An interview with Mike Hall of Rust Valley Restorers RUST TO RICHES INSIDE AKZONOBEL’S ONTARIO HQ VOLUME 11, ISSUE 1, 2024 l $7.95 l Canada Post Canadian Publications Mail Sales Product Agreement No. 40841632 l 86 John Street, Thornhill, ON L3T 1Y2 SPECIAL EDITION OF VISIT BODYWORXMAG.COM NEW OEM TECH—THAT YOU MIGHT HAVE TO FIX! Dayna Kohut of Roadrunners Auto is dishing up a dedication for auto repair COOKING UP PASSION

cycle times. Bringing you the best of 3M Science, all packed into the smartest, lightest spray gun in the world.

Faster cycle times. Precision performance. Cleans in seconds. Lightest in the world. Experience the smarter way to spray.

3M.ca/CollisionSprayGun

3M and 3M Science. Applied to Life. are trademarks of 3M. Used under license in Canada. © 2020, 3M. All rights reserved. 2010-18643 E

Faster cycle times. Precision performance. Cleans in seconds. Lightest in the world.

3M.ca/CollisionSprayGun

3M and 3M Science. Applied to Life. are trademarks of 3M. Used under license in Canada. © 2020, 3M. All rights reserved. 2010-18643 E

cleanup, faster changeovers and faster

CONTENTS BW11#1 2024 | BODYWORX PROFESSIONAL 3 >>> An interview with Mike Hall of Rust Valley Restorers RUST TO RICHES INSIDE AKZONOBEL’S ONTARIO HQ SPECIAL EDITION OF VISIT BODYWORXMAG.COM NEW OEM TECH—THAT YOU MIGHT HAVE TO FIX! Dayna Kohut of Roadrunners Auto is dishing up a dedication for auto repair COOKING UP PASSION For Dayna Kohut of Roadrunners Auto in Ashern, Manitoba, a passion for the automotive industry was instead first forged in professional kitchen fires. From culinary school to collision repair, we sat down with Dayna for all the details. 12 REGULARS 06 NEWS-IN-BRIEF Stay Informed with bite-sized Industry updates. COLUMNS 04 PUBLISHER’S PAGE by Darryl Simmons 34 YOUNG GUNS by Bill Speed 38 FINAL DETAIL by Allison Rogers CONTENTS bodyworxmag.com REACH YOUR TARGET AUDIENCE PROMOTE YOUR BUSINESS GAIN VISIBILITY An exclusive interview with Canadian History Channel star Mike Hall, of Rust Valley Restorers 26 From EV air skirts to next-level sound systems—the features you’ll have to fix in the future are quite astounding. 22 ADVERTISE NOW FOR MAXIMUM IMPACT!

UPPING THE GAME

This industry has plenty of people that love a good challenge. We all know what great challenges we find in the cars of today—there’s no doubt in the phrase “you learn something new every day!” when you work in collision repair.

Alas, not all of these remarkable individuals find themselves in the right places. Some of you find your thirst for knowledge stifled by the day-in and day-out procedures, your brain thirsting for new knowledge and challenges. If you have a superior that wants you on the shop floor at all times, never giving

Good shops can’t afford to lose great talent.

you any chance to up your capabilities and pursue new training options, you are in the wrong place. Worse, even—if they fail to provide training opportunities to anyone on the team…run. Those types of facilities won’t survive much longer in this ever-evolving market.

I know, by the simple fact that you are reading these words right now, that you are capable of much, much more than what you’re doing right now. Even if you feel like you’re at the top of your game, there is always room to upskill. More skills…more money, in many cases. Why wouldn’t you want to seize the opportunity?!

On the flip side, there are countless professional shop owners and managers in our industry that remain dedicated to repairs of the highest standard. This means they are consistently providing training opportunities to their teams; hands-on sessions in modern techniques, ensuring that their teams stay among the most talented in the nation.

There is no shortage of opportunities out there—courses, programs, one-on-one consulting—all available via esteemed training facilities established and equipped by highly acclaimed professional institutions in our space. 3M just opened an impressive training facility in Minnesota—not a far trek for Western Canadians—while Fix Network has three sites dedicated to training across Canada. Volkswagen and the Canadian Welding Bureau teamed up to create the Canadian Collision Repair Academy (CCRA) in the Greater Toronto Area, and there are dozens more industry partners that house training facilities within their headquarters. Not to mention one-on-one opportunities with a long, long list of industry pros… need I go on?

So, if you were not aware, now you are. If you are the employee your boss keeps on the floor, you need not think hard to realize how valuable you are. Good shops can’t afford to lose great talent; so they treat them well. They train them up—unafraid of whether such maneuvers will send them to a “better” role—and make sure they have all they need to be the best they can be.

If you want something, a new skill, a new specialty, then ask for it. The worst answer you can get is “no.”

4 BODYWORXMAG.COM | BODYWORX PROFESSIONAL 4 BODYWORXMAG.COM | BODYWORX PROFESSIONAL PUBLISHER’S PAGE >>> BO DY WO RX PR OFESSIONAL THE VOICE OF COLLISION REPAIR TECHS & PAINTERS SUBSCRIPTION One-year $25 / Student Discount is 10% Bodyworx Professional ™ is published quarterly, and is dedicated to serving the professionals of the collision repair industry. It is published by Media Matters Inc. Material in BodyworxProfessional™ may not be reproduced in any form without written consent from the publisher. The publisher reserves the right to refuse any advertising and disclaims all responsibilities for claims or statements made by its advertisers or independent columnists. All facts, opinions, statements appearing in this publication are those of the writers and editors themselves, and are in no way to be construed as statements, positions or endorsements by the publisher. PRINTED IN CANADA ISSN 1707-6072 CANADA POST CANADIAN PUBLICATIONS MAIL SALES PRODUCT AGREEMENT No. 40841632 RETURN POSTAGE GUARANTEED Send change of address notices and undeliverable copies to: 317 Reid St., Peterborough ON K9J 3R2 “We acknowledge the financial support of the Government of Canada.” Bodyworx Professional is published by Media Matters Inc., publishers of: SATISFY YOUR THIRST FOR MORE BY DARRYL SIMMONS PUBLISHER Darryl Simmons publisher@collisionrepairmag.com ASSOCIATE PUBLISHER Orest Tkaczuk | orest@mediamatters.ca EDITOR Allison Rogers | allison@mediamatters.ca ASSISTANT EDITOR Sarah Perkins | sarah@mediamatters.ca ART DIRECTOR Yvonne Maschke | yvonne@mediamatters.ca VP OF INDUSTRY RELATIONS & ADVERTISING Gloria Mann 647.998.5677 | gd.mann@rogers.com DIRECTOR OF BUSINESS SOLUTIONS Ellen Smith 416.312.7446 | ellen@mediamatters.ca INDUSTRY RELATIONS ASSISTANT Wanja Mann 647.998.5677 wanjamann1@gmail.com DIGITAL OPERATIONS MANAGER Cassie Doyle | cassie@mediamatters.ca MARKETING COORDINATOR William Simmons | william@mediamatters.ca CONTRIBUTORS Bill Speed

