The Berardi Group is a living heritage, an evolving process which we develop day by day, to shape a better future Our know-how, innovative spirit, and attention for human relationships combine to create a business model that meets modern needs, without forgetting where it all began.

Our wide assortment and logistics services are our best products!

Will Lowry, content director, Fastener + Fixing Magazine

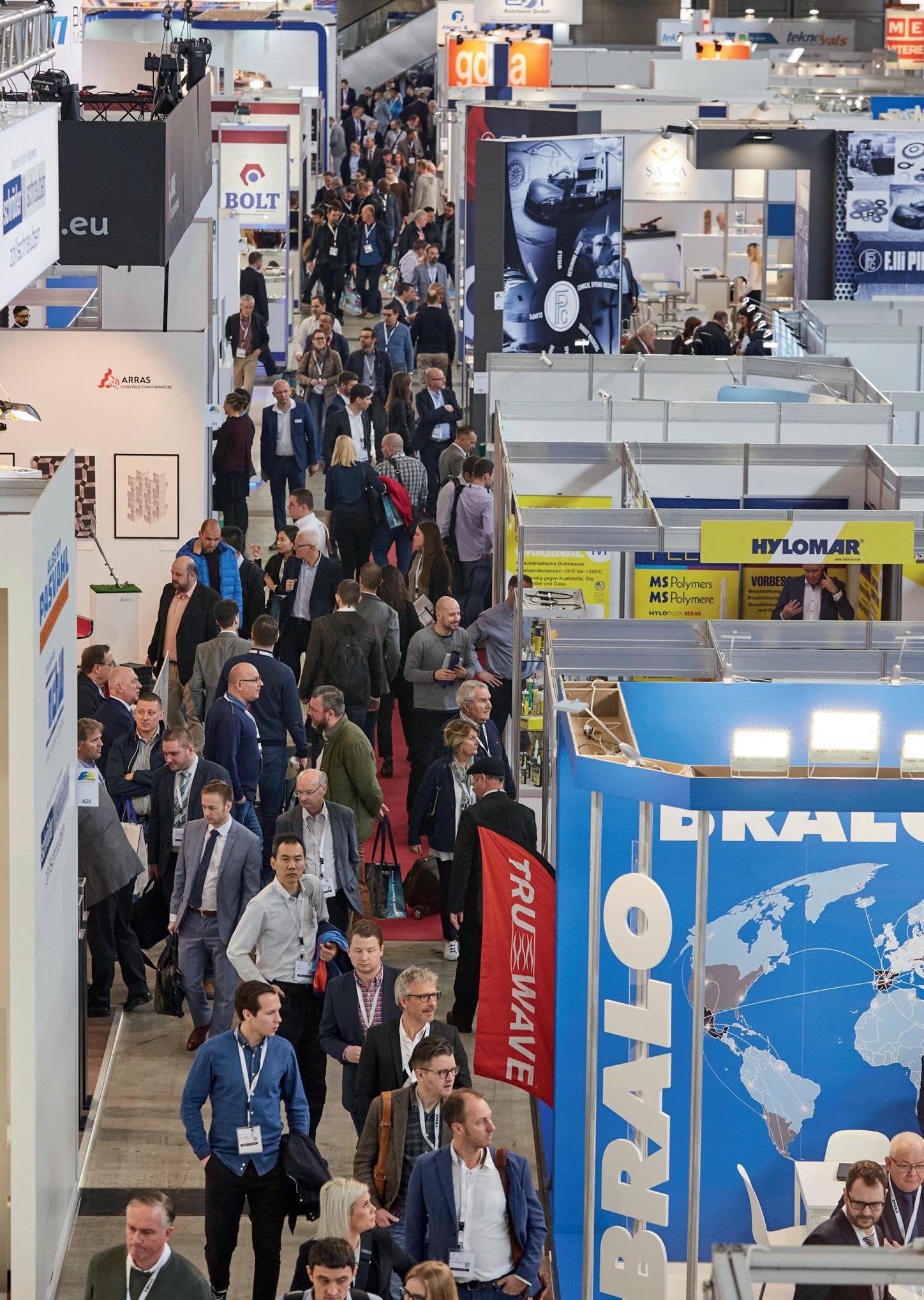

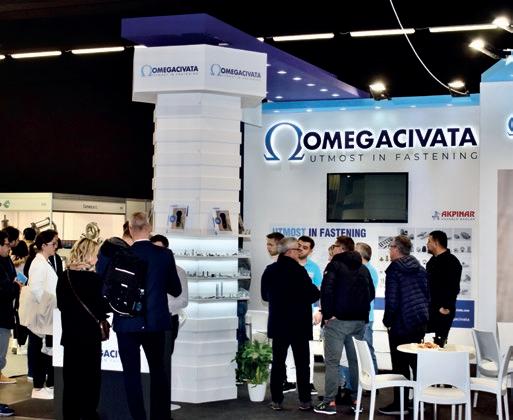

With so many challenges currently impacting every business within the fastener and fixing industry, it is nice to have something to look forward to, and Fastener Fair Global is certainly the highlight on my calendar – with it just over two months away.

Part of the Mack Brooks Group

www.fastenerandfixing.com

Managing Director Jamie Mitchell jamie.mitchell@verulammedia.com

Content Director

Will Lowry will.lowry@verulammedia.com

Deputy Editor Claire Aldridge claire.aldridge@verulammedia.com

Assistant Editor Rebecca England rebecca.england@verulammedia.com

Sales Director

Mac Rahman mac.rahman@verulammedia.com

T

aking place from 21 st – 23rd March, once again at Messe Stuttgart in Germany, Fastener Fair Global will bring together the whole industry, with the opportunity to meet face-to-face with both exhibitors and visitors. As an official media partner, we have an extensive preview of some of the products and companies that visitors can expect to see during the show, including a full exhibitor list –making it easier for you to plan what promises to be a busy three days.

One of the main highlights at the show will be the Route to Fastener Innovation competition – which once again will be hosted by Fastener + Fixing Magazine. The competition is a first-hand opportunity to assess new products and services that exhibitors have brought to the market since the last show. To find out more, read the special feature in this issue and remember to take a note of the stand numbers or look out for the distinctive Route to Fastener Innovation competition logo on participants’ stands during the show.

For this issue, our Cover Story is focused on pgb-Europe, a leading supplier and producer of fasteners, anchors, and tools, and

how it is strongly committed to digitisation and maximising its customer service.

Within our Insight section we have an exclusive interview with EFDA President Andreas Bertaggia – who talks about how 2022 progressed for EFDA, and its members, as well as what they will be concentrating on for 2023. Plus, we have a very interesting article from Brazilian manufacturer Hassmann and how it plans to continue to grow internationally through targeted investments.

Business Development Manager – Italy Emiliano Pagliaroli emiliano.pagliaroli@verulammedia.com

Business Development Manager – Europe Chantal Ridings chantal.ridings@verulammedia.com

Production & Design Manager Lee Duskwick lee.duskwick@verulammedia.com

To go alongside this we also have pieces from our regular contributors, including Barbara Sorgato, secretary general at the European Consortium of Anchor Producers, discussing the ‘Smart CE Marking’ initiative and how its goal is the digitalisation of DoPs in the CPR; Jason Bader, from The Distribution Team, highlights how even fastener distributors have to handle ‘the curse of ego’; and Peter Standring, technical secretary at Industrial Metalforming Technologies, tries to use his ‘crystal ball’ to look at the future of global aerospace.

I hope you enjoy this issue and I look forward to chatting to everybody at Fastener Fair Global, if you see me, make sure you say hello!

@fastenerfixing

FastenerandFixingMagazine

fastener---fixing-magazine

Fastener + Fixing Magazine is a dedicated, trade–only publication which is circulated freely throughout the European trade.

Disclaimer

Find us online: Subscribe for free at www.fastenerandfixing.com

The Publisher cannot be held responsible or, in any way, liable for errors or omissions, during input or printing of any material supplied or contained herein although the utmost care is taken to ensure that information contained is accurate and up to date. The Publisher also cannot be held liable for any claims made by advertisers or in contributions from individuals or companies submitted for inclusion within this publication. The opinions expressed are not necessarily those of the Editor or Verulam Media.

Copyright Entire contents copyright © Verulam Media Ltd 2022. No part of this publication may be reproduced, stored in a retrieval system, or transmitted in any form or by any means without the prior permission of the publisher.

Annual subscription (6 issues) to non–trade and outside EU is €160.00

Verulam Media Limited, Office 121, Ashley Road 134, St Albans AL1 5JR Tel: +44 (0) 1727 743 882

The European Parliament, Council and Commission have provisionally agreed plans for the introduction of an EU Carbon Border Adjustment Mechanism (CBAM). The agreement will need to be confirmed by EU member states and the European Parliament.

Part of the EU’s ‘Fit for 55’ environmental strategy, CBAM will require importers to purchase CBAM certificates to pay the difference between the carbon cost in the country of production and price of carbon allowances in the EU Emissions Trading System.

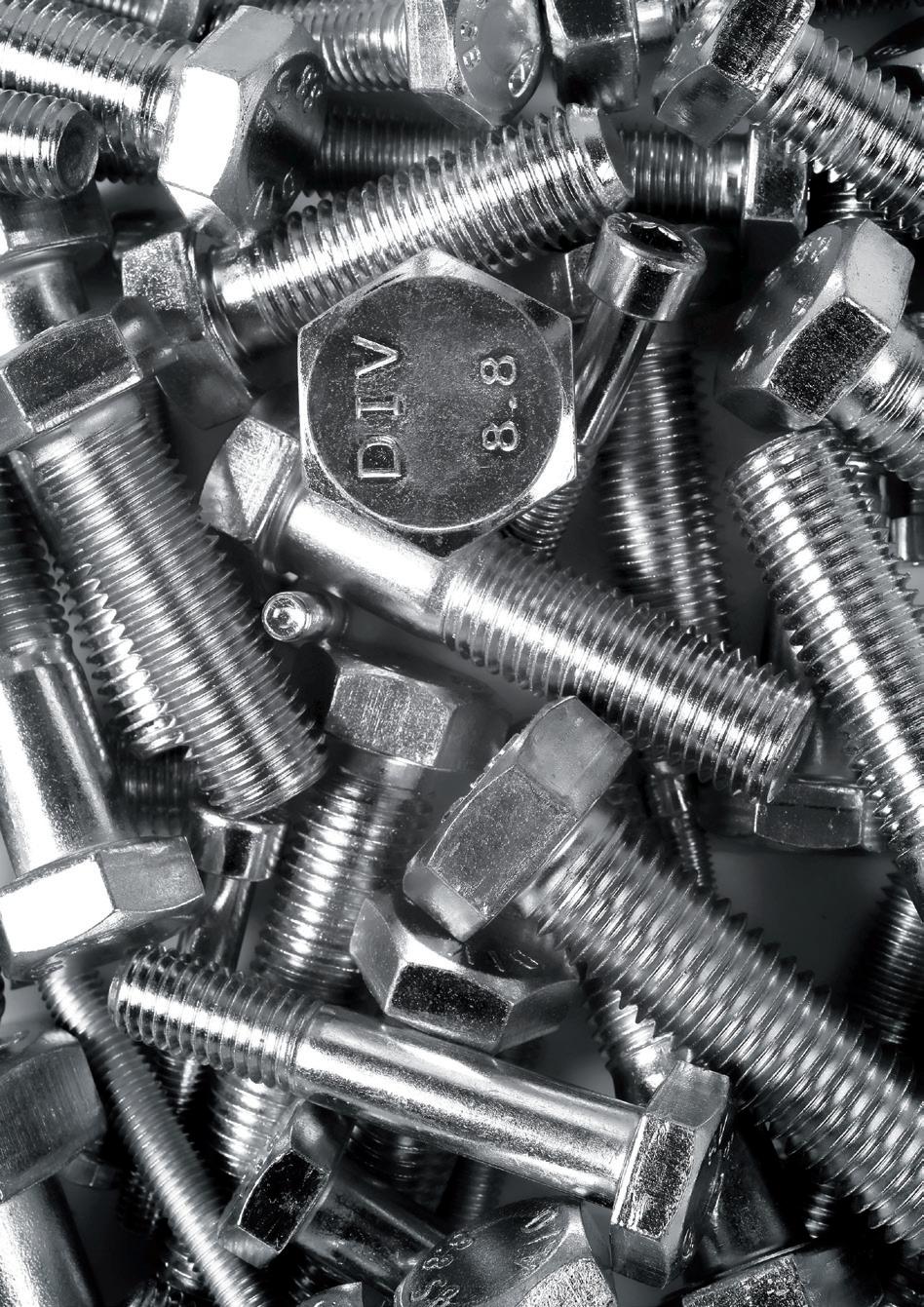

According to a European Parliament: “CBAM will cover iron and steel, cement, aluminium, fertilisers and electricity, as proposed by the Commission, and extended to hydrogen, indirect emissions under certain conditions, certain precursors, as well as to some downstream products such as screws and bolts and similar articles of iron or steel.”

A transition period with a simplified CBAM is planned to commence as of 1 st October 2023 –requiring importers to start reporting on carbon content of imports. From then onwards the full CBAM will be phased in gradually in parallel to the phasing out of free allowances until fully operational by 2026.

As part of Bulten’s strategy to maintain a strong operational platform, the company has reviewed its global distribution chain. This has prompted a decision to close one of the two logistics centres in Sweden and a manufacturing plant in the UK.

iming to bring about more efficient logistics in order to reduce lead times, and streamline processes, while also reducing costs and environmental impact, Bulten has been reviewing its global distribution chain. The company has decided that utilising capacity in warehouses close to production units to a greater extent, will enable a more efficient supply chain. Accordingly, significant investments have been made in a new warehouse near Bulten’s factory in Germany, and in a new surface treatment plant and a logistics centre in Poland. The streamlining will involve the closure of Bulten’s logistics centre in Gothenburg, Sweden.

