OUR PACKAGE IS ATTRACTIVE

Fastener + Fixing Magazine goes beyond ‘greenwashing’ with a deep dive into who is making a difference when it comes to the environment.

Use this unique platform to inform the industry about your company’s initiatives in being more sustainable.

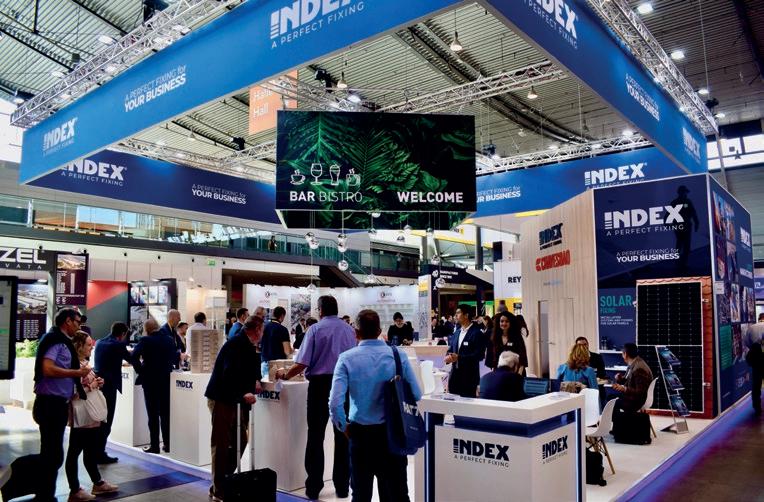

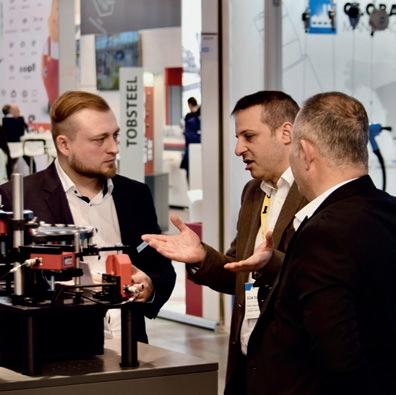

I hope you had as much fun as I did across the three busy days of the recent Fastener Fair Global show. It was great to be back meeting people face-to-face and discussing the latest developments within the fastener and fixing industry.

From the excitement of the doors opening on the first day, to the final closing announcement, the show seemed to go by in the blink of an eye. For those exhibitors and visitors I spoke to, there was unanimous agreement that it had been a standout event. As you can see from the in-depth report in this issue, nearly all the stands were busy conducting business and there are some very positive comments from exhibitors. The only negative is that we have to wait another two years until the next show!

To go alongside the Fastener Fair Global report, as usual we have a host of exclusive articles and insights that provide an overview of what is happening within the industry. Firstly, our Cover Story for this issue is focused on Chinese manufacturer ALFIRSTE and how it has established itself as a specialist screw and anchor manufacturer – who has gained a reputation for its high-quality products and excellent service.

Within our Insight section we look at another Asian manufacturer, this time its Malaysian-based Well-Union and its capabilities as a manufacturer of stainless steel bolts and screws. In the same section there is also a special interview with Dr Florian Seidl, part of the supervisory board at Keller & Kalmbach, who discusses his nearly fifty years within the fastener industry and how he believes the market has developed in this time. To add to this, there is also an article on Norm Fasteners and how its innovative solutions, and long-term business partnerships with leading companies around the world, has enabled it to develop flawless products and connections.

