HAWE Finland Smart Hydraulics. Easy Business! HAWEFinland, helppoahydrauliikkaa!

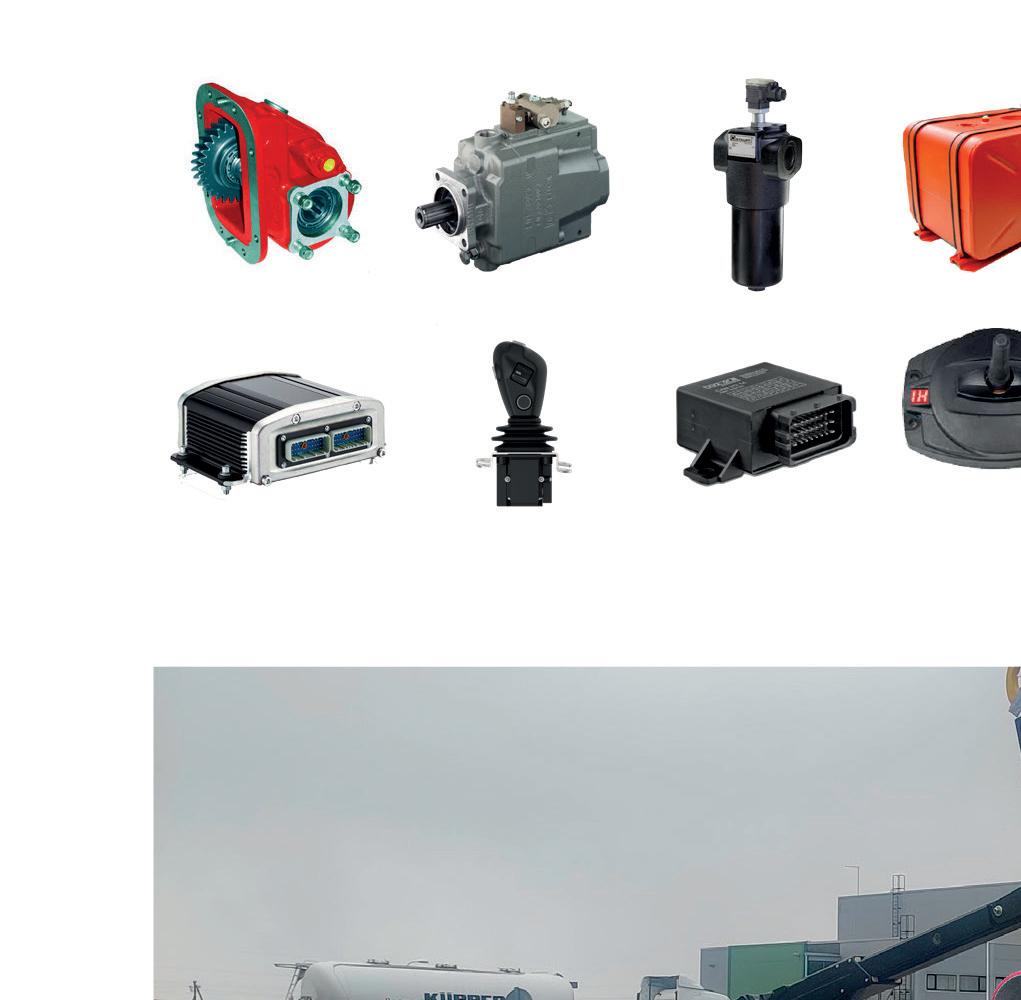

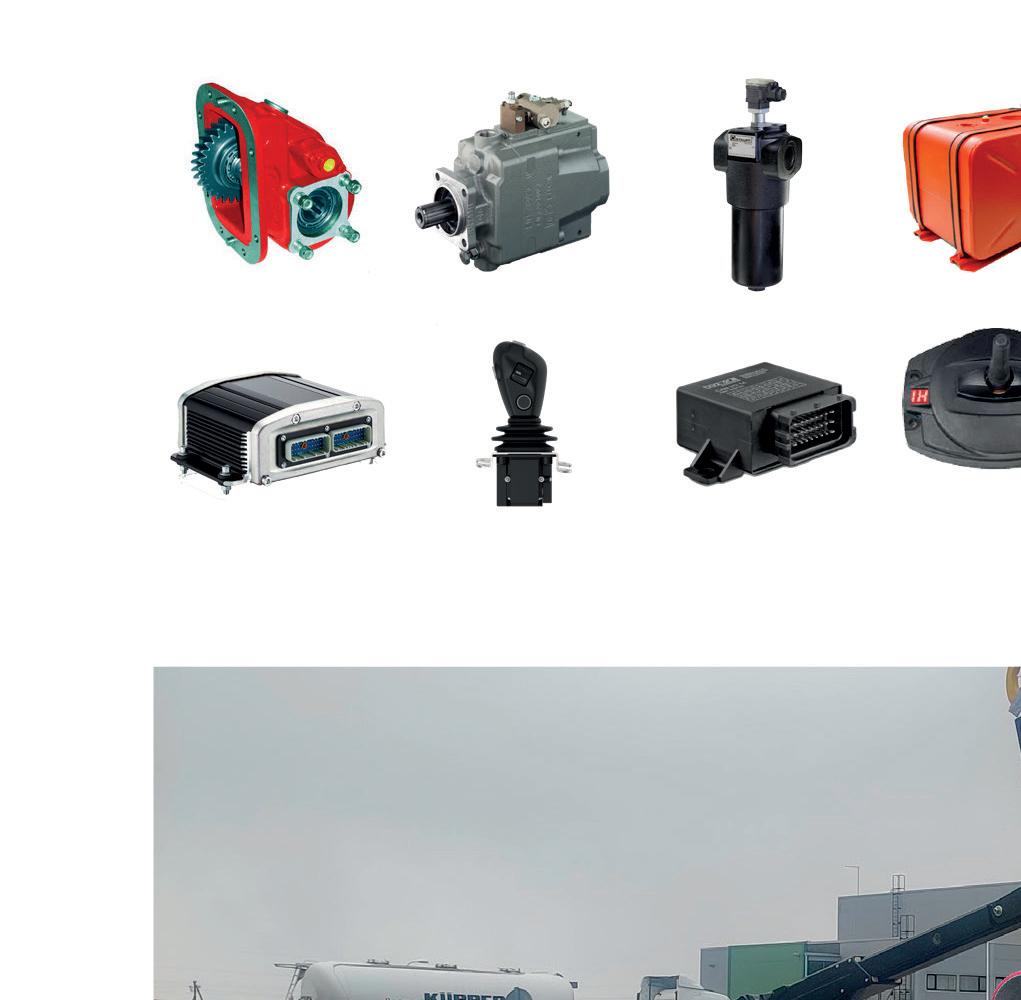

Hydraulic components and systems

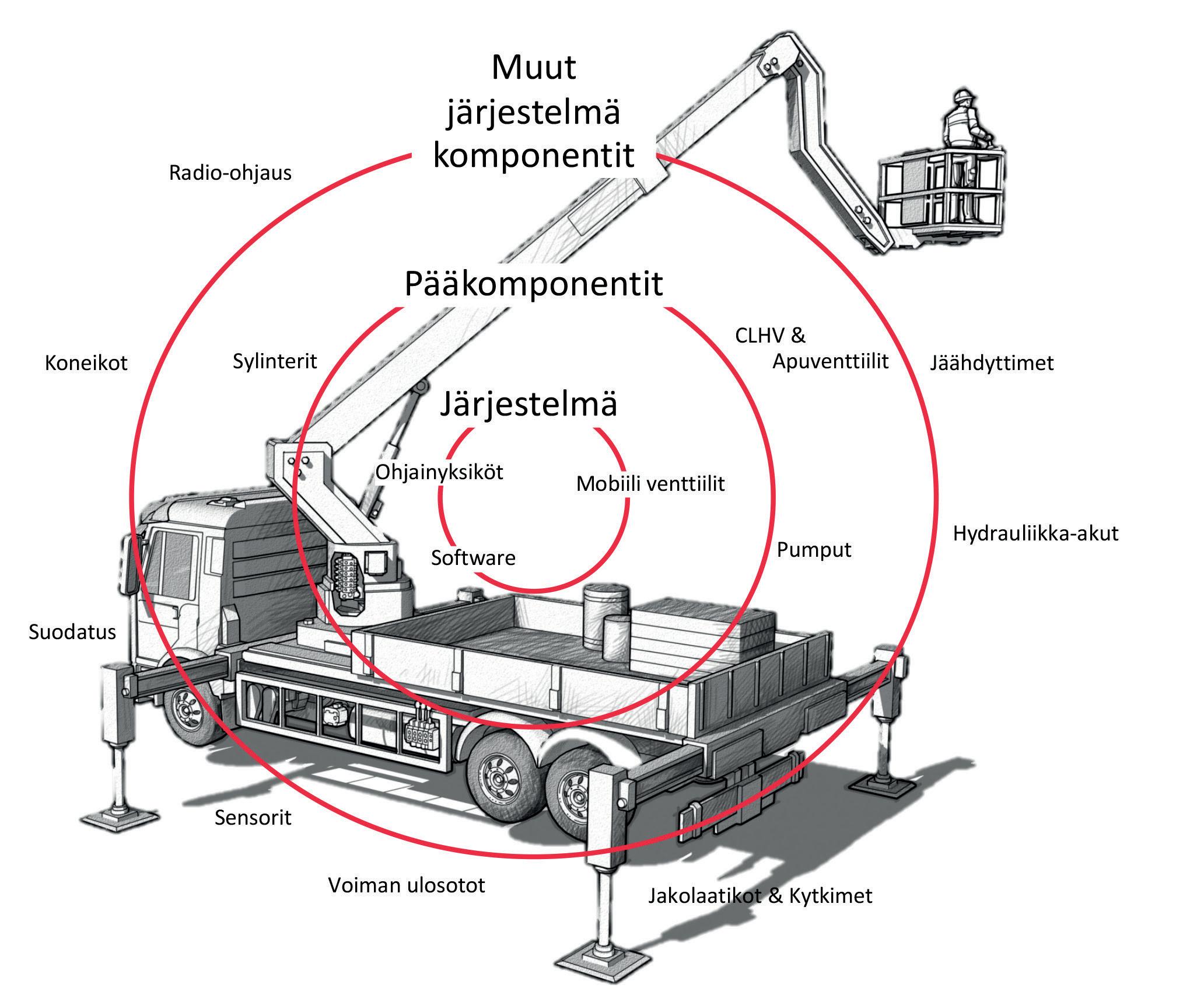

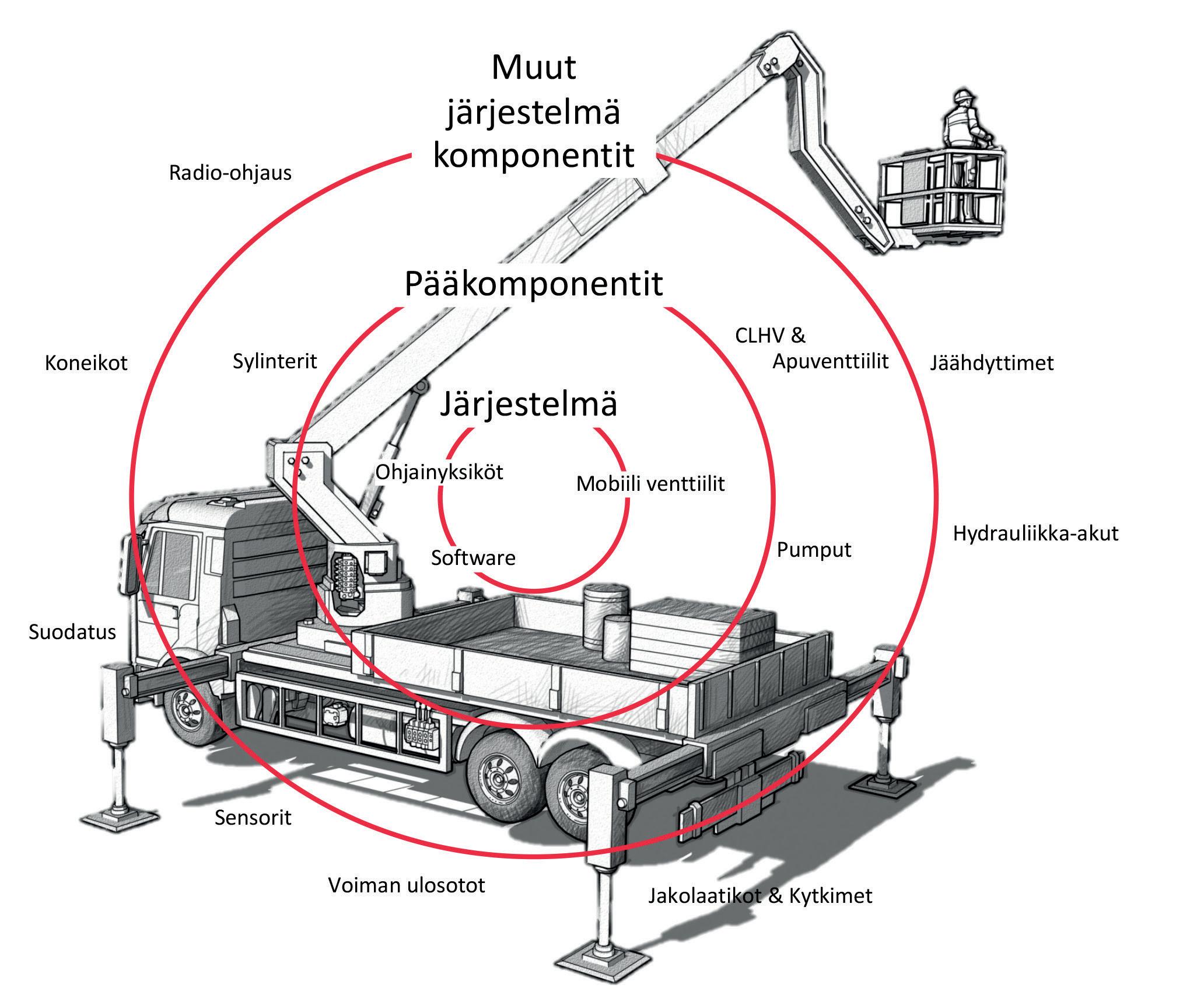

Päällirakentajille

Other system components

Main components System

HAWE Finland Oy is part of the global HAWE Hydraulik company. We have branches on all continents, and our expert distributor network covers the entire world. HAWE Hydraulik manufactures all components in-house. Our main factories and headquarters are located in Munich, Germany.

The purpose of this guide is to make hydraulic system design easier for you. In addition to our own products, the guide includes carefully selected products and solutions provided by our partners. The majority of the products listed here are readily available from us in Finland. We are happy to help you engineer the best possible system for your needs.

Contact us!

HAWE and our distributors are available near you.

HAWE Finland Oy Koskelontie 15 | 02920 Espoo | Finland | Tel. +358 (0)10 82126 00 | sales@hawe.fi | www.hawe.fi 2 Contact us now!

