www.ies.org.sg

www.ies.org.sg

APRIL 2024 MCI (P) 002/03/2024

SUSTAINABILITY: Surbana Jurong opens new global headquarters

ENERGY ENGINEERING: The importance of energy conservation

AEROSPACE ENGINEERING: Singapore Sustainable Air Hub Blueprint launched

COVER STORY: Singapore scientists develop revolutionary microelectronic device

13 Singapore scientists develop revolutionary microelectronic device

The breakthrough paves the way to more sustainable and efficient computing technologies in the future.

16 Surbana Jurong opens new global headquarters

The ‘Campus in Nature’ embodies commitment to creating a smart, sustainable future.

19 The importance of energy conservation

Analysis of energy consumption can help to reduce the carbon footprint.

22 Shifting attack landscapes and sectors in Q1 2024

Data on the growth of cyber threats is analysed.

25 Importance of digital security in protecting critical infrastructure

Ways to address the challenges are explained.

26 Simulation of shot blasting machines and processes

The benefits include lower costs and improved sustainability.

President Mr Dalson Chung

Chief Editor

T Bhaskaran

t_b_n8@yahoo.com

Publications Manager Desmond Teo desmond@iesnet.org.sg

Publications Executive Nuraini Ahmad nuraini@iesnet.org.sg

Editorial Panel

Dr Chandra Segaran

Dr Ang Keng Been

Dr Aaron Sham

A/Prof Yuzhu Pearl Li

Mr Jaime Vega Bautista Jr

Dr Victor Sim

Mr Soon Ren Jun

Dr Alexander Wiegand

Media Representative

Trevor Teh

IES@mnc-link.com

Design & layout by 2EZ Asia Pte Ltd

Cover designed by Irin Kuah

Cover image by A*STAR and NUS

Published by

The Institution of Engineers, Singapore

70 Bukit Tinggi Road, Singapore 289758

Tel: 6469 5000 I Fax: 6467 1108

Printed in Singapore

28 Applying a power cut machining strategy Shortcomings relating to tool life, productivity and process security, can be overcome.

30 Staying safe while travelling at 300 km per hour

Stringent safety protocols and advanced technology ensure the well-being of passengers.

32 Singapore Sustainable Air Hub Blueprint launched Twelve initiatives and five enablers to decarbonise Singapore’s aviation sector.

34 Strongest trade attendance in Singapore Airshow’s history This signals a renewed optimism and recovery in aviation.

35 Airbus to launch Sustainable Aviation Hub in Singapore The objective is to build a robust and environment-friendly aviation ecosystem.

36 Hydrogen to be a potential enabler to Singapore’s aviation decarbonisation

The necessary technologies, regulations, infrastructure and supply chains are being developed.

37 RTX’s Pratt & Whitney announces full operations of Singapore Technology Accelerator Over 30 innovations implemented to accelerate MRO performance.

38 SAESL expands into new facilities Advanced technologies will be deployed to meet rising MRO demand.

04 NEWS & EVENTS

40 PRODUCTS & SOLUTIONS

The Singapore Engineer is published monthly by The Institution of Engineers, Singapore (IES). The publication is distributed free-of-charge to IES members and affiliates. Views expressed in this publication do not necessarily reflect those of the Editor or IES. All rights reserved. No part of this magazine shall be reproduced, mechanically or electronically, without the prior consent of IES. Whilst every care is taken to ensure accuracy of the content at press time, IES will not be liable for any discrepancies. Unsolicited contributions are welcome but their inclusion in the magazine is at the discretion of the Editor.

Renowned Dutch microbiologist and expert in water quality and health, Professor Gertjan Medema, has been awarded the prestigious Lee Kuan Yew Water Prize 2024 for his breakthrough research and discovery, and significant contributions in the field of wastewater-based epidemiology (WBE).

His research revolutionised the application of WBE for virus detection in wastewater during the COVID-19 pandemic.

Professor Medema, Principal Microbiologist at the KWR Water Research Institute in the Netherlands, is the 10th recipient of the award which has been presented since 2008.

“It is my great honour and privilege to receive the distinguished Lee Kuan Yew Water Prize. This award is a recognition of the innovative use of wastewater as a data source for trends in COVID-19 circulation in our communities. I see it also as a recognition of the hard work of many people in the water sector globally, collecting COVID-19 data from wastewater to support our society’s response to the pandemic,” said Professor Medema.

“This tightens the connections between the water and health sectors. In the current post-pandemic world, wastewater monitoring is now firmly established as a tool for public health surveillance for an increasing number of diseases,” he added.

Contributions during the Covid-19 pandemic

With the emergence of COVID-19 in early 2020, Professor Medema and his team recognised the need for early detection and monitoring, and began collecting wastewater samples across the Netherlands to test for the SARS-CoV-2 virus.

He quickly focused his team’s research on curbing the spread of the virus in the community, through wastewater surveillance. The results were promising, when evidence of

the virus was detected in the wastewater of several cities, even before they were officially reported in these cities.

Professor Medema’s work has been foundational in establishing WBE as a tool for public health surveillance during the pandemic. The impact of his work was evident from his first publication in this area, which garnered substantial attention, with over 1,400 citations and more than 34,000 views between 2020 and 2023.

Wastewater surveillance has since been adopted, worldwide, as a powerful tool for the early detection of diseases like SARS-CoV-2, even before cases are reported through clinical testing. This, in turn, provides valuable insights into the prevalence of the virus in a community and is a proven cost-effective and non-invasive method for tracking the spread of the disease.

At the start of the COVID-19 pandemic in Singapore in 2020, National Environment Agency's (NEA) Environmental Health Institute (EHI) explored wastewater monitoring as an epidemiological tool and early warning system for outbreaks, in collaboration with PUB, Singapore’s

national water agency; the Home Team Science and Technology Agency (HTX); local universities, Nanyang Technological University and National University of Singapore; and research institute, Singapore Centre for Environmental Life Sciences Engineering (SCELSE).

Through partnerships with relevant institutions, Agency for Science, Technology and Research (A*STAR) and Public Sector Science and Technology Policy and Plans Office (S&TPPO), innovative solutions in wastewater surveillance were quickly developed to respond to the national need.

Singapore bolstered its national surveillance of COVID-19 transmission by expanding coverage to hundreds of sites, including water reclamation plants, workers’ dormitories, residential areas, town centres, student hostels and welfare homes.

Today, the wastewater sampling network covers more than 500 sites across Singapore. Apart from situational monitoring of COVID-19, wastewater surveillance has also been applied to monitor Zika transmission in Singapore. NEA and the network of partners will continue to conduct research and development to build on the wastewater testing system, to support public health in Singapore.

Significant impact on the global scientific community

Wastewater has been tested for SARS-CoV-2 in at least 72 countries at over 4000 reported sites (https:// www.covid19wbec.org/covidpoops19), with Professor Medema directly connected to about 30% of these programmes. Amidst his active involvement in international collaborations, and sharing of expertise and findings with the global scientific community, he has made great contributions to the development of international guidelines and best practices for wastewater surveillance.

Dedicated to advancing the science of waterborne pathogens, Professor Medema advises the World

Health Organization (WHO) on microbiological drinking water guidelines and Quantitative Microbial Risk Assessment (QMRA); SARS; Water, Sanitation & Hygiene (WASH); and wastewater surveillance.

He also advises the European Commission on the EU Drinking Water Directives and water reuse guidelines, thereby ensuring that the knowledge gained from his research is disseminated widely and applied effectively. His leadership in this area has helped to establish a network of researchers and practitioners dedicated to using WBE as a tool for public health surveillance.

Through Professor Medema, wastewater surveillance has been estab-

lished as a vital tool in safeguarding public health, as the world braces itself for other emerging diseases.

Professor Medema will receive the Prize, comprising an award certificate, a gold medallion and a cash prize of SGD 300,000 sponsored by the Temasek Foundation, from Mr Tharman Shanmugaratnam, President of the Republic of Singapore, at an award ceremony on Tuesday, 18 June 2024.

He will deliver a keynote lecture on Wednesday, 19 June 2024, during the Singapore International Water Week 2024 which is expected to be attended by 500 global water leaders, 2,000 delegates and more than 30,000 trade visitors.

PUB announces winners of three water-efficiency awards

PUB, Singapore’s National Water Agency, recently announced the winners of the prestigious Singapore Watermark Awards (SWMA), Water Efficiency Awards (WEA) and inaugural Water Efficiency Awards (Projects), recognising outstanding efforts in water efficiency and conservation in the non-domestic sector.

A total of 46 winners, ranging from manufacturing plants and data centres to commercial buildings and schools, received the awards.

Mr Ong Tze-Ch’in, Chief Executive of PUB, said, “Water is a critical resource to support Singapore’s economic growth. The award recipients have demonstrated an outstanding commitment to water efficiency and exemplify the spirit of innovation and stewardship in safeguarding Singapore’s precious water resource. I hope that their actions will inspire others to join the movement towards a more sustainable and resilient water future.”

Singapore Watermark Awards

The Singapore Watermark Awards (SWMA) is Singapore’s highest tribute for exceptional

achievements in water efficiency, conservation and advocacy.

