Sono electro chemistry

VOL. 27, NO. 3

Fall 2018

IN THIS ISSUE

3 From the Editor: Passing the Baton (or Ball)

7 Pennington Corner: Once in a Lifetime

24 Special Meeting Section: AiMES 2018 Cancun, Mexico

33 Looking at Patent Law

39 Tech Highlights

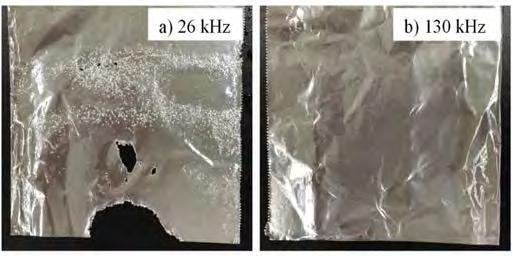

41 A Short Introduction to Sonoelectrochemistry

43 Introduction to Ultrasound and Sonochemistry

47 Sonoelectrochemistry: Both a Tool for Investigating Mechanisms and for Accelerating Processes

53 Ultrasonic Agitation for Emerging Electrodeposition Systems

59 In Situ Ultrasonic Dispersion in Multiphase Electrolysis Systems

142 The Electrochemical Society Interface • Fall 2018 • www.electrochem.org

(

A "Sound" Technology

( ( ( ( (

ECS Institutional Members

The Electrochemical Society values the support of its institutional members. These organizations help ECS support scientific education, sustainability, and innovation. Through ongoing partnerships, ECS will continue to lead as the advocate, guardian, and facilitator of electrochemical and solid state science and technology.

2018 Leadership Circle Award Recipients

GOLD (25 years)

Central Electrochemical Research Institute

AMETEK-Scientific Instruments (37)

Bio-Logic USA/Bio-Logic SAS (10)

Duracell (61)

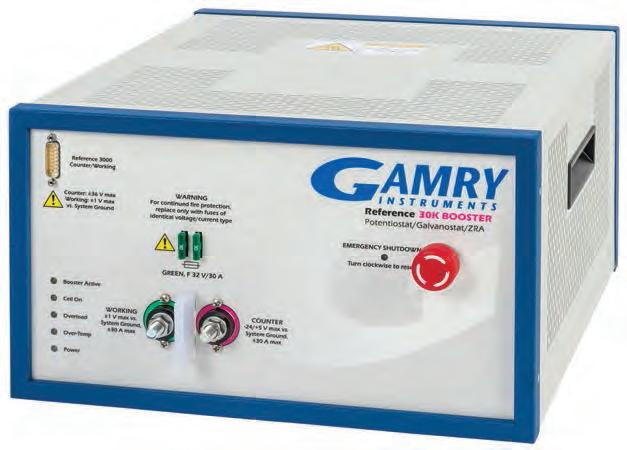

Gamry Instruments (11)

Gelest, Inc. (9)

3M (29)

Energizer (73)

Faraday Technology, Inc. (12)

IBM Corporation Research Center (61)

BASi (3)

Central Electrochemical Research Institute (25)

DLR-Institut für Vernetzte Energiesysteme e.V. (10)

EL-CELL GmbH (4)

Ford Motor Corporation (4)

GS Yuasa International Ltd. (38)

Honda R&D Co., Ltd. (11)

Medtronic Inc. (38)

Nissan Motor Co., Ltd. (11)

Axiall Corporation (23)

General Motors Holdings LLC (66)

Giner, Inc./GES (32)

International Lead Association (39)

Ion Power Inc. (4)

Kanto Chemical Co., Inc. (6)

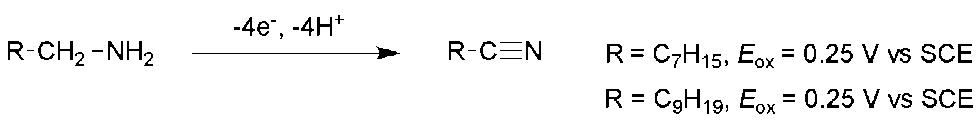

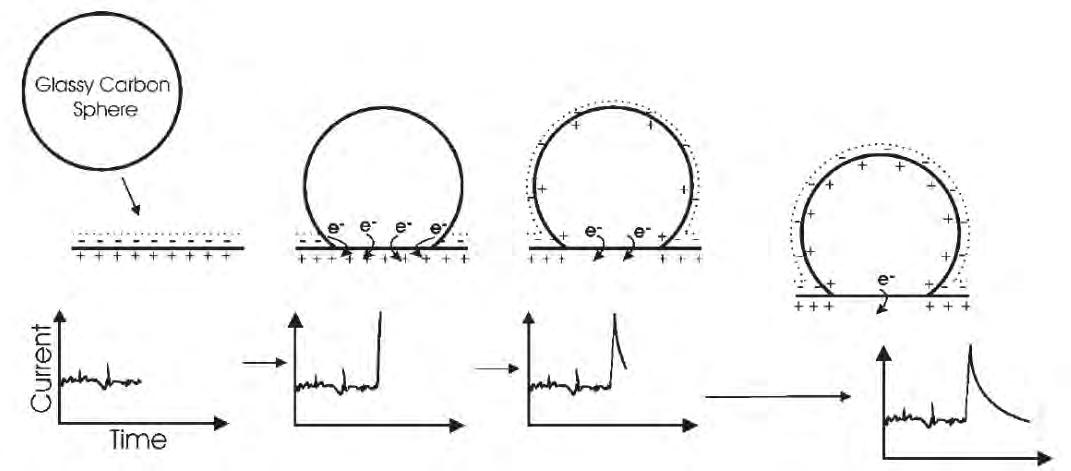

Karlsruher Institut für Technologie (2)

Leclanche SA (33)

SILVER (10 years)

Bio-Logic USA/Bio-Logic SASDLR-Institut für EnergiesystemeVernetzte e.V.

Benefactor

Hydro-Québec (11)

Industrie De Nora S.p.A. (35)

Pine Research Instrumentation (12)

Saft Batteries, Specialty Batteries Group (36)

(Number in parentheses indicates years of membership)

Patron

Lawrence Berkeley National Laboratory (14)

Panasonic Corporation, AIS Company (24)

Scribner Associates, Inc. (22)

Toyota Research Institute of North America (10)

Sponsoring

Permascand AB (15)

Technic Inc. (22)

Teledyne Energy Systems, Inc. (19)

The Electrosynthesis Company, Inc. (22)

Tianjin Lishen Battery Joint-Stock Co., Ltd. (4)

TOC Capacitor Co., Ltd. (1)

Toyota Central R&D Labs., Inc. (38)

Yeager Center for Electrochemical Sciences (20)

ZSW (14)

Sustaining

Los Alamos National Laboratory (10)

Microsoft Corporation (1)

MTI Corporation (2)

Occidental Chemical Corporation (76)

Sandia National Laboratories (42)

SanDisk (4)

Targray (2)

Please help us continue the vital work of ECS by joining as an institutional member today. Contact Shannon.Reed@electrochem.org for more information.

08/03/2018

Passing the Baton (or Ball)

The dog days of summer are in full flush in Dallas as I compose this editorial, and the curtains have just come down on a most exciting edition of World Cup soccer as well. And I get to write about the third most favorite thing in my life after chemistry and music: namely, sports. There is nothing more exquisite than a perfectly thrown Tom Brady touchdown in football (i.e., the American variety!), an inside-out forehand from Roger Federer, a Lionel Messi move in soccer, or a Kobe Bryant no-look, behindthe-back pass on the hoops floor. Similarly, seamless transfer of the baton in a relay race is satisfying to all involved. Sports teaches you about life as well, the ability to face success or failure with equanimity. On this topic, Rudyard Kipling famously wrote: “If you can meet with Triumph and Disaster / And treat those two impostors just the same.”1 (I urge you to read the full poem, titled “If—.”)

I am now passing the editorial baton to the new editor of Interface, Rob Kelly. It was most pleasing to see Rob taking the reins, as I have known him a long time, also from his role as a representative of the ECS Corrosion Division on the Interface Advisory Board. I have little doubt that Rob will run with the ball and take the magazine to new heights. He has the right combination of insightfulness, vision, and humor to handle whatever editorial challenges are hurled in his direction. This includes recalcitrant authors and guest editors.

I recall Mary Yess, the erstwhile managing editor of Interface, cautioning me when I first took over the editorial duties back in 1999. She advised me to put away my tennis racket and the guitar to focus on the more urgent tasks at hand with this magazine. I will echo similar words to you, Rob; please put away those golf clubs for a while. You will not have time to improve your handicap any time soon. And stay tuned.

Krishnan Rajeshwar Interim Editor

https://orcid.org/0000-0003-4917-7790

Most importantly, Raj—on behalf of the entire ECS— thank you for your stewardship of this great baton. Your contributions will always be part of its DNA. You have left large shoes to fill, but I will do my best to follow the Hippocratic Oath, or as my father often said, “Ok, Rob, try not to screw this up.” With both hands firmly on the baton, I will run as fast as I can until it is my turn to pass the baton to the next runner.

It is an exciting time for Interface. Its evolution will continue with the help of the Interface Advisory Board (IAB), the ECS staff, and ECS members, but its bedrock purposes will remain. Its first goal is to make the work of each topical interest area (TIA) accessible to members in other TIAs as well as to scientists in other disciplines who read these articles. Showcasing the importance of the work of ECS members to the general public is of increasing importance. Finally, its role as the historical record of the Society is important to honor those who have made ECS what it is, and as a reminder to all of what is expected of the caretakers of that baton. I will keep you in suspense about the details of our nefarious plans, but hints may be found in my answers to the Five Questions in the summer 2018 issue of this magazine. That said, I look forward to my first meeting with the IAB in Cancun (I know, rough duty), as well as any and all feedback from you, the readers. I am very much looking forward to running this portion of the race. Excuse me while I go carefully stretch out my hamstrings; they have been dormant for a long time.

Published by: The Electrochemical Society (ECS) 65 South Main Street Pennington, NJ 08534-2839, USA Tel 609.737.1902, Fax 609.737.2743 www.electrochem.org

Editor: Rob Kelly, rgk6y@virginia.edu

Guest Editor: Bruno G. Pollet, bruno.g.pollet@ntnu.no

Contributing Editors: Donald Pile, donald.pile@gmail. com; Alice Suroviec, asuroviec@berry.edu

Managing Editor: Annie Goedkoop, Annie.Goedkoop@electrochem.org

Print Production Manager: Dinia Agrawala, interface@electrochem.org

Advertising Manager: Ashley Moran, Ashley.Moran@electrochem.org

Staff Contributors: Marcelle Austin, Annie Goedkoop, Ngoc Le, John Lewis, Shannon Reed, Andrew Ryan, and Mary Yess.

Advisory Board: Christopher Johnson (Battery), Masayuki Itagaki (Corrosion), Durga Misra (Dielectric Science and Technology), Philippe Vereecken (Electrodeposition), Jennifer Hite (Electronics and Photonics), A. Manivannan (Energy Technology), Sean Bishop (High-Temperature Energy, Materials, & Processes), John Weidner (Industrial Electrochemistry and Electrochemical Engineering), Uwe Happek (Luminescence and Display Materials), Slava Rotkin (Nanocarbons), Jim Burgess (Organic and Biological Electrochemistry), Andrew Hillier (Physical and Analytical Electrochemistry), Nianqiang (Nick) Wu (Sensor)

Publisher: Mary Yess, mary.yess@electrochem.org

Publications Subcommittee Chair: Stefan De Gendt Society Officers: : Yue Kuo, President; Christina Bock, Senior Vice President; Stefan De Gendt, 2nd Vice President; Eric Wachsman, 3rd Vice President; James Fenton, Secretary; Gessie Brisard, Treasurer; Christopher J. Jannuzzi, Executive Director

Statements and opinions given in The Electrochemical Society Interface are those of the contributors, and ECS assumes no responsibility for them.

Authorization to photocopy any article for internal or personal use beyond the fair use provisions of the Copyright Act of 1976 is granted by The Electrochemical Society to libraries and other users registered with the Copyright Clearance Center (CCC). Copying for other than internal or personal use without express permission of ECS is prohibited. The CCC Code for The Electrochemical Society Interface is 1064-8208/92.

Canada Post:

Publications Mail Agreement #40612608

Canada Returns to be sent to:

Pitney Bowes International, P.O. Box 25542, London, ON N6C 6B2

ISSN : Print: 1064-8208 Online: 1944-8783

The Electrochemical Society Interface is published quarterly by The Electrochemical Society (ECS), at 65 South Main Street, Pennington, NJ 08534-2839 USA. Subscription to members as part of membership service; subscription to nonmembers is available; see the ECS website. Single copies $10.00 to members; $19.00 to nonmembers. © Copyright 2018 by The Electrochemical Society. Periodicals postage paid at Pennington, New Jersey, and at additional mailing offices. POSTMASTER: Send address changes to The Electrochemical Society, 65 South Main Street, Pennington, NJ 08534-2839.

Editor

rgk6y@virginia.edu

https://orcid.org/0000-0002-7354-0978

The Electrochemical Society is an educational, nonprofit 501(c)(3) organization with more than 8,500 scientists and engineers in over 75 countries worldwide who hold individual membership. Founded in 1902, the Society has a long tradition in advancing the theory and practice of electrochemical and solid state science by dissemination of information through its publications and international meetings.

