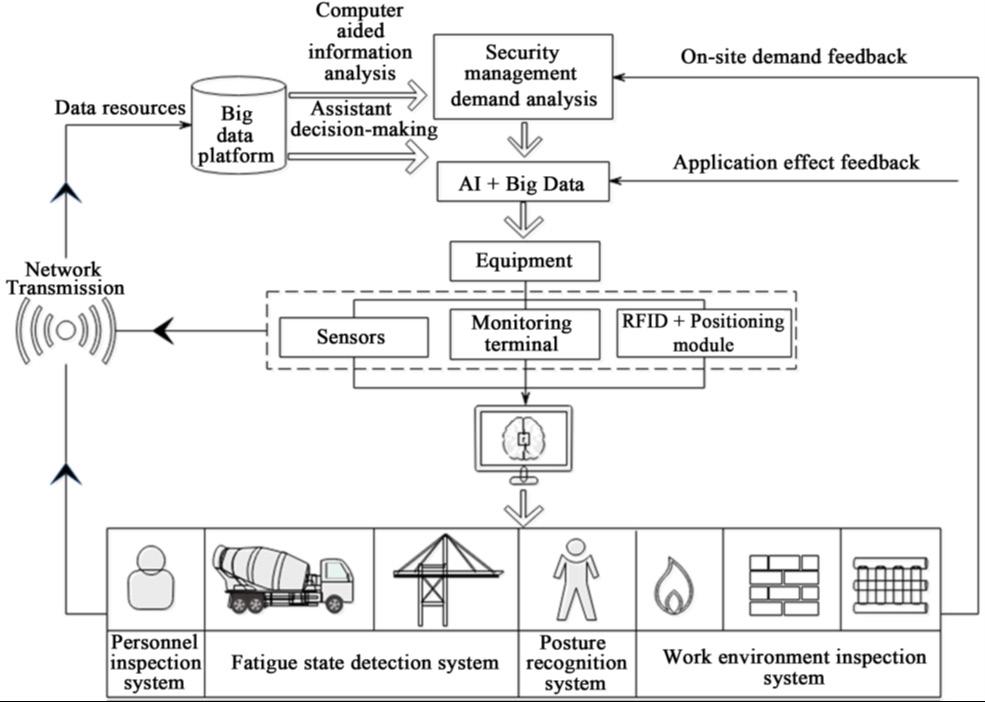

The second article by Rodaina Aboul Hosn records how the construction sector has registered the highest rate of workers’ injuries. For example, in 2017, a fifth of the US workers’ deaths was from the construction industry. As a solution, the author asks to get AI involved to secure more workplace safety. The article brings examples of how AI (e.g., cameras, drones and sensors) can monitor the construction site and detect any abnormal activities or less safety behaviour and report that to the safety managers. Moreover, the article highlights some work that researchers in academia have conducted to feed AI with massive data about possible injuries on

site. The paper also points out the positive impact of the prefabrication off-site or the robotics on the site (e.g., 3D concrete printing) in securing a safer workplace.

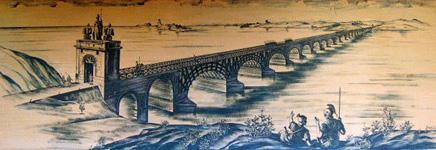

Sabih G Khisaf, in the third article, describes how massive immigration has been initiated since the 15th century because of many influencing factors such as the industrial revolution, politics, wars, etc., where the aim behind immigration is to find better living conditions. With this immigration, bridges have played a vital role in facilitating human mobility due to the massive congestion in cities. The paper takes us through the history of bridges, and it is believed that human flourishing hasn’t been achieved without them. The author also highlights the classifications of bridges besides their types and structural systems used. He also brings examples of today’s sustainability practice in the construction and design of bridges.

The final article under this theme is by Islam Badawi and Noor Zainab Habib. The authors explore the challenges facing improving transportation networks in the UAE, such as the fast development of new communities and its influence on the traffic demand, which requires design, sustainability, schedule and finance challenges. The paper suggests potential solutions for the traffic congestion in the UAE, such as applying the paid carpooling service, which is still illegal in UAE.

Acknowledgements

The Editor would like to sincerely appreciate Charlotte Turner, Monika Toth and Judy Aneiny for their continuous and invaluable help in producing and designing the CESC research bulletin.

Research Bulletin No.7 April 2023

Editorial 4

Topic of Focus The Road to (and beyond) COP28

Prof. Lynne Jack Interim Director – Centre of Excellence in Smart Construction Associate Principal (International Research) Director, Institute of Sustainable Built Environment School of Energy, Geoscience, Infrastructure and Society

Heriot-Watt

University Edinburgh, UK

L.B.Jack@hw.ac.uk

There is a real sense of excitement and anticipation across the UAE as Dubai prepares to welcome COP28 later in the year. These conference events provide a tangible marker in our journey to Net Zero and our pursuit of solutions to address climate change.

We know that buildings and construction account for almost 40% of all CO2 energy-related emissions, thus underscoring the importance of effecting change across the sector as delegates at COP28 aspire to commit to ambitious solutions to limit climate change.

At the Centre of Excellence in Smart Construction (CESC), we are also fully committed to helping deliver against the aspirations of COP28. We too are ambitious, with our main purpose being to stimulate industry-led innovations and research driven solutions to address sector challenges. In doing so, we are guided by the UAE’s growth, climate change and sustainability strategies such as the Dubai 2040 Master Plan, the National Climate Change Plan of the UAE 2017-2050 and the UAE NetZero 2050 strategic initiative.

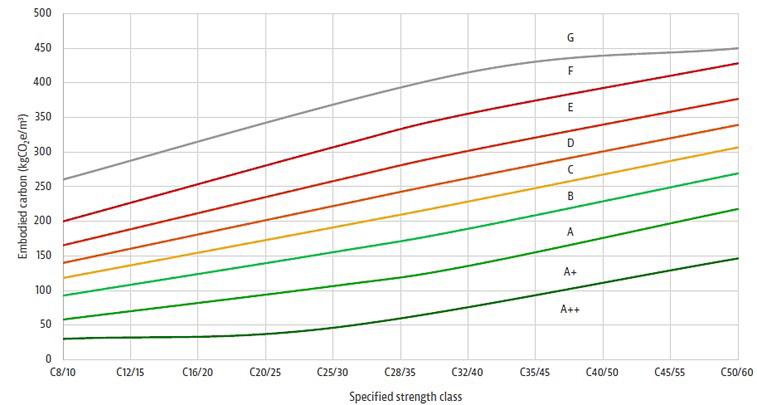

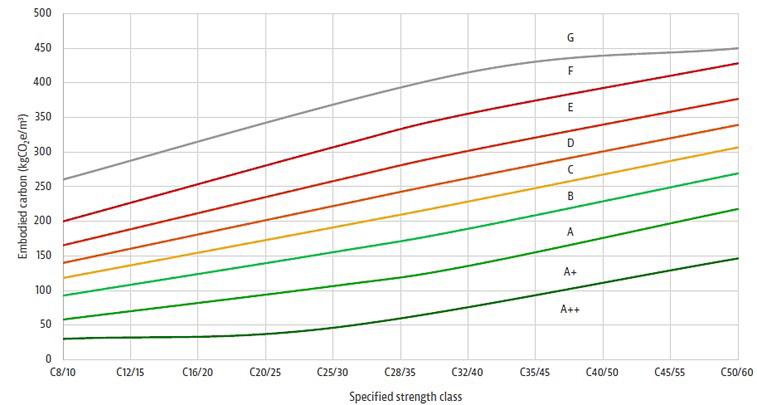

Recognising the significant role the construction sector plays, and in particular that of cement production, at CESC, we also continue with our work on Cement Decarbonisation. Readers of previous editions of the CESC Bulletin may recall that we have split this work into four themes: (i) Materials and Waste Management, (ii) Technology, (iii) Standards, Procedures and Policies, (iv) Education and Awareness. The first of these themes is already complete and the cluster one report is available upon request. These themed workstreams link to a wider roadmap that outlines a progressive approach linking low, then net-zero, carbon processes and their corresponding milestones. This roadmap not only serves a practical purpose in terms of its underpinning of this work, it also acts as an important reminder that we must be prepared for the longer journey; one that must be sustainable. This message applies equally to COP28. As critically important as the conference event is, there is a need to recognise the importance of sustained progress beyond December 2023.

With the continued growth of the construction sector, both within the UAE and globally, it is clear that research and innovation have a crucial

role to play in advancing knowledge and contributing to this longer-term goal. Collaboration is also key; especially international collaboration. We know that by working together we can deliver change and impact much faster than we could by working independently. At CESC, we operate using a triple helix model where we bring academia, industry and government together, forming a formidable partnership with multiple benefits for the sector. Such partnerships provide an exciting way to work and at CESC, we are keen to expand the scope and depth of our partnership agreements such that we can continue to strengthen our collective knowledge base.

Reducing carbon emissions across the construction sector remains an imperative. Examples of where this can be achieved include, but are not limited to, the use of sustainable construction materials, deploying modular construction methods, adopting the use of advanced technologies and smart construction, and introducing a focus on building performance. Across both CESC and Heriot-Watt University, we are committed to delivering new knowledge in support of each of these themes. As the COP conference events set the roadmap for transformational change in addressing climate change, at CESC we stand ready to respond to industry-led challenges in support of this endeavour.

If you would like to know more about the research and innovation work we undertake at Heriot-Watt University or the collaborative opportunities afforded by partnering with CESC, please feel free to get in touch.

Research Bulletin No.7 April 2023

The Road to (and beyond) COP28 5

Performance and Productivity

Cooling Systems in the Arab Gulf Region Using Energy Geostructures

École Polytechnique Fédérale de Lausanne (EPFL), Switzerland lyesse.laloui@epfl.ch

Soil Mechanics Laboratory

École Polytechnique Fédérale de Lausanne (EPFL), Switzerland elena.ravera@epfl.ch

Northwestern University Evanston, Illinois, USA af-rottaloria@northwestern.edu

Soil Mechanics Laboratory

École Polytechnique Fédérale de Lausanne (EPFL), Switzerland sofie.tenbosch@epfl.ch

The Arab Gulf region is amongst the top regions of the world in energy consumption directed to cooling. Reduction in air conditioning reliance on fossil energy would significantly reduce carbon emissions and would heavily contribute to achieving the region’s environmental goals. Energy geostructures represent a feasible clean alternative to conventional cooling systems, where the underground structures are transformed into thermal exchange units to harvest the soil’s cooling energy. The article presents a numerical analysis of a building in Dubai, UAE, and shows the effectiveness of energy geostructures in providing the cooling needs in hot-dominated climates while reducing carbon emissions.

Keywords: Energy Geostructures; Geothermal; Carbon Dioxide Emmissions; Sustainability; Energy Efficiency.

Introduction

The Arab gulf region of the middle east has experienced a surge in development and construction in the past few decades, which resulted in a significant increase in energy consumption (e.g., UAE electricity consumption in 2020,130 TWh, is almost eight multiples that of the consumption in 1990 [1]). Currently, the region is amongst the highest globally in energy consumption per capita (Bahrain, Qatar, Kuwait and UAE are among the top ten countries) [2], which is expected to grow further with the population growth and the expected future developments.

Consequently, carbon dioxide (CO2) emissions are significantly increasing in the region (UAE and KSA more than doubled their emissions in 2020 compared to 1990) [1]. In 2006, UAE was declared to have the largest ecological footprint per capita [3], which called for radical measures to closely monitor the environmental impact of the ongoing developments and to introduce legislations and incentives to improve the region’s environmental performance.

There are many local and global moves to reduce carbon emissions including “Net Zero Emissions (NZE)”, to bring energy-related CO2 emissions to net zero by 2050. Similarly, many Arab gulf countries adopted local initiatives to fulfil the same target among which is the “UAE Net Zero 2050”. For the buildings sector, this means that mandatory zero-carbon building energy standards will be introduced for new structures. Hence, it is crucial to introduce green energy alternatives to conventional systems relying on fossil energy.

2. Shallow Geothermal Energy

On average, 30% of the total energy consumption is attributed to the residential sector. From 60% to 85% of that energy is directed to air conditioning (AC) (predominantly cooling in the middle east) and to hot water production. Furthermore, air conditioning is anticipated to be tripled by 2050, which makes it among the top energy demand drivers [4].

The Arabic gulf region has an arid climate and is one of the hottest and most humid regions of the world. Hence, KSA and UAE are among the top countries with the highest AC share in household electricity consumption [5]

Research Bulletin No.7 April 2023

Prof. Lyesse Laloui

Director of EPFL Soil Mechanics Laboratory

Dr Ahmed Badr Mabrouk Assistant Professor of Civil Engineering American University in Dubai Dubai, UAE amabrouk@aud.edu

Sofie Elaine Ten Bosch Scientific Assistant

Dr Elena Ravera

Postdoctoral Researcher

Dr Alessandro Rotta Loria Assistant Professor of Civil and Environmental Engineering

Research No.7 April 2023 Cooling Systems in the Arab Gulf Region Using Energy Geostructures 7

1.

that mainly relies on fossil fuels (natural gas and oil). Thus, improving the AC’s cooling efficiency and reducing its reliance on fossil energy is crucial to achieving the NZE targets. This mandates the need to tap into new energy sources, such as geothermal energy.

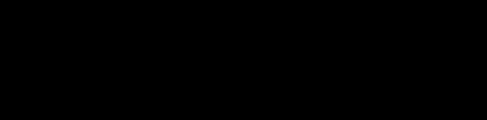

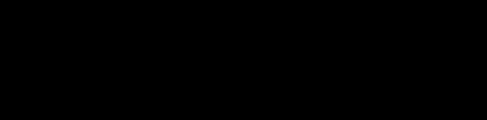

Shallow geothermal energy technologies harness the approximately constant temperature of the ground throughout the year beyond 4–6 m of depth, depending on the soil profile (Figure 1). The ground’s relatively stable temperature can be used for the structure’s cooling or heating by injecting the extra heat into the soil (or extracting heat from the soil in case of heating). This can be achieved by utilizing the already existing geostructures, with minor modifications, as explained in the next section, as a thermal exchange unit, along with their original structural function.