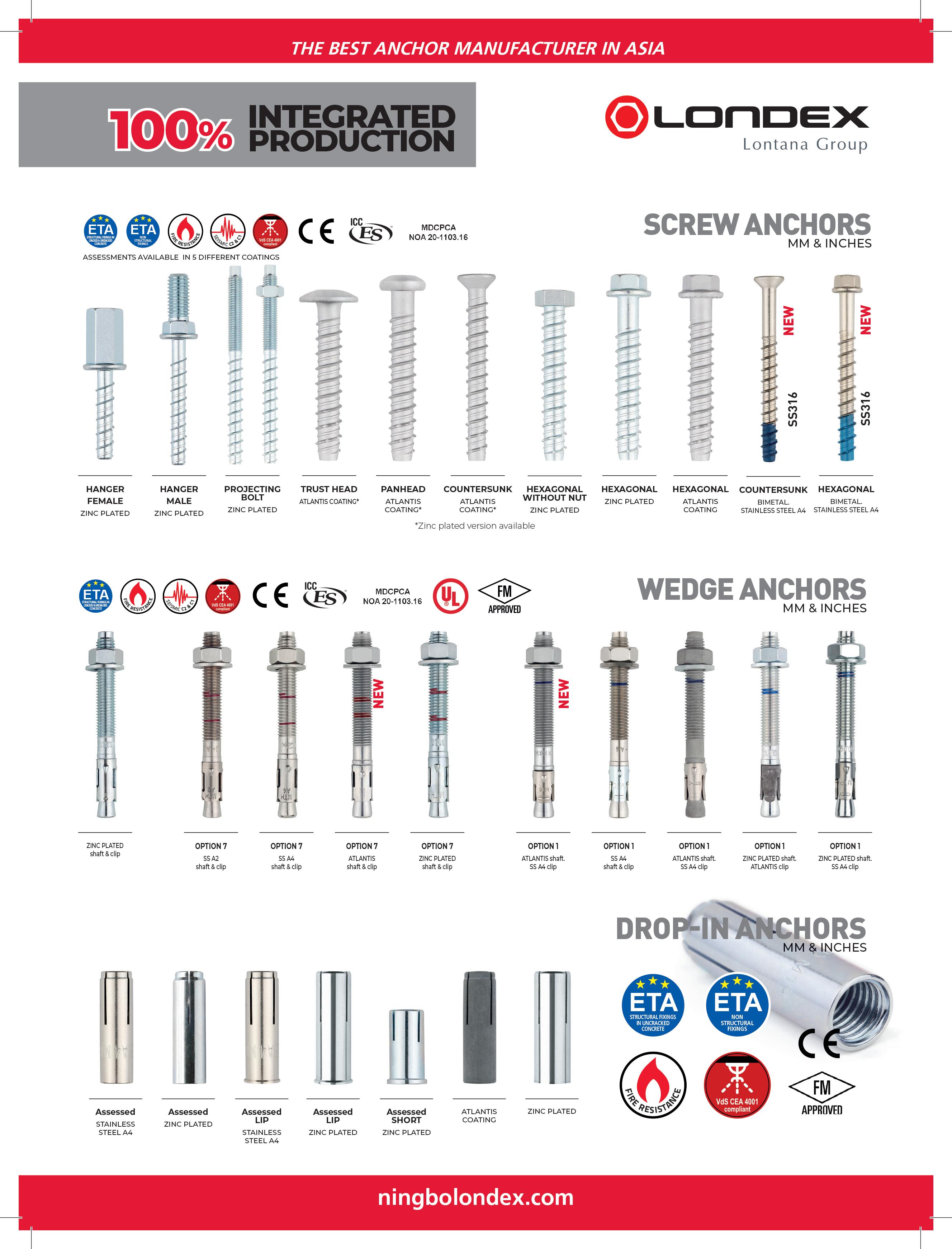

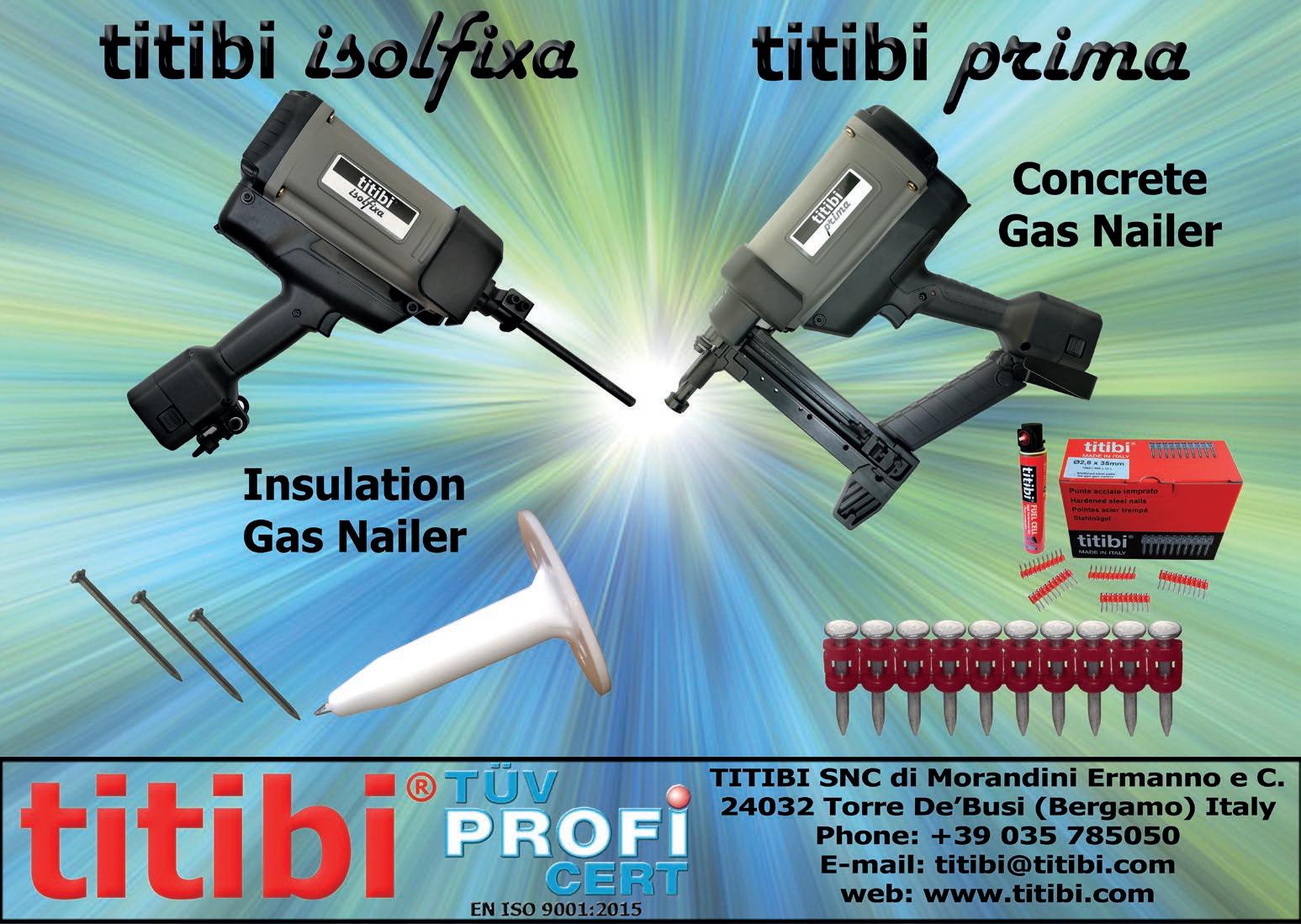

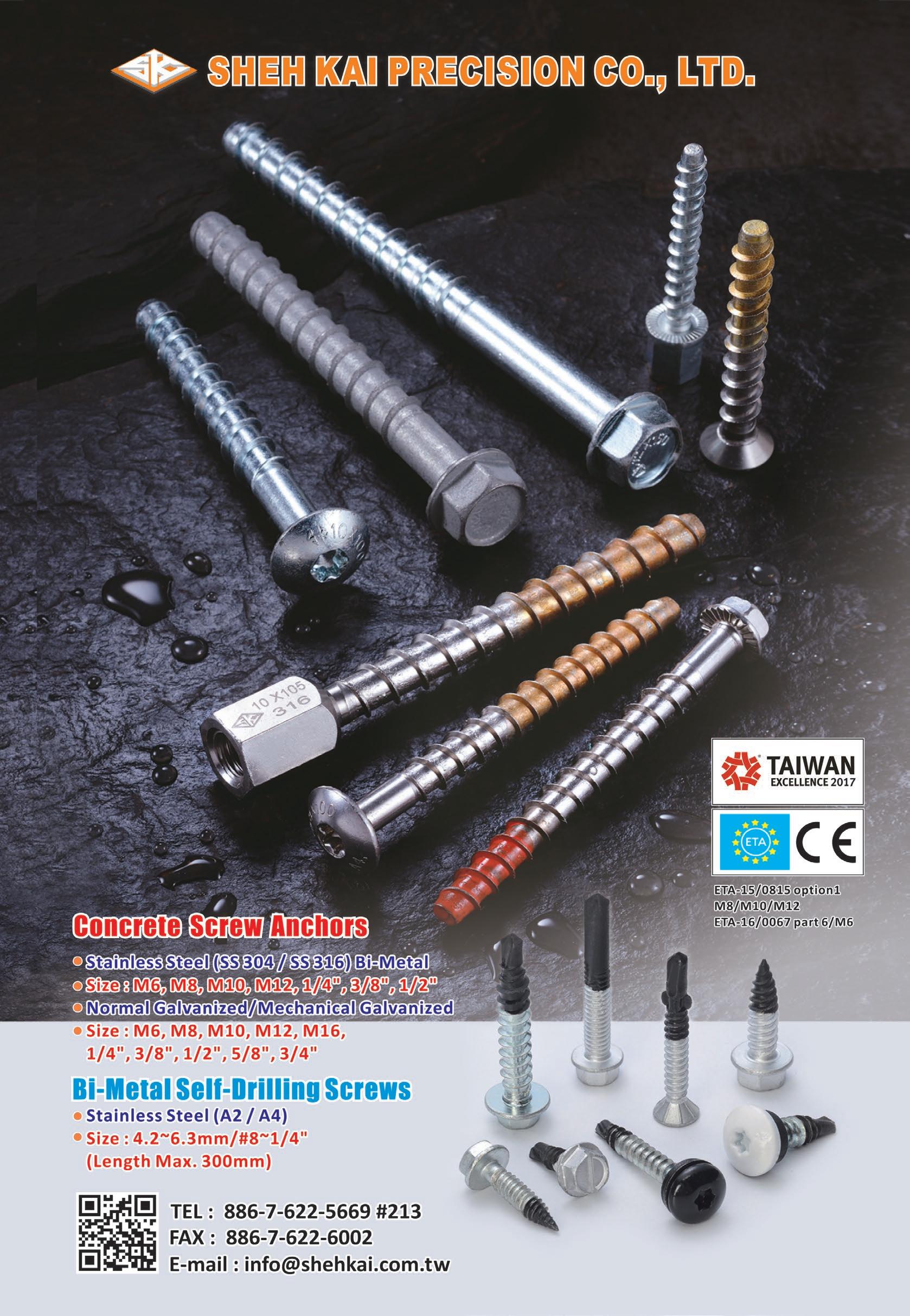

For our Construction Fixings section, we have a special feature on heavy-duty anchors with several companies highlighting their

Part of the Mack Brooks Group

www.fastenerandfixing.com

Published by

Managing Director Jamie Mitchell jamie.mitchell@verulammedia.com

Content Director Will Lowry will.lowry@verulammedia.com

Deputy Editor Claire Aldridge claire.aldridge@verulammedia.com

Assistant Editor Rebecca England rebecca.england@verulammedia.com

Sales Director Mac Rahman mac.rahman@verulammedia.com

Business Development Manager –Italy

Emiliano Pagliaroli emiliano.pagliaroli@verulammedia.com

Business Development Manager –DACH & Europe Chantal Ridings chantal.ridings@verulammedia.com

Production & Design Manager Lee Duskwick lee.duskwick@verulammedia.com

products and capabilities. This includes Reza Jafari, technical manager at JCP Construction Products, focusing on the different types of heavy-duty anchors and why and how they are different; pgb-Europe concentrates on how it has developed a complete range of heavy-duty anchors; Bossong talks about its new CLS-CE high performance concrete screw; and G&B Fissaggi reports on an upgraded version of one of its very important heavy-duty fixings.

I’ve only covered three sections and I am already running out of space, but there is so much more exclusive content for you to discover. Please do go through every page to make sure you stay informed about all aspects of the fastener market or listen to our May podcast – where I go into more detail about what you can find in this edition of Fastener + Fixing Magazine.

Fit bolts, plugs, knurled thumb screws, square head bolts, flat headed screws, hexagon set screws, brass screws and specials.

90

Bossard Group continued its growth path in the first quarter of 2023, in spite of last year’s high comparative base. Sales grew by 4.4% to CHF 304.5 million (prior year: CHF 291.6 million), equivalent to an increase of 7.7% in local currency. The Group’s organic growth corresponded to 5.8% in local currency.

Regionally, demand dynamics were mixed. In Europe, in an environment of weakening economic growth, Bossard posted a sales increase of 0.6% to CHF 170.9 million an increase of 4% in local currency. The focus on the growth industries was supportive to further growth.

Sales in America increased by 24.7% to CHF 85.3 million. Adjusted for acquisitions, growth in local currency amounted to 16.7%. The favourable business performance was driven by the ongoing diversification of the customer base. Bossard also succeeded in establishing new customer relationships in the electromobility sector, with noteworthy growth rates. Bossard Ontario Inc in Canada (formerly PENN Engineered Fasteners Corporation), consolidated since 1 st December 2022, contributed to the positive sales performance.

Sales in Asia declined by 9.4% to CHF 48.3 million a drop of 3.2% in local currency. The major contributing factors included the impact of the lifting of Covid-19 restrictions in China; the high comparative base from 2022; and the strong Swiss franc.

Notwithstanding the further normalisation of supply chains, and improved product availability, global wage and cost inflation, as well as the skilled labour shortage, remain central concerns. Bossard thinks these factors are likely to further drive demand for its automated and digital Smart Factory Logistics and Smart Factory Assembly solutions, which can significantly reduce the total cost of ownership in C-parts management and assembly for customers, thereby sustainably and measurably increasing their competitiveness. As for growth opportunities for the future, Bossard believes the course of inflation, central bank policies, geopolitical tensions, and the uncertainties on the procurement market, will continue to persist. As a result, the market environment will remain challenging. Yet even a volatile market environment offers opportunities, especially for product solutions and digital services in the growth industries of electromobility, railway, electronics and medical technology.

Bulten AB has reported a strong opening quarter of the year, with net sales at SEK 1.387 billion (€122.4 million) an increase of 34.1% on the same period last year (2022: SEK 1.034 billion). Operating earnings (EBIT) totalled SEK 116 million, equating to an operating margin of 8.4%.

Anders Nyström, president and CEO at Bulten, commented: “We have started the year with excellent financial results, and note that this is the fifth consecutive quarter with sales in excess of SEK 1 billion. Our strategy and our improvement efforts, based on 150 years of collective know-how, are clearly bearing fruit.”

He continued: “The first quarter of 2023 began with an excellent sales figure of SEK 1.387 billion, which is in line with our growth targets. This is an improvement of 34% on the same period in the previous year and slightly better than last quarter, which was itself a record quarter for sales. Furthermore, an operating margin of 8.4% indicates that we are on track to deliver on the financial targets we have set for 2024. Our resolute efforts to streamline the operation, while carefully balancing cost consciousness against the need for necessary investments, have certainly produced results. In addition, our focus on adjusting prices to customers in-line with rising costs and inflation has had a positive impact on the results.”

“For several quarters now, I have been talking about the importance of reducing our stock levels, mainly so that we can free up capital for new investments. During the first few months of the year, we have reduced stock levels by SEK 47 million, which has had a positive effect on cash flow. Our focus on stock levels has helped us to identify further potential for improvement in our internal material flows, as well as in our supply chain. We still have some work to do in order to further adjust stock levels, and also to further improve control and planning of production and material deliveries.”

NORMA Group’s final figures for the financial year 2022 showed the company generated group sales of €1.243 billion, corresponding to a 13.8% increase over the previous year. Organic sales growth was 7.1%, driven by a consistent pricing policy implemented by the group to cushion the impact of inflation.

Positive currency effects from the strong US dollar made a significant contribution to growth, and all three business regions also made positive contributions. That said, earnings and margin were impacted by higher costs for energy intensive raw materials, including steel and plastic resins, higher logistics costs and special costs incurred in connection with the introduction of a globally standardised ERP system.

The Americas region was the fastest growing business region for NORMA Group with sales reaching €574.2 million – a total contribution of 46% to group sales. Business with standard joining products developed positively overall, posting an increase of 25.8% compared to the same period in 2021. As a result of the significant increase in production figures for light and heavy vehicles in the Americas, coupled with higher prices, the automotive sector also provided positive growth momentum.

In the EMEA region, sales increased by 5.8% to €489.2 million in 2022. The automotive joining technology business recovered in the second half of the year following what, at times, were considerable disruptions to the European automotive industry, as a result of the Russian invasion of Ukraine. NORMA Group’s business in this area grew by 9.5% over the year. The main driver of this growth was higher selling prices, which NORMA Group used to compensate for inflation related price hikes for raw materials and intermediate products. In the area of standardised joining technology for distributors and wholesalers, sales were down in FY 2022, falling by 4.3%. The sluggish business was due in part to capacity bottlenecks at some production sites, which were countered with efficiency measures and an increased level of interdisciplinary cooperation.

As for the Asia-Pacific region, NORMA Group grew by 3.9% with sales of €179.6 million. Restrained development in this region was primarily due to the weak automotive business in China as a consequence of the prolonged Covid-19 lockdowns in that country. In the area of standard joining solutions, the region grew by 6.6%.

As to the forecast for the financial year of 2023, NORMA Group anticipates medium, single-digit organic group sales growth, with the management board expecting an adjusted EBIT margin of around 8% for the year. The targeted figure for net operating cash flow is around €70 million.

The NORMA Group supervisory board has appointed Guido Grandi (pictured right) as the future chairman of the management board and CEO of NORMA Group, effective 1 st June 2023. He’ll take over from current acting interim CEO, Miguel Ángel López Borrego, who, in turn, will resume his position as a member of the supervisory board.

Günter Hauptmann, chairman of the supervisory board, said: “We are delighted to gain a distinguished leader in Guido Grandi. With his extensive experience in the transformation of companies, he is the right candidate to position NORMA Group for sustainable, profitable growth in all business areas.”

Guido Grandi has many years of management experience in Germany and the US. Most recently, he was CEO of WKW, where he was, among other things, responsible for the realignment of the company into divisions, comprehensive refinancing and the acquisition of new business. He is a German citizen and graduate mechanical engineer with focus on aerospace engineering and MBA. He began his career as a development engineer at Ford Werke AG and has profound experience in supply chain management.