The Electrochemical Society Interface • Fall 2018 • www.electrochem.org 3

All recycled paper. Printed in USA.

FROM THE EDITOR

1. R. Kipling, “Brother Square-Toes,” Rewards and Fairies (1910).

Rob Kelly

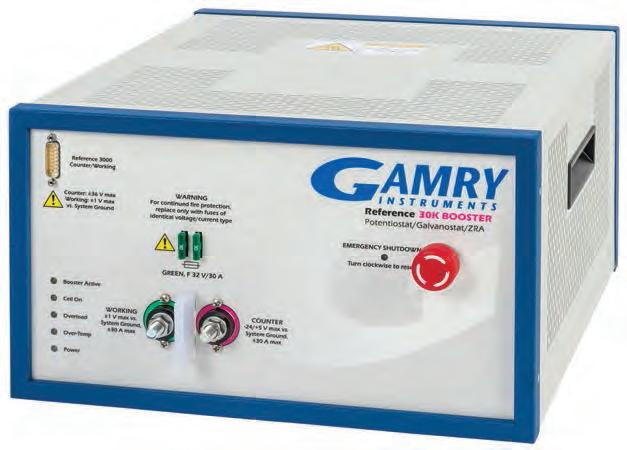

Rapid, High-Current Pulsing & Superior, Low-Impedance EIS www.gamry.com Reference 30K Booster Nobody is faster Distortion-free, rapid pulsing for charge and discharge 30 A Pulse on a 5 mOhm cell Nobody goes lower Up to 30A @ 20V, EIS to 300 kHz 200 nOhm Shorted Lead Curve 20 A rms, 0.9 m cell cable

by Bruno G. Pollet

by Wu Li and Muthupandian Ashokkumar

by Mahito Atobe and

by Mahito Atobe and

142 The Electrochemical Society Interface • Fall 2018 • www.electrochem.org Vol. 27, No. 3 Fall 2018 3 From the Editor: Passing the Baton (or Ball) 7 Pennington Corner: Once in a Lifetime 9 Society News 24 Special Meeting Section: AiMES 2018 Cancun, Mexico 32 People News 33 Looking at Patent Law 39 Tech Highlights 64 Awards Program 76 New Members 80 Student News A Short Introduction to Sonoelectrochemistry

Introduction to Ultrasound and Sonochemistry

Sonoelectrochemistry: Both a Tool for Investigating Mechanisms and for Accelerating Processes

Jean-Yves

Marie-Laure Doche, Loic Hallez, Abdeslam Et Taouil, and Bruno G. Pollet Ultrasonic Agitation for Emerging Electrodeposition Systems

S. Roy and S. J. Coleman In Situ Ultrasonic Dispersion in Multiphase Electrolysis Systems

by

Hihn,

by

Frank

41 43

47 The Electrochemical Society Interface • Fall 2018 • www.electrochem.org 5

Marken

53 59

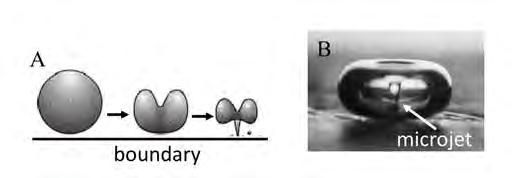

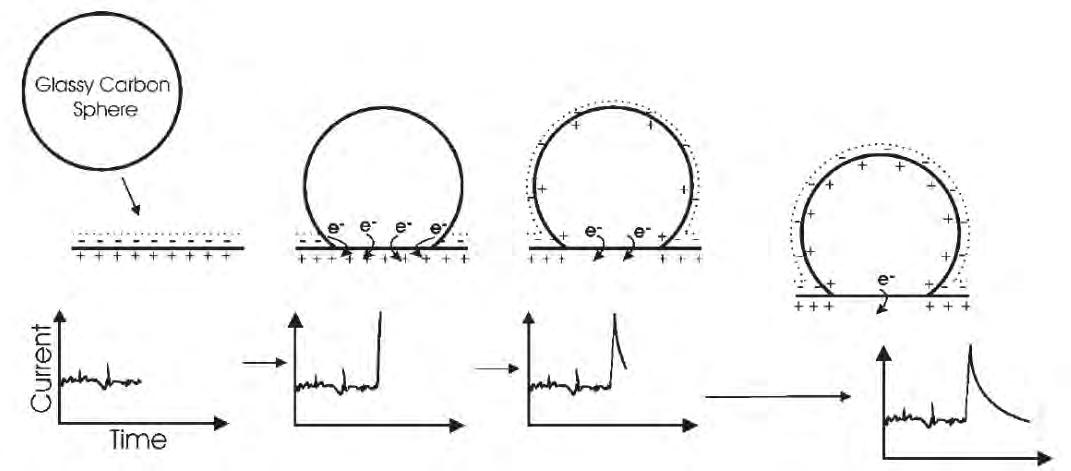

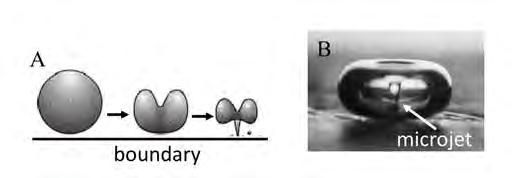

On the Cover: A cavitation bubble imploding near the electrode surface causing the formation of a highvelocity microjet of liquid hitting the surface. See article on page 41.

Cover design by Dinia Agrawala.

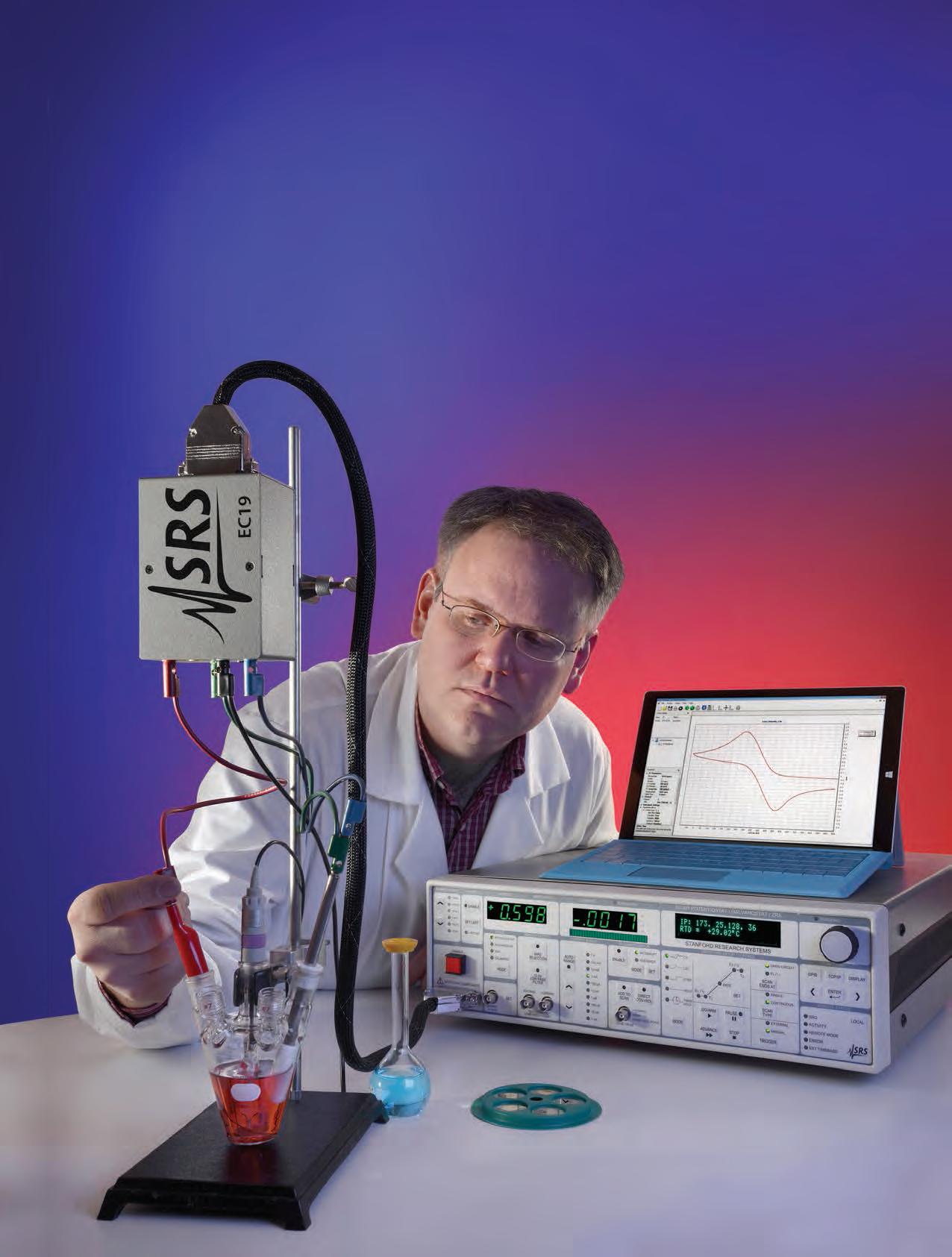

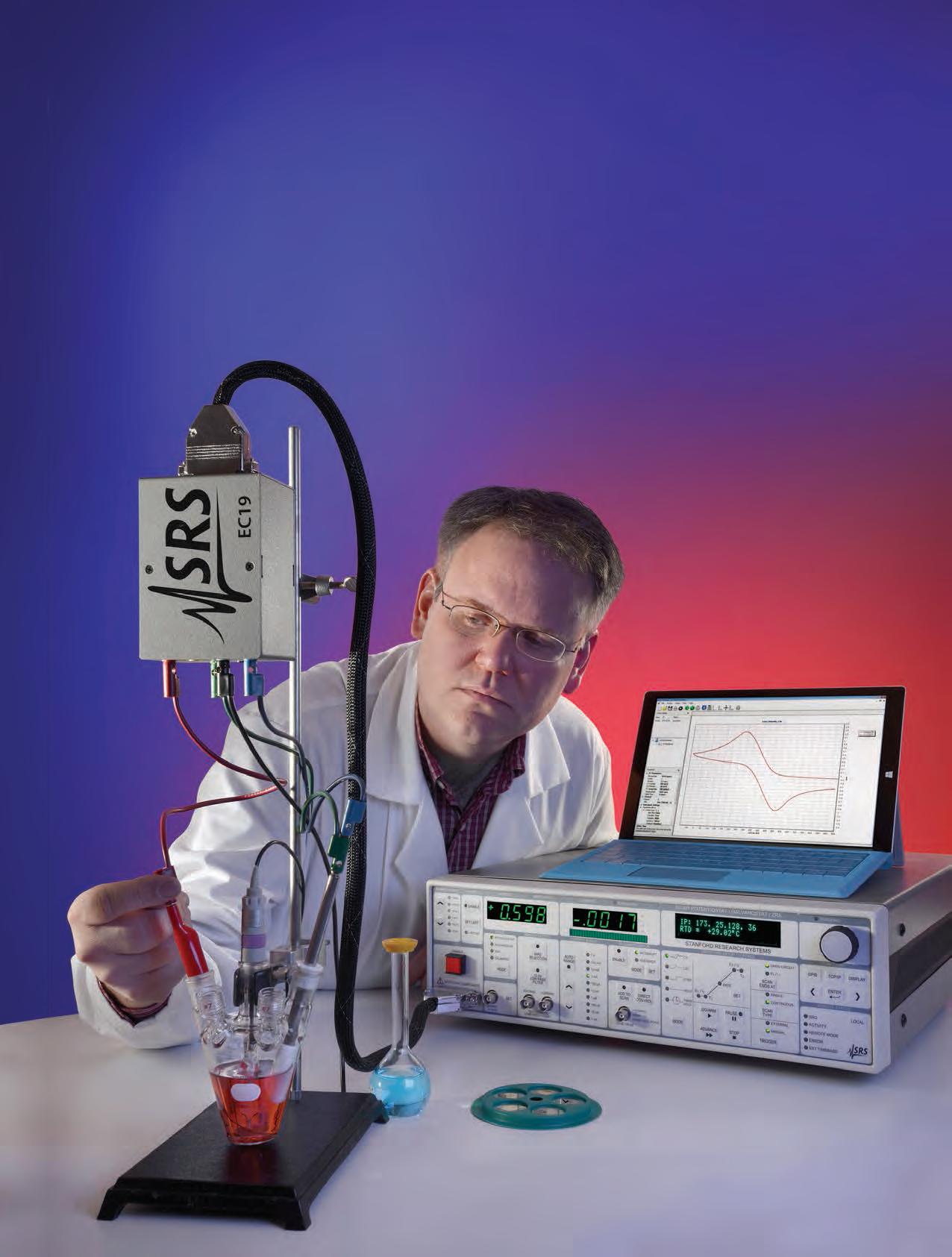

Research grade Potentiostat / Galvanostat Model EC301 ...

$7990

The new EC301 Potentiostat / Galvanostat meets the requirements of modern research while offering tremendous value. Hardware for electrochemical impedance spectroscopy (EIS) is built in to the instrument and included at no extra charge. The compliance, bandwidth, and polarization range of the EC301 let you handle the most demanding of electrochemical cells.

