BRAIN STIMULATION

Roga’s medtech wearable aids wellness p.16

BODY FREQUENCY

AntennaWare deploys wireless systems on human platform p.20

MONITORING HEALTH

Are printable sensors the key to healthcare wearables? P.22

DeepSight is reshaping the future with its AR software solutions p.12

PM 40065710 MAY/JUNE 2024 CANADA’S INFORMATION LEADER FOR ELECTRONIC ENGINEERS AND DESIGNERS EPT.CA AUGMENT YOUR REALITY

DEEPSIGHT

Montreal

CHILL

Toronto

BODY-CENTRIC NETWORKS

Antenna

SENSING WEAR YOU’RE AT Biomedical sensors become more commonplace in designing wearables.

@EPTmagazine Columns 4 EDITORIAL Wearables fit today’s designer trends 10 WEST TECH REPORT Trusted Positioning geolocates with navigation sensors 11 THINK GREEN

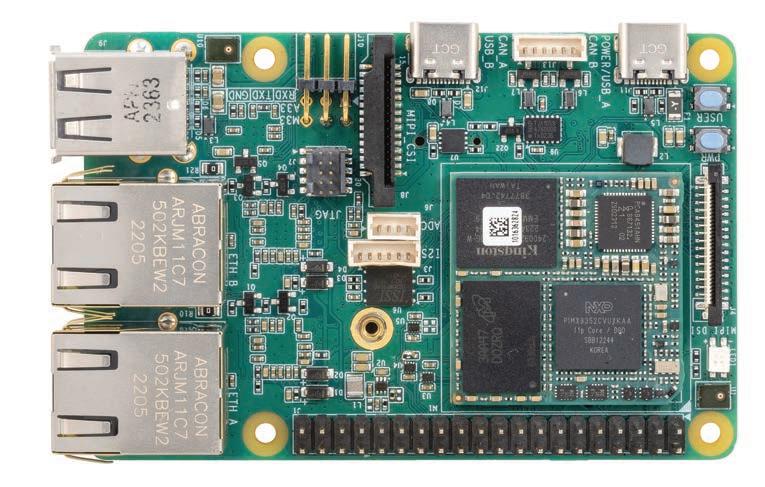

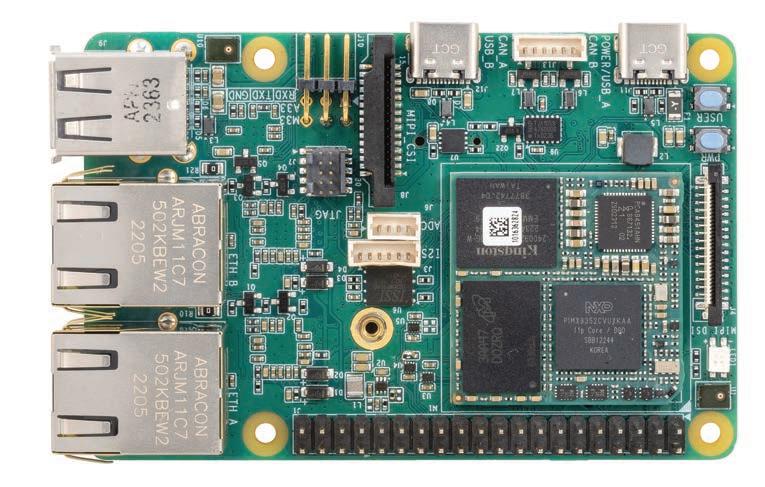

your electronics In every issue 5 NEWSWATCH 26 PRODUCT SOURCE 28 SUPPLY SIDE 29 AD INDEX 30 DEV BOARDS

Maaxboard OSM93 Dev kit MAY/JUNE 2024 1216 INSIDE Cover photo: Thinkhubstudio / iStock/Getty Images Plus / Getty Images Photos (this page, from top): Getty Images; Roga; Antennaware; Getty Images 22 20 Canada: 403-516-1888 USA: 602-833-8591 dynamicsourcemfg.com Are you outgrowing your current Contract Manufacturer? We are your solution. Connect with us today for high quality builds, fast turnaround time, and decades of experience. EPT_Dynamic_MayJune24_CSA.indd 1 2024-05-03 11:32 AM COVER STORY

Conducting enviro testing for

Avnet

HAS A VISION

reality, AI and smart glasses.

software developer leverages augmented

YOUR BRAIN

health.

wearable firm Roga seeks to sooth your mental

maker enhances wireless performance on every body.

12 16 20 22

Wearables fit with today’s designer trends

Canada leads the charge, blending fashion with functionality

When it comes to creating new wearable designs that weave so deftly into their application uses – designers across Canada are certainly turning heads on the global stage.

In the course of the past few years, many ground-breaking technologies have redefined the landscape within this design sector – and Canada finds itself at the forefront of the emerging sector. Once confined to the realm of science fiction, wearable devices now permeate every aspect of our lives, from fitness trackers monitoring our health to smartwatches keeping us connected in real-time. Look no further than this issue of EP&T – which puts the spotlight on wearables. Within the pages of this edition you will find a close-up look at DeepSight, a Montreal company pioneering in the field of augmented reality (AR) platforms. They specialize in developing cutting-edge technologies that seamlessly integrate dig ital content into the physical world, enhancing user experiences across various industries.

DeepSight’s AR platforms offer innovative solutions for businesses looking to engage with customers in immersive ways, from interactive marketing campaigns to advanced training simulations.

With a focus on pushing the boundaries of AR technology, DeepSight continues to lead the way in creating impactful and transformative experiences for both consumers and enterprises alike (pages 12-14).

As is often the case with wearables - at the heart of the designs lies a convergence of

disciplines, where electronics meet material science, software meets hardware, and innovation meets necessity. For engineering community, this presents a tantalizing opportunity to push the boundaries of what is possible. The challenges are manifold, yet so are the rewards. From optimizing power efficiency to enhancing data processing capabilities, engineers are tasked with har nessing the full potential of wearable technologies while ensuring reliability and scalability.

One of the most pressing issues facing wearable technology is power consumption. As devices become smaller and more integ rated into our daily lives, the need for energy-efficient solutions becomes paramount. In addition, data security and privacy concerns loom large in an era where personal information is increasingly digitized and interconnected.

Revolutionizing healthcare

We touch on these very issues in a Q&A conversation with Dr. Alison Smith, co-founder of Roga, a Toronto-based developer of medical wearables focused on revolutionizing healthcare. The firm’s innovative devices leverage cutting-edge technology to monitor vital signs and collect health data in real-time, empowering individuals to take control of their well-being. Roga’s wearables are designed with user comfort and convenience in mind, enabling continuous monitoring without intruding on daily activities. By providing actionable insights and early detection of health issues, Roga’s devices play a crucial role in preventative care and improving patient outcomes. With a commitment to advancing healthcare through wearable

technology, Roga is poised to make a significant impact in the medical field (pages 16-17).

From a component perspective, you can also read about how wireless antennas are gaining increasing access into wearable tech. An article (page 20-21) in this issue provided by UKbased AntennaWare details how its approach involves carefully selecting antenna types and configurations that maximize signal strength and reliability while minimizing interference. The firm works closely with wearable device manufacturers to customize antenna designs according to specific for m factors and usage scenarios, ensuring a perfect fit for each application.

Printable sensors

Lastly, the emergence of printable sensors in wearable technology designs marks a significant advancement in the field, enabling the creation of flexible, lightweight and cost-effective devices with enhanced functionality. Typically made using flexible mater ials such as polymers or organic compounds, these sensors conform to various shapes and surfaces, including clothing and accessories. Be sure to read the related story on the emergence of printable sensors (page 22-23).

