SAWLINES

Forwarders

Harvester

Head Launch

CVT Technology

New Harvester

SAWLINES

Forwarders

Harvester

Head Launch

CVT Technology

New Harvester

The Log Max 5000V is a modern and reliable harvesting head that can handle a wide range of logging challenges. This is the perfect mid-range head for both thinning and nal felling. The head can be equipped with a 82 cm saw bar and has a maximum cutting diameter of 74 cm. It also features Log Max’s multi-stemming MK2, that is agile and lightweight, making thinning work easier. The Log Max 5000V is suitable for those who seek the perfect balance between agility, capacity, and durability.

Quote from test driver Erik Wiik:

“The cutting and feeding are brutally good, and in combination with the new length measuring unit, Log Max becomes unstoppable ; )”

MiCROTEC Connect is the real fingerprint system based on CT-scanned logs. Through the integrated and innovative scanner and software solutions and the implemented MiCROTEC Ai platform, each log can be traced from virtual to real boards.

Likewise, the individual boards can be traced back to their original logs and

recognized at each production step without any gaps. This modular concept offers huge benefits for mill-wide value & recovery optimization.

www.microtec.us

15 KOSKISEN

The Japanese Agricultural Standard (JAS) established by the Minister of Agriculture, Forestry and Fisheries is used, for instance, in food products, organic products and forest industry products

16 HEKOTEK

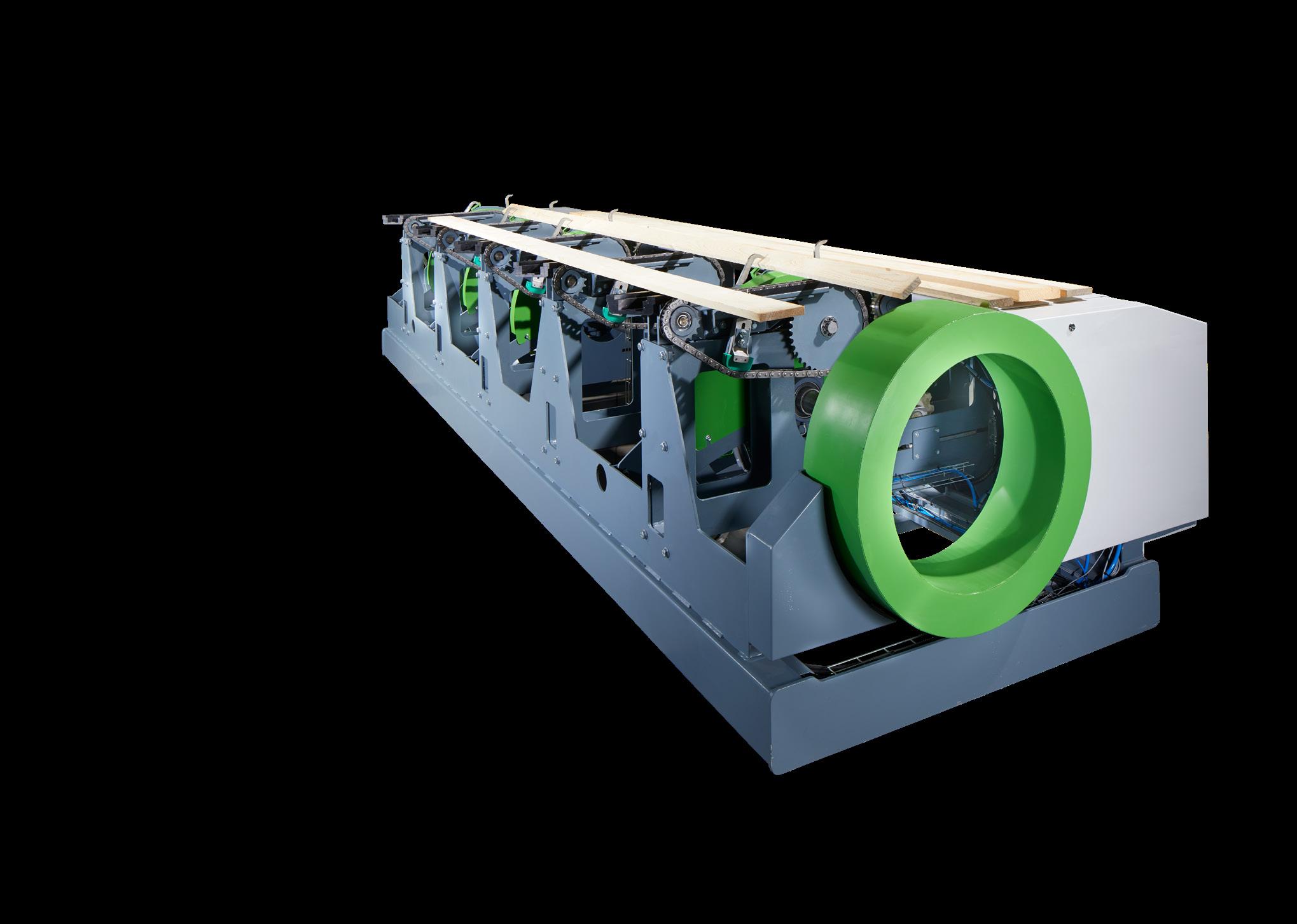

Hekotek to supply log sorting line to Société Européenne des Bois in France

24 BID GROUP

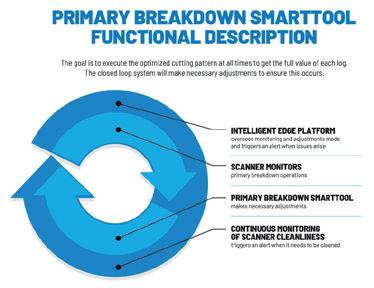

With its advanced automation capabilities, the Primary Breakdown Closed Loop SmartTool revolutionizes the wood processing industry

26 MICROTEC

Even though Piveteau Bois still has logs stacked at their log yard, the staff of the large-scale sawmill actually view the woodpiles as a virtual lumber yard already

28 RAUTE

Raute Corporation has signed a contract worth EUR 44.6 million with the THEBAULT Group, France for the technology delivery of a new greenfield LVL (Laminated Veneer Lumber) production plant

29 MICROTEC

JD Irving continues their commitment to sustainability and innovation with the purchase of a MiCROTEC CT Log for installation in its Veneer Sawmill, located in St. Leonard, New Brunswick, Canada

The QC Assist gives me quantifiable data to know that the products our mill is sending out are consistent.”

SUBSCRIPTIONS

SUBSCRIPTIONS

Tel: +44 (0)1442 877 583 emma@internationalforestindustries.com

Tel: +44 (0)1442 877 583 emma@internationalforestindustries.com

Annual Subscription

Annual Subscription

U K and Europe £160, € 230 Rest of the world US$270

U K and Europe £160, € 230 Rest of the world US$270

EDITORIAL

EDITORIAL

T: +44 (0)1442 877 583

T: +44 (0)1442 877 583

F: +44 (0)1442 870 617 www.internationalforestindustries.com

F: +44 (0)1442 870 617 www.internationalforestindustries.com

2 Claridge Court, Lower Kings Road Berkhamsted, Herts. HP4 2AF, UK

2 Claridge Court, Lower Kings Road Berkhamsted, Herts. HP4 2AF, UK

Editor

Robin Peach robin@internationalforestindustries.com

Publisher Robin Peach robin@internationalforestindustries.com

Editorial Board

Dr Patrick Moore – Chairman and Chief Professor Piotr Paschalis-Jakubowicz –Warsaw Agricultural University (Poland)

Mr Kim Carstensen

Director General

Forest Stewardship Council

Eduardo Morales

South American Forestry Consultant

WEB OPTIMIZATION

jo@internationalforestindustries.com

ADVERTISING AND PROMOTIONS

ADVERTISING AND PROMOTIONS

International Forest Industries Ltd

International Forest Industries Ltd

Advertising Manager

Advertising Manager

Emma Smith emma@internationalforestindustries.com

Emma Smith emma@internationalforestindustries.com

+44 (0)1442 877 583

+44 (0)1442 877 583

Associate Editor Robin Peach robin@internationalforestindustries.com

Associate Editor Robin Peach robin@internationalforestindustries.com

Advertising Production Enquiries

Advertising Production Enquiries

Emma Smith emma@internationalforestindustries.com

Emma Smith emma@internationalforestindustries.com

Studio Manager

Luke Evans luke@lecreative.co.uk

Accounts

International Forest Industries is published by International Forest Industries Ltd, 2 Claridge Cour t, Lower Kings Road Berkhamsted, Her ts. HP4 2AF, UK

Nicola Shukla nicolas@internationalforestindustries.com

International Forest Industries (ISSN 1755-6732) is published bi-monthly by International Forest Industries Ltd GBR and is distributed in the USA by Asendia USA, 17B South Middlesex Avenue, Monroe NJ 08831 and additional mailing offices. Periodicals postage paid at New Brunswick NJ. POSTMASTE R: send address changes to International Forest Industries, 17B South Middlesex Avenue, Monroe NJ 08831 © International Forest Industries Ltd 2007 – 2019 I FI uses, as preference, SI units throughout. All dollars are US unless otherwise stated.