The three SWMA winners are Amazon Web Services Singapore (AWS Singapore), Mee Toh School, and Systems on Silicon Manufacturing Company Pte Ltd (SSMC).

One of AWS Singapore’s new data centres has achieved top 10% water efficiency performance in the data centre sector. In this highly water-efficient data centre, AWS innovated with a local startup to deploy a homegrown wastewater recycling technology to further improve water efficiency, by allowing wastewater to be reused.

AWS Singapore also implemented employee education initiatives to raise awareness on water conservation, and supported the Science Centre’s Youth Science, Technology, Engineering and Mathematics (STEM) Empowerment Programme on sustainability, where their staff volunteers mentored students in developing project prototypes, including one that can reuse rainwater to generate energy.

Mee Toh School, a co-ed primary school located in Punggol, sig-

nificantly reduced its water usage by 30% between 2019 and 2022, through initiatives such as a rainwater collection system.

Furthermore, water sustainability is integrated as part of the school’s Environment Education curriculum.

SSMC has consistently achieved the highest recycling rate in its sector, since 2015, at an average of 67% as compared to the industry average of 45%. .

The Water Efficiency Awards (WEA) recognises the top 10th percentile of water efficiency performers in the respective sectors. This year, there are 35 WEA winners from 12 sectors.

The inaugural Water Efficiency Awards (Projects), or WEA (Projects), honours projects that have demonstrated excellent improvements in water efficiency, innovativeness and project leadership, and set the industry benchmark for best practices in water conservation. This year, there are eight WEA (Projects) recipients.

The Housing & Development Board (HDB) has awarded its eighth and largest solar leasing tender, to-date, under the SolarNova programme, to Sunseap Leasing Pte Ltd, an entity of EDP Renewables APAC.

This tender covers the installation of solar panels on about 1,075 HDB blocks and 101 government sites, creating a solar capacity of 130 megawatt-peak (MWp). This is about 15% higher than the earlier estimates of 113 MWp.

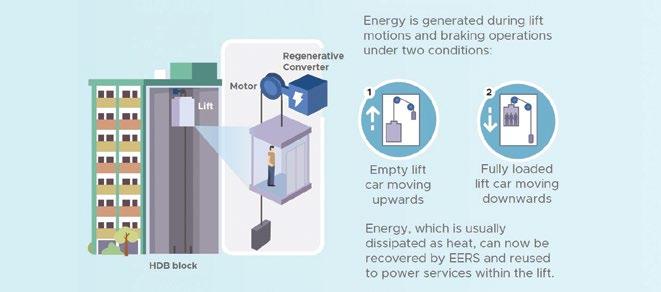

Separately, HDB has also awarded tenders to Chevalier Singapore Pte Ltd and EM Services Pte Ltd, to retrofit 4,000 lifts, island-wide, with the Elevator Energy Regeneration System (EERS).

Both the SolarNova programme and EERS, rolled out under the HDB Green Towns Programme, are part of HDB’s efforts to reduce energy consumption in HDB towns.

The HDB Green Towns Programme is a 10-year plan to bring sustainable living to all existing HDB towns, with large-scale implementation of green features to improve residents’ quality of life. It is a key initiative under the Singapore Green Plan which aims to build a more sustainable future for Singapore in the face of climate change.

HDB’s Chief Sustainability Officer and Group Director of Building & Research Institute, Mr Tan Sze Tiong, said, “The Green Towns Programme helps to mitigate climate change while creating a cleaner and more comfortable living environment for our residents, such as through initiatives that reduce energy consumption in our towns.”

“Other green initiatives introduced under the programme aim to recycle rainwater, cool our towns, encourage green commute and reduce waste. We will continue to explore new initiatives to improve residents’ quality of life, stretch HDB’s sustainability targets, and support the national goal of achieving a

green and sustainable Singapore,” he added.

SolarNova 8, the latest SolarNova tender, will include the use of a novel advanced technology to prolong the lifespan of solar panels, marking the first time that the technology is being used, since the launch of the SolarNova programme in 2014.

Generally, solar panels can last about 25 to 30 years. They undergo natural degradation due to ageing and changing weather conditions. Due to degradation, a solar panel would, on average, generate around 12% to 15% less power, towards the end of its lifespan.

To prolong the lifespan of a solar panel, EDP Renewables APAC has collaborated with EtaVolt to pilot an advanced regeneration technology for solar panels on HDB blocks, which can extend the lifespan of each solar panel by 4 to 5 years.

This patented technology developed by EtaVolt relies on intense light to re-energise the solar cells and repair them at the molecular level, and recover up to 5% of the solar panel’s efficiency, depending on panel structures, in minutes. This advanced regeneration activity only needs to be carried out, at most, once a year.

EtaVolt is a technological spin-off

from the Nanyang Technological University of Singapore, that focuses on sustainable solar renewable energy businesses in Singapore as well as in neighbouring countries in Asia.

Progressive installation of solar panels

HDB’s solar journey began in 2008 and, today, it is the largest driver for the installation of solar photovoltaic (PV) systems in Singapore. Including the eight SolarNova tenders and efforts prior to the SolarNova programme, HDB has committed a total solar capacity of 455 MWp across HDB estates, which is equivalent to powering approximately 114,000 4-room flats. This is almost 85% of HDB’s solar target of 540 MWp by 2030.

In HDB estates, solar energy that is harnessed is first used to power common services, such as lifts, lights and water pumps, in the day. Excess solar energy is then channelled to the grid. On average, HDB is able to achieve net-zero energy consumption for the common areas of HDB blocks where solar panels have been installed.

Installation of solar panels under SolarNova 8 is expected to commence in 2Q2024 and be completed by 3Q2026. HDB aims to install solar panels on as many blocks as possible. To-date, solar panels

have been installed on about 3,900 HDB blocks. For the remaining HDB blocks, where feasible, solar panels will be progressively installed, in batches, over the next three years. Actual installation will be determined, based on the site conditions for each block.

HDB has also awarded tenders to Chevalier Singapore Pte Ltd and EM Services Pte Ltd for the retrofitting of 4,000 lifts island-wide with the El-

evator Energy Regeneration System (EERS). Retrofitting works will commence in 2Q2024 and be completed by 2030.

The EERS recovers energy generated during lift motions and braking operations, to power other services such as lighting, ventilation and the lift display panel within the lift. With the EERS, lift energy consumption can be reduced by an average of 20%.

As the master developer of public

REC Group, an international pioneering solar energy company, has received the ‘Best Solar Panels’ and ‘Best After-Sales Support’ awards, in 2024, for the second consecutive year. These awards come from SolarQuotes, with insights gathered from installers across Australia.

Since its foundation in 2009, SolarQuotes has published almost 80,000 solar PV reviews, built a network of more than 600 trusted solar installers and helped almost 760,000 people to get high quality solar quotes. For ‘Best Solar Panels 2024’,

REC retains the Gold. with 45% of the vote.

The REC Alpha Pure product family, in particular, stood out for its efficiency and durability, making it a top choice among installers and homeowners alike.

In the ‘Best After-Sales Support’ category, REC has been recognised for its dedication to providing support. In an era where long-term reliability is paramount, this award highlights REC’s commitment to backing its products with customer service.

“We are thrilled to receive

housing in Singapore, HDB plays a key role in supporting the nation’s commitment to sustainable development. The award of the SolarNova 8 and EERS tenders marks another step forward in reducing energy consumption in HDB towns, and building a more sustainable and greener environment for residents. HDB will continue to explore new green initiatives that can be added under the Green Towns Programme, to intensify the sustainability efforts.

these prestigious awards for the second year in a row. This recognition from Australian solar installers is a testament to the hard work and dedication of our valued research, technical expertise and after-sales support teams at REC,” said Gus Paviani, Head of APAC and Japan at REC Group.

REC is headquartered in Norway with operational headquarters in Singapore and regional hubs in North America, Europe, and Asia-Pacific. In December 2021, REC became part of Reliance Industries Limited, India.

Underlining a landmark collaboration that underscores a shared commitment to sustainability and innovation, Meinhardt Singapore Pte Ltd, a global leader in engineering, infrastructure and project management consulting, has signed a Memorandum of Understanding (MoU) with Ngee Ann Polytechnic (NP).

This partnership aims to spearhead advancements in smart and sustainable facilities management, reflecting both organisations’ dedication to nurturing future-ready talents, and creating resilient and sustainable urban solutions.

The MoU marks a significant stride towards integrating real-world engineering challenges and digital solutions into the academic curriculum and research, and promises to unlock new opportunities for students, faculty and industry.

Under the framework of the MoU, both parties will engage in discussions in relation to sustainable and resilient buildings, carbon footprint reduction, infrastructure and environment, climate change and asset management with resilient systems, digital twins and other built environment technologies.

“At Meinhardt Group, we envision a world where infrastructure and urban developments not only embody innovation but also tread lightly on our planet. This partnership with Ngee Ann Polytechnic represents a pivotal step in that direction, offering a unique confluence of academic rigour and industry expertise to empower the next generation of green leaders in the built environment sector. By aligning our efforts, we are setting new benchmarks for what is achievable in the realm of smart and sustainable facilities management,” said Mr Omar Shahzad, Group CEO of Meinhardt Group.