The goods flow that previously passed through Bulten’s logistics centre in Gothenburg will now be handled by the centre in Hallstahammar, Sweden, and by the above mentioned logistics centres in Germany and Poland. Ten employees will be affected and

trade union negotiations have been initiated. The closure is planned for completion by the end of the second quarter of 2023.

“Streamlining the distribution chain will allow better transportation flows and thereby also reduce environmental impact. It will also help us reduce costs and capital tied up,” says Anders Nyström, president and CEO of Bulten.

Another step in Bulten streamlining its operation and improving profitability, includes the closure of its manufacturing plant in Pembroke, UK. The closure means that 50 jobs are at risk of redundancy.

The closing down process was announced in December, and the plan is to complete the process during the second quarter of 2023. Total restructuring costs amount to approximately SEK11 million (€979,000), of which SEK9 million was reserved for 2022. There will be additional

investments totalling about SEK12 million in connection with the closure. These primarily relate to relocation of equipment and production to Bulten’s other manufacturing plants, along with a few new recruitments.

“It is unfortunately difficult to achieve profitability with the mix of products made in Pembroke, and also volumes are relatively low. By moving the parts of production that have long-term potential to our other plants, we can achieve better efficiency and thereby higher profitability. This is in line with our strategy, which includes better utilisation of our production network,” explains Anders Nyström.

The operation in Pembroke became part of Bulten Group in 2020 with the acquisition of PSM International. Fifty people are currently employed at the plant, manufacturing and purchasing fasteners for different industrial segments. Bulten’s other operations in the UK will not be affected by the closure of the Pembroke plant.

TR Fastenings Hungary, part of Trifast Plc Group, is celebrating the opening of its new purpose-built facility in Budapest in response to years of rising demand in the region.

Located in the southern suburb of Szigetszentmiklós, TR Fastenings Hungary Kft is a fastener and Cat C supplier to international OEMs and their subcontractors, not just in Hungary but also in the countries that border it. The new 3,500m 2 facility has 9.5 metre eaves in its warehouse and is a high capacity distribution facility designed to support TR’s future European growth strategy.

TR Hungary was first established in 2000 and has grown considerably in that time through rising demand from large multinational household brands, many of which TR supplies to elsewhere in the world. Hungary has historically been a lower cost production region, but a highly skilled available workforce made the country ideal for this kind of strategic investment. Hungary has a central location in Europe with seven countries on its border, which is perfect for distribution hubs.

“Hungary has been a real success story for TR. Local infrastructure has been enhanced with a second airport and recently enhanced road networks. We located to a fast growing industrial park, near one of our largest customers, NCR, just 600 metres away from us. Over time, we have built a portfolio of multinational customers that expect the same excellent service that they receive from TR globally. This includes technical and engineering support, as well as logistics services,” says Glenda Roberts, global projects and marketing director at Trifast Plc.

Glenda adds: “We’re servicing major customers in each of the countries surrounding the TR Hungary operation and, inevitably, we have had to expand again. It took several years, because of the growth in Hungary, to locate a new facility close to the existing site but we are very confident in the investment. We were keen to retain trained staff, many of whom are also multilingual, so we ensured we did not move too far away. Product knowledge and an understanding of the level of service our multinational customers expect was a key staff retention factor, but we wanted to go further. The new facility is a showpiece

“I’m very proud of what the TR Hungary team has achieved. Moving an entire facility in a month to a new location was no mean feat and now that we are established, we look forward to focusing on customer and staff development and growing our business in Central Europe,” adds Andrew Nuttall, European managing director at TR Fastenings.

“We were working with a blank canvas and it enabled us to incorporate the environmental and sustainable features and benefits for a modern workplace. The facility is in a green area, with fields to the exterior, on a purpose-built estate with excellent transport links. Every feature was thoroughly researched from the solar panels on the roof to the triple glazing. Automatic shutters on the warehouse roof windows assist in cost-effective temperature control, while electric charging units have been installed to encourage the use of electric and hybrid vehicles, including company vehicles,” concludes Andrew Nuttall.

In a deal intended to expand its Canadian market presence, Bossard Group has acquired the Canadian distribution business of US fastener solution maker, PennEngineering®, for an undisclosed amount.

Based in Concord, Ontario, PENN Engineered Fasteners Corporation (PEF) was founded in 1970 and acquired by PennEngineering® in 2017. The company, which supplies various industrial sectors – such as automotive, energy, agriculture, and appliances – with innovative fastening solutions, generates annual sales of around US$25 million (€23.25 million) and has 30 employees.

Bossard, with its global focus on creating value for its customers through engineering services and innovative logistic solutions, intends to significantly expand its market presence in Canada as a supplier of high-quality fastening solutions and is convinced that, through this acquisition, it will be able to unlock additional growth in this strategic market, right in the industrial epicentre of Canada.

Bossard and PennEngineering® already have an established, successful, long-term relationship, which covers a total of 22 countries in North America, Europe and Asia.

David Jones, Bossard’s CEO America, commented: “With the acquisition of PEF, we are in a great position to continue our profitable growth strategy in the context of our Strategy 200. Building on our previous investments in Canada by adding PEF’s capability, we will be able to expand our services in this key market.”

As of 1 st January 2023, Miguel Ángel López Borrego is the new interim CEO, following NORMA Group’s supervisory board deciding to appoint him to the role until the position of CEO has been permanently filled, after previous CEO Dr Michael Schneider stepped down by mutual consent.

Chairman of the supervisory board, Günter Hauptmann, said the group was extremely pleased to have Mr Borrego fill the CEO role during this transitional period to ensure continuity of the company’s management, adding: “He is exceptionally well positioned to leverage his deep insight into NORMA Group’s business model and the challenges it currently faces, enabling him to guide the company through the current turbulent economic environment in an organised and competent manner.”

Mr Borrego has been a member of the NORMA Group supervisory board since March 2021 and as CEO of Siemens SA in Madrid, he was head of Siemens’ Spanish operations and has many years of management experience in the automotive, general industrial equipment and new energy sectors.

During the transition phase, Mr Borrego will continue to implement ongoing improvement measures in the company together with other management board members, though his role on the supervisory board will be suspended. Mr Borrego said he will be working together with colleagues to “stabilise profitability, compensate for inflation driven cost increases and enhance plant productivity.” Adding: “With its diversified business model and strong order book, NORMA Group is in an excellent position to take advantage of growth opportunities, even in challenging times.”

One of the UK’s leading manufacturers of round, flat and profile wire

Alloy Wire International’s (AWI) senior management team, comprising managing director Tom Mander, technical director Andrew Du Plessis and finance director Adam Shaw, have purchased the business from the current owners, cementing the Black Country firm’s long-term future.

The deal will see all 33 members of staff become shareholders in the business, reinforcing a company-wide commitment to each other and its 6,000 strong global customer base. The trio have also pressed the button on a near GB£1 million investment drive that will see new wet drawing and single hole dry drawing machines arrive during the course of the year, along with an annealing line spooler and several hundred tonnes of raw material.

“This is another major milestone in the history of AWI and gives us the platform to capitalise on recent growth and massive export opportunities,” explained Tom Mander. “The new owners have over 45 years’ combined experience of working here, so it was a natural progression for us to step forward and take the business on, with previous Managing Director Mark Venables moving to chairman for the next five years and R&D Director Angus Hogarth taking a consultancy role.”

Tom continued: “There’s something very special about this business and this MBO ensures we maintain and cultivate this for the next 75 years. We will continue to focus on our USPs, which include delivering the fastest industry lead times, world class manufacturing quality and an expanding range of exotic alloys. It goes without saying that the technical expertise AWI is known for will continue to be a cornerstone of our approach.”

has completed a management buyout, as it looks to target GB£15 million annual sales for the first time in its 77 year history.Picture from left to right: Mark Venables, Tom Mander, Adam Shaw and Andrew Du Plessis Hall 1, Stand 712

Marcus Söderberg, chief financial officer at Bufab Group, has decided to leave the company to take up a new position outside the group. He will continue in his post during his notice period until May 2023. A recruitment process to find his successor has already begun.

Commenting on the decision, Erik Lundén, president and CEO at Bufab, said: “I regret that Marcus has chosen to leave Bufab, but would like to take this opportunity to extend him a warm thank you for good co-operation and a valuable contribution to Bufab’s fine development in recent years. I wish him the best of luck in the future.”

During his time as chief financial officer, Lundén said that Söderberg had played an important role in the company’s development and had also made a strong contribution to the development of the group’s finance function.

In his parting statement, Söderberg said: “I am happy and grateful to have had the privilege of contributing to, and developing myself, during some of Bufab’s most successful years. After nine years in various financial roles in the group, the last five years as CFO, I have now, with mixed feelings, decided to move on to another role outside the group. I would like to take the opportunity to thank all Bufab employees, board members and shareholders for a fantastic collaboration and exchange during my time in the company.”

Atlas Copco has acquired Precision Pneumatics Ltd and Wearside Pneumatics Ltd, two compressed air distributors and service providers in the UK

Precision Pneumatics Ltd was founded in 1991 and is based near Liverpool, with Wearside Pneumatics Ltd founded in 1974 and based near Newcastle upon Tyne. Both companies are privately owned by the same owners and provide compressed air solutions to companies in all types of manufacturing industries, such as general manufacturing, electronics, automotive supply chain, food & beverage, and metal fabrication

“Both companies have strong sales and service coverage in highly dense industrial areas of the UK,” said Vagner Rego, business area president compressor technique at Atlas Copco. “The acquisitions will further increase our direct service and sales presence in those key areas and provide growth opportunities.”

The acquired businesses will become part of the Service division within the Compressor Technique business area.

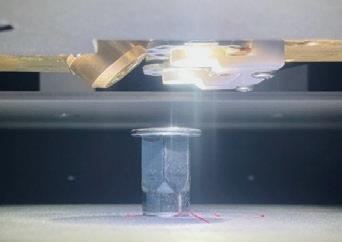

In a deal worth GB£1 million (€1.1 million), bigHead has recently installed new, state of the art machinery at its facility in Dorset, UK, which will help improve the quality of the technology it uses to make its bonding fasteners for composites.

bigHead explains that the new equipment, which was custom-made by Expert Technologies Group, will help reduce the time spent on extra machining and secondary operations, as well as leading to a 30% - 40% increase in productivity.

Indeed, the company considers long-term investment as its best strategy, adding that the new machines give it a platform to scale the business, as the company meets growing demand for composite panel fasteners beyond Europe, from Asia and the USA.

SKAKO reported that earnings before interest and taxes (EBIT) in Q3 of 2022 were DKK 9.1 million, which is 106.5% more than Q2 2022. The 2022 overall EBIT was DKK 20 million (€2.68 million) at time of going to press.

Following its quarterly report for Q3 of 2022, SKAKO announced that the period had been “the best quarter for a long time”. In fact, the entire FY22 was good for the company, with SKAKO saying it had “not seen anything like this for many years”.

Contributing to the growth were both SKAKO Concrete and SKAKO Vibration, particularly the concrete and recycling segments, which are both expanding. The company’s order backlog, meanwhile, of DDK 212 million, is historically high, some 102% higher than the order backlog in 2021.

In a joint statement, Lionel Girieud, managing director at SKAKO Vibration, and Steffen Kremmer, managing director at SKAKO Concrete, said: “Our employees are really doing a great job ensuring growth across the board. We are particularly delighted about the large order backlog. So, we are expecting a continued positive development in the upcoming months despite the Ukrainian war and energy crises.”

Qonnect has recently implemented leadership changes, which have been ‘in the works’ for some time now, but were only finalised with the October promotion of Daan Schrijen to managing director.

Daan Schrijen has expanded his function from operational management to the managing director role, effectively concluding the transition of Founder Jan Aarts, from active management as CEO to an advisory level. Daan has been active at Jan’s side with Qonnect since 2014, sharing his experience and carrying this to the current level today.

Qonnect has also recently taken on a new corporate identity and will be introducing new product groups and partnerships in the near future. As new managing director, Daan will oversee and manage the company in these new ventures, as well as navigating it through the challenges of the modern world.

At the same time, Qonnect’s focus will remain, as ever, on being a dependable stock partner – delivering high service and quality, as well as original industry design, while remaining a flexible and highly responsive partner.

Lesjöfors, via Alcomex, has signed an agreement to acquire 100% of the shares in Amatec BV, a Dutch spring distributor.

Amatec distributes stock springs and customised springs with a focus on the Dutch market. The company has high technical competence and is able to support its customers throughout the entire sourcing process, from product design to final product.

With the acquisition, Alcomex, and the Lesjöfors group, strengthens the distribution capabilities of stock springs, in line with its ambition to build the leading spring, wire and flat strip component group.

Ola Tengroth, president at Lesjöfors, comments: “Amatec has a strong position within the Dutch spring market and through this transaction, we take a step further to accelerate our stock spring business in Europe.”

Sustainability is at the heart of Henkel’s corporate strategy and pioneering spirit, which is why it is transforming its UK head office to use renewable energy – helping to create a more sustainable office, as well as reduce energy costs.

As a leader in sustainability, Henkel is continuously looking at ways it can reduce its impact on the environment across the whole supply chain. From sourcing ingredients, to manufacturing and logistics, through to energy sources.

The project to bring renewable energy to the UK head office, led by Victoria Hampstead, HSC country manager UKI, saw the installation of nearly 300 solar panels on one building, which has generated 96,000kWh of electricity in its first year.