With an intuitive front panel, the EC301 gets you up and running in seconds. When you’re ready to stream data to the PC, the Ethernet and GPIB interfaces offer speed and convenience. The software is completely free; all the techniques are included. There are no modules to unlock, no add-ons to buy.

· 30 V / 1 A compliance

· ±15 V polarization range

· 1 MHz potentiostatic bandwidth

· Grounded or floating operation

· EIS & software included

Tel: (408) 744-9040 . www.thinkSRS.com/ec

Research Systems

Stanford

Once in a Lifetime

In the summer of 2009, less than a year into my time with my previous employer, IEEE, my then boss suggested I attend a meeting of an organization with which we cosponsored several technical journals. Being new to both working for a technical society and living in the state of New Jersey, I was familiar with neither the organization hosting the meeting nor the town in which it was located. But I was eager to learn all I could about my new role, and my new home state, so I agreed to attend.

Although I cannot recall specific details about that meeting, I do clearly remember how I felt after it was over. As I walked back to my car, I called my wife, Liz, and told her how impressed I was with the organization and the people working there. Even the office building, with its homely feel and comfortable, wooden library-style meeting room, appealed to me.

“I could really see myself working here,” I said.

Over the years, Liz has heard me muse about a lot of things I could see myself doing career-wise, so she did not put a lot of stock in my comment. To a certain extent neither did I—after all, I had only recently started my position with IEEE and was extremely excited about the prospects my new job held, but I never forgot about that meeting, or the people I met that day.

As you may have surmised by now, that fateful meeting I mentioned took place at ECS. The people I met with were Annie Goedkoop and Mary Yess, long-standing members of the team I so proudly joined on July 19. What an amazing thing to ponder as I sit at my desk, on day three of my new job, writing the first of (hopefully) many Pennington Corners!

When I consider the serendipity of events that led to my joining ECS, from my long-ago interest in the Society, to the alignment of my relevant skills and experience, to my strong belief in the mission of ECS and the Free the Science initiative, this is truly a once-in-a-life-time opportunity for me and one to which I am inspired to fully commit my time, talent, and resources. However, this is also bittersweet for me, for as

excited as I am to be in my new role, I will sincerely miss the opportunity to work more closely with Roque Calvo. Being his successor is as much an honor as it is a daunting task. Though I know that if I am even half as successful as Roque has been during his tenure with the Society, I will have done a great service for ECS, its members, and the community at large.

Over the coming weeks and months, my plan is to immerse myself in all I can about ECS, to develop a deep understanding of our operations and strategic plan, and to work with the volunteer leaders and senior staff to chart our future directions. Granted, there is quite a lot of work ahead of us, and we face challenges on many fronts. However, with the insightful leadership of ECS President Yue Kuo and the rest of our outstanding volunteers, coupled with the multifaceted capabilities of the Society’s professional corps, I have every confidence that together we will be successful at maintaining and advancing ECS’s preeminence in the field of electrochemical and solid state engineering.

In closing let me say what an incredible privilege it is to serve as executive director of this remarkable organization. I look forward to working closely with each and every one of you. Anytime you have questions, comments, or just want to reach out, please do! I would love to hear from you at Chris.Jannuzzi@electrochem.org.

Thanks and all the best!

Christopher J. Jannuzzi ECS Executive Director/Chief Executive Officer Chris.Jannuzzi@electrochem.org

https://orcid.org/0000-0002-7293-7404

The Electrochemical Society Interface • Fall 2018 • www.electrochem.org 7 PENNINGTON CORNER

When I consider the serendipity of events that led to my joining ECS, from my long-ago interest in the Society, to the alignment of my relevant skills and experience, to my strong belief in the mission of ECS and the Free the Science initiative, this is truly a once-in-a-life-time opportunity for me.

Introducing Dual-Channel Functionality to the PARSTAT MC Family

PMC-200

Maximize throughput with two channels per module, each with EIS and core DC testing functionality

1-Amp of current standard allows analysis of larger batteries at higher rates

24-Bits ADC components delivering the highest quality voltage and current resolution of measured response

Installs into the PARSTAT MC Chassis in minutes with no hardware or training.

Can be operated alongside other PMC modules maximing the value of your PMC Chassis

8 The Electrochemical Society Interface • Fall 2018 • www.electrochem.org

www.ameteksi.com

ECS Appoints New Executive Director/CEO

Last year, ECS leadership set about the herculean task of finding a successor to Roque Calvo, who served as a steward of the Society for over 37 years, directing its course through periods of immense change while vastly expanding its efforts to advance electrochemical and solid state science and technology.

Now, after an intensive candidate search that spanned months of consultations, interviews, and conferences, the Society is pleased to announce that it has found its new executive director and chief executive officer in Christopher J. Jannuzzi, former executive director of two IEEE societies: the Electron Devices Society and the Photonics Society

Jannuzzi demonstrates extensive experience in all aspects of the operations of scientific societies, coupled with strategic foresight and a propulsive passion for ECS’s mission.

Prior to joining IEEE, Jannuzzi was a senior director at the College Board in New York. He received his undergraduate degree from New York University and holds an MA in organization and leadership from Teacher’s College, Columbia University. Jannuzzi lives in Shrewsbury, NJ, with his wife, Elizabeth, and their children, Michael, Raymond, and Julia.

Selecting a Candidate

The Society’s search for a new executive director and chief executive officer was conducted by a committee chaired by ECS Secretary James Fenton and consisted of past ECS presidents Larry Faulkner, Fernando Garzon, Dennis Hess, and Esther Takeuchi. With the assistance of a search firm, the committee carried out a thorough and inclusive evaluation and interview process, speaking with staff, division leaders, past presidents, and others to obtain input to guide their candidate search.

Drawing from this input, the search committee determined that the new executive director’s priorities should be to (1) expand ECS’s reach and global presence, (2) lead and organize ECS staff, (3) evaluate ECS’s financial model, (4) develop new external partnerships, and (5) strengthen governance and board relations.

“Through my work at IEEE, I was very familiar with The Electrochemical Society and had the good fortune to work with ECS staff and volunteers on several joint initiatives over the years,” says Jannuzzi. “I have long admired the Society and am honored by the incredible opportunity to serve as its next executive director.”

The Society is thrilled to welcome Jannuzzi to the position, certain that his insight, energy, and leadership will foster great success for ECS in the years to come.

About Christopher Jannuzzi

Christopher Jannuzzi joined IEEE in 2009 as the executive director of the IEEE Electron Devices Society. In his time with EDS, Jannuzzi launched several key initiatives to ensure the society maintained its preeminence in the device engineering field. From leading efforts to redesign EDS’s digital presence, to leveraging the society’s longstanding connection to the photovoltaic research community to expand IEEE’s standing in the renewable energy space, to developing EDS’s robust webinar program, he helped revitalize and reenergize the EDS community.

Building on his success with EDS, IEEE expanded Jannuzzi’s role in 2014 to include leadership of the Photonics Society, providing him with the opportunity to have impact on cross-society strategic vision in addition to managing the societies’ day-to-day operations. Among Jannuzzi’s accomplishments with the Photonics Society was the launch of the IEEE Photonics Fund to raise capital for the society’s humanitarian initiatives and to foster diversity within its membership. Launched in 2016, the fund now provides over 100 scholarships and fellowships annually to help students and traditionally underserved communities choose photonics as an educational and career path.

Beyond his work with technical societies, Jannuzzi also helped lead the IEEE Internet Initiative, which raised the institute’s influence and profile in the areas of Internet governance and cybersecurity by providing a consensus of sound technical and scientific knowledge to the technology policy development process.

The committee also concluded from this feedback that the new executive director should possess certain qualifications and personal characteristics relevant to the role, including familiarity with the significance of electrochemistry and solid state sciences as well as the abilities to work with budgets, enhance meetings, understand the scholarly publication process, build relationships with members, fundraise, and sustain commitments to transparency, open communication, diversity, and inclusivity.

Based on these priorities and sought-after qualifications and characteristics, the search committee unanimously chose Jannuzzi as the best candidate for the role. ECS President Yue Kuo then requested a motion to appoint Jannuzzi as the Society’s new executive director, a decision Kuo firmly stands by.

“According to my impression,” Kuo says, “Chris possesses years of invaluable experience managing nonprofit professional societies similar to ECS. His appointment ensures the smooth transition of this highly important position in the Society. We expect that his expertise will further extend the Society’s 116-year history of success.”

Securing the Society’s Future

Jannuzzi bears a wealth of experience that will prove vital to the pursuit of Society objectives throughout the years to come. In addition to having served as the executive director of two IEEE societies, he has successfully managed budgets of approximately $12M. He also has been conducting development work in the technical society domain for a number of years and has secured over $500K in donations.

(continued on next page)

SOCIETY NEWS The Electrochemical Society Interface • Fall 2018 • www.electrochem.org 9

I have long admired the Society and am honored by the incredible opportunity to serve as its next executive director.

—Chris Jannuzzi

By endowing our publications operations through the Free the Science initiative, ECS has aligned how we fund publishing with our core mission to serve the public interest. This is precisely how nonprofits should act and one of the things that excites me most about my new role.

—Chris Jannuzzi

(continued from previous page)

Moreover, Jannuzzi has experience managing staff and working with hundreds of volunteers. He wields a collegial leadership style, interacting with members and volunteers with ease.

“Organizations such as ECS would not, and could not, exist without the dedication of its members and volunteers,” says Jannuzzi. “Therefore, the top priority of the executive director, as I see it, is to operationalize the vision of the Society’s elected leadership. ECS is blessed with a talented staff and a dedicated corps of world-class scientists and engineers to drive the organization forward.”

James Fenton, chair of the search committee, was struck by Jannuzzi’s drive to enhance collaborations between the Society’s staff, members, and volunteers.

“I feel Chris was impressed with the passion that the members felt for the Society and the family nature of the Society,” Fenton says. “Chris also has that passion and is looking forward to help lead the Society into an ever-changing future. Chris was impressed with the way ECS ‘punches above its weight class.’”

“When one considers the depth and breadth of all that ECS does—from conferences and publications, to education, awards, and member engagement, it is the staff-volunteer partnership that makes it all possible,” says Jannuzzi. “As executive director, my responsibility is to ensure that partnership continues to flourish.”

Jannuzzi was also chosen for his extensive experience in the scholarly publishing arena. IEEE has a $200M publishing enterprise; hence, Jannuzzi is quite familiar with the strains being placed upon scientific publishing. He is familiar with ECS publishing, having worked on publishing initiatives with the Society in the past, and is a staunch proponent of the Free the Science initiative.

“One of the things that most attracted me to ECS was Free the Science,” Jannuzzi says. “I have worked for many years in scientific publishing and seen firsthand the upheavals open access mandates are having on technical societies that rely on subscription-based revenue to survive. But by endowing our publications operations through the Free the Science initiative, ECS has aligned how we fund publishing with our core mission to serve the public interest. This is precisely how nonprofits should act and one of the things that excites me most about my new role.”

Jannuzzi’s appointment renders ECS optimistic for the Society’s future—for all the ways it will grow and thrive under his leadership.

“It is quite humbling to follow in the footsteps of such a storied and long-tenured predecessor as Roque Calvo,” says Jannuzzi. “Thankfully, we will have time to work together prior to his departure, so I will be sure to learn all that I can from him. His insight and perspective will be invaluable to me as I transition into my new role.”

10 The Electrochemical Society Interface • Fall 2018 • www.electrochem.org

SOCIETY NEWS

Yue Kuo Promotes ECS in Russia and Belarus

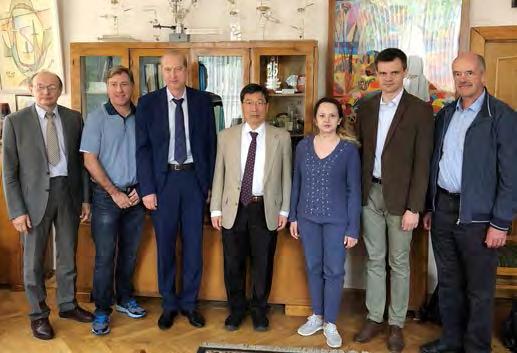

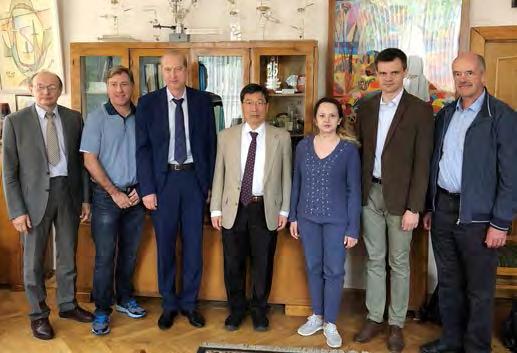

During June 2018, ECS President Yue Kuo traveled to three institutes in Russia and Belarus to meet with leading researchers, promote ECS, discuss research, and explore opportunities for future collaborations and conferences.

First, on June 11, Kuo visited the A. N. Frumkin Institute of Physical Chemistry and Electrochemistry of the Russian Academy of Sciences in Moscow, an institute home to many famous electrochemists. There, he attended a get-together hosted by Oleg Batishchev, deputy director of science at the institute, with some Russian members of ECS.

Kuo spoke with individuals who knew V. G. Levich, winner of the ECS Olin Palladium Award in 1973, as well as Vladimir Sergeevich Bagotsky, who was an ECS fellow. Several ECS members attended the meeting, including Tatiana Lastovina of Southern Federal University, who traveled over 1,000 km to meet the Society’s president.