International Forest Industries is published by International Forest Industries Ltd, 2 Claridge Cour t, Lower Kings Road Berkhamsted, Her ts. HP4 2AF, UK International Forest Industries (ISSN 1755-6732) is published bi-monthly by International Forest Industries Ltd GBR and is distributed in the USA by Asendia

Estimating the exact amount of money needed to save the rainforests is challenging due to the complex and diverse nature of rainforest conservation efforts across different regions. The costs involved can vary significantly based on factors such as the size of the rainforest area, the level of deforestation and degradation, the implementation of conservation strategies, and the involvement of local communities.

However, it is widely recognized that significant financial investments are required to effectively address the threats facing rainforests and implement conservation measures. Some of the key areas that require financial support include:

Forest Protection and Law Enforcement: Adequate funding is needed to strengthen law enforcement efforts against illegal logging, land encroachment, and other activities leading to deforestation. This includes supporting ranger programs, surveillance technologies, and the implementation of stricter regulations.

Sustainable Livelihoods and Community Engagement: Engaging local and indigenous communities and providing sustainable livelihood alternatives are critical for effective rainforest conservation. Supporting community-led initiatives, promoting sustainable agriculture practices, and providing economic incentives for forest conservation can help reduce pressure on rainforest resources.

Research and Monitoring: Investing in scientific research and monitoring programs is essential to understand the dynamics of rainforest ecosystems, assess the impacts of human activities, and develop evidencebased conservation strategies. This includes funding for biodiversity surveys, ecosystem monitoring, and

technological advancements in remote sensing and data analysis.

Restoration and Reforestation: Restoring degraded rainforest areas through reforestation and restoration projects requires significant financial resources. This includes efforts to plant native tree species, restore wildlife habitats, and rehabilitate degraded land.

International Cooperation and Funding Mechanisms: Global initiatives, partnerships, and funding mechanisms are crucial for supporting rainforest conservation efforts. International organizations, governments, and philanthropic institutions play a vital role in providing financial assistance and coordinating efforts across countries and regions.

While an exact figure is difficult to determine, a study published in the journal Science Advances in 2018 estimated that an annual investment of around $35 billion could be needed to halt deforestation in tropical regions worldwide. However, it’s important to note that this estimate includes broader tropical forests beyond just rainforests.

Ultimately, the financial resources required to save the rainforests depend on various factors and the scale of conservation efforts undertaken. Continued support and increased funding commitments from governments, private sector entities, and international organizations are crucial for achieving long-term rainforest conservation goals.

Continued on Page 47

Ponsse’s and Epec’s technology concept PONSSE EV1 has been rewarded with Finnish Society of Automation’s Automation prize. The prize is given every two years by society to reward significant research and development work done in the field of automation.

PONSSE EV1 is an electric forest machine technology concept developed by Ponsse and its technology company Epec in cooperation. It was launched as a technology concept in August 2022. The forest machine will be commercially available later. Epec’s technology can already be used in electric or hybridelectric commercial vehicles and non-road mobile machines. The concept was developed by a team whose work is strongly linked to promoting the green transition and ensuring the competitiveness of Finnish mobile work machine industry.

“The award is appreciated at Epec. Both electrification solutions and environmentally friendly machines are very imporant to Epec’s customers. In recent years Epec has invested a lot in electrification solutions,” notes product manager Mika Suonmaa from Epec.

The PONSSE EV1 concept took its first steps in 2019 when Ponsse and Epec started to investigate responsible power source solutions in line with sustainable development. The PONSSE EV1 features Epec Flow, Epec’s electromobility system solution.

On a journey towards carbonneutral logging solutions Ponsse is part of sustainable forestry and seeks carbon neutrality in its operations and solutions. PONSSE EV1 technology concept is part of the company’s strategy and a tangible step towards the goal of carbon neutrality.

Ponsse has been researching and developing innovative technology solutions for several years.

“The Automation prize is a great recognition for the entire EV1 team, their efficient work enabled the completion and release of the concept machine within the planned schedule. The concept is an important part of Ponsse’s journey towards carbon-neutral logging solutions,” says Kalle Einola, Ponsse’s product development manager.

Automation prize is given every two years by the Finnish Society of Automation. It rewards significant research and development done in automation, from the application to the use of industry or society, or other activities that have promoted the field of automation. The prize can be given to an individual, team, company, or other entity.

Astec has announced that heavy equipment dealer, Bejac Corporation, will represent the Peterson line of forestry and environmental recycling equipment in California and Arizona. Bejac was founded in 1953 and operated as an underground pipeline contracting business until 1985 when the company pivoted to the heavy, specialty equipment sector. In 2008, Bejac rapidly expanded its product line offering and now focuses on a diversified customer base that complements Astec growth

strategy.

Brian Gray, Group VP, Sales, at Astec says, “Our priority has always been our customers. From the initial equipment inquiry to aftermarket sales and service, Peterson Pacific and now Astec, have played an integral part in our customers’ success. In an effort to continue providing world-class support, we are excited to announce our partnership with Bejac in California and Arizona. They have a rich history of providing solutions to niche markets and we are confident

that they are the right partner for us.”

Ron Barlet, President at Bejac, adds, “We are excited to take on the California and Arizona territory for Astec and look forward to getting to know all of the customers that they have served and supported over the years. Bejac is a customer service-focused company, and we will work hard to provide the highest value possible to the Astec customers.”

Bejac Corporation has locations throughout California

(Eureka, Redding/Anderson, Sacramento, San Francisco/ Oakland, Castroville, Visalia, Santa Maria, Los Angeles/ Placentia, San Diego) and in Phoenix, Arizona.

Waratah recently announced the appointment of Barry Gates as Area Manager Retail for Waratah Forestry Services of New Zealand. Gates will take up the leadership of the New Zealand Retail business from Nelson Iliev whom has recently elected to retire after a remarkable 23 years of Waratah Retail Customer Service.

In this WFS Area Manager role, Gates will lead their New Zealand Retail team to support the Waratah customer base, lead the National Customer Sales Role and reinforce the Waratah commitment to the New Zealand Forest industry. He brings his passion for people, the Waratah product and a quality Customer support culture which will, without

doubt, inspire and strengthen the business.

Gates brings a wealth of previous experiences within the Waratah business including that of: Retail Customer Service Engineer, Retail Service Manager, Engineering and PV&V, Waratah Distribution Centre Customer Support, Global Product Support & Warranty Manager and most

As a leading forklift manufacturer Combilift continues its 25 years in business celebrations. Ligna saw the launch of another new model truck.

The new Combi-CB70E is a further addition to Combilift’s ever growing range of electric models which offers powerful performance, extensive battery life and unrivalled ergonomics. This model, in the vibrant Combi-green livery first seen on the recently launched Combi-CUBE product, boasts the distinction of being the shortest 7t capacity counterbalance truck on the market whilst also benefitting from multidirectional ability, enabling the versatile space saving handling of both long and bulky loads.

Design features incorporated into the highcapacity Combi-CB70E such as its large super-elastic tyres and compact wheelbase make it ideally suited for the operational demands of the timber industry. With a 7,000kg/15,500lb lift capacity, this model benefits from an impressively small footprint as well as exceptional manoeuvrability meaning that it can easily move bulky loads of timber around in confined spaces.

Occupational health and safety requirements mean that

the welfare of the workforce has become ever more important over the years. Drivers of industrial vehicles, who are often required to spend extensive periods in their work stations, quite rightly expect the highest levels of comfort and safety. Combilift’s designers have therefore gone to great lengths to ensure that the latest generation of models are kitted out with top quality components that ensure sophisticated ergonomics for a stress-free in-cab environment. Features in the spacious cab include generous glazing for excellent all-round visibility, the tilting steering column, hydraulic steering and the Grammer MSG65 seat.

What sets the Combi-CB70E apart from other forklifts is its gas strut suspension cab, which uses components such as those found in large scale industrial machinery with cab suspension. Combined with the super-elastic tyres this guarantees the smoothest of rides over uneven or less than perfect ground conditions such as those typically experienced in lumber yards.

Combilift’s newly developed Auto Swivel Seat was also premiered at the Ligna show. This optional feature automatically engages and swivels the seat and armrest

15° to the right or left to accord with the direction of travel selected by the operator - reducing driver strain, particularly when travelling in reverse. (Patent Pending Application No. 2305983.5)

The truck also features Combilift’s internationally patented and Red Dot awarded independent electric traction which provides all front and rear drive wheels with 100% traction control. This negates the need for differential lock on slippery surfaces and significantly reduces long load momentum twisting when travelling sideways. Each electric drive incorporates parking and regenerative dynamic braking for power efficiency. Roll-out access for major electrical components also simplifies maintenance tasks.