So, from the bustling metropolises of Toronto and Vancouver to the innovation hubs in Montreal and Waterloo, Canadian electronic eng ineers are spearheading the charge towards a future where wearables seamlessly integrate into the fabric of society

STEPHEN LAW Editor slaw@ept.ca

Canada’s information leader for electronic engineers and designers

MAY/JUNE 2024

Volume 46, Number 4

READER SERVICE

Print and digital subscription inquiries or changes, please contact Angelita Potal Tel: (416) 510-5113 Fax: (416) 510-6875 Email: apotal@annexbusinessmedia.com Mail: 111 Gordon Baker Rd., Suite 400 Toronto, ON M2H 3R1

EDITOR Stephen Law slaw@ept.ca · (416) 510-5208

WEST COAST CORRESPONDENT Mike Straus · mike@brandgesture.ca

SENIOR PUBLISHER Scott Atkinson satkinson@ept.ca · (416) 510-5207

ACCOUNT MANAGER Joanna Malivoire jmalivoire@ept.ca · direct 866-868-7089

SALES MANAGER Chander Verma cverma@annexbusinessmedia.com cell 437-218-0941

ACCOUNT COORDINATOR Shannon Drumm sdrumm@annexbusinessmedia.com

MEDIA DESIGNER Svetlana Avrutin savrutin@annexbusinessmedia.com

AUDIENCE DEVELOPMENT MANAGER Anita Madden amadden@annexbusinessmedia.com (416) 510-5183

GROUP PUBLISHER Paul Grossinger pgrossinger@annexbusinessmedia.com

CEO Scott Jamieson sjamieson@annesbusinessmedia.com

EP&T is published eight times per year by ANNEX BUSINESS MEDIA 111 Gordon Baker Road, Suite 400 Toronto, ON M2H 3R1 Tel (416) 442-5600 Fax (416) 510-5134 annexbusinessmedia.com

SUBSCRIPTION RATES Canada – $59.67 one year; $95.88 two years USA – $136.68 (CAD) per year International – $187.17 (CAD) per year Single copy – Canada $15.00

ISSN 0708-4366 (print) ISSN 1923-3701 (digital)

PUB. MAIL AGREEMENT NO. 40065710 Return undeliverable Canadian addresses to: EP&T Circulation Department, 111 Gordon Baker Rd. Suite 400, Toronto, ON M2H 3R1

© 2024 EP&T. All rights reserved. Opinions expressed in this magazine are not necessarily those of the editor or the publisher. No liability is assumed for errors or omissions or validity of the claims in items reported. All advertising is subject to the publisher’s approval. Such approval does not imply any endorsement of the products or services advertised. Publisher reserves the right to refuse advertising that does not meet the standards of the publication. Occasionally, EP&T will mail information on behalf of industry-related groups whose products and services we believe may be of interest to you. If you prefer not to receive this information, please contact our circulation department.

PRINTED IN CANADA

4 ELECTRONIC PRODUCTS & TECHNOLOGY / May/June 2024 EPT.CA EDITORIAL

Connect with EP&T magazine @EPTmagazine facebook.com/EPTmag/ /ept-magazine info@ept.ca ept.ca

NEWSWATCH

SEMICONDUCTORS

CMC MICROSYSTEMS & VENTURELAB SIGN MOU

Goal is to support semi growth in Canada

CMC Microsystems, a not-for-profit R&D organization that accelerates innovation in advanced technologies in Canada, and ventureLAB, a community for hardware technology and enter prise software companies in Canada, have signed a Memorandum of Understanding (MOU) to formalize their relationship and advance Canada’s advanced technology ecosystem.

A ceremony was held at the ventureLAB Innovation Centre in Markham, with industry leaders, entrepreneurs, researchers and representatives of the federal, provincial and municipal governments present. Under the agreement, the organizations will support each other’s complementar y programs to advance the advanced technology ecosystem in Canada. CMC has made a formal commitment to support the Hardware Catalyst Initiative (HCI), which provides support for hardware and silicon small- and medium-sized (SMEs) companies building transformative solutions in healthcare, telecommunications, advanced computing, connected transportation and smart energy. In addition, ventureLAB has committed to supporting CMC’s Virtual Incubator Environment (VIE), a program designed specifically for startups which provides a bundle of design tools and manufacturing technologies at accessible price points. ventureLAB is also committed to supporting the FABrIC initiative, a proposed five-year $200M project led by CMC and 14 other founding organizations to secure Canada’s future in advanced semiconductor manufacturing and design.

Hardware catalyst

ventureLAB’s Hardware Catalyst Initiative is Canada’s only lab and incubator for founders building hardware and semiconductor-focused products, enabling the creation of transformative technologies that will power our products of tomorrow — including healthcare technology, consumer electronics, telecommunications, smart energy, connected transportation, and more. Funded in part by the Government of

From left are Hugh Chow, CEO of ventureLAB; Tony Van Bynen, Member of Parliament for Newmarket— Aurora; and Gordon Harling, President and CEO of CMC Microsystems.

Source: CMC Microsystems

Canada, through FedDev Ontario, the Hardware Catalyst helps tech companies accelerate their time to market in a sector that normally incurs lengthy entry and scale times, enabling Canadian hardware and semiconductor companies to grow and scale locally, and compete globally.

VIE & FABrIC initiative

CMC’s Virtual Incubator Environment (VIE) is a suite of tools, technolog ies, and services for startups. Startups can access design and simulation tools, technical support from CMC experts, and access to state-of-the-art fabrication in microelectronics, silicon photonics, and micro-electromechanical systems (MEMS) at accessible rates. FABrIC is a proposal presented to the Government of Canada for a five-year, $200M plus project to secure Canada’s future in semiconductors. FABrIC lowers barriers for entrepreneurs in Canadian companies who develop microchip m anufacturing processes, create Internet-connected products and services, and export into a global market growing made-in-Canada microchip manufacturing, internet-connected products and services (IoT), and quantum technologies. FABrICgrows Canada’s semiconductor ecosystem by leveraging existing chip design and manufacturing facilities, providing companies with financial support, and access to the CMC Innovation Platform – a nationwide chip design and manufacturing knowledge base backed by a trusted global supply chain and deep technical expertise.

“With CMC’s extensive national presence and an international network of collaborating researchers and suppliers, the future is promising,” said Hugh Chow, CEO of ventureLAB.

For Gordon Harling, president and CEO of CMC, working with ventureLAB will bring concrete benefits

for its own network, and the entire Canadian ecosystem. “ventureLAB has a proven track record supporting, accelerating, and scaling firms that create transformative technologies which power our products of tomorrow. The Hardware Catalyst Initiative in par ticular will benefit researchers and entrepreneurs from the CMC network by providing more prototyping and test opportunities to improve development and accelerate their time-to-market.”

Canada Chips Week

Both leaders also emphasized that FABrIC is a key initiative that will boost the entire Canadian semiconductor and advanced technology ecosystem.

“Canada is recognized around the world as a leader in some of the most innovative and advanced semiconductor technologies such as compound semiconductor s, photonics, internet-connected devices, and quantum technolog ies – specialized advanced technologies with exponential growth opportunities and high value-add” said Harling.

“FABrIC is an innovative, cost-effective way to create a resilient and sustainable semiconductor ecosystem in Canada, and keep Canada at the forefront of advanced manufacturing and advance Canada’s knowledge-based economy,” said Hugh Chow.

Harling and Chow also announced that Canada Chips Week will be taking place October 7-11 in the Markham area. The event aims to bring together leaders from across the semiconductor ecosystem to plot a way forward for Canada in crucial areas such as talent development, and manufacturing innovations such as advanced process controls. Canada Chips Week will also include CMC’s Canadian Semiconductor Symposium, and ventureLAB’s HardTech Summit.

@EPTmagazine May/June 2024 / EP&T 5

TECHNOLOGY

GOV’T COMMITS $100M FOR SEMI CAPACITY IN BROMONT QUEBEC

The federal and Quebec governments are spending close to $100 million to boost the country’s manufacturing capacity for semiconductors in Bromont QC, which are vital in technologies ranging from artificial intelligence to quantum computing. Ottawa will invest $59.9 million to help fund IBM Canada’s semiconductor packaging facility in the town about 70 kilometres southeast of Montreal.

The investment will also go toward the Bromont-based MiQro Innovation Collaborative Centre (C2MI), a research group that tries to speed up the commercialization of components in digital technologies.The Province of Quebec is offering IBM Canada $38.9 million in loans to help the company buy equipment, increase capacity at the Bromont facility and create a new generation of switches.

Information provided by the federal government says the funding from both levels of government is expected to create 280 jobs in the region. IBM Canada says its Bromont plant is one of the continent’s largest chip assembly and testing facilities and that the money will solidify Canada’s place in the supply chain for advanced packaging of semiconductors.

In another related event, officials from the NewYork Center for Research, Economic Advancement, Technology, Engineering and Science (NY Creates), based in Albany NY, and C2MI (MiQro Innovation Collaborative Center), based in Bromont, have established an expanded partnership to help spur future collaborations between the two entities. The collaboration aims to enhance research opportunities, expand potential for economic and workforce development and nurture collaborative efforts between the two cross-border technology giants that are part of a growing and dynamic semiconductor corridor running from Upstate New York to the Eastern Townships in Canada.

SEMICONDUCTORS

5N PLUS COMMERCIALIZES

ITS GAN-ON-SI PATENTS

Montreal-based producer of specialty semiconductors 5N Plus Inc. has launched the commercialization rights

A portion of the Canadian and Quebec Governments’ funding will also go towards semi research at C2MI in Bromont QC.