Next, on June 14, Kuo traveled to St. Petersburg to visit the Ioffe Institute, a Russian national laboratory that boasts several Nobel Prize winners and a reputation equivalent to that of Bell Labs or the IBM T. J. Watson Research Laboratory. His visit was hosted by Mikhail Patrov, deputy science secretary of the institute.

While there, Kuo delivered a presentation on ECS’s history and current status to members of the institute. He was given tours of laboratories focused on solid state research and discussed the potential for ECS and the Ioffe Institute to collaborate to organize conferences.

Finally, on June 21, Kuo visited the B. I. Stepanov Institute of Physics of the National Academy of Sciences of Belarus in Minsk. He met with administrative leaders at the institute and gave a presentation on ECS, fielding several questions.

Many individuals Kuo met with expressed interest in collaboration with ECS. Yurii Kurochkin, vice president of the Belarusian Physical Society, entertained the idea of organizing a conference with ECS. Another researcher, an organizer of biannual plasma conferences, voiced potential interest in collaborating with ECS plasma symposium organizers. The leading researcher in the academy’s materials center, who traditionally published papers in European journals, conveyed interested in publishing in the Journal of The Electrochemical Society.

SOCIETY NEWS The Electrochemical Society Interface • Fall 2018 • www.electrochem.org 11

Attendees of the meeting at the A. N. Frumkin Institute of Physical Chemistry and Electrochemistry of the Russian Academy of Sciences in Moscow (left to right): Alexander A. Nekrasov (A. N. Frumkin Institute), Keith Stevenson (Skoltech), Buryak Aleksey Konstantinovich (A. N. Frumkin Institute), ECS President Yue Kuo (Texas A&M University), Tatiana Lastovina (Southern Federal University of Russia), Oleg Batishchev (A. N. Frumkin Institute), and Arkady Karyakin (M. V. Lomonosov Moscow State University).

ECS President Yue Kuo met with administrative leaders at the B. I. Stepanov Institute of Physics of the National Academy of Sciences of Belarus in Minsk. From left to right: Yurii Kurochkin, Irina Nikonchuk, Yue Kuo, and Nikolai Kazak

ECS President Yue Kuo (left) with Mikhail Patrov (right) during his visit to the Ioffe Institute in St. Petersburg.

ECS President Yue Kuo delivered a presentation on ECS to members of the B. I. Stepanov Institute of Physics.

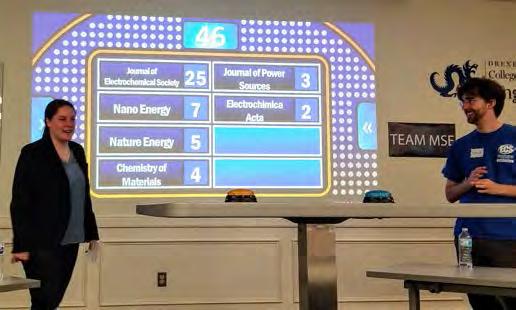

Increasing Influence of ECS Journals: 2017 Impact Factors

The journal impact factors (JIFs) for the ECS journals continue to grow, as evidenced by the data recently released by Clarivate Analytics. For the 2017 reporting year, the ECS journals continue to be among the top-ranked journals. Journal of The Electrochemical Society (JES) is in the top two for Materials Science, Coatings, and Films, and in the top ten for Electrochemistry. The JIFs are published in Journal Citation Reports (JCR), and are just one metric used to gauge the quality of a large number of scholarly journals.

For JES, the JIF rose to 3.662 for 2017 from 3.259 for 2016, an increase of over 12%. The enduring quality and usefulness of the work published in JES is significant: JES has had a cited half-life of greater than 10 years (the highest figure that JCR records) for over eight years. JES is the fourth-most-cited journal in electrochemistry, with nearly 71,000 citations; that same citation count makes JES the second most-cited journal in materials science, coatings, and films. Downloads are another important metric for scholarly journals, and for the ECS journals, there were over 2.4 million downloads for 2017.

For the ECS Journal of Solid State Science and Technology (JSS), the progress is also impressive: over 40% growth in citations for 2017 over 2016. In terms of the JIF, the growth for JSS is striking: the JIF has grown to 1.808 for 2017, from 0.917 in 2013 when JSS was launched—a 97% increase in just four years.

The increasingly influential role that the ECS journals play is due to the Society’s practice of rigorous peer review, which is based on rapid, objective, and insightful feedback, as well as evaluation

for plagiarism. The relevance of the ECS journals is due to the increasing importance of the scientific content covered by the ECS journals: batteries and energy storage, corrosion, fuel cells and energy conversion, sensors, electrochemical engineering, organic and biological electrochemistry, physical and analytical electrochemistry, electrodeposition, nanocarbons, dielectrics, electronics and photonics, luminescence and display materials, and the many subdisciplines within each.

There is a great deal of discussion about the journal impact factors, including the lagging nature of the metric (the JIF looks only at three years of published articles and comes out six months after the end of the prior, or JIF, year). Many researchers, libraries, and funding agencies are debating the validity of the metric, as well as working on developing new ways of evaluating researchers for tenure and promotion.1-3 ECS is a member of the Declaration on Research Assessment (DORA, https://sfdora.org/) which “recognizes the need to improve the ways in which the outputs of scholarly research are evaluated. It is a worldwide initiative covering all scholarly disciplines and all key stakeholders including funders, publishers, professional societies, institutions, and researchers.”

ECS is grateful for the support of its authors, reviewers, editors, and publications staff. These are the people who are responsible for the high standards to which ECS adheres, and which keep the ECS journals growing in impact every year.

2017 KEY METRICS FOR ECS JOURNALS

Journal Impact Factor*

3.662 12% increase over 2016 10% increase in citations

JSS 1.808 97% increase in just four years 40% increase in citations

Quality* 8 years in a row for the Journal of The Electrochemical Society to obtain a cited half-life of greater than 10 years.

Downloads Over 2.4 million downloads from the

Citations*

Nearly 74,000 citations for both journals

Journal of The Electrochemical Society

2nd most-cited in Materials Science, Coatings, and Films

4th most-cited in Electrochemistry

Top Rankings*

Journal of The Electrochemical Society #2 in Materials Science, Coatings, and Films

#10 in Electrochemistry

*Source: 2017 Journal Citation Reports, Clarivate Analytics

1. P. Davis, “2017 Journal Impact Factors Feature Citation Distributions,” The Scholarly Kitchen, June 27, 2018, https://scholarlykitchen.sspnet.org/2018/06/27/2017journal-impact-factors-feature-citation-distributions/

2. J. Wilsdon, “Has the Tide Turned Towards Responsible Metrics in Research?” The Guardian, July 10, 2018, www.theguardian.com/science/political-science/2018/ jul/10/has-the-tide-turned-towards-responsible-metrics-in-research?CMP=Share_iOSApp_Other

3. D. Singh Chawla, “What’s Wrong with the JIF in 5 Graphs,” Nature Index, April 2, 2018, www.natureindex.com/news-blog/whats-wrong-with-the-jif-in-five-graphs

12 The Electrochemical Society Interface • Fall 2018 • www.electrochem.org SOCIETY NEWS

Enduring

“”

JES

ECSarXiv and the Growth of Preprints

Preprints1 are growing at a faster rate than journal articles, according to a recent study from Crossref, a nonprofit organization that makes research outputs easy to find, cite, link, and assess.2 Why are preprints becoming popular? Preprints (on ECSarXiv and most reputable services) are discoverable and have a persistent link to their location on the Internet. (ECSarXiv registers its preprints with Crossref so they receive a DOI.) A preprint can be made available immediately (for ECSarXiv preprints, there’s a

quick moderation step) for grant/hiring committees, and they actually counter scooping by serving to “plant the flag” to claim your research. Preprints enhance visibility, especially for early-career researchers. They’re highly discoverable through Google Scholar, and a growing number of other databases. Preprints can come in many forms: as a classic preprint article (short or long) or even as a slide deck. Presenting your work through a preprint can aid in reproducibility: you can post new, confirmatory, or contradictory results. Learn more about ECSarXiv and our posting policies at www.electrochem.org/ecsarxiv.3

Take a look below at a sampling of preprints from ECSarXiv

Learnings from an Open Science Effort: Virtual Project on the History of ALD

Riikka Puurunen

Aalto University, School of Chemical Engineering, Department of Chemical and Metallurgical Engineering, Finland

DOI: 10.1149/osf.io/exyv3

This work summarizes learnings from an Open Science effort “Virtual project on the History of ALD” (VPHA), started in 2013 to clarify the early history of atomic layer deposition (ALD). ALD is a multi-tool of nanotechnology and has been e.g. enabler of the continuation of Moore’s law of transistor scaling. ALD has been

developed historically through two independent routes: atomic layer epitaxy (ALE) and molecular layering (ML). Especially the details on ML have remained little known to a broader audience. In this contribution, learnings in VPHA are seen from the viewpoint of its voluntary coordinator (the author self) related to historical details of ALD as well as from an organizational viewpoint and some other viewpoints. Selected details related to ALD’s history not fully accurately described in three earlier review articles are pointed out. The work made in VPHA has resulted in journal articles, presentations and an exhibition, and VPHA has in part provided the foundation for granting the 2018 Millennium Technology Prize to Dr. Tuomo Suntola. At the time of writing this contribution, in July 2018, VPHA is still on-going, and more volunteers are welcome to join the effort.

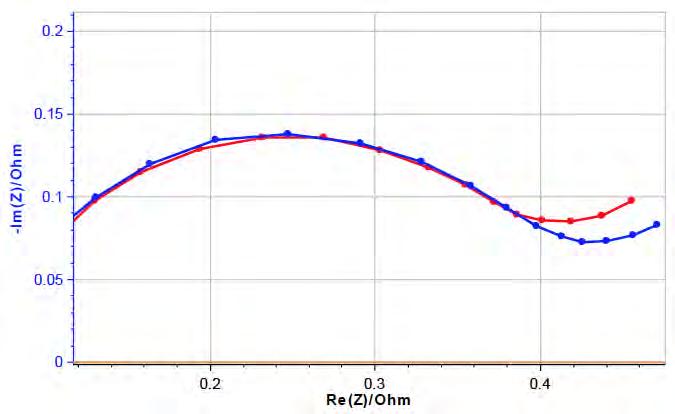

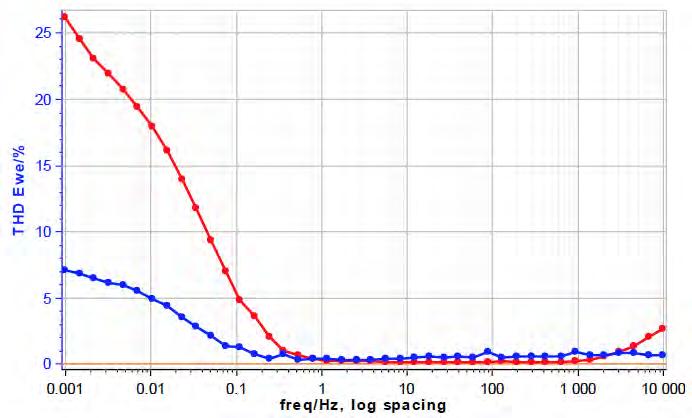

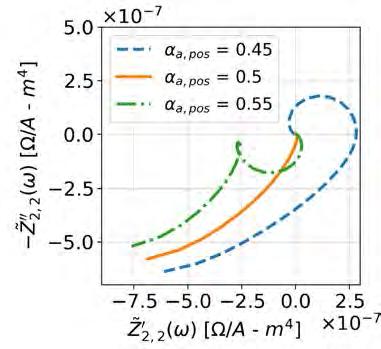

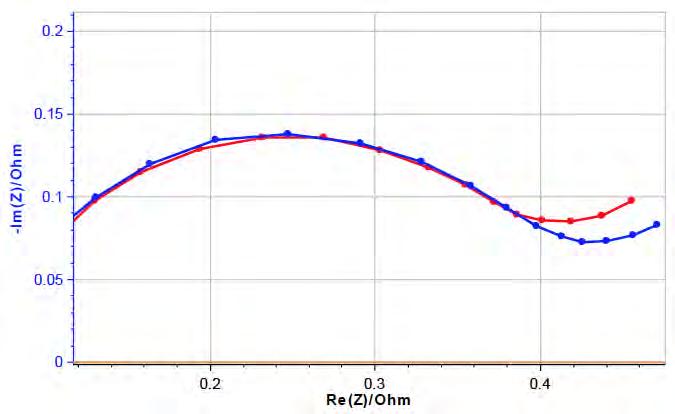

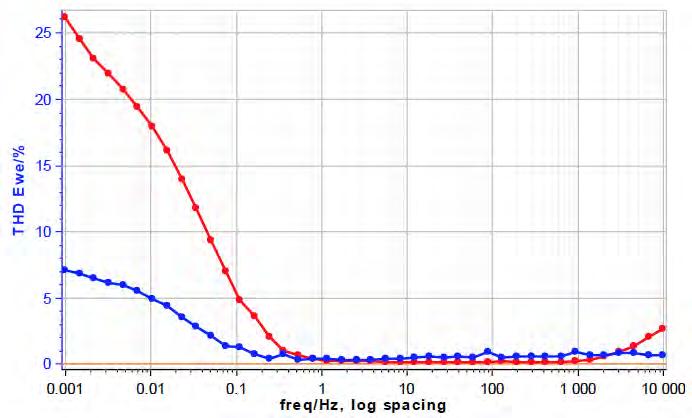

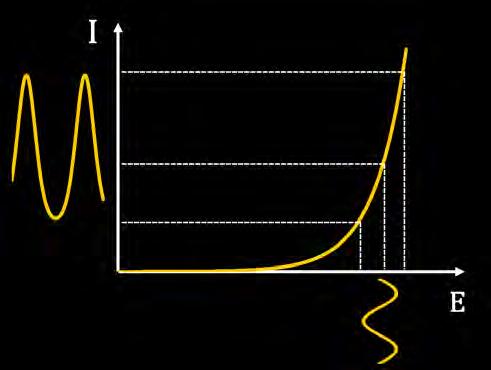

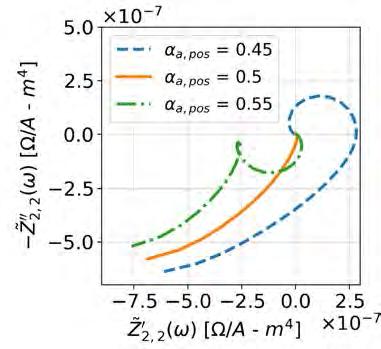

Nonlinear Electrochemical Impedance Spectroscopy of Lithium-Ion Batteries: Experimental Approach, Analysis, and Initial Findings