“Renewable energy is a major driver in the fight against climate change. For Henkel, the switch to non-carbon energy sources is one of the main levers in our efforts to become a ‘climate positive’ company by 2040,” explains Victoria. “In July 2021, the pandemic restrictions were being removed but most Henkel colleagues were still working from home. We therefore used the

opportunity to install solar panels on our UK head office building without disrupting our operations or teams.”

Since the panels have been added, the UK head office has saved 23 tonnes of CO 2 emissions. “At the start of the project, it was estimated that Henkel would recoup the investment in five years,” points out Victoria. “However, with the dramatic increase in electricity costs, the panels will pay back as soon as 18 months. Savings for the forthcoming year are expected to be approximately GB£70,000.”

Following the success of this project, Victoria is leading an initiative to consider the feasibility of extending solar energy projects to other Henkel sites in the UK and Ireland. “I hope to build on the success of the UK head office renewable energy project, and also look at other sustainability initiatives to support Henkel’s 2030+ sustainability strategy.”

Starrett, a precision measuring tool and saw blade manufacturer, has announced a new partnership with Owlett-Jaton. The new distribution partnership, which started on 1 st November 2022, introduces a range of Starrett power tool accessories to Owlett-Jaton’s 4,000 customers.

The top selling and well-known Fast Cut and Cordless Smooth Cut hole saws, for example, from Starrett’s Bi-metal range, are now available, as well as its jigsaw and power hacksaw blades, both of which use Starrett’s patented, Bi-metal Unique™ technology.

Further saw blades offered include the company’s 3x power reciprocating blades, launched in 2021, when they set a new level for performance and value on the market –with a line that includes blades for cutting wood, metal, multiple materials and heavyduty cutting.

Tom Pettit, Starrett UK sales manager, said: “I am really excited to have Owlett-Jaton onboard as a wholesale partner. They have the sales team and customer base to support our aggressive growth plan in the UK.”

Tony Williams, sales director at OwlettJaton, commented: “Starrett is a great addition to our existing list of market leading brands. Owlett-Jaton is recognised within the trade as offering a complete wholesale solution, with low minimum

order levels and free next day delivery. Customers can order multiple items in small quantities, all from one supplier. The introduction of over 130 Starrett

lines complements our existing cutting blade offering and will provide new opportunities and existing customer growth into 2023.”

Gripple, the UK-based manufacturer of suspension solutions for the construction industry, is celebrating five wins at the prestigious TMMX Awards (The Manufacturer MX Awards) in partnership with the Institution of Mechanical Engineers.

ripple beat off strong competition from manufacturers across the UK to win: Manufacturer of the year, Young Manufacturer of the Year, International Trade, Operational Excellence, and Leadership and Strategy, after being shortlisted in 10 out of 11 categories.

Gordon Macrae, special projects manager at Gripple, explains: “This was a fantastic night for Gripple and for manufacturing in South Yorkshire. The TMMX Awards are the most prestigious manufacturing awards in the country, so it is a real honour for us to win five categories. The entry process and judging criteria are, quite rightly, rigorous and the judges really do put you to the test when they visit, but we are so pleased with the feedback we received and will use this to continually improve our operations.”

He added: “The TMMX awards are an opportunity to showcase the passion for excellence we have across our business, which is driven by Gripple being an employee-owned business.”

The winners were announced at The Manufacturer MX Awards ceremony and gala dinner, which took place on Thursday 17 th November at the Exhibition Centre in Liverpool. The evening was held at the end of Digital Manufacturing Week and attended by 900 people from the manufacturing industry.

Würth Group has made a donation of €420,700 to the United Nations Children’s Fund (UNICEF) – towards an aid programme that supports schools in Bolivia affected by climate change, in order to give children access to high-quality education.

his is the fifth time the Würth Group has handed a donation cheque to UNICEF following the company’s fundraising, RW WORKOUT Week. The donation will support the UNICEF programme for resilient schools in Bolivia. Resilient schools are schools which, despite adverse circumstances such as natural disasters and the effects of climate change, continue to offer children and adolescents the opportunity to receive education.

In resilient schools there is a focus on the transfer of knowledge, one subject being that of climate change. This enables pupils to engage and interact with communities and authorities on climate change and risk management in the event of natural disasters. In addition to providing access to education, resilient schools make an important contribution to community empowerment and resilience in particularly vulnerable communities.

The Würth donation will benefit 700 children and adolescents in eight schools out of a total of 45 institutions enrolled in the overall project. The schools will be equipped with solar panels, groundwater pumps and Internet connection, plus 70 teachers will be trained on climate change. The programme also establishes a network of teachers to exchange best practices on natural disaster risk management.

“Every child should have access to education regardless of their social background. Access to an education that does not exclude anybody and offers equal opportunities to all. Children have a right to learn. Only in this way can they understand the world, shape the future and participate in social and political life. With our donation we make a contribution towards this,” said Carmen Würth.

Director of strategic sourcing for DXP Enterprises, Allan Guthrie pointed out that one of his pet peeves is the word ‘training’. “I believe our industry over uses the word.”

“What are we trying to do when we ‘train’ someone? Are we presenting them with the performance specifications of a tool, with the hope that they can increase sales? Teach them the nuances of a business process so they can perform their job more efficiently?” Guthrie asked.

“Why don’t we educate them?” asked Guthrie. The difference between ‘training’ and ‘education’ is the ‘why’: “Why does it matter, why are we doing it this way, why does it impact the customer?”

“If we can explain ‘why’ the performance specifications of the tool matters – and how that could benefit the customer – that would probably increase sales,” Guthrie explained. “But, just knowing the torque specifications of a drill without knowing ‘why’ it matters will get you nowhere.”

He adds: “Typically, folks will seek out their supervisor or team leader and ask for direction because we trained them just to follow the process and not to think. Now if we would have educated them, explained why each step of the process was important and what effect it has on the next, we would have empowered them to make an educated decision.”

Guthrie also added that the 2022 words replacing ‘pandemic’, ‘social distancing’, ‘masks’ and ‘shut-downs’ are ‘supply chain disruption’, ‘raw material shortages’, ‘high fuel prices’, ‘surcharges’, ‘rising interest rates’, ‘inflation’ and ‘inventory shortages’.

“I think Covid-19 taught us all to become better planners, we’re identifying what our customers’ critical needs are – ensuring we have sufficient safety stock, even researching alternate items that could be used as replacements if the need arises.”

Especially in the past year, open and honest communication between suppliers and distributors has made it “easier for us to inform our customers, look at other options and stay ahead of potential stock-out situations”.

Guthrie said that comes when suppliers “share the good news (we have it in stock) and the bad (we don’t have a clue when we’ll get it)”.

Another 2022 issue has been price increases. “These increases are coming from raw material providers to the manufacturer, manufacturers to distribution, and distribution to the end user. We all are trying to keep our pricing updated, keep our customers informed and not lose any money in the process,” Guthrie said. “I believe the pandemic has sharpened our business processes, made us better communicators, and if you stayed on top of your orders, brought us all closer to our customers.”

The October seasonally adjusted Fastener Distributor Index (FDI) declined further versus the previous month, coming in at 44.3 (September was 47.6).

Analysts David Manthey (CFA) and Quinn Fredrickson from R.W. Baird commented: “This represents another contractionary reading, indicating market conditions continued to deteriorate.

Demand commentary again skewed pessimistically, with comments ranging from ‘slight slowing’ to ‘noticeable declines’, and there were very few positive comments about demand. On the positive side, stainless steel pricing seems to be stabilising and many respondents noted improvement in supplier lead times and overseas transit times.

Looking ahead, the Forward Looking Index registered a sub-50 index value, reading 42.4, suggesting

further declines in the FDI could be likely. Ultimately, similar to the overall macro backdrop and the industrial economy specifically, fastener market demand conditions continue to soften.

The seasonally adjusted October FDI (44.3) registered a second consecutive month of contractionary readings as demand softened further and sentiment continued to deteriorate according to respondents. This is the third time in four months that the index was sub-50 following a 25 month streak of expansion. Sales and supplier delivery indexes were weaker month-onmonth, offsetting improvement registered in employment and customer inventory levels. Just 14% of respondents saw sales above seasonal expectations, while 54% indicated sales were worse. Pricing was mostly stable versus last month, as respondents indicated commodity prices (in particular stainless steel) have stabilised.

Overall, October saw fairly broad-based softening among respondents. While October was soft, respondents anticipate further weakening in November. The FLI registered just a 42.2 reading, which was both contractionary (<50) and at an accelerating rate (decreased month-on-month).

“Relative to last month, higher respondent and customer inventory levels month-on-month is read as a bearish sign

for future demand as it could indicate customer de-stocking ahead.”

The six month outlook was mostly unchanged, with just 11% of respondents anticipating activity levels will be higher six months from now (October) – September was 9%. Conversely, 46% expect lower activity levels (September was 43%) versus an average of just 13% over the past two years.

“We view this as an indicator that many respondents anticipate a recession occurring in 2023. Lastly, 43% expect similar trends. Key outlook themes from participants included improving supplier lead times/overseas transit times, customer de-stocking, slowing demand and general macroeconomic angst.”

The FDI employment index came in at 53.6 for October, improving from 47.8 last month. The majority of participants indicated they were at levels of employment that are seasonally normal/appropriate (64%), while 21% said employment levels were too high and 14% said they were too low. The October jobs report similarly painted a slightly better than expected job picture. 261,000 jobs were added versus economist expectations for +195,000. Forward-looking commentary again skewed more bearish as recession fears continue to build. General economic fears are beginning to translate into reduced customer orders and careful monitoring of cost.

“Commercial customers are scaling back, anticipating slowing from their customers. Aerospace is still growing from the slowdown that Covid-19 created, however, they seem to be watching their cost more closely.”

Another respondent said: “Slight slowing from customers, feeling like everyone is a little hesitant and fearful of an economic slowdown.” Inventory de-stocking is also playing a role in lower demand: “The expected drop in sales is finally here and probably will be for the next 4 – 6 months until inventory levels out.”

Supply chains seem to be freeing up for the first time since the onset of the pandemic. “Some lead times getting better. Also finding transit times from overseas are getting better into the west coast.” Echoing this, one respondent said: “Supplier lead times are still longer than pre-Covid but coming down.”

Stainless steel costs seem more stable now than any time in recent memory. Automotive is down from earlier in the year but apparently there is still enough pent-up demand. Most other industrial sectors are noticeably down and regularly scheduled shipments are slowing.”

The FDI is a monthly survey of North American fastener distributors conducted by the FCH Sourcing Network, the National Fastener Distributors Association and Baird.

LFastenal Co reached US$1 billion (€943.6 million) in eCommerce revenue within a calendar year, hitting the milestone two full months before 2022 ended. aunched more than 20 years ago, eCommerce historically represented a small share of the overall business until five years ago, when Fastenal announced a strategy that positioned eCommerce as a critical component of the company’s ‘high-tech, high-touch service model’.

“While many retailers and distributors were racing to move their offline business online in pursuit of a lower cost to serve, Fastenal took a very different approach – using its eCommerce platform to identify opportunities to migrate customer spend from a transactional (and, for the customer, higher-cost) online environment to a more strategic and efficient environment, anchored by the company’s Onsite and FMI (Fastenal Managed Inventory) programs,” explained Kirk Talmontas, vice-president of eCommerce for Fastenal.

This focus has accelerated Fastenal’s eCommerce revenue growth, going from US$245 million (5.5% of total company sales) in 2017 to US$1 billion (17.4% of total company year-to-date sales) in October 2022.

“We don’t often think of eCommerce as our primary go-to-market strategy, but it’s become a vital part of our ‘digital footprint’ – the technology we provide to streamline and illuminate the supply chain,” stated CEO Dan Florness. “Thanks to the hard work of the entire Blue Team, we’re taking eCommerce in new directions in our industry and finding new ways to create value for our customers.”

The achievement comes amid Fastenal’s success with its FAST Solutions program, surpassing 100,000 active FMI Technology devices within customer sites and 1,000 Onsite Partnership programs. In the third quarter of 2022, Fastenal reported fastener sales rose 18.2% to US$614.5 million (34.1% of overall sales), including a 15.1% increase in fastener sales during September.

Overall Q3 sales increased 16% to US$1.8 billion. Fastenal estimated adverse weather that impacted the southeastern of the USA reduced its quarterly growth by 10 to 30 basis points.

Sales during the first nine months of 2022 climbed 18% to US$5.3 billion, with operating income up 22.3% to US$1.12 billion and net income rising 21.3% to US$841.4 million.

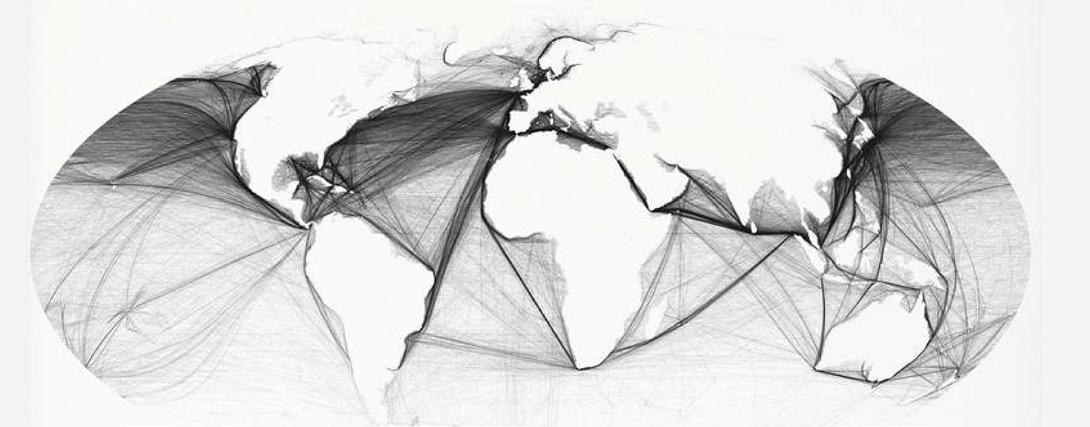

Fastener World has given a breakdown of Taiwan’s global fastener export value and volume data for the past 20 years – combining it with significant events around the world that impacted the global economy.

