ERMCO Components, Inc., is flourishing in a world economy with ever-increasing electricity demands.

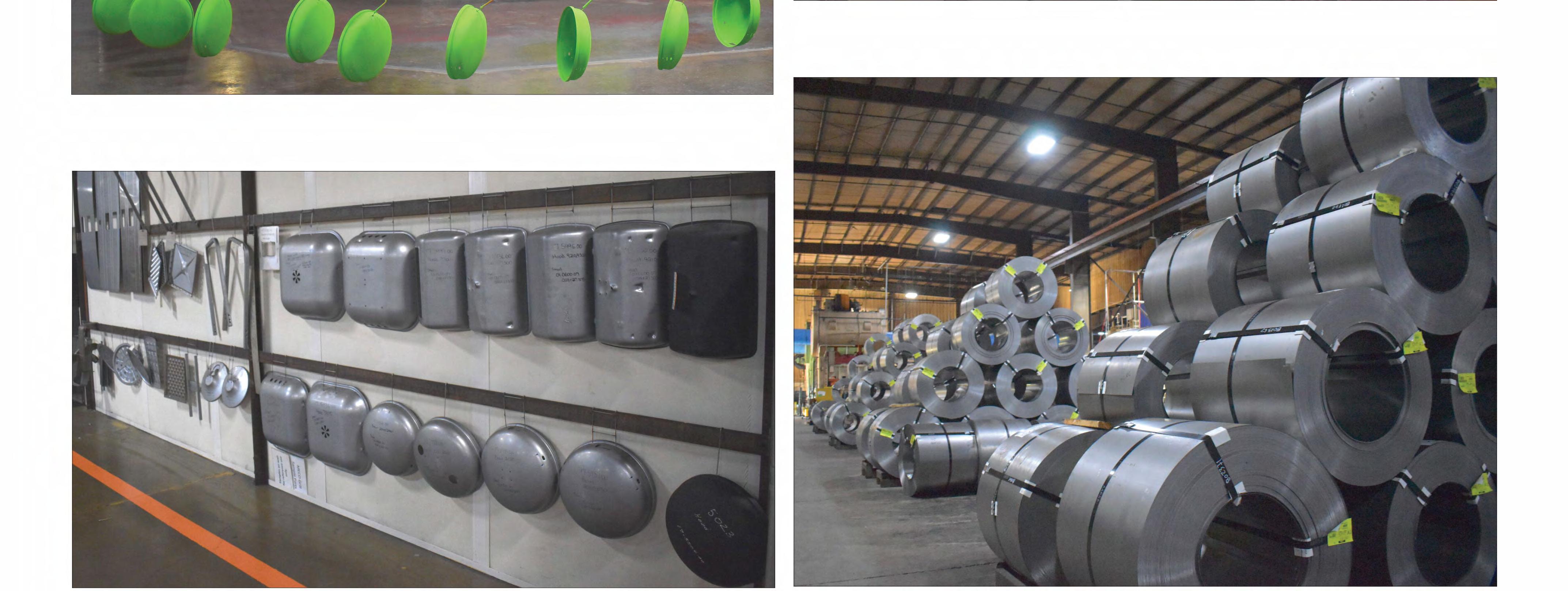

The manufacturing facility at 1607 Industrial Road in Greeneville includes about 55,000 square feet of production area and is a leading maker of electrical transformer components.

Formerly known as B.T.L. Industries, ERMCO assumed operation of the plant in October 2022, although the company has had a presence there in an administrative capacity since 1999. Demand for ERMCO products continues to grow, said Chester Greenway, site manager.

“Knowing the quality and production coming from the facility, (ERMCO) moved forward to purchase the facility,” Greenway said.

B.T.L. employees were retained. ERMCO has more than 100 employees at its Greeneville location and is in operation around the clock.

“We had 100% participation. Everybody came over and everything was business as normal,” Greenway said.”They have a lot of pride in doing their job.”

ERMCO is currently hiring, he added.

He cited competitive wages, 401k pension plan “excellent opportunities for growth” and other benefit package components as one reason employees stayed on after the transition. Many employees have been with the company for at least 20 years, Greenway said.

ERMCO’s parent company is in Dyersburg. About 3,000 employees work for ERMCO. The company has other locations in Athens, Georgia; Antioch, Illinois; and a research and development section in Raleigh, North Carolina.

“We are rooted all over the U.S.,” Greenway said.

ERMCO also has plants in Canada and Mexico to help meet the worldwide demand for its products.

“We’re very diversified in the electronic components business,” Greenway said. Finished components incorporated into electrical transformers are assembled in

Greeneville. ERMCO products are an unnoticed part of the day-to-day lives of people all over the world who use electricity power.

“In Greeneville, we primarily make the parts that go into the transformers in Mexico, Canada, wherever the need is,” Greenway said.

Transformers contain about “20 core components,” Greenway said. ERMCO makes “products within those components.”

“There can be 100 different variations. There’s a lot of engineering and science that goes into the process,” he said.

ERMCO products include circuit breakers, bushings, undercoil arrest disconnect switches, overload indicators, expulsion fuses, Bay-o-net fuses, isolation links and drywell fuseholders.

The quality and durability of ERMCO products is one reason for the company’s success. Everything made in Greeneville meets the standards of the Institute of Electrical and Electronic Enigineers, known as IEEE.

“Every component is fully tested before it leaves the facility,” Greenway said.

ERMCO quickly responds to supply demands caused by natural disasters like hurricanes that destroy transformers.

“A red flag goes up so the power can be restored (in affected areas) as soon as possible,” Greenway said. “Whenever that comes up we put 100 percent effort to get the needed components to the municipality at the time of that emergency.”