The use of shallow geothermal energy technology has been vastly growing in the last three decades (since the 90’s). There are remarkable examples worldwide of structures completely relying on that system to cover their heating and cooling energy needs. The system proves to be environmentally friendly (compared to conventional fossil fuel applications) with significant financial feasibility in most cases and short payback time.

In arid regions, where the main interest is to cool buildings, it is possible to inject heat and extract cooling energy. This technology harnesses constant and moderate ground temperature that is used to assist in the air conditioning of buildings allowing less conventional energy to be consumed for operation, which in turn results in lower CO2 emissions.

The construction of such geostructures requires the installation of polyethylene exchange tubes to exchange energy with the surrounding soil. These tubes are usually attached to the reinforcement cage of the structure before the concrete is poured or can be integrated into the drainage paths in the presence, for example, of external insulation of walls or slabs (Figure 2). The dimensions of the energy exchanger tubes and their arrangement in the geostructure are adapted to the geostructure to minimise the impact on the execution process. If installed expertly and on the basis of plans and execution recommendations, the fitting of geostructures represents an execution activity that is not on the critical path of the construction site.

3. Energy Geo-structures: An Environmentally Friendly Solution to the Problem and their Concept

Energy geostructures involve adding a geothermal energy exchanger function to any concrete structure in contact with the ground, in addition to its original role as a structural element. Like other shallow geothermal systems, energy geostructures use the low-enthalpy thermal energy present in the shallow earth’s surface and exploit the relatively constant temperature field in the shallow subsurface throughout the year for their heat exchange role [8].

The integration of energy exchangers can be done on various types of foundations and infrastructures (piles, walls, slabs, tunnels, - Figure 1) and allows to exploit of the renewable thermal energy naturally present in the ground for heating and/or cooling of buildings as well as for domestic hot water production and seasonal thermal storage.

4. Performance in Hot-Dominated Climates: A Case Study in Dubai

The simulations of energy piles performed in this work are run with the software COMSOL Multiphysics (v. 5.5) [9]. This software is used to run 3-D time-dependent thermo-hydro-mechanical simulations. Such simulations reproduce the energy piles, the ground, and the pipes embedded within them. The mathematical formulation employed for these analyses has already been presented in other studies (e.g., Batini et al. 2015 [10]; Rotta Loria 2021 [11]) and is not reported here for concision. This modelling approach showed to be effective in evaluating long-term aspects.

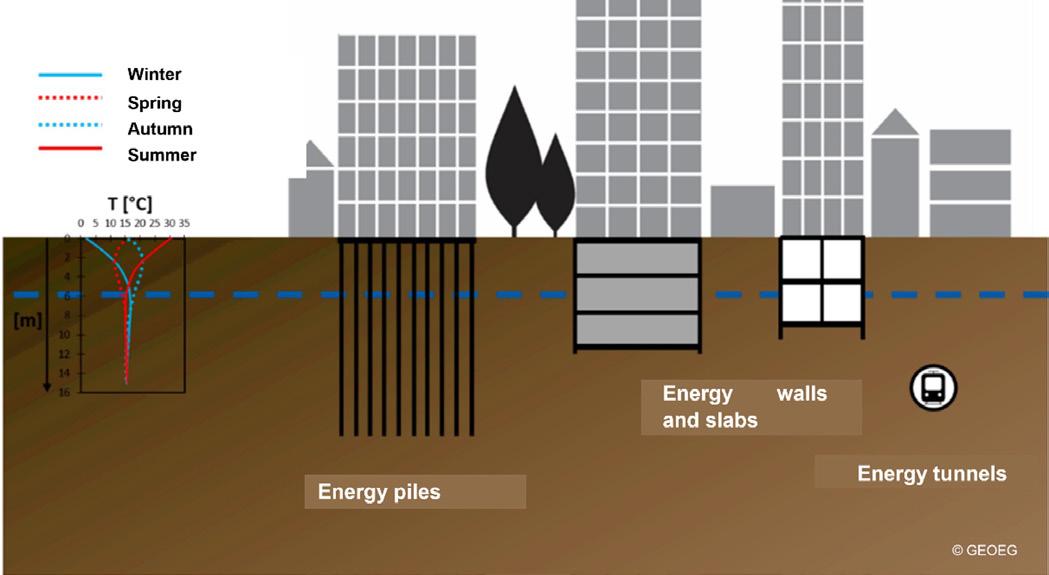

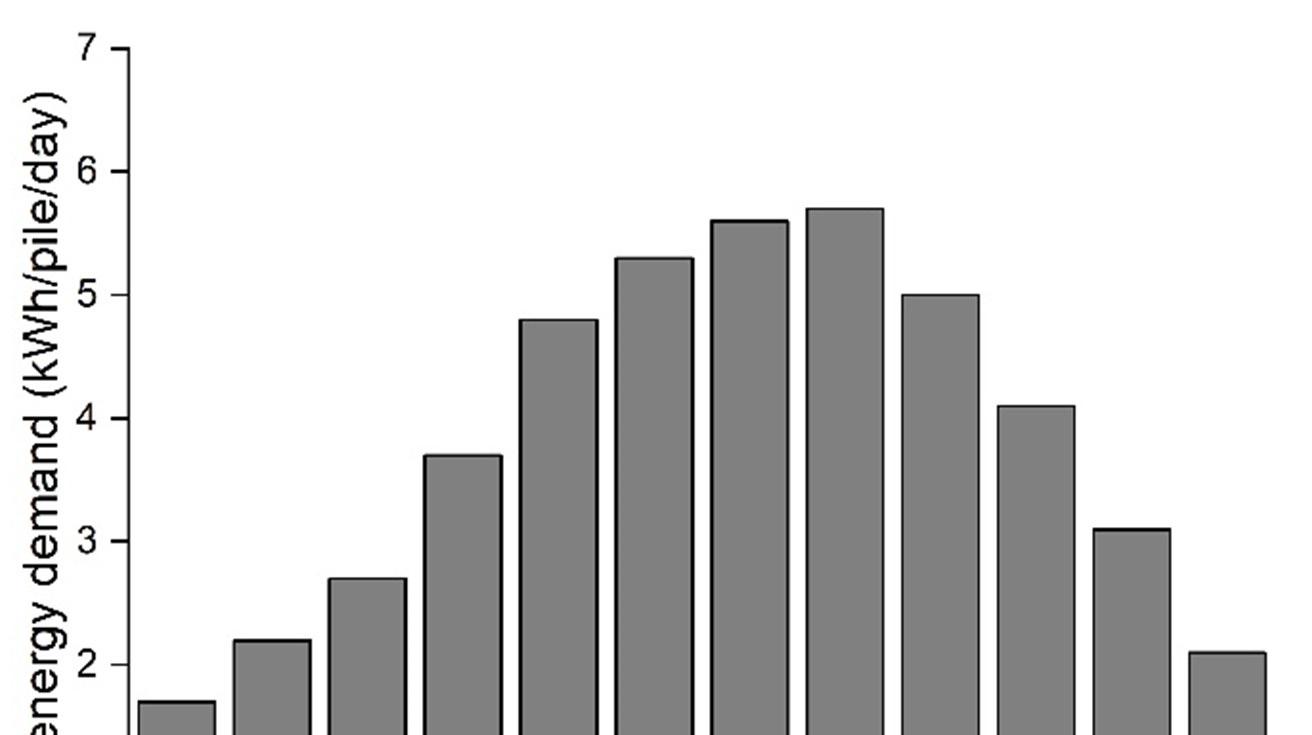

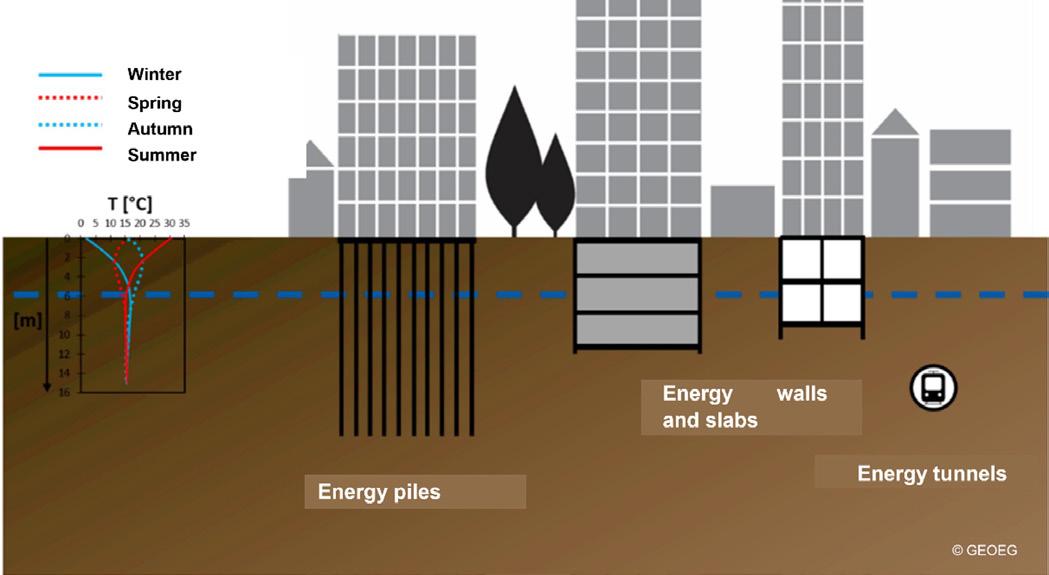

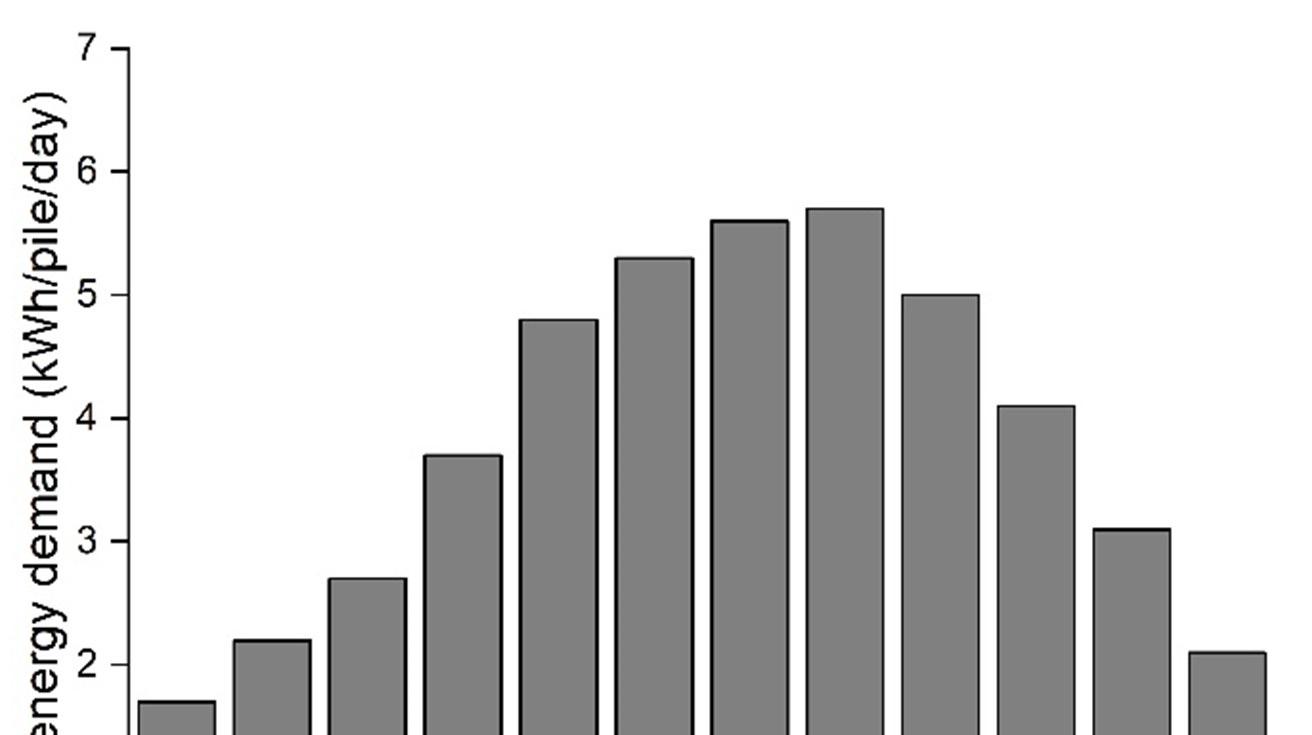

For this case study, it was targeted to provide 40% of the cooling demand of the building through its energy foundation. The daily energy demand implemented in the model for different months is shown in Figure 3.

Research Bulletin No.7 April 2023 Cooling Systems in the Arab Gulf Region Using Energy Geostructures 8

Fig. 1 Principle of energy geostructures (source image: GEOEG [7]).

Fig. 2 Installation of heat exchanger tubes on the reinforcement cages of foundation structures before the concrete is poured (source image: GEOEG [7]).

A numerical case study explores the performance of an energy pile foundation that has the specificity of providing structural support and renewable cooling energy to a building located in Dubai.

The numerical simulations represent the energy dynamics of the energy geostructure over 50 years (Figure 4) and account for all the key physical phenomena governing the actual heat exchange process within and around the designed energy system. The simulations also include the ON/OFF operation of the geothermal system, considering its interactions with the heat pump.

5. Conclusions and Perspectives

The Arab gulf region of the middle east is amongst the highest in energy consumption and, subsequently, in CO2 emissions. Air conditioning has a significant share of the energy consumption of buildings, and thus, relying on green sources for cooling would heavily contribute to achieving the NZE goals of the region.

Cooling, or heating, of structures using energy geostructures represents a clean energy alternative that can have a significant impact on CO2 emissions reduction. The existing geostructures can be turned into thermal exchange units that can harvest the ground’s cooling\heating energy. The system has been applied and tested with success in many regions all over the world, that have similar climate conditions as in the Arab gulf.

The article presents a numerical analysis of a case study in Dubai, UAE. The analysis shows the energy geostructures system performance to cover 40% of the cooling needs of a building. The study indicated a sound longterm performance of the system. Thus, it can be deduced that energy geostructures system, when properly designed, have great potential as a clean energy source alternative in hot-dominated climates in arid and semi-arid regions.