Year 2002 2003

2004 2005 2006 2007 2008

Volume (kg) 1,081,053,010 1,148,896,509 1,266,224,387 1,148,305,845 1,208,756,429 1,174,269,915 1,125,513,687

Growth 7.53% 6.28% 10.21% -9.31% 5.26% -2.85% -4.15%

Value (US$) 1,437,441,040 1,682,714,604 2,191,895,688 2,316,331,654 2,438,393,759 2,755,747,624 2,954,669,915

Value growth 4.96% 17.06% 30.26% 5.68% 5.27% 13.01% 7.22%

Big events

Euro becomes physical currency

Iraq war SARS epidemic EU eastward expansion

Indian Ocean tsunami

Inflation due to high oil price

US Subprime mortgage crisis outbreak Economic recession

Financial crisis US and Japan quantitative easing

Year 2009 2010 2011 2012 2013 2014 2015

Volume (kg) 816,653,088 1,206,369,710 1,347,746,764 1,278,585,161 1,371,098,506 1,501,697,033 1,470,992,279

Growth -27.44% 47.72% 11.72% -5.13% 7.24% 9.53% -2.04%

Value (US$) 1,927,175,716 3,066,814,297 3,808,037,696 3,586,618,369 3,679,741,858 4,048,948,068 3,880,596,255 Value growth -34.78% 59.14% 24.17% -5.81% 2.6% 10.03% -4.16%

Big events

EU AD tax on Chinese fasteners introduced European debt crisis

Arab Spring Japanese earthquake

US 2nd quantitative easing

Japan quantitative and qualitative easing

Annexation of Crimea by Russia

Euros zone quantitative easing

Year 2016 2017 2018 2019 2020 2021 Q1-Q3, 2022

Volume (kg) 1,435,750,086 1,498,070,256 1,595,705,450 1,479,292,223 1,363,249,857 1,610,697,606 1,248,941,656 Growth -2.4% 4.34% 6.52% -7.3% -7.84% 18.15% 4.37%

Value (US$) 3,610,883,236 4,090,303,303 4,638,685,129 4,316,380,032 3,969,114,428 5,319,398,407 4,744,636,991 Value growth -6.95% 13.28% 13.41% -6.95% -8.05% 34.02% 23.81%

Big events

BREXIT referendum Trump becomes US president USA vs China trade war

From analysing Table One it is possible to see patterns between Taiwan’s export values, and volumes, and when significant events have impacted the global economy. For instance, whilst Taiwan’s fastener export remained on a growth track during the first part of the global economic recession, from 2005 to 2007, in 2009 Taiwanese exports dropped by 34% due to the debt crisis breaking out in Europe, which was one of Taiwan’s top export markets. However, the Taiwanese fastener industry was highly resilient and made a comeback with a rebound of nearly 60% growth in 2010. The loss and gain added up to an additional growth of 30% and Taiwan was able to regain what it had initially lost from 2009 – in part due to the EU AD tax on Chinese fasteners announced in 2009 starting to take effect.

The next crisis that followed was when many Asian countries experienced a double-digit export drop in 2015. Again, Taiwanese

Covid-19 outbreak

Biden assumed office; EU announced AD investigation

EU AD tax on Chinese fasteners introduced Russia-Ukraine war European energy crisis

fastener exports were resilient, with it only experiencing a relatively small drop of 4%.

In 2018, the USA imposed a tax tariff on China of 25%, which resulted in Taiwan’s fastener export value making a double-digit growth of 13%. Then at the start of 2022, the EU imposed duties of up to 86.5% on Chinese fasteners, which Taiwan was again able to benefit from, with Taiwanese fastener exports achieving explosive overseas sales within this two year period. This in spite of the Covid-19 pandemic, which has impacted everybody around the world significantly.

In fact, 2022 has been such a success that it saw a 23.81% increase in value in the first three quarters of 2022 when compared to the first three quarters of 2021, which in itself was a record year overall at US$5.3 billion (€4.95 billion).

A key factor throughout the last twenty years has been the Taiwanese fastener industries resilience, which has acted almost as a protective shield for the sector. A big part of this is the competitive edge that the Taiwanese fastener people provide – through their unity, division of work, and helping each other. These three pillars have helped build up a strong fastener supply chain in Taiwan.

In the face of cross-nation challenges and disruption of supply chains, which have been serious enough to shake up the global industry structure, the Taiwanese fastener industry has been able to continue to forge collaborations and redeploy capacity were appropriate in order to ‘weather the storm’ of each crisis and still achieve record breaking results, such as exports in 2021.

From looking at Figure One and Figure Two it is clear that both Taiwan’s fastener export volumes and values have shown steady growth over the last twenty years – with the only significant drops being the result of the financial crisis in Europe in 2009 and the global lockdowns in 2020 due to the Covid-19 pandemic.

Looking at the current climate, there looks to be a start of a global recession.

Global export value (USD) 6,000,000,000 5,000,000,000 4,000,000,000 3,000,000,000 2,000,000,000 1,000,000,000 0

Global export volume (KG) 1,800,000,000 1,600,000,000 1,400,000,000 1,200,000,000 1,000,000,000 800,000,000 600,000,000 400,000,000 200,000,000 0 2002 2003 2004 2005 2006 2007 2008 2009 2010 2011 2012 2013 2014 2015 2016 2017 2018 2019 2020 2021Q1-32022

In the past, the large economies of the USA and Europe have resorted to quantitative easing to boost the economies, by keeping down interest rates and providing financial support to help businesses with their cash flow and operation – thereby spurring investment and revitalising each economy. However, this global recession is currently the opposite story. The US continues to raise

interest rates and the Russia-Ukraine War is causing a material price hike that forms an ever-greater stress on companies in Europe.

Whilst these challenges will continue to impact the Taiwanese fastener market, as it has proven over the last 40 years, it has the experience and resilience to not only manage the situation, but come out of it stronger.

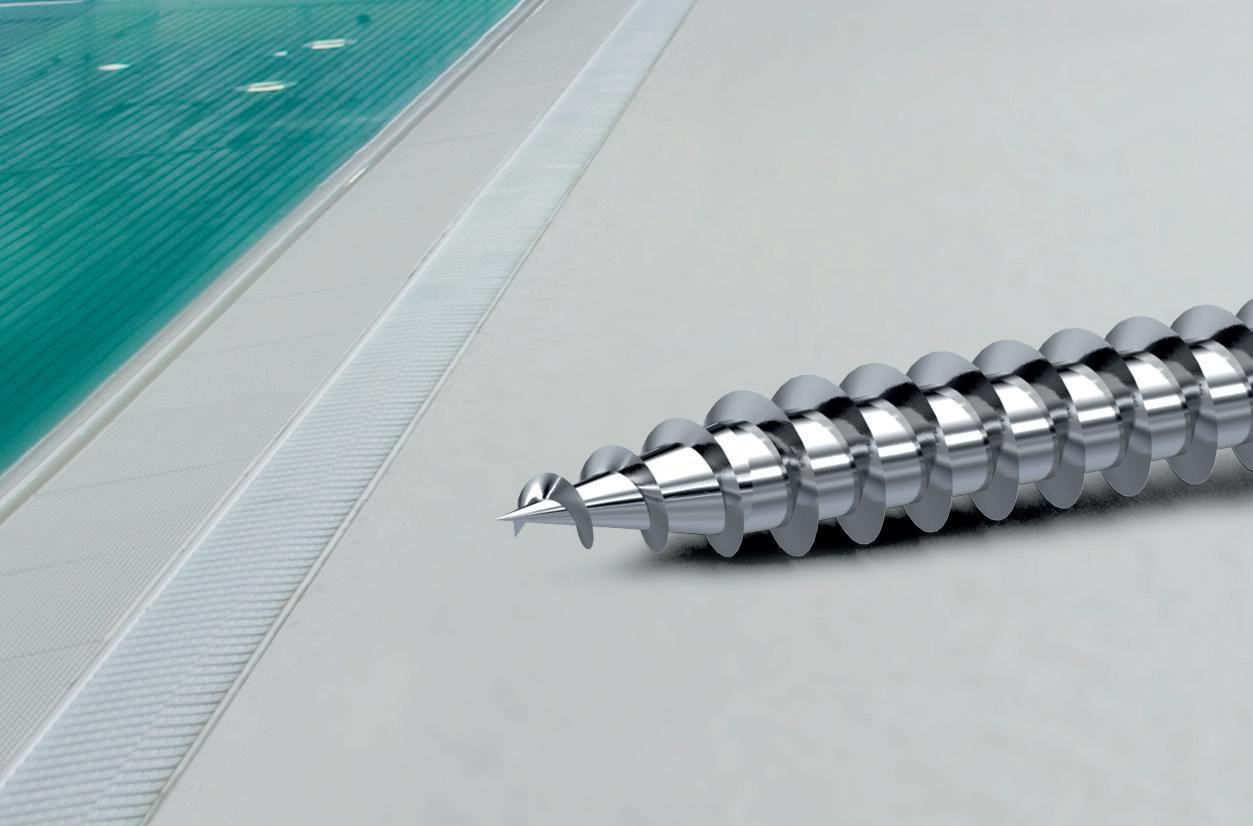

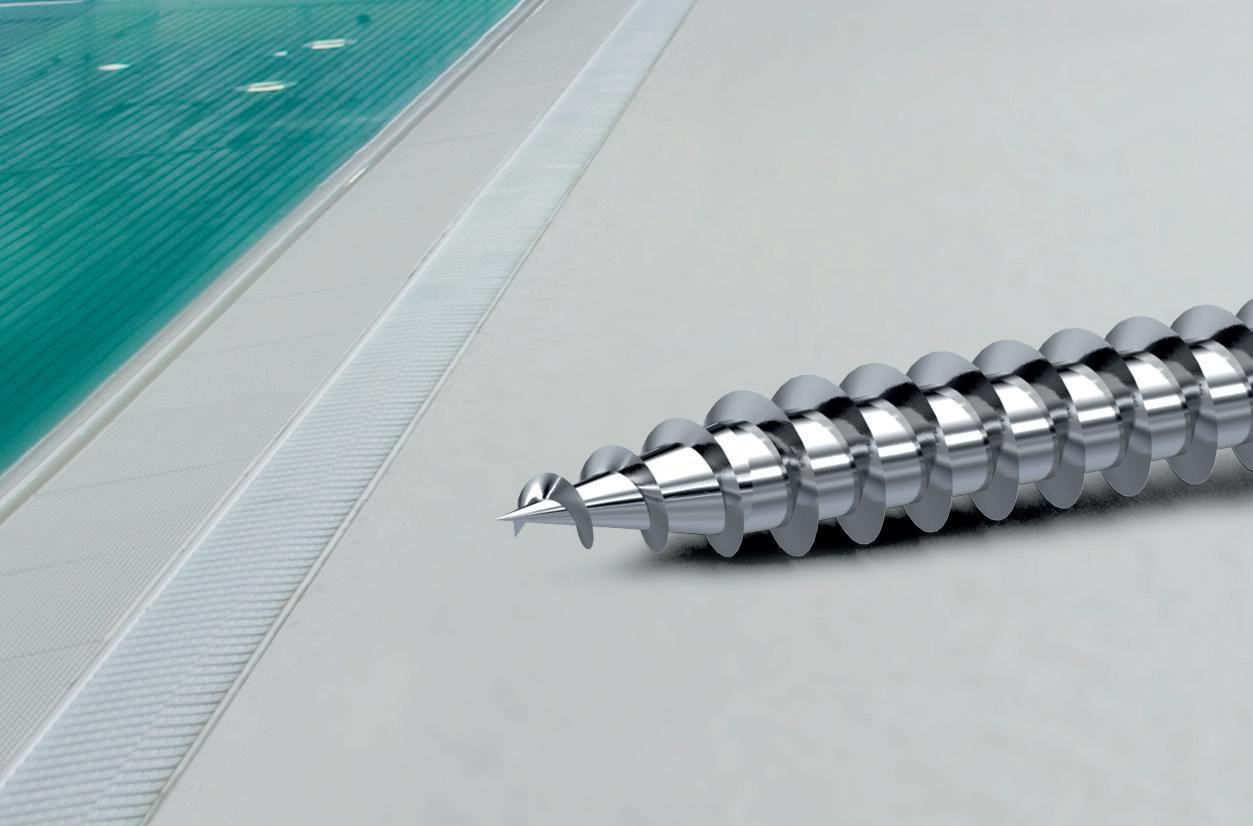

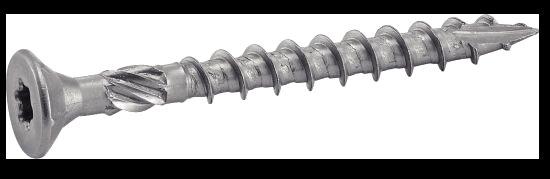

With

environmental protection greatly increasing, Bi-Mirth

For instance, in terms of electroplating, Bi-Mirth now uses ecofriendly formulas from different brands and ensures that excellent performance remains unchanged. In addition, a new eco-friendly resin-based coating is going to be used.

