State Supplement sponsored by:

PACIFIC NORTHWEST EDITION

A Supplement to:

SHIP WITHIN 48 HOURS SAME DAY PARTS AVAILABILITY

®

BACKED BY A 75 YEAR BUSINESS

November 24 2019 Vol. IV• No. 24

24 HOUR TECHNICAL SUPPORT

Thousands in Service!

“The Nation’s Best Read Construction Newspaper… Founded in 1957.”

Your Pacific Northwest Connection – Patrick Kiel – 1-877-7CEGLTD – pkiel@cegltd.com

Affordable Price. Premium Service.

CALL 800-367-4937 *On approved credit • Financing Available

Roberts Mountain Climbing Lanes Will Ease Truck Traffic By Lori Tobias CEG CORRESPONDENT

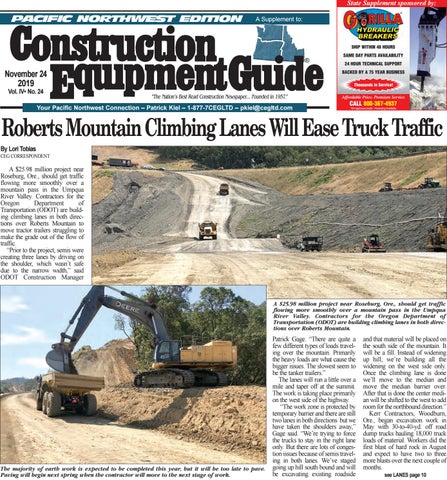

A $25.98 million project near Roseburg, Ore., should get traffic flowing more smoothly over a mountain pass in the Umpqua River Valley. Contractors for the Oregon Department of Transportation (ODOT) are building climbing lanes in both directions over Roberts Mountain to move tractor trailers struggling to make the grade out of the flow of traffic. “Prior to the project, semis were creating three lanes by driving on the shoulder, which wasn’t safe due to the narrow width,” said ODOT Construction Manager

A $25.98 million project near Roseburg, Ore., should get traffic flowing more smoothly over a mountain pass in the Umpqua River Valley. Contractors for the Oregon Department of Transportation (ODOT) are building climbing lanes in both directions over Roberts Mountain.

The majority of earth work is expected to be completed this year, but it will be too late to pave. Paving will begin next spring when the contractor will move to the next stage of work.

Patrick Gage. “There are quite a few different types of loads traveling over the mountain. Primarily the heavy loads are what cause the bigger issues. The slowest seem to be the tanker trailers.” The lanes will run a little over a mile and taper off at the summit. The work is taking place primarily on the west side of the highway. “The work zone is protected by temporary barrier and there are still two lanes in both directions but we have taken the shoulders away,” Gage said. “We’re trying to force the trucks to stay in the right lane only. But there are lots of congestion issues because of semis traveling in both lanes. We’ve staged going up hill south bound and will be excavating existing roadside

and that material will be placed on the south side of the mountain. It will be a fill. Instead of widening up hill, we’re building all the widening on the west side only. Once the climbing lane is done we’ll move to the median and move the median barrier over. After that is done the center median will be shifted to the west to add room for the northbound direction.” Kerr Contractors, Woodburn, Ore., began excavation work in May with 30-to-40-yd. off road dump trucks hauling 18,000 truck loads of material. Workers did the first blast of hard rock in August and expect to have two to three more blasts over the next couple of months. see LANES page 10

Page 2 • November 24, 2019 • www.constructionequipmentguide.com • Pacific Northwest Supplement • Construction Equipment Guide

Contact your local dealer:

WASHINGTON: Seattle, WA 8207 South 216th Street Kent, Washington 98032 206.762.5933 Manager: Brian Burke bburke@PacWestMachinery.com Spokane, WA 3515 N. Sullivan Rd. Spokane Valley, Washington 99216 509.534.5933 Manager: Scott Upton supton@PacWestMachinery.com

OREGON: Portland, OR 19255 NE Sandy Boulevard Portland, Oregon 97230 503.252.5933 Manager: Tim Hurst thurst@PacWestMachinery.com Eugene, OR 1550 Irving Road Eugene, Oregon 97402 541.302.3762 Manager: Tim Hurst thurst@PacWestMachinery.com