ERMCO is an active participant in the local community. The company recently joined the Greene County Partnership. Partnership members, elected officials and top company managers came to Greeneville in September to mark the one-year anniversary of the ERMCO acquisition with a ribbon-cutting ceremony.

“It’s just really exciting times. It’s a great opportunity to be further rooted here in Greene County,” Greenway said.

ERMCO Components was formed after the purchase in late 1998 of GE Distribution Transformer Components.

The Greeneville ERMCO property covers about 100,000 square feet. A number

of capital improvements are ongoing at the site, including an investment of more than $3 million in equipment and plant upgrades, Greenway said.

“The company last year just completed its eight millionth transformer. The world is in a critical status right now from not having enough electronic control transformers,” he said.

The Greeneville facility is an important part of the company’s success story.

“ERMCO is here and we’re looking to invest in employees and the community for a long-term relationship going forward,” Greenway said. “We’re looking forward to continuing that each and every year to maximize capacity and meet consumer demand.”

I.D. Images is a manufacturing company on West Irish Street that makes labels of all kinds for customers throughout the United States and Canada.

“We do labels for everything,” said plant manager David Crock. “We ship everywhere.”

I.D. Images currently has about 35 employees in the Greeneville plant, including four who work on a second shift.

They are tucked away in an unassuming pale yellow building at 810 W. Irish St. that has about 30,000-35,000 square feet of space, Crock stated.

“We do custom labels, digital label printing, direct thermal labels, film labels, integrated labels, and laser labels by the sheet,” he explained.

I.D. Images also does specialty products. Its customers have included Amazon (blank shipping labels), AutoZone, Bojangles, and J. Jill.

I.D. Images used to be Superior Business Associates for close to 40 years in the same building, Crock said. Stan Ritter owned the business then, and still owns the building they operate in, according to Crock.

When it was Superior Business Associates, the products it produced were mostly oriented towards business forms, he said.

In 2015, Superior Business Associates sold out to I.D. Images headquartered in Brunswick, Ohio.

Its headquarters remains in Brunswick, with 16 different facilities, including the one in Greeneville, spread around North America, said the plant manager.

“We got out of the business forms business around 2018. Now, it’s strictly labels,” he stated.

They make industrial, manufacturing, and integrated labels, including the recent large order for AutoZone, according to Crock.

Crock has been the plant manager for about three years, and involved in printing and collations for 24 years.

“Some employees in scheduling and purchasing have been here close to 40 years,” said Crock.

“It’s a climate-controlled environment, which makes it a good place to work, too,” stated the plant manager.

“During Covid, we never slowed down,” said Crock. In fact, they have two employees in customer service who continue to work from home.

“We do labels for (different industries, including) automotive, consumer durables, food and beverage, health and beauty, retail, transportation, and logistics,” said Crock.

“Most are peel-off labels. Others are integrated with perforated forms, such as shipping labels put on cartons,” he explained.

They have printed labels, blank labels, labels in a roll, and sheet labels (like the ones fed into personal computer printers or copiers).

They can also print vinyl labels, according to Crock.

I.D. Images also sells ribbons for direct thermal and thermal transfer printers.

“We sell labels to distributors who, in turn, sell them to customers,” Crock stated.

Crock stated that the company has close to 10 presses running during the daytime.

“After 2015 (when I.D. Images bought Superior Business Associates), the new company added around seven presses,” said Crock.

One of the presses is capable of printing everything from blank labels to labels with eight colors, he said.

“We have plenty of room” to add more presses should the demand require them, he stated.

They have one die-cutter, which Crock explained is similar to a press, but doesn’t have printing capability.

“A lot of customers want blank labels. From raw material to a finished roll, the die-cutter does it all,” said Crock.

A pre-press department in the facility sets up jobs, helping to design the print and label.

Carol Thacker, a pre-print specialist, explained, “We receive orders, make proofs, and send them to the customer. Once approved, they come back to us.”

Cindy Collier, the graphic designer/preprint specialist, then makes the plates in the pre-press room.

Because the I.D. Images facility on West Irish Street is so large, they can stock their label products for their customers, so that on an ongoing basis, when they need more labels, I.D. Images has them on hand and can ship them out.