Bi-Mirth has also adopted new electroplating facilities and replaced old electroplating lines with longer ones (equipment total length extended from 5 feet to 6 feet), which also means that the company’s production capacity has taken a giant leap forward. “Domestic electroplating demand surged starting last year,” mentions Bi-Mirth. “Thanks to our own upgraded electroplating lines to process wood screws ,and increase screw manufacturing capacity, customers can rest assured we can meet their needs.”

Bi-Mirth pointed out that the main challenges faced by the Taiwanese fastener industry in the second half of 2022 included European and US customers sourcing more locally; price competition from Southeast Asian counterparts; and foreign exchange losses caused by the appreciated New Taiwan Dollar.

In terms of price competition, the average price of Taiwanese steel wire rod is comparatively higher than other countries, and the prices

of other related raw materials for surface treatment and packaging are also hiking. In addition, shipping costs from Taiwan are still relatively high. For example, Kaohsiung Port to New York Port rose from US$1,500 in 2019 to US$26,500 in 2021, which then has gradually decreased to US$6,000 – US$7,000 in 2022, but still remains at a high level.

Another challenge is that more European and US industrial customers are starting to source more locally because of the current political atmosphere in Taiwan causing many uncertainties for foreign buyers. This will cause greater impact on all Taiwanese suppliers in obtaining orders. In facing all of these challenges, Bi-Mirth continues to maintain and increase sales in the US.

“US customers are facing problems like logistics, turnover, inflation, labour and procurement costs, and still do not have enough time to digest their existing inventory, so our strategy is to maintain steady growth and remain cautious,” explains Bi-Mirth. “We are also working with a US customer to develop a new type of long screws for drilling and tapping 25mm iron plates to cope with climate change. Due to the drastic increase in volumes shipped, we’ve also introduced a new logistics management system (using QR code) and shelves into our factory.”

global awareness of

has upgraded its processes and products in order to achieve better environmental protection and create a greener screw production for its customers around the world.

Sérgio Milatias, editor, Revista do Parafuso, www.revistadoparafuso.com.br

Held in October 2022, the wind energy sector celebrated the return of Brazil Windpower – the annual trade show and congress dedicated to services and products involving the entire supply chain for the Brazilian wind energy sector.

Focusing on processes involving construction, as well as structural maintenance, in addition to equipment used in capturing, managing and transmitting electricity by wind strength, the show was held in São Paulo City.

Compared with the previous edition in 2019, when the local installed capacity was around 14.34 gigawatts (GW), the wind energy capacity within Brazil is now around 24 GW, including both commercial and test use – according to the Brazil Windpower website.

In terms of fasteners and relevant products, essential for fixing everything from the bases of the towers to the wind turbines and blades, the main players in this segment have shown great enthusiasm, which made it surprising that there were so few of them in such a promising event –with two debuting fairs, the Ecofix Arruelas and Brasimpar, attracting more than 6,200 visitors during the three days of the show.

The Brazilian subsidiary of Böllhoff Group has started production of high resistance pressable nuts to meet demands of the automotive, agricultural and electric energy sectors.

Specialised in fastening technology and assembly systems, Böllhoff Brazil has announced that the new local production is composed of the KAPTI NUT® – with the new line enabling the fixing of pre-drilled thin metal sheets, resulting in the creation of a threaded fastening element for the application of a third component.

The clamping system is specially designed to suit multiple drilling of strip and thin sheet metal and can be applied to materials such as steel, alluminium and stainless steel.

“The investment to that production line aims to benefit the local and export market, with faster service, competitive prices and the

Just three months after the untimely death of Anderson Luiz Biason, CEO at Max Del, there has been another family loss, this time with Américo Maximiliano Biason, Anderson’s father, passing away.

The founder of Max Del, ‘seu Américo’ –as he was affectionately known –passed away on 29 th November 2022 in Mauá Town, SP, where the fastener manufacturer’s industrial plant and headquartered have been based since 1977.

offer of a product manufactured with the global quality standard of the Böllhoff Group,” highlights Flavio Silva, CEO of Böllhoff Brazil. “These are highly resistant pressable nuts, which can be applied via a mechanical process or through automation possibilities – adding more practicality and increasing the productivity of our customers.”

Brazil is one of the key markets for Böllhoff Group. Currently, the local unit has sold an average of more than 620 million fasteners per year, with around 30% exported to France, Germany, USA, Italy, Poland, Mexico, Japan, Argentina, Chile and Colombia. The Brazilian production supplies customers within the construction, aerospace, machinery and equipment industries.

As part of its market strategy to expand globally, Ciser, the fastener manufacturer giant from Brazil, has expanded its activities within the Asian market by opening a new office in China – further underlining its position as a relevant supplier within the Asia-Pacific region.

Ciser inaugurated the new and modern offices in Changzhou City, Jiangsu Province. The event was attended by executives from some of Ciser’s major customers, such as WEG, Marcopolo, Progeral and Karl Mayer, in addition to Henry Osvald, president of BraCham (the Brazilian Companies in China for Industry, Commerce and Technology Association), and Susan Zou, a Chinese government representative. The new Chinese company will be known as Ciser Fasteners Jiangsu Ltda.

“We want to expand our share in the Asian market, not just in China, and to consolidate the Ciser name in the Asia and Pacific regions as a whole”, said Renato Fiore, sales director at Ciser.

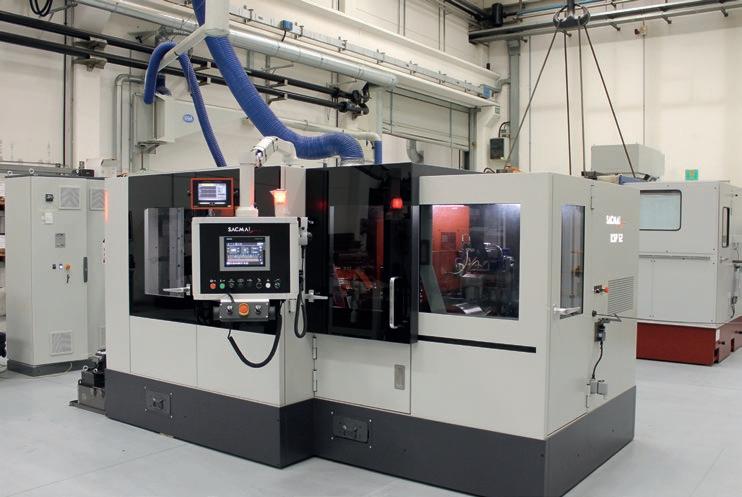

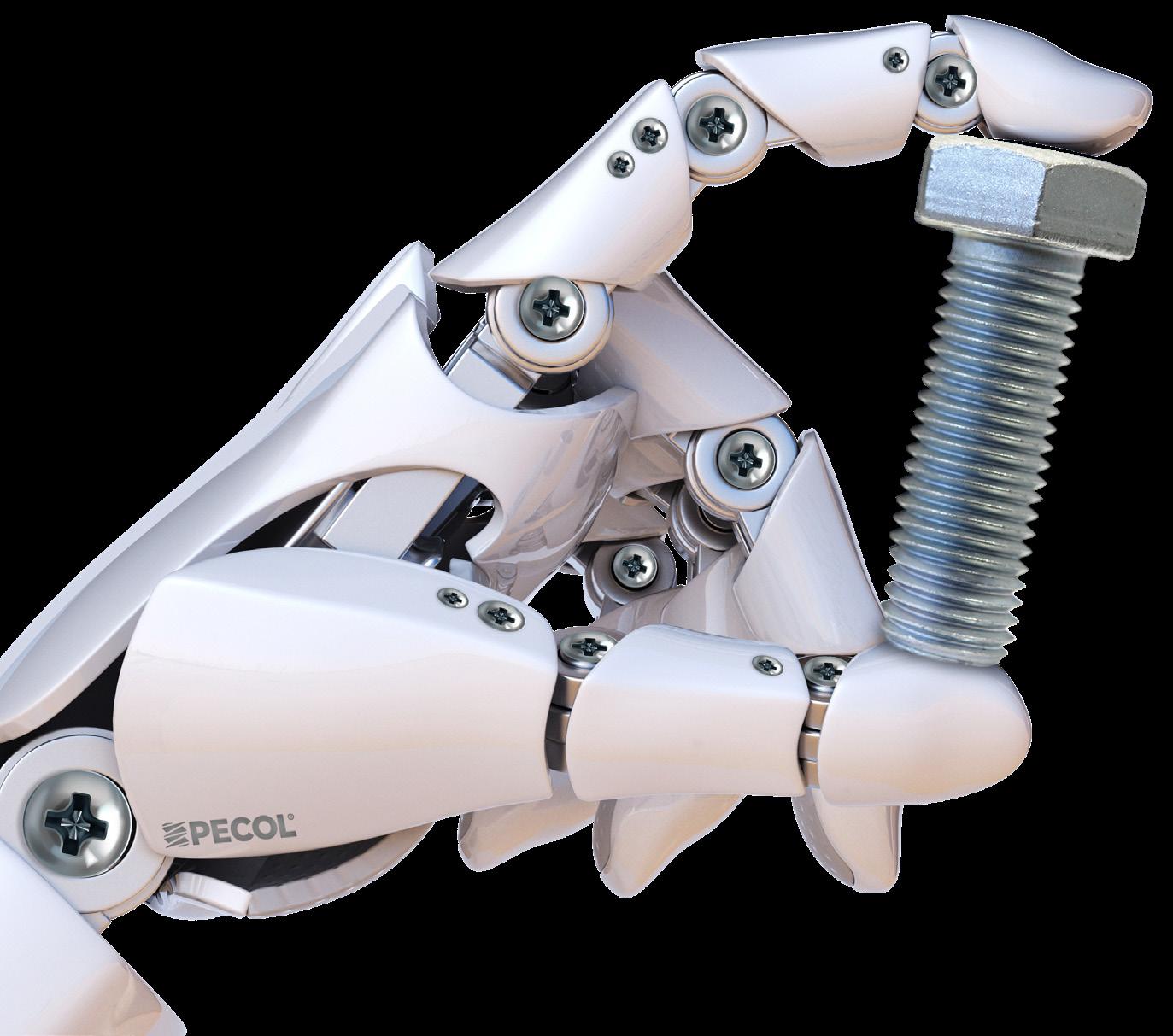

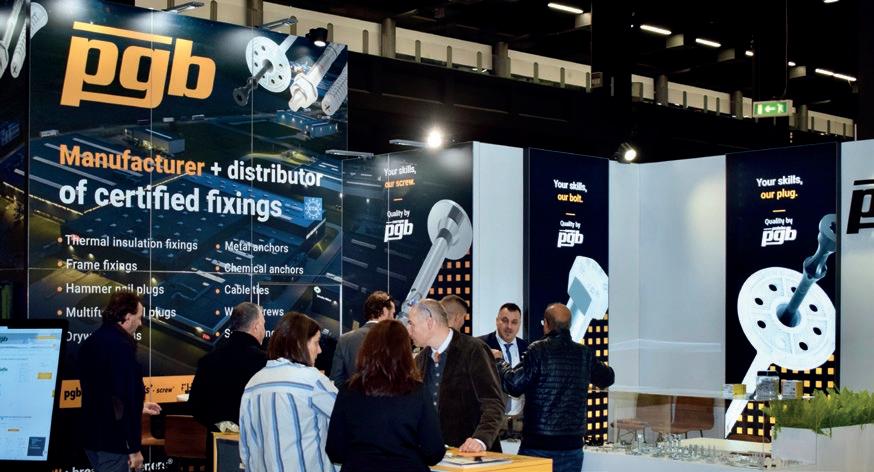

A leading supplier and producer of fasteners, anchors and tools, pgb-Europe is a European player strongly committed to digitisation and a thorough service to its customers.