PacWestMachinery.com

Construction Equipment Guide • Pacific Northwest Supplement • www.constructionequipmentguide.com • November 24, 2019 • Page 3

www.modernmachinery.com Kent, WA (800) 669-2425 Rochester, WA (800) 304-4421 Spokane, WA (800) 541-0754 Boise, ID (800) 221-5211 Pocatello, ID (800) 829-4450 Billings, MT (800) 735-2589 Kalispell, MT (800) 434-4190

“WE PU USH EVERYTTHING TO O THE LIM

Missoula, MT (800) 332-1617 Eugene, OR (800) 826-9811 Portland, OR (800) 950-7779 Magadan, Russia 011-7-41326-99298 Yuzhno-Sakhalinsk, Russia 011-7-42424-69051

See Us at North Hall: N10825

MORE RELLIABLE. “How does Komatsuu work for our construction business? First it’ their reliable, qualityy designed and built equipment. W afford downtime, andd Komatsu’s products a in our book. The support pport we receive from our dealer is outstanding as well. Trraining, parts, financing have experienced p the he best personal p care with Komatsu. They just work best for us!”

Hunter and Clint Shackelford Shackelford Construction truction / Yaazoo City,

That t’s s why hy y I am K Koma ma komattsuamerica.com

ca Corp. All Rights Reserved 036 © 2018 Komatsu America

Page 4 • November 24, 2019 • www.constructionequipmentguide.com • Pacific Northwest Supplement • Construction Equipment Guide

Doosan Adds New Authorized Dealer Serving Hayden, Idaho

The dealership is located at 53 West Boekel Road in Hayden, Idaho.

Doosan Infracore North America LLC, has expanded its dealer network with an additional location of Cascade Trader Inc. as an authorized sales, service, parts and rental provider of Doosan equipment. The company now offers its customers in Hayden and Coeur d’Alene, Idaho and Spokane, Wash., a wide range of Doosan equipment. Crawler excavators, log loaders, wheel excavators, material handlers and wheel loaders are all available from the dealer. The dealership is located at 53 West Boekel Road in Hayden, Idaho. Since 1991, Cascade Trader Inc. has operated as a new and used construction and forestry equipment sales and service business. Originally dealing exclusively in Chehalis, Wash., the company recognized the need for an additional location in Idaho to support its growing client base. “As soon as our customers in Idaho realized the value of the Doosan line, the same growth that took place in Washington started in Idaho,” said Rich Lennox, owner of Cascade Trader Inc. “Our clients are hardworking business people who expect their dollars and their equipment to work as hard as they do. We are excited for this location’s ability to better serve those clients.” “We are excited for Rich Lennox and the staff at Cascade Trader as they open a second location — expanding their reach in Idaho,” said Ron Hadaway, regional director, Doosan Infracore North America LLC. “Cascade Trader has a long history serving customers in its area, particularly in forestry and logging operations, to ensure their customers have reliable harvesting equipment. “The new location is an ideal fit for helping Doosan expand its footprint in Idaho and eastern Washington. We look forward to working with Cascade Trader in the Hayden area to provide Doosan equipment along with excellent support to its customers.” The company provides parts, service, sales, rental and finance services to their clients across all locations. For more information, call 208-762-5575 or visit dealer.doosanequipment.com/Hayden. The staff at Cascade Trader’s newest location is eager to expand the company’s presence in Idaho.

Construction Equipment Guide • Pacific Northwest Supplement • www.constructionequipmentguide.com • November 24, 2019 • Page 5

Sound Transit Breaks Ground on Redmond Link Extension Sound Transit and its partners celebrated the start of construction of the 3.4-mi. Downtown Redmond Link Extension, which will extend the Blue Line from Redmond Technology Station into southeast Redmond to its terminus in downtown Redmond. Upon opening in 2024 riders will enjoy fast, frequent and reliable service between the Eastside and Seattle, the University of Washington, Sea-Tac Airport and south Snohomish County. The extension includes two new stations at SE Redmond and Downtown Redmond. The segment’s opening will follow the 2023 opening of light rail between Downtown Seattle and Redmond’s Overlake area. The project is the result of intensive collaboration between the city of Redmond, the King County Department of Natural Resources and Parks, King County Metro Transit and the Washington State Department of Transportation. “Demand for transit on the Eastside will only increase as Redmond continues to grow as an area people want to live and work,” said Redmond Mayor and Sound Transit Board Chair John Marchione. “Today we celebrate a win for transit riders, drivers and pedestrians who will soon travel quickly,