Matthew D. Murbach, Victor Hu, and Daniel T. Schwartz Department of Chemical Engineering & Clean Energy Institute, University of Washington, Seattle, WA, USA

DOI: 10.1149/osf.io/t635x

Nonlinear electrochemical impedance spectroscopy (NLEIS) is a moderate-amplitude extension to linear EIS that provides a sensitive and complementary whole-battery diagnostic for charge transfer kinetics, mass transport, and thermodynamics. We present the first full-frequency, second harmonic NLEIS spectra for lithium-ion batteries using commercially available, 1.5 Ah LiNMC|C cells. The mathematical framework for NLEIS shows, and experiments confirm, that moderate-amplitude input modulations can generate a second harmonic output that does not intrinsically corrupt the linear EIS response. Experimental measurements at varied states-of-charge (SoC) and states-of-health (SoH) are used to illustrate and compare NLEIS and EIS data.

(continued on next page)

Nyquist plots of simulated second harmonic spectra, for varying positive electrode anodic transfer coefficients, αa,pos (with αc,pos = 1 αa,pos).

1. A preprint is a version of a scholarly or scientific document or other preliminary communication not yet published in a peer-reviewed outlet.

2. Preprints growth rate ten times higher than journal articles, www.crossref.org/blog/preprints-growth-rate-ten-times-higher-than-journal-articles, May 31, 2018.

3. See the summer issue of Interface for a story on the launch of ECSarXiv, Summer 2018, 27, 2, doi:10.1149/2.006182if

SOCIETY NEWS The Electrochemical Society Interface • Fall 2018 • www.electrochem.org 13

Direct-Gap Photoluminescence from a Si-Ge Multilayer Super Unit Cell Grown on Si0.4Ge0.6

D. J. Lockwood,a N. L. Rowell,a L. Favre,b A. Ronda,b and I. Berbezierb

aMeasurement Science and Standards, National Research Council, Ottawa, Ontario, Canada

bCNRS, Institut Matériaux Microélectronique Nanosciences de Provence, AMU, Marseille, France

DOI: 10.1149/osf.io/rt29s

Both Si and Ge possess indirect band gaps, which makes them very inefficient light emitters. One way to overcome this limitation is through band gap engineering. In this regard, M. d’Avezac et al. [Phys. Rev. Lett., 108, 027401 (2012)] predicted that a strained SiGe2Si2Ge2SiGen super unit cell on Si0.4Ge0.6 would have a direct and dipole-allowed gap of 0.863 eV, which is ideally suited for optical fiber applications. Here we report on the epitaxial growth of such a structure and its optical properties, for which purpose two similar samples were prepared by molecular beam epitaxy and solid phase epitaxy.

Top panels give AFM images of the MBE sample (left image) and SPE sample (right image). Each full image size is 5×5 µm2. The height scale has been normalized at 20 nm. Bottom panels give the two-dimensional roughness measurements on the full scale images from which the root-meansquare roughness (RMSR) is calculated: MBE sample (left panel) RMSR = 2.07 nm and SPE sample (right panel) RMSR = 0.46 nm. The inset shows a TEM cross-section image of the Si-Ge stacking layers in the SPE sample.

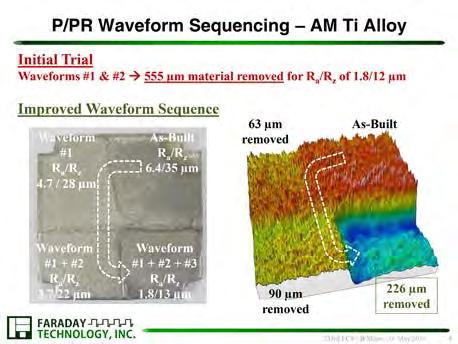

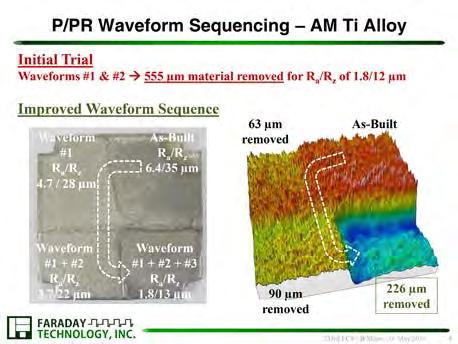

Multiphysics Modeling of Surface Finishing Performance in Pulsed-Waveform Electrochemical Machining

Brian Skinn, Timothy Hall, and E. J. Taylor

Faraday Technology, Inc., Englewood, OH, USA

DOI: 10.1149/osf.io/wybx6

Electrochemical machining (ECM) is a manufacturing technology that allows metal to be precisely removed by electrochemical oxidation and dissolution into an electrolyte solution. ECM is suited for machining parts fabricated from “difficult to cut” materials and/or parts with complicated and intricate geometries. In ECM, the workpiece is the anode and the tool is the cathode in an electrochemical cell; by relative movement of the shaped tool into the workpiece, the mirror image of the tool is “copied” or machined into the workpiece. One notable difficulty with ECM is an inability to predict a priori the tool and process parameters required in order to satisfy the final specifications of the fabricated part. Accordingly, there is potential value in development of a physical phenomenonbased design platform to predict optimal ECM tool shape. Such a capability is anticipated to dramatically shorten the process/tooling development cycle.

Using Exotic Materials Like EuD4TEA and MgD4TEA to Monitor Damage and Radiation Exposure in Extreme Environments

W. A. Hollerman,a R. S. Fontenot,b P. Darby,c N. Pugh,c and J. Millera aDepartment of Physics, University of Louisiana at Lafayette, Lafayette, LA, USA

bNaval Surface Warfare Center Carderock Division, West Bethesda, MD, USA

cCajun Advanced Picosatellite Experiment (CAPE), University of Louisiana at Lafayette, Lafayette, LA, USA

DOI: 10.1149/osf.io/94ujn

Space radiation poses a significant challenge to exploration missions to the Moon, Mars, and beyond. As we consider long duration space missions, the risk from radiation exposure increases. There is no simple technique that is capable of real-time radiation detection. Past research shows that the fluorescence yield and decay time are both functions of temperature and radiation fluence. Each of these parameters need to be investigated separately in order to fully understand the physical properties for any useful phosphor.

Once the temperature dependencies are known, then the radiation fluence in the surrounding environment can be estimated. This paper will discuss recent research on europium and magnesium tetrakis dibenzoylmethide triethylammonium (EuD4TEA and MgD4TEA) that could be used to measure radiation and temperature in real time. Both of these organic materials have been shown to be sensitive to proton radiation and to changes in temperature.

14 The Electrochemical Society Interface • Fall 2018 • www.electrochem.org SOCIETY NEWS

(continued

from previous page)

Pictures of synthesized MgD4TEA shown in standard room light (left) and ultraviolet light (right).

Focus on Focus Issues

ECS publishes focus issues of the Journal of The Electrochemical Society (JES) and the ECS Journal of Solid State Science and Technology (JSS) that highlight scientific and technological areas of current interest and future promise. These issues are handled by a prestigious group of ECS technical editors and guest editors, and all submissions undergo the same rigorous peer review as papers in the regular issues. All focus issue papers are now published open access at no cost to the authors. ECS waives the article processing charge for all authors of focus issue papers as part of the Society’s ongoing Free the Science initiative.

Recent Focus Issues

• JES Focus Issue on Proton Exchange Membrane Fuel Cell (PEMFC) Durability. [JES 165(6) 2018] Thomas Fuller, JES technical editor; Jean St-Pierre, Deborah Myers, and Rodney Borup, guest editors. The majority of the papers in this issue focus on the core PEMFC components, the membrane-electrode assembly and the majority of its constituent materials: membrane, ionomer, catalyst, catalyst support, and microporous layer. Other papers pertain to accelerated stress tests and diagnostics, which are important aspects considering the relatively large cost associated with long-duration tests to quantify degradation resistance and to diagnose degradation mechanisms. Also covered in this issue are the effects of contaminants, the reactant streams’ membrane humidifier, and the effects of operating parameters on PEMFCs.

• JES Focus Issue on Ubiquitous Sensors and Systems for IoT. [JES 165(8) 2018] Rangachary Mukundan, JES technical editor; Ajit Kholsa, Praveen Kuman Sekhar, Peter Hesketh, Charles Henry, and Luca Magagnin, guest editors. Ubiquitous sensors are becoming an integral part of IoT applications, and progress in this domain can be seen each month. The promise is that everyone and everything will be connected via wireless data collection, and services like healthcare will be brought to everyone, everywhere, anytime, for virtually any need. These devices sense the environment and provide applications in home automation, home safety and comfort, and personal health. At a macro level they provide data for smart cities, smart agriculture, water conservation, energy efficiency and Industry 4.0, and Society 5.0. Other applications include supply chain management, transportation, and logistics.

• JES Focus Issue on the Brain and Electrochemistry Honoring R. Mark Wightman and Christian Amatore. [JES 165(12) 2018] Janine Mauzeroll, JES technical editor; Lili Deligianni, Michael Wolfson, Nick Langhals, and Mekki Bayachou, guest editors. Amatore’s and Wightman’s contributions to the advancement of bioelectrochemistry, specifically the advancement of electrochemical measurements in the field of neurochemistry are impressive. Their dedication to the training of new generations of bioelectrochemists resulted in an established legacy of highly

successful faculty and researchers worldwide. Several of the articles in this issue are contributions from former students, postdocs, and colleagues exemplifying the research directions that Amatore and Wightman have molded.

• JSS Focus Issue on Semiconductor-Based Sensors for Application to Vapors, Chemicals, Biological Species, and Medical Diagnosis. [JSS 7(7) 2018] Fan Ren, JSS technical editor; Yu-Lin Wang, Ajit Khosla, Rangachary Mukundan, and Toshiya Sakata, guest editors. The papers in this issue report on the novel and advanced sensor technologies that utilize semiconductor materials to enhance device characteristics for a multitude of diverse applications. The topics addressed in this issue include biomedical sensors, gas sensors, environmental monitoring and water quality control, optoelectronics, organic semiconductor devices, packages and circuits for semiconductor sensors, and clinical diagnostics using semiconductor sensors and read-out systems.

The following focus issue is currently in production with many papers already published in the ECS Digital Library (http://ecsdl.org).

• JES Focus Issue on Electrocatalysis—In Honor of Radoslav Adzic. [JES 165(15) 2018] David Cliffel and Thomas Fuller, JES technical editors; Minhua Shao, guest editor.

The following focus issues are open for submissions. Manuscripts may be submitted at http://ecsjournals.msubmit.net:

• JES Focus Issue on Advances in Electrochemical Processes for Interconnect Fabrication in Integrated Circuits. [JES 166(1) 2019] Charles Hussey, JES technical editor; Rohan Akolkar and Peter Broekmann, guest editors.

• JES Focus Issue on Selected Papers from IMLB 2018. [JES 166(3) 2019] Doron Aurbach, JES technical editor.

• JES Focus Issue on Semiconductor Electrochemistry and Photoelectrochemistry in Honor of Krishnan Rajeshwar. [JES 166(5) 2019] David Cliffel, JES technical editor; Ajit Khosla, Nianqiang (Nick) Wu, Heli Wang, and Csaba Janáky, guest editors.

Coming soon is the call for papers for the JSS Focus Issue on Chemical Mechanical Planarization (CMP) for Sub-10 nm Technologies

SOCIETY NEWS The Electrochemical Society Interface • Fall 2018 • www.electrochem.org 15

To see the calls for papers for upcoming focus issues, for links to the published issues, or if you would like to propose a future focus issue, visit

www.electrochem.org/focusissues

Christian Amatore R. Mark Wightman

IoT

Technical

Editor Charles Hussey Reappointed

Charles L. Hussey has recently been reappointed as a technical editor of the Journal of The Electrochemical Society Hussey specializes in the electrochemical/ electroless deposition topical interest area. He is the associate dean for research and graduate education in the College of Liberal Arts at the University of Mississippi, where he also serves as a professor of chemistry. Hussey is an ECS fellow and a recipient of

Institutional Member

spotlight

TOC Capacitor Co., Ltd.