CEO-designate Guido Grandi noted: “NORMA Group’s mission critical joining components and efficient water management products, as well as its development expertise, are highly valued by customers worldwide. I am very much looking forward to the task of optimally aligning the company with the dynamic requirements of customers and markets.”

For interim CEO Miguel Ángel López Borrego, Günter Hauptmann expressed thanks on behalf of the supervisory board, for recent achievements, ensuring continuity in management, and initiating important improvement measures on which Mr Grandi will continue to build.

With the strength of our concrete screws. The only thing we don’t know precisely it’s the whereabouts of all our products. But nonetheless we are sure that some are very close to you. WEARENOTNUMBERS.IT

Lesjöfors has signed an agreement to acquire the shares of US spring manufacturer, Tollman Spring Company. Through the transaction, Lesjöfors further strengthens its US presence – following the previous acquisitions of John Evans’ Sons and Plymouth – and complements its industrial spring offering in the USA.

Founded in 1945, Tollman is a manufacturer of industrial springs with a well established market position. Its diversified customer base comprises more than 500 customers, mainly in the industrial, electrical, defence and firearms, as well as automotive markets. As with recently acquired Plymouth, Tollman, with some 100 employees, is located in Bristol, Connecticut, enabling seamless integration into the group.

The acquisition also enables other opportunities for profitable growth, such as purchasing coordination, cross-selling, as well as resource and knowledge sharing with Lesjöfors’ other US companies, especially with Plymouth, because of its close proximity. Like Lesjöfors, Tollman Spring Company has longstanding customer relationships, high-levels of technical expertise and a strong emphasis on tailored solutions.

Ola Tengroth, CEO at Lesjöfors, commented on the acquisition, saying: “Through this transaction, we increase our revenue in the US by around 30%, meaning that Lesjöfors now has a significant presence in the region. Tollman is a well managed company, which has made significant investments in recent years and we see

ample potential to accelerate revenue growth through Lesjöfors’ sales network.”

After the transaction, Tollman’s current owners, Rick Zink, Tim Dudzinski and Lisa Barnes, will remain operational during a transition period. The current plant manager, Matt Zink, will be promoted to CEO and continue to develop the business and, in-line with Lesjöfors’ decentralised organisation, Tollman Spring Company will continue to operate under its own brand and management.

Matt Zink commented: “… I would like to thank all our employees who make sure we continuously evolve as an organisation. We are all excited to join forces with Lesjöfors and we are convinced that the transaction will strengthen both companies and unlock multiple opportunities for future growth.”

Adhesives specialist, Techsil, a company within the Diploma Group, has acquired the trade and assets of Eurobond Adhesives. Techsil has been aware of Eurobond for some time and says the two companies are a great strategic and cultural fit, sharing similar values, business models and end user markets.

Formed in 1984, Eurobond Adhesives has been a very successful business under the leadership of Simon Dearing, operating with an onus on outstanding customer service and excellent products. However, Simon felt it was the right time to sell the business and find the right trusted partner to help support long-term growth – with the backing of a larger resourced adhesives’ group.

With a technical sales interface team established to smooth the acquisition, this augments Techsil’s broad technical adhesive offering with the focus on adhesive, potting and thermal management solutions for the manufacturing sector and introduces the company to some attractive new customers and market segments, such as sign, glass and sheet metal bonding, amongst others.

Since 2021, Techsil, which was founded in 1989 with a focus on distribution of technical and high performance silicones, has been part of Diploma’s ‘controls’ business unit, which distributes into the speciality adhesives, wire and cables, interconnect products, and specialty fasteners segments. The company has grown to encompass many more specialist adhesive technologies without losing its core reputation for excellent customer service. The company follows a problem solving engineering and design led approach to finding the right adhesive and sealant solution for its customers.

SPIROL has announced that Ford Aerospace Ltd – based in South Shields, UK, and specialised in the manufacture of high precision metal components and subassemblies for the aerospace, industrial and high technology sectors – will be joining the SPIROL group of companies.

With a legacy spanning 75 years as an expert in fastening, joining and assembly, SPIROL’s well established global footprint will take the UK-based Ford Aerospace’s products to a wider international market. In addition, one of SPIROL’s core principles is to continuously reinvest back into the business to ensure long-term, enhanced success and better serve its customers. This principle is also firmly held by Ford Aerospace and therefore the synergies in markets, products, history, and approach to providing value to its customers, ties SPIROL and Ford closely together.

Speaking about the sale, Chris Ford, managing director at Ford Aerospace, commented: “Ford Aerospace is, and always has been, here for the people, especially our dedicated and skilled team, and it was important that any new Ford Aerospace owner share the values that have been at the heart of the company for over 100 years. Our two companies have a long history of working together, dating back to 1980 where SPIROL licensed a specialised manufacturing process from Ford Aerospace, which is still in use today. SPIROL respects Ford’s strong position in the UK market and our product manufacturing knowledge. SPIROL and Ford’s approach to its employees and its customers align wonderfully and I am excited to see our strong business carry on as part of the successful SPIROL group.”

Ford Aerospace’s technical skills in ‘space compensating’ management – the production of laminated and solid shims that ensure fast, precision tolerance compensation – used on products such as fuselages, gearboxes and movable components – was a key

offering that attracted SPIROL. These solid and laminated shims enable clients to reduce stock of individual shims and offers the option of ‘sizing’ a particular shim, by adjusting the shim pack to the desired thickness on assembly. These products simplify the assembly process while simultaneously reducing the overall cost of the assembly.

Ken Hagan, a division president at SPIROL, said: “SPIROL is an engineering, manufacturing and sales driven company, and as such we seek to grow and expand in our product space – where appropriate. This includes acquiring and holding exceptional companies that fit well with our overall business, global strategy and culture of excellence. We are excited to have Ford Aerospace join SPIROL and to be able to offer a more complete solution to our customers in Europe and beyond. We anticipate running Ford as a standalone business unit within the SPIROL group of companies. By combining the capabilities of both companies, our objective is to enhance our value-added offering to our customers both in technical expertise and products.”

Ideal Tridon Group, a leading global manufacturer of clamping, coupling, and support products, has announced the acquisition of Advanced Couplings Limited (ACL) – a manufacturer and supplier of stainless steel clamp type tube connections for the food, pharmaceutical and associated process industries.

Shaun Henry, sales director at Advanced Couplings Limited, explains: “We are very excited for our partnership with Ideal Tridon –with its commitment to service and dedication to quality making it a great fit with ACL’s mission. We know that our customers will benefit from the combination of our companies, allowing us to leverage Ideal’s existing global footprint, product line and engineering capabilities. We are proud of the reputation that ACL has earned over the past 35 years and will be able to continue to strengthen our capabilities to better serve our customers.”

Ideal Tridon serves a diverse set of end global markets by offering a broad portfolio of highly engineered clamp, coupling and strut support systems. This is the most recent acquisition for Ideal Tridon, uniquely positioning the combined companies to serve European customers with an unmatched industrial product portfolio.

“We are thrilled to have ACL join our Ideal Tridon family,” said Rick Stepien, CEO of Ideal Tridon. “Bringing our companies together will allow us to expand into new geographies and extend our portfolio offerings into new and existing markets.”

From June 2023, BTI and the Berner Germany construction division will become the new brand BTI by Berner – and at the same time one of the largest B2B trading companies in the construction industry on the German market.

In the future, around 1,000 employees will provide building trade customers with fastening materials, tools, chemicals, work clothing and many other products and services. In the field of individual system solutions for roof and window installation, as well as for fire protection, BTI by Berner will be one of the market leading specialists.

“We are joining forces in the construction segment in Germany and thus strengthening our market position. Our construction customers benefit from a comprehensive expansion of the product and service range. By having access to each other’s top products, our sales department is now in a position to offer even more comprehensive problem solutions on-site at the customer’s premises in the future”, underlined Christian Berner, CEO of the Berner Group.

Until now, BTI and Berner’s construction division have operated separately on the German market. From June onwards, BTI by Berner customers in Germany will be able to obtain everything from a single source. BTI scores with customers above all in the areas of sanitary heating, air conditioning and electrical installation, roof and window installation, wood connection technology and fire protection. The construction division of

Berner Germany is strong in construction chemicals, metal construction, tools and DIN parts.

The decision is part of Berner Group’s growth strategy in the construction segment. In order to achieve this goal, the company has invested in the expansion of logistics; in specialist training offers for employees; and in the expansion of IT and the product range. “Bundled and united, we will also massively accelerate and consistently continue the digital transformation. The team has worked hard together to achieve this, which is why we are now one of the leading medium-sized companies in Europe when it comes to transformation and digitalisation of the business model,” emphasises Christian Berner.

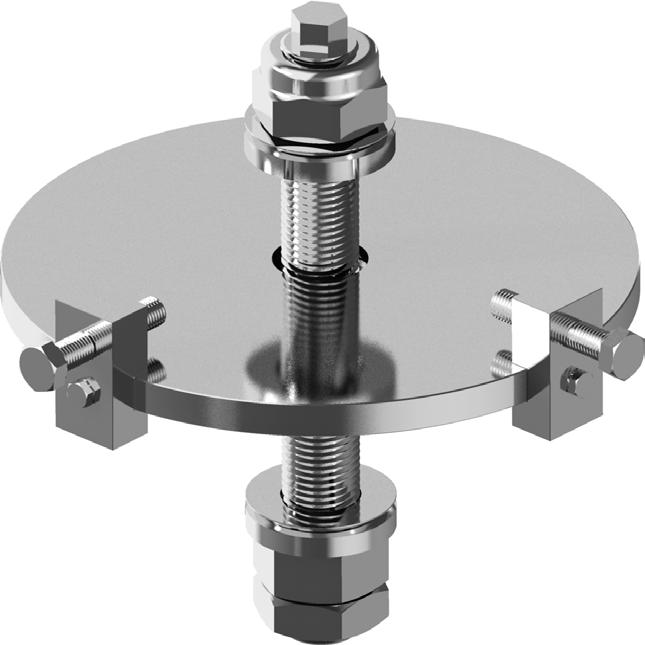

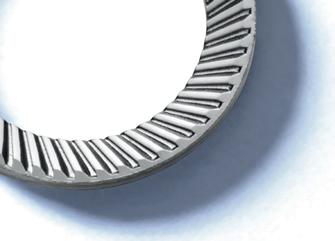

Tension Control Bolts Ltd (TCB) states it is better placed than ever to meet demand, following significant investment in its production, warehousing and Quality Assurance Laboratory – with every aspect of the business geared up for increased demand from discerning customers globally.

Firstly, TCB’s new warehouse has created an additional 9,000 pallet spaces. There has also been major investment in a new purpose built QA laboratory at its UK headquarters in Wrexham, including the recruitment of technical engineering roles and the commissioning of updated test kits to carry out tensile strength tests under wedge, core hardness, pre-load and carburisation tests, which the company points out not only meets but also exceeds the mandatory European and British standards. As always there is also full traceability with 3.1 certification now having additional detail, providing the related assurance in a transparent and comprehensive manner.

With the investments in its new QA laboratory, TCB is inviting all customers to see the laboratory and capabilities first hand. Recent visitors include a project team from Laing O’Rourke who are building ‘The People Stadium’; the new home of Everton football club, with over 30,000 TCBs being supplied to that stadium alone.