“Today’s groundbreaking follows years of planning and partnership to complete the regional transit network to Downtown Redmond.” Peter Rogoff Sound Transit

easily and traffic-free between homes and workplaces in Redmond and destinations throughout the region.” “Today we celebrate a milestone in creating a world-class transportation system that will link communities across three counties,” said King County Executive Dow Constantine. “Not only will Redmond, Marymoor Park and Microsoft be accessible by high capacity rail, but Sound Transit’s community investments will help deliver long-needed connections between regional bike trails, making it even easier to get around without a car.” “Downtown Redmond’s opening, just one year after the completion of East Link, will unlock transformative mobility and eco-

nomic opportunities,” said King County Council Vice Chair and Sound Transit Boardmember Claudia Balducci. “The 2024 opening will not only provide congestionfree trips to more jobs and schools across the region, it will create new connections to our most iconic parks and trails and it could spur much needed affordable housing on the Eastside.” “Sound Transit’s investments are creating economic opportunity for thousands of working people including hundreds of good, family-wage jobs for skilled craftspeople here in Redmond,” said Monty Anderson, executive secretary, Seattle Building & Construction Trades Council. “Through apprenticeships and training programs with

Officials in Oregon, Washington to Begin Building I-5 Bridge By 2025 PORTLAND, Ore. (AP) — Federal highway officials have endorsed an accelerated timeline proposed by Oregon and Washington transportation officials that sets the two states on a fast track toward construction on a new Interstate 5 bridge by 2025. The Oregonian/OregonLive reported that the two states requested a 10year extension on their timeline to show progress on the bridge project or face repaying nearly $140 million in planning costs tied to the Columbia River Crossing Project.That request would’ve given the states until Sept. 30, 2029, to either start buying up rights-of-way or begin construction on the I-5 project. While seeking a decade delay, the states simultaneously suggested a series of aggressive milestones, including reinitiating an environmental review of a proposed project in spring 2020 and starting construction in the summer of 2025. The Federal Highway

“We think five years is enough time for us to move forward on the project.” Thomas Fuller Oregon Department of Transportation

Administration declined the 10-year extension request but endorsed the aggressive timeline. The states now must show considerable progress, including buying up necessary rightsof-way, by the end of September 2024. If the states don’t accomplish that goal, they could owe a collective $140 million to the federal government for planning costs related to the past bridge

effort. “We think five years is enough time for us to move forward on the project,” said Thomas Fuller, an Oregon Department of Transportation spokesman. Federal officials note that the government first gave Washington money for the project in 2004 and Oregon financing in 2007.

this project, we are also building the next generation of construction workers from our local communities including women, people of color, veterans and others who are disadvantaged.” “Today’s groundbreaking follows years of planning and partnership to complete the regional transit network to Downtown Redmond,” said Sound Transit CEO Peter Rogoff. “Within five years our Link extensions to Redmond, Lynnwood and Federal Way, and Stride BRT service on I-405 and SR-522 will enable many thousands more riders to escape crippling traffic.” Stacy & Witbeck/Kuney, a Joint Venture is completing the final design and construction on the extension, which is scheduled to open in 2024. People traveling from downtown Redmond will be able to reliably reach downtown Bellevue in 18 minutes; Lynnwood in 69 minutes; the University of Washington in 49 minutes; Sea-Tac Airport in 72 minutes; and Federal Way in 87 minutes. Sound Transit predicts that by 2026 between 43,000 and 52,000 daily riders will use light rail to travel to and from Eastside destinations. More information on the Downtown Redmond Link Extension is available at soundtransit.org/redmondlink.

Page 6 • November 24, 2019 • www.constructionequipmentguide.com • Pacific Northwest Supplement • Construction Equipment Guide

Orchard Farmer Finds Success Using Doosan Equipment Situated approximately 60 miles southeast of Mount Rainier, Wash., is the Yakima Valley, a breathtaking agricultural region known for its apple, wine and hop production. The Yakima Valley has the largest variety of fresh grown produce in the Pacific Northwest because of local farmers and growers like Brad Ziemke, owner of Ziemke Farm Fresh Produce. Farming wasn’t Ziemke’s first profession, but it was one he was always interested in. After a few years working at a lumber mill in Renton, Wash., he decided he needed a change.