Acknowledgements

Some of the used data inputs were inspired for measurements made available by econstruct.ae

The long-term behaviour showed that the increase in temperature is largest in the first years and shows stabilization behaviour after. The maximum outlet temperature limit of the applied heat pump was respected for a time of 50 years, which shows the potential of energy piles in arid regions to cool the buildings when these systems are properly designed.

The obtained results provide a sound knowledge base on the performance of energy geostructures in hot-dominated climates and highlight markedly their effectiveness to decarbonize energy supply in buildings via the use of renewable energy sources.

This innovative technology can help reduce CO2 emissions for space cooling purposes in arid and semi-arid regions, where cooling demands are high.

Research Bulletin No.7 April 2023 Cooling Systems in the Arab Gulf Region Using Energy Geostructures 9

Fig. 3 Daily energy demand per pile [12]

Fig. 4 Long-term performance (50 years) of energy geostructures in hot-dominated climates [12]

https://www.iea.org/countries/united-arab-emirates

https://en.wikipedia.org/wiki/List_of_countries_by_electricity_ consumption

Laloui, L., and A. F. Rotta Loria. 2019. Analysis and Design of Energy Geostructures: Theoretical Essentials and Practical Application. Academic Press.

COMSOL. 2019. COMSOL Multiphysics version 5.5: user’s guide and reference manual. Burlington, Massachusetts, United States: COMSOL.

https://www.iea.org/news/air-conditioning-use-emerges-as-oneof-the-key-drivers-of-global-electricity-demand-growth

https://data.footprintnetwork.org/ https://www.enerdata.net/

https://www.eia.gov/international/data/world

https://www.geoeg.net

Batini, N., A. F. Rotta Loria, P. Conti, D. Testi, W. Grassi, and L. Laloui. 2015. “Energy and geotechnical behaviour of energy piles for different design solutions.” Appl. Therm. Eng., 86 (1): 199–213.

Rotta Loria, A. F. 2021. “The thermal energy storage potential of underground tunnels used as heat exchangers.” Renew. Energy, 176: 214–227. https://doi.org/10.1016/j.renene.2021.05.076.

Ten Bosch, S. E., E. Ravera, and L. Laloui. “Performance of energy pile foundations in hot-dominated climate: a case study in Dubai” (in preparation).

Research Bulletin No.7 April 2023 [1] [3] [5] [7] [9] [11] [2] [4] [6] [8] [10] [12]

References Cooling Systems in the Arab Gulf Region Using Energy Geostructures 10

3D Concrete Printing: Bus Station Case Study

BESIX3D, DED

BESIX Construct LLC

Dubai, UAE ocremens@sixco.ae

Structural Engineer

BESIX3D, DED

BESIX Construct LLC

Dubai, UAE apoorvasd@sixco.ae

BESIX Construct LLC Dubai, UAE msamoilov@sixco.ae

3D Construction Printing or Additive Construction is an additive technology that uses different materials suitable to produce structural elements, parts of the buildings, formwork, architectural elements, etc. Thanks to its well-known technology and good structural properties, concrete is widely used for structural applications.

There is no doubt that 3D concrete printing technology will be more and more used within the construction industry for applications related to structural and non-structural components, be they for temporary or permanent applications. With benefits such as high speed, repeatability, direct link to BIM and other computer-aided technology used by the various construction stakeholders, 3D concrete printing technology process can significantly improve actual construction operations with routine activities such as masonry, concrete works and formwork while offering the possibility to architects and designers to free themselves from current execution and material limits.

This article will present an application of 3D printed concrete used to construct a bus station in the UAE. Starting from the architectural concept, BESIX 3D printing division developed a design considering the various requirements of all the involved disciplines.

Keywords: Structure; 3D printing; Procurement; Logistic; Execution.

1. Introduction

As a main contractor operating in the Middle East region since 1965, BESIX Construct is directly concerned with today’s market modifications. Through its Dubai-based subsidiary, Besix3D, BESIX Construct invested from 2018 in 3D-printing technology, focusing on practical applications with the goal to diversify its operations and acquire/build knowledge of the technology that will shape the future of the construction sector.

For almost 5 years, BESIX 3D was involved in different projects with 3D concrete printing applications ranging from large architectural flowerpots for EXPO 2020, art sculptures in DIFC, the first and last in the world concrete printed facade for BESIX Dubai Head Office or a halfway house with load bearing printed walls in Abu-Dhabi which are capable of resisting all design forces without the need of reinforced concrete structure.

This paper will describe the last project BESIX 3D was involved in, which consists of an interestingly shaped bus station. The project was different from others as it pushed 3D printed material beyond its limits due to a

large cantilever and a short base. For the execution BESIX 3D, based on its experience, selected a combination of 3D printed concrete forming the exterior outline of the bus station used as a lost formwork with concrete and reinforcement added in the most stressed areas.

2. BESIX 3D

2.1 BESIX 3D Printing Set-Up

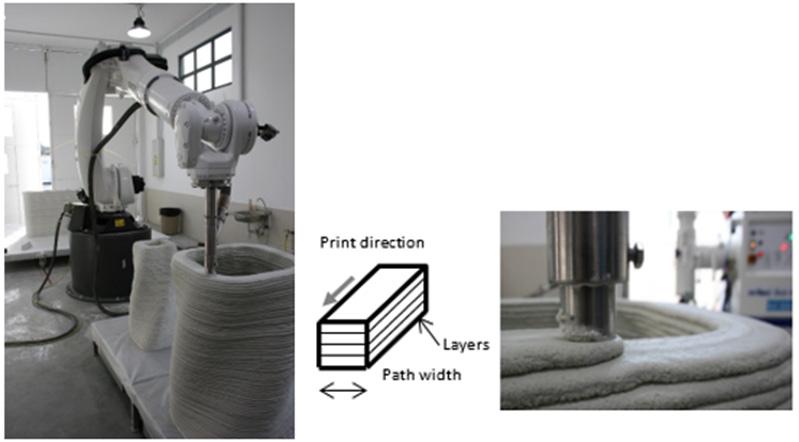

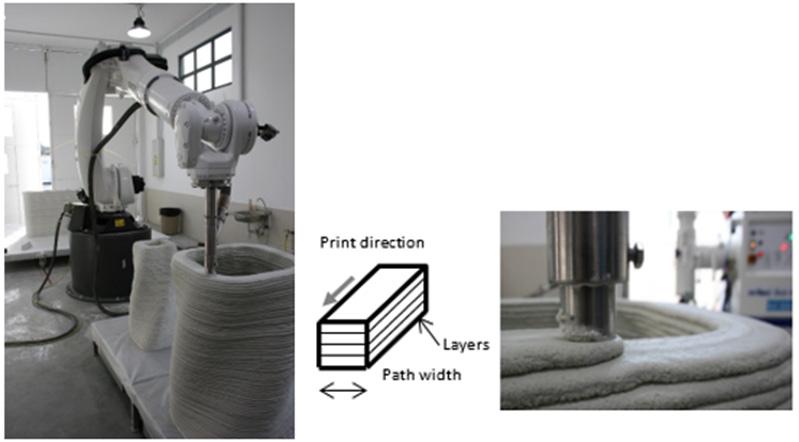

The main piece of equipment is the KUKA robotic arm, mounted on a fixed base in the middle of BESIX3D dedicated production hall. It is connected to the plastering mixing pump connected to a silo for a direct and uninterrupted supply of material.

The choice of using a fixed 3D-printer versus a mobile 3D-printer was driven by the complexity of developing a mortar mix that would meet the printing requirements (consistency and setting time), structural properties (strength) and aesthetical aspects.

Research Bulletin No.7 April 2023

Olivier Cremens Sr. Project Manager

Apoorva Doctor

Mikhail Samoilov 3D Printing Manager

BESIX3D, DED

Research No.7 April 2023 3D Concrete Printing: Bus Station Case Study 11

The mortar mix can be printed in layers of 5 to 20mm thick with a path width ranging between 30 to 80mm. Generally, a layer thickness of 10mm is found to be the best compromise between printing speed and aesthetical render when printing organic shapes.

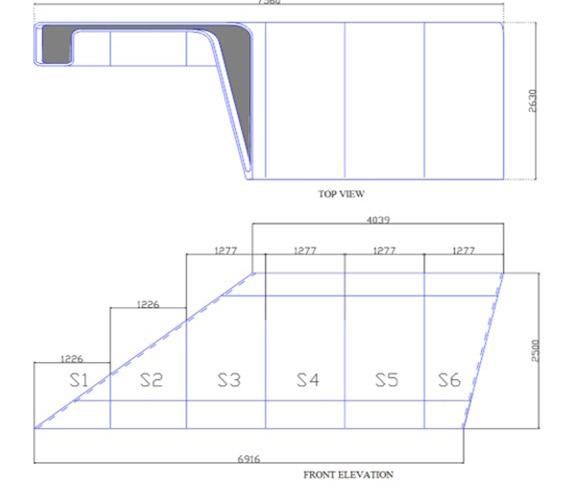

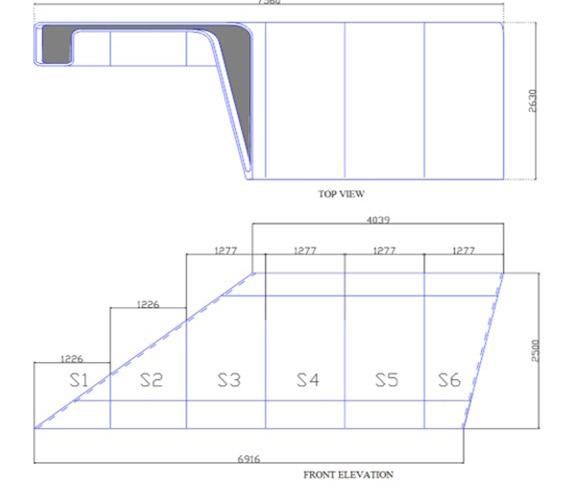

3.2 Geometry

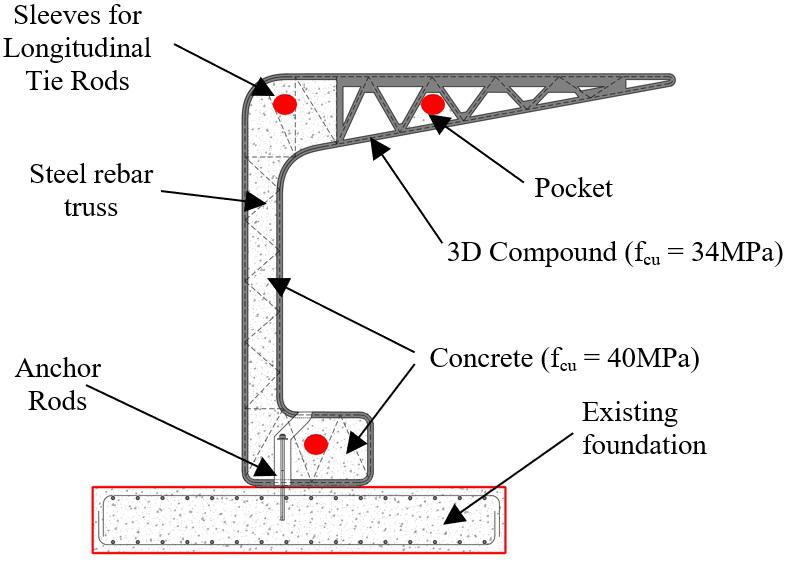

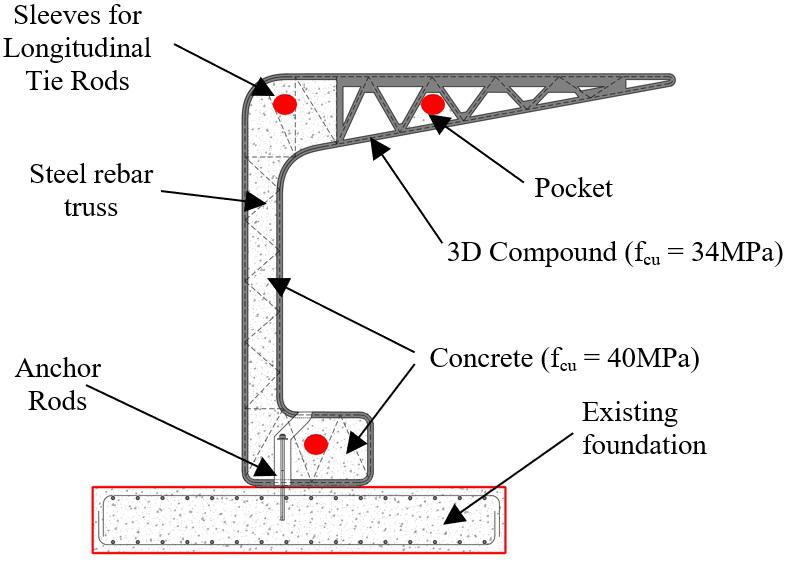

The outer boundary of the bus-station section is 3D printed. A reinforcement truss composed of 8mm diameter rebars is placed between printed layers at 100mm centre to centre. These reinforcement trusses are prefabricated by welding the rebars to each other at connection nodes.

The bus station will be made of 6nos 3D printed segments placed side by side and securely connected to each other using 3nos longitudinal rods.

To enhance stability against overturning and sliding, the bench area and the wall of the bus station are filled with concrete. A single row of anchors spaced at 540mm centre to centre secures the connection between the existing foundation and the station. An individual roof pocket is also filled with concrete for installation purposes. Refer to Figure 3 for a better understanding.

2.2 3D Printing Compound

The mortar mix is based on Sikacrete®-752 3D product (High-Performance Shrinkage Compensated Micro-concrete for 3D printing). It is a mixture of Portland cement and graded aggregates produced by SIKA and locally sourced in Dubai, which is a significant advantage in terms of sustainability.

Sikacrete®-752 has been partially developed based on the return on experience from BESIX 3D and is specifically used for the 3D printing of new structures.

It is designed to allow for easy mixing, easy pumping, and excellent interlayer adhesion. A detailed study of the mix and material properties can be found in BESIX 3D article published for the IABSE Congress [1].

3. Bus Station project

3.1 Concept and Challenges

The bus station concept design integrates a waiting bench and a long cantilever providing shade with a dynamic shape (Figure 2). It makes the bus station looks unique and futuristic. Such design freedom can now be pushed to execution thanks to the advantages of 3DCP.

