Continued learning leads to federal order

Testing of lactating dairy cows mandated prior to interstate movement

By Danielle Nauman danielle.n@dairystar.com

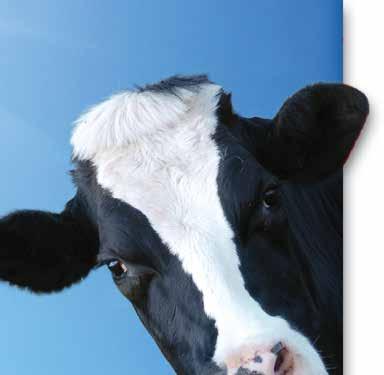

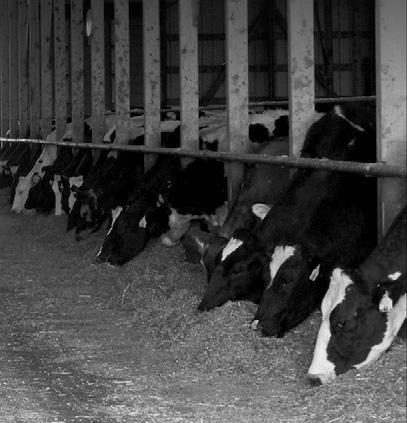

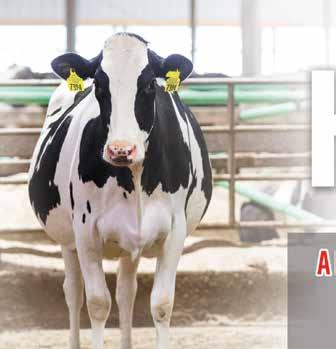

Over six weeks have passed since the illness affecting dairy cattle in the southwestern United States was identied as highly pathogenic avian inuenza H5N1, or bovine inuenza A virus. In the days since, questions about H5N1 have been answered and many more have arisen.

To slow the spread of the virus, especially because cow-to-cow transmission is yet to be understood, effective April 29, the U.S. Department of Agriculture mandated that lactating dairy cattle receive a negative test for the inuenza A virus from an approved National Animal Health Laboratory Network laboratory for interstate commerce.

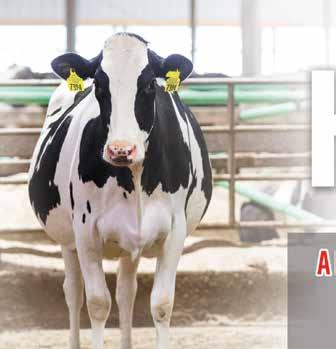

As of May 6, lactating dairy cattle have tested positive for H5N1 in 36 herds in Colorado, Idaho, Kansas, Michigan, New Mexico, North Carolina, Ohio, South Dakota and Texas.

According to a USDA press release April 24, the federal order was spurred because cow-to-cow spread was identied within a herd. As well, the spread of the virus from cows to poultry and from dairy farm to dairy farm coincided with the movement of cattle. The press release also said that cows not showing clinical signs of the virus were testing positive.

Dr. Diego Diel, director of the virology laboratory at Cornell University’s Animal Health Diagnostic Center, spoke April 30 during a webinar hosted by the National Milk Producers Federation.

Initially, producers dealing with infected cows were asked to submit a broad variety of samples for testing, including nasal swabs and samples of whole blood, serum, urine, feces and raw milk. Samples collected from euthanized cows included tissue from lungs, lymph nodes, small and large intestines, and the mammary gland.

According to Diel, a few positive results were detected in samples of whole blood, serum and nasal swabs, but the

up!

Growing from the ground up

STACEY SMART/DAIRY STAR

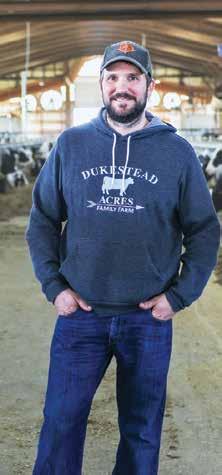

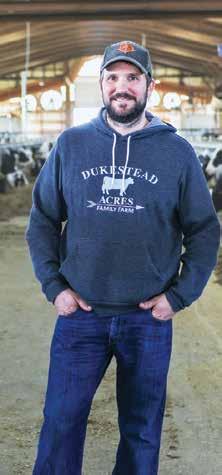

Corey and Kristen Metcalf take a break in the freestall barn April 18 on their farm near Milton, Wisconsin. The Metcalfs, along with Corey’s parents, Terry and Jane Metcalf, milk 750 cows and farm 1,200 acres.

Metcalfs double herd size in 7 years on farm built from scratch

By Stacey Smart stacey.s@dairystar.com

MILTON, Wis. — Corey Metcalf grew up on a grain farm, but in his heart, he knew he was meant to be a dairy farmer.

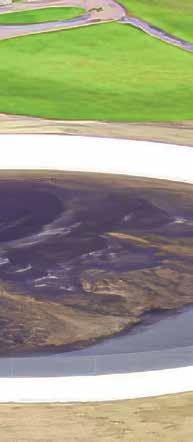

In 2017, on a piece of land void of buildings other than his parents’ house, Corey began to build the farm of his dreams. He and his family constructed a freestall barn, machine shed, milking parlor and manure pit. They bought Jerseys to ll the barn, starting with 300 cows. From the beginning, registered genetics was the focus.

“I really like the Jersey cow,” Corey said. “Everyone was focusing more on components at the time, so I decided to go with Jerseys. I bought cows from all over the country, from North Carolina to Ohio to Missouri.”

The story behind the sandwich

Wisconsin Grilled Cheese Championship honors dairy industry for 11th year

By Abby Wiedmeyer abby.w@dairystar.com

DODGEVILLE, Wis.

The 32-degree weather and snow urries did not stop attendees of the 11th annual Wisconsin Grilled Cheese Championship from warming up with an ooey-gooey sandwich and cup of soup April 20.

Held in the Ley Memorial Pavilion at Harris Park in Dodgeville, approximately

1,300 volunteers, contestants, judges and attendees honored the dairy industry with the annual competition.

The event is hosted by the Dodgeville Area Chamber of Commerce. It began when the late Loren Topper created the event to promote local dairy farmers. Jenna Vondra, director of

ABBY WIEDMEYER/DAIRY STAR

Zach Washa puts the nishing touches on his grilled cheese sandwich April 20 at the Wisconsin Grilled Cheese Championship in Dodgeville, Wisconsin. For his eighth year of compe on, Washa created a recipe with Kwik Trip maple glazed donuts, bacon and cracked pepper cheddar cheese and won second place.

May 11, 2024 Volume 26, No. 6 “All dairy, all the time”™ M

Turn to H5N1 | Page 9 Turn to GRILLED CHEESE | Page 2

Turn to METCALFS | Page 6

Sign up for our Newsletter up for our Dairy St r Milk Break Visit dairystar.com to sign

DAIRY ST R

ISSN Print: 2834-619X • Online: 2834-6203 522 Sinclair Lewis Ave. Sauk Centre, MN 56378

Phone: 320-352-6303 Fax: 320-352-5647 www.dairystar.com

Published by Star Publications LLC

General Manager/Editor

Mark Klaphake - mark.k@dairystar.com

320-352-6303 (ofce) 320-248-3196 (cell) 320-352-0062 (home) Ad Composition - 320-352-6303

Nancy Powell • nancy.p@dairystar.com

Karen Knoblach • karen.k@star-pub.com

Annika Gunderson • annika@star-pub.com

Editorial Staff

Maria Bichler - Assistant Editor maria.b@dairystar.com

Stacey Smart - Assistant Editor 262-442-6666 • stacey.s@dairystar.com

Danielle Nauman - Staff Writer 608-487-1101 • danielle.n@dairystar.com

Abby Wiedmeyer - Staff Writer 608-487-4812 • abby.w@dairystar.com

Tiffany Klaphake - Staff Writer 320-352-6303 • tiffany.k@dairystar.com

Jan Lefebvre - Staff Writer jan.l@star-pub.com

Amy Kyllo - Staff Writer amy.k@star-pub.com

Emily Breth - Staff Writer emily.b@star-pub.com

Consultant

Jerry Jennissen 320-346-2292

Advertising Sales

Main Ofce: 320-352-6303 Fax: 320-352-5647

Deadline is 5 p.m. of the Friday the week before publication

Sales Manager - Joyce Frericks 320-352-6303 • joyce@saukherald.com

National Sales Manager - Laura Seljan (National Advertising, SE MN) 507-250-2217 • fax: 507-634-4413 laura.s@dairystar.com

Assistant Sales Manager - Kati Schafer (Northeast WI and Upper MI) 920-979-5284 • kati.s@dairystar.com

Jerry Nelson (SW MN, NW Iowa, South Dakota) 605-690-6260 • jerry.n@dairystar.com

Mike Schafer (Central, South Central MN) 320-894-7825 • mike.s@dairystar.com

Megan Stuessel (Western Wisconsin) 608-387-1202 • megan.s@dairystar.com

Julia Merten (Southeast MN and Northeast IA) 507-438-7739 • julia.m@star-pub.com

Bob Leukam (Northern MN, East Central MN) 320-260-1248 (cell) bob.l@star-pub.com

Mark Klaphake (Western MN) 320-352-6303 (ofce) • 320-248-3196 (cell)

Deadlines

The deadline for news and advertising in the Dairy Star is 5 p.m. Friday the week before publication.

Subscriptions

One year subscription $42.00, outside the U.S. $200.00. Send check along with mailing address to Dairy Star, 522 Sinclair Lewis Ave., Sauk Centre, MN 56378. Advertising Our ad takers have no authority to bind this newspaper and only publication of an advertisement shall constitute

nal acceptance of the advertiser's order.

and

the chamber, said the event continues to grow while the mission remains the same.

“We have a lot of farmers in our area, and they’re very important to our community and what we do here and the food that we have,” Vondra said. “We just appreciate them so much.”

The event has 10 heats with guidelines for making sandwiches. Separate heats are held for amateurs and professionals. Categories range from classic, with one type of cheese, butter and bread, to classic plus extras, which can have multiple cheeses and unlimited additional ingredients. There is also a dessert category and differentiations for sweet and savory sandwiches.

Wisconsin cheese must account for at least 60% of the ingredients in every category. Judges are selected from the community. This year, the panel included the reigning Alice in Dairyland, Ashley Hagenow, and a member of the state assembly, the local police chief, a media personality, the Dodgeville mayor, a local farmer and other community members.

Sandwiches are scored based on presentation, taste and style. Portable stoves are set up where the contestants have 12 minutes to cook two sandwiches — one for the judges to taste and one to present. Bleachers are set up surrounding the cooking stations for spectators to watch.