“As well as the traditional core markets HRC and TCBs derived from – structural steel, highways and rail infrastructure – demand from the nuclear and wind energy sector is also up,” points out TCB. “In recent years we have also seen a surge in demand for specialist rail products. For many years TCBs have been installed in safety critical connections, connecting trains and carriage, mitigating against train derailment, with related niche applications including fixing bogey pins, drivers cabin, side panels, as well as carriage panel connections.”

Thanks to Norm Fasteners’ high-tech manufacturing skills and 50 years experience in cold forging, complex geometries are not difficult to produce anymore.

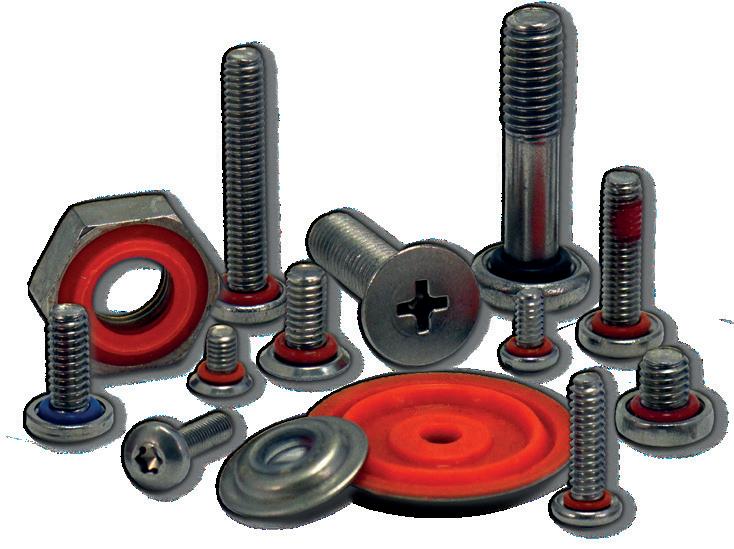

TFC Ltd, an AFC Industries Company, has added to its portfolio of services and products with the acquisition of EAP Seals. This move strengthens TFC’s position as a leading provider of Vendor Managed Inventory (VMI) solutions and technical engineering products.

EAP Seals is a leading distributor of rubber sealing products, including O-rings, gaskets and associated technical products. With almost 50 years’ experience in the industry, the business has strong and long-standing relationships both with its suppliers and customers. The business’s specialty is the O-ring, which it supplies in a range of materials including nitrile, genuine DuPont Viton, EPDM, silicone and high value chemically-inert perfluorelastomers. Alongside its product offering, the business has established complementary services including degassing, bespoke vulcanised joint manufacturing, and a bagging and barcoding service.

EAP Seals states it has one of the most varied stockholdings in Europe, and offers an individualised and personal service to its customers across several industries, including the oil and gas, food and beverage, energy and power, aerospace and defence, automotive, pharmaceutical, petrochemical, process engineering and water industries. EAP’s high-quality products are used in sealing applications in difficult environments, such as those with high temperatures and those subject to aggressive chemicals.

“The two businesses have a clear synergy, not only in their customer base but also in their commitment to delivering quality products with excellent customer service,” said Morgan Burgoyne, president of TFC. “We expect these to be popular products — there has always been strong demand for sealing products across the UK manufacturing landscape.”

Morgan adds: “Bringing EAP Seals into the TFC brand will help us better serve our UK manufacturing customers, by giving us the ability to supply seals direct from an in-house UK source.”

Dean Oliviero, managing director of EAP Seals, added: “For the team at EAP Seals, working with TFC feels like a natural fit. It opens new avenues with our existing customer base and means we can bring our 45 years of industry experience to TFC’s customer portfolio.”

EAP Seals will continue to be run by its current management team and operate out of its existing premises in Heywood, Greater Manchester, UK.

Qualified and committed human team

More than 12.000 references

E-Shop service 24 h. 365 days a year

ESHOP SERVICE

CHAVESBAO, YOUR GLOBAL PARTNER

A new scholarship programme, the Hilti IMD MBA Scholars Programme, which aims to attract more MBA applicants with a background in science, technology, engineering, and maths (STEM), and encourage the pursuit of leadership roles in STEM professions, has been launched by global construction industry player, Hilti, in collaboration with the International Institute of Management Development (IMD).

Hilti and the Hilti Family Foundation Liechtenstein have pledged CHF 3 million (€3.05 million) to establish the Hilti MBA Scholars’ Programme fund, which would make up to CHF 300,000 in scholarship funding available, annually, over 10 years. The objective is to support 60 Hilti IMD scholars over the period by covering 50% of their tuition expenses. Successful candidates are required to have an academic background and a passion for STEM subjects and need to convince IMD of their ambition and ability to use their education to pursue a leadership role in STEM professions.

Jahangir Doongaji, Hilti CEO, said: “A competitive MBA scholars’ programme aims to support the brightest MBA candidates from around the world. The new Hilti IMD MBA Scholars’ Programme also aims to nurture talent and encourage new voices, views, and perspectives, to pursue leadership roles in STEM industries.”

The two partners have worked together for many decades to develop customised educational programmes and research projects. In 2000, Hilti provided funding to establish the Martin Hilti Professorship in Marketing and Change Management at IMD. Since then, the Hilti Chair, held by Professor Seán Meehan, has been closely linked to IMD’s MBA programme. MBA graduates have worked with Hilti for decades as part of their consulting assignments, and many IMD graduates have become Hilti employees.

To further strengthen the connection between Hilti and the MBA programme, the new Hilti Chair will be filled by the Dean of the MBA programme at IMD. “It will put Hilti at the heart of the MBA programme by creating a highly visible, direct and permanent link,” said Professor Omar Toulan, current Dean of the MBA programme.

BRUGOLA WILL BE THERE

by John Wolz, editor, GlobalFastenerNews.comThe US Supreme Court declined to hear a challenge to US steel import tariffs imposed in 2018 under former President Donald Trump, Reuters reports.

John Kruzel of Reuters writes: “The justices turned away an appeal by a group of US-based steel importers of a lower court’s ruling rejecting their challenge to the Trump administration’s imposition of tariffs under a Cold War-era trade law.”

In March 2018, Trump ordered a 25% tariff on steel imports from most nations and a 10% tariff on aluminum imports – a policy he touted as defending US national security – and largely maintained by President Joe Biden.

The tariffs were justified after the Commerce Department reported that steel and aluminum imports “threaten to impair the national security”, as defined by Section 232 of the Trade Expansion Act of 1962.

A subsequent Federal Reserve study found that while the tariffs reduced competition for some industries in the domestic US market, this benefit was more than offset by rising input costs and retaliatory tariffs.

The Industrial Fasteners Institute warned against the 232 tariffs. “In our view, the negative effects on downstream consumers of steel and aluminum far outweigh any benefits that may be afforded to the domestic metals industry,” the IFI stated in an official letter sent to the White House in early 2018. “Specifically, we suggest that the negative impacts from these remedies will do more harm than good to our economy and national security than they will provide benefits to the domestic metals producing industries.”

A US federal appeals court upheld higher tariffs on some imported steel products, reversing a lower court ruling that overturned the Trump administration action, Reuters reports.

Jonathan Stempel for Reuters reports: “Tuesday’s 3-0 decision by the US Federal Circuit Court of Appeals in Washington D.C. covers imports of steel derivatives, such as nails and fasteners, that were subjected to 25% tariffs in a January 2020 proclamation by then President Donald Trump.”

At the time, Trump said the new tariffs were needed after capacity utilisation had not recovered for an extended period. China retaliated with matching tariffs on an equal amount of US goods, embracing the largest trade war with the West in decades.

In 2021, the US Court of International Trade ruled against the new tariffs, saying the White House missed statutory deadlines to impose them. However, the appeals court said a subsequent ruling allowed presidents to impose “contingency-dependent” tariff increases to fulfill their original national security objectives, assuming those objectives remained valid.

Trump imposed the new tariffs to “close a loophole exploited by steel derivatives importers ... to address a specific form of circumvention”, Circuit Judge Richard Taranto wrote.

The Biden administration supported upholding the new tariffs. The tariffs had been challenged by importers Huttig Building Products, Oman Fasteners and PrimeSource Building Products, which said Congress never granted the president broad power over foreign trade to impose them.

The case is PrimeSource Bldg. Prods. v. United States, 2023 BL 38181, Fed. Cir., 2021-2066, 2/7/23.

The Industrial Fasteners Institute (IFI) presented its 2023 Soaring Eagle Awards to Bob Hill and Henry Hogue. Nicholas Lessnau, account manager for MNP Corporation, also received the IFI’s Joe Greenslade 2023 Young Leadership Award.

The IFI Soaring Eagle Service Award recognises individuals who have contributed outstanding time and effort in the leadership of the IFI and entire industrial fastener industry. Bob Hill was the IFI’s long-time industrial products division manager, board member and former chairman.

The Soaring Eagle technology award was presented posthumously to Henry Hogue (1898 – 1953), who generated ten patents for fastener manufacturing and equipment design and had been president of Tru-Fit Screw Products.

The technology award recognizes individuals who have made significant contributions to the technological advancement of the industry. Contributions may be through work on fastener standards committees; the publication of widely acclaimed principles or documents; and/or through the development of fastener-related equipment, products or processes, which

have been widely acknowledged as advancements in fastener technology. Hogue’s most impactful inventions were apparatus for wire drawing and separately for nut manufacturing. His innovations led to important and enduring advancements in fastener manufacturing technology and equipment design. These advancements represent a foundational pillar of the state of the art of cold forging and fastener manufacturing today.

Greenslade was IFI technical director from 2007 to 2015. The Young Leadership Award recognizes individuals who, early in their career, have contributed in a significant way to the fastener industry. One of Greenslade’s passions was to mentor and encourage young people to reach their professional potential.

Nominations for 2024 Young Leadership or Soaring Eagle Awards may be submitted at: IndFast.org/info/award.asp

Fasteners and components manufacturer LoneStar Group, headquartered in the West Midlands, UK, has been acquired by private equity firm Epiris LLP. Terms of the deal were not disclosed.

LoneStar Group manufactures and supplies high performance fasteners, sealing products, precision engineered components and pipeline packages for the world’s industrial and energy markets.

Employing more than 1,000 employees across 13 businesses, LoneStar operates facilities in the UK, China, Romania, India, Singapore, Dubai, the USA and Australia.

It supplies high performance fasteners to major OEMs, distributors and end users in 100 countries. The group maintains a US$48 million global stock inventory of finished, semi-finished and raw materials to supply all sizes of SAE, ASTM and ISO fasteners.

Fastener companies owned by LoneStar include AmeriBolt, LoneStar Fasteners and Walker Bolt.

“LoneStar is typical of the kind of business in which we seek to invest,” Epiris Partner Charles Elkington told GlobalFastenerNews.com. “It is a high-quality business; a global market leader with scale and clear competitive differentiation.”

He added: “It operates in attractive markets, benefiting from growing energy demand in both traditional and renewables. Most importantly, it is one which we believe we can transform by bringing our trademark focus on strategy, operational excellence and M&A.”

Gene Simpson of Semblex Corporation is the new chairman of the Industrial Fasteners Institute and Dan Curtis of MacLean-Fogg Company is vice chair for the 2023-24 term. Jeff Liter of Wrought Washer Mfg Inc is ex-officio chair.