VOLUME 11, ISSUE 1, 2024

ELEVATE YOUR BRAND

Partner with us to unlock the full potential of your advertising campaign and position your brand for success in the competitive marketplace. Join us in shaping the conversation and leave a lasting impression on our readership. Contact us at Media Matters today to explore the endless possibilities of advertising in our magazines.

further details,

visit mediamatters.ca

Advertise with Media Matters Today! For

please

INDUSTRY

ONE-COAT WONDER

BASF’s premium refinish brand RM has launched what it calls the first-ever single-coat clear, RMC1000. The product was created to meet customer demands for speed and efficiency, reducing cycle times and providing superior sag resistance. According to BASF, RMC1000 can be applied wet in one-layer and dried at 140F° for 30 minutes. Compared to other, 1.5-layer coats on the market, there is no flash-off time and no need for a second coat, saving customers at least 10 minutes of time, reportedly. With no flash-off time or application of a second coat, [shops] can increase daily cycles, says BASF, unlocking up to $500,000 in additional revenue per year. For example, if a customer uses a competitive 1.5 coat clear with an average booth run time of 90 minutes, for four cycles per day, using an average RO of $3,750, their income would be $315,000 per month, per booth. If that same customer swapped their 1.5 coat clear with RMC1000, the time savings could allow them to run up to 4.6 cycles per day.

AMERICAN ACQUISITION

SATA, a global leader in the field of liquid paint application equipment, is proud to announce that a joint agreement has been signed for Dan-Am Company to be acquired by SATA USA, a subsidiary of SATA GmbH & Co. KG in Kornwestheim, Germany. In its press release, SATA noted that, after years of successful cooperation, this acquisition will represent a significant milestone in the company’s strategic growth initiatives to strengthen its presence in the whole North American market and expand its product portfolio. Dan-Am Company is the exclusive distributor of SATA equipment in the U.S. and Puerto Rico. SATA said it is committed to making the transition process smooth, and will maintain Dan-Am’s existing relationships with customers, suppliers and employees.

IN THE HEADLIGHTS >>> 6 BODYWORXMAG.COM | BODYWORX PROFESSIONAL

18.0

According to Mike Carlos Wolf, CSO of SATA, the acquisition “will allow [both companies] to continue to provide our industry partners and customers in the USA and Puerto Rico with the best equipment and outstanding service they know and love from SATA and Dan-Am, now and in the future.”

INDUSTRY

OFF ROAD RESTORATION

Southern Alberta automotive restorers recently received second place at the Good Guys automotive shows in Washington and California for their 1940 Ford pickup truck. Lyle Vass, owner and lead restorer outlined that the restoration project took six years to complete and required talented specialists from all over Southern Alberta.The build was financed by Wayne McLachlan, chief instructor at the Alberta Motor Association. McLachlan also found some of the main parts used in the build such as sections from two old Ford trucks in Oregon and delivered them to Vass’ shop near Strathmore, Alta., in 2016. Vass said that he initially envisioned the project because he wanted something nice to take camping and over six years, he ended up spending well over $500,000.

“It’s the biggest build that I’ve had the opportunity to do,” said Vass in reference to the restored 1940 Ford pickup truck. “I’m hoping that we’ll get to do more now that this truck is finished.”

BW11#1 2024 | BODYWORX PROFESSIONAL 7 FINAL DETAIL IN THE HEADLIGHTS >>>

accuvision-3D.com arslanauto.com Contact your distributor or Call (800) 465-8575 AUTOMATIC, INVERTER RESISTANCE SPOT WELDERS 3664 & 3680 Smart Spot welder Automatic setting of parameters Water cooled for hi productivity 22 ft. long cable, No EMF emissions Output 14,000 Amps, 450 daN or 700 daN Input 50 Amps, 208-240V, 3 Phase Approved by OEMs 3680 model wi-Fi, enabled for factory Updates and diagnostics #60-TM736 ACCUWELD® SINGLE TORCH PULSE MIG WELDER #60-TM742 ACCUWELD® 2 TORCH PULSE MIG WELDER #60-TM750 ACCUWELD® ARC DENT PULLER SYSTEM #60-TM743 ACCUWELD®3 TORCH PULSE MIG WELDER EXCEPTIONAL PROMOTION!

TRAINING

PULLING NEW SKILLS

CamAuto Pro recently hosted an open house at its Quebec training facility, where industry experts Gene Fetty and Charles Aoun conducted a comprehensive training session on paintless dent repair (PDR) and glue pull repair (GPR). The training session was divided into two parts, with Fetty leading the PDR portion and Aoun taking charge of the GPR segment. Participants learned about different tools, dent assessment methods and hands-on repair techniques as well as a deeper understanding of how to use GPR equipment for subsurface imaging and detection. At the end of the training session, three groups of enthusiastic students successfully completed the courses and received qualification certificates.

IN THE HEADLIGHTS >>> 8 BODYWORXMAG.COM | BODYWORX PROFESSIONAL

The training session was divided into two parts, with Fetty leading the PDR portion and Aoun taking charge of the GPR segment.

Powered by Collision Repair Unlock your potential in the automotive industry—explore rewarding career opportunities and find your dream job today! ARE YOU INTERESTED IN PURSUING A CAREER IN THE COLLISION REPAIR INDUSTRY? Discover Employment Opportunities Today

CAN YOU BELIEVE THIS?!

A COLOURFUL CANVAS

Presented on December 6 at the Art Basel in Miami Beach, this custom Revuelto took Lamborghini 435 hours to hand paint. Sibling vehicle to the Huracan Sterrato Opera Unica which debuted in August and took the automaker 370 hours to complete—the equivalent of working 15 days straight—the Revuelto instead took the equivalent of 18 straight working days for the exterior alone. Unlike its predecessor, the Revuelto incorporates purple and black—specifically viola passifae and nero helene—along with streaks of red, blue and other colours. Made to celebrate Lamborghini’s 60th anniversary, the Reveulto has already been sold to a collector for more than one million dollars.