This year, 30 contestants made

about 70 varieties of sandwiches. Zach Washa, a Highland native, was competing for the eighth time. He began as an amateur contestant but, after winning for ve years in a row, was moved to the professional category.

Among Washa’s new recipes this year was a creation using

Letters

of

Page 2 • Dairy Star • Saturday, May 11, 2024

views

opinions expressed

Dairy Star columnists and writers are not necessarily those of the Dairy Star / Star Publications LLC. The Dairy Star is published semi-monthly by Star Publications LLC, 522 Sinclair Lewis Ave., Sauk Centre, MN 56378-1246. Periodicals Postage Paid at Sauk Centre, MN and additional mailing ofces. POSTMASTER: Send address changes to Dairy Star, 522 Sinclair Lewis Ave., Sauk Centre, MN 56378-1246. © 2023 Star Publications LLC

Letters

articles

opinion are welcomed. Letters must be signed and include address and phone number. We reserve the right to edit lengthy letters. The

and

by

Con nued from GRILLED CHEESE | Page 1 Turn to GRILLED CHEESE | Page 5 Invest in Quality ® www.kuhn.com Visit your local KUHN Hay & Forage dealer today! Farmers’ Implement Allenton, WI D & D Farm Supply Arcadia, WI Cherokee Garage Colby, WI Beaver Machine Coleman, WI Kalscheur Implement Cross Plains, WI Eron Equipment Junction City, WI Luxemburg Motor Co. Luxemburg, WI Riesterer & Schnell Shawno, WI Lulich Implement Mason, WI Lindstrom Equipment Menomonie, WI East Side Farm Equipment Monroe, WI Steinhart Farm Service Platteville, WI

Gruett’s Inc. Potter, WI

Gibbsville Implement Waldo, WI

Midwest

New

WI GA 4201 & 4401 | Single-RotorRotary Rakes 13'9" and 14'5" working widths • mounted models

, FLUFFY WINDROWS

Carl F. Statz & Sons Waunakee, WI

Machinery Co.

Richmond, WI Osceola,

UNIFORM

Pivoting headstock allows for greater maneuverability in tight corners

consistent windrows for fast drying

Right-hand delivery maximizes

ABBY WIEDMEYER/DAIRY STAR

Robert Jake and his assistant, Pa y Wember, prepare their entry April 20 at the Wisconsin Grilled Cheese Championship in Dodgeville, Wisconsin. Jake rst entered the compe on in 2016 and this year won third place.

maple-glazed

For additional stories from our other zone, log on to www.dairystar.com Dairy Star • Saturday, May 11, 2024 • Page 3 The Day That Went Awry Second Section: Page 8 Blair, WI Metcalfs double herd size in 7 years on farm built from scratch First Section: Pages 1, 6 - 7 Milton, WI A day in the life of the McManama family Second Section: Pages 12, 14 - 15 Watertown, WI What are the best aspects of being a mother and dairy farmer? First Section: Pages 15 -16 FROM OUR SIDE OF THE FENCE: Inside the Emblem: Lancaster FFA Chapter Third Section: Pages 8 - 9 Lancaster, WI Women in Dairy: Amy Penterman First Section: Page 32 Thorp, WI Chapter closes at the Great Northern Land, Cattle Company First Section: Pages 12 - 13 Fond du Lac, WI Colby FFA dominates state dairy judging contest First Section: Page 25 Colby, WI Wisconsin Grilled Cheese Championship honors dairy industry for 11th year First Section: Pages 1 - 2, 5 Dodgeville, WI Columnists Ag Insider Page 10 First Section P Fir Fi s Ramblings from the Ridge Page 36 First Section R f Fi The “Mielke” Market Weekly Pages 6 - 7 Second Section Veterinary Wisdom Page 37 First Section Vet V W Pa Firrs From the Zweber Farm Page 38 First Section F Zwe P Fir Country Cooking Page 22 Second Section y n C C P The NexGen Page 39 First Section Celebrating PDP’s Cornerstone Dairy Academy graduates First Section: Page 26 - 27, 29 Baraboo, WI Zone 2 Zone 1

Page 4 • Dairy Star • Saturday, May 11, 2024 FOR MORE INFO - CONTACT ONE OF THESE DEALERS... Lang’s Dairy Equipment, Inc. 2337 Millennium Rd. • Decorah, IA 52101 (563) 382-8722 295 East Main Street • Lewiston, MN 55952 (507) 452-5532 Precision Dairy Equipment 24548 IA-13 • Elkader, IA 52043 (563) 245-2560 Tri-County Dairy Supply, Inc. 4107 N US HWY 51 • Janesville. WI 53545 608-757-2697 Bob’s Dairy Supply 540 E. County Rd. A • Dorchester, WI 54425 (715) 654-5252 Eastern Iowa Dairy Systems 105 3rd Ave. NW • Epworth, IA 52045 (563) 876-3087 Farm Systems 58 Interstate Drive • Melrose, MN 56352 Brookings SD • (320) 256-3276 Leedstone 222 E Co Rd 173 SE, Melrose, MN 56352 (877) 608-3877 24260 Cty. Rd. 27 • Plainview, MN 55964 (800) 548-2540 1720 Freitag Dr. • Menomonie, WI 54751 (866) 467-4717 2580 9th St. E. • Glencoe, MN 55336 (877) 864-5575 Fuller’s Milker Center, LLC 423 U.S. 61 • Lancaster, WI 53813 900 US Hwy. 14 West • Richland Center, WI 53581 (800) 887-4634 Gorter’s Clay & Dairy Equipment 1400- 7th St. SE • Pipestone, MN 56164 (507) 825-3271 Redeker Dairy Equipment W12287 Liner Rd. • Brandon, WI 53919 (920) 346-5576 United Dairy Systems 210 N. Industrial Pkwy • West Union, IA 52175 (563) 422-5355 132 W 11th St. • Monticell, IA 52310 (319) 465-5931 Advanced Dairy LLC 9 State Rd. 29 • Spring Valley, WI 54767 (715) 772-3201 913 W. Main St. • Mondovi, WI 54755 (715) 926-5777 967 West Ave. N • West Salem, WI 54669 (608) 633-6690 2195 Hwy. 23 • Mora, MN 55051 (715) 772-3201 117 West Circle Dr. • St. Charles, MN 55972 (507) 932-4288 1449 Homecrest Ave SE • Wadena, MN 56482 (218) 632-5416 Ask us about our Farm Services EXCHANGE Programs… Liner, Claw, Pulsator and Activity Exchanges. Economical ways to keep your equipment updated and running optimally! IPS-8 NC VENTED SILICONE LINER! NEW 8,000 Milkings! It’s nally here! • Durable and extended life • Cow comfort and speed of milking • Better teat health and higher quality milk • Extended life “The IPS-8 NC liner has completed 8,000 milkings with no issues. We cannot say that about any other liner we have used. It’s a one-piece liner made of a simple design, it cleans well and stays clean throughout the milking process.” - Eric Van Nurden, Van Nurden Farm LLC, Rice, MN FAST, SAFE, CLEAN MILKING LIVESTOCK PEST CONTROL SYSTEM SELF-TREATING • Adaptable to any operation - 34.5”/ 7 gal. or 69”/14 gal. - customized sizes too! • Easy to install & maintain • No valves or pumps to malfunction • Affordable • Durable construction • No pesticide waste • Patented WIK Applicators BUZZ OFF PROVEN, EFFECTIVE FLY CONTROL The Buzz-Off System comes with a spray arm that applies a broad spray pattern of product through a photo-eye. The sensitivity of the photo eye controls the amount of product sprayed. The Buzz-Off System comes with an automatic 7 day / 24 hour timer…it also can be manually programmed to dispense product up to several times per week and different times of the day! • Oil based formulation • Adheres and endures • Cost Effective • Safe for cow & environment • Ready to use thick or thin For use with AERO-MAX Synergized Insecticide 1% Permethrin 1% Piperonyl Butoxide (for resistance control) Automatic Fly Control System NG s TEM o pl on cators Leon Shirk Equipment N14725 Badger Ave. • Abbotsford, WI 54405 • 715-223-2239 Lots of Haying & Tillage Equipment TONS OF USED MACHINERY PARTS Brillion 38’ X-Fold packer crowsfoot rolls - $8,900 Brillion 28’ X-fold packer solid rolls - $15,500 Sunflower 5035 field cult. 5-bar spike w/rolling baskets, very nice, low acres! - $27,500 Kuhn MM900 merger, 30’, continuous pickup - $29,500 Agri-Metal 5600 bale grinder w/blower - $12,000 CIH 600 blower 540 pto, low wear! nice - $3,500 JD 512 5-shank disc ripper $7,900 NH 790 chopper w/890W hay head - $5,900 JD 714 9-shank disc chisel $6,900 Kuhn Knight PS150 vertical beater spreader $28,500 (2) H&S 7+4 Twin auger chopper boxes, 18’, tandem, good shape - $10,500 Dion F41 chopper w/9’ hay head - $24,500 Oxbo 334 merger continuous pickup, 2 pt. hookup $42,500 Ficklin CA15000 grain cart corner auger, nice - $13,750 (2) JD 726 soil finishers, 24’ w/5-bar spike, hyd. disc gangs, tandems, good shape - $26,500 Hyd. Squeeze cattle chute, good shape - $7,400 Teagle 8080 bale grinder w/blower - $11,500 NH FX45 chopper 4x4, non-running, as-is- $12,500 Glencoe 7-shank disc chisel $3,900 JD 7810 tractor 12K hours, runs good - $42,500 ‘20 Kubota BV4160 round baler 4x5 net wrap $21,500 NH 313 discbine 13’, rubber rolls - $21,500 IH 415, 24’ Cultimulcher, solid rolls - $15,500 Miller Pro 5300 18’ chopper box, tandem - $15,000 Gehl 600 12-wheel rake, hyd. fold - $5,900 JD 9650 combine 4x4, 3800/2500 hrs., 30.5x32, bin ext. - $38,500 NH 316 discbine 16’, rubber rolls - $27,500 MIller Pro 1060 blower, 1000 RPM, gear box - $3,900 Sukup 10’ No-till drill w/grass - $10,500 MIller Pro 5300 forage trailer truck tires, good shape $24,500 CIH 8010 combine 4x4, duals, weathered appearance $29,000

Kwik Trip donuts for the bread lled with bacon and cracked pepper cheddar cheese from Gile Cheese in Cuba City. He said the inspiration came to him a couple of weeks before the event.

“I’m not saying it was alcohol induced, but I’m also not saying it wasn’t,” Washa said.

The donut grilled cheese won second place this year.

Another contestant, Robert Jake, said the competition is about more than just cheese for him.

“I rst entered my wife into the competition in 2016,” Jake said. “She was so mad that I signed her up, but then she won third place, so she kept competing.”