By Amy Rose Staff Writer

By Amy Rose Staff Writer

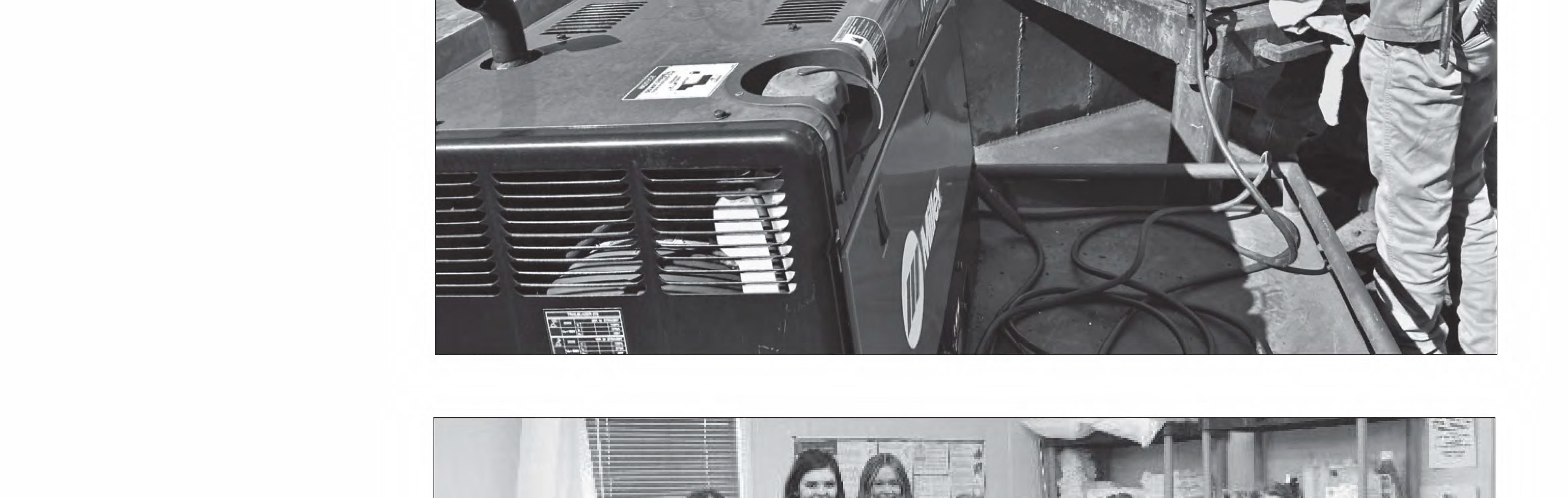

High school students who want to pursue a specialized career in industry have more options available to them through new state and local educational initiatives.

While both Greeneville and Greene County school districts are enhancing their Career and Technical Education (CTE) programs, the state has started a high school diploma distinction called Industry 4.0.

To earn the Industry 4.0 Diploma Distinction, students must complete at least nine dual enrollment or work-based learning credits aligned to their career goals.

Beginning this school year, high school sophomores interested in pursuing a career in a high-need, high-skill industry must provide their school counselor or principal with documentation signed by their parent or guardian under a new state law.

Sophomores also must register with a qualified career coach and enroll in at least one work-based learning or dual enrollment course for their junior year.

The career coach and student must meet at least once a month during the school year to develop the student’s personal attributes required for success in the workforce, assist in applying for financial aid, identify the best combination of dual enrollment and work-based learning courses, and help the student prepare for standardized tests.

As a high school junior, students must enroll in at least one work-based learning or dual enrollment course for their senior year and meet at least once a month with their career coach.

As a senior, students must complete all course requirements for graduation and may substitute work-based learning or dual enrollment credit for one science credit and one math credit.

For more information on the Industry 4.0 Diploma Distinction, visit https://www. tn.gov/content/dam/tn/education/ccte/ wbl/Industry_4-0_Diploma_Distinction_ FAQ_Final.pdf .

Along with this new state initiative, both local school districts have enhanced their CTE programs with Greene County expanding its plans for classroom additions at Chuckey-Doak and West Greene high schools.

The projects, estimated to cost $17.6 million, will be “top of the line” for Greene County students, according to discussion in a workshop of the Greene County Board of Education in July.

The Chuckey-Doak addition is planned at 27,514 square feet for programming in auto body, welding, masonry, industrial mechanics, carpentry, heating/venting/ air condition (HVAC), certified nursing assistant (CNA), and cosmetology.

The West Greene addition is planned at 22,782 square feet for programming in welding, auto body, cosmetology, CNA, and industrial mechanics.

It has been estimated that it could take 18 months to two years to build the two CTE additions.

Meanwhile, CTE classes also have been added at both North Greene and South Greene high schools with a thriving CNA program at South Greene.

In May, it was announced that both local school districts were among 21 school districts across the state to receive Innovative School Models grants from the Tennessee Department of Education.

The grants from a state investment of $500 million are designed to make students workforce ready by providing $500,000 to middle schools and $1 million to high schools to enhance CTE programs.

As a result, Greene County received a total of $6 million, and Greeneville received $1.5 million.

In June, both the Greeneville and Greene County boards of education voted to spend a portion of those funds on equipment to enhance CTE programs.

The Greeneville school board voted to spend $317,897 for engineering equipment including a plasma table, CNC cutting table, bandsaws, mini mill, lathe, vertical mill, desktop simulators, robotics kits, laser, floor drill press and 3D printers.

The city school board also voted to spend $27,540 for computer equipment for the Greeneville High School video production program.

The Greene County school board voted to spend $172,753 for a laser system, plasma cutter, welding system, drone kit, coding hand kit, collaborative robot package, and a six-color, four station press.

For more information on the Innovative School Models grants, visit www.tn.gov/ education/innovative-school-models.html .

In addition to the CTE developments a each local high school, the Greene Technology Center continues to offer a variety of high school CTE classes.

Programs include automotive, aviation, computer coding, cosmetology, criminal justice, culinary arts, cybersecurity, emergency services, exercise science, industrial maintenance, machining technology, computer networking, nursing, and welding.

John Deere is now offering a new zero-turn electric mower for residential use, and it’s being built at the John Deere Power Products facility in Greeneville.

The company says the new Z370R Electric mower is easy to use, quiet, and produces zero emissions. It provides simple charging with a standard extension cord and delivers exceptional cut-quality.

That’s not all John Deere has planned for electric products. By 2026, the company will bring to market at least one lithium-ion batterypowered option for compact utility tractors, residential mowing, commercial mowing, utility vehicles, and golf course maintenance. John Deere Power Products produces the Z300 and Z500 series zero-turn mowers and the 100 and 200 series lawn tractors.

“There is growing customer demand within these categories for battery-powered products, so John Deere is striving to meet that need,” said Fabio Castro, factory manager at John Deere Power Products.

These electric product offerings will complement John Deere’s existing portfolio of gas and diesel-powered machines in these categories, Castro said.