ECS would like to welcome TOC Capacitor Co., Ltd. as a new sustaining member!

TOC Capacitor Co., Ltd. was established in 2011 as a joint company between TPR Co., Ltd. and Okaya Electric Industries Co., Ltd. The office headquarters is located in Nagano, Japan. The company’s factory, development, and R&D are located in Osaka, Japan. Its products are electric double layer capacitors (EDLCs) with a main application of power regeneration for construction machines. The company is also performing R&D with a university to create new energy devices for IT equipment or elective vehicles.

Renewal Reminder

ECS encourages institutional members to renew their membership before the end of 2019. The institutional membership program provides academic, government, and industry partners access to research and the ECS community. Program benefits also include discounts on subscriptions, along with advertising, sponsorship, and

exhibiting discounts for ECS biannual meetings. ECS’s 50 institutional members have more than 300 member representatives. These representatives receive all ECS member benefits, including access to the ECS Digital Library and member pricing.

Contact Shannon.Reed@electrochem.org

to renew your institutional membership or inquire about the benefits of institutional membership for your organization.

the ECS Physical and Analytical Electrochemistry Division Max Bredig Award in Molten Salt and Ionic Liquid Chemistry. His current research focuses upon the electrochemistry and transport properties of a variety of room-temperature ionic liquids.

Hussey was first appointed as an ECS associate editor in 2000. Read more about his experiences as an editor—as well as his insights on peer review, the Free the Science initiative, and what distinguishes ECS journals from other journals in the field—in the spring 2018 issue of Interface.

Staff News

Ngoc Le joined ECS in April 2018 as the development associate. In this role, she is responsible for creating fundraising activities to support the Society’s goals and objectives. She will implement a comprehensive fundraising campaign for awards, grants, and the Free the Science initiative to support young scientists, scientific meetings, open access, and open science. She will work closely with the ECS executive director and leadership to engage donors and the community with ECS.

Le previously worked for the publisher Taylor and Francis Group in Philadelphia, PA, as a managing editor on the behavioral sciences portfolio. She oversaw more than 40 academic journals ensuring academic integrity, compliance, and growth. She also partnered with societies to grow their journals by developing strategic goals and budgets. She has implemented open science guidelines, resolved ethical complaints, and educated authors and editors on the concerns regarding the reproducibility crisis. Through this experience, Le found her passion for academic integrity and sustaining the future of research.

“We were attracted to Ngoc’s experience in scholarly publishing and her knowledge of nonprofit associations” says Roque Calvo, former executive director of ECS. “Her experience and knowledge will enable her to understand and effectively communicate our development message and the importance of our Free the Science initiative, which she is passionate about.”

16 The Electrochemical Society Interface • Fall 2018 • www.electrochem.org SOCIETY NEWS

Discover

TheElectrochemicalSociety @ECSorg ecsblog.org Find out what’s trending in the field and interact with a like-minded community through the ECS social media pages.

Connect Share

SYMPOSIUM TOPICS & DEADLINES

K Organic and Bioelectrochemistry

Dallas, TX Sheraton Dallas

K01 Bioelectrochemistry: From Nature-Inspired Electrochemical Systems to Electrochemical Biosensors

K02 Electron-Transfer Activation in Organic and Biological Systems

K03 Young Investigators in Organic and Biological Electrochemistry

L Physical and Analytical Electrochemistry, Electrocatalysis, and Photoelectrochemistry

L01 Physical and Analytical Electrochemistry, Electrocatalysis, and Photoelectrochemistry General Session and Grahame Award Symposium

L02 Impedance Technologies, Diagnostics, and Sensing Applications 5

L03 Computational Electrochemistry 5

L04 Polyoxometallates and Nanostructured Metal Oxides in Efficient Electrocatalysis, Energy Conversion, and Charge Storage

L05 Spectroelectrochemistry 4

L06 Supramolecular Materials

M Sensors

M01 Sensors, Actuators, and Microsystems General Session

M02 Semiconductor Electrochemistry and Photoelectrochemistry in Honor of Krishnan Rajeshwar - An Invited Symposium

M03 Sensors for Precision Medicine

Z General

Z01 General Student Poster Session

Z02 Sustainable Materials and Manufacturing 3

Z03 Nanoscale Electrochemical Imaging and Detection

Electrochemical Engineering

F01 Industrial Electrochemistry and Electrochemical Engineering General Session

F02 Tutorial on Industrial Electrochemistry

F03 Characterization of Porous Materials 8

F04 Multiscale Modeling, Simulation and Design 3: Enhancing Understanding, and Extracting Knowledge from Data

G Electronic Materials and Processing

G01 Silicon Compatible Emerging Materials, Processes, and Technologies for Advanced CMOS and Post-CMOS Applications 9

G02 Processes at the Semiconductor Solution Interface 8

and Devices 20

H02 Solid-state Electronics and Photonics in Biology and Medicine 6

H03 Wearable and Flexible Electronic and Photonic Technologies 2

I Fuel Cells, Electrolyzers, and Energy Conversion

I01 Hydrogen or Oxygen Evolution Catalysis for Water Electrolysis 5

I02 Materials for Low Temperature Electrochemical Systems 5

I03 Renewable Fuels via Artificial Photosynthesis or Heterocatalysis 4

I04 Energy Conversion Systems Based on Nitrogen 2

I05 Heterogeneous Functional Materials for Energy Conversion and Storage 2

I06 An Invited Symposium on Advances and Perspectives on Modern Polymer Electrolyte Fuel Cells – In Honor of Shimshon Gottesfeld

IMPORTANT DATES AND DEADLINES

Meeting Abstract submission opens ............................... August 2018

Meeting Abstracts submission deadline December 14, 2018

Notification to Corresponding Authors of abstract acceptance or rejection ...................... February 11, 2019

Technical Program published online February 2019

Meeting registration opens February 2019

ECS Transactions submission site opens February 15, 2019

Travel Grant application deadline ......................... February 25, 2019

ECS Transactions submission deadline March 15, 2019

Meeting Sponsor and Exhibitor deadline (for inclusion in printed materials) ............................ March 15, 2019

Travel Grant approval notification March 8, 2019

Hotel and Early Bird meeting registration deadlines

Release date for ECST issues

22, 2019

April

May 17, 2019 235th ECS Meeting – Dallas, TX ...............................May 26-31, 2019

Abstract Submission Now OPEN! www.electrochem.org/235 235th ECS Meeting

26-May 31, 2019

May

A Batteries and Energy Storage A01 Battery and Energy Technology Joint General Session A02 Lithium Ion Batteries and Beyond A03 Large Scale Energy Storage 10 A04 Battery Student Slam 3 A05 Battery Characterization A06 Battery Safety and Failure Modes B Carbon Nanostructures and Devices B01 Carbon Nanostructures

Energy

and Storage B02 Carbon Nanostructures

Biology

Carbon

From

Devices

Nano in Latin America

Fundamental Science to Applications B07 Light Energy Conversion with Metal Halide Perovskites, Semiconductor Nanostructures, and Inorganic/Organic Hybrid Materials B08 Porphyrins, Phthalocyanines, and Supramolecular Assemblies B09 Nano for Industry C Corrosion Science and Technology C01 Corrosion General Session D Dielectric Science and Materials D01 Chemical Mechanical Polishing 15 D02 Low Cost Photovoltaic Materials and Devices for Clean Energy E Electrochemical/Electroless Deposition E01 Electrodeposition for Advanced Node Interconnect Metallization Beyond Copper F

for

Conversion

in Medicine and

B03

Nanotubes -

Fundamentals to

B04

B05 Fullerenes - Endohedral Fullerenes and Molecular Carbon B06 2D Layered Materials from

G03 Organic Semiconductor Materials, Devices, and Processing 7 H Electronic and Photonic Devices and Systems H01 Wide Bandgap Semiconductor Materials

ECS Division Contacts

Battery

Christopher Johnson, Chair

Argonne National Laboratory

johnsoncs@cmt.anl.gov • 630.252.4787 (US)

Marca Doeff, Vice Chair Shirley Meng, Secretary

Brett Lucht, Treasurer

Doron Aurbach, Journals Editorial Board Representative

Corrosion

Sannakaisa Virtanen, Chair

Friedrich-Alexander-Universität Erlangen-Nürnberg virtanen@ww.uni-erlangen.de • +49 09131/85-27577 (DE)

Masayuki Itagaki, Vice Chair

James Nöel, Secretary/Treasurer

Gerald Frankel, Journals Editorial Board Representative

Dielectric Science and Technology

Vimal Chaitanya, Chair New Mexico State University vimalc@nmsu.edu • 575.635.1406 (US)

Peter Mascher, Vice Chair Uros Cvelbar, Secretary

Zhi David Chen, Treasurer

Peter Mascher, Journals Editorial Board Representative

Electrodeposition

Stanko Brankovic, Chair University of Houston srbrankovic@uh.edu • 713.743.4409 (US)

Philippe Vereecken, Vice Chair Natasa Vasiljevic, Secretary

Luca Magagnin, Treasurer Charles Hussey, Journals Editorial Board Representative

Electronics and Photonics

Colm O’Dwyer, Chair University College Cork c.odwyer@ucc.ie • +353 863.958373 (IE)

Junichi Murota, Vice Chair Robert Lynch, 2nd Vice Chair

Soohwan Jang, Secretary Yu-Lin Wang, Treasurer

Fan Ren, Journals Editorial Board Representative

Energy Technology

Andy Herring, Chair

Colorado School of Mines aherring@mines.edu • 303.384.2082 (US)

Vaidyanathan Subramanian, Vice Chair

William Mustain, Secretary Katherine Ayers, Treasurer

Thomas Fuller, Journals Editorial Board Representative

High-Temperature Energy, Materials, & Processes

Greg Jackson, Chair Colorado School of Mines gsjackso@mines.edu • 303.273.3609 (US)

Paul Gannon, Sr. Vice Chair Sean Bishop, Jr. Vice Chair

Cortney Kreller, Secretary/Treasurer

Raymond Gorte, Journals Editorial Board Representative

Industrial Electrochemistry and Electrochemical Engineering

John Staser, Chair Ohio University staser@ohio.edu • 740.593.1443 (US)

Shrisudersan Jayaraman, Vice Chair

Maria Inman, Secretary/Treasurer

Venkat Subramanian, Journals Editorial Board Representative

Luminescence and Display Materials

Mikhail Brik, Chair University of Tartu brik@fi.tartu.ee • + 372 737.4751 (EE)

Jakoah Brgoch, Vice Chair

Rong-Jun Xie, Secretary/Treasurer

Kailash Mishra, Journals Editorial Board Representative

Nanocarbons

Slava Rotkin Pennsylvania State University rotkin@psu.edu • 814.863.3087 (US)

Hiroshi Imahori, Vice Chair Olga Boltalina, Secretary R. Bruce Weisman, Treasurer

Francis D’Souza, Journals Editorial Board Representative

Organic and Biological Electrochemistry

Graham Cheek, Chair United States Naval Academy cheek@usna.edu • 410.293.6625 (US)

Diane Smith, Vice Chair

Sadagopan Krishnan, Secretary/Treasurer

Janine Mauzeroll, Journals Editorial Board Representative

Physical and Analytical Electrochemistry

Alice Suroviec Berry College asuroviec@berry.edu • 706.238.5869 (US)

Petr Vanýsek, Vice Chair Andrew Hillier, Secretary

Stephen Paddison, Treasurer

David Cliffel, Journals Editorial Board Representative

Sensor

Nianqiang (Nick) Wu, Chair West Virginia University nick.wu@mail.wvu.edu • 304.293.3111 (US)

Ajit Khosla, Vice Chair Jessica Koehne, Secretary

Larry Nagahara, Treasurer

Rangachary Mukundan, Journals Editorial Board Representative

18 The Electrochemical Society Interface • Fall 2018 • www.electrochem.org

NEWS

SOCIETY

New Division Officer Slates

New officers for the fall 2018–fall 2020 term have been nominated for the following divisions. All election results will be reported in the winter 2018 issue of Interface

Members-at-Large

Nick Birbilis, Monash University

Battery Division

Chair

Marca Doeff, Lawrence Berkeley National Laboratory

Vice Chair

Y. Shirley Meng, University of California, San Diego

Secretary

Brett Lucht, University of Rhode Island

Treasurer

Jie Xiao, Pacific Northwest National Laboratory

Members-at-Large (20 to be elected)

Khalil Amine, Argonne National Laboratory

Thomas Barrera, The Boeing Company

Josh Gallaway, Northeastern University

Dominique Guyomard, CNRS IEMN

Minoru Inaba, Doshisha University

Richard Jow, U.S. Army Research Laboratory

Kisuk Kang, Seoul National University

Robert Kostecki, Lawrence Berkeley National Laboratory

Prashant Kumta, University of Pittsburgh

Boryann Liaw, Idaho National Laboratory

Jun Lu, Argonne National Laboratory

Bryan McCloskey, Lawrence Berkeley National Laboratory

Tissaphern Mirfakhrai, Eaton Corp.