IN THE HEADLIGHTS >>> 10 BODYWORXMAG.COM | BODYWORX PROFESSIONAL

Sibling to the Huracan Sterrato Opera Unica, this custom Revuelto took Lamborghini 435 hours to hand paint. The Huracan Sterrato Opera Unica which debuted in August and took the automaker 370 hours to complete.

SHOOTING FOR THE SKY

Samson Sky, an aircraft manufacturer based out of Redmond, Oregon was recently granted a patent by the European Union for a flying sports car known as the Switchblade. To fly the Switchblade, the wings on the vehicle spread out and the tail extends in fewer than three minutes, the patent claims. The Switchblade’s first practice flight was recently held at Grant County Airport in Moses Lake, Washington. Here, the prototype test vehicle took off and flew at an altitude of 500 feet for nearly six minutes before successfully landing. The vehicle-plane combo can be registered as an Experimental Category Aircraft and as a custom motorcycle or kit car on the ground, depending on local regulations.

The vehicle-turnedplane can travel at speeds up to 200 mph and up to 13,000 feet and requires a landing distance of 700 feet. To fly the vehicle, owners will also need to have their private pilot certification.

Open Dialogue Webinar Series

Tune in - it’s just not the same without you!

Scan here to sign up for our next webinar, or to watch ones you may have missed.

To register for upcoming webinars visit www.collisionrepairmag.com/open-dialogue-webinars/

BW11#1 2024 | BODYWORX PROFESSIONAL 11 FINAL DETAIL IN THE HEADLIGHTS >>>

CAN YOU BELIEVE THIS?!

FUSING

passions

DAYNA KOHUT HAS BEEN COOKING UP A LOVE OF CARS SINCE HER DAYS IN THE CULINARY ARTS

12 BODYWORXMAG.COM | BODYWORX PROFESSIONAL ON THE COVER >>>

From Left to Right: Leah McDonald, Dayna Kohut, Kaydence Tindall. The female techs at the Ashern location.

BY SARAH PERKINS

BY SARAH PERKINS

To succeed in the trades is to be consistently developing a set of specific skills. From collision repair to craftworks, each trade requires its own techniques, training, knowledge, and body of tools in order to fuel an inherent drive for creation. However, while the demands of each trade may be distinct, the sense of passion that they require is familiar to all who work in them.

For Dayna Kohut of Roadrunners Auto in Ashern, Manitoba, a passion for the automotive industry was instead first developed while working in the culinary industry. Here, an initial love of the precision and hands-on projects found in professional kitchens transitioned into a love for all things car related.

When speaking with Bodyworx magazine, Dayna described how she had originally never considered working in the automotive industry. Despite her parents, Jeff and Andrea Dyck, having owned Roadrunners Auto locations in both Ashern—the autobody shop—and Fairford—a mechanical and auto recycler—in rural Manitoba for more than 30 years, in 2013, Dayna instead graduated high school and attended Red River College for their twoyear culinary arts program.

Following her graduation from the program, Dayna continued working as a chef in the Winnipeg area until 2017 when she decided to make a radical career change.

“I enjoyed being a chef. I loved the hands-on work that the role demanded, but I ultimately decided that I didn’t like the hours. It’s a position that can demand a lot of your time. In 2017, I decided to move back to Ashern and my parents’ shop and began helping out as an office assistant working alongside my mother. I had always liked cars, and working on them also requires a lot of hands-on work, so it seemed like a good fit.”

From here, Dayna moved up to doing estimation work, something she feels has been instrumental in her ongoing autobody technician training.

“Doing estimation work and the experiences I gained from this helped give me a very good understanding of vehicles and all their parts and components. Even for my autobody schooling, it helped give me a head start on knowing where parts go and how they can break.”

Dayna performed estimation work at the front of the shop for three years and received her I-CAR platinum in estimating before her

passion for cars carried her even deeper into the heart of repairs. After training her sister Justine Dyck to take over the job, she started working in the back of the shop alongside her father.

Jeff Dyck is a red seal autobody technician and today, Dayna is also working on getting her repairer certifications. In 2023, she took her Level 1 autobody course at Red River College and she is currently enrolled to begin her Level 2 classes in the fall of this year. The Red River college autobody and paint program is a four-level course that offers students with both a red seal as an automotive painter and autobody repairer.

“There’s lots to learn of course,” Dayna told Bodyworx, “but every day you’re working on something different, and I love that about this job. Some jobs may be challenging but I find it really satisfying when I can look back on the finished project.”

Currently, Dayna’s latest project is restoring a 1970 Roadrunner, an unintentional namesake to her parents’ shop that she originally received from a Rust Valley Restorers auction and then drove the almost 20 hours to collect from Tappen, British Columbia where she received

ON THE COVER >>> BW11#1 2024 | BODYWORX PROFESSIONAL 13

Jeff Dyck, Dayna Kohut, and Mike Hall from Rust Valley Restorers picking up the 1970 Roadrunner in Tappen, British Columbia.

14 BODYWORXMAG.COM | BODYWORX PROFESSIONAL ON THE COVER >>>

Dayna in Tappen, British Columbia, picking up the 1970 Roadrunner from the Rust Valley shop.

“There’s lots to learn of course, but every day you’re working on something different, and I love that about this job. Some jobs may be challenging but I find it really satisfying when I can look back on the finished project.”

— DAYNA KOHUT, ROADRUNNERS AUTO

Hall’s car collection.

On top of loving cars, Dayna especially loves fixing old cars.

“It can be an expensive hobby to have, but I love working on the project cars. Once the Roadrunner is complete, I would love to have another car to work on in the future. I check auction sites all the time.”

The Roadrunner, which Dayna hopes to finish restoring sometime after the summer, has already been welded, sandblasted and seam sealed with the underside having been painted with an epoxy primer and then a tinted coat of gravel guard to help keep it protected underneath. The engine bay and trunk have also been painted with an epoxy primer as well as base coat and clear coat.

Alongside the body of the vehicle, the original engine, a 383-magnum big block, has been rebuilt and will be reinstalled in the car once the body work is completed and the transmission has been upgraded to a five-speed manual Tremec TKX.

ON THE COVER >>> BW11#1 2024 | BODYWORX PROFESSIONAL 15

the vehicle alongside a tour of Mike

Dayna performing sanding on the 1970 Roadrunner at the Ashern shop.

Currently, Dayna is working on sandblasting and perfecting the bodywork on the exterior panels to prep them for a paint coat of the vehicle’s original “vitamin c” orange and “burnt orange” colours.

When the Roadrunner is finally restored, Dayna is confident that it will be one of her biggest accomplishments in the industry so far and she is very proud of the work she has done.

Alongside this pride is also love for the Roadrunners Auto Ashern team. While the automotive industry has traditionally been a male-dominated space, the Dyck’s shop has a female-forward touch.