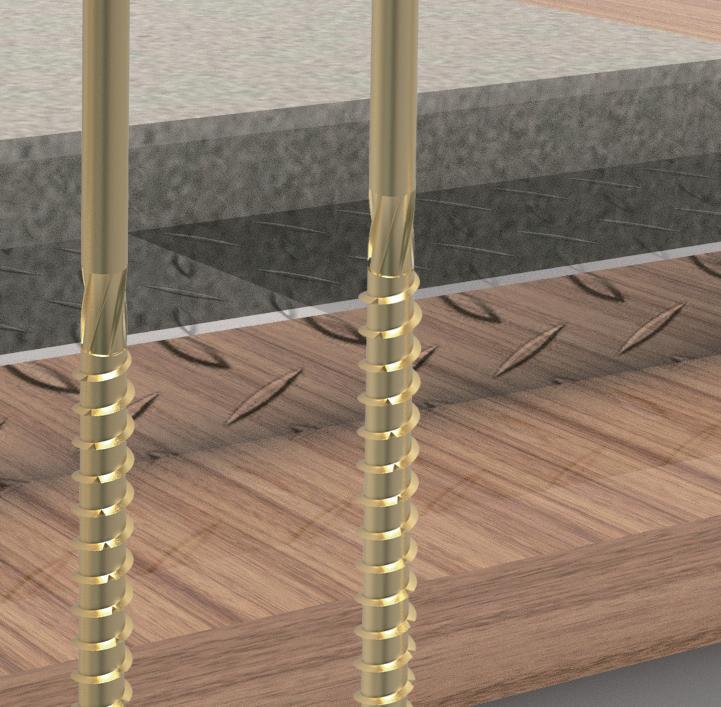

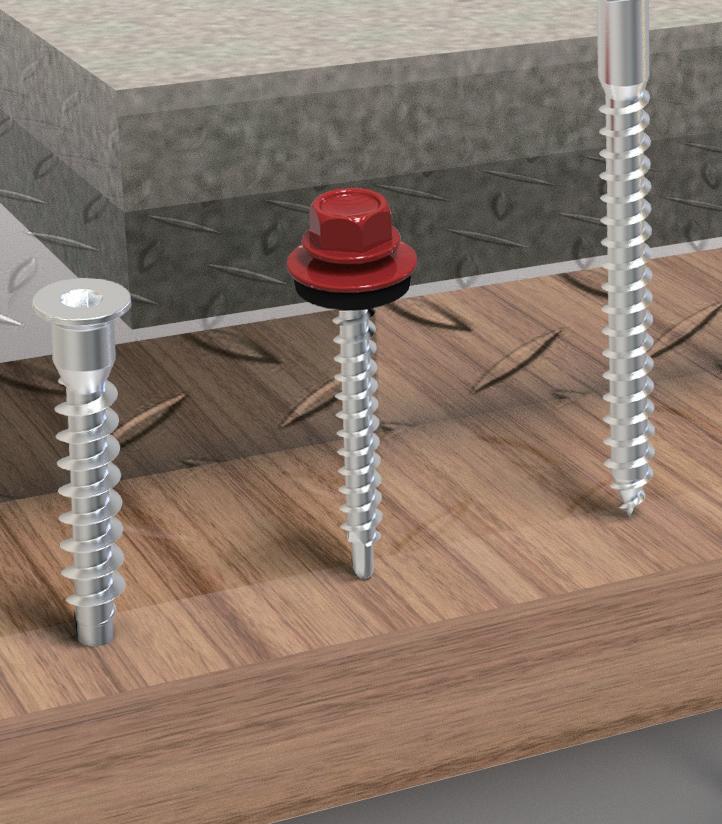

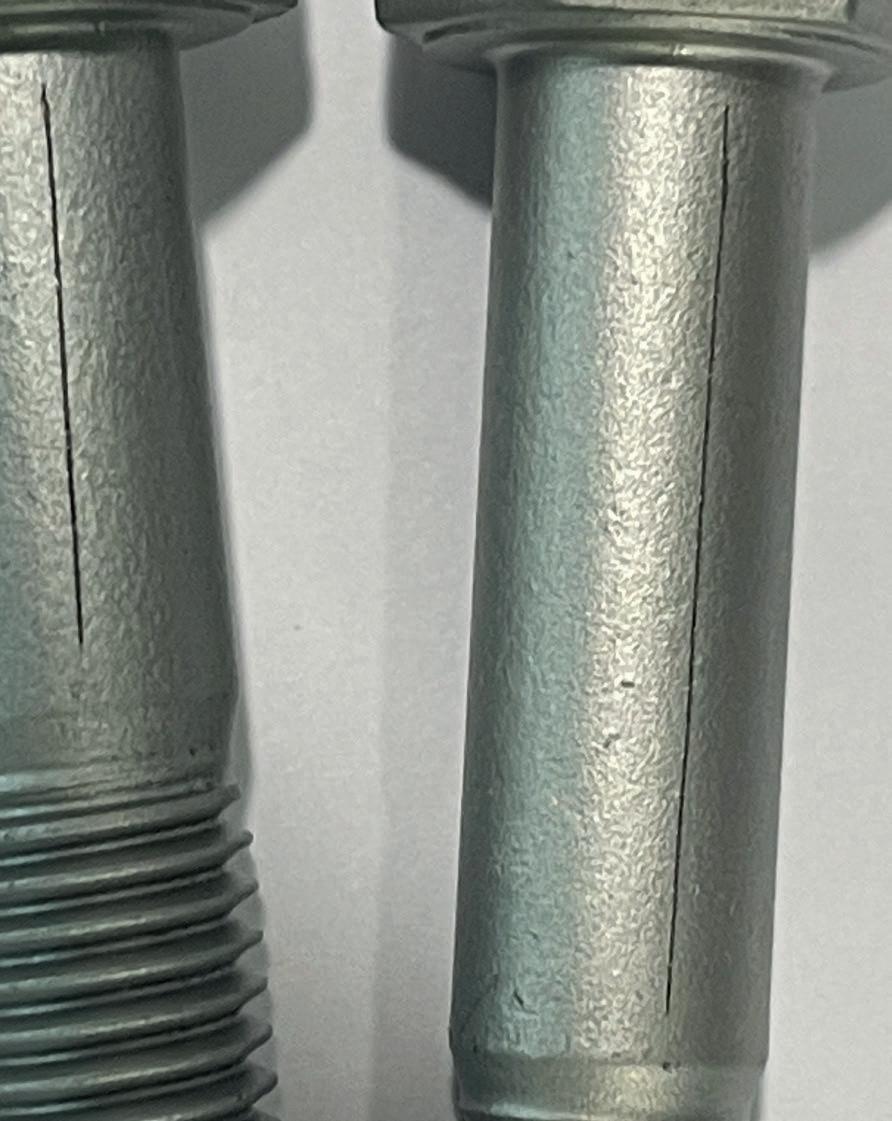

For three generations, pgb-Europe NV has been selling all kinds of fasteners for the construction sector – from small screws to European certified construction bolts and nylon plugs, to seismic-tested anchors. With a range of around 30,000 items continuously available from stock, the family business offers a solution for just about every fastening challenge.

Founded in 1956, pgb-Europe has grown into an international player, with its head office in Melle, Belgium; a production facility in Poland; sales organisations in France and the Netherlands; and a sourcing hub in Shanghai, China. A total of 150 employees work for the family business, with the management team consisting of

the managing directors Frederik Pennoit, Johannes Heye and Vincent Pennoit, as well as CEO’s Marc and Luc Pennoit pgb-Europe focuses on three sales channels – retail, industry and export. Over the years, the company has built up very strong coverage in the Benelux countries and now it is expanding to other European countries – with a special focus on the French market. The production plant for plastic anchors, pgb-Polska, is also active on the eastern European market.

“A series of investments over recent years has been leading to a complete product range and private label solutions for our customers,” explains pgb-Europe. “At the beginning of 2023 we will also finish the installation of a completely new fully automatic packaging line for boxes.”

Automation and digitisation are key to all of pgb-Europe’s processes, as well as guaranteeing it can continue to meet the increasing performance requirements from the market, which is why it will go on investing in the future. “Even for commodity products, such as fasteners and fixings, everybody wants the product they ordered yesterday. Beside a correct price and quality, speed and accuracy are very important for customer satisfaction,” points out pgb-Europe. “Digitisation can play a key role in maximising customer service and at pgb we already have a number of initiatives. We work paperless as much as possible, which starts with our incoming orders and price requests that are digitally managed. Within our different premises, we also use the same SAP ERP system, which takes away a lot of manual jobs – including PDFs being processed via an AI system that converts it to an import-ready file.”

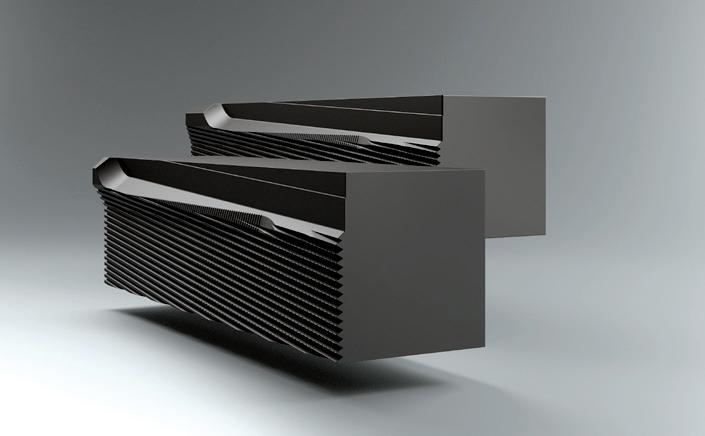

pgb-Europe’s warehouse also features a high level of automation, with over 800 incoming containers and 15,000 tonnes of goods shipped out every year. “It is very important that all the processes are well streamlined. Goods are stored in our high-bay pallet warehouse with automatic cranes and multiple AGVs (Automated Guided Vehicles) fulfilling our internal transport. Instructions are given on screen and the whole warehouse is using scanners to read the barcode locations for drop-off or pick-up zones. This dramatically reduces the chance of errors as each step is traceable – meaning the entire product chain can be mapped.”

Standardisation is also very important to optimise efficiency. For many years pgb-Europe has established a standardised line of box packaging, which is a great service for customers because they know the next time they order the same product, it will arrive in the same box. Finally, a detailed follow-up of all deliveries is possible through an extensive dispatch note, linked to the box number.

Through its web shop pgb-Europe is able to provide customers with 24/7 access to its online product catalogue. Easy navigation also helps users to quickly find the product and technical specifications they need. In addition, registered customers can enjoy all kinds of commercial conveniences, such as online ordering and checking available stock. They can also make lists with favourite articles, link their own article codes, as well as check the order history, etc. It is also possible to set authorisation levels to different users within organisations. For example, someone can prepare the order, but they have no authorisation to place it without permission. This gives customers’ control over the buying process.

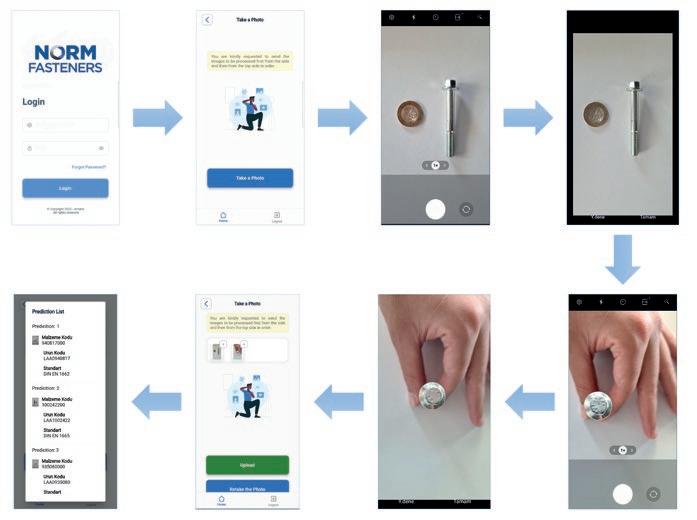

Manual ordering can be time consuming, especially with big product families such as fasteners. That is why pgb-Europe has developed an upload tool that can import txt files very quickly. Another option is the pgb-ScanApp, which is a free to download App that enables customers to quickly fill

their basket by means of scanning EAN codes. “This tool is seamlessly integrated with our web shop, which means one can shift easily from the small cellphone screen to their laptop or PC to finalise or check the order before sending,” explains the company. “Our web shop is a very important sales channel extension and is a non-stop project – with a major update of the web shop being published very soon.”

Alongside its web shop, pgb-Europe also offers a number of other digital connection possibilities. “More and more customers use fully or partly EDI integration, and currently we are deploying a PunchOut catalogue as well. This allows customers to send the order directly to their ERP system. In this way we are able to make our customers’ ordering process even more efficient,” mentions pgb-Europe.

Although as a business pgb-Europe is very digitally focused, it also attaches great importance to its people. “Technology is here to assist us, but it is thanks to our dedicated team that we are able to achieve our goals. Long-lasting relationships are vital,” states the company. “Our representatives are the main points of contact and internally two people are designated as contact persons for a specific customer. We always try to be as transparent as possible and communicate in an open way to give our customers the tools to work with their customers.”

That is also why the business has invested in a Product Information System (PIM) to capture and centralise all product-related information – such as descriptions, image and video material, area of application, etc. “This is not only relevant for us, it is especially interesting for our customers. The demand for reliable data is big. Our (retail) customers want to offer a better service themselves and rely on our data to develop their online web shops. Because we can provide this, we also offer them great added value,” concludes pgb-Europe.

www.pgb-europe.com

pgb-Europe will be present at Fastener Fair Global 2023 in Stuttgart, Germany. At its spacious stand it will proudly showcase the vast range of product possibilities the company has to offer – with its experienced team of representatives willing to guide visitors through the extensive services the company can provide.

“We sincerely look forward to meeting you soon in Stuttgart!”

Fastener + Fixing Magazine last published an article from the European Fastener Distributor Association (EFDA) back in May 2022 – regarding the association’s conference in Madrid, Spain. With that in mind, we spoke to EFDA President Andreas Bertaggia about what the association, and its members, have been focused on since the conference and what they will be concentrating on for 2023.

planned Carbon Border Adjustment Mechanism (CBAM).

“Our members from all over Europe were very happy to finally meet in Madrid after the Covid-19 pandemic. Since then, we have been able to continue our work online and with in-person meetings, most recently at Fastener Fair Italy in Milan in December. The issues that have been challenging EFDA and its member associations, and affiliated companies, are many: How secure are the procurement markets? How do we deal with increasing supply chain regulation? And how do we adjust to more sustainability?

As for 2023, I believe that supply chain regulations and compliance requirement, as well as Environmental, Social and Governance factors (ESG) – especially sustainability – will be big factors for European fastener distributors. For instance, many regulations originate in Brussels, such as the planned EU Directive on Corporate Social Due Diligence, the planned EU Force Labour Ban Regulation and the

Laws also come from the nation states that are formally only applicable to local companies, but – as always with cross-border business – they also have an impact on our members in other countries through the supply chain. One example is the German Supply Chain Act, which came into force on 1 st January 2023. Similar laws already exist in other EU member states.

EFDA and its member associations are committed to ensuring that the requirements of the legislation are appropriate for the small and medium-sized structure of its trading companies. The laws must stand up to the test of practice. It must not be the case that smaller trading companies have to give up because they can no longer cope with the bureaucratic requirements. It is therefore a question of a fair balance between the overriding interests of the public and feasibility in the company. This is what we stand up for as the voice of the European fastener distributors in Europe. Of course, we keep our members informed about the progress of the legislative process and provide them with information for the implementation.”