“When I started using Doosan equipment, I realized how much more productive I could be with a bigger machine,” Ziemke said. “I didn’t realize I needed a machine bigger than the DX180LC-3, but since I bought the DX225LC-5 it’s made my job a whole lot easier.”

Production Leads to Profit Since using Doosan equipment, Ziemke has been able to easily keep up with the increasing demand. “After bidding out a job we go in and take the DX225LC-5 or DX180LC-3 equipped with a grapple attachment,” Ziemke said. “Our excavators can pull four to eight acres a day, depending on the size of the trees and Ziemke uses the two DL250-5 wheel loaders to pick up trees and the terrain. Plus, pairing the excavator with a transport them to a grind or a burn pile. One wheel loader is grapple attachment allows me to pick up and Brad Ziemke, owner of Ziemke Farm Fresh Produce, is equipped with an optional rearview camera for better visibility on carry three times the amount that I had a direct kind of guy when it comes to choosing his equipthe farm, while the other has a high-lift option to easily load the been.” ment. When he was in the market to buy a new excavator, material into high-sided trucks. On average, Ziemke and his team are takhis local equipment dealership, Feenaughty Machinery, ing out three or four rows of apple and cherdecided to take him to a hands-on product testing and ry trees and rolling them into one windrow. education site — commonly known as The ROC — instead A windrow is a line of material heaped up of taking the machine for a demo at his jobsite. using a machine. “It really opened my eyes to what equipment Doosan Ziemke uses the two DL250-5 wheel has available,” Ziemke said. “It really impressed me.” loaders to pick up the remaining trees and transport them to a grind or a burn pile. One “I had been there for three years and was wheel loader is equipped with an optional the second-highest-paid worker in the mill, rearview camera for better visibility on the but I felt like the lumber industry was going farm, while the other has a high-lift option to south and the job was a dead end to me,” easily load the material into high-sided Ziemke said. “So, I ended up quitting.” trucks. Ziemke drove to Yakima, Wash., in his The decision to grind or burn the material pickup truck, bought a bin of apples and is up to the farmers and Ziemke and his cherries and started selling fruit on the side crew. of the road. In three short years, business “Grinding is considerably more expensive was booming, and he had five produce for farmers,” Ziemke said “But, there are no stands throughout Seattle and Tacoma, permits or regulations when grinding mateWash. But, after a few years, he had a diffi- Derrick Hough, sales specialist, Feenaughty Machinery, and Brad Ziemke, owner, rial. We can usually move and grind about cult time getting farmers to supply his Ziemke Farm Fresh Produce. 10 acres a day. However, there are some stands. As a solution, he decided to buy a strict regulations on nectarines. The produce is packed and sold farm to grow the fruit. burning. We have to go “Honestly, I was working myself to death directly from the farm to local grocery stores in and push, pile, and driving back and forth between my stands,” and produce stands around Idaho, Montana, pile, burn and then Ziemke said. “I decided that I enjoyed farm- Oregon and Washington. come back 30 days later “We typically have five or six jobs going ing more than the stands, so I closed them to remove the debris. on every day,” Ziemke said. “We stay busy.” and started exclusively farming.” Most of the time we are Ziemke began farming a few acres as a grinding the material Doosan Delivers hobby for himself and to provide produce for since it’s more environTo keep up with his expanding business, his friends and neighbors, but it quickly mentally-friendly.” Ziemke decided to upgrade his heavy equipturned into a full-time business. Once the crew grinds “About five years ago, I wanted to find a ment fleet and met with his local equipment Ziemke owns three Doosan crawler excavators — a or burns the material, way to keep my guys busy year-round,” dealership, Feenaughty Machinery. DX225LC-5, a DX180LC-5 and a DX180LC-3 — and two they use another brand “When we started looking for a new exca- DL250-5 wheel loaders. Both the excavators and wheel of equipment to rip out Ziemke said. “So, I decided to get into the orchard removal business in addition to vator, we looked at many manufacturers,” loaders are used with attachments for efficient tree the roots and to disk the growing produce. There was a need for it in Ziemke said. “We don’t build roads or work removal. ground. Then the the area, and now it’s a full-fledged business. in construction, so we had to have the right my color, even my pickup is orange.” ground is ready to It’s really ballooned into something quite equipment for orchard removal. I was weary replant in the spring. Ziemke owns three Doosan crawler excaof trying a new brand since buying a vators — a DX225LC-5, a DX180LC-5 and substantial.” While orchard removal is the company’s Today, Ziemke has six employees and machine is a sizable investment. However, a DX180LC-3 — and two DL250-5 wheel primary job, Ziemke also uses his equipment farms 150 acres of vegetables, including when I came across the Doosan equipment loaders. Both the excavators and wheel load- year-round around his farm for tasks such as cucumbers, peppers, tomatoes, as well as brand I took a chance. Now, much of my ers are used with attachments for efficient building a greenhouse and digging irrigation fruits like apricots, cherries, peaches and equipment is orange. Orange has become tree removal. ponds.