The collaboration will unfold across various initiatives including joint research and consultancy projects; the co-creation, development and showcasing of systems,

platforms and solutions at NP; the formation of tripartite partnerships with other educational and research institutions; and the development of specialised training, attachment and internship programmes for NP students and faculty alike.

These programmes span the gamut, from online and face-to-face seminars, webinars and workshops to specialist training courses, career transition programmes, short courses and part-time diplomas.

Dr Eugene Seah, Chief Operating Officer of Meinhardt Singapore Pte Ltd, highlighted the importance of this collaboration in driving forward the group’s mission to deliver sustainable and buildable solutions.

“This MoU represents Meinhardt’s commitment to nurturing talents who are not just adept at navigating today’s challenges but can also envisage and engineer the sustainable solutions of tomorrow. Together with Ngee Ann Polytechnic, we are eager to co-create a future where innovation leads the way to environmental stewardship and societal well-being,” said Dr Seah.

“This endeavour aims not only to enrich the learning experience but also to equip participants with the practical skills and knowledge essential for addressing the environmental and technological challenges of the future, by expanding the boundaries of classrooms into the working world, making each space a living and learning lab,” he added.

In conjunction with the MoU, NP has unveiled the SEED (Sustainability Education & Ecosystem Development) initiative, aiming to cultivate sustainability-intelligent graduates poised to contribute to the green economy. By embedding sustainability across its curriculum and fostering industry partnerships, NP sets a precedent for educational institutions striving towards environmental excellence.

“We are invested in forging strategic alliances to innovate sustainable solutions. The synergy between Meinhardt Singapore and Ngee Ann Polytechnic through this MoU provides a robust platform for pioneering sustainable practices and technologies in the built environment sector. It reflects our shared aspiration to play an instrumental role in Singapore’s transition towards a greener future,” said Mr Lim Kok Kiang, Principal and CEO of Ngee Ann Polytechnic.

As part of the SEED initiative, NP will focus on developing sustainability-focused curricula, greening its campus, and forging strategic industry partnerships, including with Meinhardt Group, to drive innovation and talent development in sustainability. By leveraging Meinhardt’s extensive experience in delivering large-scale and complex projects worldwide, and NP’s innovative educational approaches, this partnership hopes to make significant contributions to the field of smart and sustainable facilities management.

Advanced Substrate Technologies Pte Ltd (AST), a Singapore-based subsidiary of TOPPAN Holdings Inc, a Japanese pioneer in printing technologies and a leading supplier of high quality Flip Chip Ball Grid Array (FC-BGA) substrates, recently broke ground in Singapore for the construction of its new factory.

An FC-BGA substrate enables the interconnection between one or more silicon dies and the system board and also between those silicon dies, through its multiple layers of high density wiring.

This factory will be the first in Singapore to manufacture high-end FC-BGA substrates used in bleeding edge semiconductor products such as Network Switches and Artificial Intelligence (AI) / Machine Learning (ML) devices. The production rampup is part of TOPPAN’s strategic growth plan to address the increasing global and regional demand for advanced substrates, and complements its main production hub in Japan.

Research and development (R&D) on advanced substrate technologies will also be conducted at AST’s new facility, to meet future performance demands of products for such applications.

With a target to start production by the end of 2026, AST’s factory will implement advanced factory automation to produce substrates of high quality and yield. The factory, with about 95,000 m2 floor area, will also employ over 200 high-tech engineers and skilled technicians, besides other operators, providing them with an opportunity to learn and lead in the field of FC-BGA substrate manufacturing and development.

TOPPAN will bring the company’s most advanced substrate manufacturing know-how for implementation in AST’s production lines. TOPPAN’s large-body and high-layer-count substrate technology is

proven in the products of several well-known large semiconductor companies worldwide. AST’s initial and key hires for FC-BGA substrate manufacturing will undergo intensive training in TOPPAN’s Niigata factories in Japan.

Broadcom Inc, a global technology leader that designs, develops and supplies a broad range of semiconductor, enterprise software and security solutions, is also supporting the establishment of this world class manufacturing facility in Singapore.

“AST will be our first ever FC-BGA manufacturing facility outside of Japan. AST will provide high-end FC-BGA substrates that are essential for cutting-edge semiconductor products,” said Mr Tetsuro Ueki, Senior Managing Executive Officer and Head of TOPPAN’s Electronics Division.

“By leveraging the design and manufacturing expertise developed at TOPPAN Japan’s Niigata Plant and combining it with stateof-the-art automation technology, AST will achieve the highest quality and production efficiency. We sincerely appreciate the unwavering support from the Singapore government agencies, EDB and JTC, and the invaluable assistance from our esteemed client, Broadcom, which made this project possible,” Mr Ueki added.

Mr Pee Beng Kong, Executive Vice President of the Economic Development Board of Singapore, said, “AST’s new facility is a significant

addition to Singapore’s semiconductor ecosystem, which today already hosts a diverse range of manufacturers and suppliers. Singapore continues to strengthen our business-friendly environment, innovation ecosystem and connectivity to the world, to remain a critical global node for semiconductors”.

“We are therefore glad to be chosen to host TOPPAN’s first FC-BGA substrate manufacturing facility outside Japan. This is one of Japan’s largest investments, overseas in the past decade, for a key component in the semiconductor supply chain. EDB remains keen to partner with semiconductor companies globally across the value chain, and we look forward to achieving future milestones with partners like Broadcom and TOPPAN,” he added.

“As TOPPAN’s largest customer for FC-BGA substrates, we welcome the additional capacity AST brings for large body, high layer count substrates,” said Dr Charlie Kawwas, President of Broadcom’s Semiconductor Solutions Group.

“We are also delighted that this factory is getting established in Singapore, with a world class talent pool, a vibrant semiconductor ecosystem and outstanding support by the Singapore EDB and government agencies. Advanced technologies developed at AST will be strategically important to us for differentiating our next generation Networking and AI/ML products and sustaining our market leadership,” he added.

The Association for Materials Protection and Performance (AMPP) was launched in January 2021, following the merger between Houston-based NACE International – The Corrosion Society, formerly the National Association of Corrosion Engineers (NACE) and Pittsburgh-based SSPC: The Society for Protective Coatings, after more than 145 combined years of acquiring corrosion control and protective coatings expertise, and serving members worldwide. AMPP is dedicated to the protection

The

of materials, through the advancement of corrosion control and protective coatings. AMPP protects infrastructure and assets worldwide through member and workforce education and credentialling, company accreditation, innovation and global standardisation.

Today, AMPP has more than 33,000 members and is active in more than 130 countries. Headquartered in the US, AMPP has several offices within the US and in Canada, United Kingdom, China, Malaysia, Brazil and

Saudi Arabia.

Established in September 2023, the AMPP Singapore Chapter serves more than 300 members based in Singapore, whose mission is to protect infrastructures and assets from corrosion.

AMPP hosts seminars and workshops, and facilitates the exchange of ideas and solutions among its members, local authorities, private industries, academics and others.

More information on AMPP may be obtained from www.ampp.org.

The economies in the Asia Pacific (APAC) region are particularly vulnerable to nature-related risks, including biodiversity loss, pollution and fresh water availability, according to data released recently by the Asia Investor Group on Climate Change (AIGCC) and PwC.

53%, or USD 18 trillion, of APAC’s Gross Value Add (GVA) is in economic sectors that are moderately or highly directly dependent on nature.

This includes reliance on fertile soils, clean water, pollination and climate stability, all of which are in serious decline in many parts of the region.

• 20%, or USD 7 trillion, of APAC’s GVA is in sectors with higher direct exposure – including agriculture, construction, fishery and aquaculture, food systems and forestry.

• This is higher than the global figure of 16%.

• 33%, or USD 11 trillion, is in sectors with moderate direct exposure, including energy, manufacturing and services.

• The remaining 47% is in sectors including Real Estate, Healthcare,

IT and Retail, where the nature risk exposure is more likely to be indirect.

Public equities are even more exposed, with 58% of regional market capitalisation being moderately or highly directly dependent on nature.

• 11 out of the 14 APAC stock exchanges have more than 50% of market capitalisation, with higher or moderate direct dependency on nature.

• The Taiwan Stock Exchange (TWSE) (44%), New Zealand Stock Exchange (NZSE) (42%), and Shanghai Stock Exchange (SHSE) (37%) stock exchanges had the highest proportion of market capitalization, with higher direct nature dependence.

AIGCC and PwC have developed a checklist as general guidance for investors to identify and manage nature-related risks.

• Understand expectations and identify relevant information required to assess nature-related risks in their portfolio.

• Gain top management and board commitment on nature.

• Confirm priorities for action through the assessment of assets and portfolio exposure, taking into account sectors and geographical locations, to develop investors’ approach or policy on nature.

• Identify relevant industry and market-related initiatives that can be leveraged.

• Regularly engage with priority sectors and the key companies that are represented in specific supply chains within investment portfolios.

• Adopt the most relevant framework for nature-related reporting and target setting for investments. AIGCC recommends The Taskforce on Nature-related Financial Disclosures (TNFD) recommendations and the Science-based Targets Network’s (SBTN) science-based targets for nature.