Working with Dayna, her mother and sister, are also two other female apprentices; one with Level 3 training and the other going for her first level in the spring.

When asked by Bodyworx on what it’s like to be an up-and-coming woman in the industry, Dayna highlighted how wonderful it is to be surrounded by a community of other women who are learning and growing together.

16 BODYWORXMAG.COM | BODYWORX PROFESSIONAL ON THE COVER >>>

“I think we all have a really good eye for detail. We’re a small team, but that just means there’s more room for growth and variety.”

In the future, Dayna hopes to continue learning alongside the Roadrunners Auto team by continuing to work towards her Red Seal technician levels and embracing each day with ready hands and an open mind.

While she may not have originally planned on working in the automotive industry, Dayna is confident that a foundation of passion has helped her lay the groundwork for where she wants to be.

“I love painting. I love welding. I just love the whole process of working on a vehicle.”

In this way, whether working in the culinary arts or the automotive industry, Dayna’s love coupled with a sense of hardwork and dedication shows that when you’re a part of the trades, you’re also a part of a harmonious blend of craftsmanship, innovation and a shared passion for excellence.

ON THE COVER >>> BW11#1 2024 | BODYWORX PROFESSIONAL 17

Dayna scuffing the engine bay of the 1970 Roadrunner at the Ashern shop.

CRITICAL CONNECTIONS

CENTENNIAL COLLEGE HOSTS HIRING EVENT TO CONNECT STUDENTS WITH POTENTIAL EMPLOYERS

On March 6, the School of Transportation at Centennial College hosted a hiring event in Toronto, Ontario to assist employers and students in connecting for future employment opportunities.

Specifically, the event was intended to help students reach out to potential employers and establish summer co-op opportunities as well as graduate employment for diploma students in the Automotive Service Technician, Parts and Service and Autobody programs.

The event saw approximately 103 co-op students and 150 graduate students and alumni in attendance with 38 vendors from across the industry there for networking.

18 BODYWORXMAG.COM | BODYWORX PROFESSIONAL OPPORTUNITIES >>>

PHOTOS BY MIGUEL HORTIGUELA

VENDORS INCLUDED:

427 Auto Collision

Pfaff Automotive Partners

Dilawri

CCS

Performance Auto Group

Car Hub North York

Car Hub Caledon Chrysler

Driver Autogroup

Penske Truck Leasing

UPS Canada

Erin Park Lexus Toyota

WEINS Auto Group

Ontario Chrysler

GTA Transmission Repair Corp

Blackstock Ford

Airport Kia

Changes On The Fly Inc.

Bramgate Automotive Inc.

Dom’s European Auto Repair

The Humberview Group

Gyro Auto Group

Auto Canada

AutoTec Careers Inc.

Lockhart Auto Mart

Whitby Collision and Glass + Owasco RV

Zenetec Collision Centres Inc.

Leggat Auto Group

HR4

Gus Brown Hyundai

Canada Auto Solutions

Revell Ford Lincoln

Multimatic Niche Vehicles

East Court Ford Lincoln

Master Mechanic

Mister Transmission International

Vaughan Steeles Tirecraft

OK Tire Etobicoke

Formula Honda

OPPORTUNITIES >>> BW11#1 2024 | BODYWORX PROFESSIONAL 19

20 BODYWORXMAG.COM | BODYWORX PROFESSIONAL

Bodyworx Professional magazine reached out to Shawna Barnes, Cooperative Education Advisor & College Professor who stated that the event’s highlights were “seeing employers and students coming together, networking, [performing] on the spot interviews, and all of the collaboration between the vendors and the up-and-coming technicians.”

When asked why events like the School of Transportation’s hiring event are important, Barnes reported that “this event is important because we are already experiencing a labor shortage and so, it is important to recognize the need to foster and grow new talent through programs like Centennial’s co-op program. Taking on new apprentices is critical for the industry.”

Check out the flickr photo album of the event here.

OPPORTUNITIES >>> BW11#1 2024 | BODYWORX PROFESSIONAL 21

INNOVATIVE ODDITIES

EXPLORING THE ECCENTRICITIES OF MODERN AUTOMOTIVE TECHNOLOGY

WBY SARAH PERKINS

ith technological advancements increasingly seeming to defy the limits of the imagination, the automotive industry frequently stands at the forefront of innovation. Just as frequently, however, OEMs offer an array of peculiar technology that blurs the lines between science fiction and reality. From vehicles that turn the driving experience into a musical to electric vehicles that resist drag, read below to see the sometimes wonderful, sometimes wacky innovations that manufacturers hope will make it into future vehicles (and more importantly, hope that repairers will be able to fix).

22 BODYWORXMAG.COM | BODYWORX PROFESSIONAL INDUSTRY UPDATES >>>

CRUISING IN HARMONY

Recently, Mercedes-Benz in partnership with musician and entrepreneur, will.i.am, have developed a software to help take the music-driving experience to a whole new level.

Showcased at the 2024 Consumer Electronics Show (CES) in Las Vegas, Nevada, the MBUX Sound Drive aims to put drivers into the conductor’s seat by using the movements and inputs of the vehicle to augment the way a song is played inside the car’s cabin.

Specifically, MBUX Sound Drive works by using the sensors found on any vehicle—the accelerator, accelerometer, gyros, suspension, steering wheel and brake—and turns those inputs, as they occur in real time, into ways to compose, rearrange and create music being played through the vehicle’s sound system.

When the accelerator is pushed down, that turns up the bass line in the music playing; turning the steering wheel will make the synthesizers come to life; and pressing down on the brake pedal will cause the reverb to plug in.

Like a DJ spinning a new track, drivers using the MBUX Sound Drive system can create remixed versions of songs just by spinning the steering wheel in place of a turntable.

INDUSTRY UPDATES >>> BW11#1 2024 | BODYWORX PROFESSIONAL 23

Recently, Mercedes-Benz in partnership with musician and entrepreneur, will.i.am, have developed a software to help take the music-driving experience to a whole new level.

While the Active Air Skirt is still at a patent stage, once it goes through additional durability and performance testing, Hyundai plans to consider it for mass production.

ACTIVATING AIR

Another example of novel technology that hopes to someday make its way to the production stage is Hyundai Motor Company and Kia Corporation’s patent application for an Active Air Skirt technology—a system designed to improve electric vehicle range and stability by reducing aerodynamic drag at higher speeds.

According to the patent, the Active Air Skirt is installed between the front bumper and front wheels and is not visible during normal operations. The technology functions by directing the flow of air entering a vehicle through the lower part of the front bumper.