How did the second half of 2022 progress for the association and its members after the Madrid conference? What topics do you believe will be the main focus for the fastener industry in 2023?

EFDA’s

“This disproportionately high anti-dumping duty of 86.5% hit the industry at a time when it had already faced multiple challenges, such as unreliable delivery times, as well as high container and raw material prices. Now, high energy prices and geopolitical uncertainties are added to the mix, as well as the legislative requirements already mentioned. The outlook for the industry is anything but certain.

With regard to the anti-dumping duties per se, a particular challenge for our members is dealing with imports from Chinese companies, to which the lower duty level of 39.6% applies. European importers must be extremely careful to ensure that the imported goods are also subject to the lower duty rate. In practice, this can be more difficult than one might think. If mistakes are made here, the importer will end up paying the high duty rate of 86.5% for the imported goods.

For the industry, it can mean that this case of ‘internal circumvention’ within China leads to the high duty level being extended to all imports from China. A similar situation applies to circumvention via third countries. EFDA informs its members about what to consider when importing fasteners from China and also educates in Asia about the risk of circumvention.”

S ome European fastener manufacturers have looked to increase their capabilities when it comes to the products involved in the anti-dumping duties. Has this helped EFDA’s members? Where have

“Diversification in supply sources is certainly called for – due to many reasons. That is why, in addition to the People’s Republic of China, supply markets, particularly in Asia, continue to be important. For instance, Taiwan has always played an important role as a supplier of fasteners.

At the same time, it is still valid that there is no adequate supply of standard parts in the EU at all. At least according to our perception, this has not changed after the imposition of the anti-dumping duties. EFDA had repeatedly pointed out to the European Commission during the anti-dumping investigation that EU manufacturers will not produce sufficient quantities of standard parts. We have been proved right.”

It has almost been a year since the anti-dumping duties were applied to certain iron China. How has this impacted

members and the European fastener market a year on?

they looked to source these products if not within Europe?

EFDA and its member associations are committed to ensuring that the requirements of the legislation are appropriate for the small and medium-sized structure of its trading companies.”

“The anti-dumping duties are and remain wrong. The level of the general duty of 86.5% is completely unrealistic, harmful and also legally contestable. As already mentioned, the lower duty rate of 39.6%, which is to be applied to imports from some Chinese manufacturers, also leads to considerable difficulties in practice. We still see hardly any benefit in these duties for anyone, but considerable damage for many companies in Europe, especially our customers. We can look forward to the duties being declared illegal one day. One possibility is a determination by the WTO.”

“EFDA will again be present with its own stand at the upcoming trade fair in Stuttgart. The point is to have a contact person on-site for a personal discussion, also on the part of the association. In times of online meetings, face-to-face meetings are more important than ever.

We are also using Fastener Fair Global to gain new members. In addition to national member associations, companies can also become members of EFDA directly if there is no national association for fastener distribution in their country to represent their interests. These companies become members of the so-called MEFDA group, where we already have companies from Finland to Portugal, and from Hungary to Belgium.

The MEFDA group meets regularly and exchanges information on current topics in the fastener business. The companies receive important information from EFDA. We hope that many European fastener distributors will visit us in Stuttgart in March.”

the legislative processes at European level, its national members at national level. They all inform their members about the new challenges and developments so that they can adapt to the changes.

However, ESG compliance already plays a major role for almost all fastener distributors in Europe. Although SMEs are often exempted by the legislator, even the smaller companies are active in this field because in many cases a strong customer dictates what compliance is required – and EFDA members are prepared for that.

Of course, ESG compliance causes a lot of administrative costs, efforts, and complexity, that nobody likes from a company point of view. However, many European fastener distributors have also realised that ESG compliance can create a competitive advantage, in the home market, in Europe, but also in global markets. The EU has the most ESG regulations to comply with compared to other regions. We assume that Europe is and will remain the leader here, while governments in other parts of the world will sooner or later follow the same or a similar path. For this reason, it is worth being at the forefront right from the start.

“Rising energy costs and the associated uncertainties are playing a major role for fastener distributors pretty much everywhere in Europe. We hear that many companies are taking a close look at the issue and where they can make savings.

Within EFDA, we regularly exchange views on the current challenges of our industry in various committees and groups. Of course, energy demand plays an important role in this, especially as manufacturers are hit harder than retailers by rising energy costs, which they pass on to retailers or end customers in the supply chain, which in turn fuels inflation.”

“Sustainability is a big issue and is steadily gaining importance for the fastener industry and the economy as a whole. The Environment, Social and Governance (ESG) requirements for companies also continue to increase and become more comprehensive – at European and national level. As already mentioned, EFDA is involved in

Another major factor is geopolitical situation, which is more uncertain that it has been for a long time. Taiwan is a particular focus. Should the international tensions have a negative impact on Taiwan or even lead to a slump in the Taiwanese market, this would have disastrous consequences for the fastener industry.

Another unknown is the Russian war of aggression on Ukraine. We can only hope that this will come to an end soon and that stability all over the world will return.

A further challenge for our members is the difficult labour market situation. This affects basically all of Europe, some countries more, some less. The problem is that there are too few or too few qualified workers. Accordingly, the salary expectations of many applicants are rising immeasurably. With the shortage of labour, personnel costs in fastener distribution companies are rising, which has a negative impact on margins. We still expect great pressure here in 2023.

Finally, digitalisation will change the industry even faster than before, making it even stronger and indispensable. We can observe that most companies are analysing and defining their digitisation strategies. Many companies have already done a lot and have made big investments to keep up with the pace.

Throughout all this, EFDA will be active on behalf of its members and provide them with comprehensive information.”

www.efda-fastenerdistributors.org

W hat is EFDA’s approach regarding the anti-dumping duties? Is it still looking to overturn the decision?

E FDA will have a stand at the upcoming Fastener Fair Global show in Stuttgart, Germany. What are the association’s plans for the show?

A big factor over recent months has been the huge increases in energy prices. How have EFDA’s members been impacted? As an association how have you looked to support members with information, etc?

W hat do you see as being the big trends for the fastener industry in 2023 and beyond? How can your members benefit from these trends?

…many European fastener distributors have also realised that ESG compliance can create a competitive advantage, in the home market, in Europe, but also in global markets.”

Inoxdadi has announced that General Manager Giulio Gandioli passed away at the end of July 2022. Giulio lived his profession more as a passion than as a job, managing to be recognised as a gentleman both by the staff of Inoxdadi and by a very large audience of customers, suppliers, colleagues and competitors.

Born in Soncino, a small medieval village in the province of Cremona, Italy, in 1948, Giulio had a sister, Elvira, and a brother, Roberto. After completing his education, achieving a diploma as an industrial technician, Giulio quickly became a commercial director at the offices of an important multinational in the chemical sector, which was operating in Crema, Italy, at the time.

Always looking for new and more exciting challenges, he founded Inoxdadi Srl with a partner in 1973, with the company initially dealing with the production and marketing of turned nuts in stainless steel. At the beginning of the 1980s, with the need for larger volumes and the introduction of new production techniques, Inoxdadi decided to purchase innovative machinery for the cold moulding of dies. Shortly thereafter, the growing market demand led Inoxdadi to be a pioneer also in the direct importation of finished products.

In the 2000s, with the vision of Giulio, the company decided to concentrate all its resources on the production and marketing of niche nuts, which involved special processes and the use of very sophisticated and high performance materials – especially in terms of mechanical resistance, temperature and corrosion.

Through Giulio’s experience and knowledge, Inoxdadi has become a real point of reference in the fastener sector and a leading a supplier in the energy, automotive, nuclear, aerospace and construction fields. His punctuality and professionalism, as well as his capacity for objective judgment, made Inoxdadi a safe and performing ‘port’ in the immense ‘sea of bolts and nuts’.

Giulio leaves a well-organised company that can count on skills established over decades of production, as well as a first rate fleet of machines and highly qualified professionals – who have always been the key in the company’s ability to offer its customers the highest quality products and service for the last 50 years.

Going forward, Andrea and Silvia, Giulio’s children – who have long been employed at the company in the production and administrative departments – will continue their father’s work.

His punctuality and professionalism, as well as his capacity for objective judgment, made Inoxdadi a safe and performing ‘port’ in the immense ‘sea of bolts and nuts’.”