Founded in 1931, the IFI represents North American manufacturers of mechanical fasteners, formed parts and key suppliers to customers, government, and the public, and looks to advance the competitiveness, products, and innovative technology of member companies in the global marketplace.

Taiwan’s fastener exports reached the third highest volumes in history in 2022, at 1,665,300 tonnes, while their value exceeded US$6 billion for the first time, reaching US$6.355 billion (€5.77 billion), a record high reports Fastener World.

Tu-Chin Tsai, chairman of the Taiwan Industrial Fasteners Institute (TIFI), highlighted that the second half of 2022 was affected by the negative global steel economy and although the number of orders received by manufacturers was mildly affected, resulting in a slightly lower export volumes than the previous year, export values exceeding the US$6 billion mark for the first time was mainly because the Taiwanese fastener industry has gradually succeeded in transforming to the development of higher value-added products, such as automotive screws. This resulted in a higher average unit price.

Recently, with gradual improvements to the international steel economy and the market situation in Europe and the USA, this has made it favourable, according to Tu-Chin Tsai, for manufacturers to receive orders. Beginning in May this year, the fastener industry is expected to recover and export orders should improve, offering a positive outlook for the fastener export market in 2023.

TIFI also pointed out that the average export price of Taiwan fasteners in November 2022 rose to a record high for a single month, at US$3.98 per kilogram. This slipped back to US$3.94 per kilogram in December 2022, though this was up 4.78% from the same period in 2021.

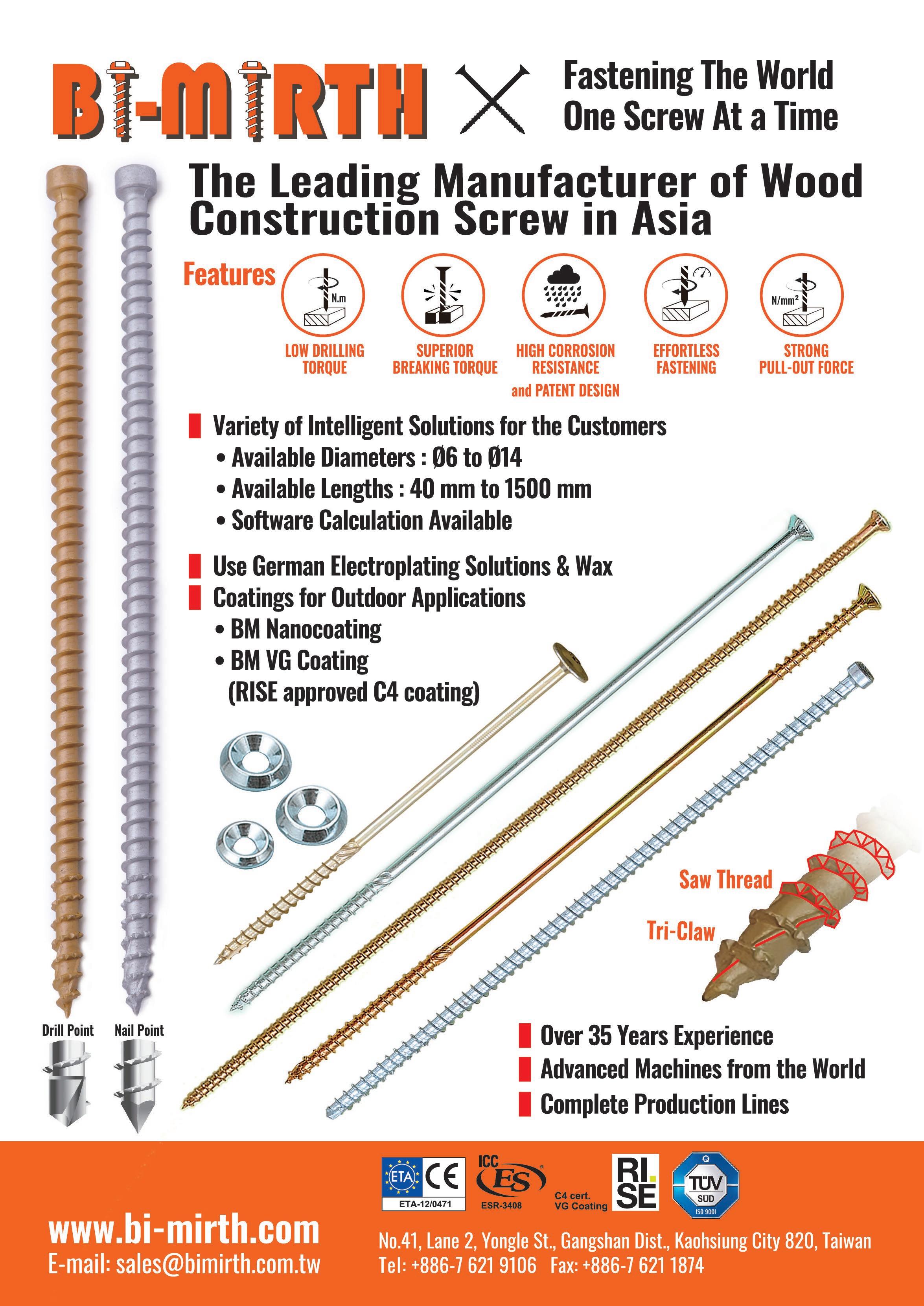

Bi-Mirth, a specialist in the R&D, production and export of structural wood and concrete fasteners, has introduced three special products – the hardwood screw, timber-concrete connector screw, and A2/A4 stainless steel wood screw – all available for customised production.

Traditionally, timber constructions usually use softwoods, but recently more and more countries are using hardwood as a building material. Hardwood uses less surface area to achieve equal or higher performance than softwood. Bi-Mirth points out that regular screws could break when drilling into hardwood, due to its high density, which is why the company conducted intensive research on hardwood and rolled out a screw made with a specific material and heat treatment technology to cope with the wood’s high density. This special screw is characterised by low insertion torque and no breakage during installation.

When it comes to timber-concrete connector screws, wood’s flexibility offers good shear resistance, while concrete performs better in resisting pressure – with the use of both concrete and timber in the renovation process bringing out the advantages of both materials. In addition, their combination creates better acoustic effects in a building. Suited for such applications, Bi-Mirth timber-concrete connector screws offer a suitable solution for timber-concrete connection – preventing displacement between the two materials and providing excellent shear resistance.

As for the new A2/A4 stainless steel wood screw, these are now part of the BM Quickdrill wood screw series, with stainless steel a new material option for the range – with A2 304/305 and A4 316 stainless steel units delivering resistance against high salinity and acidic environments. High rust and corrosion resistance also makes these screws ideal for use in harsh environments near the sea.

Source: Fastener World

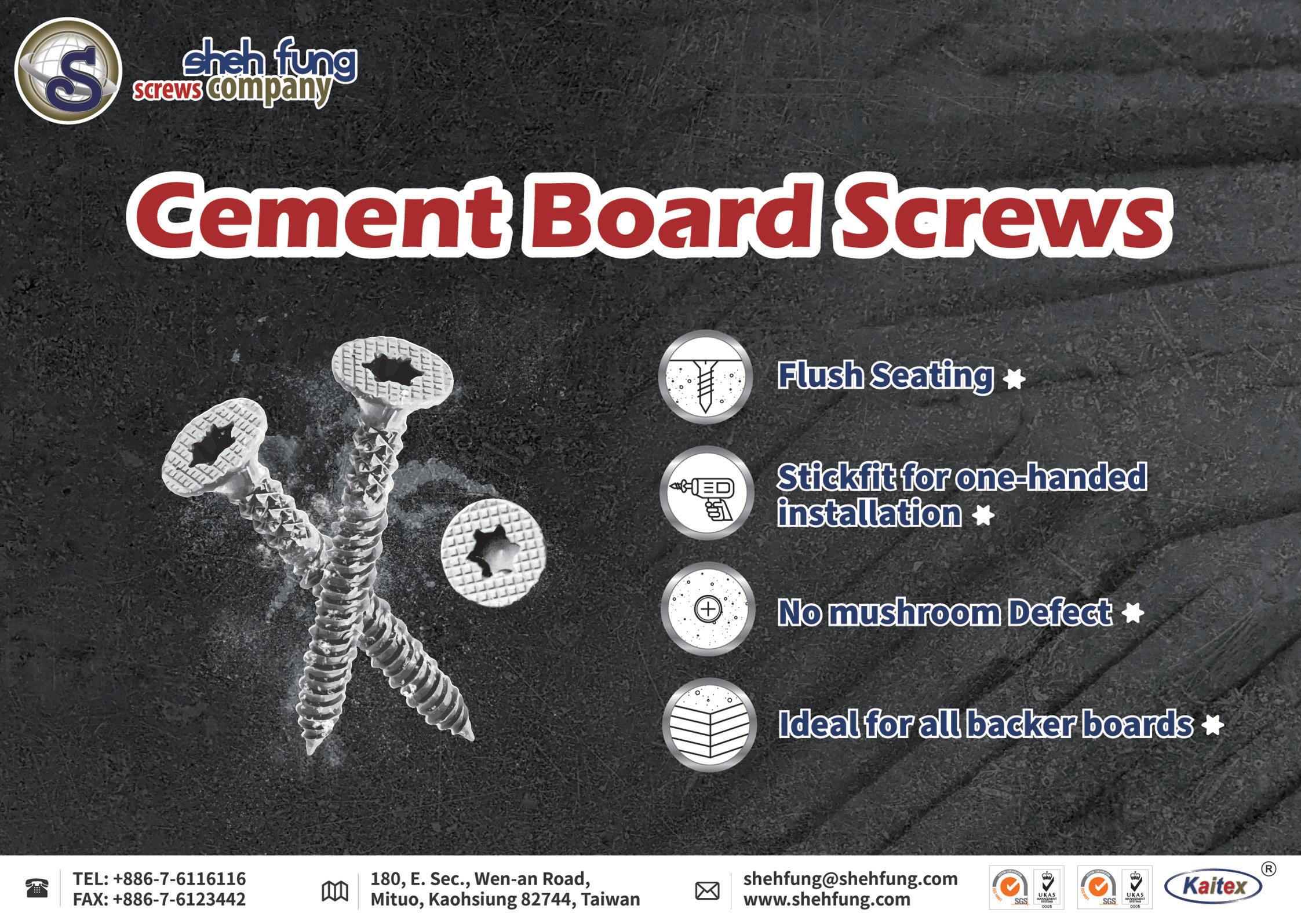

Having begun construction on its over 20 hectare Vietnamese plant last December, Sheh Fung Screws expects it to be completed this August/September and become operational in Q4 of 2023. The capacity of the Phase 1 plant will be around 800 tonnes per month, reports Fastener World.

According to the company’s president, Terry Tu – who, along with General Manager Kent Chen and the company’s task force, decided to open the new Phan Thiet City plant back in 2019, the first overseas facility for the Taiwanese screw maker and distributor –Vietnam has fewer uncertainties than other Southeast Asian countries and, together with its young labour force and easy access to raw materials, has attracted investors from many countries.