At speeds above 80 km per hour—when aerodynamic resistance becomes greater than air resistance—the system would engage and disengage again when the vehicle drops below 70 km per hour.

The technology can also operate at speeds above 200 km per hour. Hyundai says this is possible because of the use of rubber material on the lower section of vehicles which improves durability and reduces the risk of external objects damaging parts at higher speeds.

Hyundai has tested this technology in the Genesis GV60 and found it reduces the drag coefficient (Cd) in the vehicle by 0.008 (Cd), a 2.8 percent improvement or roughly six extra kilometres added at a full charge.

The technology also works to increase the downforce on the vehicle which improves traction, reduces wind noise and increases stability at higher speeds.

While the Active Air Skirt is still at a patent stage, once it goes through additional durability and performance testing, Hyundai plans to consider it for mass production.

24 BODYWORXMAG.COM | BODYWORX PROFESSIONAL INDUSTRY UPDATES >>>

Written by professionals. For professionals. Bodyworx Professional - the magazine written exclusively for professional autobody technicians. Celebrate and take pride in being an autobody technician; read about accomplishments, new releases, new techniques, and most importantly, feel the excitement that comes with being a professional autobody technician. Industry Insights Made possible with the support of Contact your sales representative today! Darryl Simmons 647.409.7070 darryl@mediamatters.ca Gloria Mann 647.998.5677 gd.mann@rogers.com Ellen Smith 416.312.7446 ellen@mediamatters.ca Wanja Mann 647.998-5677 wanjamann1@gmail.com

UPDATES FROM RUST VALLEY

BY ALLISON ROGERS

BY ALLISON ROGERS

If you look at Mike Hall, you’d think he was made for the silver screen. If you stick around and watch him work, you’d be certain of it.

With a background in rock blasting and a lifelong love for cars, Mike’s journey into car restoration and the eventual creation of the hit TV series Rust Valley Restorers is a captivating tale. With his roots firmly planted in the scenic Rust Valley near Tappen, British Columbia, Mike has become a household name among car fanatics, captivating audiences across the nation with his car restoration abilities.

In this interview, we delve into his transition from rock blasting to car restoration, the origins of the Rust Valley Restorers TV show, his selection process for builds and exciting projects on the horizon.

Bodyworx Professional: You previously had your own rock blasting/construction business. How did you end up in car restoration?

Mike Hall: I’ve always loved cars and have collected them my whole life. One of my first and favourite cars was a 1961 Sunbeam.

When I was doing rock blasting, I’d work ten months out of the year and, during the two months I had off, it was too cold in B.C. to do anything. So that’s how I ended up with 400 cars on my lot.

BWX: How did the Rust Valley Restorers TV show come to be?

MH: It was supposed to be a show about rock scaling! After some research, the network found out there was a ton of red tape and it would be a massive liability. The producers found out I had a collection of 400 old cars—that’s when the show theme changed to car restoration.

EXCLUSIVE INTERVIEW >>> BW11#1 2024 | BODYWORX PROFESSIONAL 27

Mike Hall and co-star Avery Shoaf said they were shocked at how many SEMA-goers recognized them from their TV show.

BWX: How do you choose your builds?

MH: If it’s going to be featured on the show, the build has to have a story. One that sticks with me is from Season 4 of the show when we built a 1964 Parisienne for a family with seven kids. We have a saying, on the show: No sh*t leaves the shop. When we dropped it off, all the kids were wearing custom tee shirts; each with one word of that slogan on the back. It was an awesome and heartwarming experience all in one.

Another part that goes into selecting our builds is making sure we can actually get the parts to make the dream come true. That’s why our partnership with eBay Motors is so handy. We’ve helped plenty of customers bring home their dream car with the help of the eBay Motors platform.

BWX: You held an auction in September 2022, where you listed all 400 cars up for sale. After the auction, how many cars do you have left?

MH: I sold all except for 50…but now I’m back up to 100 cars. I can’t stop.

BWX: Are you working on any exciting projects you can share?

MH: Well, there’s a lot of stuff we’re working on that I can’t share because it’s on the next season of Rust Valley.

I can tell you that we’re working on a 1970 Dodge Coronet R/T. Right now it’s just a fender tag and the VIN—but there were only 400 of them built. It’ll be painted Sublime Green.

We also have another five or six cars we want built by spring, so there’s a lot to work on.

SHIFT GEARS TOWARDS A GREENER FUTURE

LEARN MORE AT CANADIANRECYCLER.CA 28 BODYWORXMAG.COM | BODYWORX PROFESSIONAL EXCLUSIVE INTERVIEW >>>

“It was our first time at SEMA, and we wondered if anyone would even know who we were. People knew. We wanted to see the whole show, but we couldn’t make it more than ten steps without someone stopping for a picture and a chat.”

— MIKE HALL, RUST VALLEY RESTORERS

BONUS QUESTION!

Q: What would you say to someone who wants to do car restoration as a

A: To succeed in this craft, you need to be highly committed. It’s not easy—car restorations are expensive. Whatever your estimate is, you’ll need to double it. As you peel back the layers of a build, you’ll continuously find more damage— things add up. That’s why I say you should never give a customer an estimate. An estimate is a best guess—a quote is what you will do the restoration for. But, if you’re serious about restoring cars, learn to weld! Learn the basics. Finally, the best bodywork advice I’ve ever gotten: if it’s a high point, beat it down!

You can stay updated on build progress by following the Rust Bros. on Instagram at @rustbrosrestos.

BW11#1 2024 | Join the CARSTAR team and drive your career forward! We’re looking for passionate individuals to join our dynamic team in the exciting world of collision repair. Visit CARSTARjobs.ca to apply now.

positions are for independently owned and operated locations. All employment related decisions including: hiring, terminating, scheduling, and rate of pay are determined by the independent franchise owner.*

*These

career?

Bodyworx Professional editor Allison Rogers with Mike Hall of Rust Valley Restorers at SEMA 2023.