Source: C2MI

Montreal-based developers of GaN-on-Si patents aim to take semiconductors to the next level.

for its portfolio of gallium nitride on silicon (GaN-on-Si) patents – aiming to take semiconductors and power switching technology to the ‘next level’. These key patents can enable the rapid prototype development and first-to-market commercialization of novel vertical GaN-on-Si power devices by companies operating in the high-power electronics (HPE), electric vehicles (EV) and artificial intelligence (AI) server sectors.

A mechanically stable, wide-bandgap semiconductor material with high heat capacity and thermal conductivity, lateral GaN is primarily used in low voltage (<400V) applications, such as chargers, but novel vertical GaN-onSi has the potential to replace silicon carbide (SiC), which is the current preferred material for medium and high voltage applications (i.e. EV inverters operating 650V).

“Our 54 patents have now been shown to be more high-performing and efficient than the current alternative through recent academic demonstrations. As such, our portfolio of patents is uniquely positioned to enable industry-leading HPE and EV companies to rapidly develop and commercialize first-to-market vertical GaN-on-Si power devices that will revolutionize high-voltage semiconductor applications,” said Gervais Jacques, president and CEO of 5N+.

UNTETHER AI TO COLLABORATE WITH ARM

Toronto-based AI chip maker Untether AI has announced its collaboration with Arm to develop best-in-class solutions optimized for next-gen automotive applications. As part of the partnership, Untether AI will enable its inference acceleration technology to be implemented alongside the latest-generation Automotive Enhanced (AE) technology from Arm, to create solutions that

address performance, power, safety and security requirements for advanced Driver Assistance Systems (ADAS) and autonomous vehicle (AV) applications.

Compute workloads radically changed in the past several years with the deployment of AI and the increasing complexity of AI and conventional software algorithms has elevated the demand for heterogeneous computing platfor ms employing domain-specific architectures. This trend, which is especially true in the automotive sector, results in a computing platform that combines a mix of CPUs, AI accelerators, memory, and networking technologies that have been optimized for neural network acceleration and software-defined vehicles (SDV).

“The increase in advanced user experiences, ADAS, and AV applications means more heterogeneous compute is needed in the vehicle,” said Suraj Gajendra, vice president of products and solutions, Automotive Line of Business, Arm. “By collaborating with Untether AI to ensure our leading-edge AE technology can work well alongside Untether AI’s acceleration capability, we are enabling our par tners to power cutting edge AI workloads across the vehicle.”

ROBOTICS

MAGNA INKS STRATEGIC PARTNERSHIP WITH SANCTUARY AI

Magna International Inc. has signed a strategic partnership with Sanctuary AI for the development of general-purpose AI robots for use in the company’s manufacturing operations. Financial terms of the agreement, which includes a strategic equity

6 ELECTRONIC PRODUCTS & TECHNOLOGY / May/June 2024 EPT.CA

NEWSWATCH

investment by Magna, were not immediately available.

Founded in 2018, Vancouver-based Sanctuary AI has developed a number of technologies including dexterous humanlike hands and an AI control system.

Magna has been an investor in Sanctuary AI since 2021.

The Ontario-based auto parts company aims to use Sanctuary AI’s technology across multiple applications within its business.

Todd Deaville, vice-president of advanced manufacturing innovation at Magna, says that by integrating general purpose AI robots into its factories for specific tasks, the company will be able to improve its operations.

WIRELESS

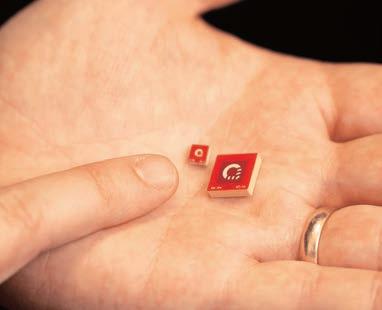

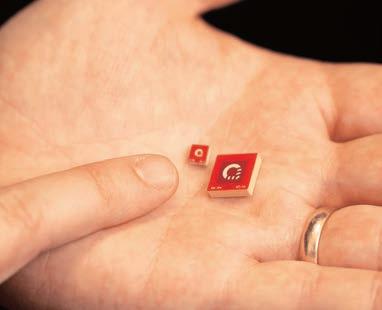

U OF WATERLOO RESEARCHERS CREATE POWERFUL, MINIATURIZED ANTENNA

University of Waterloo engineers have invented a powerful antenna small

This UofW designed ring looks like jewelry, but transmits medical data to healthcare workers.

enough to fit in a ring and capable of transmitting critical medical data to health care workers and individual patients.

The ring, small enough to be worn like a piece of jewelry, contains a tiny antenna that can safely send medical-related infor mation to smartphones or a health clinic over long distances through airwaves. This breakthrough is the first step to creating a device that can be used for non-invasive medical sensing applications such as monitoring blood and oxygen levels, assessing one’s fitness or tracking Parkinson’s disease.

ALWAYS ALIGNED FLOATING CONNECTORS

“There is a revolution going on in the wireless sensing world,” explained lead researcher Dr. Omar Ramahi, a professor at the Department of Electrical and Computer Engineering. “But this revolution cannot succeed without the antenna.”

This novel ring is classified as an Internet of Medical Things (IoMT) device, which is characterized as tools and applications that work together through a network that can monitor vital signs and track disease progression. These biomedical monitoring systems include wearable antennas which help maintain wireless links and transmit information collected by sensors throughout the body.

“When it comes to wearable medical devices, it’s the size of the antennas that causes design issues, not the transmitter s and receivers which can be easily miniaturized,” said Rania Rabhi, a visiting scholar from Tunisia who developed the ring with Ramahi.

Visit ept.ca for the latest new products, news and industry events.

@EPTmagazine May/June 2024 / EP&T 7 Harwin Flecto connectors are fine-pitch, high-pin-count board-to-board connectors offering perfect alignment, high-speed data transmission, mixed signal and power options, and multiple mating heights. CONNECT TECHNOLOGY WITH CONFIDENCE. // WWW.HARWIN. COM/FLECTO

Flecto half page horizontal April 24 EP&T Canada.indd 1 26/03/2024 11:26 EPT_Harwin_MayJune24.indd 1 2024-04-18 2:52 PM

Kick Back & Enjoy the Ride . . .

It’s been a long road, a seemingly endless road. So endless, in fact, that you consider pulling over to let our cords take the wheel, let them drive AC power when and where you need it. For the past three years, you’ve endured work restrictions, port closings, and labor disputes. You’ve endured broken supply chains just to survive. But now that you’ve had time to sit back and catch your breath, reflect on manufacturers and vendors who can provide the reliability you need for success, you realize your dreams are alive more than ever—you’re not a quitter.

And neither is Interpower. Our cords never veer from busy customer work schedules. Our cord sets are ready to plug in right out of the box, unlike the cords shipped from overseas having sweltered in the Pacific long enough to lose their shape. With optional Scheduled and Blanket orders available, our cords are manufactured and delivered when and where you need them year-round. And with no minimum orders, you won’t give purchasing a nervous breakdown—order 1 cord, or 1,000 cords.

In a time of higher prices and lower quality overseas materials, Interpower has been building inventory to ensure world-class cords, cord sets, and components reach those who dream worldwide. If our cords, cord sets and components are in stock, we’ll ship them the same day. If they aren’t, we guarantee 1-week U.S. manufacturing lead-times with international shipping arriving just days later.

We do that through innovation and customization. You’d be hard pressed to find another cord-maker who changes 100-lb-mold dies up to 40 times a week just to meet our country-specific cord set orders, including IEC 60320 products. More common is for cord-makers across the globe to run a single mold for weeks at a time to produce hundreds of thousands of the same cord—without all of our quality checks! Interpower testing exceeds the requirements and standards set by household names such as UL, CSA, and VDE. Our cords are tested throughout every stage of the manufacturing process.

INTERPOWER | P.O. Box 115 | 100 Interpower Ave | Oskaloosa, IA 52577 | Toll-Free Phone: (800) 662-2290 | Toll-Free Fax: (800) 645-5360 | info@interpower.com Order Online! www.interpower.com Business Hours: 7 a.m.–5 p.m. CST ® ® Let Interpower® Cords Do the Driving

At Interpower, what we say about our cord sets and components is actually what we make. In a world with rolling blackouts and a bleak forecast for many electrical grids, you’re going to need reliable cords whether plugging into a standard country-specific wall socket or a generator.

So why Interpower? And how is it possible to relax in a world full of chaos and anxiety?