Terry Tu explained: “The Phase 1 plant is a complete replica of our Taiwan plant, with heading, thread rolling, electroplating, heat treating and coating processes.” In the past, it’s understood the Taiwan plant mainly accepted orders for high-end products in small quantities and for diverse items, but not orders for lower end ones. “In the future, with the addition of our Vietnam plant, we can also accept orders for large quantities and specific items. Moreover, Vietnam’s advantageous geographical location could help expand our sales to the neighboring ASEAN countries and we could also benefit from the Europe-Vietnam FTA to expand sales to Europe.”

Terry Tu continued: “In the future, our Vietnam plant will also be upgraded towards intelligent automation. At present, we are also actively training staff for our Vietnam plant in Taiwan, so that we can seamlessly connect with the Vietnam plant after it is officially launched. I hope to lead Sheh Fung to play a leading role and attract other Taiwanese manufacturers to join us.”

ALL WITH WORLDWIDE PRODUCT LIABILITY INSURANCE!

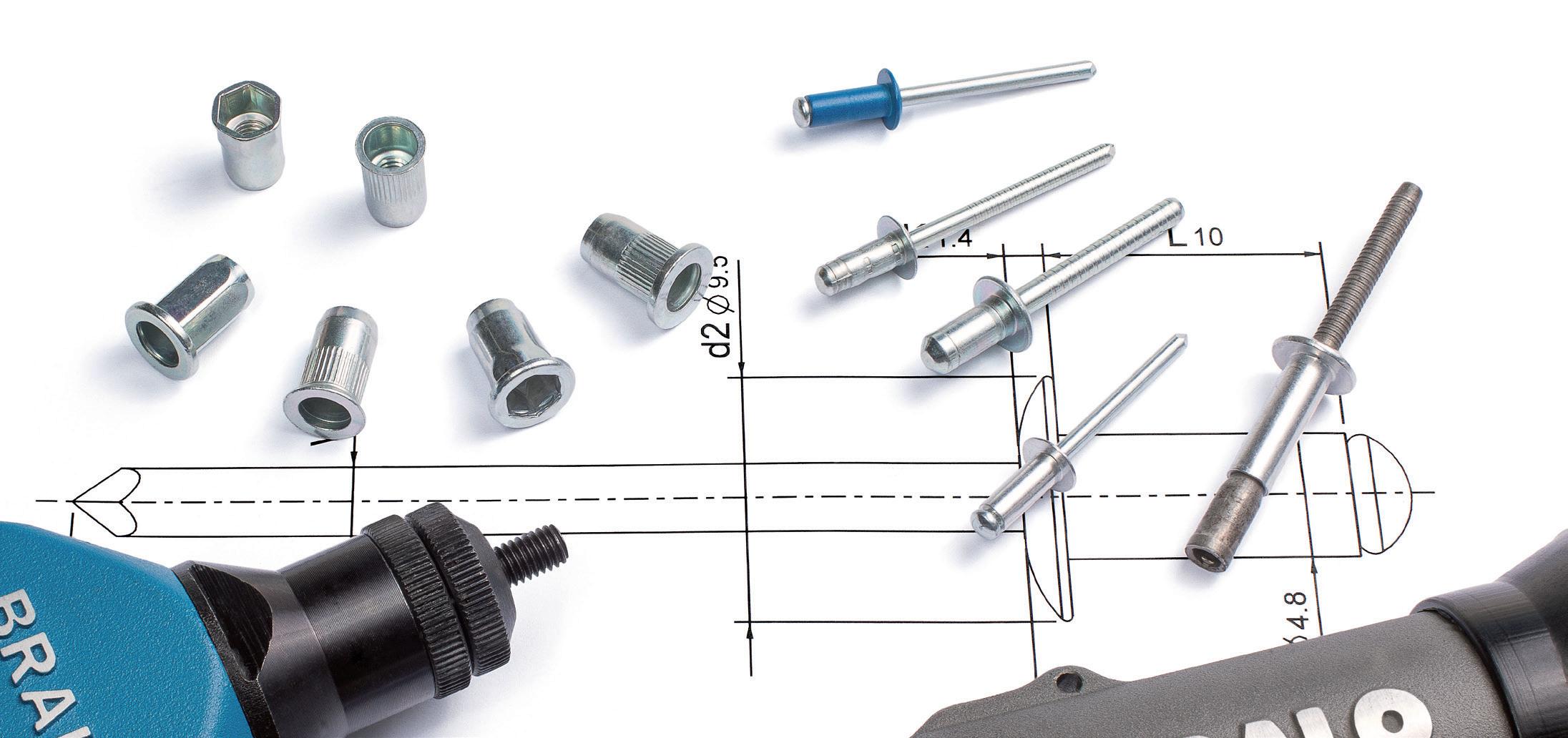

Rivet manufacturing company Special Rivets Corps (SRC) has started production at its new 45,000m 2 facility in Thailand, where it has set itself a future target of making 300 million rivets per month.

SRC chose to set-up a factory overseas in order to serve the world’s demand for fasteners; expand its client base; and exploit the ambitions of Thailand’s Prime Minister to “make Thailand the top automotive manufacturing nation in Southeast Asia”. In addition, with many clients who identify Thailand as a key market in Southeast Asia, SRC’s new plant will be able to serve such clients locally.

The company said the main task of this plant, which began construction in 2021, is to increase production of the company’s existing blind rivet product line. New equipment has been purchased in large quantities to improve quality and develop flexibility for small quantity and diverse production to meet the needs of more customers. SRC highlighted that when lead times becomes a key factor, immediate delivery is far more important than lower prices.

Although production has now begun, the new plant’s floor is currently only 50% in use, with about 110 sets of automatic forming equipment operational, so far. The target of 300 sets will be added continuously. Through automation,

manpower is also streamlined and work shifts between the plant’s departments are rationalised. At this stage, SRC is aiming at a monthly capacity of 100 million rivets from the plant, but planning to increase to 300 million units in the future – at the same time providing clients with better quality and cost performance by reducing costs.

SRC is dedicated to the research, production and sales of a full range of blind rivets, rivet nuts and high-quality riveting tools. The company has also invested in a factory in China and today has evolved into one of the largest manufacturers of blind rivets in Asia, with a monthly capacity of over 500 million units of blind rivets and 100,000 units of high-quality riveting tools. A fully automated warehouse and index system also ensures accurate and rapid order fulfillment. Established 40 years ago and with extensive R&D manufacturing and sales experience, SRC has sold its products to more than 150 countries worldwide and accumulated more than 700 customers.

Source: Fastener World

A specialist in the development and production of various screws and parts, Rexson Fasteners Inc is now operational at its new Guanmiao, Tainan City, Taiwan, facility – recently set-up in response to growing global demand for fasteners and in order to optimise its services.

Rexson’s original factory in Guiren, Taiwan, will continue to operate and it is expected that with the synergy of the two plants in Guiren and Guanmiao, the company will be able to provide the best quality products and services to meet the diversified needs of global customers.

The main purpose of the Guanmiao plant is to add to existing capacity of the Gueiren plant, which is about to reach maximum levels. In addition to expanding production capacity, the new plant, operational at the end of March, will also, according to Kevin Wu, general manager of Rexson, introduce equipment and machines with specific differences to meet customers’ needs for a wider range of products and to enable faster and more efficient delivery of products.

The new factory area of 2,380m 2 is clearly defined with dedicated areas for such activities as 1 die 2 blow forming, multi-blow forming, thread rolling, sorting and packaging, including stainless steel screw sorting and packaging areas, which are new highlights from the old factory. Equipment has also been upgraded, including the introduction of 1

die 2 blow rounding and shearing machines, 5 die 5 blow forming machines, thread rolling machines and several 1 die 2 blow thread rolling machines, which can all help provide customers with improved and consistent quality products. With the expansion of production capacity, and more brand new equipment, Rexson expects to be able to improve the development of special screws and the manufacturing of stainless steel/carbon steel products. With the addition of the new plant, the monthly production capacity of stainless steel products will also reach 80 – 100 metric tonnes.

According to Kevin Wu: “Our stainless steel products are used in a wide range of industries and can significantly reduce maintenance costs. We will also focus on the EV, stainless steel and construction screw markets in the future, as demand trends continue.” He said that with current market uncertainties, the company would first make physical adjustments to meet future challenges and, more importantly, provide customers with faster and better quality service to meet demand.

Source: Fastener World

you know him? are too costly? too far away?

Do you think Japanese fasteners... Challenge Socket boy and get a quote!

After overcoming the 36 million tonnes barrier in 2021, the Brazilian domestic production sector for steel dropped 5.84% in 2022, with 33.964 million tonnes produced in total.

Whilst there was this drop, the Brazilian domestic steel production sector has averaged around 33.7 milion tonnes per year over the last decade, with 2021 a record high.

In fact, over the last five years the Brazilian domestic steel production sector has produced a similar level to the previous five years. During 2013 – 2017 the total production achieved was 167.659 million tonnes; while the total for 2018 – 2022 was 169.426 million, just above 1% growth.

Although it is too early to draw conclusions, the results for the first few months of 2023 are 2.78 million and 2.53 million tonnes produced respectively, indicating an annual average of around 31.8 million.

Source: www.acobrasil.org.br/site/en

The recent Fastener Fair Global show in Stuttgart, Germany, marked the debut from Brazilian manufacturer Belenus on the international stage.

One of biggest and most important companies within the Brazilian fastener market, as well as in South America, Belenus manufacturers nuts, bolts and special parts and has more than 1,900 direct employees.

Recently the company had experienced some additional international business, which led to it taking a big step and confirming its presence as an exhibitor at Fastener Fair Global.

Ezio Ruocco, vice-president at Benelus, commented: “Last year we had some good experiences within the European market and attracted new business. We also started to travel to new countries and visit fairs – with the reception we received very positive, which made us take the next step and exhibit at the Stuttgart fair for the first time.”

He added: “Overall, the show was good, with only positive points to highlight. We had visitors all the time and the market was excited to have an alternative supplier from Brazil that helps them reduce their dependence on Asia. The only difficult part was making them believe that in Brazil there was a manufacturer with the size, as well as technological and productive capacity of Belenus, which we were quickly able to do.”

In addition to being a fastener manufacturer, with monthly product capacity of around 10,000 tonnes, Belenus has divisions that distribute hardware, tools and various types of equipment. These divisions operate in a unified management model, based on sustainability, which values the reduction of carbon emissions, water reuse and waste recycling throughout the process.

The trade fair NT Expo, the meeting point for the rail sector of Latin America, was held between 28 th February – 2 nd March in São Paulo City, SP, Brazil – with around 4,300 visitors.

Amodest event, the NT Expo could be bigger than it is today, a situation consequently caused by a lack of development by successive governments –dating back to the 19th Century.

Just to compare, the national railway network in Brazil is just 29,000km long, which is less than the 38,000km between 1940 – 1950. Unfortunately, practically all governments have promised to prioritise this sector, but they leave more promises than tracks.

However, since 1992 the sector has made a comeback to receive many private investments, which keep the hope better days are ahead for the rail sector. Today, around 75% of railroads are at the service of commodities such as iron ore, 12% for soybeans.

The only fastener manufacturer attending NT Expo as an exhibitor was J. Lanfranco Amsud, a French fastener company specialised in the production of self-locking split nuts to use in tracks, from dimensions M2 to M48, in Classes 8.8 to 12.9.

“At the NT Expo the highlight was our lines of nuts for critical fastening systems – where there are high levels of corrosion and vibration,” commented Karin Schinasi, Lanfranco global export manager.