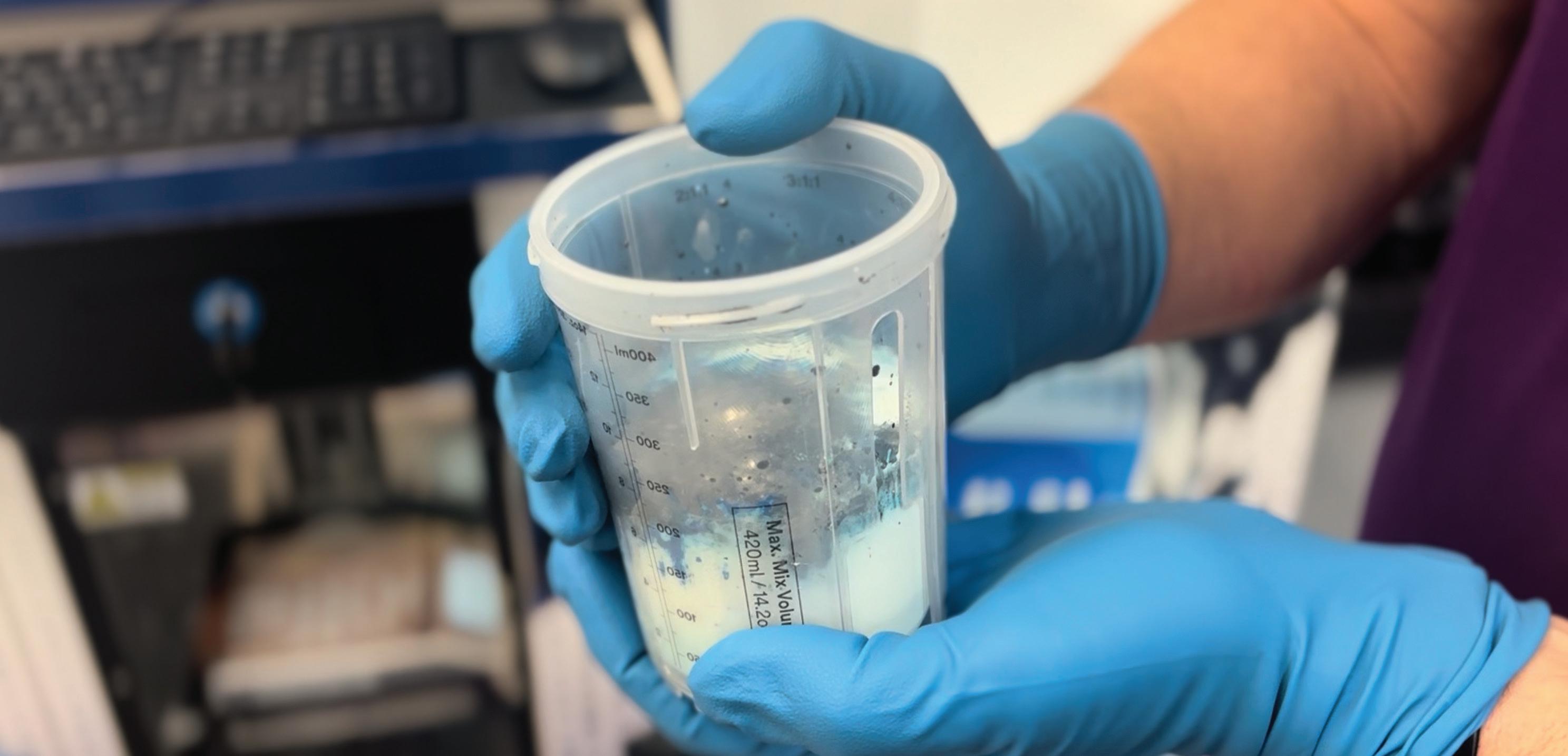

MODERN MIXOLOGY

ROBOTIC REFINISHING PROCESSES, RADAR-SAFE REPAIRS AND MORE AT AKZONOBEL OPEN HOUSE

BY ALLISON ROGERS

Dozens of Canadian industry reps were at the AkzoNobel Ontario headquarters and training facility in early February as the coatings company hosted an Open House for its valued partners and customers.

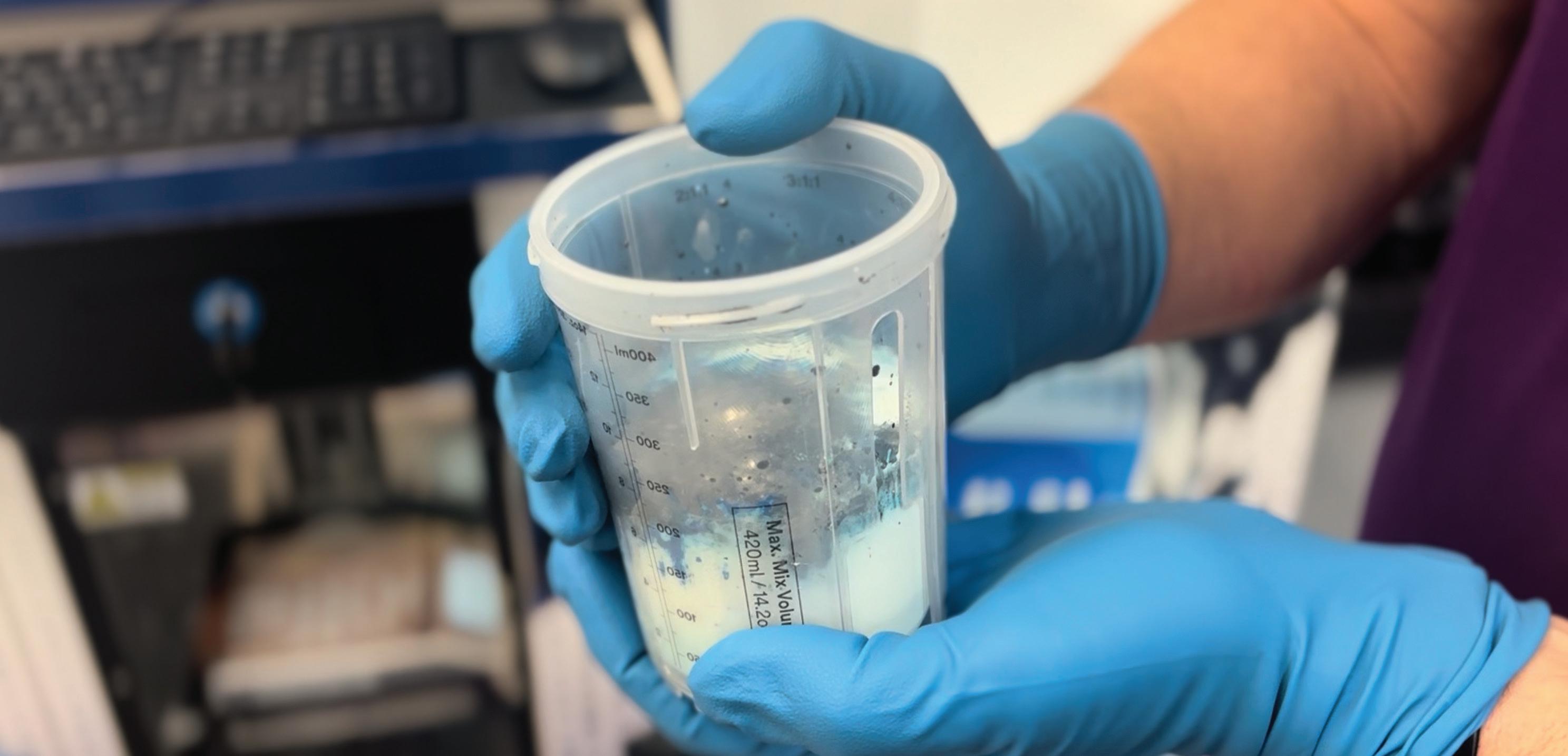

The main feature of the day was AkzoNobel’s brand-new AC100 automated paint dispensing machine, created with Santint, which, according to AkzoNobel technical trainer Dave Woolley, allows anyone in the bodyshop to mix a perfect cup of paint.