No worries:

• 1-week U.S. manufacturing lead-times

• Same-day shipping on in-stock products

• Quick-change molding process

• No minimum orders

Perfecting the science of geolocation

Trusted Positioning delivers with inertial navigation sensors, systems

BY MIKE STRAUS, WEST COAST CORRESPONDENT

Boasting more than 60 million sensor-enabled devices and sensor positioning solutions embedded within a wide variety of industries across Canada and globally, you get the sense that Calgar y-based Trusted Positioning Inc. has ‘arrived’. President & managing director Chris Goodall, Ph.D., says the company got its start 25-years ago while he was pursuing his doctoral degree in integrated positioning and GPS sensors at the University of Calgary. Upon reaching the end of his doctoral program, Goodall says he realized the technology he was working on was ahead of its time.

“It’s not like we could go to Garmin and do this,” Goodall says. “We had to start a company on our own. We were licensing some of the software at the time, but the companies we were working with were trying to figure out what they could do with our technology in five to ten years. So we figured we’d found a company and make a go of it.”

Founded in 2009, Trusted Positioning initially served the automotive market and created handheld navigating devices for hikers. At the time, smar tphones did not exist as they do today; automotive and personal GPS systems were often inaccurate and were prone to interference.

Fraught with challenges

“I actually got lost in the Yukon once because I relied on a GPS system,” Goodall notes. “The GPS system wouldn’t work under alder bushes that were 15 feet high.”

The process of building Trusted Positioning was fraught with challenges, both technical and financial. Goodall says that building up a financing base was a struggle; initially, the company founders relied on friends and family for funds. Furthermore, forming a team proved to be difficult.

“Getting people to join for stock options and very little salary was challenging,” Goodall explains. “You can do that with students, but once you get past the first 10 or so employees, people want real money. So it was a never-ending cycle of growing a team

and then trying to finance it.That’s the real challenge of any startup – trying to make something out of nothing.”

Goodall says that over time, the more things snowball, the easier growth becomes. Eventually, the company secured investment and support from the previous CEO and CFO of Novotel, which enabled further growth.

Primary tech applications

Since its inception, Trusted Positioning has pivoted to serve the indoor market and urban areas. The rise of the smartphone has also prompted Trusted Positioning to adapt; the company is now tracking IoT devices in areas where GPS doesn’t work. Currently, the primary applications for the company’s technology involve positioning people and machines in enterprise environments.

“Pretty much every application, whether indoors or outdoors, is about efficiency and safety,” Goodall notes. “Instead of avoiding traffic in an urban centre, we’re now focused on avoiding forklifts crossing human foot traffic. We do some consumer applications like micromobility, for instance, finding the closest e-scooter or e-bike. Obviously, the entire autonomous realm is something we’re looking into right now – autonomous vehicles, goods delivery, those types of applications.”

Goodall says that over time, the company has had to make its sensors more and more accurate; sensors now need to detect the proper lane on a road and have an error budget to prevent collisions with surrounding

obstacles. The company is currently working on solving this challenge:

“The problem with inertial sensors is that they only know what’s happening r ight now, and they have errors. So if you want to know how something has moved over the last minute, you have to add up those motions, which also means adding up errors. The errors grow with respect to time and distance. That’s why inertial sensors, in terms of positioning, should be incor porated with a GPS system. We also use electromagnetic positioning indoors, where you use electromagnetic signatures to get absolute positioning.”

Trusted Positioning recently discovered a new niche during the COVID-19 pandemic: Contact tracing. During the pandemic, privacy bar riers broke down for a period of time, which enabled Trusted Positioning to develop personal sensors for contact tracing. While privacy barriers have returned and this solution is no longer feasible, contact tracing serves as a prime example of a much needed and rapid pivot of this technology.

The company’s micromobility work, Goodall explains, is quite simple: Enabling orderly parking.

“We’re targeting mainly shared vehicles in urban centers where GPS doesn’t work well,” Goodall says. “You can drop off your e-bike at a certain location and orient it a certain way. We’d like to see the market go a little more autonomous, where the vehicles can drive themselves to high-traffic pickup areas, but there’s a profitability barrier there.”

Trusted Positioning is now focused on scaling its operations in indoor spaces. The company anticipates that autonomous vehicles in indoor settings will be the next major mobility innovation, and is preparing its technology accordingly.

Trusted Positioning is a Calgary-based subsidiary of TDK Group. The backbone of Trusted Positioning’s technology is inertial sensors, which are always-on and provide continuous and reliable positioning information everywhere. https://trustedpositioning.tdk.com/

10 ELECTRONIC PRODUCTS & TECHNOLOGY / May/June 2024 EPT.CA

WEST TECH REPORT

Chris Goodall is president and managing director of Trusted Positioning Inc., a Calgary-based developer of sensor positioning solutions.

Photo: Trusted Positioning

Environmental testing for electronics

BY AURY HATHOUT, LAB QUALITY MANAGER, ENVIROPASS

RoHS, REACH, California Proposition 65, PFAS... Following supply chain audits and risk assessments, you may have to conduct environmental testing for your electronics. Let’s uncover some of the main analytical instruments to determine controlled chemicals

XRF fluorescence

X-ray fluorescence (XRF) is the most well-known instrument for RoHS testing. Indeed, XRF instruments enable the detection of heavy metals like lead, mercur y, or cadmium.

First, the XRF’s non-destructive nature makes it favorable, requiring minimal sample preparation, often just cleaning the sample’s surface. During analysis, X-ray beams stimulate the emission of fluorescence in the sample. This phenomenon occurs as electrons undergo transitions between energy states. This transition results in emitting photons whose energy levels are characteristic of the elements present in the sample. However, XRF has limitations. It can only detect individual elements, not compounds. Despite this, portable XRF devices offer on-site analysis of heavy elements.

In short, XRF’s non-destructive nature, minimal sample preparation, and applicability in various industries make it a valuable analytical tool, particularly for heavy metal detection and regulatory compliance.

FTIR enviro testing for electronics

Like XRF, Fourier Transform Infrared Spectroscopy (FTIR) is a widely utilized analytical tool across scientific fields. Notably, FTIR proves effective in detecting phthalates, crucial for compliance with regulations like RoHS, although achieving detection limits below regulatory thresholds presents challenges

How does the FITR technology work? FTIR operates

by characterizing molecular structures through infrared absorption within distinct regions of spectrum. Two sampling techniques employed in FTIR are Attenuated Total Reflectance and Transmission Mode, each suitable for various sample types.

The greatest challenge of FTIR may be the detection level. As a result, advanced sample preparation methods, like thin filmmakers and meticulous calibration, are essential for improving detection limits, emphasizing FTIR’s role as a pre-screening technique alongside other analytical methods.

The unavoidable GC-MS

Gas Chromatography Mass Spectrometry (GC-MS) emerges as a vital tool for ensuring compliance with regulations in electronics, like EU REACH or RoHS. This analytical technique combines gas chromatography and mass spectrometry, enabling efficient analysis. In the GC-MS process, the sample undergoes gas chromatography to convert it into the gas phase, followed by separation through a stationary phase, which determines elution time and helps identify substances.

After gas chromatography, the sample proceeds to the mass spectrometer, where electron beams ionize it and enable its analysis.This process aids in qualitative and quantitative analysis of

compounds present in the sample. GC-MS is advantageous for testing electronic products for restricted substances like phthalates and volatile organic compounds. Additionally, it facilitates root cause analysis by detecting unknown substances interfering with product functionality.

Despite its benefits, GC-MS has limitations, such as the inability to test non-volatile heavy metals, unlike XRF. Matrix interference and low analyte concentrations pose challenges, particularly in electronic components with intricate layers. Consequently, the gas chromatography-tandem mass spectrometry (GC-MS/ MS) technique is employed, offering enhanced sensitivity and specificity by conducting mass spectrometry analysis twice.

DART-MS

Direct Analysis in Real-Time Mass Spectrometry (DART-MS) is a groundbreaking technique in chemical analysis, swiftly detecting substances like flame retardants, phthalates, and polyaromatic amines without extensive sample preparation. Combining Direct Analysis in Real Time (DART) and Mass Spectrometry (MS), DART-MS ionizes molecules in the sample using DART as the ionization source, then separates and detects them based on the mass-to-charge ratio (m/z).

The DART-MS process involves sample introduction, ionization, mass spectrometry, ion detection, and data analysis.

DART-MS offers advantages such as speed, ambient ionization, sensitivity, minimal sample requirement, minimal sample preparation, versatility, and relatively low cost. However, it also has limitations, including limited ionization efficiency, matrix effects, and limited structural information compared to other techniques. Despite these drawbacks, DART-MS finds wide-ranging applications in environmental analysis, detecting substances like

persistent organic pollutants and volatile organic compounds. It is also instrumental in flame retardant testing, phthalate analysis, and screening for polyaromatic amines, making it invaluable in regulatory compliance and consumer safety enforcement.