Radio control

Power

Coolers CLHV & auxiliary valves

Cylinders

packs

Pumps Hydraulic accumulators Mobile valves Control units

Sensors

Table of Contents

2.HAWE Bodybuilder guide

3.Table of Contents

PUMPS

4.HAWE hydraulic pumps

5.HAWE V60N pumps

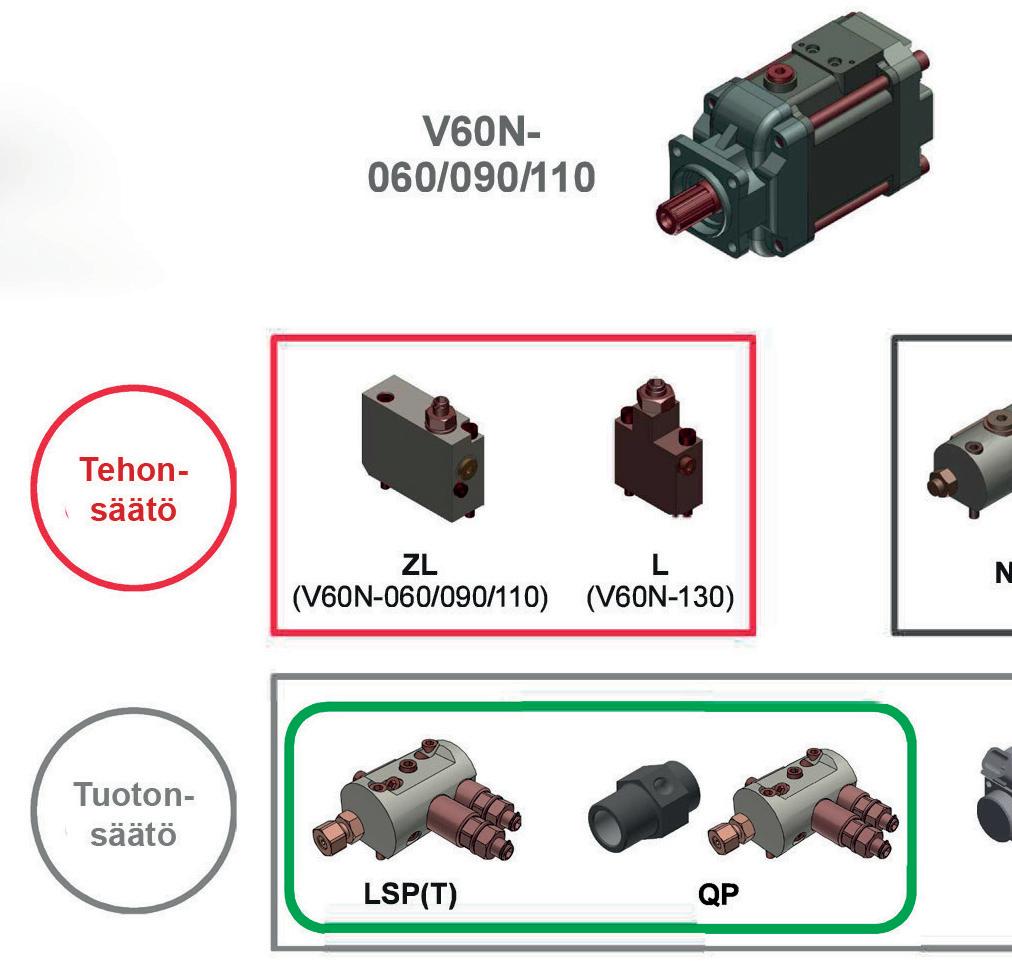

HAWE V60N controllers

6.Sunfab SAP pumps

7.Sunfab pumps

By-pass valves

8.Sunfab SAP and SCPD pumps

9.Sunfab SCPD pumps

Dual by-pass valves

10.Sunfab SLPD pumps

12.HAWE C40V pumps and code key

13.HAWE HP5V pumps and code key

14.HAWE V30E pumps and code key

15.HAWE V30G (L) pumps and code key

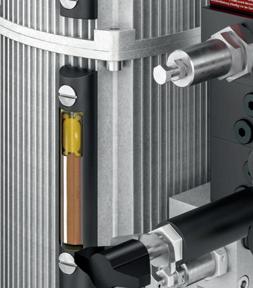

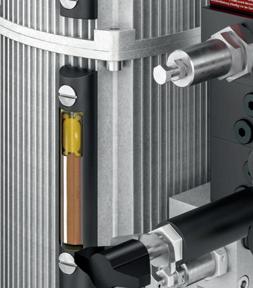

16.HAWE V80M pumps and code key

CONNECTORS

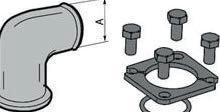

18.Pump–PTO gaskets

Flanges

Pump assembly grease

19.Suction couplings

VALVES

20.HAWE PSL valves for mobile equipment

21.HAWE CWS and EDL connectors for mobile equipment

CLHV load-holding valves

22.Auxiliary valves

Check valves

Flow control cartridges

23.Pressure limiting valves

HAWE ROLV and other CETOP valves

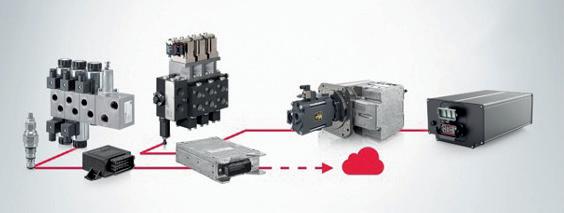

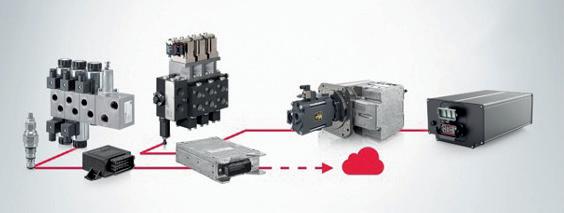

HAWE CONTROL SYSTEMS

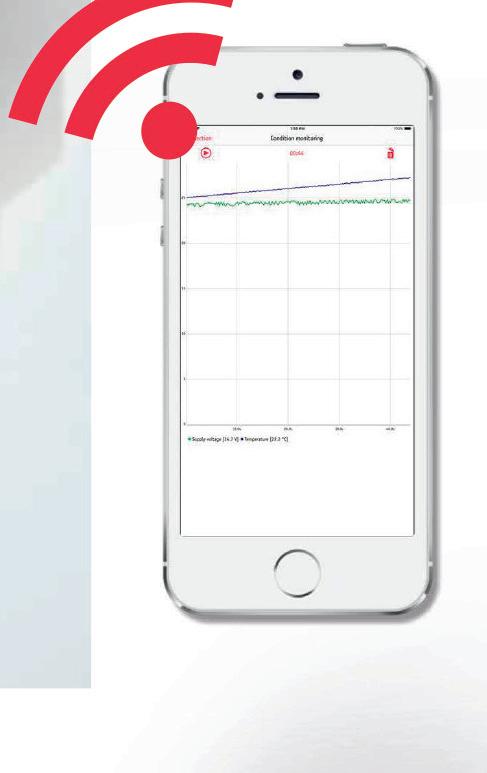

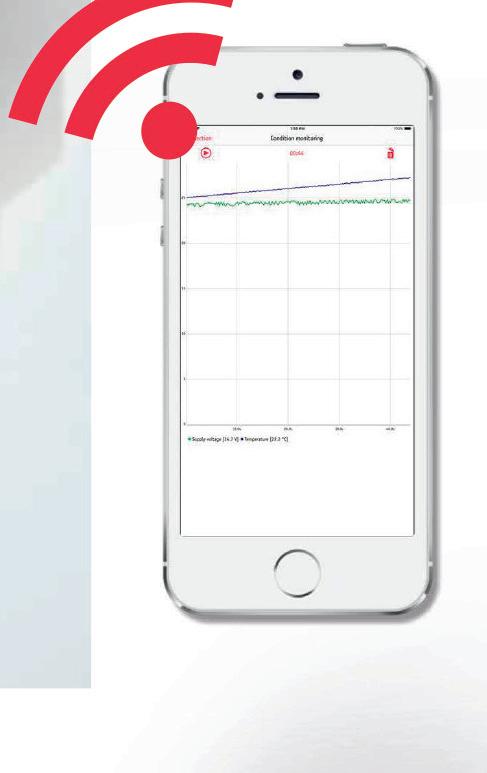

24.EV2S – Hirschman/DIN connector

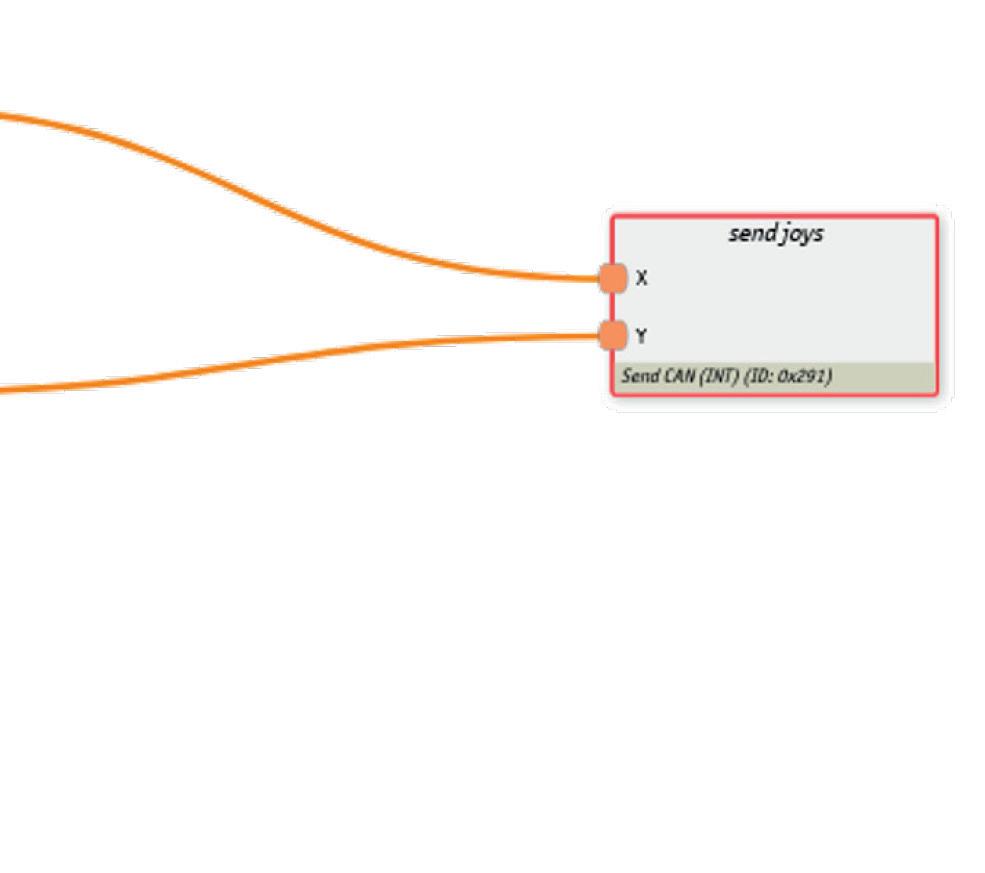

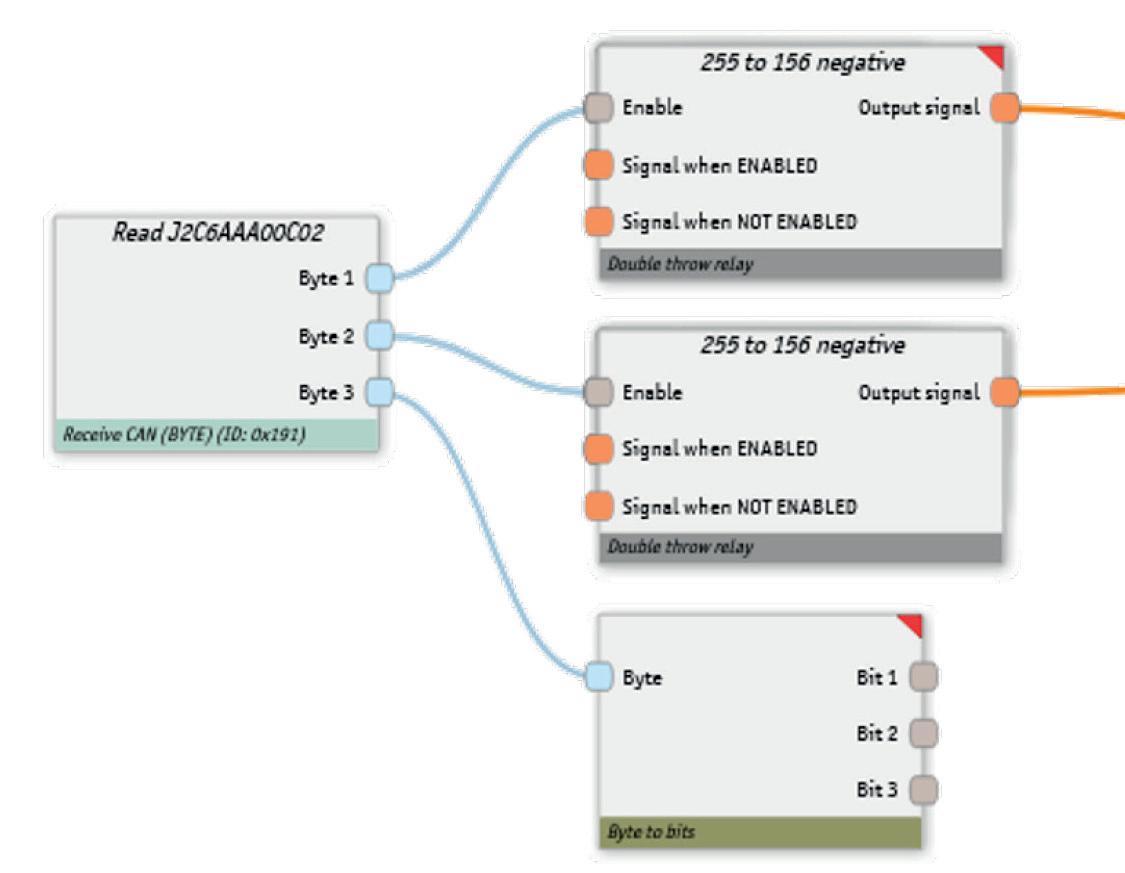

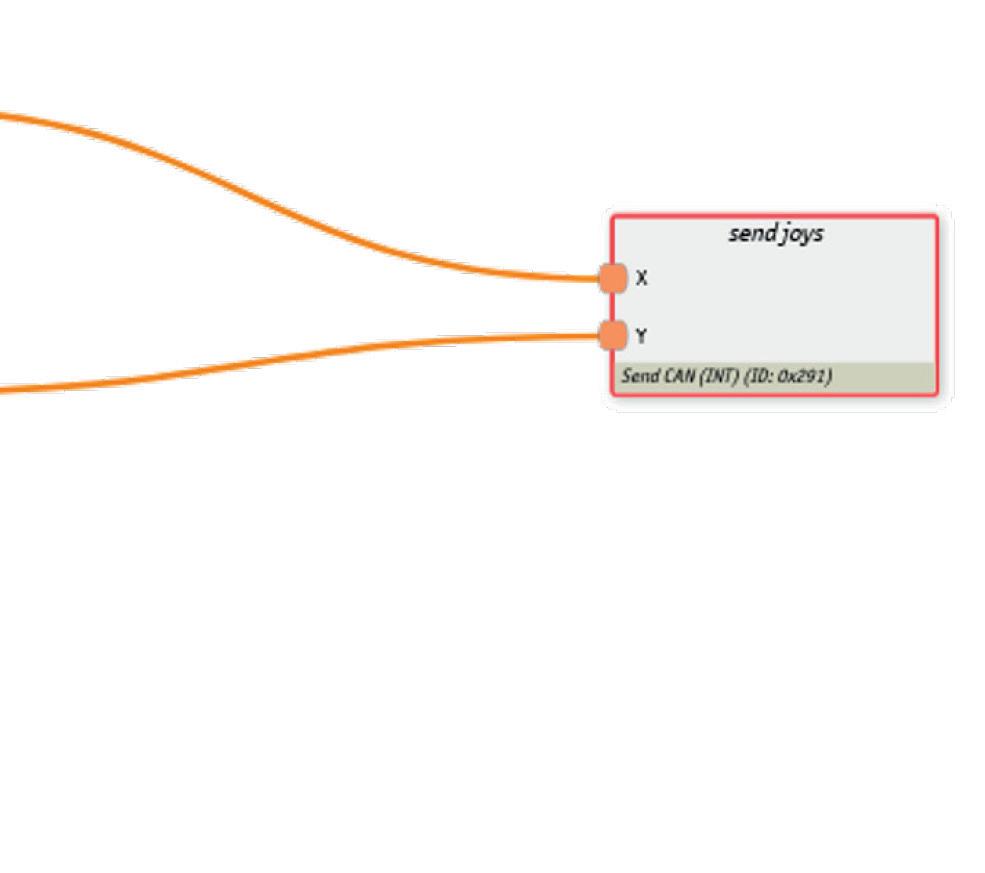

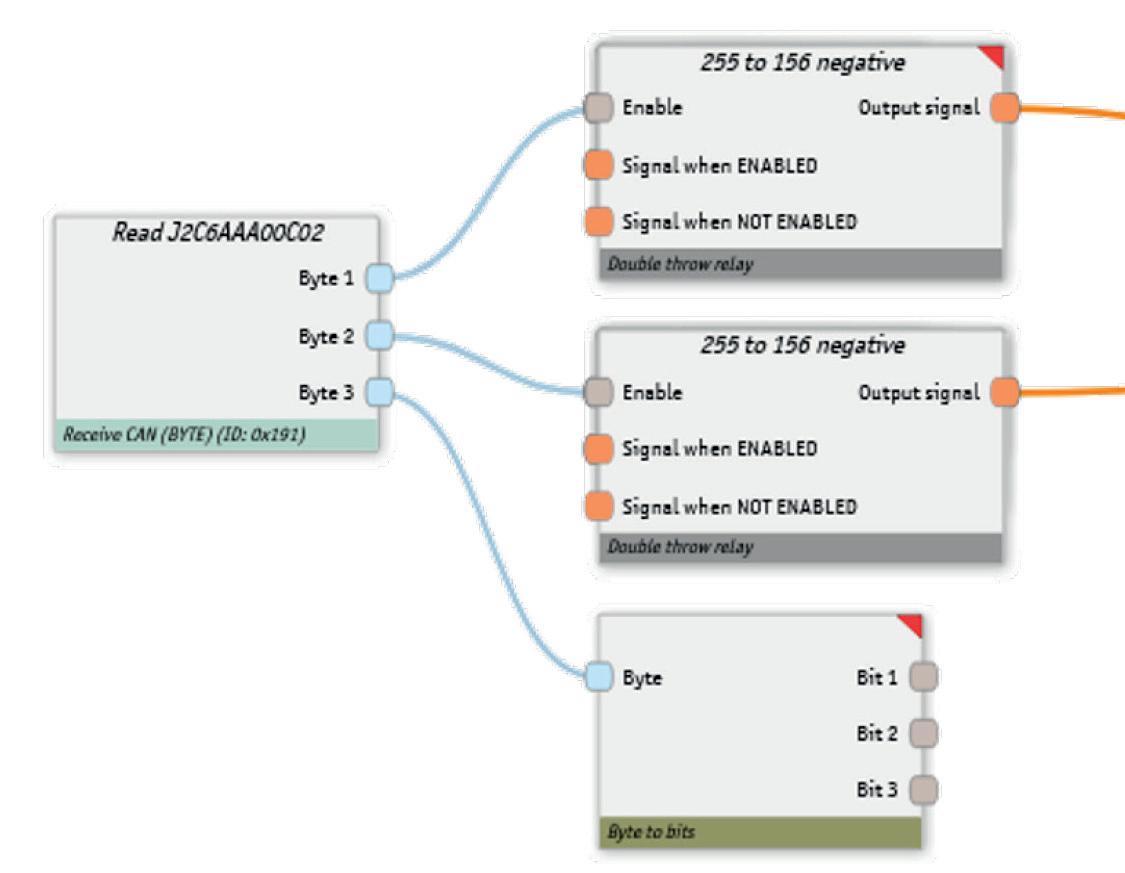

CAN 1/0 electric control systems

25.PLVC8, 3CS and 3CM electric control systems

eDesign programming interface

26.HAWE joysticks

HAWE radio control systems – Scanreco

27.HAWE displays

HAWE pressure transmitters

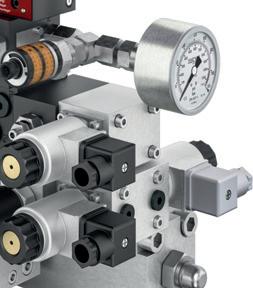

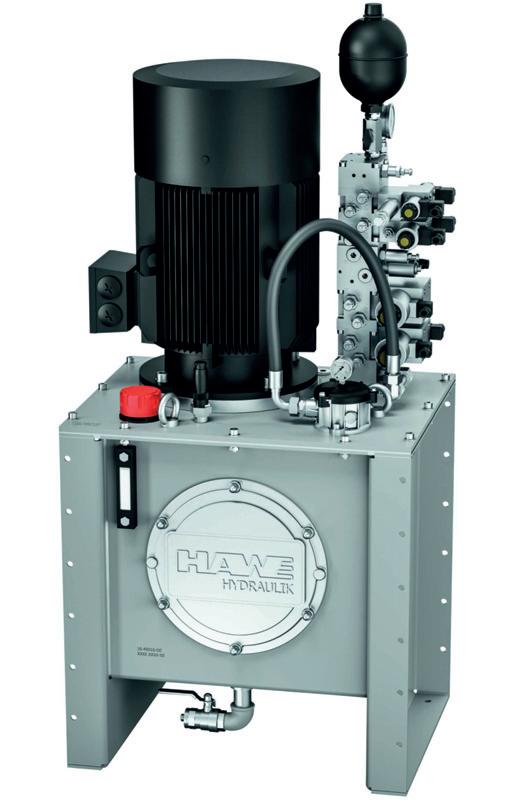

POWER PACKS

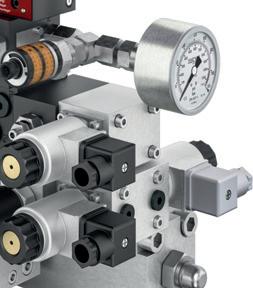

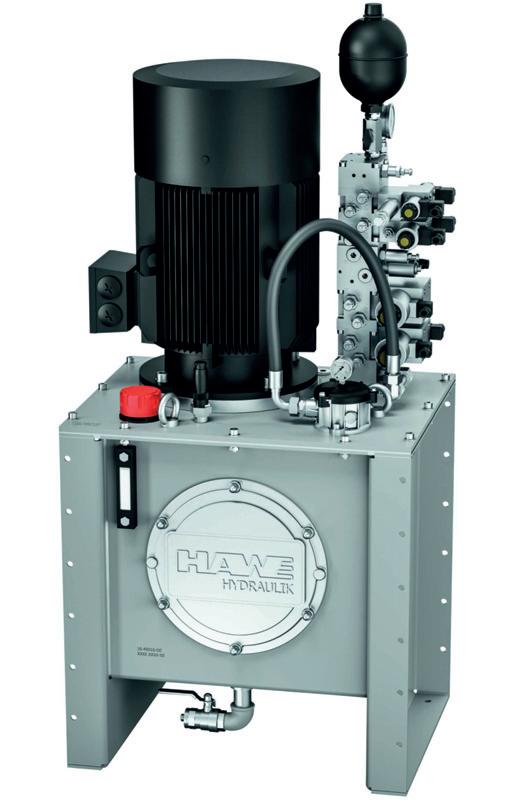

36.HAWE power packs

HR mini power packs

HICON seawater-proof power packs

37.KA compact power packs

INKA power packs

FXU power packs

Piston and diaphragm accumulators

Hand pumps

COOLERS

38.Coolers

WINCHES AND TEST PRODUCTS