Jake’s wife has since passed away, so he continues to compete in her honor using her recipe. He uses Texas toast, a butter and mayonnaise combination, lobster, Old Bay Seasoning and gouda cheese. The sandwich earned him third place this year.

The competition holds a special category for rst responders. The winner of this category receives a traveling trophy that stays in the winner’s station for the year and a $75 cash donation to the station.

Vondra said they are looking for more competitors in that category.

“We only had one rst responder who competed this year, so no award was given out,” Vondra said. “We thought about opening it up to different areas to make it more like a hero category, but right now, it’s just rst responders.”

The event also hosts food trucks and local vendors, a bloody mary bar and a beer garden featuring Spotted Cow.

There is also a family area where kids can get their faces painted and play. Vendors grew from 12 last year to

ABBY WIEDMEYER/DAIRY STAR

The 2024 Wisconsin Grilled Cheese Championship hosted 1,300 volunteers, contestants, judges and a endees from across the United States for its 11th annual contest. The compe on is hosted by the Dodgeville Area Chamber of Commerce with a mission to honor Wisconsin dairy farmers.

17 this year. They sell wares like baked goods, artisan cheese, homemade candles, Wisconsin apparel and more.

Vondra said that while attendance has remained steady, the event has grown in competitors and reach.

“It’s really special because the number of contestants and the number of sandwiches have grown so attendance might be similar but the number of people participating has grown,” Vondra said. “It’s super fun because this event is not just for people from Wisconsin; it brings in people from all over the United States. One of our contestants grew up in Highland, but he lives in Hollywood, California, and competed this year.”

Attendees also traveled from Maryland, Florida, Iowa, Illinois and Ohio.

Vondra said that prior years have presented weather challenges, but it is something they can always work around. The event is indoors but not heated. Food trucks are parked by open garage doors so the outside air does get in.

The Dodgeville chamber is already planning for the April 26, 2025, event.

“It’s really an amazing event and something that we like to host because it does bring in so much tourism to our area,” Vondra said. “It’s people coming from outside Wisconsin to experience the wonderful cheeses and different dairy products that we have.”

this year.

Dairy Star • Saturday, May 11, 2024 • Page 5 03 May, 2021 8:30am WORKWITHTHEEXPERTS WORKWITHTHEEXPERTS PROFESSIONALLYINSTALLED.PROFESSIONALLYSERVICED. PROFESSIONALLYINSTALLED.PROFESSIONALLYSERVICED. ZUMBROTA,MNRENNER,SD MENOMONIE,WI KAUKAUNA,WIWESTON,WI 920-759-9223715-298-6256715-235-5144 507-732-4673605-274-3656 WWW.MIDWESTLIVESTOCK.COM MEADOWVALEDAIRY-DOUBLE41WITHSCRMETERSANDINDIVIDUALID’S COMPLETELINEOFDAIRYHYGIENE&SUPPLIESFORYOUROPERATION! Con nued from GRILLED CHEESE

| Page 2

ABBY WIEDMEYER/DAIRY STAR

Sandwiches wait for judging April 20 at the Wisconsin Grilled Cheese Championship in Dodgeville, Wisconsin. The annual compe on hosted 30 compe tors who made 70 varie es of sandwiches

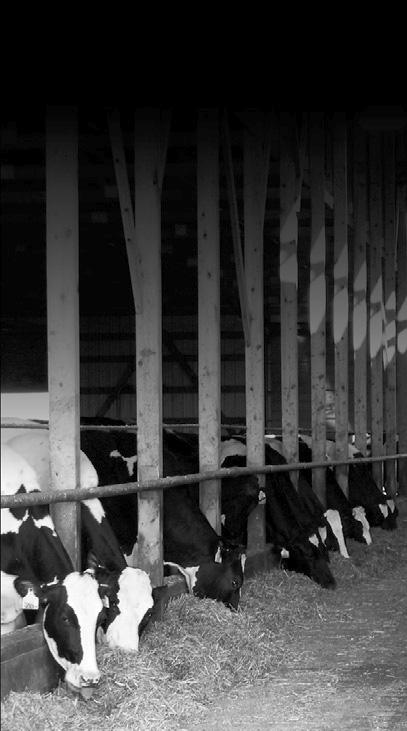

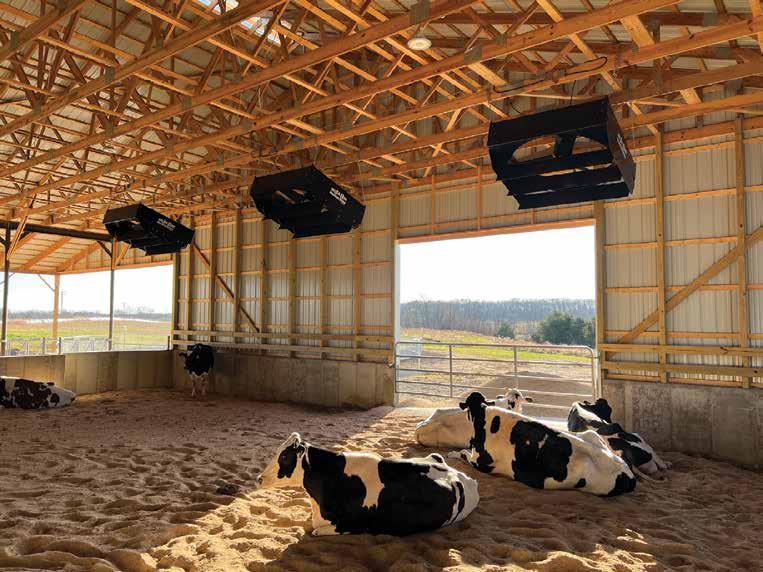

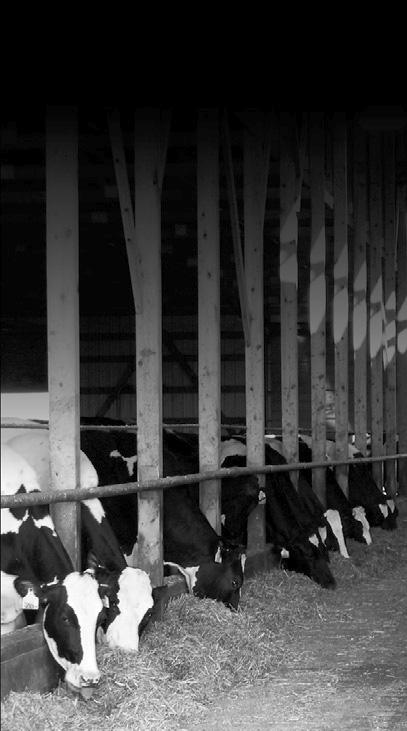

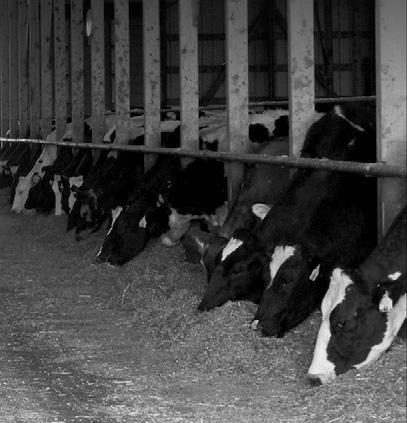

Cows are milked in a double-12 parallel parlor April 18 near Milton, Wisconsin. The Metcalfs began milking three mes a day in November 2023.

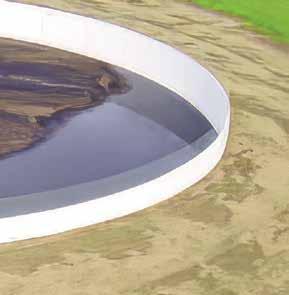

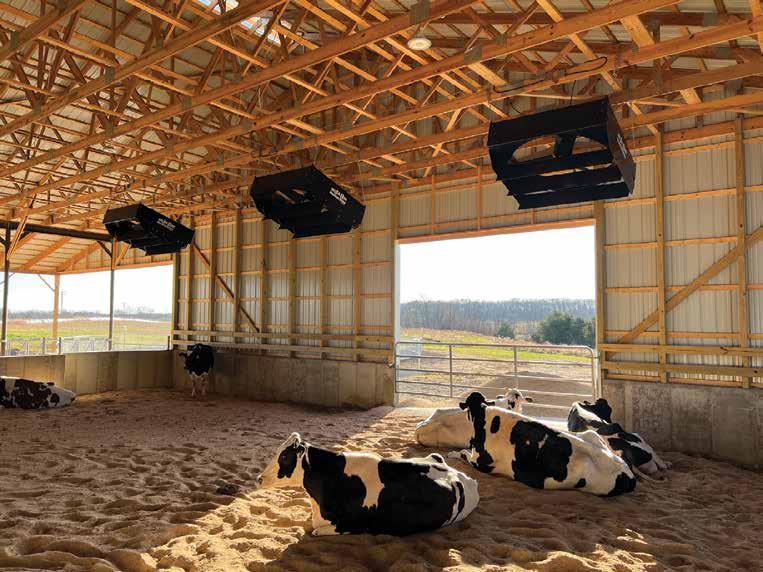

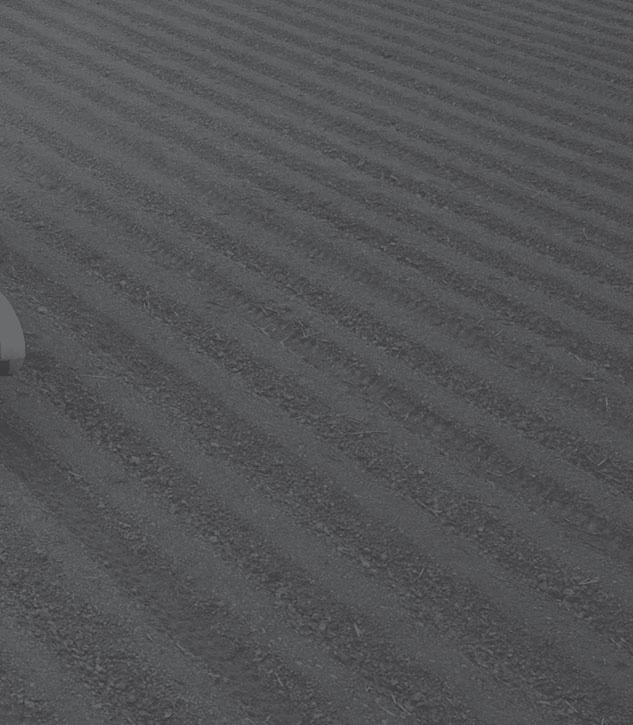

Glacier Edge Dairy had the potential to grow, and within six years, the Metcalfs were ready to double the size of their herd.

“We had 700 cows in mind when we built this setup to make it cost-effective,” Corey said.