John Muldoon, Toyota Research Institute of North America

Jagjit Nanda, Oak Ridge National Laboratory

John Vaughey, Argonne National Laboratory

Gabriel Veith, Oak Ridge National Laboratory

Chao-Yang Wang, Pennsylvania State University

Martin Winter, Westfälische Wilhelms-Universität Münster

Kang Xu, Army Research Laboratory

Marina Yakovleva, FMC Corporation

Won-Sub Yoon, Sungkyunkwan University

Chair

Corrosion Division

Masayuki Itagaki, Tokyo University of Science

Vice Chair

James Noël, University of Western Ontario

Division Secretary/Treasurer

Dev Chidambaram, University of Nevada, Reno

Sean Brossia, INVISTA

Philippe Marcus, CNRS-ENSCP (UMR 7045)

H. Neil McMurray, Swansea University

Eiji Tada, Tokyo Institute of Technology

Chair

Sensor Division

Ajit Khosla, Yamagata University

Vice Chair

Jessica Koehne, NASA Ames Research Center

Secretary

Larry Nagahara, Johns Hopkins University

Treasurer

Praveen Sekhar, Washington State University, Vancouver

Members-at-Large

Sheikh Akbar, Ohio State University

Michael Carter, KWJ Engineering, Inc.

Pengyu Chen, Auburn University

Bryan Chin, Auburn University

Jay Grate, Pacific Northwest National Laboratory

Peter Hesketh, Georgia Institute of Technology

A. Robert Hillman, University of Leicester

Gary Hunter, NASA Glenn Research Center

Sangmin Jeon, Pohang University of Science and Technology

Mira Josowicz, Georgia Institute of Technology

Dong-Joo Kim, Auburn University

Jing Li, NASA Ames Research Center

Chung-Chiun Liu, Case Western Reserve University

Vadim Lvovich, NASA Glenn Research Center

Sushanta Mitra, University of Waterloo

Milad Navaei, Georgia Institute of Technology

Antonio Ricco, Stanford University

Michael Sailor, University of California, San Diego

Yasuhiro Shimizu, Nagasaki University

Aleksandr Simonian, National Science Foundation

Leyla Soleymani, McMaster University

Thomas Thundat, University of Alberta

Lok-kun Tsui, University of New Mexico

ECS Redcat Blog

The blog was established to keep members and nonmembers alike informed on the latest scientific research and innovations pertaining to electrochemistry and solid state science and technology. With a constant flow of information, blog visitors are able to stay on the cutting-edge of science and interface with a like-minded community.

www.electrochem.org/redcat-blog

SOCIETY

The Electrochemical Society Interface • Fall 2018 • www.electrochem.org 19

NEWS

Roque Calvo Next Generation Scholarship Fund

Without ECS support, 66% of travel grant recipients would not have been able to attend an ECS meeting.

Support student travel by making a donation today!

20 The Electrochemical Society Interface • Fall 2018 • www.electrochem.org

The Electrochemical Society and Toyota North America Announce 2018-2019 Fellowship Winners for Projects in Green Energy Technology

The ECS Toyota Young Investigator Fellowship, a partnership between The Electrochemical Society and Toyota Research Institute of North America, a division of Toyota Motor North America, is in its fourth year. The fellowship aims to encourage young professors and scholars to pursue research in green energy technology that may promote the development of nextgeneration vehicles capable of utilizing alternative fuels.

Electrochemical research has already informed the development and improvement of innovative batteries, electrocatalysts, photovoltaics, and fuel cells. Through this fellowship, ECS and Toyota hope to see further innovative and unconventional technologies borne from electrochemical research.

The ECS Toyota Young Investigator Fellowship Selection Committee has chosen two recipients to receive the 20182019 fellowship awards for projects in green energy technology. The awardees are Kimberly See, California Institute of Technology, and Iryna Zenyuk, University of California, Irvine.

The selected fellows will receive restricted grants of $50,000 to conduct the research outlined in their proposals within one year. They will also receive a one-year complimentary ECS membership as well as the opportunity to present and/or publish their research with ECS.

The ECS Toyota Young Investigator Fellowship is an annual program, and the 2019-2020 request for proposals will be released in the fall of 2018.

Kimberly See, California Institute of Technology

ECS Battery Division

“Structural Distortions in Multi-Electron Cathodes for High Capacity Batteries”

Iryna Zenyuk, University of California, Irvine

ECS Energy Technology Division

“Addressing the Activation

Overpotential in Fuel Cell Cathodes”

Special Thanks to the 2018-2019 ECS Toyota Young Investigator Fellowhip Selection Committee

John Muldoon, Toyota Research Institute of North America, Chair

Koji Suto, Toyota Research Institute of North America

Tomoyuki Nagai, Toyota Research Institute of North America

Tim Arthur, Toyota Research Institute of North America

Peter Pintauro, Vanderbilt University, ECS Energy Technology Division

Brian McCloskey, University of California, Berkeley, ECS Battery Division

John T. Vaughey, Argonne National Laboratory, ECS Battery Division

Silver/Silver Chloride

Reference Electrode

Stable Reference

0.047 Volts vs. SCE

Widely used

Non-toxic

Custom glass available

SOCIETY NEWS The Electrochemical Society Interface • Fall 2018 • www.electrochem.org 21

Always in stock. Made in USA. “Fine electrochemical probes since 1966” www.koslow.com

Your article. Online. FAST! More than 141,000 articles in all areas of electrochemistry and solid state science and technology from the only nonprofit publisher in its field. ECS Proceedings Volumes Over 450 historic proceedings volumes have been added to the archival content available through the ECS Digital Library. Visit www.ecsdl.org to learn more.

websites of note

by Alice H. Suroviec

Dryad

• The Dryad Digital Repository is a curated resource that makes the data underlying scientific publications discoverable, freely reusable, and citable. Dryad provides a general-purpose home for a wide diversity of data types. Dryad’s vision is to promote a world where research data is openly available, integrated with the scholarly literature, and routinely reused to create knowledge. www.datadryad.org

CEDI University

• CEDI University is a single website that has tutorials and frequently asked questions about continuous electrodeionization (CEDI). This technology uses ion exchange membranes for water treatment. The website covers the history of the technology, how it works, as well as the possible future directions. www.cediuniversity.com

Electrochemical Education

• If you are looking for a teaching lab to use in one of your courses, this website by Pine Research provides several different exercises for use in the college labs. The exercises cover a variety of topics and would be of use in both general chemistry and advanced chemistry labs. www.pineresearch.com/shop/knowledgebase/laboratory-exercises/

About the Author

Alice Suroviec is an associate professor of bioanalytical chemistry and chair of the Department of Chemistry and Biochemistry at Berry College. She earned a BS in chemistry from Allegheny College in 2000. She received her PhD from Virginia Tech in 2005 under the direction of Mark R. Anderson. Her research focuses on enzymatically modified electrodes for use as biosensors. She is currently the chair of the ECS Physical and Analytical Electrochemistry Division and an associate editor for the physical and analytical electrochemistry, electrocatalysis, and photoelectrochemistry topical interest area of the Journal of The Electrochemical Society. She may be reached at asuroviec@berry.edu.

https://orcid.org/0000-0002-9252-2468

UPCOMING ECS SPONSORED MEETINGS

In addition to the ECS biannual meetings and ECS satellite conferences, ECS, its divisions, and its sections sponsor meetings and symposia of interest to the technical audience ECS serves. The following is a partial list of upcoming sponsored meetings. Please visit the ECS website (www.electrochem.org/upcoming-meetings/) for a list of all sponsored meetings.

2018

• 69th Meeting of the International Society of Electrochemistry; September 2-7, 2018; Bologna, Italy; http://annual69.ise-online.org/; ECS–ISE Joint Symposium: Theory: From Understanding to Optimization and Prediction

• International Conference on Solid State Devices and Materials (SSDM); September 9-13, 2018; Tokyo, Japan; www.ssdm.jp/index.html

• Redox Films for Energy Conversion –Bioelectrochemical and Molecular Systems; September 10-11, 2018; Marseille, France; https://redox-shields.org/

• III Colombian Congress of Electrochemistry; October 2-5, 2018; Cali, Colombia; https://sites.google.com/view/cceq2018/

• 7th Baltic Electrochemistry Conference: Finding New Inspiration (BEChem 2018); November 4-7, 2018; Tartu, Estonia; http://BEChem2018.ut.ee/

2019

• International Battery Association meeting (IBA 2019); March 3-8, 2019; San Diego, CA; www.international-battery-association.org/

To learn more about what an ECS sponsorship could do for your meeting, including information on publishing proceeding volumes for sponsored meetings, or to request an ECS sponsorship of your technical event, please contact ecs@electrochem.org.

22 The Electrochemical Society Interface • Fall 2018 • www.electrochem.org SOCIETY NEWS

research

Intheissueof

• The winter 2018 issue of Interface will feature the ECS Electronics and Photonics Division. The issue will be guest edited by Jennifer Hite from the U.S. Naval Research Laboratory. The issue will be titled “Frontiers in Electronics with Focus Articles on Atomic Layer Deposition, Power Electronics, and 2D Materials,” and is scheduled to include the following articles (titles are tentative): “Emerging Technologies for Nanofabrication: MLD, SAMs, and CCD,” by Alain E. Kaloyeros, Jonathan Goff, and Barry Arkles; “GaN Power Devices – Current Status and Future Directions,” by Travis Anderson and Srabanti Chowdhury; “Cheap Ultra-Wide Bandgap Power Electronics? Gallium Oxide May Hold the Answer,” by Marko Tadjer; and “The Future of Electronics in the Flatland: 2D Semiconductors Materials in Next-Generation CMOS,” by Paul Hurley and Colm O’Dwyer.

The PAT-Chamber-16

• Highlights from AiMES 2018, the ECS and SMEQ joint international meeting. News and photos from the upcoming meeting taking place in Cancun, Mexico. (See page X of this issue for a preview of the meeting.)

• A report on the First International Conference on 4D Materials and Systems, an ECS cosponsored meeting happening August 26-30, 2018, in Yonezawa, Japan.

• The 2018 ECS Summer Fellowship Reports from the recipients of the 2018 Colin Garfield Fink Fellowship, the 2018 Edward G. Weston Fellowship, the 2018 F. M. Becket Fellowship, the 2018 Joseph W. Richards Fellowship, and the 2018 H. H. Uhlig Fellowship.

SOCIETY NEWS The Electrochemical Society Interface • Fall 2018 • www.electrochem.org 23

Temperature controlled docking station • Temperature range: 10 - 80°C • Ready for up to 16 PAT-Cells or PAT-Cell-Press for pressure monitoring • Integrated data logger • Compatible with all of today´s potentiostats and battery testers Please visit our website for more information: el-cell.com/products/docking-stations/pat-chamber-16

CANCUN MEXICO

September 30-October 4, 2018

Moon Palace Resort

The Americas International Meeting on Electrochemistry and Solid State Science (AiMES 2018), is a joint conference of the 234th Meeting of The Electrochemical Society (ECS), the XXXIII Congreso de la Sociedad Mexicana de Electroquimica (SMEQ), and the 11th Meeting of the Mexico Section of The Electrochemical Society, with the technical cosponsorship of the Sociedade Brasileira de Eletroquímica e Eletroanalítica (SBEE), the Sociedad Iberoamericana de Electroquimica (SIBAE), and the Asociación Colombiana de Electroquímica (ACEQ).

Join us at this joint international conference of ECS and SMEQ, as scientists, engineers, and researchers from academia, industry, and government laboratories come together to share results and discuss issues on related topics through a variety of formats, such as oral presentations, poster sessions, panel discussions, tutorial sessions, short courses, professional development workshops, and exhibits. The unique blend of electrochemical and solid state science and technology at an AiMES meeting provides an opportunity and forum to learn and exchange information on the latest scientific and technical developments in a variety of interdisciplinary areas.

If that isn’t enough, you will be spending your time at the beautiful Moon Palace Resort, a gigantic allinclusive luxury resort located along Cancun’s Mayan Riviera and set amidst 55 acres of lush tropical foliage. Just minutes from the Cancun International Airport, it features a full-service spa, a 27-hole golf course, a larger-than-life pool, and numerous restaurants and dining options, making for an unforgettable experience.