John Deere has four overarching design principles for battery-powered equipment. First and foremost, it will be a quality product. It will also be easy to operate and maintain, will reduce overall operating costs for the customer, and finally, it will operate with zero tailpipe emissions.

“The introduction of battery-powered machines plays a key role in

meeting our sustainability goals,” said Sumukh Bahulekar, a senior project engineer leading the electrification efforts in Greeneville.

Along with the use of biofuels, and additional enhancements to existing internal combustion engines, John Deere will reduce overall product emissions by 30% by 2030.

“Electric equipment isn’t the right choice for every customer and every job,” Bahulekar said. “John Deere will continue to offer a broad portfolio of equipment across all product categories, while aiming to provide an alternative to those seeking electric equipment.”

Castro said this is an exciting new era for John Deere Power Products, which is celebrating its 35th anniversary this year. He expressed his appreciation for the many employees involved in the company’s history here.

“Since 1988, our local factory has built the industry’s highest-quality equipment,” he said. “Millions of machines have left these doors - from gas-powered walk-behind mowers in the beginning to electric zero-turns now. We’re so excited about the product journey and proud of the dedicated men and women who continue to make it happen.”

The new Z370R Electric mower can be ordered now for delivery in time for spring 2024 mowing. Those interested in ordering and availability details should see their local John Deere dealer.