Corey and his wife, Kristen, farm with his parents, Terry and Jane. Corey’s sister, Lauren, also helps on the farm along with eight full-time and several part-time employees. A focus on production and type has brought success to the Metcalfs, who milk 750 cows and farm 1,200 acres near Milton.

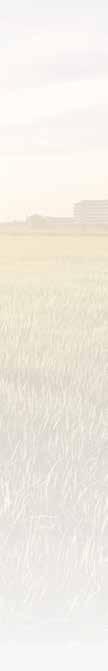

In a recent expansion, the Metcalfs built the second half of their freestall barn while doubling the size of their herd. They also adjusted the milkhouse to allow for direct shipping and switched to milking three times a day.

“Milking three times a day allows us to direct ship our milk and makes better shifts for our employees,” Kristen said. “They were going back and forth for morning and evening milkings. But now, we run two 12-hour shifts. It’s also nice having people here 24 hours a day.”

Kristen said. “We also hired more people when adding that third milking.”

Cows are milked in a double-12 parallel parlor, which has room to expand to a double-16. The herd’s 2023 lactation average was 23,087 pounds of milk, 1,043 pounds of butterfat and 825 pounds of protein on a mature equivalent basis.

The addition also includes a separate pen for Kristen’s 30 Holsteins and Red and Whites, which now have bigger stalls. Kristen and her sisters show at local, state and national shows.

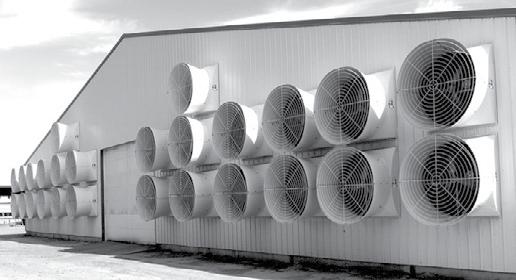

Built with a focus on cow comfort, the cross-ventilated barn features 2-row pens to provide extra bunk space.

“We really like the cross-vent for keeping ies out and preventing things from freezing in winter,” Corey said. “This system provides a consistent climate year-round.”

Cows are bedded with sand. However, they do not lie on deep sand beds.

“It’s unique in that we have mats in the stalls with 3-4 inches of sand on top,” Corey said. “That cuts our sand usage in half, and it feels just as comfortable.”

Robotic feed pushers and cow brushes are other amenities for the barn.

The barn addition was completed October 2023, and the family began milking three times a day in November. Between December and February, they freshened 250 rst-calf heifers, and now, 55% of the herd is rst-lactation cows.

“It was a big winter of change,”

“The brushes keep the cows very clean,” Corey said. “They have really nice hair coats.”

Page 6 • Dairy Star • Saturday, May 11, 2024 The World’s Best TMR Processor Keep your cattle happy & healthy with a great TMR mix. A Supreme vertical mixer is powerful, thorough & accurate, providing the best TMR mix on the market. Unlike other mixers, a Supreme is built to last, providing exceptionally accurate mixes throughout its entire life. With proper care & maintenance, a Supreme will offer the same great mix from the first cow to the last - Guaranteed. 600T, 900T, 1200T & 1500 Triple IN STOCK! 920-853-3516 Potter, WI 920-477-5292 Eden, WI 920-324-3597 Waupun, WI 920-261-5301 Watertown, WI WEaupunquipment g A 1250TTM Gen !!! In Stock & Ready To Go! Electronic Dairy Board Repair Service Specializing in: WestfaliaSurge, BouMatic, & DeLaval pulsators & Takeoffs, circuit boards, Mueller milk tank circuit boards. Call: (c) 406-590-7764 www.circuit xer.wixsite.com/ boumaticboardrepair Repair vs. Replace SAVE INSTANTLY Planting is in full swing in some areas, and so are our tire deals. Firestone Ag radial tires with Advanced Deflection Design (AD2) technology are IF- and VF-designated tires that can carry more load at the same pressure (up to 20% or 40% respectively) as standard radial tires for a larger footprint that helps minimize compaction. Through May 31 save on eligible AD2 radial and non-AD2 radial tires at your local Firestone Ag Dealer: SPRING SAVINGS FOR YOU ON 2 OR MORE FIRESTONE AG RADIAL TIRES $200 off all eligible non-AD2 radial tires $300 off all eligible AD2 radial tires Friedrich’s Tire & Oil – Sauk Centre, MN • (320) 316-3701 Rule Tire & Auto – Willmar, MN • (320) 403-2783 www.LangeAgSystems.com Specializing in Livestock Equipment and Construction, New and Used Bagging Machines, Silage Bags, Bunker Covers and Grain Storage! Con nued from METCALFS | Page 1

STACEY SMART/DAIRY STAR

to METCALFS | Page 7

Turn

The Metcalfs also plan to add a hoof trimming area to the new part of the barn to trim more efciently.

“I appreciate how quiet the barn is,” Kristen said. “We focus on cow comfort in everything we do, and the cows are happy.”

The family added on to their milkhouse and removed the 5,000-gallon bulk tank, replacing it with three ports for shipping milk. The family ships to Rolling Hills Dairy Producers Cooperative, sending one truckload per day, or about 50,000 pounds of milk.

“It made it more efcient with the economy and trucking situation to go to direct shipping,” Corey said.

Corey’s roots are in dairy, as his father grew up dairy farming and continued milking cows with his two brothers until 1997. Corey was 6 years old when the cows left.

“Our family farmed a lot of grain acres and decided to focus on that instead,” Corey said. “I always had a greater interest in livestock production. Instead of selling grain, I wanted to make feed and feed it ourselves.”

At age 14, Corey began working on dairy farms. He was exposed to the Jersey breed while helping on a neighbor’s farm. It was here that he also met Kristen, who worked there as well.

“I was really focused on genetics

from the start,” Corey said. “Every calf here is genomically tested, and we’ve used sexed semen and beef semen from the beginning.”

The parlor records milk weights, which Corey nds helpful for identifying replacements.

“We’ve done quite a bit of ushing and in vitro fertilization since we started,” he said. “We identied a couple of good families right away, and we tried to make as many daughters as possible.”

Since the farm’s inception, the Metcalfs have tested milk and classied. They also participate in the American Jersey Cattle Association Registration, Equity, Appraisal and Performance program.

“The Jersey association has been really great to work with in helping us nd cows,” Corey said. “We bought a lot through them.”

Creating well-balanced, long-lasting cows is the goal of Corey’s breeding philosophy, and he selects bulls that can deliver on these traits.

“We are production-focused but also type-focused, too, and I look more at type traits than production traits when choosing bulls,” Corey said. “We’re not necessarily breeding animals to show, but we want them to be long-lasting.”

The Metcalfs have sold ve bulls to A.I. stud within the last couple of years.

“That’s impressive because we started from the conglomeration of many herds,” Kristen said.

Previously holding a job off the farm, Kristen is happy to be on the farm full time since the expansion.

“We’re pretty fortunate with our team,” she said. “Everyone we originally started with is still here and taking over management roles.”

Corey agreed.

“Our employees have been a huge part of our success,” he said.

As this progressive couple settles into the next phase of their dairy operation, Kristen said Corey is always looking ahead and asking, “What’s next?”

“I like to think about different possibilities and plan for the future,” Corey said. “But for now, I’m content where we are.”

Dairy Star • Saturday, May 11, 2024 • Page 7 THE NATION’S LEADER IN AGRICULTURAL CONCRETE (920) 948-9661 | www.pippingconcrete.com dennis@pippingconcrete.com 37+ years in business | U.S. Navy Veteran owned dennis@pippingconcrete.com Con nued from METCALFS | Page 6

STACEY SMART/DAIRY STAR

Glacier Edge Dairy was built by the Metcalf family in 2017 near Milton, Wisconsin. In 2023, the Metcalfs built the second half of their freestall barn while doubling the size of their herd and making adjustments to the milkhouse for direct shipping.

Congratulations Metcalfs on your expansion! Janesville, WI (608) 757-2697 tricountydairysupplyinc.com Thank you for choosing us for your freestalls!

Changes to WIC disappoint dairy industry

Advocacy did not deter new USDA rules

By Jan Lefebvre jan.l@star-pub.com

WASHINGTON — In November 2022, the U.S. Department of Agriculture revealed proposed rule changes to the Supplemental Nutrition Program for Women, Infants, and Children. Many in the dairy industry were surprised and alarmed because the rule changes included a reduction in the amount of milk program participants would be allotted.

“There wasn’t a good explanation for why USDA was working to reduce milk,” said Matt Herrick, senior vice president of public affairs and communications for the International Dairy Foods Association. “There wasn’t really any forewarning. We were surprised, confused and frustrated, and the more we talked to WIC agencies and moms who are in the program, the less we understood the proposal. It just didn’t make a lot of sense.”

felt like we were making headway — the arguments we had were factual, relevant and supported by people in the (WIC) program — but at the end of the day, the USDA still decided to reduce (the allotted amount of) milk.”

On April 9, USDA issued a nal rule, making the changes ofcial. For milk, the allotted amount per month through WIC will be reduced from 16 quarts to 12 quarts for children 12-23 months of age, from 16 quarts to 14 quarts for children ages 2-4, and from 22 quarts to 16 quarts for pregnant and breastfeeding women.

USDA’s website states what it aims to achieve through the changes to WIC.

of all U.S. production by volume.”

The 0.5% estimate is for the reduction in milk due specically to the new rules, Herrick said, but that is just part of the equation.

“That’s only if all the people who are in the program stay in the program,” Herrick said. “It doesn’t account for people leaving WIC if they are dissatised with this rule.”

counterproductive to USDA’s efforts to increase the number of eligible families who enroll. According to USDA statistics, only half of those eligible for WIC apply for the program.

For making changes to WIC rules, the USDA said on its website that it relied on research from the National Academies of Science, Engineering and Medicine. It also used research from the National Institute of Medicine which suggested increasing access to fruits and vegetables within the program, leading to a reduction in access to milk.

“The changes will provide WIC participants with a wider variety of nutritious foods to support healthy dietary patterns and accommodate special dietary needs and personal and cultural food preferences,” USDA said. “The revisions provide foods in amounts that are more consistent with the supplemental nature of the program, encourages fruit and vegetable consumption, and strengthens support for breastfeeding.”

When IDFA was advocating to deter the new rules, it interviewed moms in the WIC program and sent videos of those moms talking about their experiences with WIC to the USDA and Congress. IDFA found that many moms were enrolled in WIC specically for access to milk and were not happy about the new rule.

“What we learned is that there are a lot of women in the program who may just leave it because they are in it for milk,” Herrick said. “If the amount of milk they are used to receiving is no longer there, why participate, why give all your information to the government, because it’s a very prescriptive program as it is. It’s not like (the Supplemental Nutrition Assistance Program) where you can go to the grocery store and buy almost anything you want in terms of food and beverages.”