The forthcoming report ‘Nature at a Tipping Point’ by AIGCC and PwC, substantiated by case studies from corporates and investors, demonstrates how to effectively manage nature-related risks.

From 22 to 25 October 2024, EuroBLECH, the 27th International Sheet Metal Working Technology Exhibition, will be held at the Hanover Exhibition Grounds in Germany. It is the world’s largest exhibition for sheet metal processing, covering the entire supply chain in 15 different technology sectors.

Visitors can look forward to a number of live demonstrations and world premieres which provide the opportunity to explore, assess and discuss the benefits and gains of specific technology solutions for their own production processes.

Organised by RX, EuroBLECH 2024 will occupy nine halls at Hanover Exhibition Grounds, the world’s largest exhibition centre. The uptake on stand space has been strong, in particular, from international exhibitors, with more than 60% of exhibitors joining from outside Germany.

Over 90% of available stand space has already been booked. As such, the show mirrors the global significance of the sheet metal sector in the wider economy. Besides Germany, the major exhibitor countries are Italy, Turkey, China, Spain, the Netherlands, Switzerland, Taiwan, Belgium, Austria, France and the US.

Live on the show floor

EuroBLECH provides numerous opportunities to watch innovative machinery live in action. For many of the regular visitors, EuroBLECH offers access to a broad spectrum of tech suppliers, with exhibits on the processing of metal sheet, tubes, profiles, plastic hybrids and other related applications.

Exhibits on display will include stamping presses, CNC punching machines, press brakes and other machines and tools for cutting, punching and forming, joining, welding and fastening, surface treatment and finishing; solutions for process control and quality assurance; machine elements and components; CAD/CAM/CIM systems; warehouse

and factory equipment; material recycling equipment; and more.

For the first time, visitors will be able to book curated visitor tours. Also reflected in this year’s motto for EuroBLECH, ‘The Power of Productivity’, the organised visitor experiences will focus on productivity-enhancing technology. The tours will include 10-minute presentations at each stop, followed by a short Q&A session. There are two different tour options to choose from:

Tour 1: ‘Industrial Internet of Things (IIoT)’ will cover key topics such as big data, remote analysis, predictive maintenance, production monitoring, and part traceability. Participants will discover various products, tools and software to help them plan, optimise and monitor production, with a view to improving their overall productivity, efficiency and sustainability.

Tour 2: ‘Automation and Robotics for Efficient Production’ will demonstrate how integrated, bolton or stand-alone automation and robotics systems can streamline production operations for greater sustainability and productivity, even for small batches. These can range

from handling, sorting, conveying, storage and stacking systems to robots, cobots and autonomous mobile robots (AMRs).

In addition to the innovations and numerous live demonstrations on the exhibition stands, attendees can benefit from the EuroBLECH 2024 Speaker Forum at two dedicated presentation theatres for expert talks and panel discussions.

Sessions will run on all four show days and offer insights into the latest projects and product developments, as well as valuable networking opportunities and meaningful exchanges amongst peers.

The EuroBLECH Industry Awards are making a comeback at EuroBLECH 2024. Recognition will be given for the most innovative products, solutions and digitalisation concepts, in various categories. The winners will be selected by industry professionals via online voting, starting in autumn 2024, and the awards will be presented at the exhibition.

More information on EuroBLECH 2024 may be obtained from www.euroblech.com.

The demands and challenges associated with industrial parts production have changed significantly in recent years.

The PARTS FINISHING trade fair, which will be held for the first time, at the Karlsruhe Exhibition Centre, Karlsruhe, Germany, on 13 and 14 November 2024, addresses the changing needs of the manufacturing industries. The new format features a comprehensive focus on the production steps of deburring, component cleaning and surface finishing – from standalone processes right up to networked production lines.

In order to be competitive in growth markets, companies are required to be more flexible and agile, and to focus more sharply on process sequences and value chains. At the same time, industrial production has to fulfil ever-increasing demands in terms of component quality, costeffectiveness and sustainability.

“This leads to a steadily growing need for information and knowledge in manufacturing companies. Technical trade fairs play an important role in this regard. However, the focus of the respective exhibitions has thus far been limited to a great extent to individual production steps, which means that several trade fair visits are required to obtain comprehensive information, which is becoming increasingly difficult in times of personnel shortages and cost efficiency,” said Mr Hartmut Herdin, Managing Director of private trade fair promoters fairXperts GmbH & Co KG, initiator and organiser of PARTS FINISHING.

“PARTS FINISHING has been specifically developed to provide suppliers and users of solutions for deburring, component cleaning and surface finishing with an ideal platform,” he added.

Suppliers from the quality-relevant fields of deburring technologies, industrial cleaning technology and surface finishing will present their spectrum of solutions at the

new event. Beyond this, attention will be focused on trends and innovations for automation, the digital transformation, process networking and improving resource efficiency in these production steps.

The trade fair together with integrated expert forum is a platform for companies, experts and research institutions who want to showcase innovative solutions and technologies, exchange knowledge and experience, and discuss industrial trends.

Benefits for exhibitors and visitors Exhibitors can significantly reduce costs and the allocation of resources thanks to the compact two-day event. Premium exhibition booth concepts and fixed costs minimise preparation expenses and increase the profitability of trade fair participation. The event concept also promotes the establishment of strategic partnerships and the development of joint projects amongst exhibitors.

Visitors to PARTS FINISHING will

benefit from a comprehensive overview of the state-of-the-art, current developments and trends, as well as practice-oriented presentations held at the expert forum. This makes it possible for visitors to find targeted solutions for individual challenges, in order to optimise processes or adapt their range of products and services to changing requirements.

PARTS FINISHING is thus leaner, shorter and more cost-effective than conventional trade fairs.

More information on PARTS FINISHING can be obtained from info@ fairxperts.de.

As one of the leading global water events focused on innovation and solutions, the 10th Singapore International Water Week (SIWW), to be held from 18 to 22 June 2024 at the Sands Expo and Convention Centre in Singapore, will once again play host to over 2,000 global leaders, experts and practitioners from governments, cities, water utilities, agencies, industry and academia to share and co-create innovative solutions to solve the world’s urban water and associated climate challenges.

SIWW2024 is organised by PUB, Singapore’s National Water Agency, and Singapore’s Ministry of Sustainability and

the Environment. Key themes such as climate mitigation, water sustainability, net zero and decarbonisation, resource circularity, digitalisation, and a new pillar on climate adaptation, will be featured across SIWW flagship programmes including the Lee Kuan Yew Water Prize Presentation, Leaders Roundtable and Summit, Water Convention, and Water Expo.

In anticipation of the event, a roadshow was held in Hanoi, Vietnam, recently, which was attended by more than 100 local senior utility and industry leaders, distributors, industrial water end-users, as well as trade associations and chambers.

The breakthrough paves the way to more sustainable and efficient computing technologies in the future.

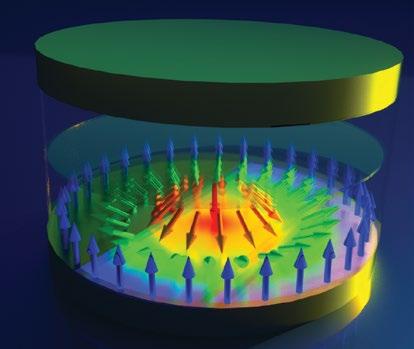

A research team, led by the Agency for Science, Technology and Research (A*STAR) in partnership with National University of Singapore (NUS), has created an innovative microelectronic device that can potentially function as a sustainable, high-performance ‘bitswitch’.

Bit switching, the process of changing a bit from 0 to 1 and vice versa, is a fundamental operation for computing. Computers encode information in sequences of bits. Each bit represents either 0 or 1.

This breakthrough, by the research team, paves the way for future computing technologies to process data much faster while using significantly less energy.

By harnessing tiny, stable and speedy magnetic whirls called skyrmions, the device can operate using 1,000 times less power than commercial memory technologies.

This discovery was reported in the scientific journal, Nature, on 21 March 2024.

The need for more sustainable and efficient AI computing

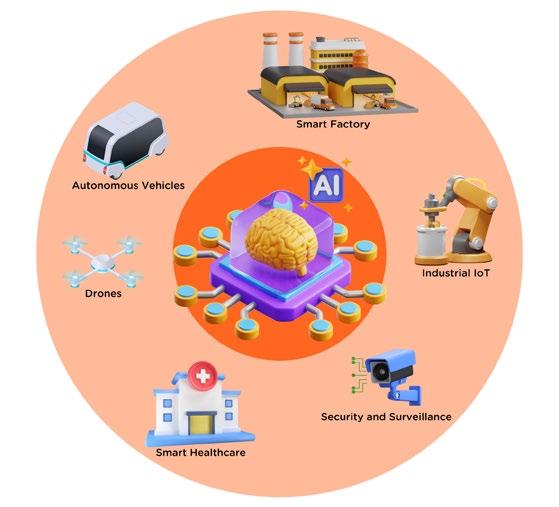

Emerging AI technologies such as ChatGPT require large amounts of data to be processed at blazing speeds, which draw on immense computing power. Infocomm technologies already consume nearly 20% of global electricity [reference: ‘Impact of Information Technology on Global Energy Consumption’ (goglobe.com)].