This mix of next-gen performance, extensive battery life and exceptional

recently leading the Waratah New Zealand Factory team as the Factory Production Manager.

ergonomics combined with all the advantages of the CombiCB range, makes this the most powerful compact electric multidirectional forklift to date.

Combilift CEO and CoFounder Martin McVicar said: “The increased capacities that we are offering in our electric range will answer the demand for ever more powerful products which at the same time help companies to achieve their aims for more sustainable operations. We chose Ligna as the platform for launching the Combi-CB70E due to its innate suitability for customers in the timber sector, but we are confident that this model will be a popular addition to our portfolio for many other industry applications.”

Amazing performance, extensive battery life and unrivalled ergonomics combined with all the advantages of the Combi-CB range make the CB70E the most powerful, compact multidirectional forklift yet.

The new 2956G offers optimal horsepower and hydraulic capability.

• Helping ease transportability, the 2956G design offers an overall shipping width of less than 11’6” and a 90,000 lbs operating weight.

• Customers looking to increase efficiency can benefit from the 2956G horsepower and hydraulic capabilities to quickly load trucks or effectively run a Waratah 624 head.

Designed for logging contractors of all sizes, John Deere recently introduced the new 2956G. The 2956G crawler log loader is an ideal solution for customers looking for a machine that provides the best combination of engine horsepower and hydraulics capability, while maintaining a machine weight of less than 90,000 lbs.

“We are always listening to customer feedback to bring ideal solutions and technologies to the forestry industry,” said Jarvis de Groot, global product marketing manager, forestry swing machines, John Deere. “The new 2956G crawler log loader

machine not only provides optimal power and hydraulic capabilities but is still easy to transport due to its excellent width and weight combination.”

Aimed to help ease transportation, the 2956G crawler log loader features an overall shipping width of less than 11’6” and a 90,000 lbs operating weight. As machine weights and widths increase, so do costs associated with transportation. The design on the 2956G not only helps simplify transportability, but also helps save on costs relating to transport due to its less restrictive transportation requirements. In addition, the new mounting of the log deflector adds additional strength to the right-front corner of the machine and the new, clean, and simple design of the hood profile, aligned with counterweight, helps to enhance debris shedding.

The 2956G crawler log loader machine features excellent engine power for a machine of this size. When combined, the engine power and hydraulic flow significantly boost loading capability, speed, and the capacity to run the

Waratah 624. Also, customers looking to increase efficiency in roadside processing can expect improved productivity when running the Waratah 624 head as compared to the 2654G.

Visibility enhancements have also been prioritized in the design of the new 2956G. Enabling additional visibility to the right track, as well as reduce overall impact, the RH front corner log deflector has been strategically moved to the back on the machine. This improves operator visibility to avoid obstacles and impact, reducing potential damage and downtime. Lastly, a rearview camera, light and JDLink antennas have been integrated into the counterweight for additional protection.

Offering ease of serviceability, the 2956G features strategic service access to the machine’s filters and checkpoints. With exceptional access to filters, maintenance points, and the cooling package, operators can stay up and running on the job for longer. These machines are also easy to inspect and change filters with wide open access, helping simplify daily inspections and routine maintenance.

The Komatsu S92 is an established and popular harvester head with a reliable and service-friendly design. The 2024 model upgrade introduces several new functions and improvements that make the head even more reliable and productive, including a brand-new Constant Cut saw unit.

As the basis for the upgrade is requests from users of the harvester head and the response to the improvements has been positive from customers who have tested.

Among the new benefits, the improved measurement characteristics stand out. The new design enables the measuring wheel to follow the contours of the stem more

closely, providing excellent measurement characteristics.

A major new feature is also the new intelligent saw motor controller, Constant Cut, which now becomes standard on the S92, and ensures that the head maintains a constant and high chain speed without the risk of overspeeding.

The Find End function now has a new design and together with new mechanical stops at the rear knife this extends the service life of the head. The new feed system reduces energy losses and enhances the head performance, and an improved hose routing simplifies servicing the feed system. For even better service friendliness, all lubrication points are now easily accessed

with the head in an upright position.

In addition to the above and several other improvements, the head has also been equipped with a new head computer that enables future development opportunities.

The new COMBi-CB70E electric multidirectional forklift is the shortest 7,000kg counterbalance truck on the market. Multidirectional ability enables the handling of both long and bulky loads, maximising the safety, storage & efficiency of your logistics.

The CB70E is loaded with a host of ergonomic features that greatly enhance operator comfort, including excellent all-round visibility, a spacious gas-strut suspension cab, independent electric traction and our newly developed Auto Swivel Seat which intelligently swivels 15O in the direction of travel.

Amazing performance, extensive battery life and unrivalled ergonomics combined with all the advantages of the Combi-CB range make the CB70E the most powerful, compact multidirectional forklift yet.

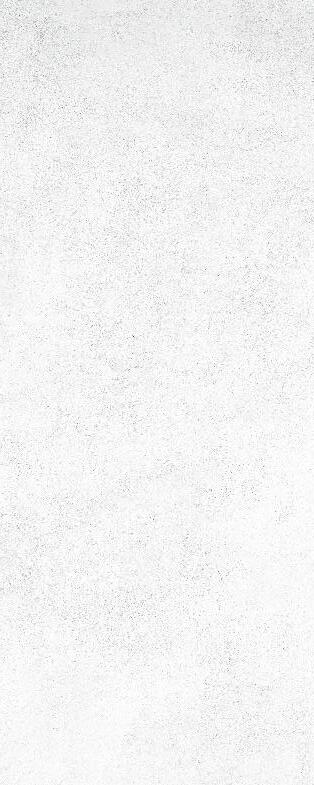

For the future, technology and innovation leader ZF is up to many more projects in the field of forestry, seeking into electric drive solutions already today.

Zero emissions without compromising on performance – the electric drive system eTRAC eCD70/90 from ZF

The eTRAC electric drive system satisfies all the expectations for performance and productivity found in traditional drivelines and combines them with the extensive benefits and opportunities that electric systems have to offer. Thanks to its modular design this new range of electric central drives can easily be adapted for various vehicle applications.

A newly launched system for forestry applications consists of a 2-speed powershift transmission, electric motor, and inverter. It can be scaled up to peak torque 850 Nm and continuous power of 80 kW. Three power classes of the electric central drive system eCD50, eCD70 and eCD90 are available to cover different vehicle sizes in the targeted applications.

To complete the customers´ demand, not only in regards of traction drive, ZF also offers the so called ePTO, e.g., to run the working hydraulic.

Main features:

• One supplier for transmission, eMotor and inverter

• “Best in class solution“ for power density

• Zero emissions without compromising on performance

• Low noise level

• Efficient electrical components

• Robust and reliable mechanical driveline

• Compact installation space

Key Figures electric central drive eTRAC eCD50/70/90

• Modular platform for 650 V

• Up to 80 kW continuous power

• Liquid cooled PSM e-motor

• 2 speed powershift transmission

• Integrated park brake

• Optional axle disconnect (2WD/4WD)

To complete the range of electric drives for larger construction vehicles, ZF is offering the eTRAC eCD110210 series, consisting of an electro-mechanical powershift transmission and one e-motor for traction and ePTO each. An electric drive control unit for overall system performance and power management completes the system. With a 650 V operating voltage, the system can be scaled up to 120 kW continuous power; the ePTO ranges from 30 to 70 kW continuous power. Thanks to its modular design, the system can be integrated in various other vehicle applications as well and can be driven independently from the power source. The company´s solutions fit in both batteryelectric vehicles and fuel-cell battery electric vehicles, which will also play a big role in the future of construction machineries.

Key Figures electric central drive eTRAC eCD110 - 210

• e-drive: 650 V (50-120 kW continuous power)

• ePTO: 650 V (30-70 kW continuous power)

• eDCU: Drive Control Unit for overall system performance and power management

• Drop-In replacement for current conventional driveline

ZF eTRAC eCD50-90 –electric central drive

UNMATCHED PRODUCTIVITY. UNMATCHED

The Tigercat 1075C forwarder is unmatched in terms of productivity and reliability. Innovations like low-wide® and hooked crane sets Tigercat apart from the competition.

Experience the Tigercat 1075C forwarder for yourself.

From June 1st to June 3rd, 2023, Yokohama Off-Highway Tires (YOHT) participated in the Swedish Forestry Expo as the brand-new meeting place for the professional, largescale forestry industry. On stand C10, YOHT presented a line-up of equally innovative and proven tires for modern forest management and timber harvest. “We used the 2023 edition of the Swedish Forestry Expo to showcase our portfolio of high-performance forestry tires. We put particular focus on our 2.5 bar campaign –i.e. highlight the unique soil preserving properties of the Alliance 344 Forestar ELIT –and showcased the world’s first low-pressure tire for harvesters and forwarders. An international team of Yokohama Off-Highway Tires representatives were present to discuss all issues related to forestry tires”, says Ole Baek, Head of Sales for Northern Europe.