42.Winches

43.Test products

Gauge fittings and instruments

Digital Stauff test sets and particle analysers

HAWE FINLAND SOLUTIONS

44. Gravel hopper trailer truck and road maintenance truck– examples

45. Forest machine and gravel spreaders – examples

46. Timber truck and refuse truck – examples

47. Bulk crane and hook-type vehicles – examples

48. Chipper truck and concrete mixer truck – examples

49.Fire fighting truck – examples

INSTALLATION INSTRUCTIONS

50.HAWE variable displacement pump V60NLSP installation instructions

52.Sunfab fixed displacement pump installation instructions

53.By-pass valve installation instructions

54.Dual flow Sunfab pump installation instructions

55.Sunfab SL pump installation instructions

56.Sunfab SAVTEC pump installation instructions

57.Scania side-mounted power take-off installation instructions

58.Hydraulic system – general troubleshooting distributors

act details of HAWE Fi

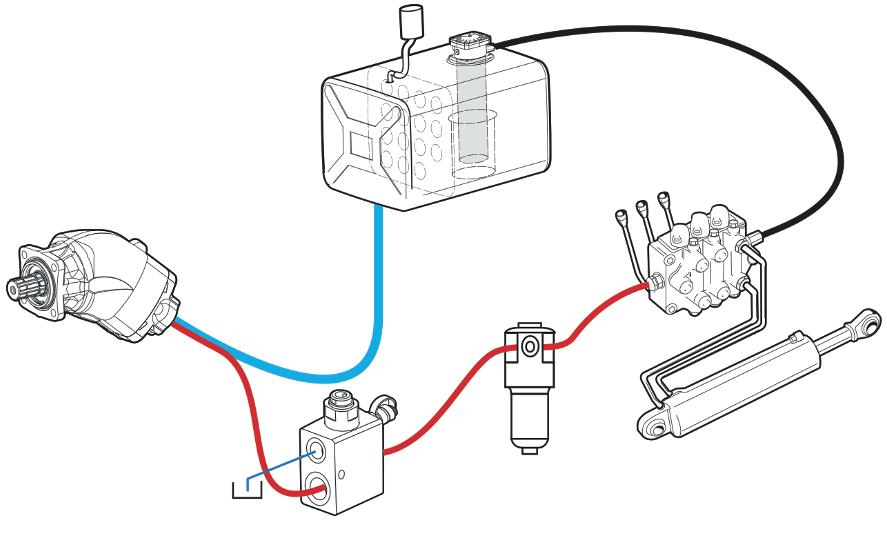

28.Example of a road maintenance truck’s hydraulics

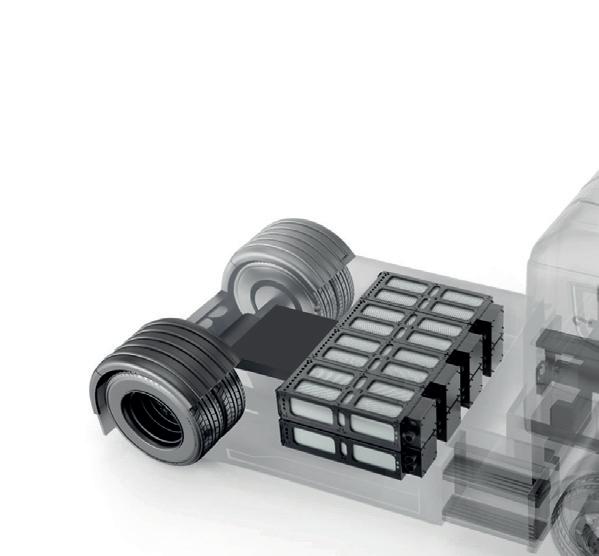

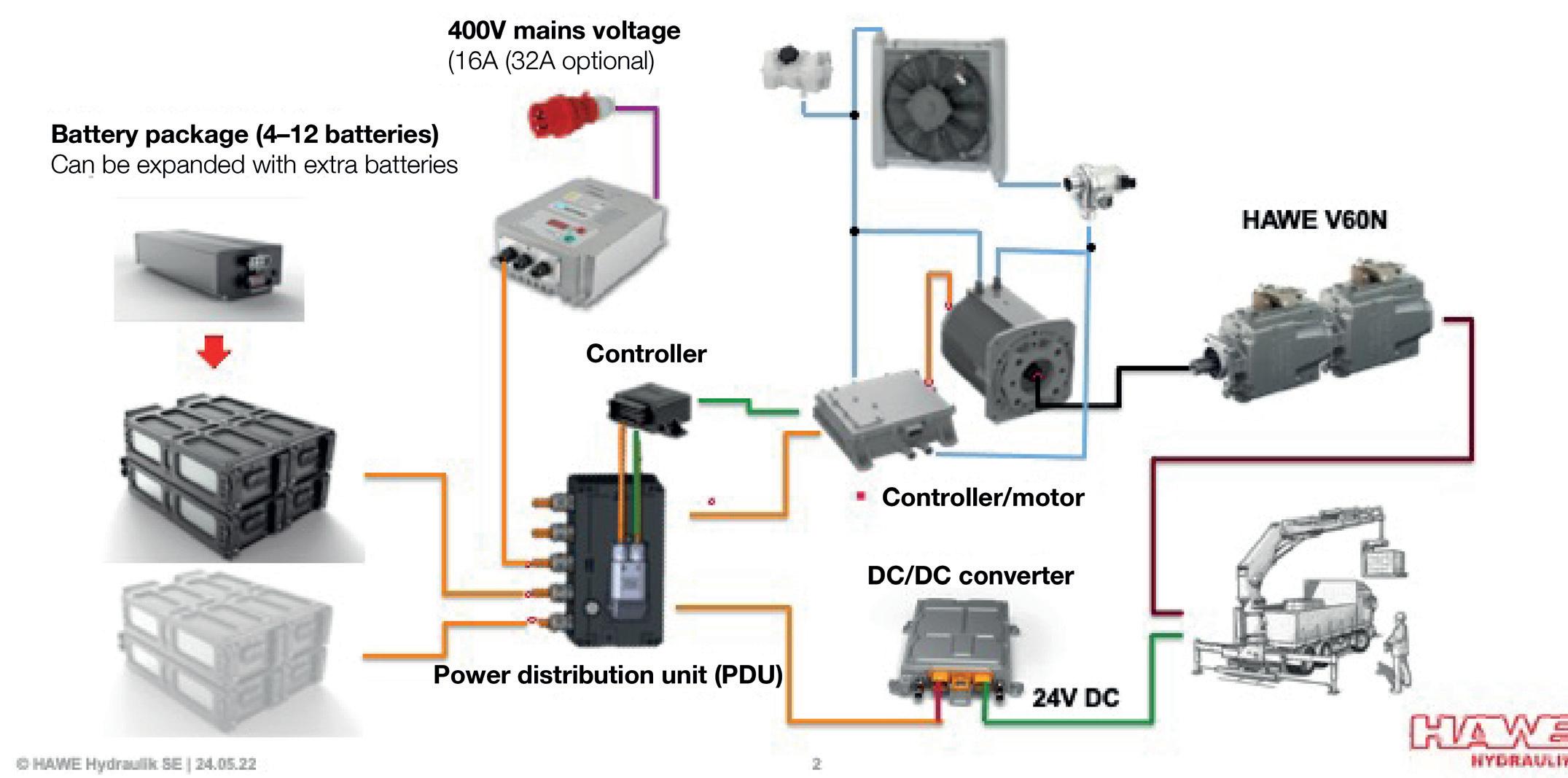

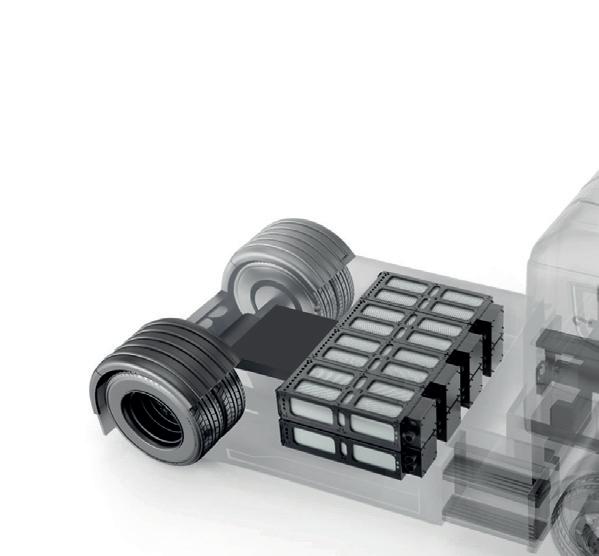

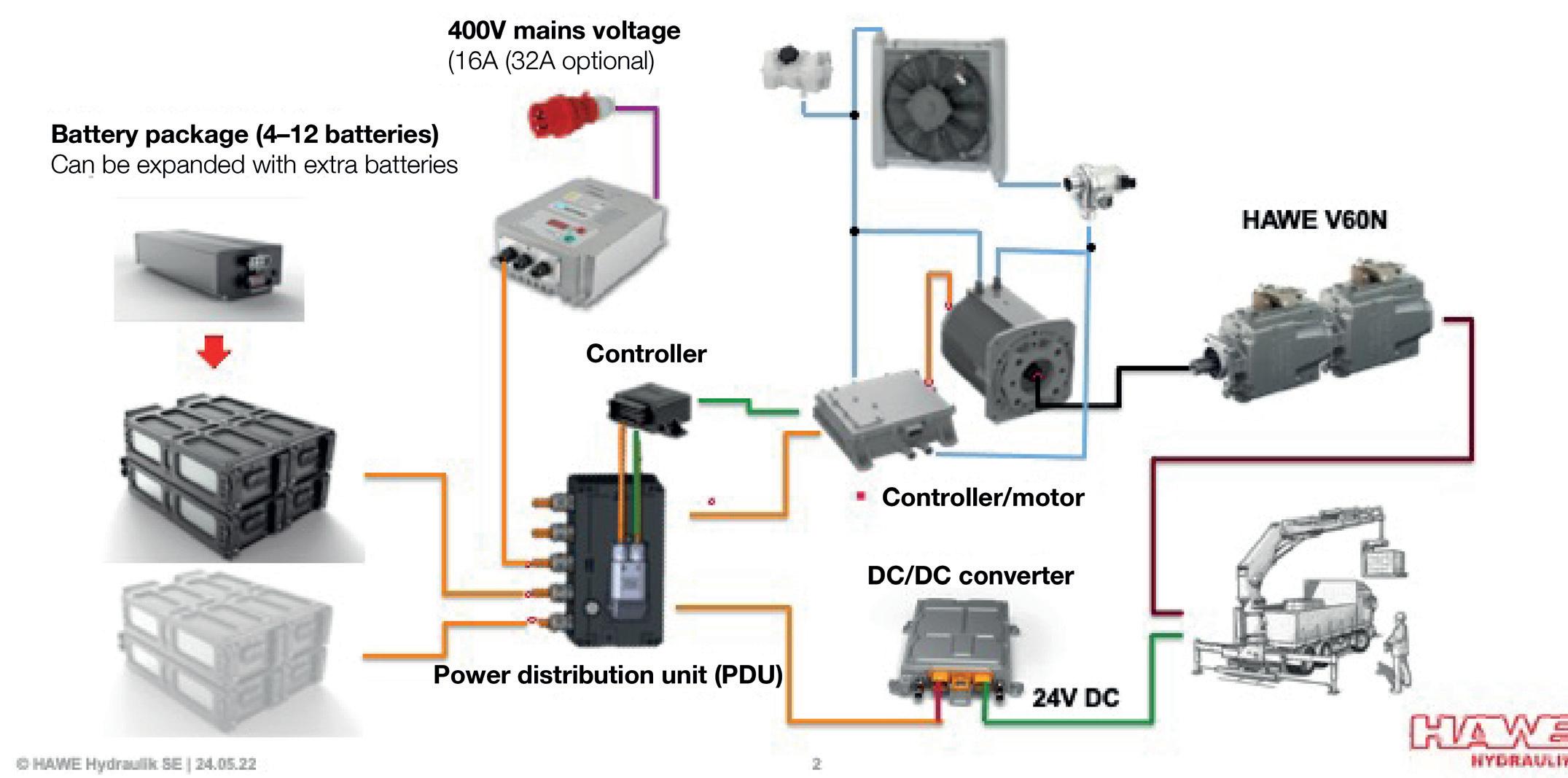

30.HAWE electric drives for mobile equipment

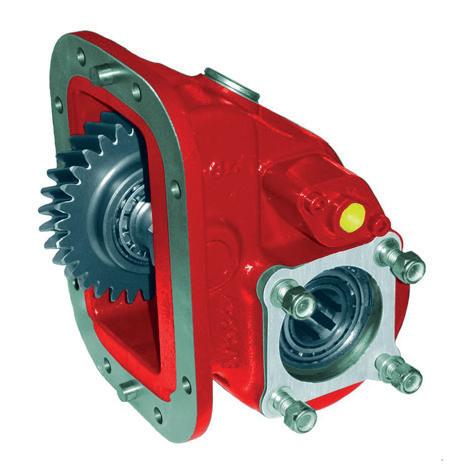

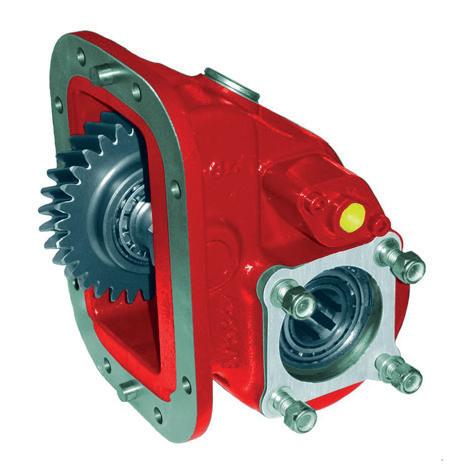

PTO AND ADAPTERS, CARDANS AND SHAFT FLANGES

32.PTO and adapters

Tipping valves

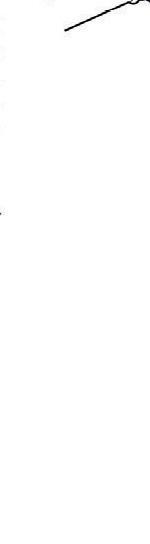

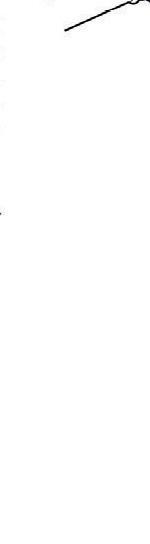

33.Cardan flanges

TRACPOWER trackpower gear boxes

FILTERS AND TANKS

34.Filters

Pressure filters

Return filters

35.Tank accessories

ulics

HAWE hydraulic componentsandsystems

HAWE Finland Oy Koskelontie 15 | 02920 Espoo | Finland | Tel. +358 (0)10 82126 00 | sales@hawe.fi | www.hawe.fi 3

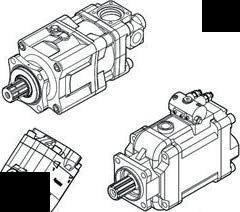

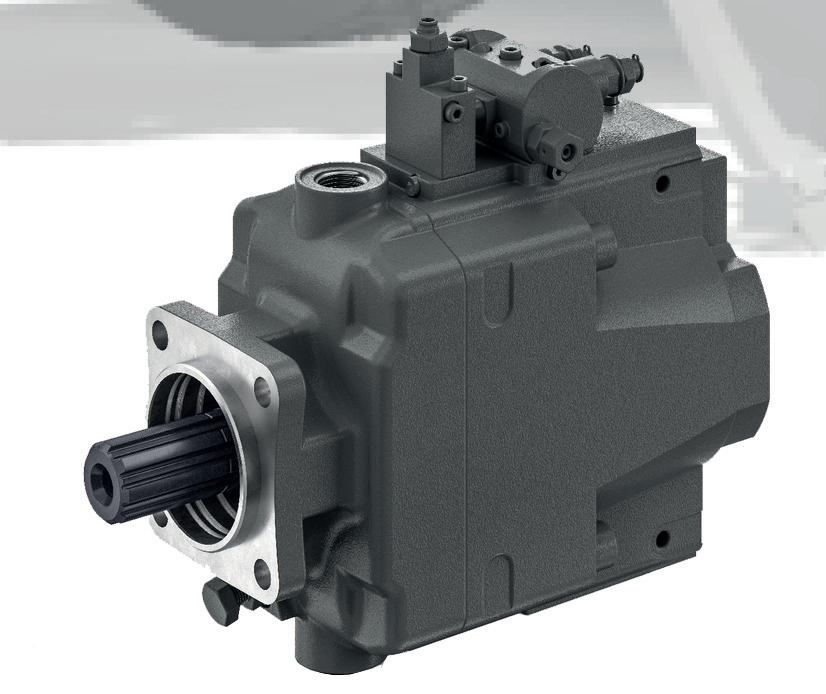

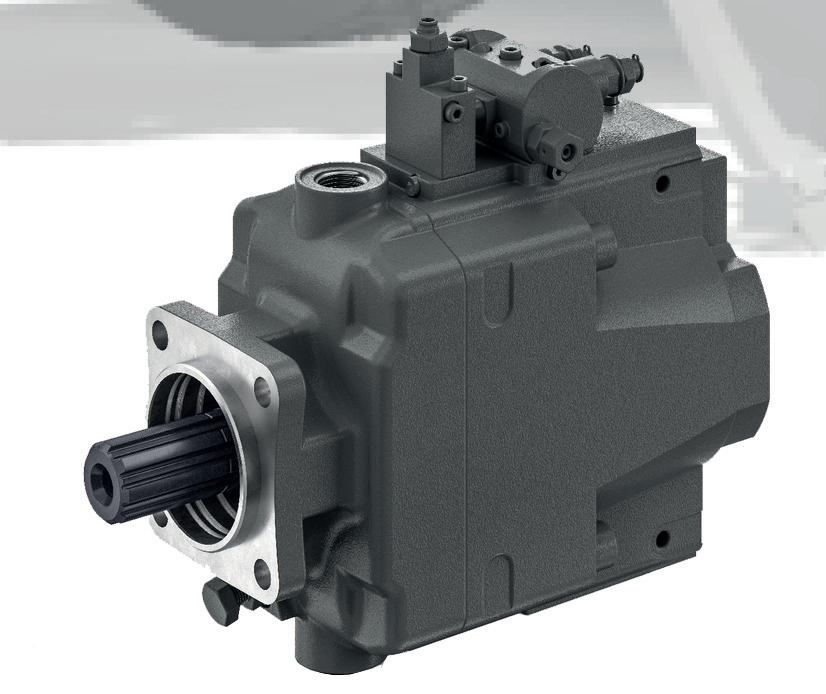

Hydraulic pumps

HAWE’s legendary highperformance V60Npump!

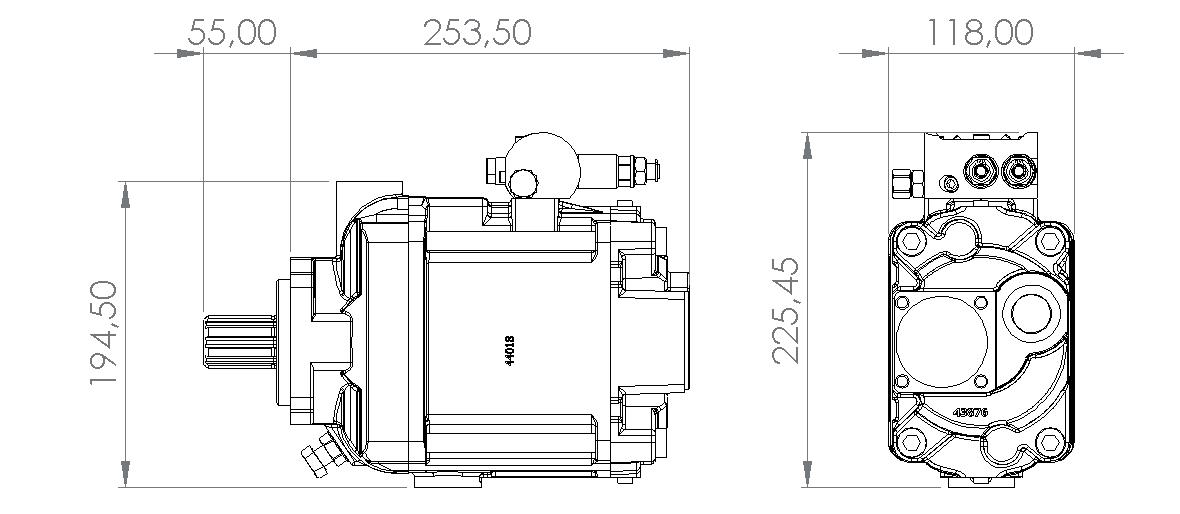

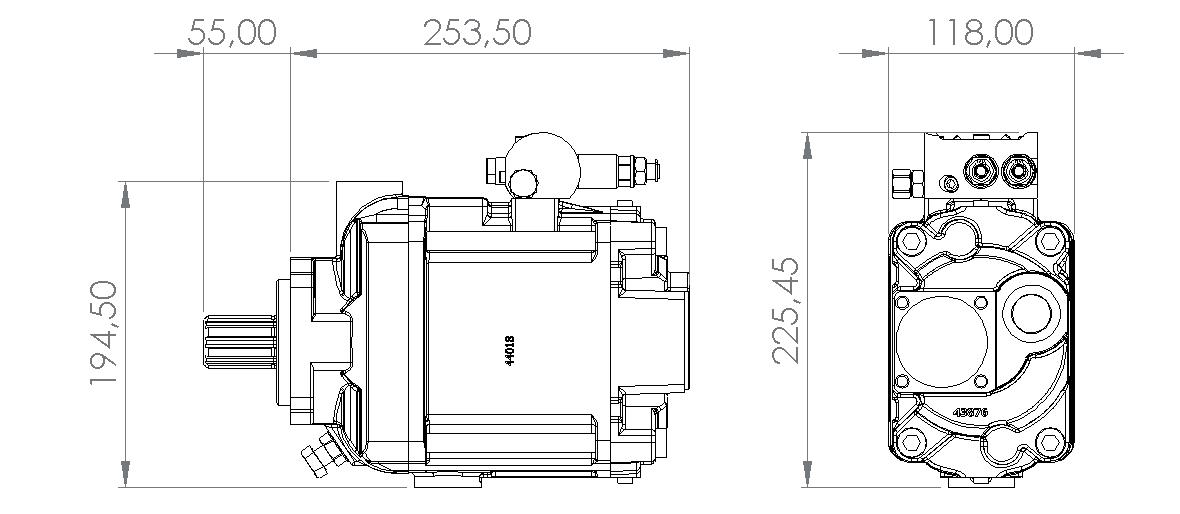