By Spencer Morrell Staff Writer

By Spencer Morrell Staff Writer

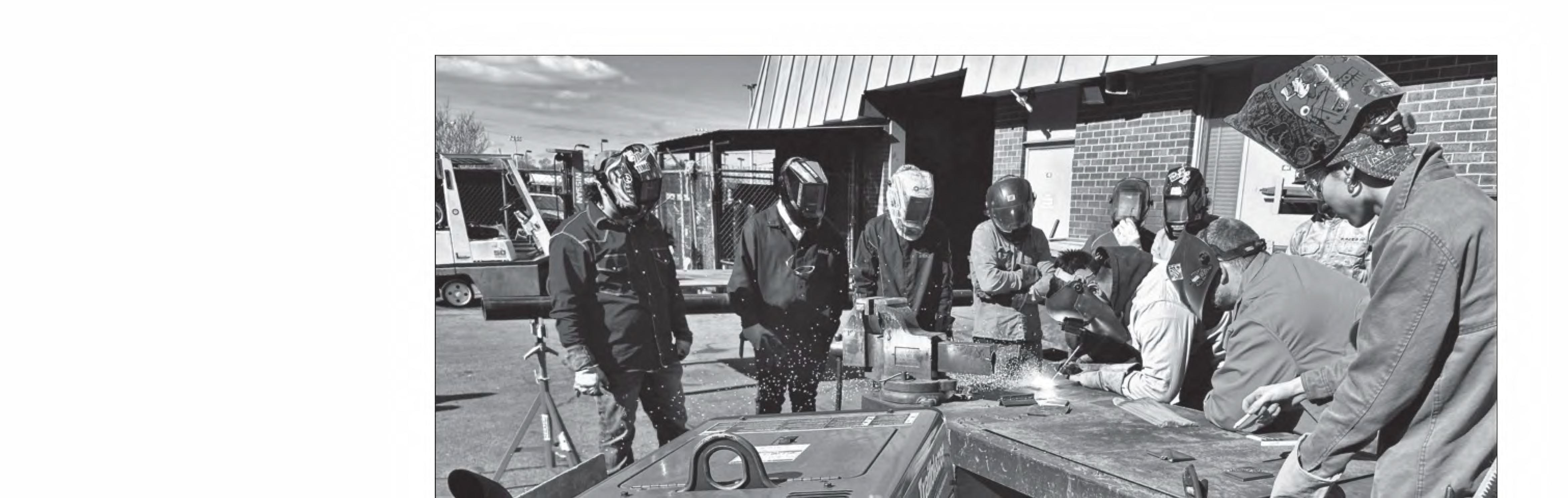

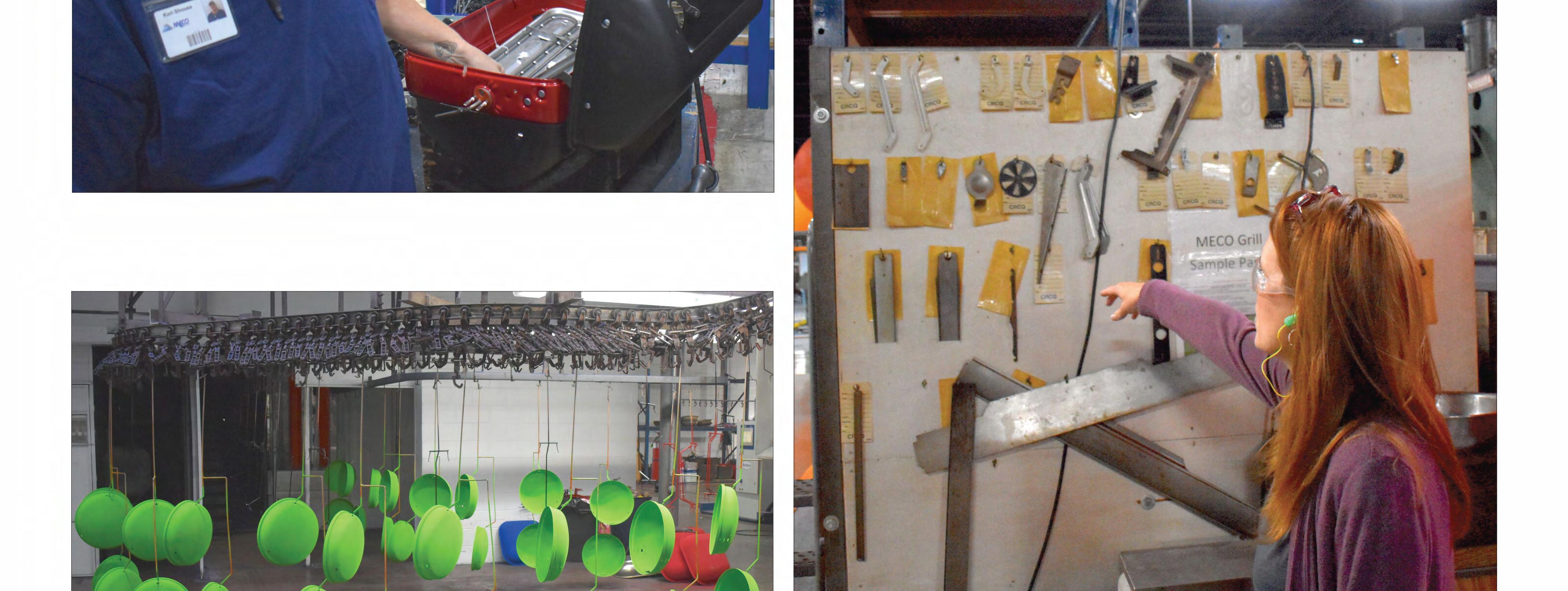

Meco Corp. has an extensive history in Greene County, and the grill manufacturer is now planning for the future.

Founded in 1959 by Robert Austin Sr., Meco has manufactured steel folding furniture, step stools, OEM (orginal equipment manufacturer) components, and barbecue grills. It also ships imported folding furniture from its Greeneville warehouse. The company has manufactured millions of grills in Greeneville from U.S.-sourced and imported components.

The company is now owned by Austin’s son, Robert Austin Jr., and Robert’s wife, Kathryn Gamble.

The company continues to build and ship out barbecue grills, and is now investing millions of dollars in its Greeneville plant to upgrade its grill manufacturing process and bring on more employees.

The local manufacturer announced in May that it would be investing $27.8 million in its Greeneville headquarters over the next five years, creating 67 new jobs and upgrading its facility through the investment.

Over the next 5 years, Meco plans to increase the number of full-time employees for reasons including department expansion, moving toward full-time employment over temporary staff, and company growth.

Meco Corporation President Whitney Winter believes moving toward more regular full-time employees will create a positive impact on the community, employees, and local economy.

Winter called the investment an “interior expansion” as there will not be an addition built onto the Meco facility on Industrial Road, rather all improvements will be made within the existing footprint of the current facility.

Meco was awarded Fasttrack Job Training Assistance Program Grant in the amount $294,197 from the Tennessee Department of Economic and Community Development as a part of its announced multi-million dollar investment. The grant helps expanding companies such as Meco with funding to support the training of new full-time employees.

In late August, Meco purchased a new deep draw press to improve its manufacturing capabilities.

“Meco recently purchased and put into service an RMT H-SMART HSA 440 USton hydraulic press. The press was purchased to replace a piece of equipment that was no longer efficient for production operations. The new press will provide a more efficient process, minimizing downtime, and ensure production requirements can be met,” a press release from the company stated

The new press is a part of the company’s 5-year investment plan in its Greeneville facility, and was purchased with the assistance of a USDA grant.

“The press was recently named the ‘Tweed Press’ in honor and recognition of Hugh and the late Peggy Tweed for their commitment and dedication to Meco for over 70 combined years of service,” the press release from Meco stated.

For Winter, Meco’s employees, or the “Meco family” as she calls it, are what make it special.

“It’s important to us that we pay an honest day’s wage for an honest day’s work. One of the things we value is providing our employees an experience here so they want to come to work. We don’t consider you just a floor worker. You are a part of our Meco family. How can we engage you and let you know we care about you? I think a lot of times that means a whole lot more than just the paycheck that comes in, not that that’s

not important,” Winter said. “If they know that we’re supporting things that they care about, that’s important. We’re family and if you feel like you’re a a part of a family you’re going to be more successful.”

Winter credited Meco’s floor workers and management staff and her plant manager, David Burgner for Meco’s success, and particularly expressed gratitude to the company’s floor leads.

Winter said that stamping supervisor Brian Finchum, paint lead John Shouse, assembly lead Andrea O’Bannon, specialty projects assembly lead Kari Shouse and assembly and paint supervisor James Ramey were integral to Meco’s success.

“They are the ones that make all the magic happen out in the plant,” Winter said. “I really want them to get the credit. The focus should be on them.”

Meco manufactures charcoal grills, electric grills and water smokers, shipping them all out of the Greeneville facility. The components for the fully assembled grill are almost entirely fabricated at the Greeneville plant out of cold rolled steel. The entire process of manufacturing the grills and shipping them takes place in Greeneville.

Meco ships grills to retailers such as Walmart, Lowe’s, Home Depot, Ingles and Kroger, just to name a few, and manufac-

tures over 4,000 grills per day.

Winter, who has been with Meco for 25 years and been in the position of president for about a year, said that retailers appreciate the importance of a reliable domestic manufacturer and shipper such as Meco.

“I think it’s the recognition of the retailers that they need a domestic resource. That coupled with, I think we have an amazing management and leadership team that’s focused on putting more cars into the parking lot. We all have a passion about domestic manufacturing and fortunately our retailers are learning, especially through Covid, that that’s an important passion to have,” Winter said.

Winter said Meco did not fully shut down at any point during the challenges of the COVID-19 pandemic, and noted that the company’s management team worked the lines on the manufacturing floor at one point to keep production going.