“This seemed more like a shell game … like they were looking for some food item in (WIC) that they could reduce, whether it was fruit juices or milk, and then nd the resources to increase fruits and vegetables without needing to ask for additional funding from Congress for the program,” Herrick said. “Milk was simply the victim of looking for other alternatives to increase in the program.”

The rules come at a time when research is showing the benets of dairy consumption while also showing that most Americans do not get enough dairy in their diets.

IDFA and other groups in the dairy industry worked to deter the proposed changes.

“We felt that if we advocated enough, we could change their minds,” Herrick said. “We had a signicant and aggressive advocacy program on this that lasted more than a year. We really

Many in the dairy industry see the changes as negative for both nutrition and the dairy industry itself.

“The reduction is as much as 3 gallons per mother per month, which would be for a mother who has at least one other child and is pregnant,” Herrick said. “We estimate that’s about 150 million gallons per year, or about 0.5%

WIC enrollees are limited to a specic list of about 25 items that they are allotted through the program.

“For a lot of people, (WIC’s limitations are) generally frustrating anyhow, and with reduced milk, we believe there will be reduced participation, unfortunately,” Herrick said.

The new rules, therefore, seem

In an April 9 press release issued by the National Milk Producers Federation, Gregg Doud, president and chief executive ofcer, addressed the nutrition aspect of USDA’s decision.

“NMPF is disturbed by (USDA’s) decision to reduce access to the essential nutrients dairy adds to the diet,”

Page 8 • Dairy Star • Saturday, May 11, 2024

BONGAR D S’ STORE 16th anniversary Celebration JUNE 19, 2024 11am-2pm Free fried cheese curds & soft serve ice cream! Face painting spinning wheel Balloon Man Sign up for prizes! Music by Nick Stadick Bring the kids to see sic Stadick g th gthe he 13200 Co. Rd. 51 Norwood, MN 952-466-3545 www.bongards.com Joın the fun! CELEBRATING DAIRY DAYS &

Turn to WIC | Page 11

Matt Herrick International Dairy Foods Association

vast majority of positive polymerase chain reaction results were found in samples of raw milk and mammary gland tissue.

“It seems like the virus is actively replicating in the mammary gland tissue based on the results we have,” Diel said. “Is there an infectious virus being shed in milk from those affected animals? The answer to that is, yes. The milk samples contain high viral loads in clinically affected animals and can serve as a source of spread to other animals.”

In an April 26 webinar hosted by the University of Minnesota Extension and the Minnesota Board of Animal Health, Dr. Joe Armstrong, UMN Extension, said that while the majority of affected dairy cows tend to be multiparous cows in mid-to-late lactation, the virus has been seen in other populations in affected herds.

“It is important to look at all animals in the herd and monitor them for symptoms,” Armstrong said. “Symptoms in individual cows are lasting about 3-5 days. Herds appear to be impacted for 14-21 days before returning to near normal feed intake and milk production.”

In addition to the rst-reported symptoms that included decreased feed intake, rumination and milk production, and abnormal milk appearance, Armstrong said that some cows present with diarrhea while others present with dry, tacky feces as a result of dehydration. Fever, clear nasal discharge and lethargy have also been reported among affected cows.

Armstrong said on average, about 5% of the cows in affected herds present with clinical symptoms. The only treatment for infected cows is supportive care.

According to a USDA press release, on April 16, Animal and Plant Health Inspection Service microbiologists identied a shift in an H5N1 sample from a cow in Kansas that could indicate that the virus has an adaptation to mammals. Based on their analysis of that specimen sequence, the Centers for Disease Control and Prevention has not changed its overall risk assessment for the general public, because the substitution has been seen previously in other mammalian infections.

In the UMN Extension webinar, Dr. Stacy Holzbauer, the CDC’s epidemiology eld ofcer for the Minnesota Department of Health, detailed concern surrounding the control of H5N1, which prompted the issue of the federal order.

“This particular virus is an inuenza A virus, which is circulating in wild birds,” Holzbauer said. “They are constantly changing. Inuenza A virus widely circulates in humans, wild birds, domestic birds, swine and equine. But all of these viruses, including the seasonal inuenza viruses we get vaccinated for every year, have an origin in wild birds at some point in time.”

Holzbauer said these viruses have epidemic potential because they are constantly changing and exchanging genes with other viruses. The virus can mutate and infect other species.

“The concern is that we have more mammal-tomammal spread, that this virus may mutate to where it can then spread to people more easily and then spread person to person,” Holzbauer said. “That is why we are very interested in what is happening in both our poultry and dairy industries. We have people and animals in the same environment working together. The fear is we will have a person who is infected with a human seasonal inuenza virus and then also happens to get infected with the avian H5N1 virus and those two viruses essentially swap their genes. Then, we have this new human virus that could circulate person to person.”

According to Holzbauer, avian inuenza viruses are typically spread to people through direct contact with infected birds or their environment.

“Person-to-person spread of these viruses is rare and limited,” Holzbauer said. “We expect there to be occasional spillover for the people who have direct contact, especially with poultry, but we don’t see person-toperson spread. So, it’s not a risk to the public, and it’s not a food safety risk either.”

Based on what they have learned through avian inuenza infections in domestic poultry ocks, Holzbauer said the response to monitor people having direct contact with infected dairy cattle would be to initiate active surveillance for 10 days after the cows on the affected dairy farm have recovered from clinical signs.

Holzbauer said the use of personal protective equipment by people working with infected animals is their best defense to avoid infection from the H5N1 virus.

“Our PPE recommendations for people working on dairy farms in direct contact with ill cattle are gloves, goggles, N95 masks, coveralls and boots,” Holzbauer said. “We know these PPE recommendations are difcult in operations where these are not normal types of PPE.”

The key message is to protect mucus membranes — eyes, nose and mouth — to prevent uids that may be carrying the virus from entering the body through these access points as much as possible.

THE NO COMPROMISE FABRIC STRUCTURE DAIRY, MACHINERY & HAY STORAGE

NELSON’S AGRI STRUCTURES

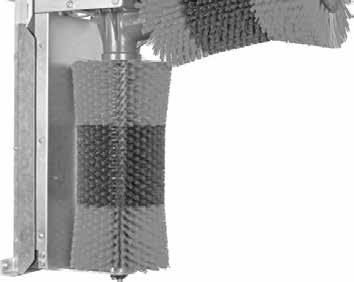

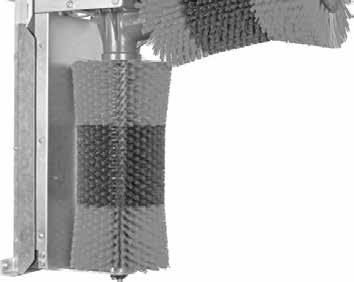

The FutureCow® Prep System features a mechanical brush unit that gently washes, disinfects, stimulates and dries all in one visit to the cow.

Dairy producers can potentially reduce labor costs and can certainly reduce operating costs by eliminating towels and laundry.

Streamlined and consistent cow prep — allows for a more efficient parlor and greater parlor labor productivity — even increasing the number of cows milked per hour.

Superior udder stimulation — can increase milk flow rates and decrease milking times, further improving parlor throughput.

Improved teat health and milk quality — the durable, yet soft, multi-layered brushes accommodate all teat lengths and ensure teat-ends are properly cleaned before the milking unit is applied.

FutureCow Blending Devices

Fixed cost for pre-milking prep — flat rate per cow pricing provides consistent and easily managed cost.

A system for all herd sizes — whether you milk 50, 500, or 5,000 cows or more, there is a FutureCow® Prep System to accommodate any herd size.

Installed and supported by GEA dealers — a professional network with unsurpassed dairy equipment experience available 24/7.

GEA now offers three different automated blending systems to blend cleansing solution ingredients with water to create a ready-to-use (RTU) product that cleans and disinfects the teats.

FutureCow Air-Operated Pump

The pump delivers product from the blending system to the FutureCow Control and Brush Unit.

FutureCow Control and Brush Unit

Controls the dispensing and use of the solution.

Dairy Star • Saturday, May 11, 2024 • Page 9

Dairy EquipmentService & Installation Electrical Services

Dean Nelson • Central and Northern Minnesota • Grove City, MN •

US

75 At IA/MN Stateline • Steen, MN •

320-857-2633, Cell 320-699-3297 RIVERSIDE HOOP BARNS, INC.

Hwy.

507-392-2870 • Fred A. Tilstra & Sons

Steel Tubing Supplied by Allied Tube & Conduit Heaviest gauge steel in the industry Pre-engineered truss buildings ASK US ABOUT GOVERNMENT FUNDING FOR HAY STORAGE WE ALSO SELL REPLACEMENT TARPS! LAKESIDE HOOP STRUCTURES, LLC Eastern Minnesota and Wisconsin • Harris, MN • 651-248-6302 • Craig Moline SKIDLOADERS TRACTORS BACKHOES EXCAVATORS & BULLDOZERS joewelcheq.com 507-724-3183 Here Today. Gone Tomorrow. Give Classieds a try. Con nued from H5N1 | Page 1

Commercial Agri Buildings Single and Truss Arch available from 20’-120’ wide Flo-Coat® Galvanized

Stabenow unveils her farm bill

Animal and Plant Health Inspection Service has at this point is only positive in dairy cows,” Lester Moftt said. “As we do more mandatory testing and gather more information, hopefully, we will be able to get a better understanding of what’s happening across the landscape in other states and across livestock.” Lester Moftt emphasized there is no evidence of a live virus in pasteurized milk. Cooking ground beef to the proper temperature is also recommended.

Chairwoman of the Senate Committee on Agriculture, Nutrition & Forestry Sen. Debbie Stabenow said it must be a bipartisan bill to get a farm bill done. When unveiling her farm bill plan, the Michigan senator said she had three major goals: keeping farmers farming, families fed and rural communities strong. The bill enhances crop insurance “for small farmers, for specialty crops as well as large farmers.” The commodity title includes a minimum of a 5% reference price increase for all crops. Traditionally, dairy policy is in the crosshairs during a farm bill debate. Stabenow took steps to strengthen the dairy titles. “The Dairy Margin Coverage program seems to have worked really well,” Stabenow said. “The biggest concerns we heard about was with smaller farms; they go to tier 1 basically.”