ICP-MS

Another analytical instrument is ICP-MS, which stands for Inductively Coupled Plasma Mass Spectrometr y. This method involves coupling an inductively coupled plasma (ICP) ion source with a mass spectrometer (MS). Here’s how it works: Inductively Coupled Plasma (ICP): Introducing a carrier gas (typically argon) into a radio frequency (RF) coil creates a high-temperature plasma source. ICP creates a high-energy environment where atoms are stripped of their electrons, forming ions.

Ionization: The sample, often in liquid form, is introduced into the ICP for vaporization and atomization. The high temperature of the plasma causes the atoms to lose electrons, forming positively charged ions.

Mass Spectrometry (MS): Similarly to CC-MS and DART-MS, the ions are then introduced into the mass spectrometer.

Detection and Quantification: The mass spectrometer detects the ions whose abundance is measured. Finally, if we compare the signal obtained for each ion to known standards, we can determine the concentration of the elements present in the sample.

Interestingly, ICP-MS is highly sensitive and capable of detecting traces of elements in a wide range of samples.

What’s the bottom line? Since more restricted chemicals impact manufacturers of electronic products, it becomes critical to develop the right strategy and find the appropriate analytical testing method.

https://www.getenviropass.com/contact

@EPTmagazine May/June 2024 / EP&T 11

THINK GREEN Photo: Enviropass

The portable XRF analyzer is one type of X-ray, which is fluorescent.

DeepSight has vision for future of augmented reality

BY STEPHEN LAW, EDITOR EP&T

Infusing leading edge technology to enhance the reality around us, DeepSight (Réalité Augmentée) Inc. is reshaping how industries interact with digital content through its cutting-edge AR software solutions.

Setting out to revolutionize the way individuals and businesses engage with their environments, the Montreal-based software development company has built a platform leveraging augmented reality (AR) artificial intelligence (AI) and smar t glasses.

At the core of DeepSight’s mission lies a commitment to revolutionizing the way individuals and businesses engage with their environments. Leveraging state-of-the-art technology and a deep understanding of user experience, the company has positioned itself as a trailblazer in the AR landscape.

In 2024, the firm has commercialized five main modules: Studio, Holo, Console, DS Connect and Knowledge Capture. The Holo module is a native app, device agnostic, available on the Microsoft Hololens 2 and iOS mobile devices. The firm is planning on integrating the new Apple Vision Pro as a compatible headset and it should be ready this summer.

“We are looking at other 3D smart glasses such as XReal and Magic Leap 2, but we want to be sure they are industrial proof,” said DeepSight CEO and co-founder, Nicolas Bearzatto. The Holo app allows users to view the augmented content created in the Studio (a no-code web app often compared to MS Powerpoint for its user-fr iendly environment).

While most AR/VR/XR platforms run on two main 3D engines - Unity or Unreal, DeepSight decided early on that it did not want to rely on external engines as they were not designed specifically for AR applications and hardware. So, the firm took a longer journey and built their own: the DeepSight Engine.

“This allows us to be completely independent and efficient in terms of product development and, more importantly, not to rely on major pricing model changes that could ultimately affect our processes and clients,” says Bearzatto. “Also, it gives us the power to improve the performances of the 3D experiences lived in the smart glasses, that are not designed for heavy virtual environment used in VR. Finally, it allows us to be device agnostic and gives the freedom of

DeepSight is commited to revolutionizing the way people and businesses engage with their environments.

Nicolas Bearzatto, CEO & co-founder of Montreal-based DeepSight Inc.

choice in terms of hardware for each clients wants to use DeepSight.”

In the early stages as a start-up, DeepSight joined Centech, one of Quebec’s major incubators, and participated in two of its main programs: ‘Acceleration’ and ‘Propulsion’. DeepSight was quickly matched with some of Montreal’s top entrepreneurs, including Richard Chenier, Mar tin Enault and Dominic Gagnon of Connect & Go, an integrated attractions management platform.

“This allowed us to be coached and challenged by some of the most successful mentors in Canada, as well as spending time with other start-ups founders,” said Bearzatto. “It takes a while to get through the ecosystem, but as a tech entrepreneur, you must get involved because there’s so many opportunities to get financial and commercial help.”

Bearzatto says that he is already seeing a shift in the market since the release of Apple Vision Pro. Companies in many industries are now under standing the power of this technology and real use cases are being demonstrated by DeepSight’s clients.

DeepSight did not want to rely on external engines, so the firm took a longer journey and built its own.

“We envision our platform being deployed in the manufacturing industry as a whole to help reduce the skills gap between expert leaving to retirement and a young generation of frontline workers coming in with different experiences and cultural baggage/languages,” said Bearzatto. “We are also seeing a major use case of our technology with some OEMs

12 ELECTRONIC PRODUCTS & TECHNOLOGY / May/June 2024 EPT.CA

WEARABLES FEATURE

DeepSight Inc.

Photos:

to help limit traveling time of technicians with remote support (using smar t glasses or tablets).”

Today, DeepSight is working with market leaders such as Galderma (pharmaceutical manufacturing), St-Hubert (ag ro-food), Agnico Eagle (mining industry), L. Fournier & Fils (transportation), just to name a few. The AR technology is helping these companies train their operators and technicians more rapidly, in a more efficient way and reducing the risks of accidents and errors, according to Bearzatto.

“The status quo and fear of change are probably the main challenges we are still facing today. We are introducing a disruptive technology in a process that hasn’t change since the 1950s (training production line workers with job-shadowing and paper catalogs), Bearzatto noted. “To push through, we have had to make our platform as easy to use as possible, from the content creation side in the Studio up to the use of smart glasses/ tablets (Holo) and the data dashboard (Console). Our product development works hard every day to take care of the complex programming to improve the platform while creating the best and easiest user experience possible for our clients.”

Growing rapidly, Bearzatto says that his team is “very lucky” to have DeepSight’s offices in Montreal, situated within the vibrant Old Port location. In the early stages, he paired up with a childhood friend Francis Dubé, who is the company’s CTO today.

DeepSight has partnered with IBM - permitting integration of its advanced AI tech into DeepSight’s AR-powered learning platform

“We started in small cubicle office - and now we hold almost the entire floor,” Bearzatto enthused.

DeepSight employs 15 in total, which includes a leadership team of five, plus eight software developers and computer engineers (full-stacks and Core C++ developers) and seven people in the customer journey (Sales and par tnerships employees, a customer success team and management). The firm has plans to continue g rowing, as it intends to hire another C++ developer /machine learning specialist and a marketing manager in coming months.

“We are still active in the tech ecosystem and leaning on advisors’ and counselors’ feedback and coaching,” Bearzatto said. “DeepSight is the fr uit of the union between two friends, combined by our interest in new technology like AR and the

desire to impact the world around us positively,” he explained. “Back when we started, no company offered a simple way to generate meaningful AR content, so we decided to build our own solution. It is a long and difficult journey to develop complex technology solutions and so we had to create a strong culture of high-performers and creative minds.”

Teaming up with IBM

Lending support to the firm’s momentum in the AI space, DeepSight recently par tnered with tech giant IBM, which will integrate its advanced AI technology into DeepSight’s AR-powered learning platform to support manufacturing businesses in training the next generation of operators. The platform provides real-time training and guidance for completing projects with precision and efficiency.

This partnership marks a significant advancement in addressing t he challenges posed by an aging workforce in the manufacturing industry. With more than one-fifth of the working-age population nearing retirement in Canada, the impending skills gap threatens production efficiency and knowledge retention.

“With our partnership with IBM, we are unlocking a powerful immersive learning experience that saves time, reduces costs, and maintains production flow. By accelerating skill development for the workforce, we are setting a new standard in innovation.” said Jean Pinsonneault, director of partnerships & alliances at DeepSight.

With DeepSight’s innovative platform powered by IBM’s AI technology, however, organizations can now streamline training processes, reduce costs, and maintain production flow. Workers receive real-time auditory instructions in their own languages and on-screen text guidance through AR headsets or tablets, enabling them to acquire skills more rapidly and effectively.

“When businesses automate repetitive tasks with AI, they’re able to overcome skills gaps and quickly optimize processes for digital transformation,” added Peter McKay, director of ecosystems at IBM Canada. “IBM’s advanced AI technology, integrated within DeepSight’s platform, enables organizations to train, validate, and deploy machine learning models seamlessly.”

@EPTmagazine May/June 2024 / EP&T 13

Roga’s medtech platform targets mental health

Non-invasive brain stimulation device reduces anxiety

Aimed at reducing reducing stress, anxiety and burnout in its users, Toronto and LA based neurotech start-up Roga Life Inc. is making brainwaves in the med-tech com munity with its mental health platform.