3.3 Material Properties

Concrete Material Properties

3D Printed Compound, fcu = 34 MPa

Concrete, fcu = 40 MPa

Reinforcement Steel Properties

8mm dia. Rebars and 20mm dia. Tie rods, fy =500 MPa

Steel Anchors.

Hilti Chemical Anchors, HIT-HY 200 + HAS-U 8.8 HDG M20 with 6mm thick steel plate (S275)

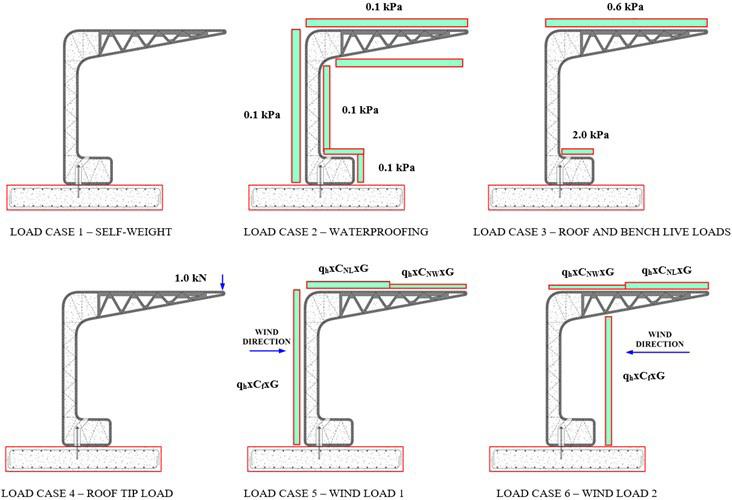

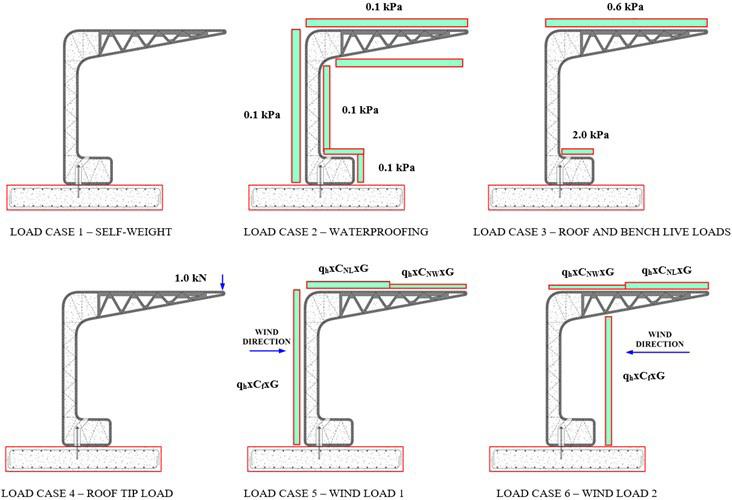

3.4 Loadings

The following loads were considered in the design,

Self-Weight

Water-proofing Load of 0.1 kPa on entire station

Pedestrian Load on the bench – 2.0 kPa

Load on the roof – 0.6 kPa (with Pedestrian bench load)

Load on the tip of roof – 1.0 kN (Independent action)

Research Bulletin No.7 April 2023 12

Fig. 2 Bus Station Geometry.

Fig. 3 Bus Station Details

Fig. 1 KUKA 3D Printer and 3D Printer Output.

3D Concrete Printing: Bus Station Case Study

Wind Loads – Based on 30m/s wind speed

All the above loads were combined as per combinations provided in ASCE 7-05 for Ultimate and Service Limit States Design.

Software

3.5 Handling and Sequence

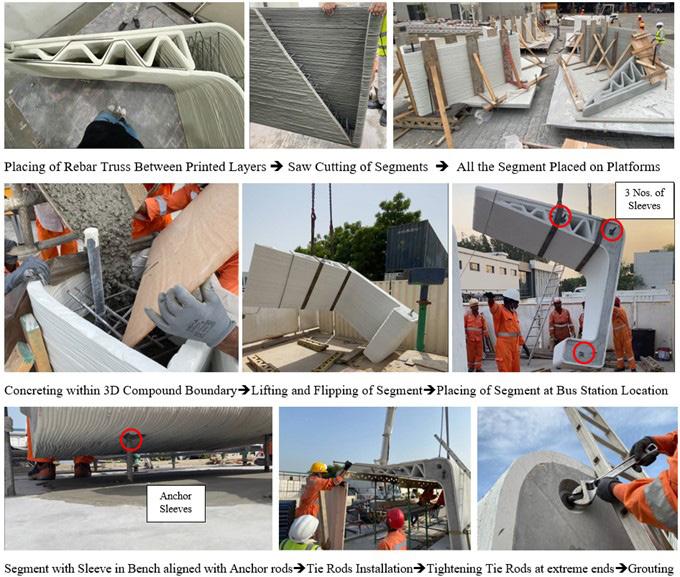

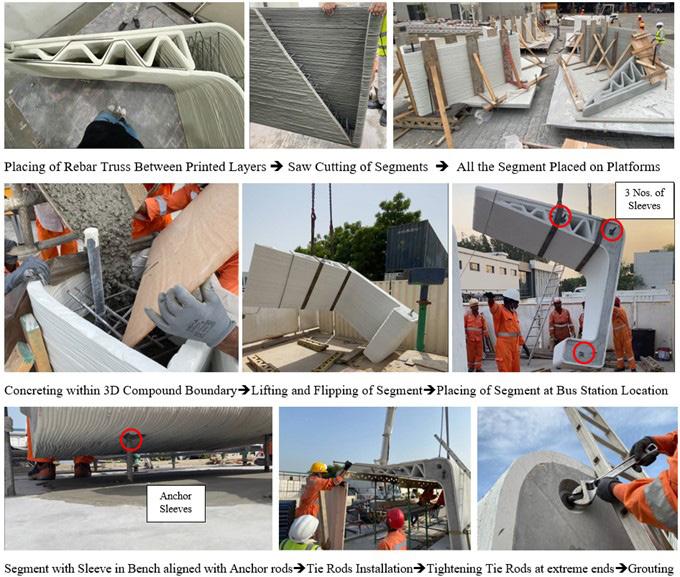

The complete bus station was subdivided into 6 parts due to the KUKA robot limitation and installation procedure. The following steps briefly explain the handling process, which is also summarized in Figure 5.

Printing of 3D elements with a maximum height of 1.28m and installation of the pre-assembled reinforcement trusses between layers.

Saw cut of relevant segments on the same day to match the architectural concept shape.

3 nos. longitudinal sleeves installed at various locations for tie rods placing. Additional sleeves are provided in the bench for the anchor connection to the existing foundation.

Concrete casting in relevant areas (See Fig. 3 & 5)

Installation of anchors in existing slab

At 7 days strength, each element is lifted and transported to the bus station mockup location.

Each of the bus station elements is flipped and placed on the foundation slab so that each anchor rod slides into the sleeves prepared in the bench of each segment.

Once all the elements are placed on the foundation slab, each of these elements is pulled close to each other with the help of the longitudinal tie rods passing through the sleeves present in the wall, roof, and bench of each bus station element. These tie rods are tightened at each end.

Finally, grouting of the anchors and tie rods sleeves are done. This is followed by polishing and spraying waterproofing agent all over the bus station.

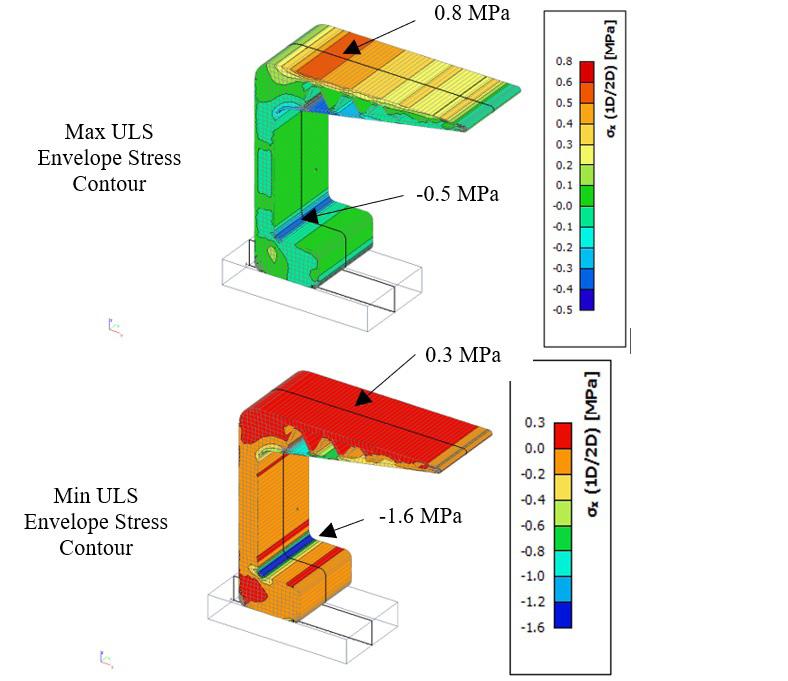

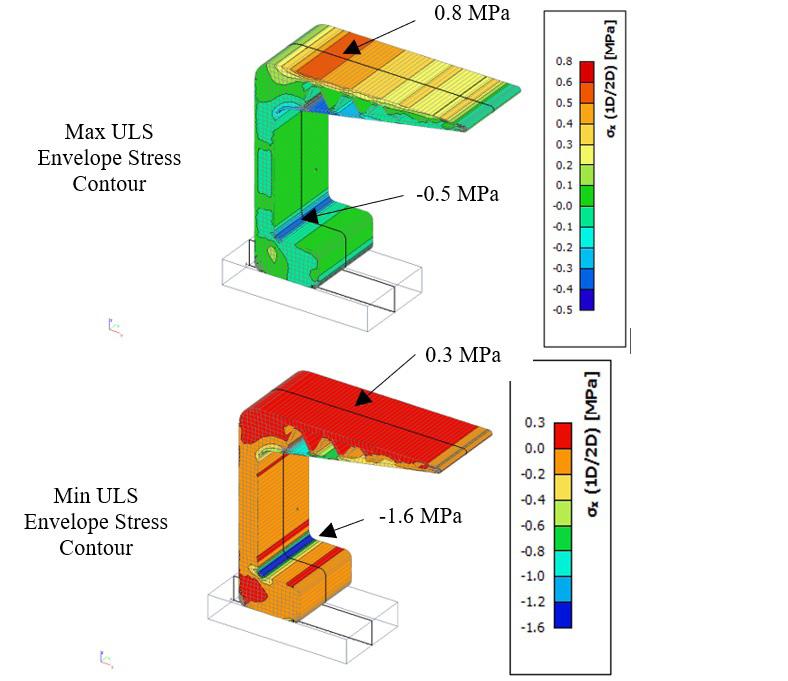

3.6 Design Results

3DCP being a new technology there is no set of standardized codes. Therefore, traditional design codes (ACI 318-08) and basic engineering principles are followed. The analysis is performed with FEM software – Scia Engineer.

ULS stress contour results are studied under all the loads and load combinations. These show that, as expected, the maximum tension (0.8 MPa) is found in the top face of the cantilever roof, and the maximum compression stresses are observed within the wall and bench of the bus station (Figure 6).

As the maximum 3D printed layer width is 35mm, the induced tensile force is 0.8 x 35 = 28 kN/m. The provided T8-100mm mesh has a tensile force capacity of 226 kN/m which is far greater than the exerted tensile force, but in order to limit the risk of cracks formation, it was decided to limit the stress in the rebars to a fraction of its yield stress.

The free-standing height of the wall is approximately 2.5m and therefore, it is also checked for biaxial buckling effect. In all cases, the provided reinforcement is found to be sufficient.

Anchor rods are designed to resist the tension forces due to the self-weight combined with the extreme wind effect. These forces are resisted by 2 nos. Hilti Chemical anchors, HIT-HY 200 per segment, are post-drilled into the existing foundation.

3.7 Lessons Learned

To ensure smooth delivery up to the required expectation, it is crucial that continuous discussions are held with the Client/Architect from the very beginning creating a synergy between all the stakeholders. Indeed, 3DCP is a strong technology with huge potential, but it still has some limitations, and projects need to account for these limitations.

Research Bulletin No.7 April 2023 3D Concrete Printing: Bus Station Case Study 13

Fig. 5 Handling and Sequence

Fig. 4 Loads Applied in FEM

This project proved that 3DCP is a flexible tool which is as reliable as traditional methods and is even better at certain stages, but it also has limitations with regard to complex sizes and shapes. Since there are not many references or standardized codes, most of the time, the structure design is heavily dependent on engineering judgement and on-site testing of mock-ups, which directly impacts the cost of the project. Execution methods, logistics, manutention and transportation need to be sufficiently detailed when pricing such projects as they substantially affect the cost.

Conclusion

Since its creation, BESIX 3D has been very active in the 3DCP industry in UAE. It is continuously working towards the development of 3DCP technology by investing in selected partnerships with suppliers and Universities and experimenting with several new ways where 3DCP can be utilized in combination with traditional construction projects.

The Bus station project was a good opportunity for BESIX 3D team as it uncovered new 3DCP advantages while overcoming unexpected challenges. Further developments are planned as the technology is rapidly evolving, more equipment options are available, and a new generation of materials is becoming accessible.

Acknowledgements

BESIX 3D would like to thank SIKA for the support and collaboration in the 3D compound development and printing activities.

References

[1] [3]

Olivier C. (BESIX3D), Benoit M. (BESIX3D), Luai A.K. (BESIX3D), Sami B. (AECOM). First Operational Ground Floor Building using load bearing 3D Printed Elements, IABSE Congress – Resilient Technologies for sustainable infrastructure September 2-4, Christchurch, New Zealand.

[2]

https://en.wikipedia.org/wiki/List_of_countries_by_electricity_ consumption

ACI 318M-08, 2008. Building Code Requirements for Structural Concrete and Commentary. An American Concrete Institution, United States of America.

[4]

ASCE 7-05, 2005. Minimum Design Loads for Buildings and Other Structures. An American Society of Civil Engineers, United States of America.