Sérgio Milatias, editor, Revista do Parafuso, www.revistadoparafuso.com.br

ALFIRSTE has established itself as a specialist screw and anchor manufacturer who has gained a reputation for its high-quality products and excellent service –enabling it to meet the varying needs of its global customer base.

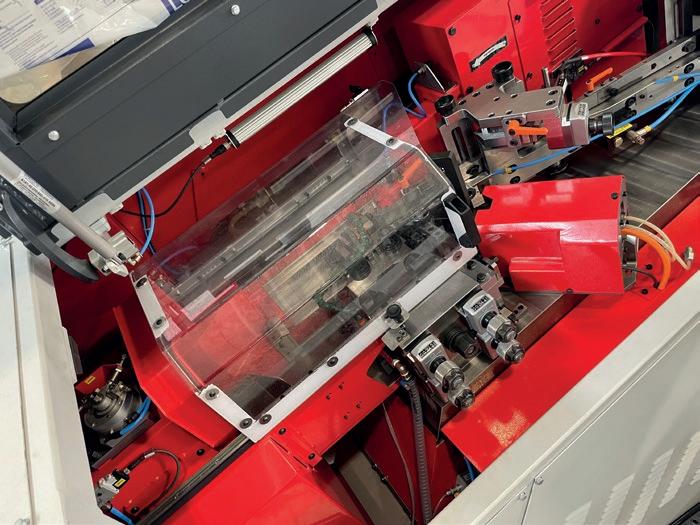

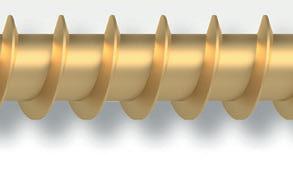

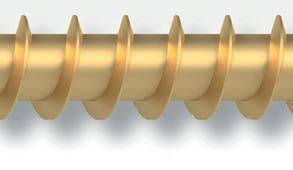

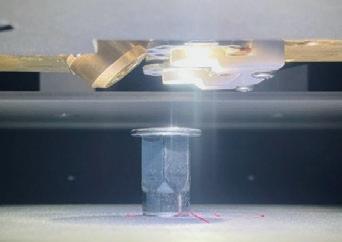

Founded in 2006, ALFIRSTE has developed into an international business with a factory – based in Yuyao, Zhejiang province, China – covering 15,000m 2 and a monthly production capacity of 1,500 tonnes. Within its factory the company uses only the latest production machinery, including heading machines, thread rolling machines, drilling machines, point cutting machines, straightening machines, multi-station machines, as well as other equipment.

This extensive production capability has enabled the company to become renowned for the production of screws and anchors, especially drywall screws, hex head/truss head/CSK head/pan head self-tapping/drilling screws, chipboard screws, construction wood screws, sleeve anchors, metal frame anchors, as well as threaded rods. “Initially, we only produced standard parts,” mentions Michael Wu, sales manager at ALFIRSTE. “However, through the addition of leading experts, and the ongoing improvement of the in-house laboratory, we have continued to grow our product portfolio and now have the ability to develop products in-house.”

In recent years the company has used this technical know-how to develop the production of stainless steel products and bi-metal screws. “We see these two product ranges as a key factor in the future growth of the business,” underlines Michael. “At the same time, we have not given up optimising the production of our carbon steel products to make sure they continue to be competitive within the global market.”

Alongside the development of its product range, ALFIRSTE has also been committed to developing the quality of its products –helping to ensure customers receive only the highest quality. “As a company we continuously look to optimise our production processes to guarantee we are consistently producing quality

includes a salt spray test machine, a high and low temperature humidity box, image measuring instruments, a universal testing machine, a drilling testing machine, a Rockwell hardness machine, a metallographic specimen Mosaic machine, a Vickers hardness machine, a metallographic specimen polishing machine, a FISCHERSCOPE® X-RAY, a torque testing machine, a concentricity meter, a bending measuring machine, a metallographic microscope, a SPECTRO spectrometer, a temperature and humidity meter, as well as the standard callipers, groove depth gauges, torque wrenches, electronic scales and angle rulers.

“Our dedication to quality across every aspect of our business has enabled us to create strong relationships with customers, with our products being sold to customers in around 20 countries, including in Europe and the USA,” points out Michael. “As a business we are always looking to create close partnerships with our customers, which is why we invest a lot of money in participating

During the development of its production processes, expansion of its product portfolio, and continuous focus on quality, ALFIRSTE has always ensured innovation is at the centre of its business, which has been fundamental in the company’s success and growth. “Innovation is undoubtedly a core competitiveness for us,” states Michael. “The expansion of the company cannot be separated from the role of innovation, which in turn depends on investment in the business. The two complement each other, which is why, in order to continue to innovate, you need to continue to invest.”

An area ALFIRSTE is currently investing and therefore looking to innovate is its sustainable development. “Since the establishment of ALFIRSTE, we have looked to serve our customers, employees, and partners, in the correct way. It is the basis for the healthy and sustainable development of the business,” mentions Michael. “The topic of sustainability has become a key factor within every sector and as a business we want to make sure we are meeting the needs of our customers. That is why we are already taking the initiative to adopt cleaner production processes, which includes reducing waste generation. We are also looking at ‘greener’ procurement and how we can work more effectively from an environmental perspective.”

Michael concludes: “Thanks to our sophisticated production equipment, innovative methods of production and material combinations, as well as in-depth product range, we are optimistic about our future place within the fastener industry. We will continue to invest funds and innovate as a business, especially the production of our range of stainless steel and bi-metal screws. At the same time, we will continue to work with our customers and manufacture products with the spirit and heart that has seen us reach where we are today.”

Dr Florian Seidl, part of the supervisory board at Keller & Kalmbach Holding & Co KG, has spent nearly half a century involved within the fastener industry –experiencing every aspect of the sector and its defining trends and advances. With that in mind, Content Director Will Lowry asked for his perspective on how the market has developed over the last 50 years.

You joined Keller & Kalmbach in 1975, nearly 50 years ago. How has the fastener industry changed and grown in this time?

“When I look back, I think one of the biggest differences, when compared to today, is back then both the production and distribution aspects of the market were only national and to some extent, especially within distribution, even regional. Most German companies were not even active across the entire country and especially not across the borders into other countries within Europe.

Over time manufacturers branched out and started to work with customers within the European market, whilst distributors were still predominately national – as distribution was often slightly behind the manufacturers. It wasn’t until the early 1990s that the majority of distributors started to import significantly more and supply customers across Europe.

This type of internationalisation was possible because boundaries between countries had been lowered. The Berlin Wall came down in 1989 and suddenly we had a European market where there were no tariffs between states and imports from other countries were a lot easier.

For instance, at Keller & Kalmbach we imported from Italy very early on, even before my time with the company. However,

in the 1990s a lot of companies started to import from Asia, which really changed the market. This meant distributors were a lot more competitive within the industrial market and could compete with European manufacturers.

Of course, as the market has become more international, the competition has also grown, which has created a pressure on prices within the sector. Until the early 2000s, customers would have to ring around different suppliers to check prices and stock availability. We would have common lists of all German/ European distributors with discounts being given. Today, with digitalisation, customers can compare the products a lot easier, and quicker, and know exactly what stock and prices they can get from suppliers across Europe. This means even though there might be higher demand from an international market, you must be more price competitive and keep an eye on costs to make sure they are under control.

In addition to the internationalisation of the sector, I think another factor that has changed is the quality level of the

products has risen significantly – as has the demands of the customers. For instance, over recent years a lot of customers have decided they do not want multiple suppliers, but rather have one company that is able to supply all the products, especially C-parts, as a Full Service Provider. Naturally this would be a distributor, which led to distributors becoming a lot more important within the supply chain and having to take on a lot more responsibilities – such as providing additional products and services to meet all the requirements. Being a Full Service Provider means you handle literally every aspect of the supply chain when it comes to fasteners. Customers put their full trust in a company and expect them to handle everything.

A final area that has changed is transportation costs, which have significantly reduced over the years. When I started within the sector, transport costs were very expensive, but over the years they have decreased step by step. The reliability and speed of the deliveries has also increased to the point that products can now be shipped within one day, especially within Germany. That means you don`t need many warehouses, a central one is sufficient.”

“With all these changes – internationalisation, digitalisation, Full Service Provider requirements – Keller & Kalmbach has invested as a business to guarantee it is able to go on meeting the needs of customers and this has led to it becoming one of the leading businesses within the market.

Keller & Kalmbach’s turnover is twenty-five times higher than 47 years ago; we have about seven times more employees; and we now have twenty sites in ten countries. To put that into perspective, when I started we only had two sites – both in Germany.

Over this period our market relevance has also undoubtedly grown. When I joined, we were number eight in the German market when it came to turnover size and, today, we are number three and perhaps number one when it comes to the industrial fastener market in Germany.

A fundamental part of this growth has been the markets and customers we have looked to target. At the beginning we supplied the DIY and craftsman sectors, which was our core business. However, around seven years ago we decided to not be as active in that market and instead to concentrate on industry – including machinery, automotive, rail and others such as electricity, etc. We looked to include a lot of technical knowledge and logistic knowledge, which was a big success.

A lot of customers in these segments were also international and not just based in Germany or Europe. This gave us the opportunity to also look to supply each customer location. Of course, in those other markets the plants are independent from the headquarters, so it wasn’t assured. However, by supplying one part of the business, it gave us a better possibility to also supply the others. This is one of the reasons we have looked to move into some of these important countries – to better serve our customers’ different sites, which has led to further growth.

Whilst supporting existing customers was a factor in moving to these specific countries, we also saw further opportunities within the different regions. In our experience it does not make sense to go into developed markets or markets where there are already established competitors, as it makes it very hard to gain a meaningful part of the market share.

This is why as a business we have always looked to move to developing countries, whether it be in Eastern Europe or in Asia, such as China or India. It is only in the USA and Sweden, where we had identified opportunities within the markets, that we

have acquired companies to enter these particular markets. The acquired companies still have a similar market share as before, but we can also supply the Keller & Kalmbach customers as well.”

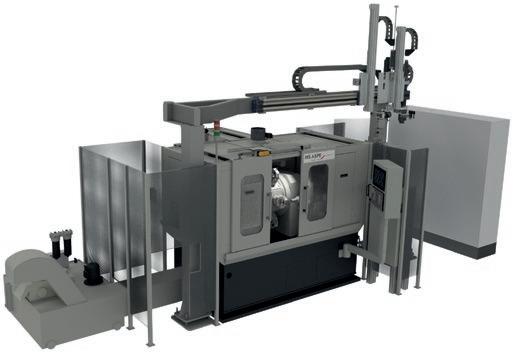

Keller & Kalmbach is renowned for its automated central warehouse, with the first phase of the construction process starting in 2009. What led to the company committing to automation at that point – when it was relatively a new concept for the fastener industry?

“In 1990 we built a semi-automatic warehouse in Munich, Germany, which underlined the advantages automation could provide to us as business. However, it was only ‘half a step’. We still had sites and products in different locations, so we could not fully benefit from the advantages.

With the price of transportation reducing, and the opportunity to bring our different sites together, we decided to have one central warehouse. We bought some ‘green land’ and designed a completely new warehouse that was fully automated and state of the art.

It was a big investment and it was made in 2009, which was during the height of the financial crisis. However, I can say without any doubt it proved to be the right decision and it was such a success that after five years we enlarged it even further – so we could bring all the other warehouses we had within Germany and Europe together.