The consumption is set to spike even further, with the growth of such large AI models. To meet these rapidly growing demands, the fundamental computing ‘switch’, or memory-bit, has been scaled down to ever-smaller sizes, and is approaching its physical limits.

A binary digit or bit is the basic

unit of data in digital computing and digital logic, representing a state that can be either 0 or 1. Much like a light switch, it can have two positions – on or off. In the context of computing, these two states translate to 0 (off) and 1 (on).

A prominent approach to mitigate the energy crisis, especially for mobility, healthcare and manufacturing domains, is edge computing. Here, data is processed within individual appliances, such as phones, smart home appliances and vehicles, rather than in power-intensive, largescale data centres.

However, edge appliances are presently unable to perform complex computational tasks due to limited computing capacity and power constraints. There is a pressing need to develop a radically different microelectronic platform, in order to achieve efficient and sustainable AI computing.

AI appliances and applications. Image: A*STAR.

Skyrmions for the future of computing

Skyrmions are tiny magnetic whirls – 10,000 times smaller than the width of a human hair – that form within specific magnetic layers when they are made extremely thin. Discovered only a decade ago, these whirls can be extremely stable and compact, and can be efficiently moved between magnetic regions. They form ideal mobile switches for efficient, large-scale data processing for AI technologies.

Activating the potential of skyrmions

To tap on the vast potential of skyrmions, it is critical to access them using electrical pathways such as those employed in computers. While skyrmions can be seen under special microscopes and have been manipulated using bulky magnets

for over a decade, the absence of electrical control has been a critical impediment to their technological relevance.

The team from A*STAR and NUS is the first to achieve electrical readout (identification) of a skyrmion and electrical switching between states (e.g. from ‘0’ to ‘1’ and vice versa). To do so, the scientists employed a device known as a tunnel junction which is operable under ambient conditions and is used extensively in commercial memory and hard disk applications. The team discovered that the special attributes of skyrmions enable the switching between states using 1,000 times less power than commercial devices. They also found that more than two states can be achieved within a single device, which circumvents the need

to scale down the device size for enhanced performance.

Future directions

“Skyrmions have unique and elusive attributes that can be exploited to implement various AI architectures with unprecedented efficiency and functionality. Our microelectronic device provides the long-awaited key to unlocking their vast potential. It will help cement skyrmions as an integral component for the future of computing,” said the team leader, Dr Anjan Soumyanarayanan, Principal Scientist at A*STAR’s Institute of Materials Research and Engineering (IMRE) and Assistant Professor at the NUS Faculty of Science’s Department of Physics.

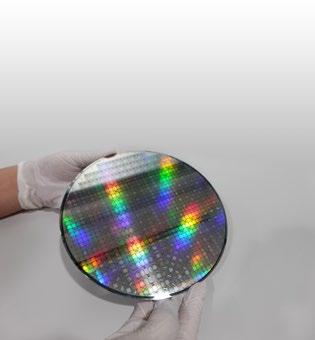

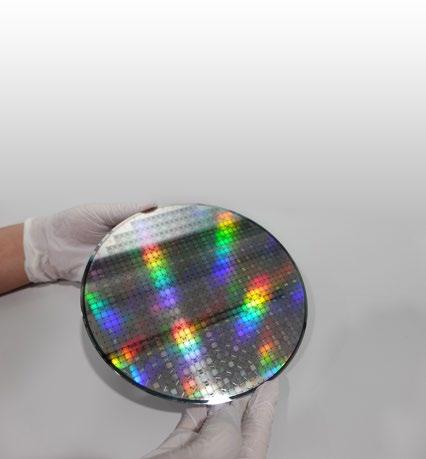

“Our microelectronic devices are fabricated on 200 mm silicon wafers using materials and methods readily

employed in existing microelectronic foundries in Singapore and globally. We hope to collaborate with the electronics cluster ecosystem to accelerate the practical integration of these devices with existing edge computing technologies,” said Dr James Lourembam, Senior Scientist at IMRE’s Electronic Materials Department.

The team hopes that with further refinement of the electrical performance, the enhanced computing switch can be readily inte-

grated into microprocessors using established approaches. The team is looking to collaborate with semiconductor manufacturing companies and system integrators to scale up the technology for wider adoption.

The Agency for Science, Technology and Research (A*STAR) is Singapore’s lead public sector R&D agency. Through open innovation,

A*STAR collaborates with partners in both the public and private sectors to benefit the economy and society. As a Science and Technology Organisation, A*STAR bridges the gap between academia and industry.

The organisation’s research creates economic growth and jobs for Singapore, and enhances lives by improving societal outcomes in healthcare, urban living and sustainability. A*STAR plays a key role in nurturing scientific talent and leaders for the wider research community and industry. The organisation’s R&D activities span biomedical sciences to physical sciences and engineering, with research entities primarily located in Biopolis and Fusionopolis.

National University of Singapore National University of Singapore (NUS) is Singapore’s flagship university and offers a global approach to education, research and entrepreneurship, with a focus on Asian perspectives and expertise.

NUS has 16 colleges, faculties and schools across three campuses in Singapore, with more than 40,000 students from 100 countries enriching the vibrant and diverse campus community. NUS has also established more than 20 NUS Overseas Colleges and entrepreneurial hubs around the world.

The multidisciplinary and real-world approach to education, research and entrepreneurship enables NUS to work closely with industry, governments and academia to address crucial and complex issues relevant to Asia and the world.

Researchers at NUS’ faculties, research centres of excellence, corporate labs and more than 30 university-level research institutes focus on themes that include energy; environmental and urban sustainability; treatment and prevention of diseases; active ageing; advanced materials; risk management and resilience of financial systems; Asian studies; and Smart Nation capabilities such as artificial intelligence, data science, operations research and cybersecurity.

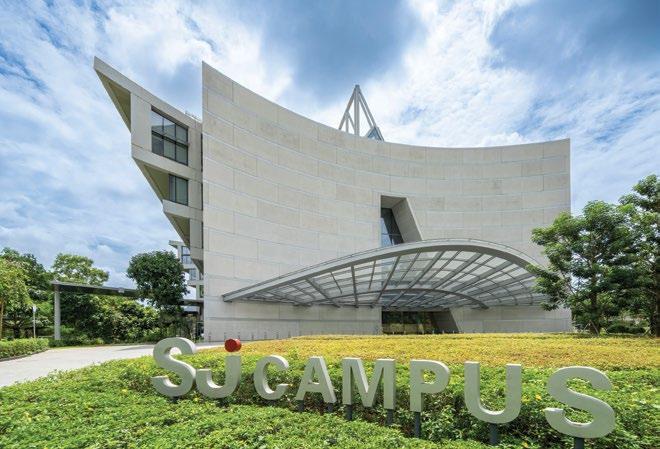

The ‘Campus in Nature’ embodies commitment to creating a smart, sustainable future.

Surbana Jurong (SJ) recently announced the official opening of the SJ Campus in Singapore, the company’s new global headquarters, at a ceremony graced by Singapore Deputy Prime Minister and Minister for Finance, Mr Lawrence Wong.

Set within CleanTech Park in Jurong Innovation District (JID) and with a built-up area of 1,200,000 ft2, the campus is a strategic centre for collaboration and learning, and a living lab for innovative solutions for the built environment.

JID is a vibrant ecosystem of enterprises pursuing smart city and urban solutions.

Designed by Safdie Architects working with SJ’s architects, the SJ Campus re-envisions the relationship between nature and the workplace. Aligning with the character of Singapore as a ‘City in Nature’, the SJ Campus is a ‘Campus in Nature’ that can accommodate 4,000 onsite employees and the wider community.

For the first time since SJ’s formation in 2015, as a collective of built environment consultants, employees in Singapore, from different entities within the firm, can finally congregate under one roof. The campus has been designed with both the SJ community and the community-at-large, in mind, creat-

ing uplifting spaces that maximise engagement, facilitated by the site’s natural setting.

Mr Sean Chiao, Group CEO, Surbana Jurong, shared, “This campus is more than a global headquarters. It is a living lab for innovating solutions and pushing the boundaries of sustainable development. Over the years, SJ has assembled a portfolio to inject new thinking and talent into the group, and fuel our capabilities to transform the built environ-

ment. In SJ Campus, our diverse talents come together to collaborate and solve our clients’ most complex problems, fulfilling our purpose –Real impact, made together.”

SJ’s multidisciplinary team undertook much of the work that brought the campus to life, providing consultancy services, from architecture, landscape architecture, engineering and project management, to workplace strategy, integrated facilities management, and security services.

Mr Chaly Mah, Chairman, Surbana Jurong, said, “Today marks a signifi-

cant milestone in SJ’s evolution. We have a strong platform to continue our aspiration of becoming a leading global architecture, engineering, design consultancy. As we open our doors to the wider community, we invite all to join us in shaping a smart, resilient and regenerative future. Working together with our clients, partners, our people and the community, we are committed to creating a future legacy that is greater than our collective past, one that serves generations to come.”