344 Forestar ELIT: Performance plus soil protection

is the ‘main actor’ of YOHT’s 2.5 bar campaign. Increasing awareness of forest soils – and of advanced technologies to ensure soil protection – are at the centre of this campaign. The 344 Forestar ELIT was designed with improved construction and flexible strong sidewalls which enable the tire to carry the same load as a standard forestry tire with half the inflation pressure. It offers a large footprint which leads to low soil compaction and a comfortable ride for the driver, equally providing high traction, reducing fuel costs and increasing overall productivity. The 344 Forestar ELIT was designed to handle all terrains with or without chains or bogie tracks, and was presented in the size 750/55-26.5.

643 Forestar III: Ultimate track compatibility

YOHT also presented the Alliance 643 Forestar III in size 710/45-26.5, a tire engineered for ultimate track compatibility. Even without tracks, this tire provides exceptional grip also under critical forestry conditions. The construction ensures

excellent puncture resistance and high load carrying capacity. The tread pattern enhances track compatibility and overall lateral stability. Excellent selfcleaning, superior grip and resilient construction make the Alliance 643 Forestar III the perfect choice for professional forestry operations.

644 Forestar III: Low ground pressure

Specially designed with a dual lug angle to provide incredible grip and traction, the Alliance 644 Forestar III comes with an improved construction for excellent puncture resistance and high load carrying capacity. The large tread width ensures a wider footprint that results in low ground pressure. Outstanding stability and remarkable resistance against damage make the 644 Forestar III the perfect solution for machines such as harvesters, forwarders and trailers. Size 710/45-26.5 was on display.

The Alliance 343 Forestar flotation tire represents a sophisticated design for forestry machines such as harvesters and forwarders. This tire is characterised by wide and robust lugs with low angles providing excellent grip on wide range of forestry terrains. It comes with the known bogie track standard design defined by leading track producers.

With the Alliance Agro Forestry 333, YOHT also presented a dedicated agro forestry tire

designed for forestry tractors –with front and rear combination – as well as forwarders. Its specially designed tread lug profile with the overlapping central lug ensures high stability on uneven surfaces and makes it suitable for a wide range of terrains. Along with sharp and aggressive shoulders, the tire’s high non-skid depth (NSD) provides reliable traction.

Alliance 342 Forestar: Flotation tire for forestry tractors

Developed for harvesters, forwarders and forestry tractors, the Alliance 342 Forestar range covers the entire flotation radial segment relevant for forestry tractors. The specific tread pattern allows for excellent traction, grip and reliability particularly when working on slopes. The tread pattern is reinforced by small lugs located on the shoulders. A special compound in the sidewall structure ensures high stability even at high tilt angles.

Alliance 328 Flotation: Master of heavy loads

The impressive line-up at YOHT’s stand C10 was completed by the Alliance 328 Flotation tire. This tire was designed to carry heavy loads in harsh conditions. Mounted on forestry trailers, it provides improved stability in comparison to a dual-tire configuration. In addition, the Alliance 328 Flotation provides much better ride comfort, higher machine mobility, better self-cleaning and a better overall performance on the road.

The Japanese Agricultural Standard (JAS) established by the Minister of Agriculture, Forestry and Fisheries is used, for instance, in food products, organic products and forest industry products. There are altogether 12 forestry product standards, e.g. for logs, plywood and sawn timber.

JAS is a way of showing that a product meets the criteria set by Japan,” says Koskisen’s Export Manager Juha Virmiala. “In timber it is used, for instance, in dimensioning and provides guidelines for planning,” he adds.

The certification process was initiated at Koskisen in spring 2022, and in October the US inspection agency Timber Product Inspection TP granted the certification. An essential part of the process is the company’s quality manual, which describes the

At the end of 2022, Koskisen’s structural timber was granted JAS 600 certification, which will enable the sale of new products in Japan. In order to retain the certification, the company has committed to continuous quality control.

qualifications of the production employees, the tools used in production, and quality control, among other things. As a result, the planing mill’s measurement equipment was calibrated, and personnel took part in a full day of training organised by the inspection agency.

“JAS is based on US strength grading rule number two. Seeing as we previously made small volumes of products for the US market, we already had some experience with it,” says Jere Kylökäs, Production Planner at Koskisen’s planing mill and head of quality control.

Virmiala was responsible for the quality manual and for preparing the certification

application. JAS at its core is like visual strength grading, which sets certain requirements, e.g. for knot size, dimensional deviations and discoloration.

“Japanese buildings feature a lot of visible wood surfaces, and the visual aspect is

Continued on Page 48

Hekotek and Société Européenne des Bois S.A.S., a woodworking enterprise located in Saint-Amans-Soult, France, signed a contract for the supply of a log sorting line. The new project is not the first experience of cooperation between the two companies – earlier Hekotek has implemented projects in their sawmill and for upgrading of their pellet production facility.

Based on local conditions and understandings this log sorting line is also equipped

with a debarker (Valon Kone, Finland) and a butt-end reducer. After passing through these units, the logs, as usual, follow along the sorting conveyor to the sorting bins (20 bins).

Delivery of the line equipment and start of installation works are scheduled for July 2023 and the launch of the equipment for August 2023.

Hekotek is the largest Baltic manufacturer of sawmill and bioenergy sectors equipment.

The Board of Directors of Rottneros has decided to invest a total of approximately SEK 86 million ($8.4 million) in renewable electricity at Rottneros Mill in Sweden. The investments include a solar park and a battery storage and are part of a long-term strategy to reduce the groups exposure to the electricity market. The start-up is planned for 2024.

The solar park is expected to generate over 3 GWh annually, which can be compared to the company’s annual purchased electricity demand of around

220 GWh. The purpose of the battery storage is primarily to contribute to an improved balance on the electricity market, which also generates revenue from Svenska Kraftnät and thus a favourable return on investment.

With a clear focus on sustainability, these energy investments are well suited to achieve favourable bank financing. Initial contacts with the banks have been made and the results will be announced.

Rottneros is an independent producer of market pulp.

The company had already entrusted ANDRITZ with major supplies for the pulp mill last year.

ANDRITZ’s scope of supply for the woodyard includes two debarking lines with rubber tire supported debarking drums for excellent debarking results with very low wood losses as well as horizontally fed HHQ-Chippers ensuring high capacity without compromising on chip quality. The line has a capacity of 300 m3 hardwood solid-over-bark per hour. The scope also includes a bark handling system with three BioCrusher BSX machines and bark storage with two ParaScrew travelling screw reclaimers.

The order will be completed on an EPS (Engineering, Procurement, Supervision) basis. Start-up is scheduled for the third quarter of 2024.

This order shows the excellent business relationship between ANDRITZ and Liansheng Pulp & Paper.

ANDRITZ is already in the process of supplying stateof-the-art, environmentally friendly technologies for all main process islands in the fiber production plant and the chemical recovery plant to the Zhangzhou mill.

Liansheng Pulp and Paper (Zhangzhou) Co., LTD., founded in April 2020, is a new forest, pulp and paper integrated production base being built

by Liansheng Paper, which is the largest packaging board producer in Fujian Province, China. Liansheng Paper pays special attention to environment friendly production.

International technology group ANDRITZ offers a broad

portfolio of innovative plants, equipment, systems, services and digital solutions for a wide range of industries and end markets.

Grinding process is now made simpler with the latest addition by VOLLMER as they showcased the first of its kind precision grinding of circular saws for saw mills recently at LIGNA.

In saw mills, circular saws are indispensable when it comes to cutting wood on chipping and profiling lines. Sharpening specialist VOLLMER has designed its CS 860 and CSF 860 grinding machine duo specifically for grinding these carbidetipped circular saws. They have R2 axes for axial lateral adjustment, centre brakes for an opening blade clamping mechanism and co-rotating mounting systems to protect clearing blades.

Saw manufacturers, sharpening services and saw mills use this pair of machines from VOLLMER to manufacture or resharpen different circular saws safely and precisely, without manual intervention and around the clock.

In saw mills, the cutting edges of carbide-tipped circular saws must have a perfect geometry, surface and edge to optimally cut logs on chipping and profiling lines at feed rates of 250 metres per minute. And that’s not all – the saw blade must be very rigid if the kerf is to be as thin as possible.

Saw manufacturers therefore rely on bores with keyway or spline to effectively transfer high torsional forces from the shaft to the saw teeth. Internal clearing blades ensure that the huge amounts of sawdust are removed from the kerf and that the heating of the saw blade is kept within limits.

Saw manufacturers, sharpening services and saw mills can use the CS 860 and CSF 860 duo to sharpen both the tooth faces and tooth tops as well as the flanks of saw teeth in a single set-up.

The machines automatically detect the geometry of a saw tooth and grind it precisely to

the required size. The grinding machines automatically detect newly inserted teeth and machine them to size using oscillation. The feed pawl registers broken teeth in order to prevent the grinding wheels from breaking and determines the tooth pitch. This means that it is not necessary to enter this manually and prevents operator errors. In addition, the VOLLMER machines are networked via the standard IoT gateway (Internet of Things) and record all operating and machine data in order to determine the machine utilisation in real time, for example.