Research Bulletin No.7 April 2023

14 3D Concrete Printing: Bus Station Case Study

Fig. 6 Max/Min ULS Envelope Stress Contours (+ve Tension)

Fig. 7 Complete Erected Bus Station

Metal additive Manufacturing in Construction: Review of Current State, Challenges and Opportunities

Dr George Vasdravellis Associate Professor Institute of Sustainable Built Environment Heriot-Watt University Edinburgh, UK g.vasdravellis@hw.ac.uk

This paper presents an overview of the current state of metal additive manufacturing with an emphasis on applications relevant to the construction sector. Metal additive manufacturing presents some unique opportunities in the market of steel construction. Major challenges that should be overcome to allow wider use of additive manufacturing are presented. Some recent case studies and potential applications are discussed.

Keywords: Additive manufacturing; 3D printing; steel construction; sustainability; material efficiency.

Introduction

Metal Additive Manufacturing (AM), also referred to as 3D printing, is a rapidly growing field that has seen significant advancements in recent years. AM uses a layer-by-layer material deposition method to fabricate a part in a controlled environment, e.g. a machine chamber, or using a robotic arm. In contrast, traditional manufacturing is usually subtractive, i.e. the fabrication of a steel part will start from a bigger geometrical entity, and material is removed through cutting or drilling to form the final parts. These parts will often be welded or assembled together to the final desired component. This method requires substantial man-hours and energy consumption and results in large amounts of material waste (scrap material) and waste by-products that are sent to landfill.

Metal additive manufacturing, on the other hand, offers the following advantages: a) resource efficiency and reduced waste, as only the material needed for a specific steel component is used; b) geometric freedom, as AM techniques allow for the creation of parts of virtually unlimited complexity at no extra cost; c) creation of a complex part in one process, i.e. the actual 3D-printing, starting from a CAD model; d) optimisation of the geometry in terms of structural behaviour, which is particularly relevant to performancecritical components, such as connections or energy-dissipation elements in a structure. Another advantage of metal 3D printing in construction is the potential for on-site printing using mobile 3D printing robots. This would allow for the construction of structures in remote or inaccessible locations, as well as the reduction of transportation costs and emissions.

Overall, metal additive manufacturing has the potential to revolutionize the construction industry by enabling the creation of more efficient, sustainable, and customizable structures.

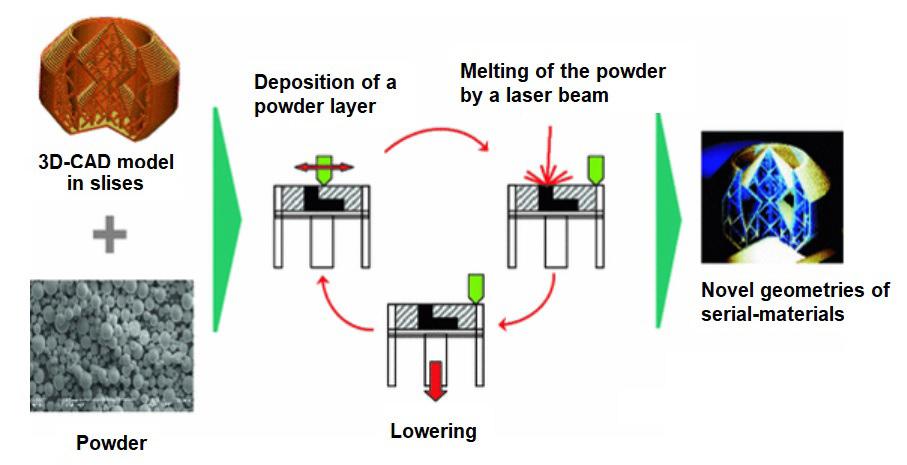

2. Additive manufacturing techniques

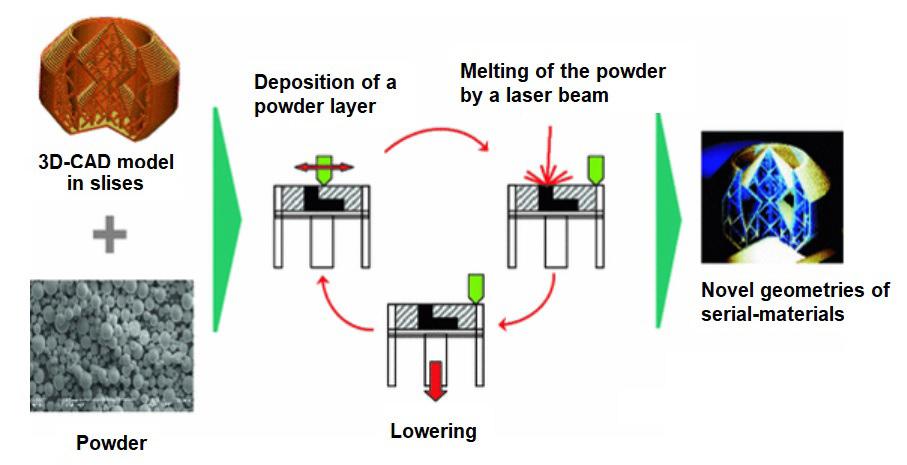

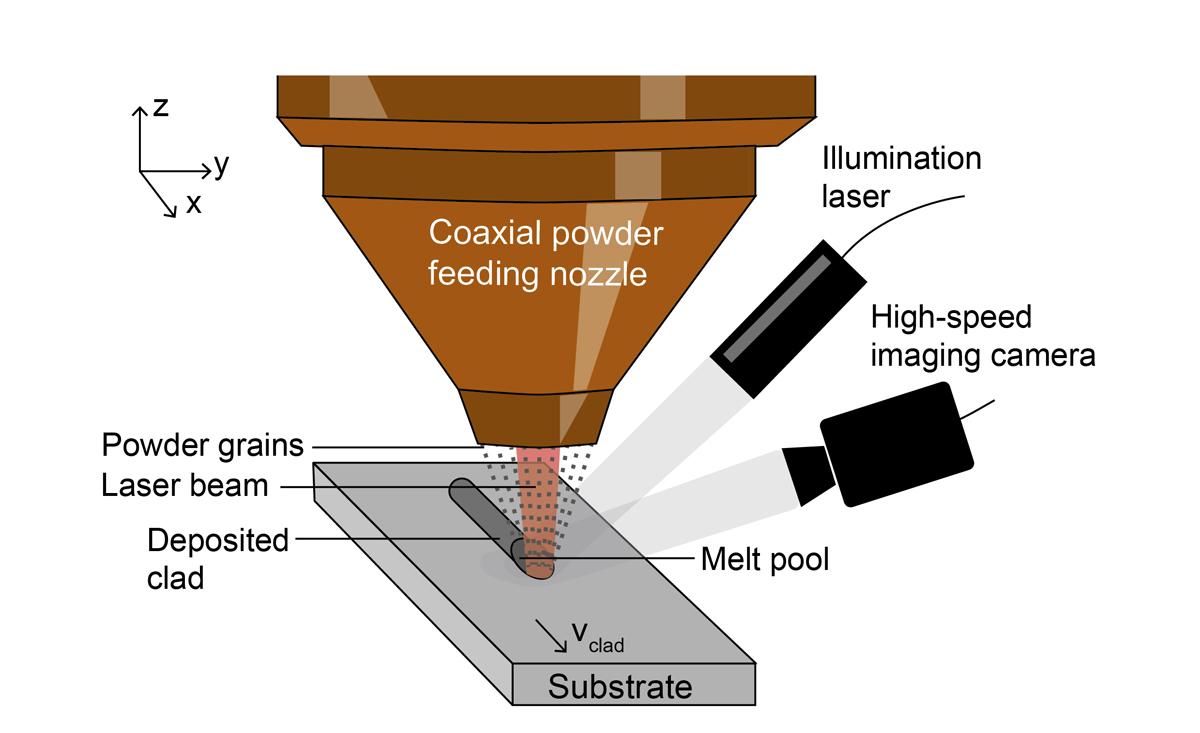

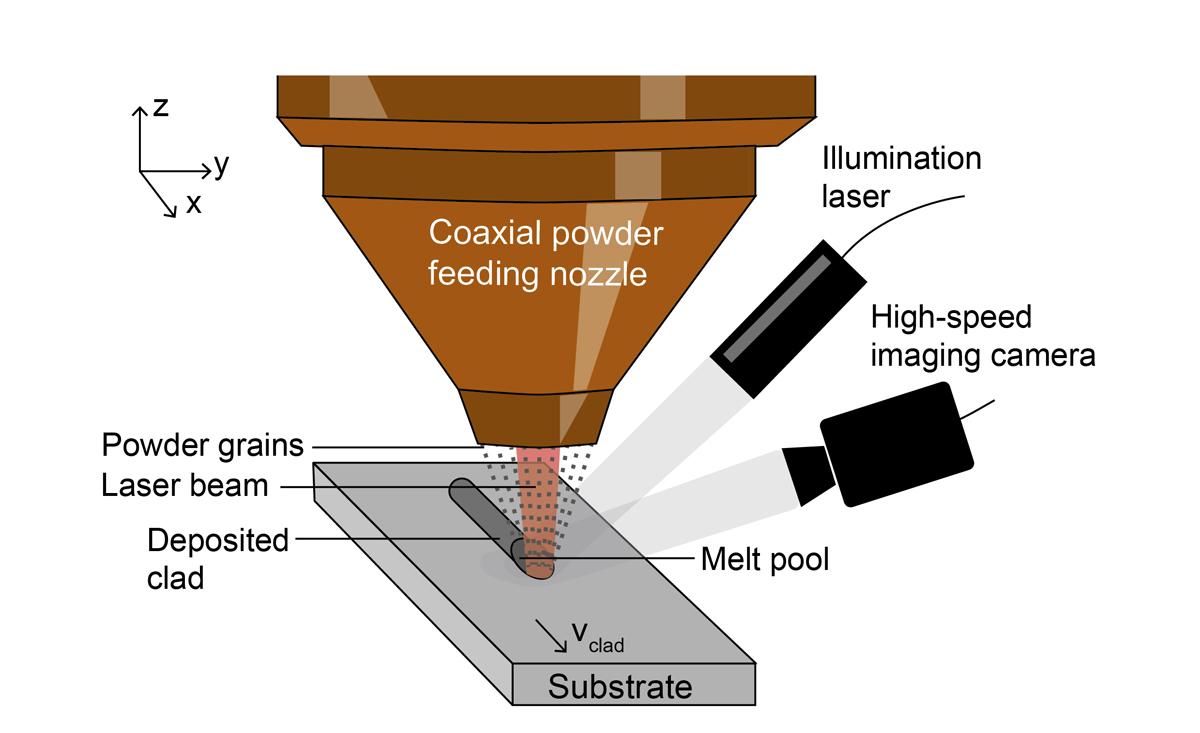

The two AM techniques that are most relevant to the construction of steel parts are Powder Bed Fusion (PBF) and Directed Energy Deposition (DED).

PBF processes (Figure 1) use the material in the form of a powder that is initially spread on the base of a chamber, and then the material is fused to the final shape using a laser or electron beam (Herzog et al. 2016). PBF can produce parts of great geometric complexity, and the final surface is relatively smooth. However, a drawback of this technique is that the production times are long (current deposition rate is around 50 g/hr) and that the parts are limited to relatively small sizes (max size is currently approximately 250 x 250 x 250 mm3).

Research Bulletin No.7 April 2023

Metal Additive Manufacturing in Construction: Review of Current State, Challenges and Opportunities 15

Fig. 1 Process of Powder Bed Fusion (PBF) 3D printing (https://www.twiglobal.com/technical-knowledge/faqs/what-is-powder-bed-fusion)

1.

Research Bulletin No.7 April 2023

DED uses an electron beam, an electron or a plasma arc to melt material powder that is fed on the surface of the printed structure (Evans et al. 2022). The wire arc AM, or WAAM, uses an electron beam and metal wire to directly weld steel in layers using a robotic arm (Figure 2). The WAAM is most suited for large-scale construction components, as the deposition rate is high (approximately 5-9 kg/hr), and there is no need to use a controlled environment (chamber), thus allowing the printing to take place in any site. The drawbacks of WAAM are that it results in printed components with relatively high surface roughness, which usually needs considerable postprint treatment, and the process results in residual stresses and distortions that should be taken into account.

has been tested and extensively analyzed using a digital twin (Gardner et al. 2020; Kyvelou et al. 2022). MX3D has also produced a steel node for timber structures, which was designed in collaboration with engineers of Takenaka, an engineering firm in Japan (https://mx3d.com). The node was printed using duplex stainless steel. Tests and numerical analysis have shown satisfactory results. The MX3D bridge and the Takenaka connector show the potential of WAAM in producing optimized bespoke geometries for large-scale construction.

Overall AM offers tremendous opportunities for a more resource-efficient and sustainable construction sector (Gardner 2023). As the cost of producing full-scale members such as girders and columns is still prohibitively high, the most promising solution appears to be the combination of AM with traditional manufacturing to produce hybrid structures, i.e. structures in which the members will be traditionally manufactured but the connections, various connectors, and/or other intricate performance-critical elements will be optimized and 3d printed. As the technology evolves and the costs are reduced, production of full-scale optimized structures may be possible in the near future, especially if the deposition times and control of printed parts are improved. AM will enable greater automation in construction, with the off-site fabrication of components, rapid plug-and-play assembly of structures on site, and improved health and safety working conditions. The use of functionally graded materials, novel material grades, and the automatic inclusion of stiffeners in elements are all promising possibilities that AM offers.

4. Major challenges

There is a fast-growing body of research on the mechanical properties of 3d printed steel of various grades [e.g. Chen et al. 2017; Buchanan et al. 2017). The results show that the material exhibits an evident anisotropy, with the properties such as Young’s modulus and yield strength varying according to the direction of printing. Most studies show that the mechanical properties of 3d printed stainless steel are comparable to those of conventional stainless steel. Further research is needed to fully understand the fundamental behaviour of 3d printed steel in terms of constitutive relationships; more so for the fatigue and fracture behaviour for which data is currently limited.

3. Available research and opportunities in the construction sector

Steel tubes of circular (CHS) or rectangular (SHS or RHS) cross sections have been printed using the PBF technique and tested under monotonic loading up to failure ( Buchanan et al. 2017; Yan et al. 2019; Zhang et al. 2021). Test data at member level for CHS short columns that have been printed using the WAAM technique have also been reported (Kyvelou et al. 2021; Laghi et al. 2020). The results have shown that the strength is not far from the one predicted using familiar design approaches, e.g., Eurocode 3, and the failure modes were not unusual. The tests highlighted, however, the higher geometric variability and imperfections of the 3d printed members as compared to conventionally produced ones.