Situated on a previously undeveloped greenfield site, the SJ Campus design preserves more than half of the site’s existing green space and replaces built-upon green areas with rooftop gardens, lush interior gardens, and extensive exterior landscaping. At the outset, a detailed mapping and analysis of the site was performed to plot the specific location of the existing flora, including a Banyan tree estimated to be over 60 years old.

The 10 towers of the campus are linked by a pedestrian spine and enclosed courtyards, that allow for natural light and fresh air. Amenities further enhance the experience, including a 1,000-seater multipurpose area, a junior ballroom, rooftop terraces, a team lounge, table tennis and a soon-to-be opened gym. Many of these spaces take advantage of natural views, with large windows looking onto gardens.

The campus is a destination for walking trail enthusiasts, birdwatchers, cyclists and families exploring the Jurong Eco-Garden, home to a freshwater swamp, streams and Singapore’s last two dragon kilns. Cyclists are welcome to secure their bicycles at the onsite racks and utilise the campus shower facilities. To complete an outing, visitors can enjoy a meal at the cafeteria nestled within the campus grounds.

The project was awarded the BCA Green Mark Platinum Super Low Energy (SLE) and BCA-HPB Green

Mark Platinum for Healthier Workplaces certifications, by Singapore’s Building and Construction Authority (BCA).

The campus is designed for maintainability and deploys integrated facilities management to optimise operational efficiency. It is also WELL Pre-Certified by the International WELL Building Institute for having demonstrated a commitment to incorporate health and well-being features and practices.

The campus is distinguished by several features including the following:

• Engineering for sustainability: Through Design for Manufacturing and Assembly (DfMA), SJ constructed precast post-tensioned concrete frames in a unique arrangement, resembling inverted pyramidal cantilevered blocks. These structures form self-shading terraces, reducing solar radiation by a significant 36%. SJ’s design and engineering teams rigorously pursued a perfor-

mance-based approach, aligning with key sustainability objectives of the project.

• Best-in-class energy efficiency: The campus has adopted one of the largest underfloor air distribution systems in Singapore. This provides efficient cooling from below, to target occupied space and improve indoor air quality and generate additional energy savings of up to 16% of the cooling energy required.

Other smart facilities management solutions include an Integrated Command Centre, where IOT devices leverage artificial intelligence and machine learning to monitor energy, water, occupancy patterns and indoor air quality, to optimise carbon management and improve productivity.

These active systems and natural design elements work in combination to achieve an overall energy savings of 41%. SJ Campus is estimated to generate 4.4 million kWh/ year operational energy savings which is equal to avoiding 1,785 tons of carbon dioxide per year, based on Energy Market Authority’s grid emission factor.

• Renewable energy: SJ Campus has successfully integrated a next-generation solar photovoltaic (PV) system using bifacial PV panels which can produce clean energy when sunlight falls on either of its surfaces. The solar rooftops in SJ Campus serve as a testbed for advanced PV technologies, energy storage and the deployment of a smart grid.

Located in four towers, the solar PV system has a combined energy yield of 389 MWh per year, which is equivalent to powering 120 threeroom HDB flats every year. On-site renewable energy helps to offset Scope 2 emissions, saves energy costs, and earns renewable energy certificates (RECs).

• Role as a living lab: The campus serves as an incubator for real-world urban solutions to demonstrate the scalability of emerging technologies in the built environment industry. SJ is working with BCA to test-bed low carbon technologies to save energy and improve occupant health.

Financing the project

SJ adopted a ‘develop and lease’ model to fund the development of SJ Campus. SJ secured 100% funding for the development of the property and subsequent lease agreement for the entire land lease tenure, from M&G Real Estate, one of the world’s leading financial solutions providers for real estate investors. This arrangement has provided SJ with a compelling long-term and cost-effective solution in developing the property.

Surbana Jurong

Surbana Jurong (SJ) is a diverse collective of problem solvers for the built environment, continually reimagining ways to create a smart and sustainable future.

Headquartered in Singapore, the group has a global talent pool of 16,000 in its member companies, AETOS, Atelier Ten, B+H, CHIL, KTP, Prostruct, Robert Bird Group, SAA, SMEC and Surbana Jurong, based in more than 120 offices in over 40 countries. They include architects, designers, planners, engineers, facilities managers and other specialists, driven by progressive thinking and creative ideas.

Its technical experts deliver sustainable solutions that cover the entire project life cycle, from planning and design, through to delivery and management, as well as a full suite of multidisciplinary consultancy services across a diverse range of sectors including transportation, water, aviation, healthcare, hospitality and renewables.

A global urban, infrastructure and managed services consulting firm, with a track record of over 70 years in successful project delivery, SJ has built more than a million homes in Singapore, created master plans in more than 60 countries and developed over 100 industrial parks globally.

SJ is #23 in Engineering News-Record’s 2023 Top 225 International Design Firms; #14 in World Architecture 100 2024; and Asia Pacific FM Technology Provider of the Year 2022, awarded by International Facility Management Association.

SMEC awards funding for innovative green hydrogen methodology

SMEC is embracing green hydrogen as a part of the future energy mix by awarding Research and Development (R&D) funding to one of its specialist teams for the expansion of an innovative methodology for Green Hydrogen projects.

The novel methodology aims to capture and incorporate the complexity of the integration between renewable energy resources and the production of green hydrogen and its carriers, by using a holistic approach between components, and analysing the impact of the variability and complementarity of the renewable energy resources on the optimal system’s architecture.

Given the fast and evolving green hydrogen sector, clients and the market are looking for suitable methodologies and comprehensive energy models that capture the complexity of the different components of the system and provide reliable solutions.

This funding will assist the team in further developing novel scientific methodology to fill the engineering and scientific gaps, and include the variability and complementarity of different renewable energy sources needed to assist clients with their hydrogen projects holistically.

SMEC’s R&D Fund INNOVATE has been developed to foster continuous improvement and growth, through investment in innovation, research, software development and technology.

SMEC’s engineers will be collaborating with green hydrogen specialists from parent company, Surbana Jurong, bringing together global expertise to deliver the projects of the future.

Analysis of energy consumption can help to reduce the carbon footprint.

Introduction

Unprecedented technological advancements over the last few decades have resulted in an exponential growth in energy consumption around the globe, including in Singapore. Most energy consumed around the world is primarily from fossil fuels and their derivatives. In addition to the indirect emission of Green House Gases (GHGs), resulting from an imprudent use of electrical energy, direct emission also takes place through onsite burning of fossil fuels such as coal, diesel, and natural gas etc.

An ever-growing industrial sector, trying to catch up with the requirements of an expanding urban population, consumes the bulk of this energy, followed by the commercial and transportation sectors. So, it is of paramount importance to ensure that the mitigation strategies respond adequately to the ever-increasing energy consumption.

In this article, a brief account of the GHG phenomenon and the resulting climate change around the world will be discussed. In addition, a short discussion on the Significant Energy Use (SEU) systems in Singapore and the various energy efficiency improvement strategies legislated by the Singapore government is included.

The significance of rising Greenhouse Gas Emissions

The main human-generated GHGs are carbon dioxide (CO2), methane (CH4) and nitrous oxide (N2O). Emission of CO2 occurs from three main human activities – burning of fossil fuels, cement production as well as deforestation.

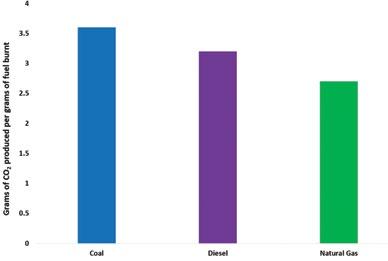

Figure 1 shows the quantity of CO2 produced, in grams, per gram of the common fuels burnt.

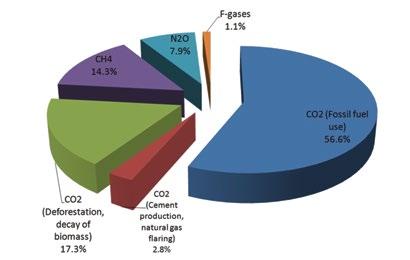

Figure 2 shows the percentage of GHGs (in CO2 equivalent) produced by different sources of emissions.

The overwhelming industrialisation around the globe along with deforestation increases the CO2 lev-

el in the earth’s atmosphere in an unprecedented manner, with a current reported level of 450 parts per million (ppm). The natural removal mechanisms of CO2 from the earth’s atmosphere are by dissolving of CO2

in the sea water as well as through the absorption by vegetation. In the pre-industrial era, this CO2 removal process was effective because of a low level of atmospheric CO2.

But in the modern industrialised world, there is a huge imbalance in the CO2 generated and the absorption capacity of the CO2, resulting in the formation of a CO2 blanket trapping the heat within the earth’s atmosphere. This produces global warming which is the principal cause of climate change.

Advanced computer climate models created by the scientists around the world predict a CO2 level of 450 ppm and a temperature rise of about 0.5 °C to 1.0 °C in the 2020s. The worst-case scenario predicted for the end of Year 2090 is a CO2 level of 958 ppm and a temperature rise of 4 °C, while an optimistic prediction, for a stabilised 540 ppm CO2 level and a temperature rise of 1 °C to 2 °C, has also been reported.