“We have specifically developed the CS 860 and CSF 860 to meet the strict requirements of saw mills,” says Thomas Wenger, Product Manager at the Biberach-based VOLLMER Group. “Thanks to the wide-ranging machining scope of the machines, as well as their high flexibility and productivity, we have come up with a real innovation in the global grinding technology market.”

BID Group announces a strategic capital investment of $4.7 million towards the modernization of its equipment to increase production capacity in its Saint-Georges and SaintÉphrem-de-Beauce facilities in Quebec, Canada.

In Saint-Georges, preparations are underway to introduce state-of-the-art equipment, including a new large band saw, a plasma cutting table, two CNC machine tools and a CNC Multi-task Mazak Integrex to increase its machining capacity. These changes represent a cumulative investment of $2.4 million.

Similarly, BID’s SaintÉphrem-de-Beauce facility is actively being prepared to accommodate new equipment, namely an Automated Part Storage System, a CNC boring machine and a grinder with a robotic feeding system to increase production for Comact

BLADE cutting tools. The collective investment for this equipment amounts to $2.3 million.

Through the incorporation of this new equipment, BID Group aims to increase its ability to deliver an extensive range of innovative technologies to

its highly valued customers while enhancing operational efficiency.

Start-up and installation of the new equipment began in April 2023 and will be carried out until June 2024. The equipment modernization initiative will result in the

Raute Corporation (“Raute”) has signed a contract worth EUR 29 million with AS Latvijas Finieris (“Latvijas Finieris”), Latvia for the delivery of technology to a plywood mill expansion. Following the terms of the contract, the project has become effective by signing of a delivery contract.

Latvijas Finieris, the leading producer of birch plywood in Europe and the Baltic countries, will expand their Verems, Latvia plywood factory to increase the production capacity by 35000 m3.

The order for Raute’s technology includes all main production processes from

veneer drying to plywood overlaying: veneer drying line, veneer scarf-jointing line, veneer composing lines, plywood layup line, plywood pressing line, panel trimming line, and panel overlaying line, with extensive service package and long-term on-site management. The lines are a complete solution compiled of the proven R5- and most modern automated R7-Series technologies. All lines are equipped with analyzers for grading and MillSIGHTS software for data capturing.

The ordered machinery and equipment will be delivered between March 2024 and

June 2025. The equipment will be manufactured at Raute’s production units in Lahti and Kajaani in Finland, and in the company’s partnership network.

This new expansion, which will be in full operation in 2025, is part of Latvijas Finieris’s strategy to develop and innovate sustainable birch plywood production enabling further processing of special end products.

“We are happy to work with Latvijas Finieris on yet another project to promote resource-efficient society. We believe our unique solutions enable Latvijas Finieris in

creation of multiple new jobs, primarily for industrial mechanics and machinists.

BID Group is a global leader in transformational wood processing technologies and integrated solutions.

reaching their increased targets for sustainable plywood production”, says Mika Saariaho, CEO of Raute.

Latvijas Finieris Group is a multi-sectoral international company with key business in research, development, production, and sales of tailored birch plywood products under the brand Riga Wood. Their birch plywood and veneer factories are located in Latvia, Lithuania, Estonia and Finland. The plywood products and solutions are delivered to 32 industries world-wide. Further information on Latvijas Finieris can be found at www. finieris.lv

Kastamonu Entegre Ağaç Sanayi ve Ticaret A.Ş. (KEAS) started up its new fiber preparation line for MDF (Medium Density Fiberboard) production at its mill in Balikesir, Türkiye. KEAS is the largest wood panel producer in Türkiye and now successfully operates three production lines supplied by ANDRITZ.

Hasan Akpinar, Global Investment and Projects Director of KEAS, says: “We have relied on ANDRITZ MDF technology and service for many years and are very satisfied with the results. Our new line from ANDRITZ is equipped with a pressurized refining system for low electricity and thermal

energy consumption. This perfectly contributes to our sustainability strategy.”

The new line has a capacity of 60 t/h and processes pine, beech and oak wood. Its centerpiece is the pressurized refining system, which includes a 24” plug screw feeder and a high-capacity S2070M refiner.

The high dewatering efficiency of the plug screw feeder ahead of the high-pressure zone ensures low thermal and electrical energy consumption, which is one of the major benefits of the ANDRITZ pressurized refining system. ANDRITZ’s scope also included supply of a gravity-fed HQChipper, a chip bin discharger and a digester, as well as

Part of the ANDRITZ scope is a high-capacity S2070 refiner

supervision of mechanical installation and start-up. KEAS, part of Hayat Holding, was established in 1969 and specializes in the production of wood-based panels for the furniture, interior decoration, and construction industries. It has more than

six locations in Türkiye and several manufacturing plants worldwide.

Finnos and Vaagen Brothers Lumber Inc have agreed about a delivery consisting of Finnos Fusion log scanner (3D+X-ray) enhanced with state-of-theart AI software. Additionally Finnos delivers a board scanner for planer mill with moisture meter and board end vision scanner.

Holmen Wood Products AB commissioned Brinkab, part of Veidekke Entreprenad AB, and Veidekke’s newly started construction business in Gävle to build a new planer at Iggesund Sawmill near Hudiksvall, Sweden. The order, worth around SEK 90 million, is scheduled to be completed in early 2024, said Veidekke in a statement.

The project includes the new construction of a 4,000 m2 planing house adjacent to a sawmill. When the new planer and sorter is installed, it is anticipated that sawmill capacity could increase to just over 450,000 m3 per year from today’s 380,000 m3. Full capacity is expected to be reached by the end of 2024

Finnos Fusion will be used at log sorting line to sort logs not only to their geometrical features but also according to the internal quality features such as knots etc. Additionally the mill can sort the logs by the wood species as well. The scanners will be delivered to Vaagen Brothers Lumber Inc.

mill in Colville, Washington. Finnos is the forerunner in AI-based X-ray technology offering superior log X-ray solutions for sawmill, pulp, energy and plywood industries.

Cut waste & stack productivity sky-high.

An advanced motion controller gets forest product machinery to move faster, smoother, and more precisely, which enables higher productivity, improved product quality, and ensures less wasted raw material.

The difference with Delta is measurable. Precisely coordinate multi-axis applications 10X faster. Scrap will diminish, throughput will rise, and profits will stack up as a result.

With its advanced automation capabilities, the Primary Breakdown Closed Loop SmartTool revolutionizes the wood processing industry.

This cutting-edge technology allows you to break down each log precisely, extracting its full value and maximizing production value. By ensuring optimal recovery, this SmartTool offers significant benefits to sawmills seeking to streamline and optimize their primary breakdown operations.

The Closed Loop SmartTool operates seamlessly, making necessary adjustments automatically in real-time. This relieves the pressure on your team members, freeing them to focus on other crucial tasks. Through the use of data provided by Comact scanners already in place, the SmartTool provides complete information about the log’s shape, guaranteeing unparalleled accuracy.

One notable feature of the Primary Breakdown Closed Loop system is its innovative Multi-offset Adjustment function. This function accelerates the execution of adjustments and corrects offsets swiftly, enabling a more

efficient workflow. Moreover, the Pattern Deduction function sets a new standard for closed loop reaction time in defining cutting patterns, providing the fastest response on the market. Additionally, the system automatically corrects offsets to cutting tools and infeed modules. Mechanical breakdowns or problems are instantly identified and

displayed on a real-time dashboard, ensuring prompt attention and minimal fiber/ value loss. This comprehensive approach optimizes performance and keeps production running smoothly.

To ensure continuous performance, the Primary Breakdown SmartTool function monitors and makes necessary adjustments, while also monitoring the cleanliness of the scanner. Regular checks of dimension readings further enhance accuracy and performance. By consistently executing optimized cant cutting patterns, each log’s value is maximized.

Installation of the Primary Breakdown Closed Loop system typically requires a short downtime period, usually over a weekend. Once installed, production can resume after calibration, testing, and adjustment of parameter thresholds, alarms, and notifications.

Monitoring the system’s performance and reliability is made easy with real-time dashboards that display primary breakdown operations. Additionally, a comprehensive history of all adjustments performed is available for reference. The technology has been thoroughly tested and improved since its development in 2020, ensuring maturity and reliability. The BID team provides support at every

step, offering quick start-up and technical training, backed by the renowned 24/7 service and the reliability program.

More than 10 Closed Loop systems are now up and running in different sawmills across North America and results are witnessed as soon as the “start” button is pressed.

In one particular case, a sawmill had unknowingly been producing off-size boards, in a consistent pattern, for several months. This was caused by cylinders not properly calibrated unable to reach the correct position. Unaware that the output was incorrect and certain that all boards were on target, managers were surprised to conclude the system was right. It was only 15 minutes after turning on the system that the detection occurred, leading to an immediate resolution of the issue.