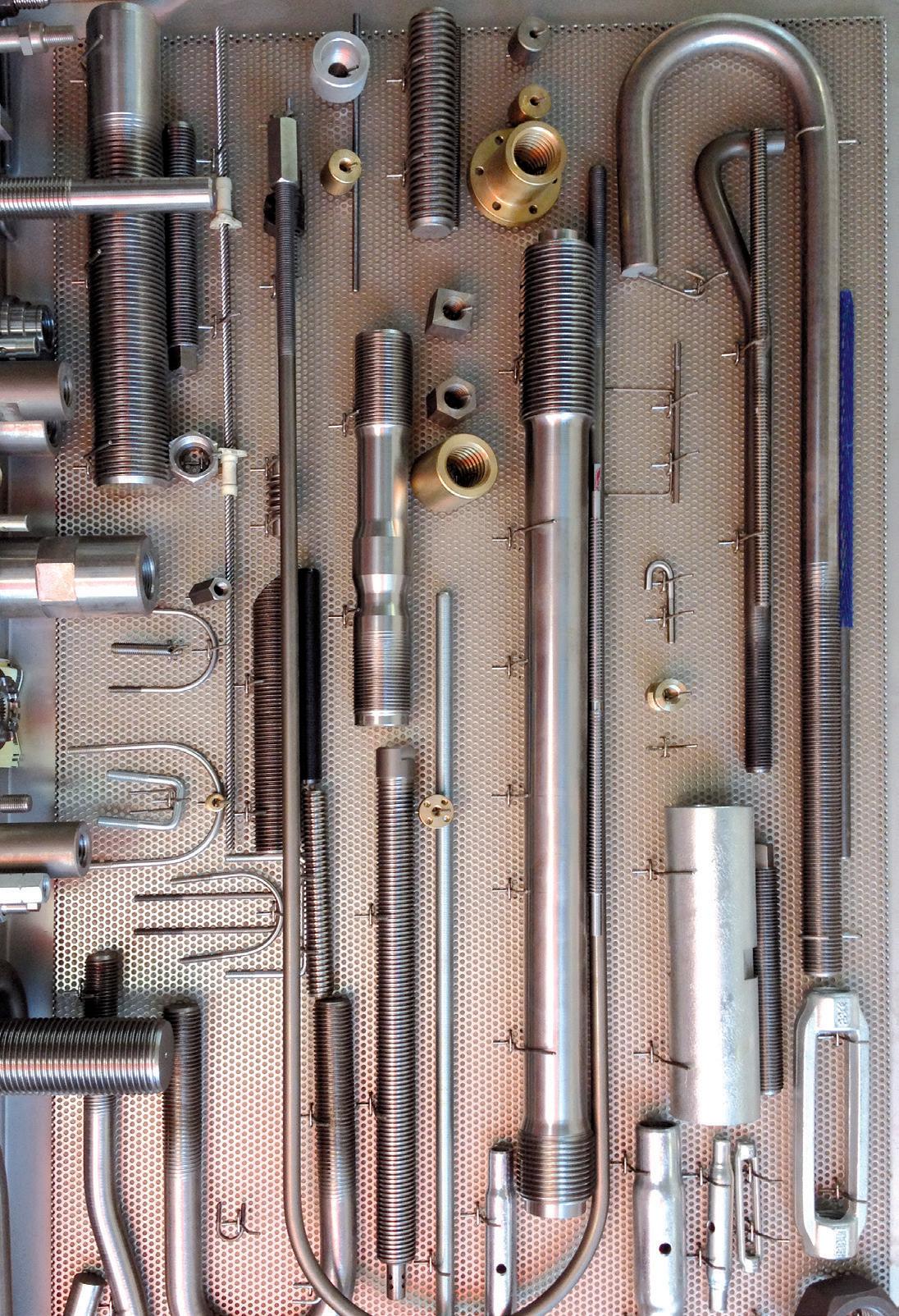

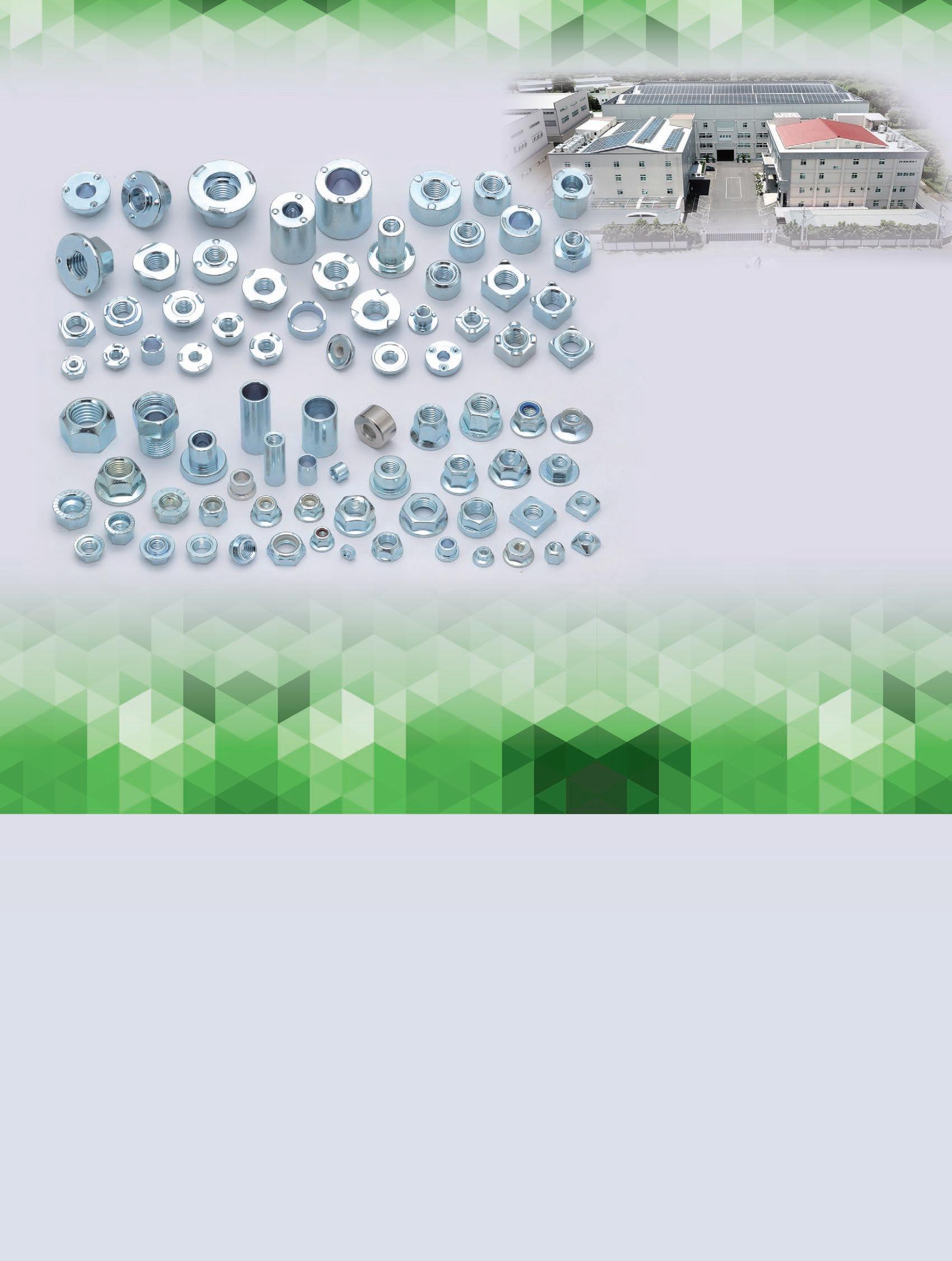

At the beginning of this year Brazilian manufacturer Hassmann will start the construction of a new 10,000m 2 facility to expand its production plant, which will enable it to continue to produce high performance industrial fasteners for customers around the world.

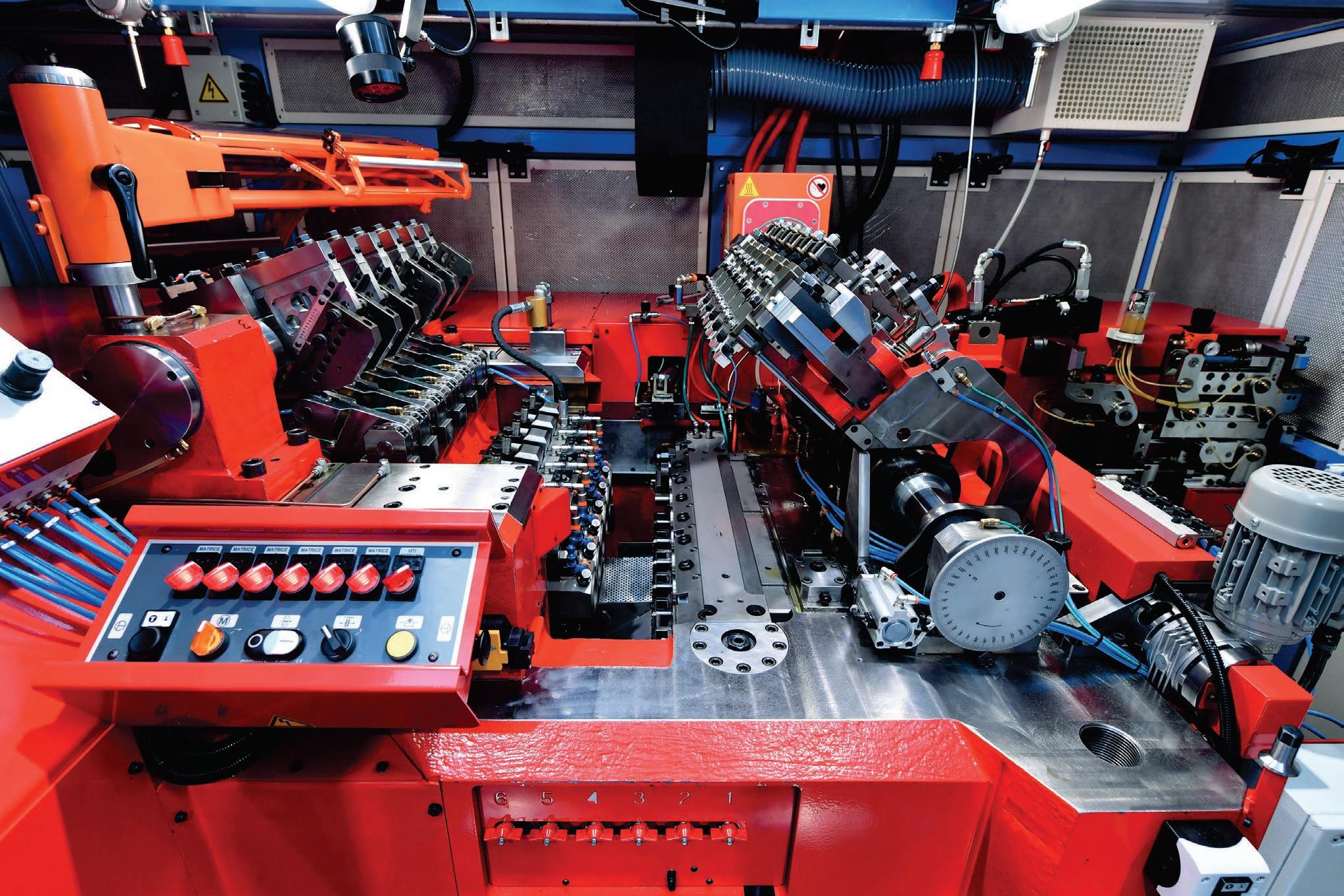

With a current site of over 40,000m 2 , and more than 400 employees, Hassmann S.A currently has a production capacity of 2,000 tonnes per month. Through continuous investments to increase production, the company is looking to grow this capacity even further. “In the last twelve months we have invested approximately US$10 million,” explains Diego Jezler, business developer at Hassmann. “This includes a new 800kg/h heat treatment line, two new combined 5-stage presses, two new CNC lathes and an automatic line for applying phosphate – in a galvanic plant we previously purchased.”

This production capability has led to Hassmann being able to manufacture parts according to international standards, as well as special parts according to customer drawings. Its product family is very diverse and includes hexagonal, flanged, french, weld, six-lobe, internal hexagon screws, as well as studs, rivets, pins and U-bolts, among others. In the nut segment it can offer hexagonal and flanged – with mechanical lock and nylon rings – as well as weld nuts.

However, what sets Hassmann apart in the market is its ability to manufacture special parts based on customer requirements, especially when it comes to the more diverse applications – such as engine screws, suspension screws, axles, brake system screws, seat belts, etc – all of which are extremely critical applications where there can be no failures or errors. “We are able to produce these high performance

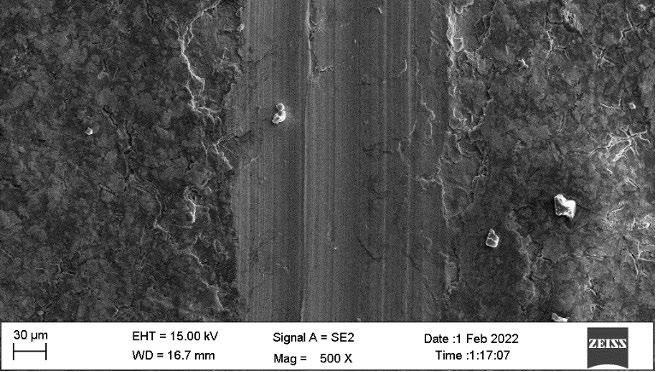

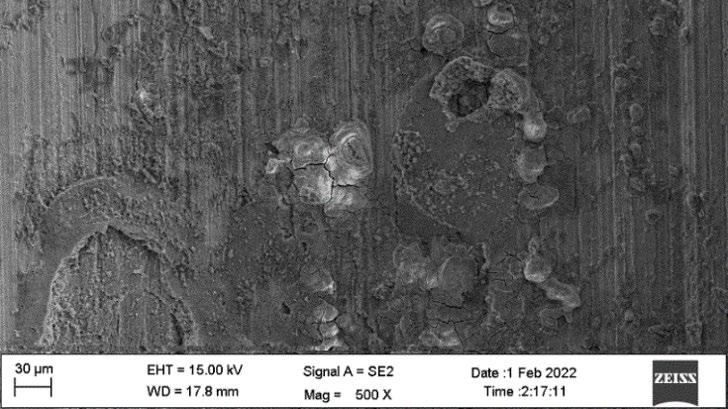

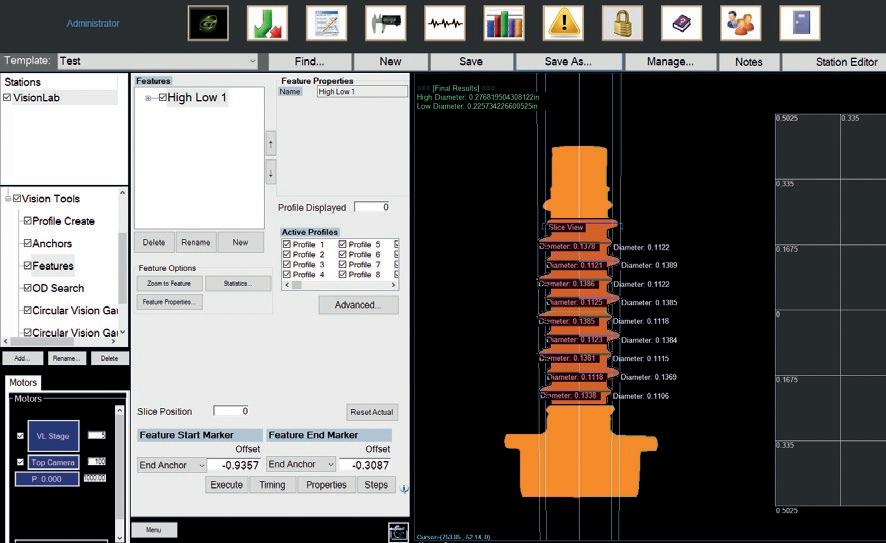

fasteners thanks to the quality assurance we are able to provide customers,” points out Diego. “Through our internal controls we can carry out numerous tests during every product process, including dimensional controls and visual inspections. Everything is standardised and through our modern, state of the art equipment we are able to maintain process stability, which has seen us achieve ISO 9001 and IATF 16949 certification.”

Hassmann’s vast array of capabilities and knowledge is thanks to its long history. After the second World War, in 1950, Austrian Engineer Karl Hassmann moved to São Paulo, Brazil, in search of better living conditions – having obtained a work contract from Vass Ernest, his brother-in-law’s company, who was already a resident in Brazil.

On a bus Journey in 1952 Karl met Elka Lagemann, a Brazilian teacher who struck up a conversation with Karl as she was also fluent in Germany. After several more meetings the two got married in São Paulo. In August 1955, Karl and Elka returned to Rio Grande do Sul, to live in Elka’s hometown, Imigrante, and in October of that year they founded Hassmann e Lagemann LTDA, along with three other shareholders.

Hassmann’s vast array of capabilities and knowledge is thanks to its long history.”

At the beginning of its activity, Hassmann was nothing more than a simple workshop, where small repairs, equipment maintenance, as well as the manufacture of spare parts for local industries, among other activities, were carried out. In the following years, the company began to manufacture metallic mechanisms for windows and doors. Only in 1960 did the production of fasteners begin. The reason was the search for a serial product, which obeyed international standards, combined with the needs of Brazil – until then, a country with little industrialisation. In just five years, Hassmann was able to attract several large customers. From this point the company has evolved from generation to generation, with the business remaining 100% family owned – with the second generation currently in management and the third actively participating in decisions.

Today, Hassmann offers much more than just an in-depth family of fasteners, the company can also supply a range of logistical services and solutions through two warehouses in Imigrante, Rio Grande do Sul, Brazil, and another in Tampa, Florida, USA –including the ability to manage stock levels for customers, with weekly or daily deliveries. Hassmann can also store all parts for customers, helping eliminate certain management costs; ensuring delivery on demand; and eliminating any risk of missing parts.

the best and most modern solutions in fasteners and in order to provide a differentiated service every day,” explains Diego. “We already export to every continent and are currently in a phase of internationalisation as a business. For instance, we already have a representative within the UK. This internationalisation is also underlined in our long-term planning, in which we are even considering taking part of our operation abroad to be ever closer to our customers. This idea is still in the early planning stages, but it shows how we are looking forward and how we can offer our high performance fasteners to the most diverse markets – meeting every need and expectation.”

To add to this, Hassmann also has a technical division, including an in-house laboratory, which focuses on the needs of the fastener industry – with the ability to use forming simulation software to help customers develop new products. The company’s export team can also handle all the procedures for customers, delivering parts to anywhere in the world.