HAWE V60N variable displacement pump is mounted directly on the vehicle’s power take-off. Stroke limitation screw standard in all pumps. Power controller standard in 130cc pumps. NB! All installation positions possible. See the installation instructions starting from page 50.

tion

HAWE Finland Oy Koskelontie 15 | 02920 Espoo | Finland | Tel. +358 (0)10 82126 00 | sales@hawe.fi | www.hawe.fi 4

V60N 060 Displacement Working pressure Maximum peak pressure Required suction line pressure (abs) Maximum suction line pressure (abs) Maximum housing pressure Maximum torque Maximum rotation speed with full angle, self-priming mechanism, maximum capacity, suction line pressure 1 bar abs Minimum rotation speed, continuous operation Torque 100 bar Power 250 bar, 2000 rpm Weight with LSP controller Tare-weight torque Moment of inertia cm3/rev. bar bar bar bar bar Nm rpm rpm Nm kW kg Nm kgm2 62.4 350 400 0.85 30 3 430 2500 500 100 53 24 30 0.005 87.2 350 400 0.85 30 3 530 2300 500 151 79.5 27 35.3 0.008 110.4 350 400 0.85 30 3 900 2200 500 184 97.2 30 40 0.01 130 400 450 0.85 30 3 900 2100 500 230 120 31 40 0.011 V60N 090V60N 110V60N 130 MODEL

-2

Compact and reliable pumpsdisplacementvariable in stock!

HAWE V60N pump code key

V60N 110 R D Y N 1 0 03

Type Displacement 60 90 110 130

Direction

RClockwise

Shaft type

DSpline shaft DIN ISO ISO14 (lorry)

MSpline shaft DIN 5480 (V60N 090, 110)

SSpline shaft SAE-C J 744

HSpline shaft SAE-B J 744 (V60N 060)

TSpline shaft SAE-B B J 744 (V60N 060)

USpline shaft SAE-B J 744, short (V60N 060)

QSpline shaft SAE-C S (V60N-090, -110,-130)

Mounting flange

YFlange ISO 7653-1-985 (lorry)

P Flange ISO 7653-1-985, 10°(lorry, V60N-110,-130)

GFlange ISO 3019-2 (V60N-090)

FFlange SAE C4 ISO 7653-1-985

ZFlange SAE B-4, J 744 ISO 3019-1 (V60N-060)

X Flange SAE B-2, 45° offset J 744 ISO 3019-1 (V60N-060)

Shaft seal

NNitrile V Viton (FKM)

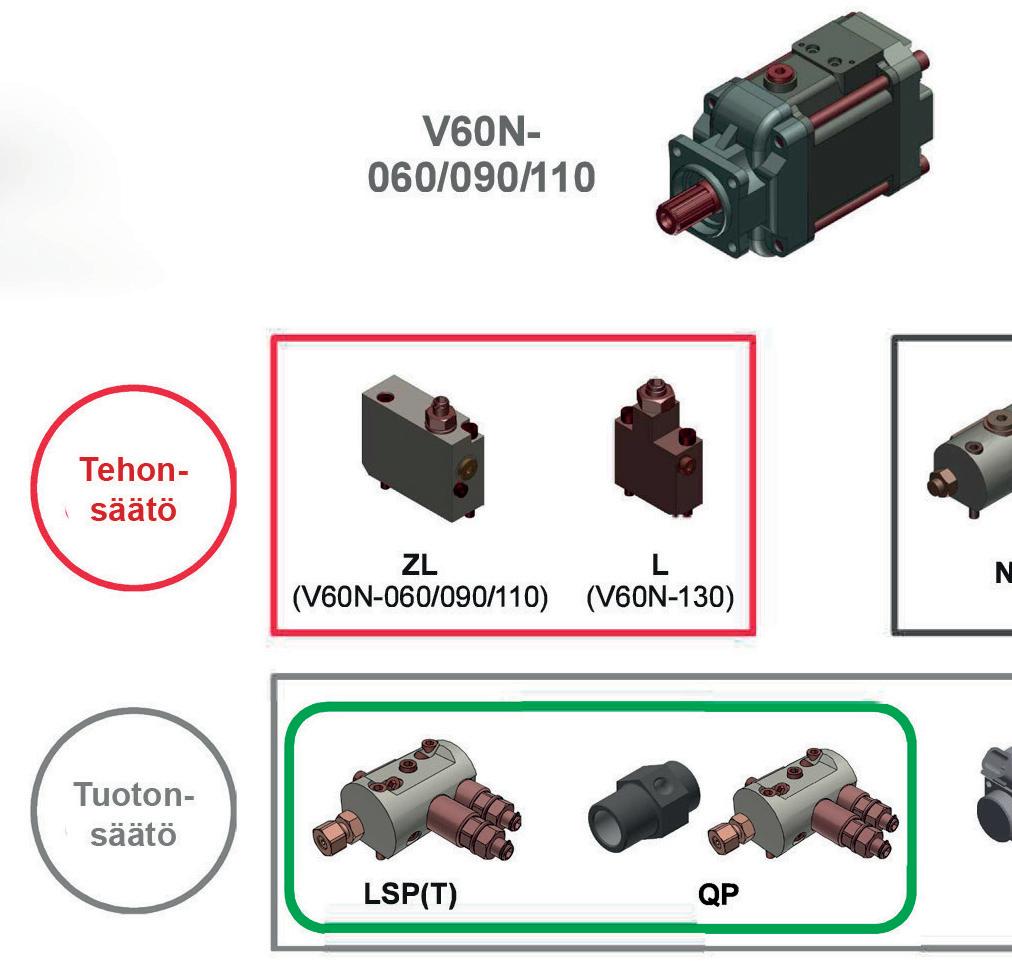

V60N controllers

Power control

Flow control

BASIC PUMP

PUMP

V60N-060 R(L)DYN-1-0-03/LSP

7956501.00.IL( R )

7956499.00.IL (L)

V60N-060 R(L)DYN-2-0-00/LSP/L-2

7956980.00.IL

7956547.00.IL

DIN/SAE ask about options!