Severe droughts and floods are the adverse effects of global warming, with scientific studies suggesting that in 270 years, 20% of the world’s glaciers will melt, resulting in a significant rise in sea levels and flooding.

Based on the ‘Stern Review on the Economics of Climate Change’ (October 30, 2006), the worst impacts of global warming can be avoided if the CO2 equivalent level is stabilised at between 450 ppm and 550 ppm. This indeed would require emissions to be decreased by 25%, by 2050.

According to the report, without any action taken, CO2 levels could double by Year 2035. It also suggests that the resulting overall cost to the world would be at least 5% of the world’s economic productivity.

However, reduction of global warming would require an undertaking involving not more than around 1% of the world’s gross domestic product. This leads to the conclusion that the benefits of early action plans to mitigate the CO2 emission far outweigh the

economic and social costs of not acting.

Because of the adverse effects of GHG emissions, in particular, CO2 emissions, and their consequences such as climate change (causing severe floods and droughts), it is of paramount importance that the human community collectively resorts to a robust action plan to minimise the GHG emissions through prudent use of energy in all aspects of our lives.

We are living in an industrialised world with an unprecedented level of energy demand, especially by industrial companies, followed by commercial sectors such as data centres, office buildings, hospitality venues, shopping malls etc. Therefore, the solution to minimise GHG emissions lies in operating the SEUs in these sectors with the best possible energy efficiency.

Main energy consumers in Singapore

In Singapore, the main energy consuming sectors are the industrial and commercial sectors, with industry leading the list followed by the commercial sector. The industrial sector in Singapore comprises oil & gas, petrochemical, pharmaceutical, semi-conductor and food manufacturing companies.

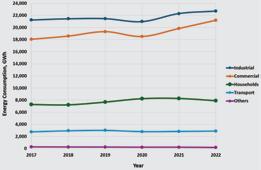

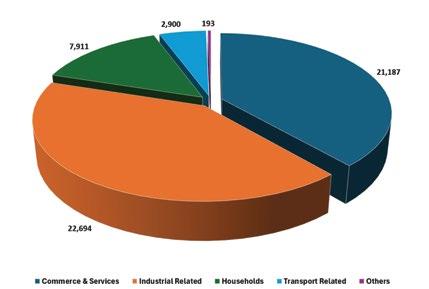

Figure 3 shows the sector-wise energy consumption in Singapore, as of Year 2022, as published by Energy Market Authority (EMA), Singapore. As can be seen from Figure 3, the industrial sector leads in energy consumption, with about 41%, followed by the commercial sector, with a consumption of about 39% in Year 2022.

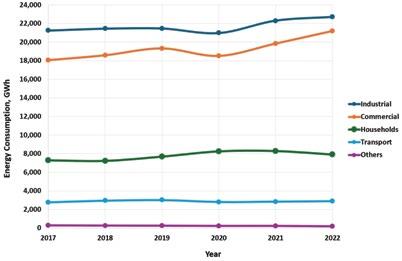

Figure 4 shows the energy consumption trend in Singapore, in various sectors, from Year 2017 to Year 2022, as also published by EMA, Singapore. Again, the industrial sector has led in energy consumption.

The energy consumption by Significant Energy Use (SEU) systems includes both fuel and electrical energy. For the heating requirements

of industrial companies, mostly natural gas fired steam generators / hot water boilers are in use, with diesel as a back-up fuel and with a fuel switching option available. Industrial companies emit CO2 both directly (through onsite burning of fuel) and indirectly (through using electricity from grid).

The main SEU systems in the industrial sector in Singapore are boiler systems, Compressed Dry Air (CDA) systems and chiller systems. SEU systems in Singapore’s commercial sector comprise mainly chiller systems and air distribution systems.

Energy efficiency improvements in the industrial sector, with a reduction of GHG emission as the goal, are spearheaded by the National Environment Agency (NEA), with legislations such as Energy Efficiency Opportunities Assessment (EEOA) and the Minimum Energy Efficiency Scheme (MEES) for chiller systems, subject to certain operational criteria.

The MEES is applicable to industrial companies with a total installed chiller cooling capacity of 300 RT and with the target of achieving a minimum chiller system efficiency of 0.67 kW/RT, again subject to certain operational criteria.

The MEES is expected to be completed for most companies by December 2025. More information is available at the NEA web portal (nea.gov.sg).

Both the above energy efficiency legislations are applicable to industrial companies, under the Energy Conservation Act (ECA) which has been in place since 2013. The operations of an industrial company consuming 54 TJ and above of energy will come under the purview of the ECA and the company will be required to have a mandatory Energy Efficiency Opportunities Assessment (EEOA) performed by a certified, independent, EEO Assessor.

A list of registered, independent EEO Assessors, with their areas of expertise, can be obtained from https://eeoa.sg/certified-eeoassessors/.

With several years’ experience in

the energy conservation sector in Singapore, my view about the opportunities for energy efficiency improvements in the industrial sector is optimistic. With a well-regulated energy efficiency sector under NEA, Singapore should be able to achieve the target of a 36% reduction in CO2 emissions over the reference year 2005, by Year 2030.

In this regard, SMEs consuming significant energy, but whose operations do not come under the ECA, could also volunteer and contribute to the cause, by having a detailed energy audit performed by an accredited Energy Services Company (ESCO).

A list of accredited ESCOs can be obtained from the NEA webpage.

The alarming rise in GHG emissions, in particular, CO2 emissions, around the world, is causing adverse effects such as climate change. The eradication of GHG emissions is impossible, however, their effects can be minimised through swift intervention and ensuring that the operation of SEU systems is at their highest efficiency levels.

The potential for energy savings in the industrial sector in Singapore can be identified thorough a detailed energy audit of the SEU systems, such as chiller systems, boiler systems and CDA systems. Even in the commercial sector, detailed energy audits can be performed on chiller systems and air distribution systems, to identify potential energy saving measures.

The realm of cybersecurity is an ever-evolving battlefield. As we stepped into 2024, the shadows of 2023’s massive cyber threats still loomed, setting a precedent for what was to come. The first quarter of 2024 has seen an intriguing shift in the landscape of cyber attacks,

both in the frequency and in the nature of threats.

Global cybersecurity trends for Q1 2024

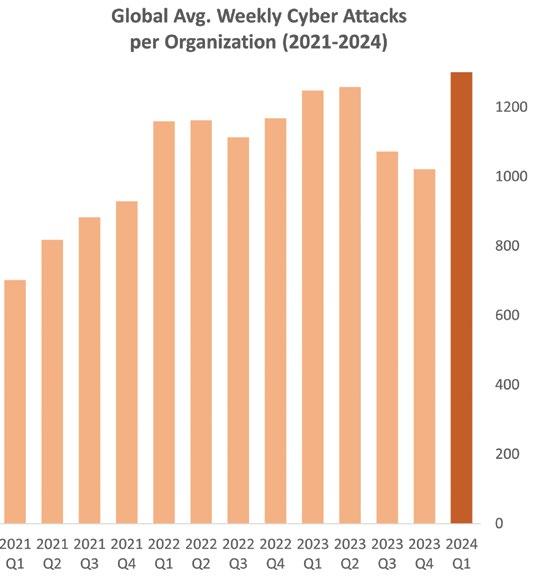

In Q1 2024, Check Point Research (CPR) witnessed a notable increase in the average number of cyber at-

tacks per organisation, per week, reaching 1,308 – marking a 5% increase from Q1 2023 and a 28% increase from the last quarter of 2023.

This escalation is not just a number but a stark reminder of the persistent and evolving threat landscape, and

the substantial increase from Q4 2023 accentuates a worrying trend of rapid escalation in cyber threats.

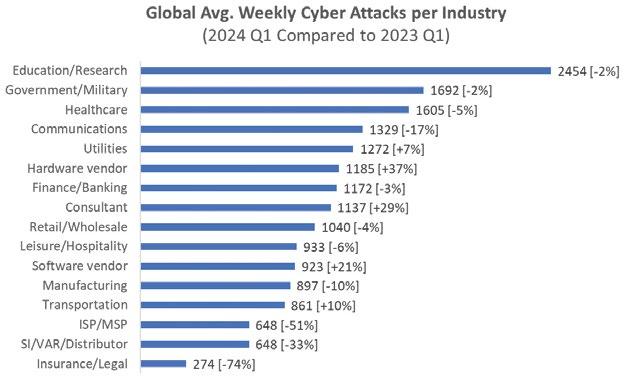

Global attacks per industry

The Education/Research sector experienced a significant blow, with an average of 2,454 attacks per organisation, weekly, leading the chart in targeted industries, followed by the Government/Military (1,692 attacks per week) and Healthcare (1,605 attacks per week) sectors –

signalling an alarming vulnerability in sectors that are pivotal to societal function.

However, it is the substantial year-on-year increase in attacks on the Hardware Vendor industry, rising by 37%, that underlines a strategic shift in target preference for cybercriminals. This industry’s increasing reliance on hardware for IoT and smart devices makes these vendors lucrative targets for cybercriminals.