As Meco begins its five-year investment plan in its facility, Winter said that the Greene County Partnership and its President Jeff Taylor had been a “fantastic partner” in helping Meco learn about opportunities to assist with growth. She also noted that the University of Tennessee Center for

A new industry is now ramping up operations in Greeneville.

Regenx Tech Corp. began operating in a 30,000-square-foot facility in early 2023 in Greeneville and is now set to begin scaling up its business.

Regenx is a green technology company that carries out the removal and recycling of precious metals from diesel engine catalytic converters.

A proprietary filtration process is used to extract the precious metals.

The filtration process, which is considered “green” by the Tennessee Valley Authority, uses a propriety cleaner formulated from household chemicals to separate platinum and palladium from the pulverized interiors of recycled diesel catalytic converters.

Regenx USA President Rick Purdy describes what the facility produces as a “unique” and “refined” product.

It is a product and process that Regenx worked diligently to developed that involved repeated testing and engineering.

The company is currently using one “module” to carry out the filtration process, that it has now mostly fine-tuned. A module contains numerous tanks, augurs, hoses, and filters that all play a role in the filtration operation. Purdy says the company is now ready to grow and the facility will contain four modules running filtration processes simultaneously within about two years.

The company fabricates much of its materials itself as a way to ensure they meet finely tuned specifications and needs in running its modules.

“We are commercialized now. We’ve proved it all out,” Purdy said. “Each piece you’ve got to make sure it’s all tuned efficiently together. So your input analysis of PGMs (platinum group metals) are measured against your output for recovery to show your efficiencies and purities for the end product. So we test the material, and let’s say it has one gram of something, one gram of another. On the other side we should get pretty close to that on recovery or even more because its not buried in a bunch of inert tailings.”

For now, the company is working to have multiple batches run through it single module each day, which Purdy said will begin “in short order.”

The household cleaners used in the process can be found on local store shelves. There is no high pressure, high temperatures or any outgassing involved in the process.

The low impact process is a new one that is meant to comply with new environmental regulations. Previously, the process of getting the precious metals out of catalytic converters involved using smelters that heat to thousands of degrees Fahrenheit, which is not as “green.”

Once the precious metals are extracted, an inert powder, “tailings,” is all that is left over from the process that are to be used in a net-zero “green” clean-up product. The precious metals are sold back to industries for their previous uses of auto parts and other manufacturing.

Purdy said that the company is partnered with Davis Recycling as its source for the pulverized interiors of catalytic converters. Davis Recyclying is licensed to handle catalytic converters and tracks what vehicle the parts came off of in an effort to avoid accepting stolen catalytic converters.

No catalytic converters are delivered to, stored or used at the Greeneville facility.

Davis Recycling, a company based in Johnson City, collects catalytic converters across the eastern United States. Davis Recycling cracks open the catalytic converters, grinds their contents into a fine powder, and then that powder is delivered to the Regenx facility in large sacks for the recycling process.

Purdy called the sacks “super sacks.”

The material in the “super sacks” is placed in a large tank where it is given a chemical wash that separates the waste from the precious metals. The bath is then pumped into a centerfuge where solids are separated from liquids. It is at that stage that the solid waste is removed from the liquid. The metal-laden fluid is then pumped to a separate tanks and the precious metals are then filtered from the fluid into a “filter sock.”

Once operating at full production, Purdy said the single module will cycle

process.

through about two and a half to three tons of material each day, which is about five or six “super sacks.” Purdy said the facility will be able to handle 10 tons per day once all four modules are installed.

Regenx is a Canadian company that has mostly been known for mining operations, but found a home for its new recycling operations in east Tennessee partly through Purdy’s connection to the region.

Purdy, orginally from the Canadian

province of Alberta, met the family of Davis Recycling owner Ben Davis while on a mission trip in Africa, where Purdy established a relationship with the family.

Purdy’s sister-in-law also lives in east Tennessee, and he established a working partnership with Davis while on a family visit. Purdy then aimed to establish the metals recycling operations near Davis

Sergeant Sudz, LLC, has hit the ground running since makings its debut in Greeneville earlier this year.

The family owned company, which produces electrical control panels for the automatic car wash industry, opened its Greeneville location at 1515 Industrial Road in February, and since that time it has grown to over 30 employees.

The company was born in New Windsor, New York, and was built from the ground up by James Vanderwiele and his wife, Subeth. Both have strong backgrounds within the electricity industry.

Following his military service in the United States Marine Corps, Vanderwiele decided to pursue a career as an electrician. He became the youngest individual in his home county to obtain a master electrician license and has been working in the electrical field for more than 15 years. His wife also has a background in the electric utility industry, in which she served as a project manager with a bachelor’s degree in science.

“I had the chance to apply my skills as a licensed electrician in the car wash industry. This subsequently led to the emergence of additional promising opportunities within the field,” Vanderwiele noted. The Vanderwieles know that it takes much more than soap and water to thoroughly clean a dirty vehicle inside an automatic car wash. It’s takes power.

“The most efficient car washes are powered by Sergeant Sudz,” the company’s website notes. “We build our Motor Control Panels to not only meet, but exceed the UL-508A standards (the industry certification for industrial control panels), so when we build, produce, and distribute Motor Control Cabinets, you know that you’re getting the best.”

“As president of our cutting-edge electrical control panel company, I am truly excited to announce our relocation to Greeneville,” Vanderwiele said. “Our decision to make Greeneville our new home is rooted in our commitment to growth, automation, and the pursuit of excellence in serving the automatic car wash industry.