Closed Loop SmartTool offers a holistic view of the production, enabling quick detection of errors in patterns or overall performance. As previously mentioned, alarms can be promptly dispatched, allowing action to be taken rapidly

to rectify any issues. Email notifications can also be sent. Let’s talk about numbers

Maximizing material yield is a critical objective for sawmills, as it directly impacts financial performance and sustainability. The process of optimizing material yield involves implementing new technologies to extract the highest value from available resources. Even a small 1% improvement in material yield can result in significant benefits. Studies have shown that in a sawmill with an

annual production capacity of 100 MBF, a 1% increase in material yield can translate to cost savings or additional revenue ranging from $250,000 to $300,000 per year. BID’s Closed Loop System enables better control over dimensions and surface adjustments, leading to this outcome. Furthermore, a tighter control of dimensions has been proven to reduce target size by 0.020’’ which equates to a 1% increase in material yield. Additionally, data indicates that optimizing surface adjustments has the potential to save up to 1.6% in

yield at a sawmill. By adopting efficient and advanced technologies, sawmills can enhance their profitability, minimize waste, and contribute to a more sustainable operation.

Don’t miss out on the opportunity to maximize your production value. Call now to learn more about the Primary Breakdown Closed Loop system!

450-435-2121

www.bidgroup.ca

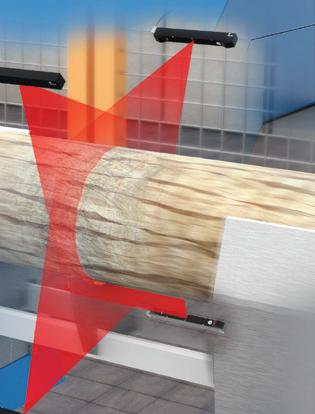

MiCROTEC’s sophisticated scanning system significantly increases log yields

Even though Piveteau Bois still has logs stacked at their log yard, the staff of the large-scale sawmill actually view the woodpiles as a virtual lumber yard already. This approach has changed the entire production process for the French company: Before cutting even starts, they already know exactly which boards they will get out of the logs. This is made possible by means of the CT Log and the one-of-akind fingerprint system provided by MiCROTEC.

The Piveteau Bois sawmill in Sainte-Florence near the French Atlantic coast has several different mainstays. Only a small part of its cutting volume is sold fresh, the rest is dried, planed, glued or otherwise processed. Pine, Douglas fir and spruce wood are used to make wooden floors and facades as well as glulam and CLT elements. In the manufacturing of these products, Piveteau Bois pays particular attention to the optimum utilization of roundwood. “Our sawmill in Sainte-Florence is located in a region with few wood sources. This makes the raw material even more valuable,” R&D Manager Ugo Gerard explains, referring to the unconventional location for a sawmill far from large forest areas

Against this background, the company implemented numerous optimization measures in recent years with the aim of increasing the log yield step by step. The collaboration with MiCROTEC has been particularly close and equally fruitful. In the sawmill

alone – from log infeed to lumber sorting – the scanner specialists from South Tyrol implemented three systems that optimally complement each other.

Directly after the log infeed, the long and short logs are brought into the CT Log at feed rates of up to 120 m/min. The computed tomography technology integrated in the machine enables the digital reconstruction of the logs’ complete inner life. Specifically, a comprehensive

three-dimensional density profile of each log is created which primarily shows the size, position and condition of knots. Furthermore, the system detects whether there are rotten knots, cracks, resin pockets or spiral grain. “This allows us to precisely predict the quality of the boards and their corresponding location even before cutting, and to adjust the sawing schedule accordingly for each log. Essentially, this means we are no longer accessing the individual logs for cutting but our virtual lumber yard within the logs,” Gerard explains and adds that this has changed the approach to the entire production process. “We now know exactly which logs to use for which products, and what volumes of the various assortments we can produce each year. This not only increases the value of the used wood but also facilitates the logistics for the markets.”

Directly before the sawing line, the logs are passed through the Logeye 302, a multi-sensor quality scanner with fingerprint. Equipped with X-ray technology, multi-sensor cameras and other sensors, the Logeye performs a 3D measurement of the log and again determines its density profile. With the density profiles of the logs – each being as unique as a fingerprint – each log is recognized and rotated according to its optimum value yield before

the full traceability from board to log.

“In the past, when we did not know in advance what we would get out of each log, we had to put some boards to a lower-value use than originally planned. Today, the rate of this unwanted downgrading is effectively zero,” Gerard reports, adding that this has increased the value output of each log by 5%.

A great result, but one that doesn’t lead Piveteau Bois to sit back and relax –quite the opposite, in fact:

The 3D density profile shows the size, position and condition of knots in the log. Cracks, resin pockets and other wood defects are also detected

“To keep getting better, we are continuously working on new projects, and Microtec is a reliable and trusted partner that keeps pushing us forward with

new ideas and innovations.” MiCROTEC presented the next evolutionary stage of the fingerprint system at LIGNA 2023 in Hannover.

cutting. “We are optimizing the sawing schedule for each individual log,” Gerard emphasizes. In addition to the Microtec scanners, this is made possible with the help of a modernized profiling line from Linck, designed to adjust to every single log which would even allow for a completely unsorted cutting process.

The third MiCROTEC system is the Goldeneye 900 multisensor quality scanner in transverse transport. It is responsible for quality grading of the fresh boards as well as the definite identification of each lamella. Thus, Piveteau Bois can recognize and allocate each log and each board by means of this digital fingerprint. This results not only in added value, but also

Raute Corporation has signed a contract worth EUR 44.6 million with the THEBAULT Group, France for the technology delivery of a new greenfield LVL (Laminated Veneer Lumber) production plant.

The plant, which will be the first LVL plant in France, will eventually produce 100,000 m3 of LVL entirely ‘’Made in France’’, with this agreed delivery covering a first phase at 70,000 m3.

The order for Raute’s technology includes all the production processes from veneer peeling to LVL billet handling, including extensive service package. The lines are a complete solution compiled of the latest most automated R7-Series technologies.

The ordered machinery and equipment will be delivered during 2024. They will be manufactured at Raute’s production units in Lahti and Kajaani in Finland, and in

After partnering with Raute for three generations of our family history, collaborating again with Raute in this important investment for our company is a guarantee

The THEBAULT Group, a family-owned industrial company, is the leading French plywood manufacturer with annual production of 125 000 m³ making almost 50% of the total domestic plywood production and ranks among the top five European producers. 70% of the produced plywood is exported, mainly in Europe but also in the rest of the world. The group employs 400 people and generated a turnover of €100 million (2022).

www.groupe-thebault.com/en/

the company’s partnership network.

This new plant, which will be in full operation in 2026, is part of THEBAULT’s development to extend its offering particularly to the construction industry. Driven by a fast-growing market, this French production of engineered wood products will expand the offer of biosourced materials contributing to the decarbonization of the building sector.

MiCROTEC’s Logeye 301 DC will be delivered to Luopajärvi in August 2023, and MiCROTEC Espoo is fully responsible for the delivery. This means that commissioning, maintenance and spare parts deliveries are done from Finland.

“The new log scanner is an investment far into the future. We made a comparison between different options and companies, and MiCROTEC was able to offer us the most suitable solution. Since the X-ray investment is not current,

a 3D log scanner equipped with bark cameras is definitely the best solution for us at this stage. The decision was also supported by the fact that the cameras can automatically perform bark correction and snow/ice reduction. In the future, MiCROTEC also offers a wide selection of other measuring devices suitable for our production,” says Juha Anttila, forest manager of Luopajärvi Sawmill.

MiCROTEC’s Logeye 301 is the world’s most used log

scanner model. Logeye 301 achieves stable and reliable bark measurement accuracy in all seasons without X-rays. The system can be expanded with end cameras, so that rot and blue stain are also detected automatically at the ends of the log.

MiCROTEC is one of the most innovative scanning & optimization provider for the sawmilling and wood processing industry.

THEBAULT is our longterm customer, and we are very pleased to continue our close partnership with them on this new project

Raute

for success and sign of trust.

Antoine THEBAULT, President and CEO of THEBAULT Group.

JD Irving, Limited, a producer of maple, birch, and poplar wood products, headquartered in Saint John, New Brunswick, Canada, continues their commitment to sustainability and innovation with the purchase of a MiCROTEC CT Log for installation in its Veneer Sawmill, located in St. Leonard, New Brunswick, Canada.

MiCROTEC’s CT Log is a worldwide unique computed tomography scanner in the wood products industry, allowing JD Irving, Limited to scan and digitally reconstruct the internal features of their logs in 3D. Delivering the optimal cutting

solution in real time, this technology is consistent with JD Irving, Limited’s mission to ensure the use of 100% of every tree. The computed tomography scanner provides a complete reconstruction of the internal features of the logs, allowing the logs to be graded and sorted by quality and optimization. The CT Log solution developed by MiCROTEC’s industry-leading engineers provides quality grading and virtual grading information in addition to the full 3D log description.