“Painters, of course, but customer service reps, technicians, apprentices—anyone, really. And it takes about five minutes.”

“It saves a ton of time for the painter. And, if you can get one more cycle in per day because of this tool, then that’s money on the table.”

30 BODYWORXMAG.COM | BODYWORX PROFESSIONAL PAINTER’S CORNER

In under five minutes, the machine produced an accurately measured cup of paint in the desired shade.

Attendees, which included shop representatives, insurance partners, OEM reps, networks and more, were also given the option to sit in on a training session led by Brad Kruhlak, technical trainer, who delved into the specifics of refinishing radar-enabled cars.

One interesting fact noted by Kruhlak was that Mercedes-Benz has recently taken up the strategy of housing its radar sensors in non-painted parts, saving the technician quite the headache when deciphering what can and cannot be painted during a repair.

One of the most intriguing parts of the day was a room dedicated to brainstorming potential solutions to the skills shortage. AkzoNobel posed questions like, “When should the industry begin engaging with youth?” and “What is not working when it comes to engaging our youth?” and attendees were invited to write their thoughts on the board.

PAINTER’S CORNER >>> BW11#1 2024 | BODYWORX PROFESSIONAL 31

Technical trainer Brad Kruhlak educates attendees on refinishing ADAS vehicles with radar sensors. Did you know that the reason you’ll never see a reflective-coated plane is because those types of finishes interfere with radar sensors?

32 BODYWORXMAG.COM | BODYWORX PROFESSIONAL EXCLUSIVE INTERVIEW >>>

A Coat Selected Canadian services manager John Cox delivers a demonstration on Carbeat, AkzoNobel’s touch-screen enabled visual shop management tool.

Special thanks to AkzoNobel content manager Sue Jaszkowski for the invite. Pictured here, left, with Ellen Smith of Media Matters.

AkzoNobel’s Canadian headquarters is located in Etobicoke, Ontario, at 110 Woodbine Downs Boulevard.

REFINISHING RADAR » FAST FACTS

• Automotive OEMs use more radar sensors today, moving from 22 GHz to 77 GHz. Radars are used to help detect surroundings, other automobiles and other objects up to 200 metres away.

•Repair methods can differ from OEM to OEM; even within an OEM, different models can have different procedures.

• The use of primer and body filler is, in general terms, not allowed in the radar at zone. Welding and the use of repair staples is most definitely not allowed within repair methods issued by OEMs.

• Dependent on the colour and other factors, some OEMs will give guidelines dictating what is possible to refinish up to three times. This is only possible when the existing OEM finish has not been damaged or sanded through preparation. Only approved colours can be refinished.

• On most OEMs, there is strict guidance on the layer thickness for each refinish material applied. This includes adhesion primers, primer filler, base coat and clear coat.

“It’ll show us here exactly what toner it’s loading in, and tells us what it’s going to do,” Dave Woolley told onlookers during a Santint AC100 demonstration session.

INDUSTRY INSIGHTS >>> BW11#1 2024 | BODYWORX PROFESSIONAL 33

Located just outside of Toronto, AkzoNobel’s Ontario headquarters offers a sprawling space for training up-and-coming and established industry talent alike.

WHERE HAVE ALL THE TECHNICIANS GONE?

AFTER NEARLY 30 YEARS IN TEACHING, I’VE NEVER SEEN THE SITUATION MORE DIRE

BY BILL SPEED

As a retired high school autobody teacher, I spent my entire career trying to promote the automotive collision industry to my students by giving them real life experiences. These experiences varied from real world projects on live vehicles, field trips, co-op opportunities and competing in skills competitions at the local, provincial, and national levels.

Of my students that were interested in a career in our industry, I guaranteed that I would do my very best to find a job for them. For those that did find roles, they are currently working in the industry and are doing quite well. To my knowledge at least, since many students don’t stay in touch. I have about a dozen former students working in the trade. I have a couple that did it for a few years and then transferred over to the construction industry. I retired in 2017, but I still have former students contacting me if they are looking to move or use me as a sounding board for their concerns.

In my 28-year teaching career, I can only recall one or two times where shops had called the school looking for young people to train as technicians. This is over and above those progressive shops that were involved in the co-op program.

During my time in the Toronto District School Board, I saw eight autobody programs shut down. As chair of the Skills Ontario Auto Body competition, I have seen many school boards stop competing in the autobody category because they no longer had a program running to support a competitor. The excuses I have heard for closing a program usually came down to how to deal with isocyanates in the paint products.

The federal and provincial governments have tried throwing money at the problem, but autobody repair is not one of the skilled trades that is getting any of this influx, from

what I have heard. The Ontario Ministry of Education mandates one minimum credit in technological education as part of the total credits to graduate high school. On the surface this sounds great, but the barn door has been closed after the horse has left.

In the 90s, the provincial government introduced Broad Based Technology courses. It was basically a smattering of curriculum from the technological education umbrella. Transportation, construction, communications, services, etc. If you took transportation as a course, it was supposed to cover land, sea, air and space travel.

This, in my opinion, was the cause of many tech programs to be shuttered or gutted. If you can teach everything in one classroom, you don’t need all the specialty rooms and the specialty teachers to teach them. The big problem with this thinking is that, depending on the teacher’s background, they will teach to their specialty and not provide the students necessarily what they may want.

In my retirement job, I have had the opportunity

to be in shops on a regular basis. Nowadays, shops are consistently asking if I know of any technicians looking for work or to move. This is not the question to be asking. The question to be asking is what I can do as a shop owner to recruit young people to my business.

As mentioned previously, I only had a handful of shops reach out during my entire teaching career. When that did happen, I would ask if the shop knew of an autobody program in a high school in their area. Has the shop reached out to a local high school looking for a co-op student? Has the shop offered up an opportunity for local schools to come for a tour of their facility? Has the shop offered up a workplace opportunity for students to spend a day or two in the shop to see if this is the industry that the student may be interested in?