Arup engineers have used AM to optimize nodes used in a tensegrity structure and achieved a 75% weight reduction per node while maintaining the same load-carrying capacity (www.arup.com/projects/additive-manufacturing). The nodes have been printed using the PBF technique. The first large-scale 3d-printed structure is notably the pedestrian bridge that was constructed by MX3D using robotic WAAM in Amsterdam (https://mx3d.com). The bridge

Despite the promising research conducted so far on additive-manufactured metallic components, there are still limitations that should be overcome in order to allow for the wider practical application of AM in construction. The current limitations of AM are mainly the lack of standardized processes and procedures to produce parts, lack of certification of 3d printed material, and lack of codified provisions for the design of 3d printed components and structures. Additionally, the cost of metal 3D printing equipment and materials can be high, and the process is relatively slow compared to traditional manufacturing methods.

The sustainability aspects involved with the AM process are mainly attributed to the savings in material and transportation impact, which translate into waste reduction, preservation of natural resources and transportation-related carbon emission savings. In terms of the actual manufacturing process, AM is energy intensive and requires substantial electricity to operate. Recent research has highlighted that there is no clear advantage of AM compared to traditional manufacturing of a metallic component in terms of environmental footprint (Kanyilmaz et al. 2022; Nagarajan et al. 2018), considering the whole life production of the component. The main contributor to the environmental impact of AM is the electrical energy use; therefore, it is crucial to adopt future solutions that generate clean electrical energy and reduce the postprocessing demands of an AM part, which are currently high, in order to justify the use of AM in terms of environmental impact.

Research Bulletin No.7 April 2023 Metal Additive Manufacturing in Construction: Review of Current State, Challenges and Opportunities 16

Fig. 2 Process of Directed Energy Deposition (DED 3D printing (https:// www.metal-am.com/articles/additive-manufacturing-of-aluminium-partsby-directed-energy-deposition-possibilities-and-challenges/)

Conclusion

Overall, there is an exponential increase in research on additive manufacturing of metallic components in recent years, and the research results are expected to increase even more. Research has been done at the material level, fatigue and fracture behaviour, component level and member level. The data provide promising results in terms of structural behaviour of printed steel parts. It is expected that when the body of research data will be adequately reliable, it will unlock the road to the adoption of AM in construction practice, initially in the form of hybrid structures, and once certified procedures and codified design rules are implemented in official documents. Additive manufacturing has the potential to open a new era in the construction sector, with structures that are architecturally pleasing, and at the same time robust and safe with minimum material use. Design concepts such as design for deconstruction and reuse, offsite fabrication, digital fabrication, and design for manufacturing will most probably be mainstream in the near future and will enable the realization of a more sustainable construction sector.

References

Buchanan C, Matilainen VP, Salminen A, Gardner L. (2017). Structural performance of additive manufactured metallic material and cross-sections. J Constr Steel Res 2017;136:35–48.

Chen X, Li J, Cheng X, He B, Wang H, Huang Z. (2017). Microstructure and mechanical properties of the austenitic stainless steel 316L fabricated by gas metal arc additive manufacturing. Mater Sci Eng A, 703:567–77.

Evans et al. (2022) ‘A review of WAAM for steel construction –Manufacturing, material and geometric properties, design, and future directions’, Structures, 44, pp. 1506–1522. doi: 10.1016/j. istruc.2022.08.084.

Gardner, L. (2023) ‘Metal additive manufacturing in structural engineering: Review, advances opportunities and outlook’. Structures, 47, pp. 3–4. doi: 10.1201/9781003348450-1.

Gardner L, Kyvelou P, Herbert G, Buchanan C. (2020). Testing and initial verification of the world’s first metal 3D printed bridge. J Constr Steel Res 2020;172:106233.

Herzog D., V. Seyda, E. Wycisk, C. Emmelmann (2016). Additive manufacturing of metals. Acta Mater, 117 371–392, https://doi. org/10.1016/j.actamat.2016.07.019

Kanyilmaz, A. et al. (2022) ‘Role of metal 3D printing to increase quality and resource-efficiency in the construction sector’, Additive Manufacturing, 50. doi: 10.1016/j.addma.2021.102541.

Kyvelou P, Buchanan C, Gardner L. Numerical simulation and evaluation of the world’s first metal additively manufactured bridge. Structures 2022;42:405–16.

Kyvelou P, Huang C, Gardner L, Buchanan C. Structural testing and design of wire arc metal additively manufactured square hollow sections. J Struct Eng ASCE 2021;147(12):04021218.

Laghi V, Palermo M, Gasparini G, Girelli VA, Trombetti T. Experimental results for structural design of wire-and-arc additive manufactured stainless steel members. J Constr Steel Res 2020;167:105858.

Nagarajan, H. P. N. and Haapala, K. R. (2018) ‘Characterizing the influence of resource-energy-exergy factors on the environmental performance of additive manufacturing systems’, Journal of Manufacturing Systems, 48, pp. 87–96. doi: 10.1016/j. jmsy.2018.06.005.

Shah, I. H. et al. (2023) ‘Life cycle assessment of wire arc additively manufactured steel structural components.’, Journal of Cleaner Production, 389, p. 136071. doi: 10.1016/j. jclepro.2023.136071.

Yan J-J, Chen M-T, Quach W-M, Yan M, Young B. Mechanical properties and cross-sectional behavior of additively manufactured high strength steel tubular sections. Thin-Walled Structures 2019;144:106158.

Zhang R, Gardner L, Buchanan C, Matilainen VP, Piili H, Salminen A. Testing and analysis of additively manufactured stainless steel CHS in compression. Thin-Walled Structures 2021;159:107270..

Research Bulletin No.7 April 2023

17 Metal Additive Manufacturing in Construction: Review of Current State, Challenges and Opportunities [1] [9] [5] [13] [3] [11] [7] [2] [10] [6] [14] [4] [12] [8]

3D Concrete Printing at Dubai Municipality: Achievements, Responsibilities, and Future Agenda

R&D at Dubai Municipality

Dubai Municipality Dubai, UAE eng.waleeed.wm@gmail.com

Al Ghurair Construction Readymix Dubai, UAE Abdellatif.badr@al-ghurair.com

Dubai, UAE maljanahi91@gmail.com

3DCP is the future of the smart construction system due to its advantage towards green and sustainable buildings by reducing waste and site accidents. Dubai 2030 vision of achieving 25% of Dubai buildings to be 3D printed will make Dubai as a hub of 3D printing worldwide. As a government employee, our main target currently is making 3DCP technology easier and regulating the usage of the technology together with our strategic partners and market specialists in order to attract industry leaders from everywhere in the world to Dubai to reduce the high current cost of machinery and supporting our local manufactures with the latest researches and information to produce the 3D concrete locally. We aim to reach a stage where machinery and material are produced 100% locally. Therefore, we designed and built the largest 3D building in the world as a model for the construction market and to have a full study of the technology in order to be able to regulate it. The main goal of this paper is to show the case study of the largest 3D printed building in the world and how the 3D concrete has been designed, as well as the next step of regulating the technology and making Dubai a hub of 3D printing technology.

Keywords: 3DCP, Concrete, Sustainability, Regulation, 3D Hub, Smart construction.

As workers in the government sector, our job is to facilitate and regulate all work in the emirate of Dubai, which is more preventive when it comes to building. As employees in the building and supervision department at Dubai Municipality, our roles are more supervisory in nature, we create rules and regulations depending on the latest information that spans from work processes to new technologies.

Here comes 3D printing technology and especially 3D Concrete Printing (3DCP). The reason for adopting this technology and going to the challenge of making the biggest 3d printed construction in the world as a pilot came out of necessity and obligation to find a solution for a series of challenges and to open the stage for new opportunities to be adopted in the building and construction fields.

Dubai Municipality undertakes to develop and implement an integrated system to plan, design and implement construction work using the 3D printing technology as per the approved engineering standards and specifications, the civic body said today. “This is an important step towards strengthening Dubai’s leading position as the first city in the world to adopt a 3D printing strategy and regulate the usage of this advanced technology in the construction sector”.

Fig. 1 As a government strategy, 25% of Dubai buildings will be 3D printed by 2030.

2. What is 3DCP?

3D printing technology is used to build product parts or the first model in layers, drawing the required model with AutoCAD software and then dividing the design (so that each shape converts it to a digital data sheet, the Algorithm array). It is a whole process from the material selected with details of each layer.

3DCP is the digital fabrication of cementations materials in the form of layers on top of each other.

Research Bulletin No.7 April 2023

Waleed Mosad Abdulghafar Construction Technology Specialist

Abdellatif Badr Masoud Technical Manager

Marwan Aljanaahi Senior Structural Engineer Building permit and supervision Agency Dubai Municipality

Research Bulletin No.7 April 2023 3D Concrete Printing at Dubai Municipality 18

1. Introduction

Many advantages 3DCP offers are as follows: 1. Reduction in projects cost by:

Decreasing number of labors

Reduce the need of concrete forms (typically accounts for 30 to 60% of total construction cost)

Reducing construction time.

2. More sustainable by utilizing material more efficiently and by creating very less waste.

3. Reduction in site accidents.

4. Freedom to create very complex shapes.

The planning stage considered selecting the best 3D printing machinery for the outdoor environment through negotiations with different companies.

3.2 Designing of 3D-printed concrete mix

3D concrete is a mixing of materials that consist of cement, fibers, supplementary cementitious materials, fine and/or coarse aggregate and additives such as (rheology modifiers, accelerators, and retarders).

Designing 3D-printed concrete was a very challenging topic back to 2018 as Dubai municipality decided to design it with 100% local materials, more than 200 lab trials were done trying many Cementitious and SCM with many types of additives such as (rheology modifiers, Accelerators, Retarders, and Fibers) in order to achieve the required Strength and setting time. The targeted strength was 25 MPA with 30 to 35 minutes targeted initial setting time and 45 to 60 minutes targeted final setting time, the approved mix as of lab trials was with the following performance:

Strength 30 MPa

Initial setting time 35 Minutes

Final setting time 48 minutes

The second step was site trials with the printer to check the concrete mix buildability & bond strength between the layers.

On the other hand, some disadvantages face using 3DCP technology:

1. Currant high cost of the printer.

2. Non-availability of the material.

3. Lack of standards and regulations.

3. Case Study (biggest 3D printed building in the world)

3.1 Planning stage

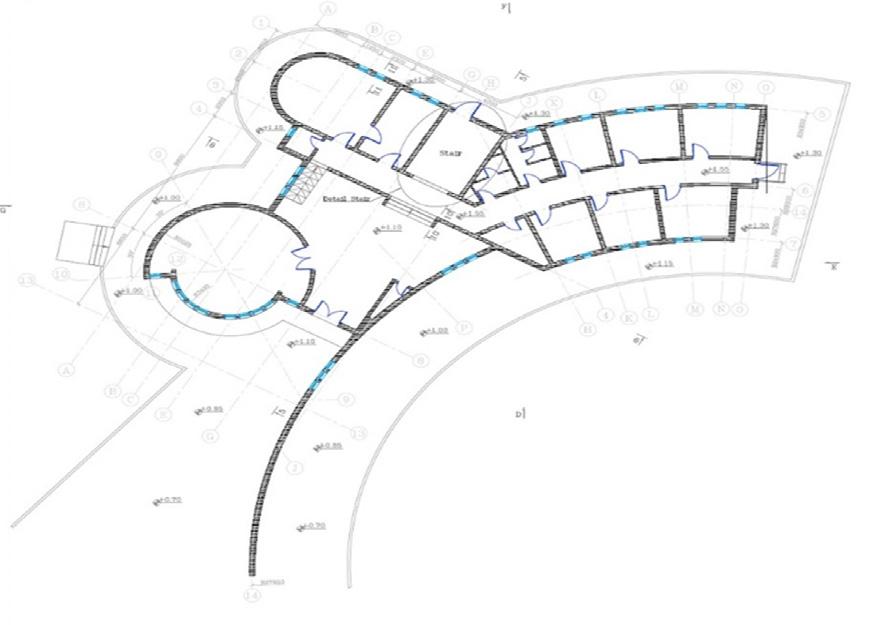

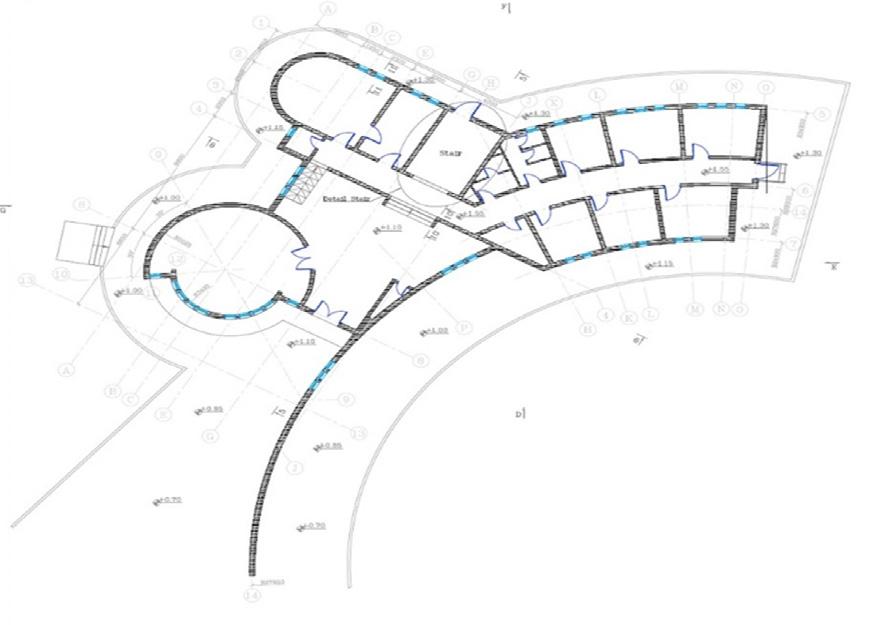

Figure 3 shows the architectural plan of the 3D concrete-printed building, which is a 2-story building of 9.5m in height and 640 m2 area with architectural challenges such as curves, openings, etc.

Buildability is the ability of the printed 3D concrete layer to retain its dimensions under increasing load, while bond strength is the strength of the bond between layers; both Buildability and Bond strength are mainly related to the interval printing time between layers and setting time of 3D printed concrete, especially in hot weather concreting.