Highlights

• Five days of technical programming across 53 symposia

• Over 2,100 abstracts

• More than 1,700 oral presentations, with 400+ invited speakers

• 450+ posters during three evenings of poster sessions

• 14 hours of exhibit hall time over three days

• Daily morning and afternoon coffee breaks and networking breaks

• Complimentary Wi-Fi in meeting rooms

• Special program for nontechnical registrants

• All meals and drinks at the Moon Palace, including alcoholic beverages

• Special program for non-technical registrants

The ECS Lecture

Monday, October 1

“Electro- and Photo-Electro-Chemical Generation of the Fenton Reagent. Some Approaches for the Development of Electrochemical Based Advanced Oxidation Processes for Water Treatment”

Luis A. Godínez, Center of Research and Technological Development in Electrochemistry

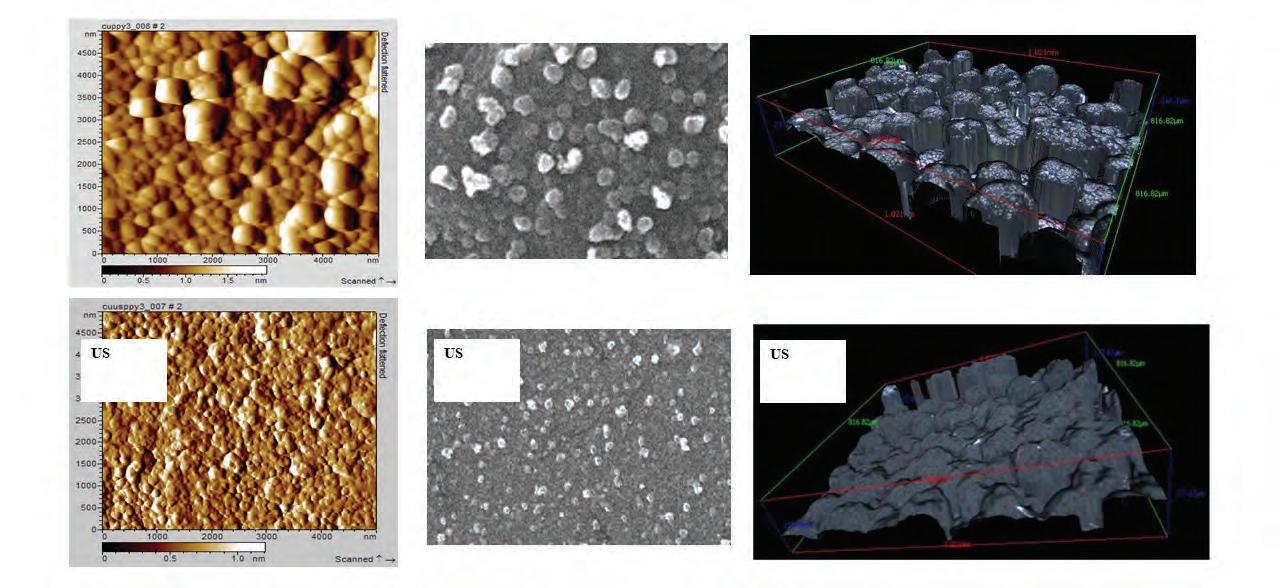

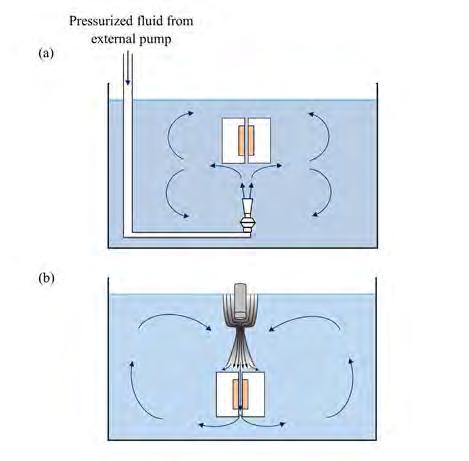

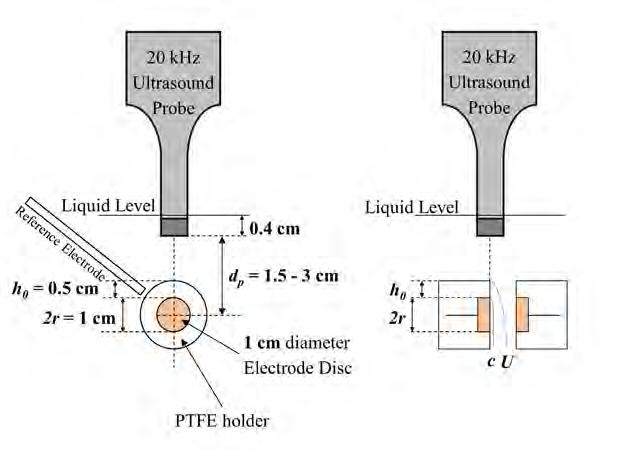

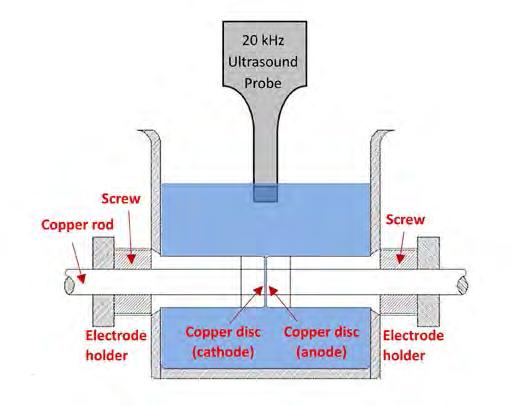

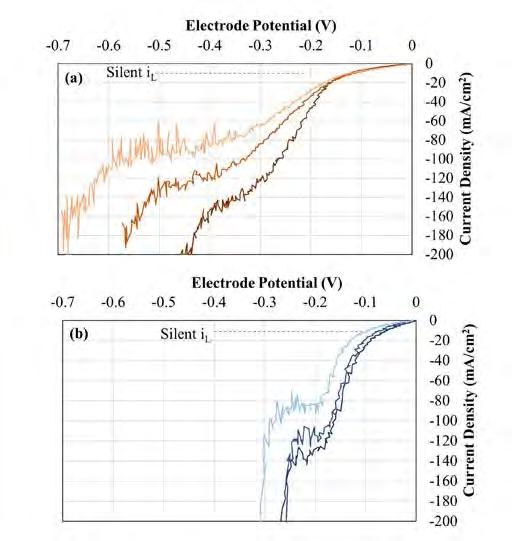

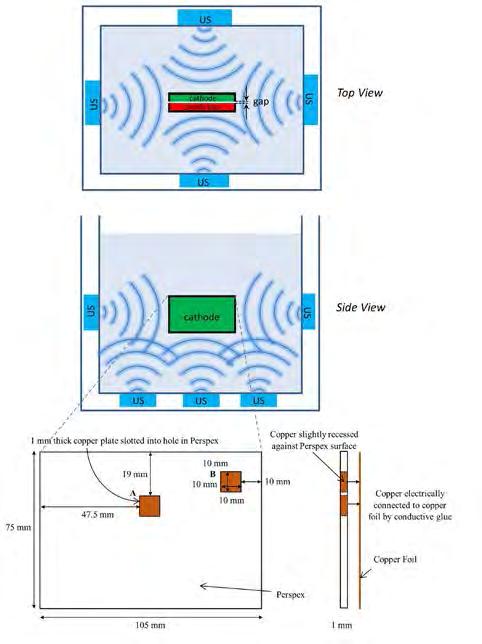

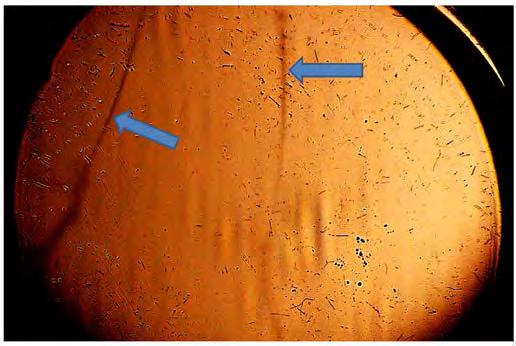

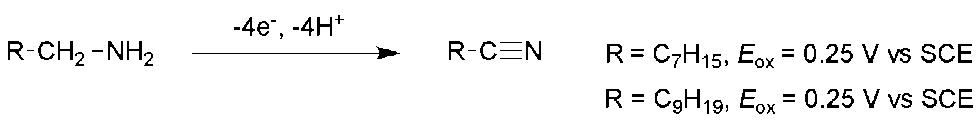

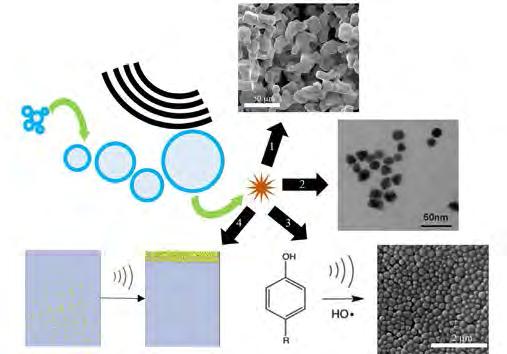

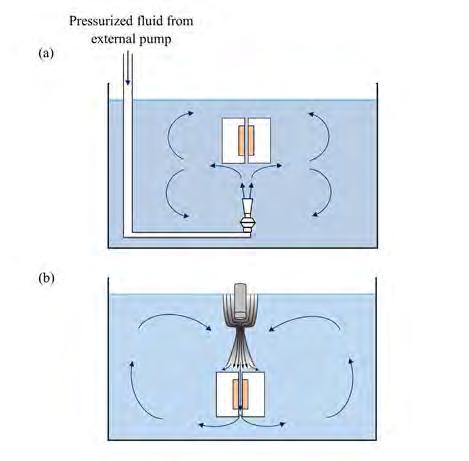

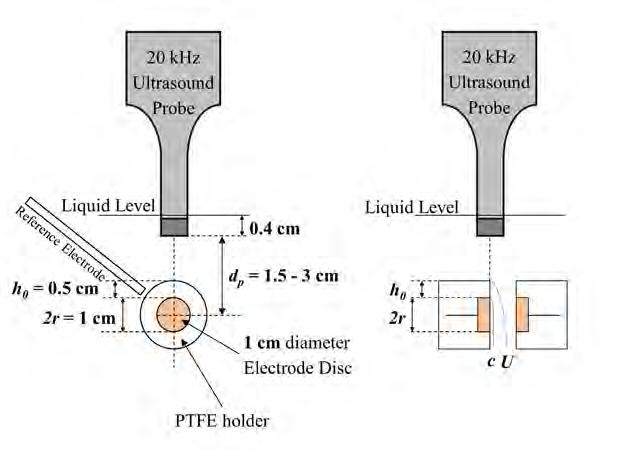

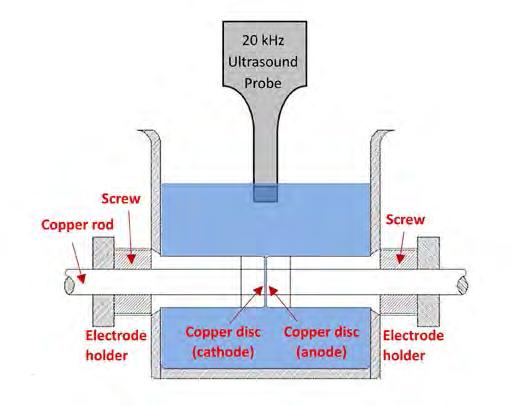

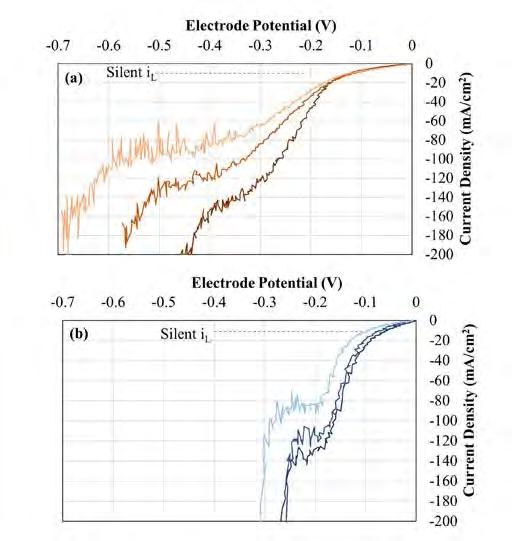

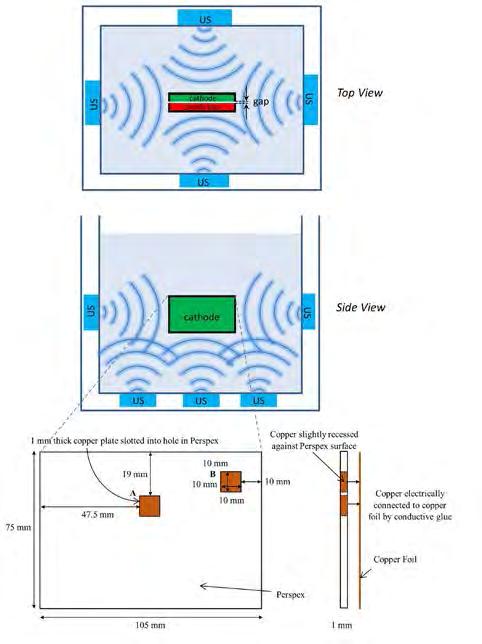

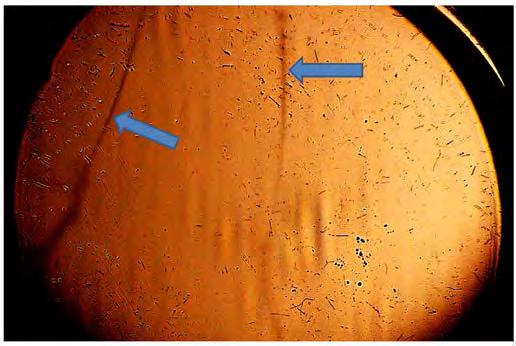

Luis A. Godínez was born in Mexico City in 1967. After completing a chemical engineering degree and an MSc degree in physical chemistry at the National Autonomous University of Mexico, he moved to the U.S. to pursue graduate studies at the University of Miami, where he obtained a PhD in physical chemistry, and later completed a postdoctoral appointment at the University of South Florida, after which he moved back to Mexico to work as a researcher at the Center of Research and Technological Development in Electrochemistry (CIDETEQ).