For this article, EP&T interviews Toronto-based Dr. Alison Smith.

What was the inspiration behind Roga as a wellness product?

Roga emerged from the founders’ deeply personal journey grappling with intense stress and witnessing its toll on those they cherish. Motivated by the quest for relief, and to develop an effective solution beyond just medication or talk therapy, the company founders crafted a science-backed wearable device that is more scalable, cost-effective, discreet yet fashionable than any other wearable device to relieve stress on the market.

Described as a neurotech device, the product offers a science-backed wearable device to reduce brain activity associated with intense stress, paired with an app that provides highly personalized, guided meditations and tracking progress analytics using AI. Voted as one of the ‘World Changing Ideas’ by Fast Company, Roga’s pocket-sized and fashionable form factor allows users to get the help they need wherever they are: at home, at work, or on the go.

The therapeutic wearable provides small electrical pulses to the peripheral nerve behind the ears, which sends a feedback

technology underlying Roga is backed-up by years of neuroscience research. Roga is currently conducting further research at the University of Waterloo with support from MITACS.

Roga was founded by Ami Lebendiker, CEO, former hardware product manager of Google Home and Pixel phones, alongside Dr. Alison Smith, chief scientist, a Ph.D. neuroscientist originally from the University of Waterloo. Combining their respective exper tise in AI enabled hardware and neurotechnology, the duo created an innovative wearable for effective stress management.

considerations did you encounter

Crafting an attractive, high-quality device posed intricate technical challenges. Fitting all the electronics into a pocket-sized brain stimulation wearable while maintaining efficacy and safety demanded precision engineering. In designing our headset, we specifically considered the preferences and lifestyles of younger audiences who suffer the most from stress and burnout. Recognizing that this demographic values discretion and style, we engineered the device to be more concealable and fashionable, ensuring it aligns with their desire for privacy and aesthetics. Balancing the aesthetic look of the device with performance was crucial to promote seamless ration into daily life. The headset is ultra-lightweight and discrete, looking very much like a pair of headphones: a conscious design choice to promote device adoption and usage in public spaces. o increase usability, we transitioned into using soft, flexible materials. The result is a headset that not only delivers effective stress relief but also integrates seamlessly into daily life; when worn, it’s almost invisible to the casual observer. This design idea ensures that users feel comfortable and confident and makes mental wellness support as accessible as possible.

Q. How do you balance the integration of cutting-edge technology with user-centric design principles?

Continuous feedback loops and usability testing guide us to harmonize innovation with user needs, creating products that seamlessly enhance well-being. We meticulously integrate advanced features while pr ioritizing user experience, ensuring intuitive interfaces and comfortable wearability. Photos: Roga

16 ELECTRONIC PRODUCTS & TECHNOLOGY / May/June 2024 EPT.CA WEARABLES FEATURE

For example, based on user feedback, we developed an app that provides highly personalized, AI-generated guided meditations based on user inputs, alongside tracking progress analytics. Our early customers communicated their desire to listen to relaxing content while using the Roga device and tracking their progress over time. We are continually integrating cutting-edge technology based on user feedback.

Q. Share any breakthroughs that have contributed to the effectiveness of your creations?

We’ve made significant investments in the development of AI-driven data analysis and content creation. Using multistage Large Language Models, we can create personalized and useful content for the user, broadening our reach and enhancing user engagement. The content engine we offer in the Roga App adapts to the specific needs and progress of the user, providing targeted mental health support when it’s needed. We’ve been training our datasets to refine and optimize the AI’s responsiveness, ensuring that the content remains relevant to the user.

Q. What role does user feedback play in the iterative design process?

User feedback is pivotal in shaping the iterative design process of our wearable tech. It guides us to refine features, optimize usability, and enhance overall effectiveness. By actively engaging with our device and the Roga AI, users contribute valuable insights that enable us to fine-tune their experience.This ongoing chat dialogue ensures that our product truly supports and resonates with our customers’ well-being journeys, making each iteration more effective and user-centric than the last.

Q. How do you ensure that your wearable devices are both aesthetically pleasing and technically proficient?

Ensuring our wearable wellness devices blend aesthetics with technical prowess involves a multifaceted approach. Our most engaged user demographic is between the ages of 18-38 years old; we regularly reach out to them through surveys, focus groups, and user testing to understand preferences deeply. Collaborating with designers and engineers, we craft sleek, versatile designs without compromising functionality. Iterative prototyping allows us to refine form f actors while integrating cutting-edge technology seamlessly. User-centric design principles guide every decision, ensuring our devices resonate visually and functionally across a spectrum of tastes and needs. For example, Roga comes in three different

colours: sky blue, rose gold, and charcoal with more to come. We pride ourselves on creating wearable wellness solutions that not only delight the eye but also empower users on their well-being journeys, regardless of their unique preferences.

Q. Elaborate on any collaborations or partnerships that have been pivotal in the development of your products?

All our designs and electronic development has been done in-house. We have assembled a stellar team of electrical and industrial engineers who collaborate closely to drive the innovation and functionality of the wearable. This team is crucial in transforming complex technologies into user-friendly products. Additionally, our designers play a pivotal role, ensuring that each device is not only visually appealing but also ergonomic, enhancing the overall user experience.

Q. What measures were taken to address data privacy and security?

We prioritize data privacy and security in both firmware and software. This includes end-toend encryption to safeguard health-related data during transmission and storage. We adhere strictly to industry standards and regulations like HIPAA. Transparent privacy policies ensure users understand how their data is collected, used, and protected. Regular security audits and updates fortify our systems against emerging threats.

Q. With the rapid evolution of wearable tech, how do you stay ahead of the innovation curve?

It requires relentless innovation and market foresight. We have ongoing investments in research and development of new emerging technologies. We are constantly focused on improving the efficacy of our solutions. Close collaborations with industry experts

and academic partners facilitate access to cutting-edge insights and resources. Agile development processes allow us to swiftly iterate and adapt to changing market demands. We also actively engage with our user community, soliciting feedback to inform our roadmap and ensure our products remain relevant and impactful. By embracing innovation, agility, and user-centricity, we continuously strive to lead the way.

Q. Can you share insights into the materials and components used in the Roga products?

We try to only use premium materials and components to prioritize durability, comfort, and functionality. Soft, hypoallergenic silicone ensures comfort during extended wear. Each component undergoes r igorous testing to ensure reliability, risk management, and performance under various conditions. By combining quality materials with cutting-edge technology, we deliver wearable wellness solutions that seamlessly integrate into users’ lifestyles, empowering them to prioritize their well-being with confidence.

Q. How do you envision the future of wearable wellness tech evolving?

The future holds exciting possibilities, with advancements poised to revolutionize how we monitor and enhance our well-being. We foresee greater integration of AI and machine learning, enabling personalized insights and interventions. Wearables may evolve beyond passive tracking to actively modulating physiological states, such as stress reduction or mood enhancement. Our company is committed to driving this evolution by pioneering innovative solutions that empower users to proactively manage their health. Through continued research, collaboration, and user-centric design, we aim to shape a future where wearable wellness tech becomes indispensable in fostering holistic well-being for individuals worldwide.

Q. How does the local tech & design ecosystem influence your work?

Toronto’s tech and design ecosystem serve as both a source of inspiration and a platform for collaboration. The city’s rich cultural diversity fosters unique perspectives, driving innovation in our work. Collaborating with local talent and startups amplifies our creative endeavours, while access to global networks enhances our reach. Challenges include fierce competition for talent and funding, yet Toronto’s supportive community and burgeoning tech scene provide a solid foundation for our company’s growth.

https://rogalife.com/

@EPTmagazine May/June 2024 / EP&T 17

The key to unrestricted access

Explore millions of components for your next design

Although you can't access the global Svalbard Seed Vault, we can give you unlimited access to millions of electronic components, from well over a thousand leading brands engineers know and trust. Find the vital components to seed your new designs.

mouser.com

Enhancing wireless performance on everybody

The human form is among the most difficult platforms for

deploying wireless systems

BY DR GARETH CONWAY, CEO & CO-FOUNDER, ANTENNAWARE

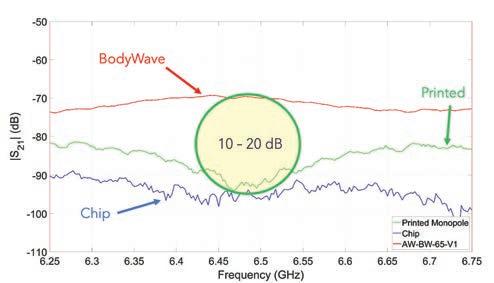

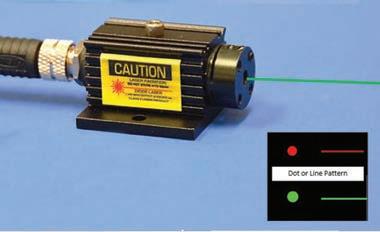

With advances in the frontend physical layer of wireless systems, extra gains of up to 20dB in non-line-ofsight link budgets are demonstrated in comparison to conventional practice. A combined antennas and propagation approach is explored to improve the physical layer performance of wireless body-centric networks. The techniques and understanding from the experimental measurements can be used to solve wireless connectivity problems on broader platforms, such as close to metal for other communication applications.