I think a big advantage at the time was we still had our old warehouse, so we could move over products step by step and ensure the automated warehouse was fully operational before completely moving over to it. Having one ‘big bang’ where you just switch to an automated warehouse from one day to the other is very risky, so we made sure we avoided that scenario.

There is no doubt it was a big investment, and risk to a certain extent, but it has undoubtedly paid dividends and ensures we stay at the forefront of the industry and continue to provide the products and services our customers need.”

What were the steps that Keller & Kalmbach took to handle these different challenges and how did they enable the business to grow?

Another area Keller & Kalmbach has been at the forefront is digitalisation and the introduction of C-parts management systems. What led the business to adopt these systems so early on and how have they developed over recent years?

“In 1987/88 one of our customers, Siemens, came back from visiting Japan and had seen a Kanban system working. They wanted to trial the system at a plant near Munich and offered several suppliers within the area the opportunity to be involved. I heard about it and thought it would be interesting. After talking with them, we decided to go ahead. It was a bold decision and I remember I even had some competitors calling me at the time and questioning why we were doing it and how it would be too costly for it to be implemented fully within the fastener industry. However, I could see there was huge advantages of self-serving systems, with orders fulfilled automatically, so we went ahead with it.

As soon as we started, we had customers who were asking for this type of service, which was initially just a ‘two bin’ system. However, then came digitalisation with barcoding, RFID technology, etc, and we continued to add all of these aspects to help increase processes and make everything more automatic and effective.

This is an area we are continuously working on, for instance we are currently looking at advance analytics to foresee the demand of the customer in the future – with the aim to avoid any stops in production. This has already proved very useful during the global supply problems in Asia last year. As a business we have a huge stock, which can prove very costly, but the advance analytics has been very helpful in these difficult times. This type of extra service is all part of our business – so we can guarantee the customers get the products they need when they need them.

In fact, that is a fundamental part of the market now. Customers do not want to hold as much stock themselves and the manufacturers do not want to hold stock either. So, as the company in between, you need to have the capacity and capital to store it.

At Keller & Kalmbach we look to use digitalisation and C-parts management systems as an opportunity to provide a better service to customers and make it easier for them to buy products. One of our slogans is: ‘You don’t need to care about C-Parts… we care’. Many customers really see it as a huge advantage.”

“One of the big challenges going forward will be regulations, especially on a European level. The number of regulations and requirements have increased significantly, with the supply chain a lot more regulated. The costs involved in handling these new regulations hinders a lot of European industry compared to other parts of the world. I also believe the current political situation could lead to additional tariffs that will make it difficult for distributors to buy from suppliers who offer the best prices.

Another challenge is inflation, which is a big issue. There is a huge uncertainty within the market on whether prices will go down or even up. At the moment, steel prices are going down a little, but general inflation is very high. Wages are also going up as well, so it is unclear what will happen with inflation in the future. For us, and for all fastener companies, it is very hard to bring the higher prices to the customers, especially when it is industrial customers were there are often long-term contracts.

That being said, Keller & Kalmbach will continue to invest in its capabilities and services. We have further plans to automate the central warehouse and we are currently carrying out studies into robotics and how they can possibly play a role.

If you are to continue to grow and develop as a business you always need to be looking at trends and opportunities, so you can check if they will give you an added advantage within the market. At Keller & Kalmbach we have always looked to be at the forefront of the industry and make sure we provide the products and services that guarantee we can take care of every customer need.”

Celebrating its 50th anniversary, Norm Fasteners reports that its innovative solutions, and long-term business partnerships with leading companies around the world, has enabled it to develop flawless products and connections that have been the key to its growth and success.

The value of Norm Fasteners’ vast capabilities and service were underlined to its customers last year, when it was able to continue to provide uninterrupted service to its business partners despite the global supply chain crisis. Thanks to its 14 logistics and sales centres, located in 9 countries, as well as its experienced in-house engineers, Norm Fasteners was even able to increase customers’ satisfaction during this period.

Fatih Uysal, chairperson at Norm Holding, points out: “In a report that the Norm Holding board of directors uses to assessed the structure and operations in the ‘Best Practice’ category, the Corporate Governance Rating of Norm Holding

and all our companies was determined as 9.04 out of 10, which shows how we have been able to meet and exceed customers’ needs.”

In addition to its commitment to its customers, thanks to its development and organic growth oriented strategy, Norm Fasteners has also managed to double its turnover in the last two years using its own production resources. “With our production capacity of 200,000 tonnes, 400 forging machines, 21 heat treatment lines, and the projects that will be initiated, we aim to grow by 20% in 2023,” states Fatih Uysal. “To make this possible we are also progressing with our investments as always to achieve this goal.”

Norm Fasteners recently attended Fastener Fair Global, which took place in March, where it had the opportunity to meet with its customers and examine the market and opportunities together after a four year break. “With our VR experience corner located on our stand, our business partners had the opportunity to visit our production facilities virtually with a 360 degree video,” mentions Fatih Uysal. “This enabled visitors to see our Full Service Provider (FSP) identity, global service network, sustainability vision, and competence in manufacturing complex parts, which helped bring about new collaboration opportunities.”

Fatih Uysal continues: “With successful companies in our group, such as Norm Coating, Norm Tooling and NRM Engineering, we provide end-to-end in-house

production support to our customers through our R&D, engineering, surface treatment, cold forming, tooling, machining, heat treatment, machinery and automation, coating, sorting, packaging, and logistics services. Having further strengthened our production processes with investments, we work with the goal of providing our business partners with a faster, high-quality, costfocused and sustainable service.”

This enables Norm Fasteners to supply solutions that meet the needs of its business partners in various sectors such as automotive, white appliances, aftermarket, wholesaler and agriculture. The company also continuously improves its expertise in the fasteners industry, as well as in different and new product groups – such as hot forging, stamping, turning parts and additive manufacturing. “When these technologies are added to our 50 years of experience in cold forging, advanced technology production infrastructure, and expert engineering teams, we are able to provide a first class service when it comes to production of complex parts,” states Fatih Uysal.

“For instance, with Norm Additive, which operates in the additive manufacturing field, we provide services not only to the automotive industry but also to many different sectors such as aviation, white appliances, machine manufacturing and medical – both domestically and internationally. We can provide engineering and manufacturing support for weight reduction and performance improvement in structural parts of our customers, by providing cost and supply speed advantages compared to traditional production technologies.

We also offer prototyping and series production services through our modular production systems.”

In 2022, through a new sales centre in Canada, Norm Fasteners further added to its sales and logistics centers in Germany, Poland, Romania, France, and the USA –strengthening its logistics network. “Through the new sales centre we will continue to grow rapidly in the Canadian market in 2023, as we did in other countries. We always focus on customer satisfaction to better understand the desires and expectations of our customers and offer sector-based solutions,” explains Fatih Uysal. “We also prioritise our R&D and innovation activities accordingly. For instance, we are proud that our patented products such as HexLight® and NormSelf TM are included in automotive specifications and that we are the preferred fasteners partner of automotive manufacturers as a joint designer.

Fatih continues: “In 2023 we also incorporated the global production and sales license of TRILOBULAR® and REMFORM® of CONTI Fasteners AG into our company. With these licenses, we can also supply fasteners that provide productivity increase and cost advantage –due to their self-tapping abilities in metal parts such as steel, aluminium and plastic applications.”

Now in its 50th year, Norm Fasteners has established itself as a FSP and a

leading manufacturer within the sector. “We also supply other fasteners that our customers need besides the products we manufacture ourselves. We thereby have succeeded in becoming the ‘single business partner’ for our customers – with our R&D, design, engineering, production, sourcing, supply chain management services,” states Fatih Uysal. “We have also completed the installation of our Gölcük warehouse, where we will manage Europe’s largest commercial vehicle program. With our strengthened team, we are ready to further highlight our professional FSP identity in future projects.”

In Norm Fasteners development journey towards the future and success, together with all its employees, the company aims to spread, sustain and develop the business and its culture. “We see sustainability as providing for the present needs without compromising the needs of the future generations, based on economic issues, as well as environmental and social development,” explains Fatih Uysal.

“Therefore, we strive to create value for our world and community. From installing solar panels in our manufacturing facilities to measuring our corporate carbon footprint; from transitioning to sandblasting technique to our digital transformation; all our actions are thoroughly planned to create a better future and more sustainable world.”

To add to this, Norm Fasteners has looked to incorporate digitalisation into every process, from production to packaging. “We have continued our digital transformation journey to facilitate our business processes without slowing down,” highlights Fatih Uysal. “A prime example is the integrated RPA systems into our production lines and offices with our digital colleague Normie.”

Fatih Uysal concludes: “At Norm Fasteners our main goals in 2023 will be to continuously advance our standards for quality and customer satisfaction and strengthen our steps in the sustainability field – whilst continuing our work toward being a responsive business partner for our customers. We will also continue to develop our main strategy, especially in regards to environmental, economic and social issues.”

Malaysian-based Well-Union has established itself as a manufacturer of stainless steel bolts and screws – with a production capacity of 180 tonnes per month and exports to partners in more than 50 countries, including in the USA, Europe, Asia and the Middle East.

An associate company of LINKWELL Industry Co Ltd, Well-Union Metal Sdn Bhd was founded in 2005 and, through its factory in Johor Bahru, is able to produce a variety of products according to DIN, ISO, and JIS, including stainless steel (A2/ A4/ SS305/ SS410/ SS430) screws and bolts, machine screws, tapping screws, chipboard screws, woodscrews, deck screws and screws according to customer drawings – from 2.2mm to 12mm in diameter and 4.5mm to 150mm in length.

“We have many years of professional experience in the production of stainless steel screws and thanks to our skilled management system, advanced technology, good reputation, and the latest production equipment from

Germany, Taiwan and Japan, we have established ourselves as a key supplier within the fastener market,” states Well-Union.

The company also puts it success down to its commitment to the principle: ‘Quality and the customer always come first’. “Our quality is underlined by our certification to the Japanese Industrial Standard (JIS) B1111 and JIS B1122,” mentions WellUnion. “In addition, we have obtained a Certificate of Conformity for Factory Production Control, which fulfils the evaluation and verification of performance stability as described in a European Technical Assessment (ETA). To ensure production efficiency and product quality, we also continuously introduce advanced inspection instruments and computerised operations, which are able to control quality and meet international requirements.”

The company adds: “Another important factor is that we look to introduce high value-added products and continuously work on product improvements, which enables us to meet customers’ needs and create more competitive niche markets for us as a business.”

Well-Union points out that being based in Malaysia is also a great benefit to the business, as it helps it to differentiate itself from the traditional fastener manufacturing hubs of China and Taiwan. “Malaysia has two major ports in southeast Asia, Port Klang and the Port of Tanjung Pelepas, and it is also close to the Port of Singapore. This provides Malaysian companies with great advantages in import and export,” explains Well-Union. “Malaysia also has a well developed infrastructure, with it only taking 1 to 3 hours to reach the three ports by road. This can ensure high-quality supplier networks and allows for efficient and cost-effective manufacturing and transportation of goods.”

Another key advantage related to the fastener industry is that Malaysia has the MTFTA (Malaysia-Turkey Free Trade

Agreement) with Turkey, which gives Well-Union the opportunity to attract more business partners from within the Turkish market.