Hesston 565A Round Baler

‘20 MF 3983 Hicap Rake, 12 wheel

‘19 Kuhn GA7501 Rotary Rake

‘22 MF 1393, 13’ Disc/Mow Cond. ‘16 Pottinger NovaCat Triple Mower w/rolls

‘17 JD 835 9’ MoCo, center pivot

‘14 CIH DC112 Disc Mow/Cond. Gehl 2450, 15’ hydro swing

JD MX7 3PT Brush Mower Patz Bale Chopper

‘21 Rhino 3150-15’ Batwing Mower

‘20 Rhino TS12 flex wing mower

‘23 NH 313 plus 13’ disc mower cond

‘22 MF 4707, MFWD, MF ldr., Only 520 hrs. ‘21 MF 2850, CAH, hydro, loader, ONLY 139 HOURS!

IH 966, 9,000 hrs. MF GC2400, 60” deck, 600 hrs. ‘21 MF GC1723, ldr., mower, 180 hrs. JD 2640 w/146 loader JD 2940, WF MF 285 w/246 loader

700 hrs.

‘23 Bobcat T770, high flow, 114 hrs., LOADED!

‘22 Bobcat T770, 200 hrs.

‘20 Bobcat T770, 240 hrs.

‘21 Bobcat T770, highflow, 958 hrs.

‘19 Bobcat T770, SJC, 500 hrs.

‘20 Bobcat T770, CAH, highflow, SJC, 765 hrs.

‘20 Bobcat T770, SJC, 300 hrs.

‘18 Bobcat T770, SJC, 2,400 hrs.

‘18 Bobcat T770, A91, highflow, SJC, 2,000 hrs.

‘21 Bobcat T770, 165 hrs ‘07 Bobcat T300, CAH, SJC, 1,900 hrs.

‘18 Bobcat E50 long arm, 700 hrs.

‘14 Bobcat S770, 3,200 hrs.

Bobcat S300, 4,200 hrs.

S650, 9,000 hrs.

Bobcat S590, 3,900 hrs.

Bobcat S570,

By Don Wick Columnist Ag Insider

By Don Wick Columnist Ag Insider

Farm bill on the way to the House Ag Committee

House Committee on Agriculture Chairman Glenn “GT” Thompson will mark up the farm bill May 23. After the release of Thompson’s bill Wednesday, ranking member David Scott rejected the proposal saying it includes poison pill policies with “an untenable funding scheme.” In a briefing with farm broadcasters, Thompson said that complaint is disingenuous. In a brieng with farm broadcasters, the Pennsylvania lawmaker said he is willing to pass the farm bill out of his committee with just Republican votes. “I’ve got a number of different options of getting to the House oor,” Thompson said. “The process through the House has yet to be determined, but I’m condent that I will nd a successful pathway.”

Congressional calendar complicates farm bill timeline

National Council of Farmer Cooperatives President and CEO Chuck Conner has seen his share of farm bills and said this is the most partisan farm bill he has ever seen. Conner, who was the U.S. Department of Agriculture deputy secretary during the George W. Bush presidency, said this farm bill process needs to start. “Even if it’s a partisan process, get a bill that people can begin to look at, start marking it up in committee, and get us started,” Conner said. “You can’t nish something that never starts, so we’ve got to start.” Timing is critical for this important piece of legislation. “Congress is in session so few days between now and the end of the year; it’s a presidential election year, you’ve got party conventions, and they’re never in session during any of those kinds of periods,” Conner said. “It’s just going to be hard to get done with the farm bill.”

Bipartisanship is a farm bill must

With the hyper-partisan environment in Congress, it is difcult to nd compromise on any piece of legislation. American Farm Bureau Federation Director of Government Affairs Joe Gilson said compromise is a must for the farm bill. “In the House ag committee, if we have a party-line vote, I think it’s going to be very difcult for Speaker Johnson to even bring it to the House oor,” Gilson said. “The Republicans have a majority of one, two or three seats depending on the day. A bipartisan bill will be essential to get this across the nish line in the House.”

H5N1 in beef?

The H5N1 virus has been identied in dairy cattle in nine states. USDA limited the interstate movement of dairy cattle and implemented mandatory testing. In a meeting with farm broadcasters, USDA Under Secretary for Marketing and Regulatory Programs Jennifer Lester Moftt was asked if it was safe to assume the virus is also in the beef herd. “The information and data that

New traceability rule announced

USDA’s new standard for traceability in cattle is electronic ID tags. This replaces the 2013 rule that called for visual ID tags. In a statement, USDA said the decision was being made to respond quickly to foreign animal diseases. This rule applies to sexually intact cattle 18 months of age or older, rodeo and exhibition cattle, and dairy cattle moving interstate.

Ag industry responds to USDA announcement

A statement released by National Milk Producers Federation President and CEO Gregg Doud said USDA’s action on testing and interstate movement of dairy cattle is appropriate. Doud also stressed milk is safe and pasteurization leaves all viruses inactive. Meat Institute President and CEO Julie Anna Potts also released a statement, saying properly prepared beef remains safe to eat. The Meat Institute also called on the USDA and the Centers for Disease Control and Prevention to ensure the movement of healthy animals to slaughter.

Enough is enough

A coalition of 16 farm groups has launched the Enough is Enough Tour to protest commodity research and promotion checkoff programs. This coalition claims the checkoff programs work against the interests of the farmers who pay into the program. The tour will be making a stop in Osseo, Wisconsin, May 22. The state event is hosted by the Wisconsin Farmers Union.

El Nino is fading fast

Long-range forecasts are leaning toward a drier summer. “Some of that has to do with the transition from El Nino to La Nina which is happening as we speak,” said Brad Rippey, USDA meteorologist. “El Nino is fading fast, and La Nina’s on the way; that tends to be a drought maker for the country as a whole. Perhaps as early as this summer, we’ll see drought encroaching from the West back across the Great Plains.”

Dairy ambassadors coming to Wisconsin State Fair

A new state fair dairy promotion opportunity has been announced. The Wisconsin State Fair Dairy Promotion Board is adding Dairy Lane Ambassador positions. These individuals will be trained in networking, public speaking, social media and more. The goal is to enhance the dairy experience for fair-goers. The ambassadors will receive training, a stipend, food and lodging during the Wisconsin State Fair.

Trivia challenge

The Ayrshire breed originated in Scotland. That answers our last trivia question. For this week’s trivia, what has been the best-selling pickup truck in the U.S. for nearly 50 straight years? We will have the answer in our next edition of Dairy Star.

Don Wick is owner/broadcaster for the Red River Farm Network of Grand Forks, North Dakota. Wick has been recognized as the National Farm Broadcaster of the Year and served as president of the National Association of Farm Broadcasting. Don and his wife, Kolleen, have two sons, Tony and Sam, and ve grandchildren, Aiden, Piper, Adrienne, Aurora and Sterling.

Page 10 • Dairy Star • Saturday, May 11, 2024 REISERIMPLEMENT Waukon,IA 563-568-4526 AfterHours: Ken563-380-3137•Dave563-380-8680 www.reiserimpl.com CHECKOUTTHE 7700SERIES Used Equipment PLANTING/TILLAGE MISCELLANEOUS TRACTORS ‘20 Kinze 3660, 16R30, bulk fill ‘12 CIH 1250, 16R30, bulk fill ‘97 Kinze 2600, 31R15” DMI 530B Disc Ripper CIH MRX690, 5 shank disc ripper disc JD 980 Field Cult., 44’ w/harrow CIH 4800 30’ Field Cult, w/3 bar coil tine harrow BUILT TO KEEP GOING. BECAUSE A FARM NEVER SLEEPS. Kory 185 Gravity Box, 250 bu w/gear Brent 640 Gravity Box Loftness 20’ Stalk Shredder, NICE!! ‘08 AGCO 3000 corn head, 8R30, poly JD 146 loader w/bucket Skid Loaders HAY & FORAGE ‘11 MF 8947 Telehandler, 3,000 hrs. ‘18 Bobcat 3400 SideXSide, C/H, 6,700 hrs. ‘16 Bobcat E50, long arm, thumb, 1,510 hrs. ‘23 Bobcat UW 56 Toolcat, 235 hrs., LOADED! ‘20 Bobcat V923 Telehandler, 1,100 hrs. ‘19 Bobcat E26 Mini Ex, OS,

2900 hrs. ‘13 Bobcat S570, CAH, ACS, 3,800 hrs. ‘13 Bobcat S570, CAH, 3,400 hrs. ‘15 Bobcat T550, ACS, Open Station, 1,855 hrs. ‘15 Gehl R190, 1,900 hrs. ‘13 Mustang RT2100 track ldr. 3,000 hrs ‘23 NH L318, C&H, 1,400 hrs. ‘95 Case 1840 CROPS, ONLY 2245 hrs. ‘22 JCB 409 CAH 1,786 hrs ‘21 Bobcat S76, SJC, 1,500 hrs. ‘20 Bobcat S76, 233 hrs. ‘22 Bobcat S64, 4,100 hrs. ‘21 Bobcat T76, SJC, 600 hrs. ‘21 Bobcat S76, CAH, SJC, 1,800 hrs. ‘23 Bobcat T76, 65 hrs. ‘23 Bobcat T64, CAH, 13 Hours! ‘22 Bobcat S64, SJC, 4,100 hrs. ‘21 Bobcat S64, foot, 2,900 hrs. ‘15 Bobcat T870, SJC, highflow, 1,700 hrs. tfn Les Kuehl Repair Service 30+ Years Experience No Emergency Charges--Ever! • Sealed silo parts & service • Best chains on the market • Used and rebuilt unloaders • Stainless steel roofs • Stainless steel conveyor chains 320-760-2909 Eve. 320-762-1827 YOUR CENTRAL MINNESOTA GOLIATH REPAIR SERVICE! • All parts needed to service your Goliath Unloaders Not af liated with the Harvestore brand Call for early maintenance specials Tell the advertisers you saw their ad in the Dairy Star!

‘02

‘12 Bobcat

‘16

‘20

Doud said. “Nutrition science demonstrates that dairy products like milk, yogurt and cheese are especially important for women, infants and children. Meanwhile, nearly 90% of Americans don’t meet the number of dairy servings recommended by the 2020-25 Dietary Guidelines for Americans.”

Doud also said the change is counterproductive.

“This rule works against the WIC program’s goal of ensuring all Americans have consistent and equitable access to healthy, safe and affordable foods,” he said.

Herrick said the rule change will make budgeting and shopping for food more difcult for moms in the WIC program.

“If you think about WIC moms, they are low income, and they’re likely also on the SNAP program, so they have these two supplemental programs for grocery shopping,” Herrick said. “If you’re going to use your SNAP benets for the majority of your grocery shopping, you’re going to look for items that are available through WIC that you don’t need to use your SNAP benets for.”

For many of those moms, one of those main items is milk, Herrick said.

“Now they no longer have as many benets available for that milk,” Herrick said. “For moms in particular, that’s deeply disappointing.”

The new WIC rules were not all negative for dairy.