7941589.00.IL

Adjusted working pressure

Stroke limitation

Standard empty

2 stroke limitation

Controller

LSP LS controller with pressure limiter

NR constant pressure controller

L power controller V60N 130

ZL power controller V60N-060, -090, -110

PR electric pressure controller, positive

PR1 electric pressure controller, negative

V electric flow controller, positive V60N-130

V1 electric flow controller, negative V60N-130

ZV electric flow controller, positive V60N-060, -090, -110

QP constant flow controller

Model Generation

0Standard

Pump type

1Standard, axial ports

2 3 4

Thru-shaft, radial ports

Thru-shaft, radial ports

CONTROLLER

7956436.00.IL (R)

7956506.00.IL (L)

V60N-090 R(L)DYN-2-0-00/LSP/L-2

7956981.00.IL

Available. Ask for the code!

DIN/SAE ask about options!

7941602.00.IL

7945241.00.IL

Pressure control

Top properties with V60N electric pressure controller PR. Ask more!

V60N-130 R(L)DYN-1-0-00/LSP/L-2

7956271.00.IL (R)

7956312.00.IL (L)

V60N-110 R(L)DYN-2-0-00/LSP/L-2

7956945.00.IL

Available. Ask for the code!

DIN/SAE ask about options!

7941506.00.IL

7945241.00.IL

7956394.00.IL (R)

7956510.00.IL (L)

V60N-130 R(L)DYN-2-0-00/LSP/L-2

7956508.00.IL

7956943.00.IL

DIN/SAE ask about options!

7942901.00.IL

HAWE Finland Oy Koskelontie 15 | 02920 Espoo | Finland | Tel. +358 (0)10 82126 00 | sales@hawe.fi | www.hawe.fi 5