Introduction

In a world where the population just want ‘wireless that works’ with ubiquitous communication devices that seamlessly connect in any environment on any host platform that devices are positioned on, there are still significant performance gains to be exploited with careful physical layer choices.The human body is often seen as one of the most difficult platforms for the deployment of wireless systems,

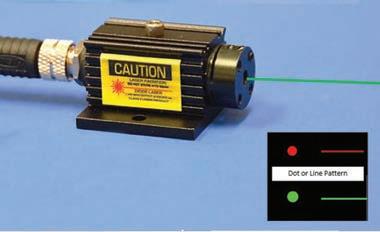

BodyWave UWB antennas serve as a BoA solution to the challenges of wireless body blocking and detuning.

due to the variability of the properties across different positions on the body, and across the different morphologies of the human population.

Conductive platforms make wireless communication difficult, particularly when the device is mounted close to the structure. Just like metal, the human body appears electrically conductive to electromagnetic waves, and appears more conductive as frequency is increased. A lot can be learned from devices designed to operate in close proximity to the human body, as it is a ‘lossy’ and dynamic platform, that obstructs and drastically limits wireless coverage in the microwave frequency range (300+ MHz). Improvements in the physical layer performance are advantageous for more robust and reliable connectivity, longer communication ranges, lower transmit powers or simply more confidence in design before product deployment.

Wireless systems operating close to the human body

The physical layer of the wireless system, namely the antenna, is the part of the system that interacts with the environment that it is placed in. Placing the antenna close to different

materials, will impact the performance of the antenna. It can change the impedance of the antenna and its radiation characteristics. Antennas that are sensitive to being placed next to conductive materials, such as printed antennas, or chip antennas with bespoke printed circuit board (pcb) keep-out areas, often exhibit the greatest performance variation. Nonetheless, the wireless performance of the system then becomes very dependent on the host platform.

For some applications, where the platform is known, and the materials are well defined, the antenna can be optimised specifically for that platform. However, for applications such as the distribution of wireless sensors, where they are expected to consistently perform, wherever they may be deployed, needs a different approach to achieve optimal and reliable communication links. The human body presents a unique challenge for wireless technology, with complexities, that mean the wireless performance for devices in close proximity to tissue are difficult to characterise and ensure robust and reliable operation on every person, in every application use case.

20 ELECTRONIC PRODUCTS & TECHNOLOGY / May/June 2024 EPT.CA

WEARABLES FEATURE

Figure 1

Numerical FDTD simulation showing E-field cross section of torso with body shadowing.

Photos: AntennaWare

The right approach

The antenna is one of the most vital components of any wireless system. It is responsible for converting an in-circuit guided alternating current produced by a transmitter into a freespace, propagating EM wave. There are a number of metrics which are important when considering an antennas performance, but, for difficult platfor ms, the top three are: input impedance stability, total radiation efficiency and the correct radiation pattern to meet the propagation needs of the application. To evaluate end-to-end communication link performance, Received Signal Strength Indicator (RSSI) or forward path gain (|S21|), are important metrics to quantify the propagation mode effectiveness. It is advisable to test for worst case body-blocking scenarios, with non-line of sight (NLoS) propagation, and no significant nearby objects for the electromagnetic waves to reflect and diffract off (low multipath environments).

In this type of environment the received signal strength will be weakest, and performance is marginal at distance. A communication system that performs effectively in NLoS anechoic environments, is not dependant on the proximity of nearby objects for multipath communication. Thus, has more reliable performance, as the platform moves through or is deployed in different environments. Therefore, to get the best quality of performance from a wearable wireless device it must strive to exhibit the following characteristics on different

people and at different antenna-body spacing distances on the same person:

• Stable Retur n Loss |S11| or Resonant Frequency.

• Minimal power absorption into the tissue

Dr. Gareth Conway is CEO & co-founder of Antennaware, developers of commercial antennas for wireless wearables.

• Predictable or repeatable Radiation Efficiency Reduction

• Overcome Body Shadowing (Limited Wireless coverage)

And finally, tested and validated for worst-case scenarios, i.e when the wireless received signal weakest and the communication link becomes marginal or drops-out.

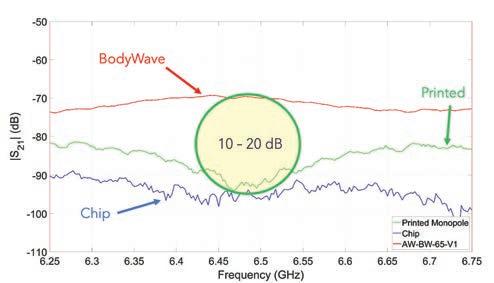

NLoS performance enhancement

When all of the above is understood, and the right antennas are used, gains of 10-20dB in worst case NLoS can be achieved compared to conventional printed antennas and chip antenna approaches. The gain can be validated in the forward path gain, measured between the transmitting and receiving wearable antennas. The path gain of the antennas |S21| was measured from ear-ear, for the BodyWave antenna in comparison to a chip and printed monopole UWB antennas. The path gain results in Figure 2 show that even for a short link around the head, that the path loss could be as great at 95dB, when using printed and chip antennas as the antenna under test (AUT).

Conclusion

An antenna that is agnostic to the platform holds the key to unlocking the wireless performance and differentiating product performance. To mitigate the effects of near-field coupling from the antenna to the tissue, and the

A major problem with all wireless wearables is the issue of body blocking.

absorption of energy into the tissue, the antenna must be decoupled from the platform. Printed antennas for pcbs and ceramic chip antennas are not the right approach. They were never designed to be placed close to a difficult platform, thus radiate inefficiently and are subject to varying impedance caused by nearfield coupling. By launching the electromagnetic waves to support on-body propagation, in addition to isolating the antenna from the tissue by placing above the pcb ground-plane, significant performance gains of up to 20dB have been demonstrated.

To achieve optimal performance from the wireless link on difficult platforms, and maximise available link budget, it is recommended to start with the antenna radiation characteristics and selection, rather than treating antennas as an after thought. The stepchange improvement in link budget performance by overcoming body blocking could translate to more than doubling the communication distance, significantly reducing the power and battery size, or simply give a more robust and reliable quality connectivity, which is core to wearable audio, sport and healthcare applications.

AntennaWare is a UK-based developer of commercial antennas designed for wireless wearables - in sectors including IoT, audio, healthcare and sports. antennaware.co.uk

@EPTmagazine May/June 2024 / EP&T 21

Figure 2b

|S21| Path gain measurements around the head at 6.5GHz.

Figure 2a

|S21| Path gain measurements setup around the head at 6.5GHz.

Printable sensors: A key technology for health wearables?

BY LIAM CRITCHLEY, SENIOR SCIENCE COMMUNICATIONS OFFICER, NANOTECHNOLOGY INDUSTRIES ASSOCIATION (NIA)

The adoption of healthcare monitoring devices that are both flexible and conform to the wearer have gained traction - spurred on by the need for remote care dur ing the COVID-19 pandemic combined with technological advances in sensor accuracy. As a result, wearable sensing and monitoring devices have become more ubiquitous, including telemedicine operations. Used in clinical environments to provide an analysis, much of their potential remains in remote health monitoring.

Flexible materials

These sensing devices typically make use of flexible materials, such as polymers, thin films, 2D materials and other nanomaterials. Health monitoring devices often consist of a flexible material that conforms to the wearer and is integrated with electronic components, including sensors, a power source - be it a batter y, solar cell, or some other type of energy harvester like a nanogenerator. Sometimes they are used in communication technologies if it transmits data to

a central processing system, and any relevant circuitry.

Building electronic components that are small and flexible enough to be used in wearable technologies is not that straightforward and is why different nanomaterialsespecially 2D materials - are often used to create the components because they fit the bill and can be easily integrated.

However, another approach is gathering interest: printing sensors - the most crucial aspects of a monitoring system - directly onto the wearable device. These printed sensors are sometimes made of 2D materials and other nanomaterials, but other materials can also be used as well.