So many on-site printing trials were done to align the interval time between layers with the setting time of 3D printed concrete in order to achieve the optimum buildability and bond strength, the shear bond strength was tested with different interval printing times between the layers in order to find the best interval time which assures the highest bond strength. Trials show that as interval time between layers reduces as the bond strength increase. The results of the shear bond strength were:

1- 5 minutes interval 5.3 MPa

2- 15 minutes interval 4.1 MPa

3- 25 Minutes interval 2.6 MPa

4- 35 minutes interval 1.1 MPa

One of the challenges was the ability to control the 3D-printed concrete shrinkage. The study was done using several types of fibers and shrinkagereducing additives. The results show that, with fibers, shrinkage, and volume change test of the concrete as per ASTM C157 was as low as 0.065%.

The size of aggregate was designed based on the printer nozzle dimensions, many sizes of aggregate were tested in the lab trails and site trials ranging from 1 to 5 mm, and the layer diminutions were 4 cm in Hight and 3 cm in width, which gave us an opportunity to try an aggregate size up to 5 mm.

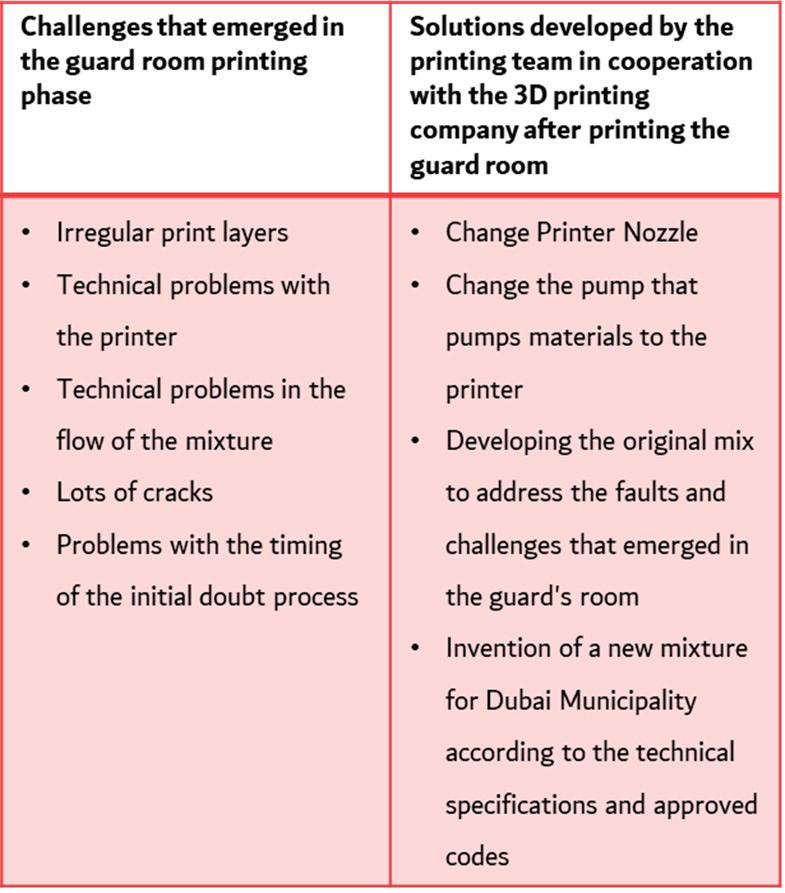

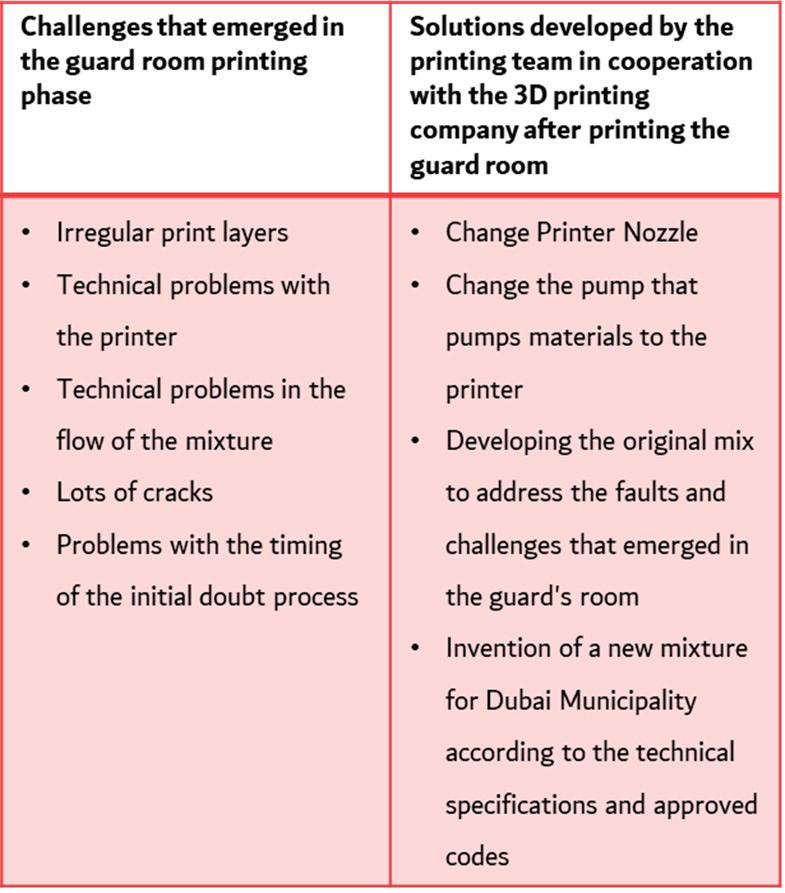

3.3 Project challenges

Project challenges with solutions during the printing process are summarized in Table 1:

Research Bulletin No.7 April 2023 19 3D Concrete Printing at Dubai Municipality

Fig. 3 The architectural plan of the printed 2-story building.

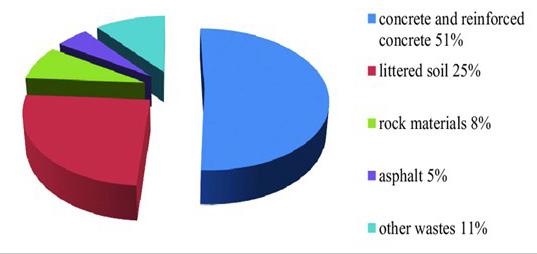

Fig. 2 Waste per each activity in regular construction site.

4. What is Next?

4.1 Dubai as a hub of 3D printing

Dawood Al-Hajri, director general of Dubai Municipality, said: “Dubai Municipality aims to regulate the use of the 3D printing technology by organizing and promoting it and providing support and consultation to startups in the field. This will be in addition to inviting international companies to enter this field in Dubai, as part of our directives to make Dubai an international hub for 3D printing activities.”

“3D printing is an advanced technology, which has been advancing rapidly in many sectors around the world, which is supposed to contribute to reducing

cost and time. We aim to enhance the use of this technology through the new activities launched by Dubai Municipality for contractors and consultants,” he added.

4.2 Dubai Municipality responsibilities

Dubai Municipality is responsible for regulating this technology, issuing licenses and monitoring construction works. This will be done by developing and implementing an integrated system to plan, design and execute construction and structural work using 3D printing technology and ensuring its use in accordance with approved engineering standards and specifications, as well as qualifying, registering, and classifying engineers and contractors who use 3D printing technology in their work.

The municipality will also conduct technical studies and experiments and cooperate with research, scientific and engineering entities specialized in this field to develop this technology. It will also prepare templates for the contracts related to the 3D printing technology and enter partnerships with international establishments and specialized consultancy to promote the use of this technology and derive the maximum benefit from it.

Research Bulletin No.7 April 2023

3D Concrete Printing at Dubai Municipality 20

Fig. 4 Printing trials performed to the guard’s room.

Fig. 5 Building construction during printing

Fig. 6 Guinness World Records certificate about the achievement of DM printed building.

Table 1 Printing challenges and solutions

Acknowledgements

Eng. Layali Al Mulla: Director permits, Head of 3D printing Team at Dubai Municipality

Eng.Aisha AlMulla: Director of Research & Development at Dubai Municipality

Eng.Ahmad Alsalami: Head of Research and development at Dubai Municipality

References

Kajaste R., Hurme M., 2016. Cement Industry Greenhouse Gas Emissions – Management Options and Abatement Cost, Journal of Cleaner Production, 112, 4041-4052. http://dx.doi.org/10.1016/j. jclepro.2015.07.055.

Ali S.T.M., Batikha M., 2018. Producing green concrete by using recycled materials in UAE, 2nd American University in the Emirates International Research Conference (AUEIRC’18), Sustainable Development and Social Responsibility, Dubai, UAE, November 13-15 November, 10p.

De Brito, J., Saikia, N, 2013. Recycled Aggregate in Concrete: Use of Industrial, Construction and Demolition Waste. Green Energy and Technology, Springer-Verlag, London. http://doi. org/10.1007/978-1-4471-4540-0.

Zhang K., 2013. Recycled glass concrete, in: Pacheco-Torgal F., Jalali S., Labrincha J., John V.M. (Eds), Eco-efficient concrete, Woodhead Publishing Limited, Cambridge, 241-270. https://doi.or g/10.1533/9780857098993.2.241.

Abaqus 6.12, 2012. Abaqus 6.12 documentation. Simulia, Dassault Systemes, Providence, Rhode Island, USA.

[CISION, 2015. Cement Market in the UAE 2015-2019, available at: https://www.prnewswire.com/news-releases/cement-marketin-the-uae-2015-2019-300113860.html (accessed: 31 July 2019).

BS EN 196-1:2005, 2005. Methods of testing cement - Part 1: Determination of strength, British Standards Institution, London.

ASTM E518/E418M-10, Standard test methods for flexural bond strength of masonry

BS 1881 Part 114 and 116:1983, Compressive strength and density of hardened concrete.

ASTM C109/C109M-02, Compressive strength of hydraulic cement mortar

ASTM C78 – 02, Standard test method for flexural strength of concrete

ASTM C157, Standard test method for length change of Hardened hydraulic cement mortar and concrete.

Ingemar Lofgren (M.Sc. in civil engineering) and Kent Gylltoft (professor. Dr. department of structural engineering, Chalmers university of technology, Sweden.) Dr. Tomas Kutti – Head of research of Thomas concrete group.

Decree No. (24) of 2021 regulating the use of three-dimensional printing in construction works in the emirate of Dubai.

Research Bulletin No.7 April 2023

21 3D Concrete Printing at Dubai Municipality [1] [5] [11] [3] [9] [7] [13] [2] [6] [12] [4] [10] [8] [14]

Sustainability

Accelerating System Solutions for a Just Transition to Net-Zero

Prof. Mercedes Maroto-Valer Champion and Director, UK Industrial Decarbonisation Research and Innovation Centre (IDRIC)

Deputy Principal for Global Sustainability and Director of the Research Centre for Carbon Solutions (RCCS)

Deputy Principal for Global Sustainability and Director of the Research Centre for Carbon Solutions (RCCS)

Heriot-Watt University

Edinburgh, UK m.maroto-valer@hw.ac.uk

Dr Phil Renforth Associate Director Research Centre for Carbon Solutions (RCCS) Heriot-Watt University

Edinburgh, UK p.renforth@hw.ac.uk

This article presents the role and impact of the UK Industrial Decarbonisation Research and Innovation Centre (IDRIC) and its unique approach to co-creating solutions that are accelerating the decarbonisation of UK industrial clusters. IDRIC works on a wide range of solutions, including Negative Emission Technologies (NETs), and a brief description of an IDRIC NET project relevant to the cement and steel sectors is included here.

Keywords: Decarbonisation; Net Emmisions Technologies; Emissions; Urbanisation; Industry; Clusters

1. Introduction

Our net zero and collective energy transition must accelerate across the world, encompassing all regions and including industry as well as urban and rural areas. Employing a whole systems approach is key. It is only through co-creation and co-delivery of whole systems initiatives that solutions can be deployed at scale and pace.

The exciting news is that we have the tools to do this, and innovation and practical solutions are progressing fast due to a huge collaborative effort between industry and academia. However, our systematic approach must accelerate further, so that we can effectively green our industries at the same time as making our cities and regions across the world more sustainable and resilient.

2. The Industrial Decarbonisation Research and Innovation Centre (IDRIC)

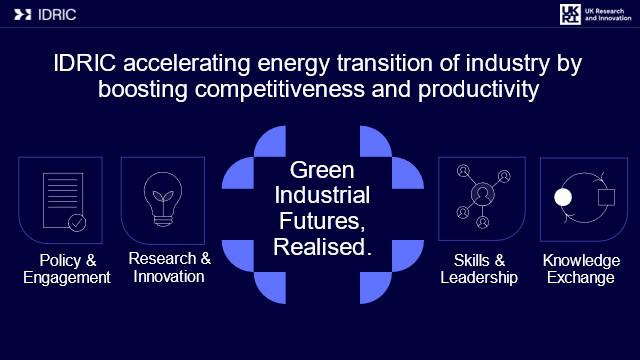

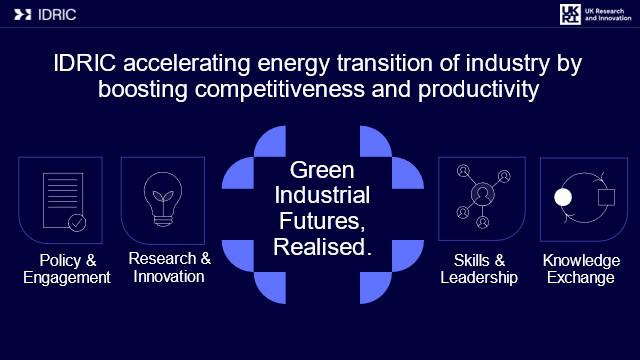

Based in the UK and launched in 2021, IDRIC is a key player in pioneering decarbonisation solutions. It is doing this by accelerating the green industrial revolution through collaboration with over 250 partners and stakeholders and bringing together the research and innovation ecosystem. These include academic institutions, industry, community representatives and policymakers, who are all working together to address urgent innovation priorities.