Sadly, I have more questions than answers, so I put a survey out to a number of my former students, former skills competitors and even a couple of shop managers/owners—I will conclude, for now, there.

34 BODYWORXMAG.COM | BODYWORX PROFESSIONAL SPEEDY CHAT >>>

Four of Bill’s former protégés. Three of the four moved forward to the Skills Canada competition winning two gold medals and a silver. Three of the four went into the industry.

SURVEY RESULTS

The majority of survey answers, in a nutshell were:

Q1: Did you take an autobody course or co-op in high school?

A: YES

Q2: Did you take one, or both? (i.e. just auto class/just co-op, or both options)

A: BOTH

Q3: Did taking either course help you to decide to pursue a career in the trade?

A: YES

Q4: Would you have considered a career in the autobody industry, had you not been exposed to it in high school?

A: NO

Q5: Was your high school program similarly equipped to what you found in the workplace?

A: YES

Q6: Did your high school experience prepare you for the workplace?

A: YES

Q7: Did your teachers help you in your decision to pursue a career in autobody?

A: YES Teacher guided me through various repair procedures and techniques for modern day repairs and restoration. Preparation and painting techniques. Given multiple projects to help me to identify what kind of technician I would like to become.

Challenged me to be the best that I could be. Teacher paid attention to my strengths and weaknesses and helped me to turn my weaknesses to strengths.

Q9: How, in your opinion, could the industry better support high school autobody programs to keep them alive, and be able to better prepare youth for the workplace?

More workshops for middle school students, where they can learn and try new tools and equipment.

Industry leaders should be more involved in course and curriculum development, as well as training opportunities for students. Shops/ manufacturers could donate equipment, materials and vehicles for training purposes.

Workshops with bodyshops and manufacturers to have in-class speaking sessions about the industry as a whole.

Demonstrations of paintlessdentrepair, demonstrationspolishing,equipmentthatmay entice students.

Q8: What, if anything, would have helped you to be better prepared for the workplace?

More estimatingmultitasking; as a potential career path; more hands-on experience.

SPEEDY CHAT >>> BW11#1 2024 | BODYWORX PROFESSIONAL 35

CAPTURING MOMENTS

EXPLORE OUR INDUSTRY PHOTO ALBUM

Our journalists put you right in the action at major industry events. The biggest trade shows and conferences can be viewed online in the Collision Repair mag flickr albums.

Visit rebrand.ly/1jl4fea

COLLISIONREPAIRMAG.COM

BODYWORXMAG.COM

CRAFTING MEMORIES

ADVERTISE NOW FOR MAXIMUM IMPACT!

REACH YOUR TARGET AUDIENCE

PROMOTE YOUR BUSINESS

GAIN VISIBILITY

BODYWORXMAG.COM

CONTROLS

ARE WE FOCUSED ON RECRUITING YOUTH, OR RECRUITING PARENTS?

BY ALLISON ROGERS

You’d be hard-pressed to find an industry event where the current skills shortage is not mentioned. Heck, get two shop owners together and the topic will likely come up in less than five minutes of conversation. I’m not making fun—truly!—it’s a real issue facing hundreds of shops in Canada and beyond.

But, since I’ve joined the industry, I’ve found one major factor utterly befuddling: why, oh why, do we focus so many recruitment efforts on parents, rather than the youth we’re trying to hire?! It seems recruiters in the industry need a refresher on who they’re actually aiming to recruit to the industry. Are we trying to recruit young people, or are we trying to hire their parents?

eyes, many of the recruits that emerge from this process will not stick around. Today’s youth want to be in love with what they do, and the chances of them falling in love with whatever career their parents told them to do versus something they are genuinely passionate about…those margins are slim.

So, to anyone reading this complaint, answer me this: would you be more likely to buy into a career if your parents were pushing it?

Personally, as a Gen Z-er myself, I would be far less likely to consider it. I love my parents; I respect my parents. But when I was considering my future, I—quite literally kicking and screaming—refused to even apply to the same schools my parents went to.

It seems recruiters in the industry need a refresher on who they’re actually aiming to recruit to the industry. Are we trying to recruit young people, or are we trying to hire their parents?

You’ve heard the term ‘Gen Z’. It stands for anyone born between the years 1997 and 2012; i.e., a big majority of the potential hiring pool. Following Gen Z is ‘Gen Alpha’—anyone born from 2013 to the present. Sure, 2013 may sound like it was yesterday—but those kids are turning 11 years old this year. Five more years and they’ll be making major career decisions or considering co-op programs; two years after that, they could be part of the workforce.

Both Gen Z and Gen Alpha are known to value independence and autonomy in decision-making. These are generations that have grown up with technology at their fingertips; every answer is a mere Google away. For some members of these generations, subverting their autonomy and going straight to their parents can be considered a direct infringement on their values.

I understand the parents-first strategy. The idea is that, if we convince the parents that bodyshops are not smoke-and-dust-filled spaces where everyone swears like a sailor, they’ll be on board. If we convince them that their kids will be safe, have a lifelong and successful career, why wouldn’t they buy in?!

As much as I understand the logic, it frankly does not work with today’s youth. Sure, some of them may respond to this; but, in my

Let’s huddle up and refocus. We’re all here because, in some capacity, we love cars. Car culture, despite the rumours, is not dead. There are thousands of car-loving kids out there just waiting to get their ear talked off about collision repair. We just need to know how to reach them—not their parents.

38 BODYWORXMAG.COM | BODYWORX PROFESSIONAL FINAL DETAIL >>>

Allison Rogers is the editor of Bodyworx Professional. She can be reached at allison@mediamatters.ca, or 905-370-0101.

PARENTAL

GLOBAL FAMILY, HAS YOUR LOCAL VALUES

When you invest in a Fix Auto franchise, you invest in a business model with a proven track record in 12 countries around the world. You invest in a fully branded business with a roadmap for success. You invest in the same values and work ethic that grew your local business to what it is today.

Drive your business forward with:

• Solid performance-driven operational model and ongoing training.

• Full branding and marketing support for local awareness and promotion.

• Proven experience in winning insurance work.

• Established global supply and fleet arrangements.

Our owner started as a franchisee, and this inspires our commitment to the success of the local business owner. OUR

fixauto.com

visit the “Join the

at fixauto.com to find out more.

Contact Amin Youssef at ayoussef@fixnetwork.com or

Network” page

BY SARAH PERKINS

BY SARAH PERKINS

BY ALLISON ROGERS

BY ALLISON ROGERS