R

L

R

GASKET

7945241.00.IL LSP

PUMP THRU-SHAFT PUMP

PUMP L PUMP THRU-SHAFT PUMP FLANGE

SET

V60N-090 R(L)DYN-1-0-03/LSPV60N-110 R(L)DYN-1-0-03/LSP

of

7945241.00.IL

rotation

LAnticlockwise

300

Standard, axial ports SAE J 518

LSP/ZL

Additional functions

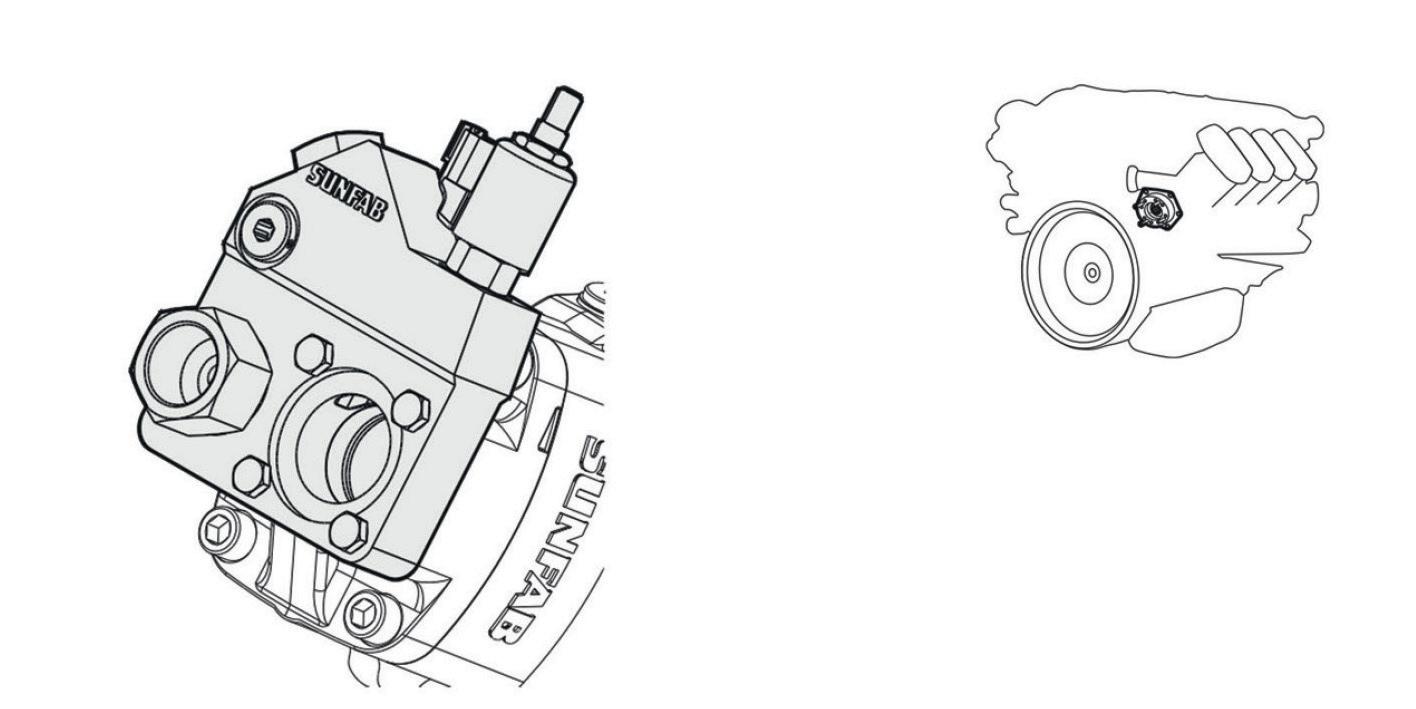

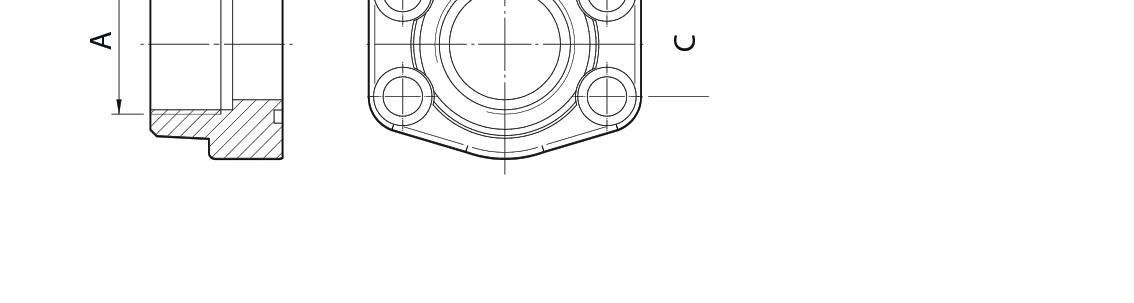

Sunfab SAP pumps

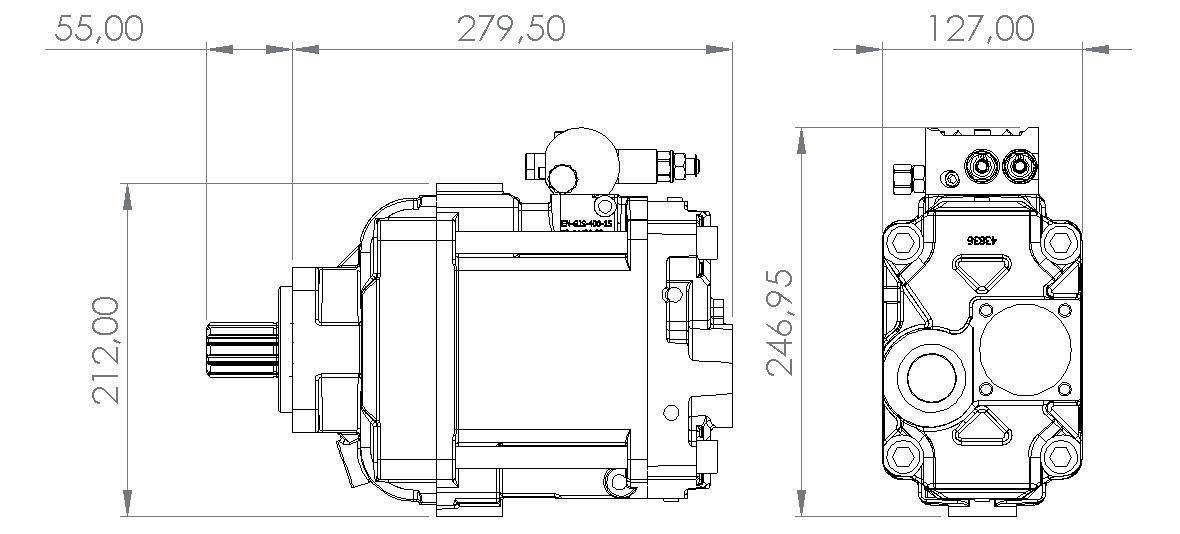

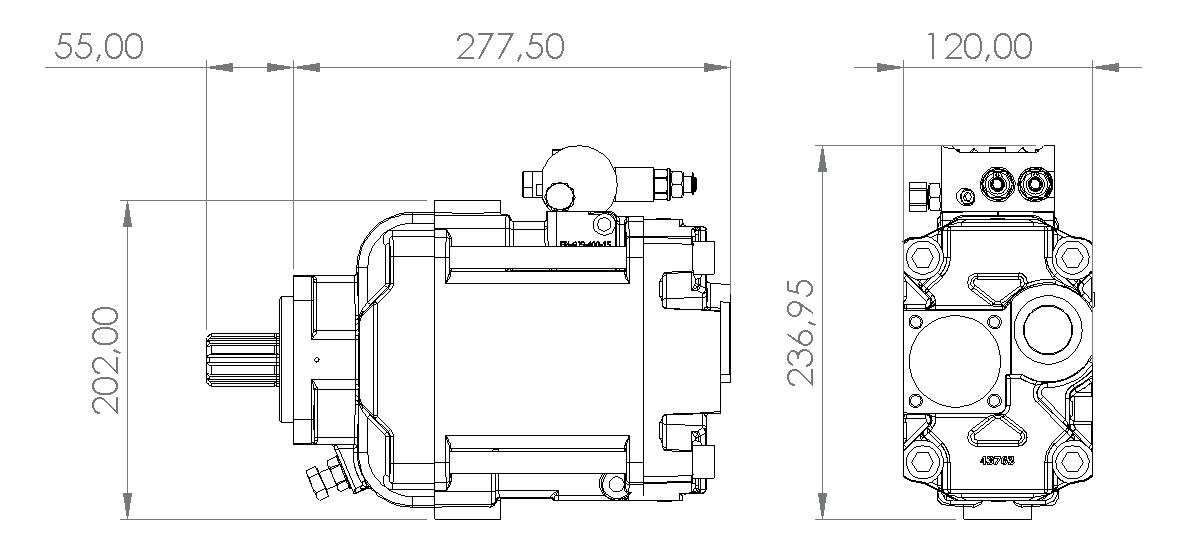

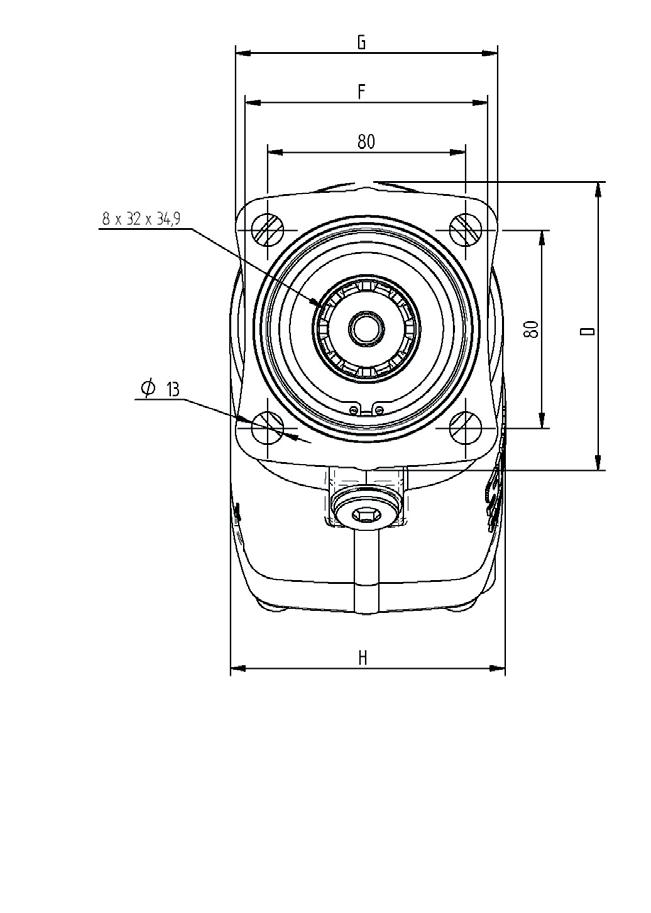

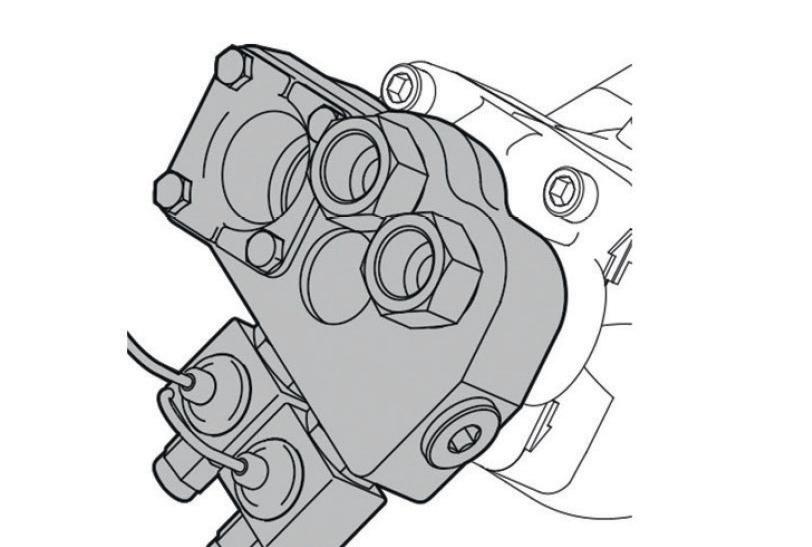

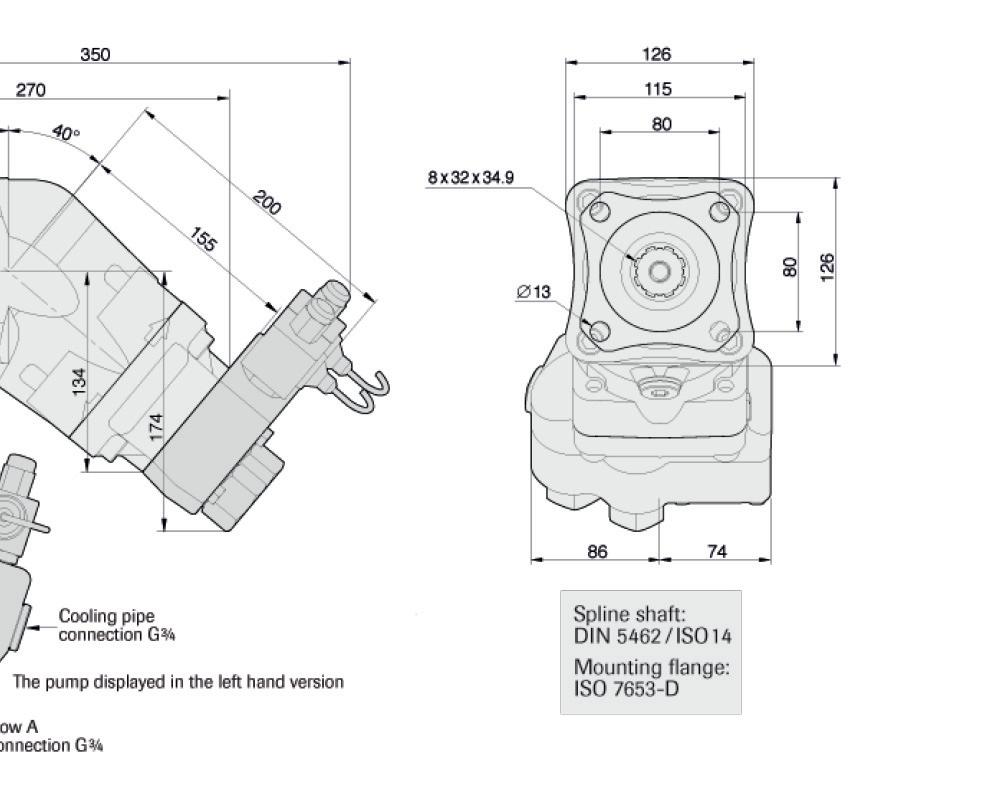

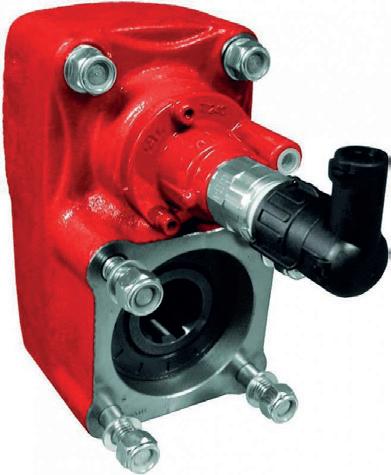

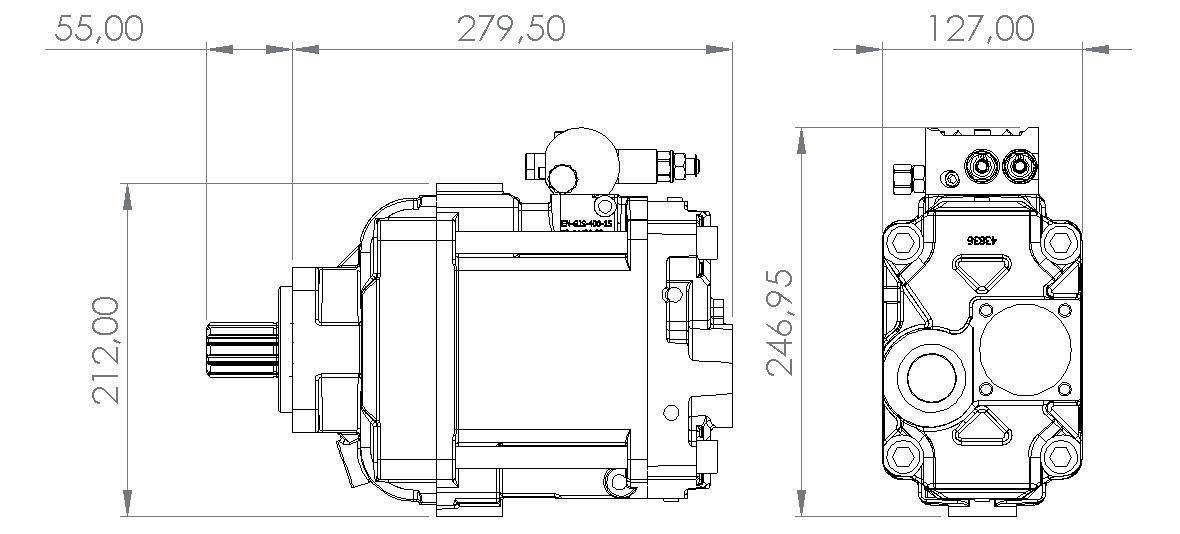

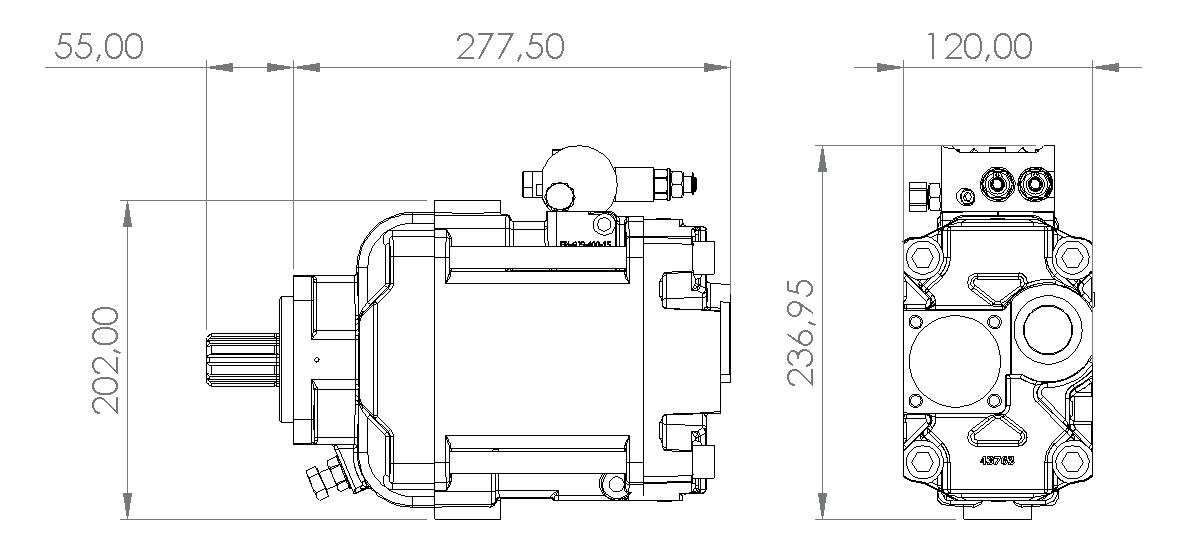

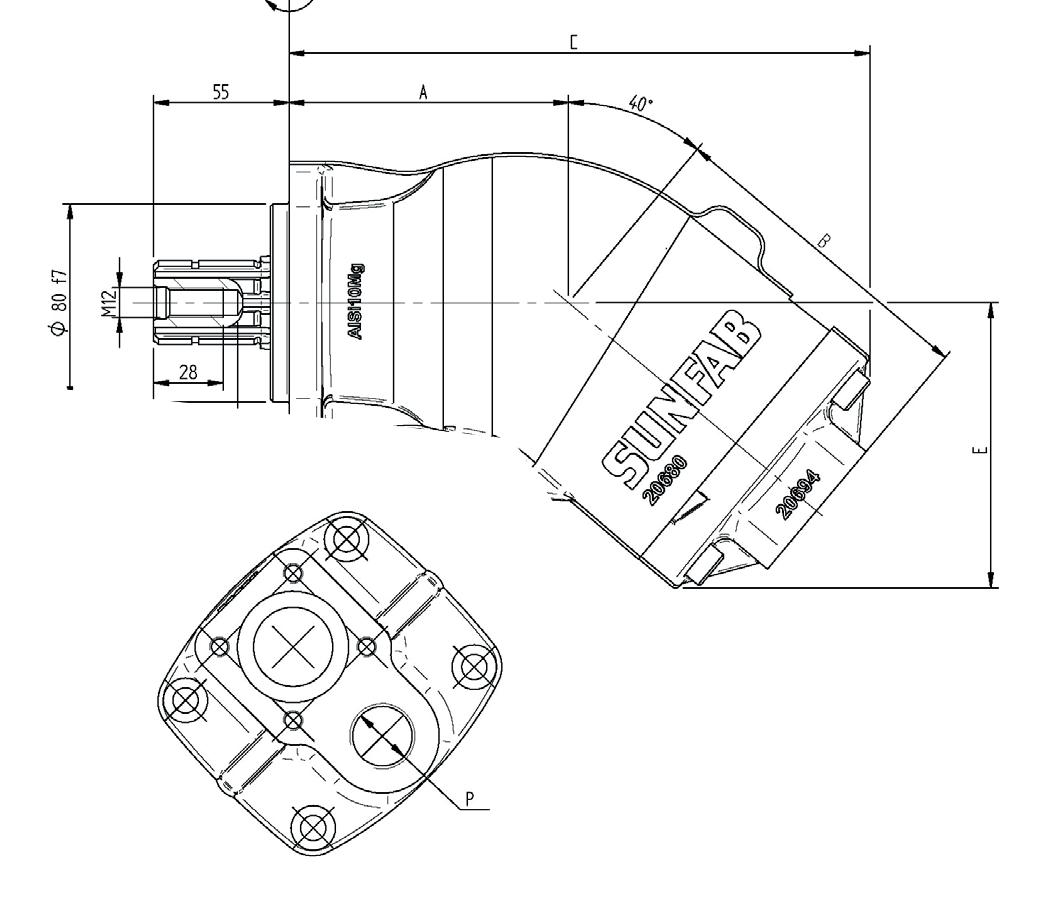

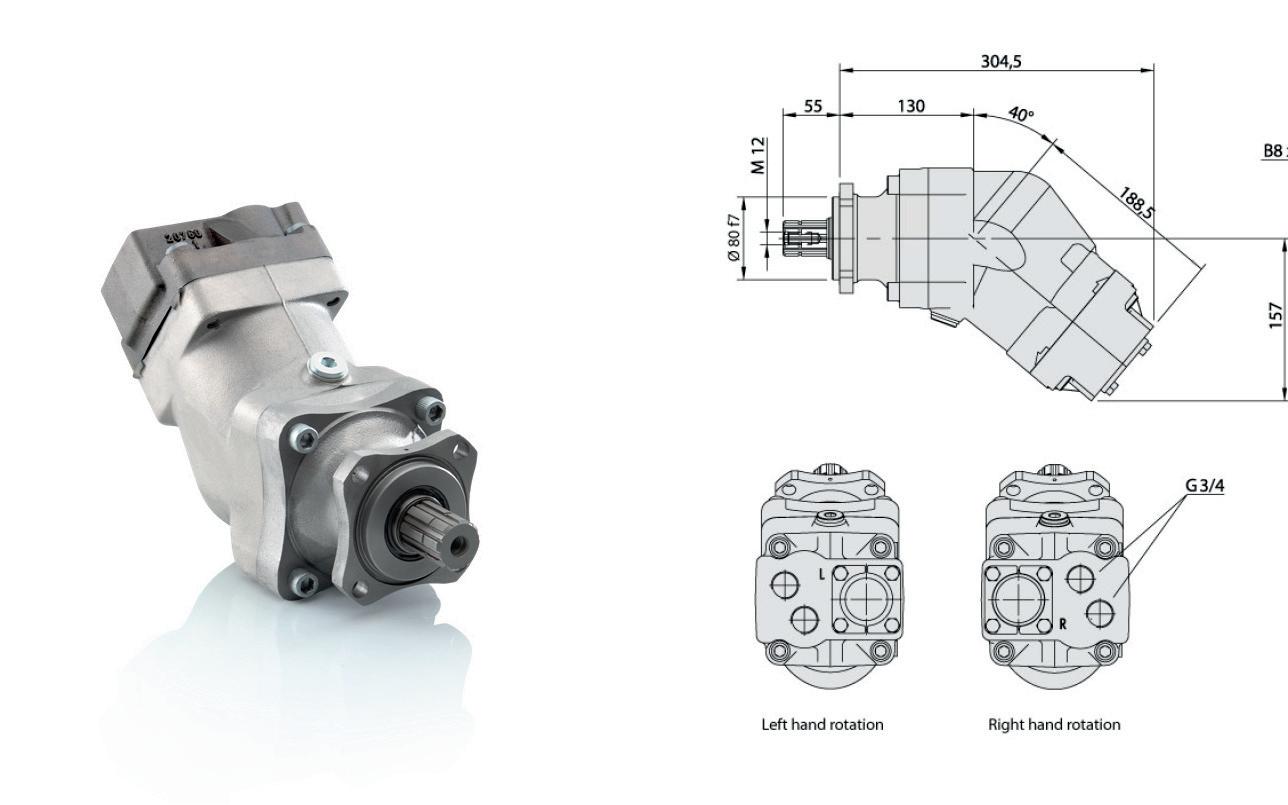

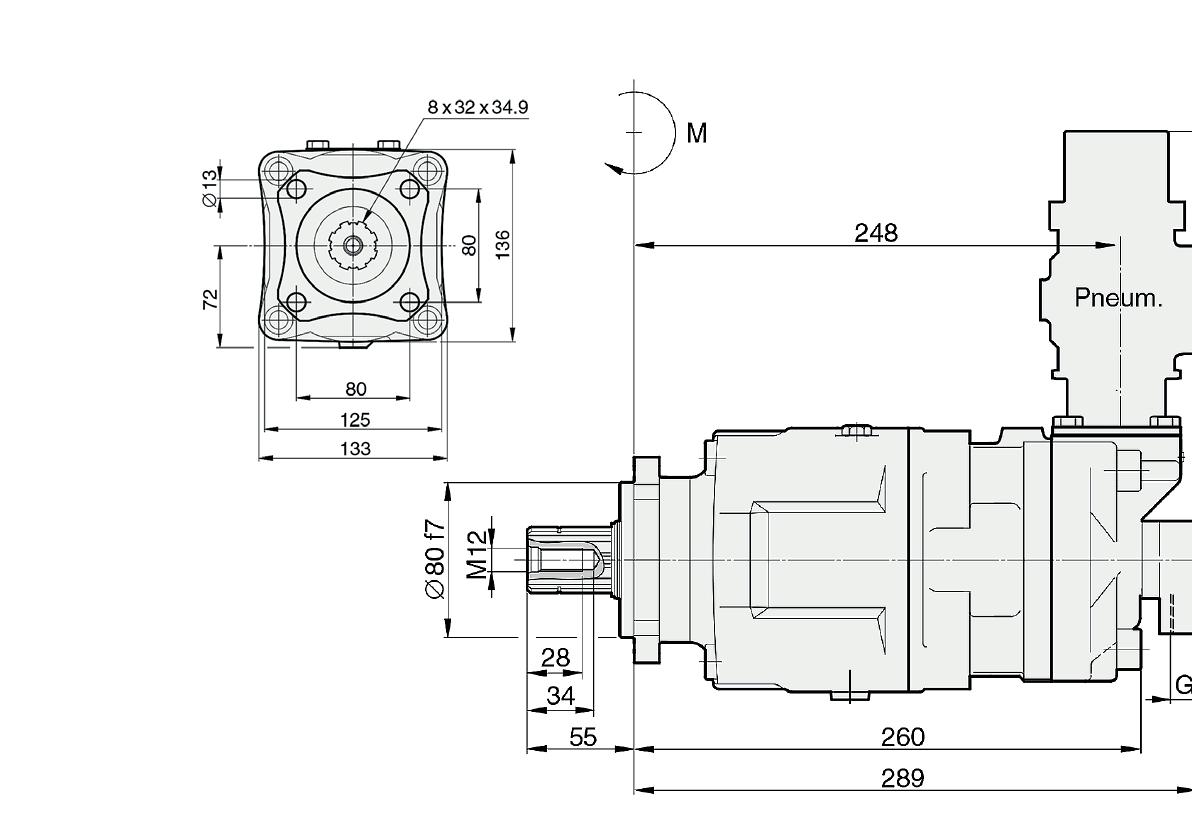

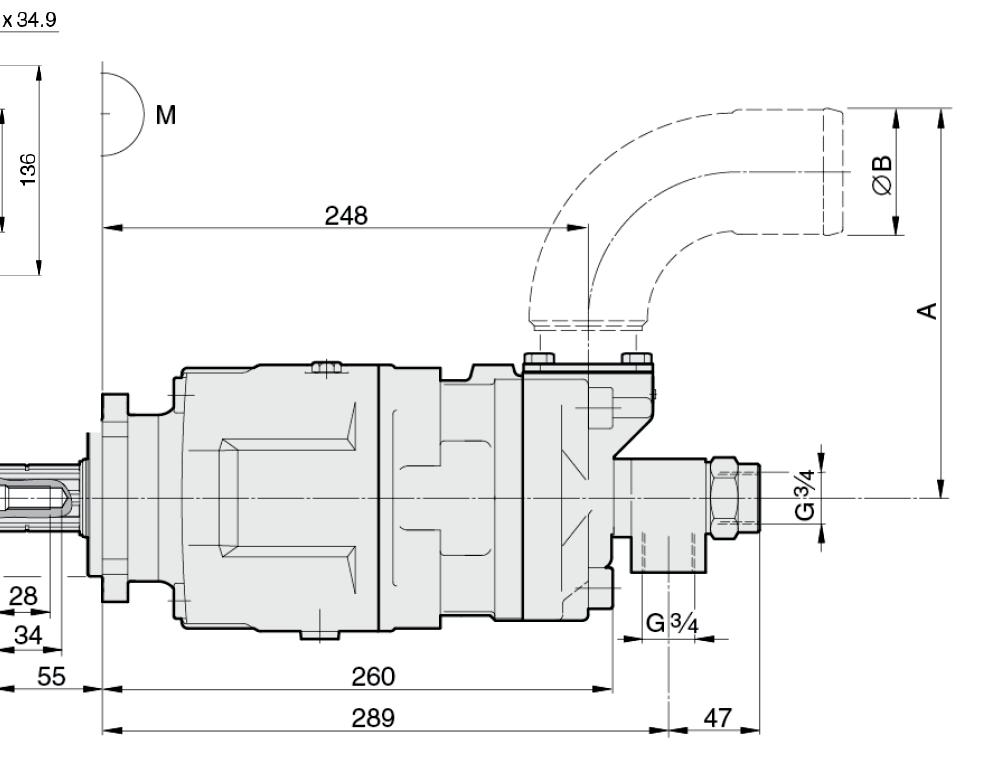

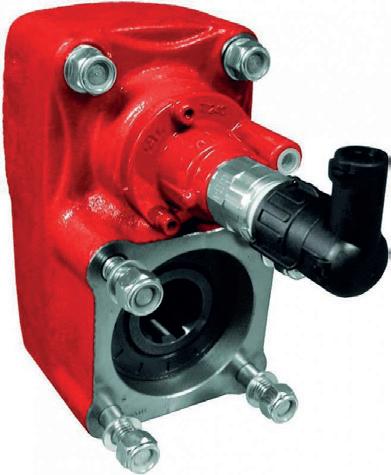

Sunfab SAP 012-108 DIN is a piston pump with a fixed displacement for demanding mobile hydraulics.