Hands-on Demo

Construction Equipment Guide • Pacific Northwest Supplement • www.constructionequipmentguide.com • November 24, 2019 • Page 7

Your new Doosan dealer in Idaho

RUN STRONG. Packed with the features that operators demand, D san® wheel loaders bring streng th to ever y job. Doo

See machine features and specs: DoosanEquipme ent.com/MyWheelLoader

Authorized Doos o an Dealer s

www.cascadetrader.net 1380 NW State Ave Chehalis, WA 98532 360-748-1182

53 W Boekel Road Hayden, ID 83835 208-762-5575

Doosan ® and the Doossan logo are registered trademarks of Doosan Corp. in the U United States and various other countries around the world. w ©2018 Doosan Infracore North America, LLC. All rights reserved. | 61137-4

Page 8 • November 24, 2019 • www.constructionequipmentguide.com • Pacific Northwest Supplement • Construction Equipment Guide

Budco Custom Body & Paint Inc. Photo

Budco Custom Body & Paint Inc. uses top-of-the-line PPG paint products along with its paint booth and highly experienced professionals to work on the vehicles and equipment.

Budco Tricks Out Trucks With Custom Paint Creations By Lori Lovely CEG CORRESPONDENT

It’s hard to miss the purple logging truck driven by Alex “Tater” Opdahl for Whitco Inc., a trucking company owned by Rick and Barb Whitcomb in Kamiah, Idaho. Whitco was founded on Sept. 5, 1984. On the day Rick married Barb, Rick’s father escorted the couple to Farmers State Bank in Uniontown, Wash., to get a loan for a 1977 Peterbilt 359. That was followed by a second truck in 1986 and later by a third. Buying and selling trucks along the way included trading in one truck on the purchase of two Peterbilt glider kits in 1990. On May 5, 1996, Whitco incorporated and bought seven Mack trucks from KJ Weller Inc. Budco Custom Body & Paint Inc., owned by the Whitcomb’s son Bud, painted the purple 2019 W900 L Model Kenworth log truck in La Grande, Ore., for the Whitco driver. The truck, which features a 265 wheel base, also displays striping and lettering by Paul Mackie. In addition to logging trucks, Bud Whitcomb, owner of Budco since 2012, has painted long-haul trucks, insurance truck wrecks, show trucks built and customized specifically for shows, cars, pickups, motorcycles, boats, horse trailers and more. The Beginning Budco, a full-service auto, heavy truck and recreation body repair and paint shop, began as a one-man-show — a business launched in the back of Whitco Inc. “He spent many nights and weekends [going] back and forth from Lewiston to Kamiah, trying to get his business rolling,” said Whitcomb’s wife, Courtney, who works in the office.