“At the core of our company’s mission,” he continued, “is a dedication to providing state-of-the-art electrical control solutions that empower businesses in the automatic car wash sector to operate efficiently and sustainably. With our team’s collective expertise and relentless drive for innovation, we have consistently delivered groundbreaking solutions to our clients, enabling them to thrive in a competitive market.”

Vanderwiele went on to say that he believes “success is not just measured in terms of business achievements but also by the positive impact we can make on the communities where we operate. Greeneville, with its rich history and vibrant community spirit, provides the perfect backdrop for us to continue growing while contributing to the region’s prosperity.

There were several reasons that factored into the Vanderwieles’ decision to make Greeneville their new home.

“We chose Greeneville as the location for our second site due to several compelling factors,” he said. “Firstly, Greeneville offers a strategic geographical advantage, allowing us to expand our reach to a broader customer base. Additionally, the community’s strong workforce and talent pool align with our company’s growth objectives.

“The welcoming and business-friendly environment in Greeneville, along with its proximity to key suppliers and partners, made it an ideal choice for our expansion efforts,” Vanderwiele continued. “Overall, we believe that Greeneville provides us with a solid foundation for our second location and aligns with our longterm business goals.”

The Vanderwieles pride themselves on making Sergeant Sudz a great, family friendly place to work.

“We prioritize a healthy work-life balance, and as part of our commitment to this, our employees follow a dayshift schedule from 7:30 am to 4:00 pm, Monday through Friday, with minimal to no mandatory weekend work required,” he said.

“I am particularly proud of the strong family values that underpin our company culture, and I bring that same commitment to family into my role as President,” he continued. “My wife, who also serves as the Vice President of our company, as well as our three children have been my

greatest source of inspiration and support. I look forward to weaving these values into the fabric of our company’s presence in Greeneville.”

In the coming months, Vanderwiele said he and his family look forward to establishing themselves and their company as “an integral part of the Greeneville community, forging partnerships, and creating job opportunities for local residents.

“We are excited about the journey ahead and are confident that our presence in Greeneville will not only be a testament to our dedication to excellence but also a reflection of the warmth and unity that defines this beautiful town,” he added. “Thank you for welcoming us into your community, and we look forward to a prosperous future together.”

As Sergeant Sudz continues to grow, Vanderwiele said plans are to hire additional workers at the Greeneville location.

“We aim to have 60-plus employees by the end of 2024,” he said.

Among the special skills needed for the company’s workforce are:

- the ability to follow blueprints and/ or schematics;

- a strong attention to detail and quality control;

- proficiency in using hand tools and power tools, and

- good communication skills and the ability to work as part of a team.

Interested candidates can apply on the company’s website at Sergeantsudz.com, on Indeed as positions are posted, as well as paper applications available on site.

SoPakCo stores and ships a variety of products from its 13 warehouses in Greeneville and Kingsport.

“We store food products, such as canned goods; products for storage, such as empty cans; retail; paper products; and different plastics, such as pellets,” said President Wesley Keller.

SoPakCo’s headquarters are located off Snapps Ferry Road, at 102 Coile St., in Greeneville, where it has 10 of its warehouses.

Overall, the company has over 1 million square feet of warehouse space in Greeneville and Kingsport, said Keller.

SoPakCo also has a small fleet of eight tractor-trailers to serve its customers, within about a 150-mile radius from Greeneville, he noted.

Its headquarters on Coile Street has warehouse space, as do four other locations in town.

“We lease the facilities, and store products. We manage all of our space,” Keller

stated. “We don’t operate businesses in our warehouses.”

He explained that SoPakCo “receives product, stores it, and ships it out to different stores” as needed. They also manage the inventories of companies’ products in the warehouses, he said.

“We’re a full-service company that receives product physically, puts it in the computer system, and ships it per their instructions,” Keller stated.

“Today, our occupancy rate is 80-85%. That’s actually above average. We operate on an 80% level, but I’m thankful we’re above it. Very much so.”

He said that supply chain issues, which have gotten a lot of news media coverage in recent years, occur “if production or sales are up (which) depletes the inventory, and, in effect, the supply chain.

“Right now, from the perspective of the companies we service, the economy’s relatively strong.”

He confirmed that having warehouses located in northeast Tennessee are a plus geographically.

“It’s very true,” Keller said. “We’re cen-

trally located. We can service a large part of the East Coast within a day’s drive.”

SoPakCo is owned by a corporation, Unaka Corporation, which is located on Industrial Road in Greeneville. Robert Carter Austin is the owner of the company.

SoPakCo began as a business in 1943, in Greeneville. Buildings they currently have on West Irish Street date from the original start of the company, he said.

“There’s fewer and fewer companies we hear that have that long of a run,” said Keller.

“We ship across the country, and export to Asian companies,” he said. “We also receive both domestic and import products.”

Stated Keller, “We do LTL (less than a full truck load) shipments. We have a great relationship with Norfolk Southern. We ship and receive from all over the country by rail. That’s a big part of our business.”

SoPakCo has a total of 65 employees, including 57 in Greeneville, he said.

“We have a very strong team that flows together to provide service to our customers,” Keller stated, adding, “I can’t say enough about the team of employees.

They’ve driven the success of the business.”

He said SoPakCo has “a large group” of employees who have been with the company for 20-40 years, “and a few 40-plus years.” Several employees have worked for the company 20-plus years, he stated. Keller has been president of SoPakCo for three years, and was a general manager from 1996 to 2020.

He said he truly likes working for the company. “It’s a great company to work for,” said Keller. “We have a very supportive ownership of the company.

“We’re a very service-oriented business,” Keller said, emphasizing the word “very.” He said that’s why having their high caliber of employees is so important. They have two shifts - first and secondfor employees and drivers.