Can be mounted directly on the vehicle’s power take-off. See the installation instructions starting from page 50.

HAWE Finland Oy Koskelontie 15 | 02920 Espoo | Finland | Tel. +358 (0)10 82126 00 | sales@hawe.fi | www.hawe.fi 6

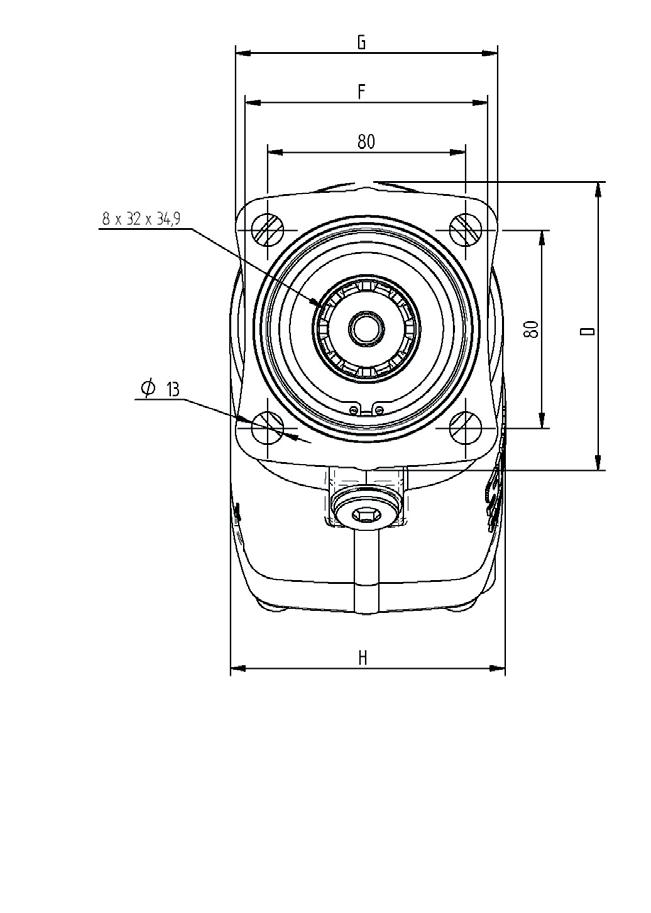

012 500 1000 1500 A B C D E F G H P 6.3 12.6 18.9 12.6 2300 3000 400 6.9 97 116 206 115 102 98 106 97 3⁄4 6.0 rpm cm3/rev. rpm bar kg mm ISO G Nm left (L) or right (R), exchangeable Theoretical output Displacement Max. pump speed Continuous Limited Max. working pressure Weight Dimensions Tare-weight torque Direction of rotation 017 8.5 17.0 25.5 17.0 2300 3000 400 6.9 97 116 206 115 102 98 106 97 3⁄4 6.0 025 12.7 25.4 38.1 25.4 2300 3000 400 7.1 97 116 206 115 102 98 106 97 3⁄4 6.5 034 17.1 34.2 51.3 34.2 2300 3000 400 7.1 97 116 206 115 102 98 106 97 3⁄4 6.5 040 l/min 20.6 41.2 61.8 41.2 1900 2500 400 9.8 113 13 235 118 115 98 106 111 3⁄4 11.5 047 23.5 47.1 70.6 47.1 1900 2500 400 9.8 113 131 235 118 115 98 106 111 3⁄4 11.5 056 28.0 56.0 84.0 56.0 1900 2500 400 9.8 113 131 235 118 115 98 106 111 3⁄4 11.5 064 31.8 63.6 95.4 63.6 1900 2500 400 9.8 113 131 235 118 115 98 106 111 3⁄4 11.5 084 41.5 83.6 125.4 83.6 1600 2100 400 13.9 122 147 264 127 133 98 106 118 1 18.0 108 54.0 108.0 162.0 108.0 1600 2100 400 13.9 122 147 264 127 133 98 106 118 1 18.0

Pumps and by-pass valves always in stock!

Shaft DIN 5462 / ISO14 Mounting flange ISO 7653-D

S SA SAP 0121008 DIN N

umps pass ays

Sunfab pump code key

SA P - 064-L - N - DL4- L35- S0 S- 0 00

Model

SASunfabAluminium

SLSunfab Line

SCSunfab Compact

Type

PPumps

PTTipper pump

PDDual flow pump

Displacement

012-130

Direction of rotation

LAnticlockwise

RClockwise

Seal material

NNitrile

VHNBR, high temperatures

VFKM (SCPD, SLPD)

Mounting flange

SB4SAE B4 J-744 (010-064)

SC4SAE C4 J-744 (040-108)

DL4DIN 4-h, ISO 7653 DIN (012-130)

By-pass valves

00 Without accessories

0No housing flushing

4Savtec (SLPD)

Pressure connections and suction fittings

S Sunfab standard

Pump back cover

S040°C, Sunfab standard

S4SunfaSunfab standard SLPD

Shaft

B13SAE B J499b 13-slot 16/32DP

H13

C14 L35

H35

SAE B 13-slot 16/32DP

SAE C 14-slot 12/24DP

DIN 5462 / ISO 14

DIN 5462 / ISO 14 o 8.15

SAP-064L-N-DL4-L35-S0S-000

SAP-064R-N-DL4-L35-S0S-000

SAP-084L-N-DL4-L35-S0S-000

SAP-084R-N-DL4-L35-S0S-000

SAP-108L-N-DL4-L35-S0S-000

SAP-108R-N-DL4-L35-S0S-000

PUMP TYPE

SAP, SCP 012-064, SAPT 090 SAP, SCP 012-064, SAPT 090 SAP, SCP 084-108, SAPT 130 SAP, SCP 084-108, SAPT 130 Cable 2.5 m - Deutsch connector

HAWE Finland Oy Koskelontie 15 | 02920 Espoo | Finland | Tel. +358 (0)10 82126 00 | sales@hawe.fi | www.hawe.fi 7

12 V 24 V 12 V 24 V

91071.HS 91073.HS 91075.HS 91077.HS 91078.HS PRODUCT NUMBER

VOLTAGE

PRODUCT NUMBER 23064.HS 23064R.HS 23084.HS 23084R.HS 23108.HS 23108R.HS PRODUCT 50906 50906 50934 50934 50934 50934 GASKET SET

l

SAE versions of SAP pumps available. Ask more!