Integrated with MiCROTEC’s Maxicut Pro, Winlog, and MiCROTEC Connect, the CT Log communicates with the Logeye Stereo, providing the head rigg operator the exact degree of log rotation to provide maximum value. Working with the CT Log, MiCROTEC’s Maxicut software optimizes cutting patterns based on value.

The newest investment is part of JD Irving, Limited‘s continued partnership with MiCROTEC. Beginning in 2014 with a Lucidyne scanner installation at their Dixfield, Maine, USA location, JD Irving, Limited has since installed Lucidyne scanners at their Doaktown and Kedgwick, New Brunswick, Canada locations, with another Wanescan installation at their Dixfield,

Maine facility in 2023. Their recent investment of the CT Log is accompanied by a commitment of 5 MiCROTEC Logeye Stereos, which execute 360° scans during rolling, adding to the information gained before the log is sawn.

Speaking to the solutions provided by MiCROTEC, Jerome Pelletier, Vice President of JD Irving, Limited Sawmills Division says, “We are very excited to further grow our

partnership with MiCROTEC. We firmly believe that this strategic investment in the newest scanning technology will allow us to maximize log yield as well as improve the value of the products offered to our customers.”

The CT Log solution and Logeye Stereo applications will be installed early 2024. For more information about the CT Log or Logeye Stereo, please visit microtec.eu

Like any other building, a sawmill building must meet the stipulations of both the Building Act and the Rescue Act. Fire safety planning must take into account construction materials, fireextinguishing systems, emergency exits and fire protection. Sitowise Group Oyj has been responsible for fire safety planning at Koskisen’s sawmill.

The new sawmill is a concrete building, and while the exterior walls are made of wood elements, there is concrete underneath them. Inside the sawmill, the intermediate walls of the production areas are made of sheet metal and wool elements, and all the spaces with high ceilings and separate spaces are firecompartmented. Since only 4 or 5 people normally work in the sawmill during a shift, there was no need to plan extra emergency exits. Besides the normal access routes, there are also emergency exits leading to the roof, from where it is possible to climb down ladders to safety in the event of a fire. Every emergency exit door is equipped with a push-button fire alarm,” explains Tauno Tonteri, Koskisen’s fire chief since 2017.

Tonteri, who has worked at Koskisen since the 1990s, says that once the fire safety plans were completed, a discussion with the insurance company began.

“The insurance company gave the green light, as the sawmill’s fire safety systems exceed the minimum legal requirements. For example, instead of fire hydrants, we have a separate fireextinguishing water system in our yard area,” he says.

Located on the lot of the sawmill is southern Finland’s second-largest water-pumping station, whose task is to ensure the supply of water to the fire sprinklers and fireextinguishing water system in case of a fire.

“The volume of the sprinkler water reservoir is over a million litres, and each of its three diesel pumps can pump 6,000 litres of water per minute at 9.5 bar. The fire water reservoir has roughly 600,000 litres of water and two pumps, which are as powerful as the pumps in the sprinkler pumping station,” says Tonteri.

Both the sawmill’s and the dimension-sorting plant’s ceilings are equipped with sprinklers, and an automatic extinguishing system can also be found on the platforms of the maintenance levels and auxiliary spaces. There are a total of 1,540 sprinklers in the sawmill and its related spaces. Automation is also used in the sawdust extraction pipes.

“ATEX spaces are potentially explosive spaces, in which a flammable substance – in this case sawdust – can, in combination with normal air pressure, cause an explosive atmosphere. For that reason, the sawdust extraction pipes are equipped with a spark

Sawmills are often associated with a high risk of fire, given that a high fire load – timber – is produced and stored in them. The fire safety systems in Koskisen’s new sawmill go beyond the requirements, although the hope is, of course, that they will never be needed.

Before any work is started, the issuer of the hot work permit specifies, among other things, what is to be cleaned, what fire extinguishing equipment is to be provided and whether something needs to be covered. In spaces that may contain dust, a foam layer is applied before the hot work begins. Hot work is always performed by two people, and at Koskisen, the post-work fire watch is two hours instead of the usual one hour

Tauno Tonteri, Fire Chief

Tauno Tonteri, Fire Chief

extinguishing system whereby a spark will automatically trigger a dense water mist that prevents an explosion,” explains Tonteri.

Some spaces also have multi-criteria fire detectors, which measure temperature, changes in temperature, and smoke. All electrical rooms and exterior transformers, as well as timber storages, are equipped with these detectors.

“The starting point for planning is compartmentation. If that is not possible, the spaces are equipped with sprinklers. If sprinklers are not possible, fire detectors are used,” says Tonteri.

Although the prevention, detection and extinguishing of fires is highly automated, human input is still needed. All employees have completed

Occupational Safety Card training, in addition to which, maintenance personnel have also completed Hot Work Card training. If necessary, AS1 first-hand extinguishing training is organised, and the exercises are also part of the sawmill’s routines. The exercises go over, among other things, the use of fire blankets, foam extinguishers and fire hydrants.

“Our approach is to first try to extinguish the fire on our own, and if that doesn’t work, we press the fire alarm button. We must not put ourselves or others in danger, of course. Not everyone will be able to leave the area immediately, however, because there must

be people around to guide the fire brigade. In many cases, the forklift drivers are responsible for guiding traffic,” says Tonteri.

Precise guidelines

The equipment is maintained and tested every month, serviced every year, and inspected for operation by authorities every few years. The most important measure of all, however, is fire prevention. Tonteri says maintaining cleanliness is a priority in that respect to ensure that flammable substances do not accumulate in places where they do not belong. Production spaces should also be free from sawdust or fine dust,

HALCO AD:Layout 3 3/8/10 17:22 Page 1

which at Koskisen is collected and transported by conveyors and pipes for use in heat production. Fires can also start outside the sawmill, which is why machinery must be parked at least 30 metres from a potentially burning structure.

“People are well-informed, and they understand the risks. We don’t see deliberate acts of negligence or recklessness here,” stresses Tonteri.

Sometimes maintenance work that entails a risk of fire does take place in the sawmill. Koskisen has its own hot work plan that again begins with cleaning.

“Before any work is started, the issuer of the hot work permit specifies, among other things, what is to be cleaned, what fire extinguishing equipment is to be provided and whether something needs to be covered. In spaces that may contain dust, a foam layer is applied before the hot work begins. Hot work is always performed by two people, and at Koskisen, the post-work fire watch is two hours instead of the usual one hour,” explains Tonteri.

If a fire were to ignite somewhere in the sawmill, however, flames are not the

only threat: burning wood quickly generates considerable smoke. Smoke extraction has been a focus of the new sawmill, and mechanical fans efficiently blow smoke through the smoke exhaust vents.

Koskisen no longer has its own mill fire brigade and is instead served by the contractual fire brigade Järvelän VPK. Tonteri says the fire brigade carries out drills in the mill areas ten times a year and describes the co-operation as excellent. The fire brigade’s main “area of attack” is the inside yard of the mill. Tonteri considers the area difficult to navigate and, particularly to outsiders, confusing. Despite the drills and a visit from Päijät-Häme Rescue Services to familiarise themselves with the area, more signs are needed in order to ensure the fire extinguishing equipment gets to the optimal stations as quickly as possible.

“We believe we have done our best and taken all factors into consideration to ensure fire safety. My greatest wish, however, is that this is all unnecessary and these systems and equipment will never be needed,” Tonteri sums up.

Agility, power, ergonomics, weight distribution and economic efficiency – these are the features that set PONSSE forwarders apart. You can

choose from various models suitable for soft terrain and steep slopes alike. Power and some the best comfort features in forests are standard equipment.

All PONSSE forwarder models have more than enough power for changing conditions and difficult terrain types. The excellent weight to load-carrying ratio, the

smallest turning radius in their size classes and dimensions that distribute loads evenly to all wheels are prominent features. The extreme tractive force of their forwarders

This forwarder has what it takes to ensure productive operations even in the most demanding logging sites.

LOAD CARRYING CAPACITY

25 000 kg (55,116 lbs)

POWER

210 kW (286 hp) EU and North America

220 kW (299 hp) other countries

TRACTIVE FORCE

320 kN (71,938 lbf)

LOADER

K121 M/S

LOAD SPACE CROSS-SECTION

6.8 m² (73.2 sq ft)

VLA 8.0 m² (86.1 sq ft)

GROUND CLEARANCE

800 mm (31.5 in)

MINIMUM WEIGHT

28 500 kg (62,832 lbs)

TYPICAL WEIGHT

28 500 kg (62,832 lbs)

TIRES

28,5’’

Powerful engine, never-ending tractive force and 20-ton load-carrying capacity.