The ability to print sensors onto wearable health monitoring devices could pave a way to a much simpler and easier route to commercializing more wearable monitoring devices - especially if conventional, inexpensive, or easy-to-use printing technologies are used to print the sensor.

Why printed sensors?

While a range of advanced deposition and nano deposition

Screen printing is highly versatile and can be used with many materials to create sensors that monitor different aspects of a person’s health - from heart rate to detecting a chance of disease, and more.

methods exist that can fabricate thin-film sensors on the substrate for wearable devices—often a soft polymer due to their flexibility and confor mability - a number of biomedical sensors can be printed using screen printing techniques. Other techniques, such as inkjet and transfer printing, can be used as well, but screen printing is seen as the best option for printing sensors.

Screen printing equipment is widely available, has a relatively low cost, and is easier to use than more advanced deposition methods, so it offers a much more scalable and commercially feasible route for using printed sensors in healthcare monitoring devices. Screen printing can also be used with many materials— from polymer solutions to conductive nanomaterial inks - so it is a versatile platform for printing a number of sensors.

So, why print sensors instead of creating them through other manufacturing routes? Screen printing is a simple, fast, and efficient printing technique that can produce a large number of identical patterns in a single print. For large-scale operations and commercialization potential, screen printing can easily be adapted for mass production at a lower cost than other methods.

From a performance perspective, screen printing provides

high-resolution patterning and can print over large areas. The ability of screen printing to deposit material on demand in any given location also helps to reduce waste - especially on large scales - compared to traditional manufacturing methods because it is all done in a single step.

Sensor materials

There are, therefore, several manufacturing benefits with using printing methods. Beyond that, a greater design capability exists for health wearables because printing methods enable the production of sensors that are not only very thin but also provide the ability to print on the surface of the device.

This approach is much simpler than trying to integrate devices into the material matrix of the wearable.You can also create a more customized sensor because you can print on demand, and the printing process can be changed to make a different sensor much easier than a typical manuf acturing line.

In terms of the materials compatible with screen printing, the scope is vast. Depending on the type of sensor being created, a whole host of materials can be used. On the one hand, a range of metals can be made into printable conductive inks to build the sensor. Common metals for wearable health sensors include

22 ELECTRONIC PRODUCTS & TECHNOLOGY / May/June 2024 EPT.CA

WEARABLES FEATURE

Photo: metamorworks / iStock/Getty Images Plus / Getty Images

gold, copper, platinum, nickel, aluminum, and silver. Beyond metals, a range of nanomaterial composites (graphene, carbon nanotubes composites), functional nanomaterial inks, and silver composites have all been used as the active sensing surface in printed health wearable sensors.

The sensors also need a platform to be printed on. This often takes the form of a conductive polymer so that the sensor can better interact with the skin and the other components to provide higher sensitivity and reliability.

PEDOT:PSS is the polymer platform that is most widely used for printed sensors, but other polymer materials include polyacetylene, polypyrrol, polyphenylene, poly (p-phenylene vinylene), and polythiophene polyaniline.

Healthcare monitoring applications

Just as many materials can be used to create printed health sensors, many different types of printable sensors are used in health monitoring devices. Take, for example, strain-based sensors. Strain-based sensors measure a form of movement, and these wearable sensors are used in human-physiological signal monitoring and human-joint motion monitoring approaches.

Another healthcare specialty measures different biomolecules and human signals. Non-strainbased sensors detect the biomolecule of interest directly or by directly measur ing a physiological parameter that the patient exhibits. From a molecule-sensing perspective, a number of biomolecules in the blood can be detected, with glucose levels being a common one as well as the presence of sweat on a person’s skin. From a signal detection perspective, printed sensors can now detect respiration and heartbeat levels in a patient and

Miniature RF & Power

provide remote electrocardiogram (ECG) monitoring.

Another class of pr inted sensors for wearables is sensor arrays. In sensor arrays, multiple sensors work together to detect more complex issues or issues that require analysis from several stimuli angles. Sensor arrays are helpful in monitoring gait during walking, monitoring the sitting posture of wheelchair users, and monitoring the skin.

Finally, there’s been advances in the development of printed temperature sensors for wearable health devices. Thermal sensing is a key area in disease detection because the body suffers thermal stresses when there is a disease present, and the rise in both skin and deep body temperature can be a primary indicator of a serious disease. Using printed temperature sensors, health wearables can detect a range of chronic diseases, such as cardiovascular, diabetic, and pulmonological diseases, as well as cancer.

Conclusion

Health monitoring wearables are gaining acceptance as an effective way to remotely measure

many health factors of a patient. The most important aspect of these wearables is the sensing system that provides the analysis on the patient.

For patients to be willing to wear the health monitoring device over an extended amount of time, the sensors and other components need to flex with the wearable component. While integrating flexible sensors is possible—for example, by using thin nanomaterials—printing sensors on the device’s surface is much easier, requires less material, and is much more scalable.

A variety of printed health wearables are already in existence (commercially and academically. The printing methods discussed offer a route to achieve widespread distribution of health wearables. While many options are available, screen printing is the leading printing technology because it is highly versatile and can be used with many materials to create sensors that monitor different aspects of a person’s health—from heart rate to detecting a chance of a disease, to the different biomolecules in their blood, and many more in between.

Liam Critchley is senior science communications officer at the Nanotechnology Industries Association (NIA) in Europe and has spent the past few years writing for companies, associations and media websites around the globe, including Mouser Electronics. https://resources.mouser.com/wearables

@EPTmagazine May/June 2024 / EP&T 23

Magnetics

•

•

LED display drivers Learn more @ coilcraft.com EPT_Coilcraft_MayJune24.indd 1 2024-04-18 3:37 PM

for Wearable Technology • Wirewound RF chip inductors as small as 01005 size

Shielded power inductors as thin as 0.5 mm

Coupled inductors as small as 2.2 x 1.5 mm for

Elevating manufacturing quality

Four best practices for high-tech industries

BY CONWAY HUI, DELTA-Q TECHNOLOGIES

Smart factories, cyber-physical systems, augmented reality—it seems like every passing day brings new tech that promises to improve manufacturing efficiency and quality. In other words, Industry 4.0 is here, and with it, revolutionary opportunities.

Ironically, these very same advancements place unprecedented demand on manufacturers. As the world grows increasingly reliant on electronic equipment, systems, and components, high-tech businesses must expand their focus beyond product innovation. They must redefine the manufacturing process itself.

This article aims to provide decision-makers with real-world insights into the introduction and implementation of modern manufacturing techniques. By bolstering proven methods with the latest technology, manufacturers can develop and sustainably maintain operations that unlock new levels of precision and productivity.

#1. Adopting lean manufacturing principles

The twofold approach of eliminating waste while increasing efficiency underpins lean manufacturing ideology. As simple as this sounds in theory, the reality is that modern industry almost encourages the opposite. New innovations, software, tools, and systems ever seek to “improve” upon the manufacturing process—often simply bogging it down along the way.

But lean manufacturing does not mean simply adopting every new innovation that promises to reduce production times and costs. These principles begin at a more fundamental level:

• Define value – Identify what value means—both from the customer’s perspective and your own. What

aspects of the product are customers willing to pay for? Which KPIs do you prioritize in your operations?

• Map workflows – Once value is defined, the next step is to map out all workflows and processes involved in creating the product, from raw materials to final delivery. Aim to visualize your current state of operations, identifying any non-value activities or bottlenecks that can be eliminated or improved.

• Align systems – With a clear understanding of value and detailed workflow maps, you are now positioned to implement systems and processes that add genuine value. Integrate new technologies, tools, and innovations in a way that supports lean objectives rather than complicating them.

• Continuously improve – This step embodies ongoing “Kaizen” initiatives, instilling a work culture where all employees actively suggest and implement improvements. Operating as both a philosophy and concrete action plan, Kaizen aims to incrementally refine wasteful or inefficient manufacturing processes.

Amidst revolutionary advances in AI and automation, sometimes the biggest advantage lies in going back to basics. By returning to these fundamental principles, manufacturers can navigate the complexities of modern industry and emerge more competitive, resilient, and aligned with market demand.

#2. Optimizing line layouts and facility design

The physical layout of a manufacturing facility also plays a crucial role in deter mining the efficiency and quality of production. Strategic decisions surrounding these factors can significantly impact the flow of materials, the movement of workers,

By bolstering proven methods with the latest technology, manufacturers can develop and sustainably maintain operations.

and the overall productivity of the manufacturing process. When designing (or revamping) a manufacturing facility, it is essential to consider the specific requirements of the final products. This includes factors such as:

• Component size and weight

• Assembly operation sequence

• Necessar y equipment and workstations