The company is thriving and may expand in the future, he said.

“We are looking at expansion possibilities, but those are yet to be determined,” stated Keller.

“It’s been a great ride,” Keller stated. “It’s been very interesting.”

Quality is paramount to Titan Display & Packaging.

The supplier of specialty and graphic packaging located in Mt. Pleasant Industrial Park has grown rapidly since its beginning in July 2020, during the COVID-19 pandemic.

Titan’s current workforce is a little more than 100 workers who are passionate and committed to what they do, according to Bruce Korman, general manager.

During a recent interview at the plant, Korman said Titan’s mission is to be the leading supplier of specialty and graphic packaging in the Northeast Tennessee and Carolina markets within a 300 mile radius of the plant.

This mission will be achieved, he said, through several goals and strategies:

• Zero defect rate to customer;

• No late or missed deliveries;

• Quality is an individual and team responsibility;

• Commitment to get the job done;

• Strive to be a world class supplier to the markets Titan services; and

• Strive for excellence.

“We set lofty goals,” Korman said.

Titan Packaging makes corrugated displays you might see in grocery or retail stores that hold products like pet food, bottles of toiletries or packaged pastries.

Their customers are very diversified, from automotive products, to durable goods, to food and beverage, and they include a lot of big brand names, Korman said.

“It’s all about the customer experience and taking care of the customer,” he said of Titan’s work.

When Titan began in 2020, supply chain delays made things very difficult, Korman recalled. Now supplies are ready next day, but during COVID the delay was three to four weeks, he said. Titan remained steadfast and was committed in starting its business, said Korman, a New York native who holds a degree in packaging engineering from Michigan State.

Titan’s core team has worked together for over 20 years before starting the company and has over 100 years collectively of corrugated manufacturing experience. They wanted to create a company that not only puts customers first but also cares about its employees, Korman said. He described Titan’s growth as “miraculous” saying the company has been very fortunate and blessed.

Production employees work three shifts, five days a week. Titan also has four sales representatives and runs a fleet of four trucks to deliver products to customers.

In year three, they are processing as many as 600-700 orders a month and have surpassed where they predicted they would be in year five, Korman noted. For more information, visit https:// www.titan-box.com /.

Industrial Sciences and Kenny Smith had been a “significant partner.”

She said that the new deep draw press uses significantly less energy than the previous piece of equipment, and is a definite upgrade. Winter noted that it shows employees that Meco cares about keeping the facility going strong, as well.

“That’s the first new deep draw press we’ve had probably in over 40 years. You can imagine that the technology has changed significantly in 40 years. Investing in our machinery is not only going to produce a more efficient part, but it’s encouraging to our associates out on the floor that they see we’re investing in this facility. They see we’re investing in machines that make their life easier, because it was a struggle with a lot of those old machines,” Winter said.

The next investment being made in the Greeneville facility will improve the employee experience at Meco even further.

“We are getting ready to kick off an investment to completely refurbish our cafeteria for our associates. It’s going to give them more space, and we are going to have a quiet room, we are going to have an activity area and have televisions and charging stations. We want them to know that we’re investing in the future, and I think that’s a very tangible point that they can see that we’re here to stay and that we’re investing in them as associates, because we have found that’s one of the keys to our success, is investing in associates,” Winter said.

Meco is continually investing in training its 170 associates, and Winter said that the facility has been focusing on making employees feel a part of the “Meco family.”

“It’s making sure that they want to come to work every day, because if they want to come to work, they are going to be more

Recycling, which led him and Regenx to Greeneville.

Purdy said he drove all over east Tennessee searching for a suitable facility to house a large-scale recycling plant without much success. However, he found information online about the Greene County Partnership and its president, Jeff Taylor. Purdy called Taylor up, and Taylor found Regenx a suitable facility for their operations in Greeneville.

Purdy and his family, and Regenx’s new recycling processes, now call east Tennessee home.

productive. So we really spend a lot of effort here on fun activities, employee engagements, picnics and cookouts. We have food trucks on Wednesdays. Just something to always keep them engaged. We just opened a fresh market in the satellite cafeteria and up front so they have a nice selection of fresh foods to choose from, rather than having to go out to eat, and it’s a price that’s more economical than driving through McDonald’s,” Winter said. “Employee engagement, I think, is key.”

As a part of expanding its number of employees, Meco is looking toward more permanent hires.

“We have established new guidelines for transitioning our temp labor workforce into permanent hires. It is our goal to get them permanently hired and not just run a temp workforce,” Winter said. “It’s allowing us to find the right fit for Meco and find the right employee.”

Meco is hiring new engineering and technical positions as a part of its expansion and new product development, and Winter said the facility generally has relatively low turnover but is “always looking” for associates.

As Meco prepares for its next 60 years in business, Winter said the company is focusing on new product development, creating products that are key to consumers’ desires and gaps in the market while also staying “a step ahead of China” and attempts to undercut domestic manufacturers.

“We are continuing to work on ways to protect our intellectual property,” Winter said.

As Meco grows, it plans to do so based on its firm Greene County roots.

“We are dedicated to remaining in Greene County. The company’s roots were formed here,” Winter said. “We’re dedicated to keep manufacturing in Greene County.”

“We love it. We love Tennessee and we love the people. We’re happy here,” Purdy said.

As Regenx grows, Purdy says his goal is to have four modules installed in the facility in about two years, and once all four modules are running at full capacity, Purdy said the company plans on having about 80 employees.

Purdy said that while Regenx may be a new industry in Greeneville, it plans on sticking around.

“We plan on being here a long time. We have invested a lot here. This is our home now,” Purdy said.