“(USDA) did make some changes that were helpful,” Herrick said. “You no longer have to buy a big 32-ounce tub of yogurt. You can buy smaller, individualized containers that equal 32 ounces, which is how people mainly eat yogurt, or you can swap your milk for

yogurt or cheese, which is helpful to the overall dairy category.”

State WIC agencies have two years to implement the changes. In the meantime, the only remaining avenue for changing the rules is through Congressional action. Herrick said some industry organizations are already contemplating legislative recourse.

“The WIC rule demonstrates that when the government issues rules that impact our industry in some way, it’s an opportunity for us to come together and advocate, and it requires us to have our eyes and ears open to pay particular attention to the rules that impact our industry,” Herrick said.

This, he said, includes federal nutrition programs because they are vital to the industry.

“For those with low income and for kids at school, nutrition programs are often their introduction or connection to dairy products,” Herrick said. “We’ve got 30 million kids in schools getting meals every day, 6-7 million women and kids in the WIC program and 40 million people in the SNAP program. Those are all very important to our industry, to the vitality and growth of our industry, and to creating generations of dairy consumers and milk drinkers.”

Herrick said it takes work and collaboration to protect dairy.

“Anytime there’s a rule proposal out there, I encourage people to work with their associations and with their networks to advocate for whatever is in the best interest of themselves as farmers or processors or as our industry in general,” Herrick said. “It’s an important lesson that we shouldn’t take anything for granted, and we need to work hard to protect our interests.”

Accurate records that tell which cows are more profitable

How long have you been testing with DHIA?

We have been testing with DHIA since the early 70’s when my grandpa, Fred, started testing with DHIA.

What tests do you use and what do you like about those tests? We just do the milk analysis test and like to look at butterfat, protein, and somatic cell count. Our nutritionist likes to look at the sheets to see if he needs to make changes to our ration to boost protein or butterfat.

How does testing with DHIA bene t your dairy operation? DHIA bene ts our operation because of the accurate records and tells us which cows are more pro table and which cows it doesn’t pay to have in the herd. DHIA also helps with choosing which bulls to use on certain cows to improve components of the next generation of cows. I really enjoy the simplicity of getting the information. I can download the results of the tests through dairy comp to my computer to see the last test results.

Tell us about your farm. I farm with my mom, Nancy, and dad, Pat, we have 550 acres of corn and alfalfa and nish out our Holstein steers. We milk in an 85-stall tiestall barn. We also have three part-time high school kids that help.

Dairy Star • Saturday, May 11, 2024 • Page 11 CENTRE DAIRY EQUIPMENT AND SUPPLY INC. Henning Area 218-849-0211 Jon Stein 320-352-5762 • 1-800-342-2697 40625 State Hwy. 28 • Just West of Hwy. 71 • Sauk Centre, MN Aaron bought the brush from Centre Dairy about a year ago and installed it himself. Centre Dairy came out later and adjusted the mount and wiring. Since then, they have had zero issues. They have 70 cows and the majority of them love the brush. Aaron spoke highly of both Centre Dairy Aaron Wiechmann Melrose, MN Improve Cow Cleanliness & Cow Comfort Call Jon today!

Con nued from WIC | Page 8

Sauk Centre, MN Buffalo, MN 763.682.1091 www.mndhia.org DHIA: Now MORE than ever

Tanner Linn (Linn Dairy Farm) Richmond, Minnesota Stearns county • 148 cows Do You Know Where Your Roasted Soybeans Come From? NOT ALL ROASTED BEANS ARE CREATED EQUAL! • Energy • Protein • Amino Acids • Bypass Protein NOTALLROAST ?? ? Make Sure You Demand The Best... KLC SOYBEANS! Our soybeans have what your dairy ration needs: Quality Consistency KLC Farms Roasting, Inc. 320-352-3326 Visit www.roastedbeans.com Preferred By Bovines Everywhere

Ringmen Lynn Harbaugh (from le ), Brandon Ferry and Chad Ryan eld bids while a heifer is paraded in the ring June 29, 2019, during the Na onal Holstein Conven on Sale in Appleton, Wisconsin. Managing the sale was a highlight of Rick and Paula Bovres’ career.

which averaged $5,475 on 52 lots and auctioned a higher seller at $24,000.

The venue made it memorable for the Bovres.

“The cattle were housed on the rooftop of the convention center and were taken to the sale ring in the convention center via the service elevator,” Rick said. “This was kind of a thrill to watch and be a part of.”

The extra effort the Bovres put into their work became their trademark, shining through in each animal sold at the Great Northern.

“Every animal that went through the Great Northern was washed and clipped,” Rick said. “We appreciate how cattle look after you’ve done that; consignors and buyers do too. We’d have consignors come for the sale and say, ‘Where’s my cow?’ They almost didn’t recognize them. They change a lot after you clip and wash them and present them full of milk. You put the effort into presenting them and hope they bring the extra money.”

Thousands of dairy cattle have been struck off at the Great Northern and many are memorable, Rick said.

“A number of animals that became high-prole cows went through our sales,” Rick said. “They weren’t high prole at the time, but they became cows that impacted the breed.”

Two that come to mind for Rick and Paula are Stookey Elm Park Blackrose-ET and Wesswood-HC Rudy Missy-ET.

“It’s been interesting to watch how all that evolved, and everybody who has kicked themselves for overlooking animals like that after the fact,” Paula

said. “A lot of cows like that have gone through the ring here, but those two stick out because you see them both in so many pedigrees.”

Blackrose passed through the sale ring as a bred heifer Dec. 6, 1991, where the nal bid was for $5,400 to Mark Rueth and Mark VanMersbergen. She achieved acclaim and became a prominent brood cow in both sectors of the Holstein breed.

Selling as a 5-year-old cow, Rudy Missy’s potential attracted the attention of Matt Steiner of Pine Tree Holsteins Feb. 14, 2003. A locally bred cow, Missy was the top seller, garnering a bid of $8,100. Missy’s inuence continues across three decades.

While their role in helping breeders market the best genetics is documented, the Bovres are most proud of the role they have played in helping develop leaders throughout the industry.

“I enjoy watching these people that we had employed here as young kids,” Rick said. “There have been hundreds of young kids that have worked here over the years: clipping, washing, watching nightline and that kind of stuff. A few have turned into Klussendorf winners, have nice farms and herds of cattle now. They are the people others are wanting to hire to clip for them.”

Paula agreed. She said the relationships developed with their workforce strengthened their commitment to their work.

“It’s not only been a good place for them to practice but to learn not only about tting and caring for cattle but many life lessons in general,” Paula said.

Dairy Star • Saturday, May 11, 2024 • Page 13 Get a FREE Dairy Scratchy * ($175 value) With Purchase of a Lely Luna Cattle Brush NEW PRODUCT/ NEW DEAL! • Rubber animal scratcher • Improves cow comfort • Feels like a rubber-comb • Gently massages • Shock-absorbing to avoid injury caused by jostling • No sharp corners; hock-protection design • Automated cattle brush • Rotates with touch-activation • Lasts longer, soft-start motor • Automatic reverse rotation with cow contact • New design for greater functionality! Contact us today to get this FREE deal and for product details. Melrose, MN Jake—320.761.9630 jmoline@Leedstone.com Glencoe, MN Paul—320.510.0200 pbecker@Leedstone.com Plainview, MN Gregg—507.696.5518 gluebke@Leedstone.com Menomonie, WI Mark—507.259.8047 mjurgenson@Leedstone.com CONTACT YOUR LEEDSTONE REP TODAY! Leedstone.com/equipment-team • • Family & veterinarian owned since 1994 Follow us on social media for the lastest news on Lely and more, with Leedstone! NEW! *Free offer expires July 31, 2024! Con nued from GREAT NORTHERN | Page 12

PHOTO SUBMITTED

www.arnzenconstructioninc.com Warmer days ahead! Keep your barn cool with NCF 52” Panel Fans • Durable and innovative 6-blade design • Heavy-duty galvanized frame • Unique and flexible mounting systems Heavy-duty, Extremely Ef cient Fan for Quiet Dairy Barn Ventilation 320-836-2284 1-888-276-1751 29033 Co. Rd. 17, Freeport, MN In St. Rosa

Page 14 • Dairy Star • Saturday, May 11, 2024 SAUK CENTRE, OFF I-94 ON THE CORNER OF HWY. 28 & 71 SOUTH Haybuster CMF830 #21112 - $49,900 Kuhn Knight SLC126 #2291 - $42,900 2018 Penta 8030HD #22140 - $72,500 2020 ARTEX SBX800 #2425- $58,900 2009 Houle EL48-6D6100 #2285 - $38,500 No Reasonable Offer will be Refused!! 2021 Kuhn Knight VTC1120GII #23130 - $195,000 2018 Supreme Intl 1200T #22109 - $59,900 M i n n e s o ta ’s LargestFeeding and ManureHandli n g D e a rel Ifyouhavea barn, we haveasolution. www.dairylandsupply.com SPREADERS Call for availability Parts In Stock In Stock Penta 6730 Parts in Stock! Many Different Sizes In Stock , 2 Inventory Reduction BLOWOUT! Parts In Stock HYDRA-SPREAD In Stock In Stock The KUHN Knight PS 250, 260, 270 & 280 ProSpread® apron box manure spreaders are high-capacity, non-commercial spreaders designed for feeder, cow/calf, and dairy operations that process a wide array of semi-solid and solid materials. Parts In Stock VT600 T WIN-SCREW VERTICAL MIXER In Stock

Rachel Zwieg Lebanon, Wisconsin Dodge County 70 cows

Tell us about your family and any special plans for your family this year. My husband, Kyle, and I have three kids: Theodore, 8, Landon, 7, and Logan, 7. Being on a farm, our plans are very uid. We will take three days off in August between chopping hay and harvesting wheat. Taking the train to Chicago and visiting the Dodge County Fair are our usual plans. Then again in winter, right after harvest, we like to take a trip to Wisconsin Dells, Wisconsin.

What are the best aspects of being a mother and dairy farmer? Growing up on a dairy farm myself, it is seeing them rediscover all the fun things that I used to do as a child. Anything from swinging on a rope to riding their bikes as fast as they can down all the driveways and paths. They have such a joy for adventure.

What challenges do you have with your dual role? The biggest challenge is balancing everyone’s schedules. Some weeks, I won’t know when I will be able to go grocery shopping or to the gym until I wake up in the morning. You have to go with the ow while also working around bus stop times and after school activities. During the really busy season, you have to make time for dinner and getting the kids to bed only to go back out to the barn to nish chores.

What lessons from the farm do you instill in your children? I have two big ones. One is that working hard doesn’t have to feel like work. Kyle and I put in a lot of hours, and we try to show our kids the best aspects of what we do. The other is nding the good on bad days. Farming can take a toll when one of your favorite animals is sick, or the weather takes a turn for the worst and ruins crops. It could even be that they can’t go to a birthday party because the weather is good, and we have to make hay. Teaching them to spend some time in nature or snuggling with the dog or a cow can make a bad day a little better. They are beginning to understand that not all kids have the opportunity to go exploring in the woods or hug an 800-pound animal.