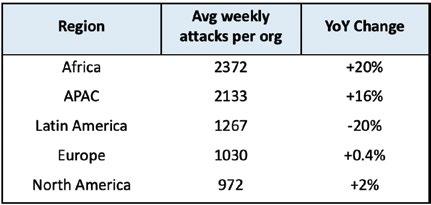

Regional analysis of overall attacks

Regionally, Africa surged to the forefront, with an average of 2,372 attacks per week, per organisation, a 20% jump from the same period in 2023. In contrast, Latin America showed a 20% decline, perhaps indicating a shift in focus or improved defensive measures in the region. Another reason could be a temporary shift in focus by cybercriminals on other more vulnerable regions across the world. The data also revealed a nuanced picture of varying intensities and types of cyber threats in different regions, underscoring the complex and dynamic nature of cyber warfare.

Ransomware attack insights per region and industry

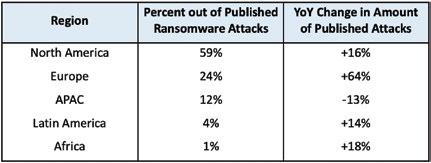

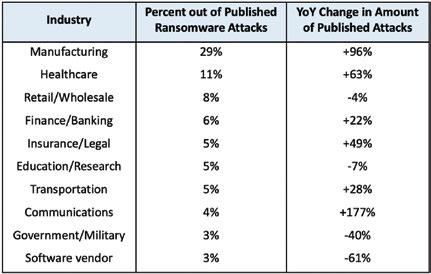

In Q1 2024, North America was the region most impacted by ransomware attacks, accounting for 59% out of close to 1,000 published ransomware attacks, followed by Europe (24%) and APAC (12%).

The information is derived from ransomware ‘shame sites’ operated by double-extortion ransomware groups which posted the names and information of victims. The data from these shame sites carries its own biases, but still provides valuable insights into the ransomware ecosystem.

The largest increase in reported attacks compared to Q1 2023 was seen in Europe, with a significant 64% increase. This significant increase could be attributed to factors such as increased digitisation of services and regulatory environments that may make organisations more vulnerable or visible targets. In contrast, the North America saw a 16% increase, indicating a sustained focus by attackers on this region.

The most impacted industry globally was Manufacturing, accounting for 29% of published ransomware attacks and having almost double the amount of reported attack YoY, followed by Healthcare with 11% of the attacks (and 63% increase YoY), and Retail/Wholesale with 8% of the attacks.

The Communications sector saw the highest increase YoY in ransomware attacks with 177%, though it constituted only 4% of the published attacks in the quarter. The Communications sector’s surge in cyberattacks YOY could have been fuelled by rapid digital transformation, integrating technologies, like 5G and IoT, which expand vulnerabilities, while its critical role and handling of sensitive data make it a prime target for diverse threats, including state-sponsored espionage and data theft.

The Manufacturing sector had the second highest increase in ransomware attacks with 96% YoY, and is a common prime target due to its heavy reliance on interconnected technology and weakened security capabilities due to use of legacy industrial technologies.

Practical organisation strategies

According to Check Point, businesses must adopt a multi-faceted approach to cybersecurity, encompassing

robust data backups, frequent cyber awareness training, timely security patches, strong user authentication, and advanced anti-ransomware solutions. Proactive engagement with AI-powered defences can significantly bolster an organisation’s resilience against these threats.

In response to these escalating threats which are becoming more sophisticated, advancements in defence techniques especially in threat detection and analysis and spotting anomalies and new attack patterns early, particularly in AI, have become pivotal.

For instance, Check Point’s ThreatCloud AI, which underpins all its solutions, leverages AI and big data to counter sophisticated threats, while minimising false positives. It processes vast amounts of data and indicators of compromise daily. A practical example of its effectiveness is in handling zero-day attacks.

A malicious link identified in the US is instantly blocked and this intelligence is shared globally, allowing a similar attack in Australia to be thwarted within seconds, averting potential harm.

The drive to defend continues

The first quarter of 2024 has underscored the need for adaptive cybersecurity strategies to combat the evolving threat landscape. The increased attacks on specific industries and regions, coupled with the complexity of ransomware tactics, highlight the necessity for comprehensive and prevention-first approaches to cybersecurity. While continuing to navigate this challenging terrain, awareness, preparedness and innovation in defence strategies remain the strongest allies.

(Check Point Software Technologies is a global leader in cybersecurity solutions.)

The Singapore Engineer (TSE): How has the threat landscape advanced in terms of critical infrastructure in Singapore?

Koh Ssu Han (KSH): Firstly, threat actors are bolder and have access to ever more powerful malware. Secondly, digital transformation has narrowed the gap between operational technology and IT systems. We are already seeing how these two factors are playing out. CyberArk found that 96% of the Singapore organisations surveyed experienced ransomware attacks between 2022 and 2023, and 60% of these were likely victims of double extortion campaigns.

Given the state of play, identities are crucial to restricting attacker movement within IT and OT networks, especially as cloud adoption or legacy app migration makes access ubiquitous.

TSE: What would be the repercussions of cyber-attacks on our critical infrastructures?

KSH: Critical infrastructure typically underpins sectors like healthcare and government facilities, as well as electric grids and water systems, which is why there are certain obligations involved with securing them.

Operators of critical infrastructure are also accelerating cloud adoption, which is expanding the attack surface. This is why it is also important to protect critical information infrastructure (CII). Singapore is constantly studying ways to do just this, which include the current tabling of a Cybersecurity (Amendment) Bill in Parliament, that requires the CII sectors to report more types of cybersecurity incidents, including those that happen in their supply chains, among other changes.

Certainly, this initiative is timely because attackers continually become

more adept at using new, advanced tools like Gen AI, to roll out faster and more sophisticated attacks, including identity-related attacks. Indeed, 67% of global respondents surveyed in the energy and utilities sector told CyberArk they were inadequately prepared to withstand attacks.

TSE: How can critical infrastructures adopt a proactive approach to cyber defence through identity security?

KSH: The big challenge is, of course, understanding the role that identities play in an attack. Simply put, access to key assets is what attackers want. Organisations know this. That is why they overwhelmingly told a CyberArk survey that they expect their organisations to suffer identity-related compromise.

An identity-centric risk plan allows decision-makers to figure out what is most valuable to their organisations and ensure that they are at the heart of the cyber strategy. This riskbased approach provides the backbone for zero trust and strengthens defences and compliance.

TSE: What is ‘zero trust’ and how can organisations adopt it to defend themselves effectively against such attacks?

KSH: Zero trust is centred on the belief that organisations should not automatically trust anything, whether it is outside or inside their network perimeter. Zero trust models demand that anyone and everything trying to connect to an organisation’s systems must first be verified before access is granted. The ‘assume breach’ mentality shifts the focus to identifying, isolating and stopping threats by scrutinising behaviour. This eliminates unnecessary privileges and strategically removes excessive permissions.

These principles can be upheld using more modern methods of identity security including strong adaptive authentication, zero standing privillege (ZSP), among others, that ensure users are who they say they are and are accessing their systems with ‘just right’ privileges required for performing their tasks, thus reducing risk to the organisation. Meanwhile, through automated identity provisioning, organisations can uphold zero trust as they can continuously approve and authorise identities. Another key element in implementing zero trust is securing authentication tokens while removing local administration rights. Organisations should also equip themselves with tools to maintain compliance with recorded key events and tamper-resistant audits. This also includes being able to secure and centrally store session recordings for easy security, audit and compliance, to increase accountability and compliance.

Singapore, represented by the Cyber Security Agency of Singapore (CSA), has been working closely with ASEAN Member States (AMS) to establish the ASEAN Regional Computer Emergency Response Team (CERT) to promote and facilitate information-sharing related to cyber incident response, and to complement the efforts by national national CERTs in each AMS. Singapore had made the recommendation for a single AMS to host the ASEAN Regional CERT and proposed to host and fund its physical activities in Singapore.

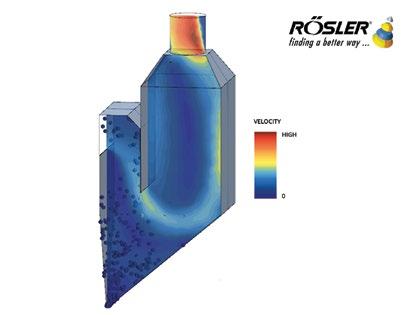

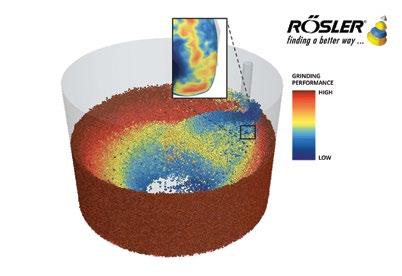

The benefits include lower costs and improved sustainability.

In many industries, shot blasting is an indispensable surface treatment process. It is an excellent tool for surface cleaning, deburring, surface preparation for painting or coating and shot peening. As such, shot blasting technology is used to create optimal surface finishes, be it to ensure problem-free downstream manufacturing operations or to optimise the functional characteristics of a product.