IDRIC is funded by the UK government through the Industrial Decarbonisation Challenge (IDC). With an investment of £210 million (matched by funding of £261 million from industry), the IDC supports the development of lowcarbon technologies and infrastructure in order to reduce the carbon emissions from energy intensive industries and lay the foundations for the world’s first net-zero industrial cluster by 2040. Consequently, it will boost the competitiveness of key industrial regions and drive inward investment, creating and protecting jobs for a low-carbon global economy with growing low-carbon export markets.

3. Whole System Approach to Challenging Industrial Emissions

The four areas of activity are briefly described below:

Policy and Engagement: informing the development of effective policy and regulatory frameworks.

Research and Innovation: creating a programme of whole systems solutions, integrating technology, policy and business models.

Skills and Leadership: creating and supporting collaborations at scale and pace across the innovation ecosystem.

Knowledge Exchange: supporting and initiating cross-learning, evidence-gathering and independent advice.

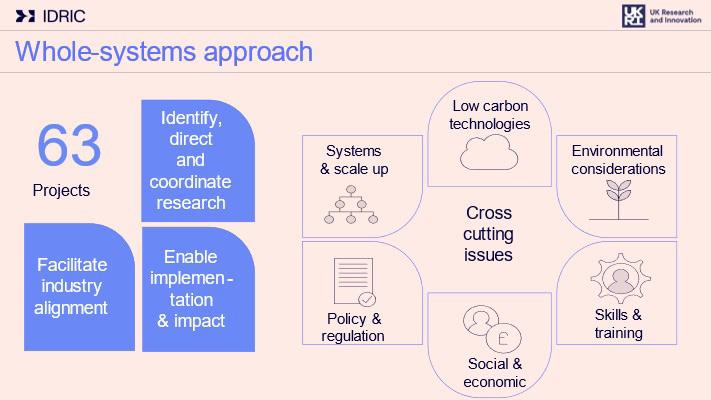

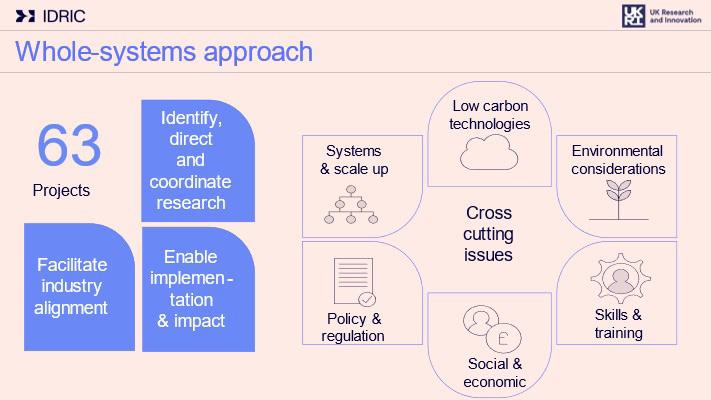

As part of its role in enabling transformation and innovation, IDRIC’s research portfolio currently consists of 63 projects and adopts whole systems thinking,

Research Bulletin No.7 April 2023

Accelerating System Solutions for a Just Transition to Net-Zero 23

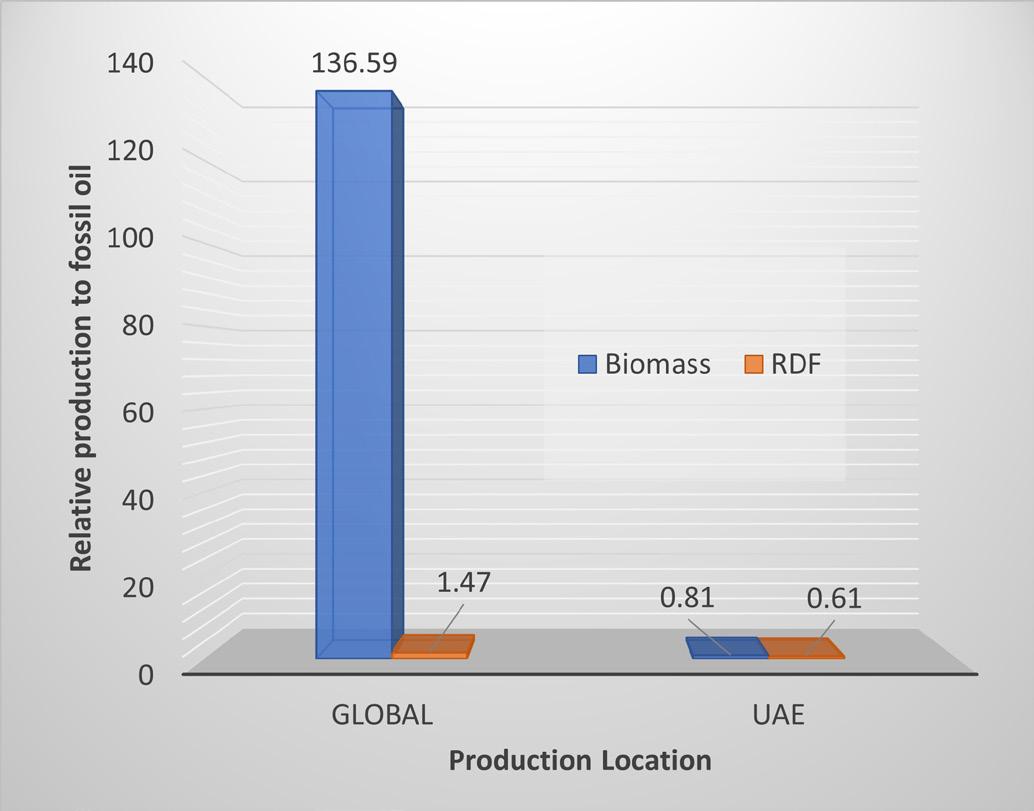

IDRIC’s programme of activity is organised broadly into four areas, as presented in Figure 1.

Fig. 1 IDRIC’s programme of activities.

Research Bulletin No.7 April 2023

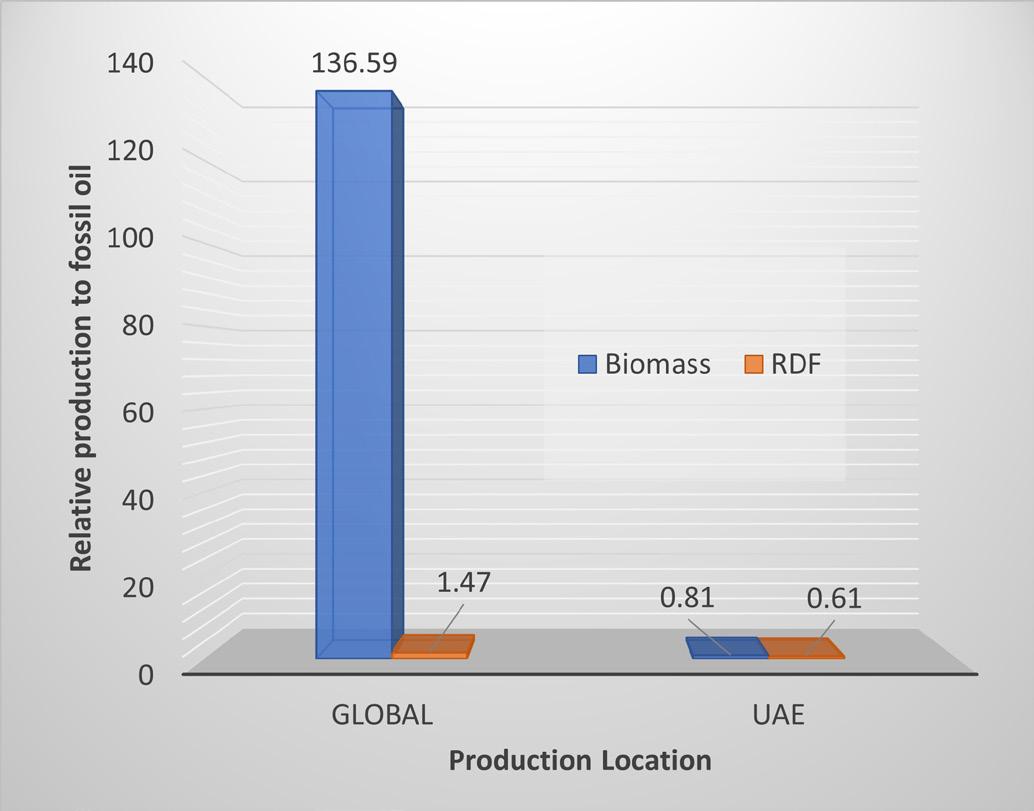

whilst addressing key cross-cutting challenges of industrial decarbonisation, as shown in Figure 2 [1].

Bringing together insights from a year of this extensive stakeholder engagement, IDRIC recently published the Policy Synthesis Report 2022 [2], which discusses seven priority areas for industrial decarbonisation policy, as follows:

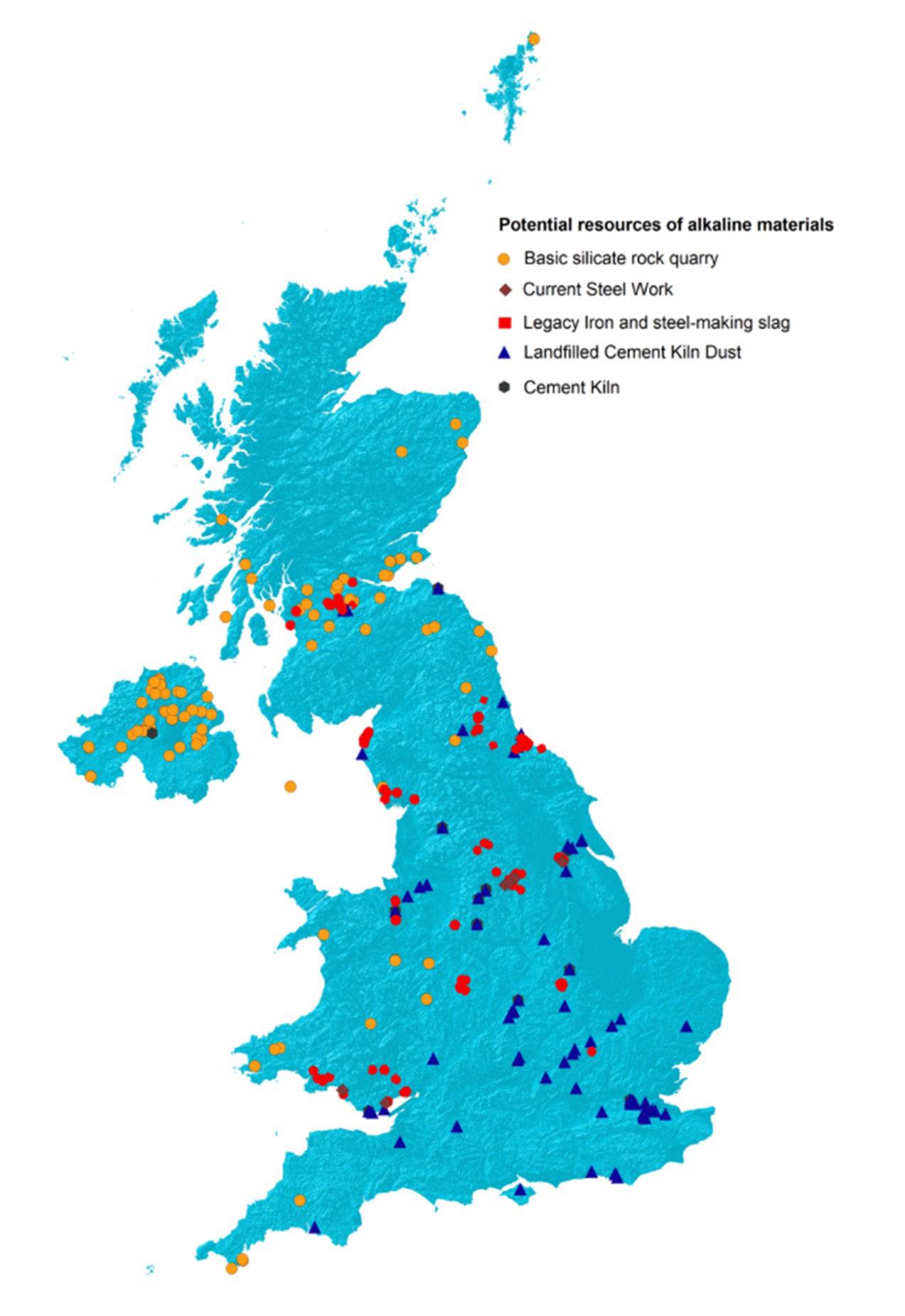

Working across a wide range of low-carbon technologies, IDRIC funds research in areas such as carbon capture, utilisation and storage (CCUS), hydrogen, fuel switching, energy storage and Negative Emissions Technologies (NETs). Crucially, it also focuses on systems and scale-up. An example of this is in the development of innovative planning and decision-making tools for infrastructure and supply chains which can then also inform the design of business models and regulatory frameworks. Moreover, in addition to covering technical aspects of decarbonisation, IDRIC also addresses key social, economic and policy aspects in order to have a UK-wide impact.

4. Accelerating impact to decarbonise industrial clusters

Building on this whole systems approach, IDRIC’s work focuses on industrial clusters. This is because much of the UK’s industry takes place in clusters which are characterised by a concentration of related industries or several industrial sites grouped within proximity to one another. These clusters consist of large-scale energy-intensive industries, such as iron and steel, cement, refining and chemicals, which have developed near ports and estuaries.

Whilst industrial clusters are major economic contributors to both their local economy and their communities, they also contribute significantly to CO2 emissions, accounting for over 50% of UK industrial emissions. Therefore, decarbonisation of the clusters seeks to harness their scale to find costeffective solutions, while remaining competitive on a global scale. IDRIC’s areas of activity are summarised under the following sections

4.1 Policy

By supporting the development of effective policy and regulatory frameworks for industrial decarbonisation, IDRIC:

Supports key policy and regulatory initiatives through reliable and impartial expertise and analysis.

Briefs on relevant technologies, innovations and research developments.

Convenes stakeholders for ongoing dialogue between industry, academia and policymakers.

Enabling fuel switching and electrification.

Supporting Infrastructure for transport and storage of electricity, hydrogen and CO2.

Business model support for scaling up low-carbon technologies. Timely planning, consenting, and permitting processes.