What is a highlight of your dairy career as a mother? Seeing how much our boys want to emulate us. They can’t get enough of learning, and they are constantly disappointed when we tell them they are not big enough or old enough to do something. Whenever the stars align, and the holding pen is almost empty, I let them go in with me to put a cow in the robot and their faces will light up as soon as they step in and help.

What little things on the farm make you smile? Watching my kids stand and get licked by cows. Some days they are covered from head to toe in cow slobber.

What would be the perfect Mother’s Day gift? Lots of rain on Saturday night and beautiful weather all day Sunday. Then, we could spend time outside as a family on actual Mother’s Day. Some owers to plant would also be great.

Tell us about your farm. My husband and I own and operate a robotic dairy and crop farm. My father-in-law, Joe, mother-in-law, Lisa, and brother-in-law, Kevin, also work on the farm. Our children are the seventh generation. We milk 70 cows with one DeLaval VMS V300 robotic milking system. Our milk is sold to Dairy Farmers of America Inc. We farm about 2,000 acres in addition to the dairy.

Jennifer Lemke Grover, Wisconsin Marinette County

50 cows

Tell us about your family and any special plans for your family this year. My husband, Jake, and I have four children ages 5 and under, two boys and two girls: Sophie, Cheyenne, Chas and Luck. Since our youngest is only 3 months old, our plan is to enjoy every moment and survive during the busy farm season ahead.

What are the best aspects of being a mother and dairy farmer? I’ve always wanted to be a farmer and raise my kids on the farm. My husband likes to say he made my dreams come true. I love physical work, being outside and getting dirty. Kids can never complain of being bored in this lifestyle.

What challenges do you have with your dual role? With each child, my farm duties grew less and less. I miss being in the barn and helping my husband, but I wouldn’t trade being with my kids every day. We both agree the stress and safety are not worth bringing the kids out for chores until they are older and more responsible. Our oldest daughter, Sophie, earned her very own pink toolbox so she can work and x with Dad or Mom.

What lessons from the farm do you instill in your children? I want my children to learn life on the farm: hard work, caring for animals and jack-of-all-trades skills. I want them to be xers and problem solvers.

What is a highlight of your dairy career as a mother? I grew up on my dad’s family farm until I was 4. I milked cows through school and worked at an agricultural plant, but I’ve learned more from my husband and this journey. I know most people do not comprehend what a farmer’s duties actually entail. I nally drove a tractor.

What little things on the farm make you smile? When I am outside with my family and look at our place with a lane through our land to the creek, I feel instant happiness, knowing our cows have the option to go out to pasture daily, weather permitting.

What would be the perfect Mother’s Day gift? One large swing set with several swings so Mom can swing too. It’s on the ol’ honey-do list.

Tell us about your farm. My husband bought his herd 10 years ago, but he is the sixth-generation farmer on this farm, established in 1856. We are located in Grover, Wisconsin, and his family rebuilt after the Peshtigo re and have been the only family on this property. The barn has 56 stanchions and tie stalls. We ship our milk to Agropur. My father-in-law always helped with eldwork, and since retiring, he is here most mornings to help with chores just like his dad did. We have a cousin who helps with evening chores and uncles and brothers who drive tractor also. This is our rst year without our beloved Grampa Bud driving through the lane, scouting crops and visiting, so we’re missing him but know he’s watching over the operation.

Your Leading Supplier of Manure Handling Equipment in Southern Minnesota Your Yo FEATURING OUR CUSTOM DESIGNED, QUALITY BUILT, AND FASTEST OFFLOADING TANKER TRAILERS IN THE INDUSTRY. We are also a proud dealer of: Give Joey Burns a call: 507-461-0038 Email: parts@bosssupplyinc.com 414 South Main St. Janesville, MN 56048 We are also Give Joe Email: part s 414 South Now Introducing our new line of replacement parts compatible with Houle & GEA Liquid Manure Equipment! *Parts are not OEM, manufactured, or aff iliated with Houle/GEA* WWW.BOSS- S UPPLY.COM SEEOUR INVENTORY Dairy Star • Saturday, May 11, 2024 • Page 15 Turn to OUR SIDE | Page 16 from our side our side OF THE FENCE THE What are the best aspects of being a mother and dairy farmer?

Ashley Canter Cashton, Wisconsin Vernon County 60 cows

Tell us about your family and any special plans for your family this year. I homeschool my ve children, four girls and one boy, who range in age from 7 to 15. This year, we’re celebrating everything from the nal rst Holy Communion to the rst driver’s license. The farm is growing and so are the children, and as the seasons change for us, my goal is to help each of them assume new farm, household and academic responsibilities so that our values continue to t naturally with our work.

What are the best aspects of being a mother and dairy farmer? Not only am I able to stay at home and care for my family, but I am privileged to work alongside them too. My roles as farmer, homemaker, teacher and mother form a seamless whole such that each supports and nurtures the others. My children benet from my work in every way. From the fresh milk they drink for breakfast every morning to my guidance when they’re struggling with chores or facing a tough loss, I am thankful to be present and able to provide for them.

What challenges do you have with your dual role? There are never enough hours in the day, and sometimes, I feel a tension between my responsibilities on the farm and in the home. Often, I have to choose which ones deserve my full attention rst and which ones can wait for another day. Then, I need to be content with the outcome. Managing healthy priorities for the whole working family is a constant balancing act.

What lessons from the farm do you instill in your children? Life is fragile and precious. Earthly trials prepare us for heaven, and there is no substitute for diligent labor.

What is a highlight of your dairy career as a mother? When my eldest daughter offered to milk the cows on Christmas morning so I could stay in with the younger children and prepare our celebrations. For once, I didn’t have to focus on striking that balance between the house and the barn, and I was proud that she was so perceptive and prepared to accept extra duties to ease another person’s burden. The world could use some more of that.

What little things on the farm make you smile? New babies, sunrises and bumblebees on the clover owers. Fistfuls of dandelions and the trill of the red-winged blackbird. Snowmen and random hugs. The hen who jumps out of the chicken run every single morning. The little girls singing loudly while they scrape out the holding area.

What would be the perfect Mother’s Day gift? A clean house and a nap.

Tell us about your farm. My husband and I are rst-generation farmers; we moved here from Ohio and retrotted an old red barn with a swing-8 parlor and freestall facility when we started milking eight years ago. We began the transition to organic immediately and became certied grass-fed ve years later. Two years ago, we started shipping to Organic Valley’s Grassmilk line. We follow an intensive grazing protocol on about 100 acres of refurbished pasture, with a mixed herd of high-component breeds. Our teenage daughters help with milking, fencing and moving the herd during grazing season. Our son raises calves and the younger girls help with cleaning. Everyone pitches in to help with small stock, housework and other projects to keep the operation running smoothly. We always seem to have another crazy idea to plant in this good earth.

Casey Welke

Osseo, Wisconsin

Trempealeau County

35 cows

Tell us about your family and any special plans for your family this year. My husband, Cody, and I farm near Osseo, Wisconsin, with our two children Evan, 4, and Hailey, 1. With Cody changing jobs, we have weekends freed up to make it to some of our local events such as fairs and town celebrations. Also, we make it to the pond for the kids to do some shing.

What are the best aspects of being a mother and dairy farmer? The best part of dairying and raising a family is the togetherness whether it is daily chores or welcoming new calves.

What challenges do you have with your dual role? Limitations on time because of obligations of farming and being a mother.

Tammy Sikora Boyd, Wisconsin Chippewa County 70 cows

Tell us about your family and any special plans for your family this year. My husband, Kyle, and I have four children: Bailey, 15, Kendall, 14, Drew, 12, and Ty, 10. They are all active in sports, so a lot of our time away from the farm is spent at ball games. We were able to take a family vacation to Florida this spring to go deep-sea shing, which we all highly recommend.

What are the best aspects of being a mother and dairy farmer? I have always been so thankful that we have been able to raise our kids on the farm and not have to send them to day care. They grow up so fast, and it was nice not to miss that time with them. I am always sad when summer ends and they have to go back to school because I love having them home. We have the exibility to start a little earlier or later if there is something fun we would like to do.

What challenges do you have with your dual role? Some challenges I have come across as being a mom and a dairy farmer is that you can’t just call in to work when the kids are sick. The chores still need to be done. I also feel like it’s hard to prioritize self-care. The kids and the cows always come rst, so sometimes it is hard to set aside time to make those doctor and dental appointments for myself. There never seems to be enough time, and there always seems to be guilt if I miss something the kids are involved in. On the ip side, I also feel guilty if I get someone to milk for me so I can make it to their games. I am sure it is something many farm moms can relate to.

What lessons from the farm do you instill in your children? I hope they learn how to sacrice, compromise, and prioritize time and nances. I hope they appreciate team work and that many hands make light work; and that you get out what you put in most of the time Sometimes no matter how hard you work, things don’t go your way, and you have to accept that. I also hope the farm shows them that you need to have faith that the sun will shine, the rain will come and the crops will grow. Finally, I hope it gives them the foundation to succeed in whatever career they choose to pursue.

What is a highlight of your dairy career as a mother? Our family was part of a Culver’s commercial. Seeing our kids help get the farm ready for the video shoot and having them see what goes on behind the scenes and being a part of the video, this was something we will always remember.

What little things on the farm make you smile? I love a good sunrise or sunset. It is always a great way to start or nish a day. When the kids learn new task, like driving the skid loader, helping mix feed, running the feed cart or digging the cow yard up, seeing the pride in their eyes from a job well-done always puts a smile on my face. I also love a newly cleaned and bedded heifer barn.

What would be the perfect Mother’s Day gift? The best Mother’s Day gift would be to have the whole family home to help with chores morning and night, grill out and play ball in the backyard.

Tell us about your farm. We milk in a 56-stall tiestall barn with seven automatic takeoffs Our milk goes to LaGrander’s Hillside Dairy Inc. in Stanley, Wisconsin. We do not have any hired help but are fortunate to have our niece, her ancé and my brother to help when we want to make it to ball games or take a family vacation.

What lessons from the farm do you instill in your children? Responsibility, work ethic, patience and the understanding of what it takes to get the job done.

What is a highlight of your dairy career as a mother? The fact that I am able to produce a quality product as well as being able to do all the work myself.

What little things on the farm make you smile? When Evan is pushing the broom to help or running the lever to get the total mixed ration fed. It is entertaining to watch Hailey interact with the new calves, play with cats and her latest action of playing in the drinking cups.

What would be the perfect Mother’s Day gift? Most of all, to be with my family and potentially sleep in.