To get his own business off the ground, Whitcomb tried sandblasting and towing, but custom paint jobs put him on the map. Customers came from all over the Northwest for his work. The company may have been new, but Whitcomb wasn’t a novice at his work. While still in high school and college, when he studied business and auto body repair at Lewis Clark State College in Lewiston, Idaho, Whitcomb won awards for outstanding auto body work and painting. His senior project was completely restoring a 1966 Chevy Impala. After college, he worked at local shops, gaining experience — although his wife says his dad taught him everything there is to know about a truck before Whitcomb could even walk. Whitcomb built on that knowledge by working in his dad’s shop when he was in school, sweeping up and performing routine maintenance. Growth As business increased, Whitcomb bought a shop down the street from his father’s shop and added four new employees to his crew — but more changes were in store. His wife explains that Whitcomb fell in love with La Grande, Ore., after attending a few games to watch one of his best friends play football for Eastern Oregon University. When the owners of Crisp Colors, an auto repair shop, were ready to retire after 29 years in business, Whitcomb decided to buy it and move his family and a few employees to Oregon. On July 1, 2016, Budco officially expanded to serve Union County. “This was a big change in business,” Courtney recalled. Double the number of employees, customers — and opportunities. Since July 2016, the shop has completed more than 200 custom paint jobs.

Change It’s an impressive record, especially considering the changes in the paint industry. Budco uses top-of-the-line PPG paint products along with its paint booth and highly experienced professionals to work on the vehicles and equipment. Budco has to grow and change with the industry. Employees have taken numerous classes provided by PPG to learn new techniques and understand new products. The process begins with prep work, such as sanding, body work and repairs. Next, the vehicle undergoes masking to protect areas that don’t need paint. Once that’s done, painters apply a primer coat, perform a final sanding of any blemishes and then apply the paint, a clear coat and a sealer. Continuity Not everything has changed. The homemade paint booth that Whitcomb and a few of his friends built one weekend is still standing and training in state-of-the-art equipment and techniques is ongoing. They still offer auto, truck and recreational vehicle body repair, specializing in sandblasting and custom painting. It’s not just a way to make a living, Courtney explained. Because they love what they’re doing, she says it doesn’t feel like work. They’re doing what they are passionate about, taking pride in producing exceptional results from using quality paint and products and providing top-notch customer service. The Whitcombs intend to continue producing the same, consistent quality of work in the future. And, just as Whitcomb once worked in his dad’s shop after school and on the weekends, now his children are frequent visitors at his shop. CEG

Construction Equipment Guide • Pacific Northwest Supplement • www.constructionequipmentguide.com • November 24, 2019 • Page 9

SEATTLE/TACOMA 253.722.5560 SPOKANE 509.534.1900 MT.VERNON 360.488.3948 PORTLAND 503.254.5100 BEND/PRINEVILLE 541.447.5293 EUGENE 541.342.7700

Triad, Link-Belt Contribute to Whidbey Island Project Ice Flow LLC dba Nichols Brothers Boat Builders (NBBB) of Freeland, Wash.’s new 250-ton (227-t) 298 Series 2 lattice crawler was put to the test quickly following its delivery to Whidbey Island in Puget Sound from Triad Machinery. NBBB is a custom vessel construction company established in 1964. The first major project on the books for its Link-Belt 298 Series 2 was lifting a 125,000 lb. (56,700 kg) pilot house for a new 100 ft. (30.4 m) by 40 ft. (12.1 m) hybrid tractor tug scheduled for early 2019 delivery to Baydelta Marine of San Francisco, Calif. The pilot house was lifted 47 ft. (14.3 m) in the air and placed on the main module or hull of the tug. For Operator Supervisor Kyle Statia and the team at NBBB, on-time delivery of a 100 ft. (30.4 m) long tug requires maneuvering in a tight shipyard environment and safely providing all necessary components for construction. Portable containments which measure up to 85 ft. (25.9 m) long by 50 ft. (15.2 m) wide are constantly moved around during all phases of the construction process. “We replaced a 1970’s era lattice crawler crane with this 298 and really like it for a lot of reasons but maybe most importantly is the offset main lifting sheaves,” said Kyle Statia,

For Operator Supervisor Kyle Statia and the team at NBBB, on-time delivery of a 100 ft. (30.4 m) long tug requires maneuvering in a tight shipyard environment and safely providing all necessary components for construction.

Nichols Bros. operator supervisor. “We really like the updated boom pendants on the 298, which allow for quick stowage and assembly, plus we don’t need to lube boom pendants anymore. The ability to meter individual hydraulic controls is also very handy,

like adjusting winch speed while booming down and holding the load.” For NBBB the offset main lifting head feature replaces a jib for movement of the portable containments and other components. see WHIDBEY page 10

“We are a really tight facility and

maneuverability for the 298 is great,” said Kyle Statia, Nichols Bros. operator supervisor.