LOAD CARRYING CAPACITY

20 000 kg (44,093 lbs)

POWER

210 kW (286 hp) EU and North America

205 kW (275 hp) other countries

TRACTIVE FORCE

240 kN (53,954 lbf)

LOADER

K121 M/S

LOAD SPACE CROSS-SECTION

5.8–6.7 m² (62.4–72.2 sq ft)

VLA 5.2–6.7 m² (56–72 sq ft)

GROUND CLEARANCE

800 mm (31.5 in)

MINIMUM WEIGHT

22 900 kg (50,486 lbs)

TYPICAL WEIGHT

23 700 kg (52,249 lbs)

TIRES

26,5’’ 25T 20T

guarantees excellent comfort and efficiency, particularly over longer distances. Ponsse’s range has some of the most productive forwarders in the markets, both for thinning and regeneration felling.

Ponsse’s forwarders are the only forest machines in the world that use a continuously variable transmission (CVT). This enables higher fuel economy and tractive force, particularly in difficult terrain.

PONSSE forwarders, equipped with ultimate tractive force, guarantee efficient timber transportation – while saving the environment as much as possible.

This workhorse gets the job done in conditions which often are too challenging for others.

LOAD CARRYING CAPACITY

18 000 kg (39,683 lbs)

POWER

210 kW (286 hp) EU and North America

205 kW (275 hp) other countries

TRACTIVE FORCE

220 kN (49,459 lbf)

LOADER

K121 M/S

LOAD SPACE CROSS-SECTION

5.8–6.25 m² (62.4–67.3 sq ft)

VLA 5.2–6.7 m² (56–72 sq ft)

GROUND CLEARANCE

800 mm (31.5 in)

MINIMUM WEIGHT

22 000 kg (48,502 lbs)

TYPICAL WEIGHT

22 800 kg (50,265 lbs)

TIRES

26,5’’

A straightforward, yet extremely dependable tool with well-thought-out technical systems.

LOAD CARRYING CAPACITY

18 000 kg (39,683 lbs)

POWER

210 kW (286 hp) EU and North America

205 kW (275 hp) other countries

TRACTIVE FORCE

210 kN (47,210 lbf)

LOADER

K100+ M/S, K101 M/S, K111 M/S

LOAD SPACE CROSS-SECTION

5.2–5.8 m² (56–63 sq ft)

GROUND CLEARANCE

730 mm (28.7 in)

MINIMUM WEIGHT

20 600 kg (45,415 lbs)

TYPICAL WEIGHT

21 100 kg (46,517 lbs)

26,5’’ 18T 18T

TIRES

This forwarder goes where you want it to go, easily and effortlessly.

LOAD CARRYING CAPACITY

14 000 kg (30,865 lbs)

15 000 kg (33,069 lbs) with balanced bogies

POWER

210 kW (286 hp) EU and North America

205 kW (275 hp) other countries

TRACTIVE FORCE

185 kN (41,589 lbf)

LOADER

K90+ M/S, K100+ M/S, K101 M/S, K111 M/S

LOAD SPACE CROSS-SECTION

4.5–5.5 m² (48.4–59.2 sq ft)

VLA 4.5–6.0 m² (48.4-64.6 sq ft)

GROUND CLEARANCE

680 mm (26.8 in)

MINIMUM WEIGHT

18 600 kg (41,005 lbs)

TYPICAL WEIGHT

19 800 kg (43,651 lbs)

TIRES

26,5’’

An exceptionally fast forwarder that moves slickly in all types of terrain and even over longer distances.

LOAD CARRYING CAPACITY

16 000 kg (35,274 lbs)

POWER

210 kW (286 hp) EU and North America

205 kW (275 hp) other countries

TRACTIVE FORCE

210 kN (44,961 lbf)

LOADER

K90+ M/S, K100+ M/S, K101 M/S, K111 M/S

LOAD SPACE CROSS-SECTION

4.5–5.5 m² (48.4–59.2 sq ft)

VLA 4.5–6.0 m² (48.4-64.6 sq ft)

GROUND CLEARANCE

680 mm (26.8 in)

MINIMUM WEIGHT

22 000 kg (48,500 lbs)

TYPICAL WEIGHT

22 600 kg (49,824 lbs)

TIRES

26,5’’

A powerful and durable forwarder with a first-rate load-carrying capacity.

LOAD CARRYING CAPACITY

13 000 kg (28,660 lbs)

POWER

150 kW (204 hp) EU and North America

145 kW (197 hp) other countries

TRACTIVE FORCE

175 kN (39,341 lbf)

LOADER

K70+ M, K90+ M/S

LOAD SPACE CROSS-SECTION

4.5–5.0 m² (48.4–53.8 sq ft)

VLA 4.5–6.0 m² (48.4–64.6 sq ft)

GROUND CLEARANCE

670 mm (26.38 in)

MINIMUM WEIGHT

17 700 kg (39,022 lbs)

TYPICAL WEIGHT

18 800 kg (41,447 lbs)

TIRES

26,5’’

An agile, lightweight forwarder with excellent power, visibility, and load-carrying capacity.

LOAD CARRYING CAPACITY

12 000 kg (26,455 lbs)

POWER

150 kW (204 hp) EU and North America

145 kW (197 hp) other countries

TRACTIVE FORCE

165 kN (37,093 lbf)

LOADER

K70+ M

LOAD SPACE CROSS-SECTION

4.0–4.5 m² (43.1–48.4 sq ft)

GROUND CLEARANCE

645 mm (25.4 in)

MINIMUM WEIGHT

16 300 kg (35,935 lbs)

TYPICAL WEIGHT

17 300 kg (38,140 lbs)

26,5’’ 13T 12T

TIRES

Don’t let the familiar appearance deceive you. The all-new E-cabin by Rottne is a testament to cuttingedge engineering at its finest. Building upon an already exceptional design, from now on all forwarders will feature the revolutionary E-cabin, marking a significant leap forward in cabin development.

While at first glance everything may seem unchanged, the E-cabin has undergone extensive advancements. The result is a groundbreaking innovation that prioritizes enhanced ergonomics and functionality. With integrated displays on the control panels and additional buttons on the joysticks, the work environment becomes more flexible and efficient. Rest assured, the E-cabin is manufactured in full compliance with relevant standards and regulations.

“We’ve dedicated a considerable amount of time to optimizing ergonomics, button placement, and functionality. It’s not just about adding more buttons; we’ve carefully utilized them to ensure an ample supply,” explains David Selstam from Rottne’s Development Department.

“Rottne’s machines have always provided an exceptional cabin environment with

excellent control panels, and the E-cabin allows us to maintain this advantage well into the future.”

Step into the spacious and comfortable cabin, boasting a modern design that combines form and function. The large windows and lowset instrument panel offer an unobstructed view of the surroundings and overhead area. Equipped with numerous storage compartments and even a food warmer, the E-cabin provides both convenience and comfort. Notably, the noise levels inside the cabin are quieter than those found in cars.

“The E-cabin ensures that Rottne’s machines continue to offer an exceptional cab environment with excellent control panels. This new addition undoubtedly helps us maintain this advantage in the future,” emphasizes David Selstam.

The collaboration between Rottne Industri’s Product

Development Department and Hydraulkompaniet, based in Umeå, Northern Sweden, began spontaneously three years ago. It came at the perfect time as Hydraulkompaniet was developing a completely new control panel and sought a potential customer, while Rottne was actively seeking ways to enhance and update their control panels.

“The greatest outcome is the improved ergonomics. The compact and flexible control panels now accommodate all the necessary buttons for operating the machine. For instance, in harvesters, we’ve added two extra buttons on each joystick, bringing the total to seven instead of five, enabling more tasks to be performed directly from the joystick. The integrated displays offer even greater possibilities for seamless interaction with the operator,” states Niklas Anens, CEO of Hydraulkompaniet.

“Every aspect of the development focuses on the needs of machine operators. We’ve paid attention to the spring force in the controls, regulating the pressure required to activate the buttons, and we’ve upgraded the silicone mats. These improvements enhance comfort, provide a tactile response, and improve overall ergonomics.”

With the introduction of the innovative Rottne Crane Assistance (RCA) system and an upgraded Comfort Line cabin suspension, Rottne sets a new standard for forwarders, regardless of model. Whether operating the compact Rottne F10E or the mighty Rottne F20E, the modular cabin design remains consistent across the entire range, simplifying matters for drivers and the Rottne service department alike.

“We have implemented several updates to enhance the overall cabin experience,” adds David Selstam.

“These include an upgraded lighting system, a new air conditioning system, redesigned control buttons, new displays, and even a new steering wheel. To provide a truly immersive experience, we’ve equipped the cabin with bass speakers.”

One of Rottne’s remarkable innovations is the Rottne Comfort Line, a system that not only reduces shock but also greatly improves crane operations and driving in challenging terrains. Initially introduced in 2007 as the forestry machine industry’s first anti-shock system, Rottne has continuously improved it with updated software, a sturdier structure, and precise positioning. Now, in conjunction with the launch of the new E-cabin, Rottne presents an enhanced version

of the cabin suspension system – Rottne Comfort Line 3.