Page 10 • November 24, 2019 • www.constructionequipmentguide.com • Pacific Northwest Supplement • Construction Equipment Guide

Climbing Lanes Require Bridges, Walls, Tons of Stone LANES from page 1

Still ahead are 80,000 tons of paving and placing approximately 100,000 yds. of stone embankment material. “That’s rock we place in areas that might have potential for landslides and stacks better and wears better than dirt would be,” Gage said. “There’s some specific stag-

ing and excavator methods we are doing because we know we have an active landslide that has been repaired with a buttress, and we are replacing it with a bigger and longer buttress for long-term stability.” There also is bridge work, including building retaining walls, and extending a box culvert no

longer used for cattle, but is a wildlife crossing under the freeway. Workers will extend it so it will be still available for wildlife to cross I-5. Two other key components include building a steel pile wall to replace an existing wall that is failing at a landslide and relocating a creek that is a direct tributary to the S. Umpqua River.

Kerr Contractors, Woodburn, Ore., began excavation work in May with 30-to-40-yd. off-road dump trucks hauling 18,000 truck loads of material.

There’s a long reach excavator, lots of different sized dozers and compactors. It’s a 3-mi. work area. They can have things staged on multiple parts of the project.

Equipment on the job includes Bell B60E off road haul trucks, with about 12 running per shift, articulated dump trucks, Cat D11 bulldozers and excavators “There’s a large menagerie of equipment,” Gage said. “There’s a long reach excavator, lots of different sized dozers and compactors. It’s a three-mile work area. They can have things staged on multiple parts of the project. “It’s become standard to use all the GPS automated controls to run the cuts in the grades. Pretty much stakeless. The machines pretty much run off ODOT provided

models. It was new 10 years ago and we were always troubleshooting, but we pretty much check all the finished projects, collect data points and compare to the model to make sure they are running the way we want.” The majority of earth work is expected to be completed this year, but it will be too late to pave. Paving will begin next spring when the contractor will move to the next stage of work. Winter weather conditions could have an impact on the schedule, but the project is currently on schedule to be completed by June 2021. CEG

Nichols Brothers Puts New Crane to Test on Whidbey Project WHIDBEY from page 9

“The tractor tug is one of seven projects we have ongoing and having the offset sheaves gives us that extra 3 to 4 feet of

clearance from the boom when doing tight lifts. This keeps everyone busy and keeps the 298 moving around our yard feeding everyone with materials,” said Statia.

For NBBB, the offset main lifting head feature replaces a jib for movement of the portable containments and other components.

“We are a really tight facility and maneuverability for the 298 is great. The LMI [load moment indicator] for setting limits is very easy to use. Because this is such a tight space the cameras and the great visibility for the operator gives everyone eyes on everything at all times. Another thing is the noise element, we’re positioned in a residential area for the most part — on either side of our property are homes — this crane is much quieter compared to the loud diesel engine we had previously,” said Statia. Delivery of the tractor tugboat was scheduled for first quarter 2019. “This is a start-to-finish construction agreement for us. The 298 has definitely increased our lifting capacity, it’s about double the capacity we had from its predecessor, 10 percent over our other large crane, and 70 percent more joint lifting capacity,” said Statia. For more information, visit www.linkbelt.com.

Tandem RTC-8050 cranes complete a lift at Nichols Bros. Boat Builders.

Construction Equipment Guide • Pacific Northwest Supplement • www.constructionequipmentguide.com • November 24, 2019 • Page 11

NORTHWESTERN PUBLISHING 2019 Issue# 26

Closing

Publishing

December 12

December 22

Page 12 • November 24, 2019 • www.constructionequipmentguide.com • Pacific Northwest Supplement • Construction Equipment Guide

Efficiency & High Performance.

The LH50M Industry material handler represents efficiency and high performance. The standard Liebherr regenerative power system assures maximum handling while, at the same time, achieving lower fuel consumption. Quiet operation with the highest payload is guaranteed by the large, sturdy undercarriage. The attachment of the machine is available in a variety of versions and is thus always optimally matched to your respective application.

18060 Des Moines Memorial Dr. Seattle, WA 98148 3909 NW Fruit Valley Rd Vancouver, WA 98660