Accessories Optional

Sunfab SAP pumps

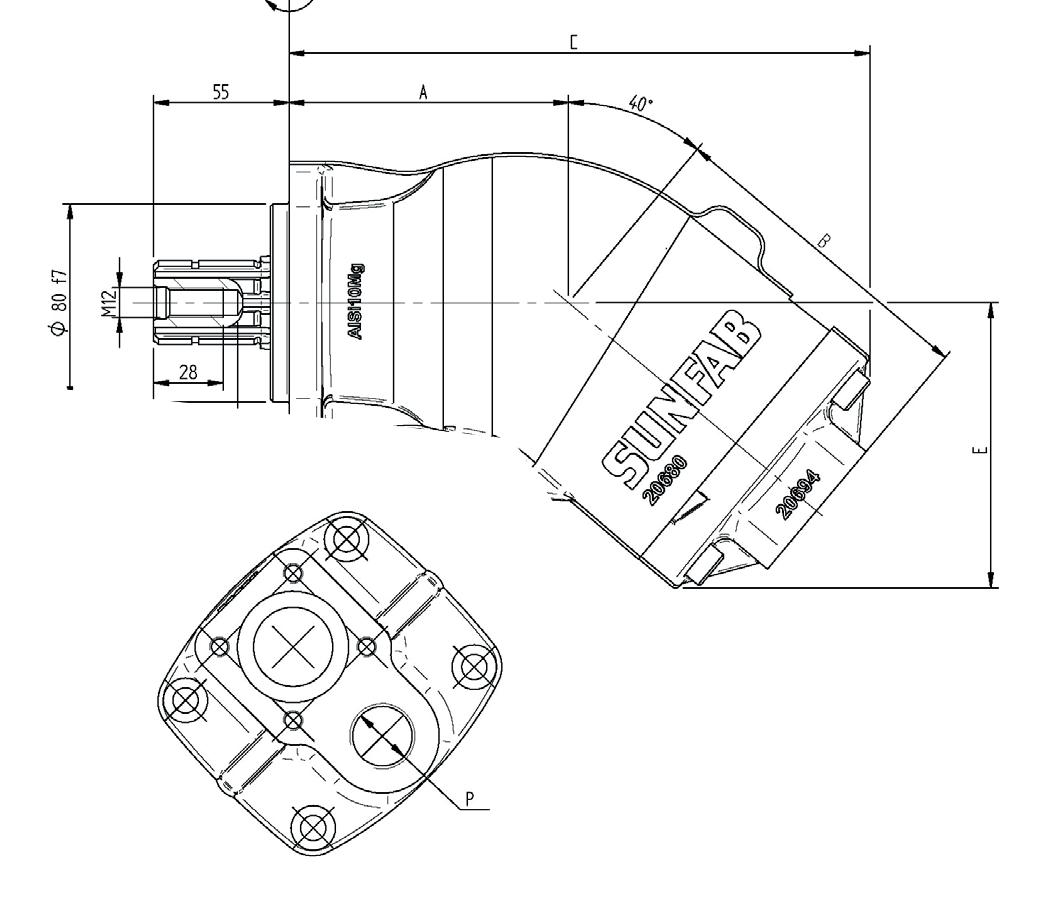

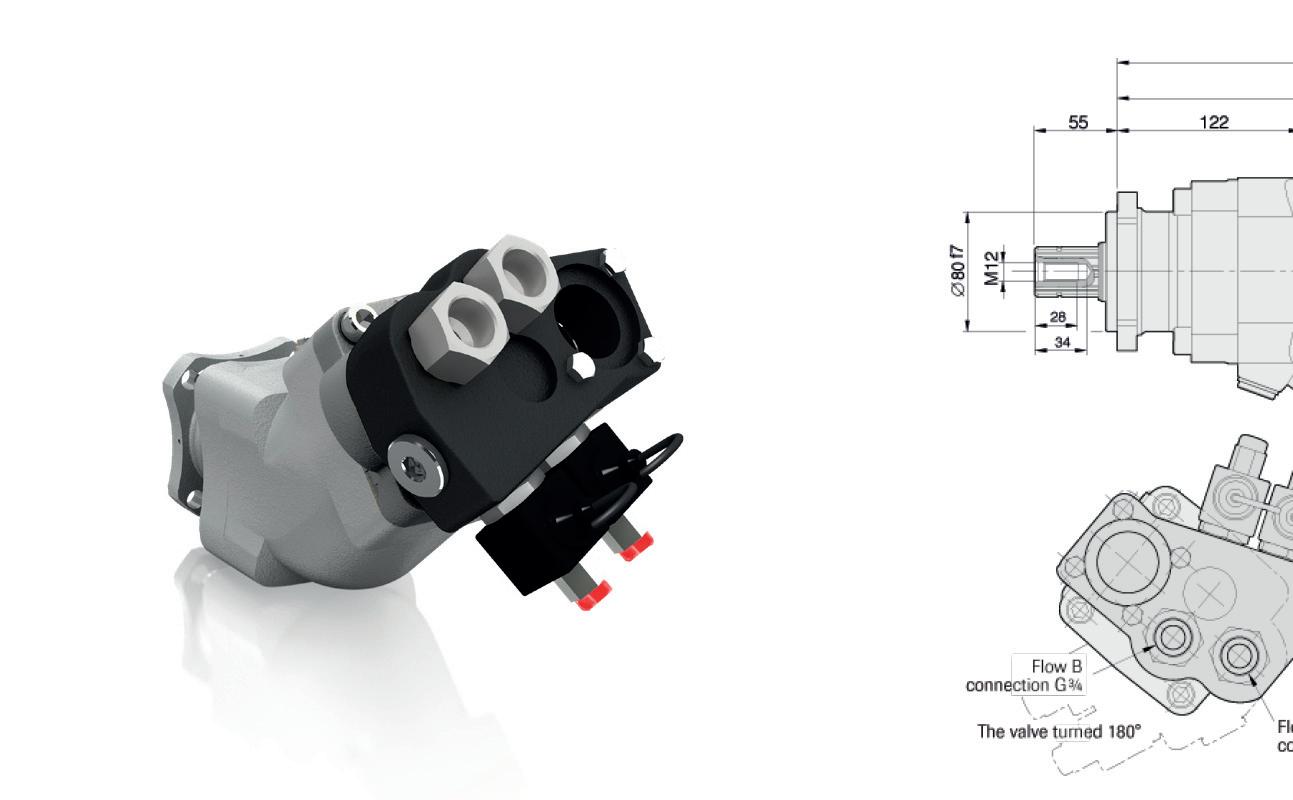

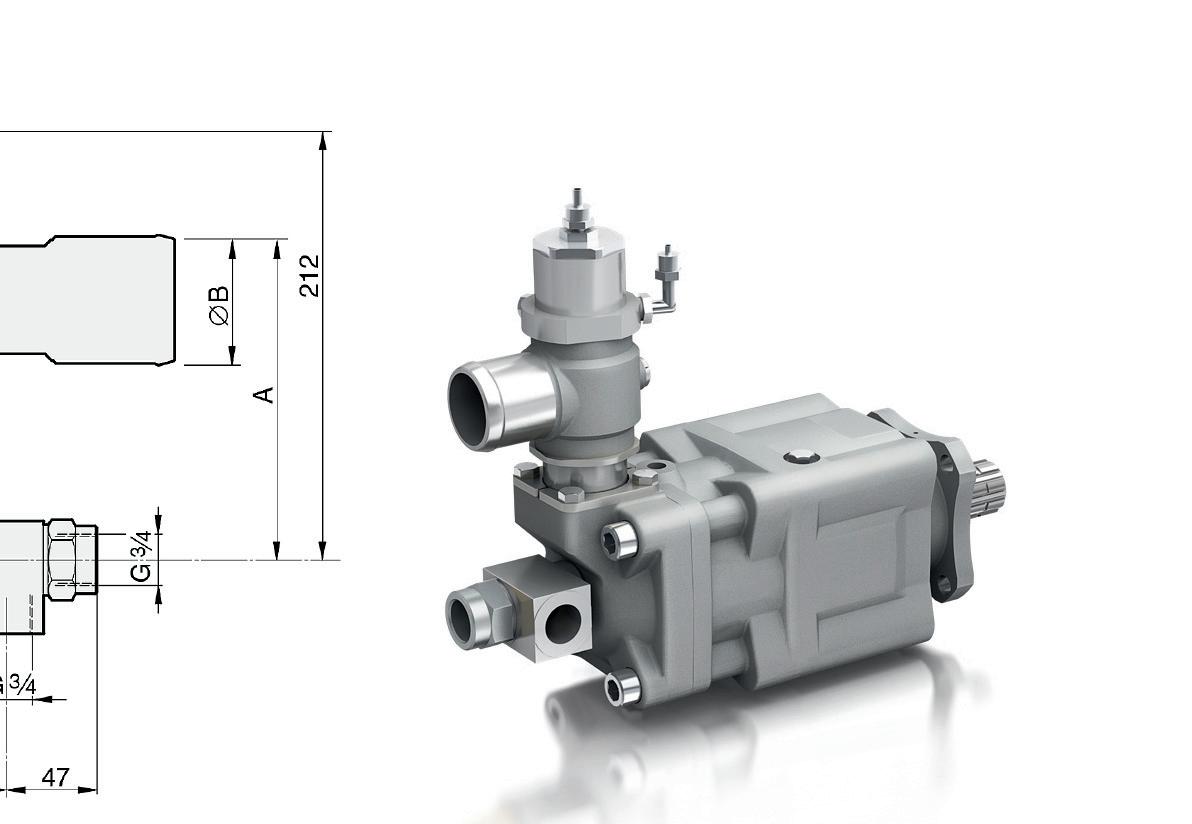

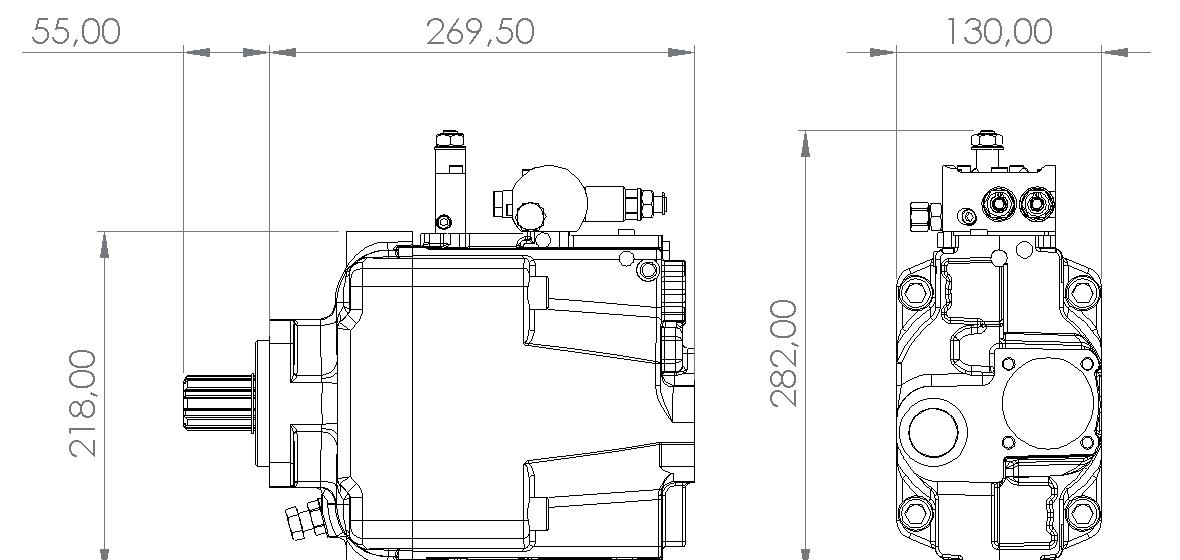

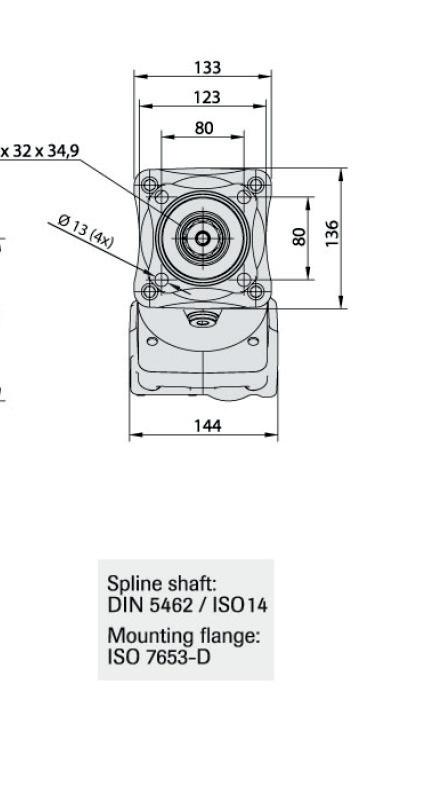

Sunfab SAP 084, 108 DIN Optimised is a piston pump with a fixed displacement for demanding mobile hydraulics. Can be mounted directly on the vehicle’s power takeoff.

Sunfab SAPT 090, 130 DIN is a pump with fixed displacement for tipper trucks and for mobile hydraulics that supports higher flow. Can be mounted directly on the vehicle’s power takeoff. Maximum pressure 300 bar.

See the installation instructions starting from page 50.

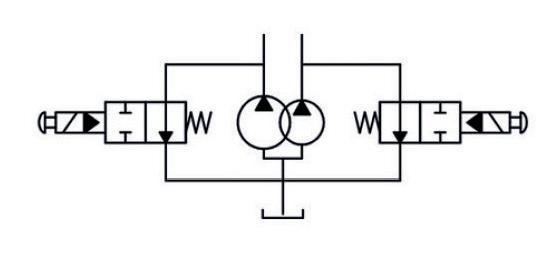

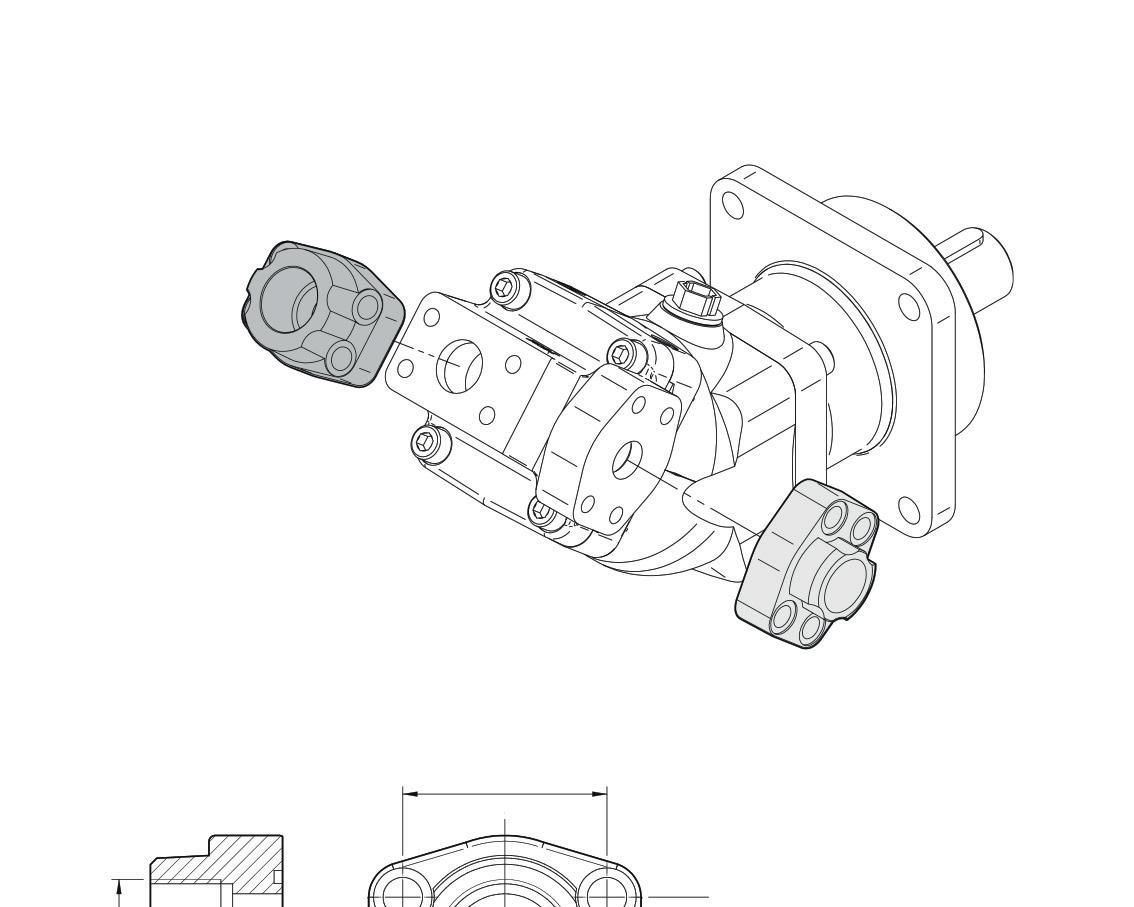

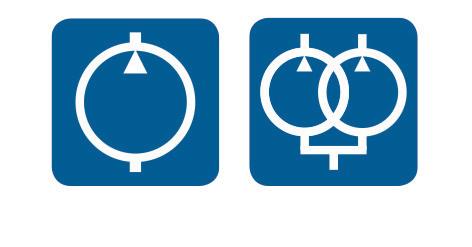

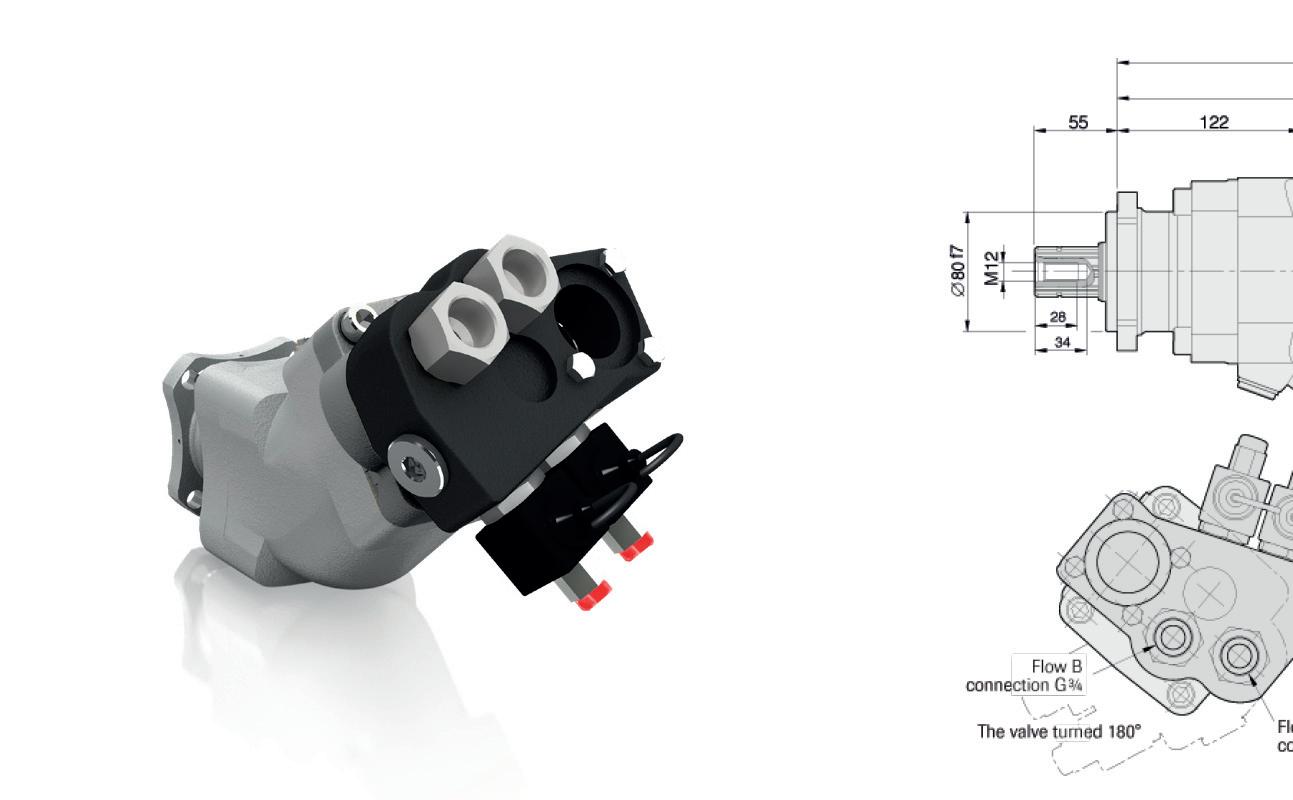

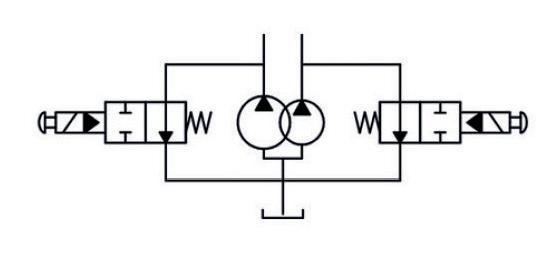

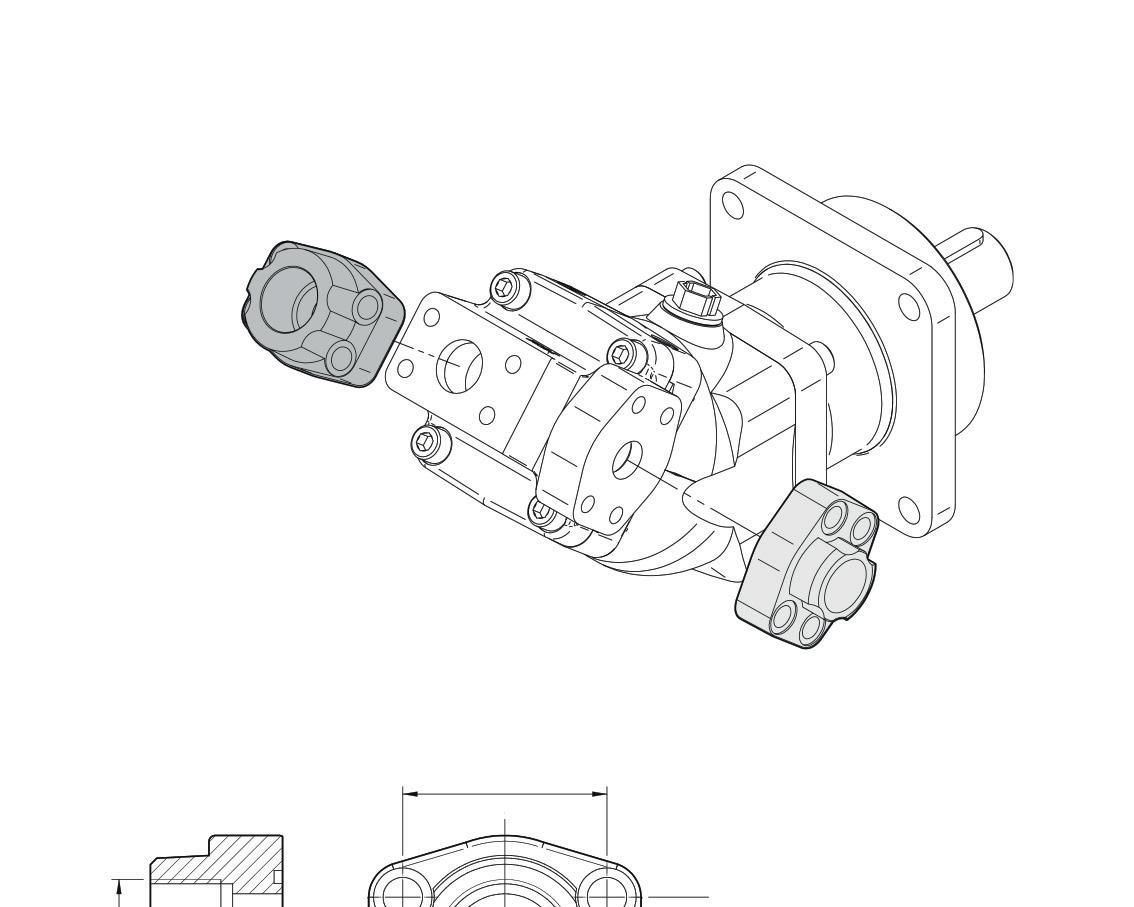

Sunfab SCPD twin flow pumps

090L-N-DL4-L35-SOS-000

Sunfab SCPD 76/76

DIN is a twin flow pump with two separate flows of equal sizes. Can be mounted directly on the vehicle’s power take-off.

See the installation instructions starting from page 50.

SCPD7 D 76/76D 6 DIN

The pump speed must be HIGHER than 1000 rpm!

HAWE Finland Oy Koskelontie 15 | 02920 Espoo | Finland | Tel. +358 (0)10 82126 00 | sales@hawe.fi | www.hawe.fi 8

rpm 1000 1500 75 + 75 1500 1700 350 23.2 34.5 1000 1500 cm3/rev. rpm bar kg Nm rpm left (L) or right (R), not exchangeable Theoretical output Displacement Continuous Limited Max. working pressure Weight Tare-weight torque Theoretical power at pressure and pump speed Theoretical torque on pump shaft at different pressures Direction of rotation l/min 75.0 + 75.0 = 150 112.5 + 112.5 = 225 200 Bar 25.0 + 25.0 = 50 kW 37.5 + 37.5 = 75 kW 200 Bar 239 + 239 = 478 Nm 250 Bar 31.3 + 31.3 = 62.6 kW 46.9 + 46.9 = 93.8 kW 250 Bar 298 + 298 = 596 Nm 350 Bar 43.8 + 43.8 = 87.6 kW 65.6 + 65.6 = 131.2 kW 350 Bar 418 + 418 = 836 Nm

084 500 1000 1500 P l/min 41.8 83.6 125.4 83.6 1800 2300 400 13.9 1 18.0 SAP 084, 108 DIN OPTIMISED rpm cm3/rev. rpm bar kg ISO G Nm left (L) or right (R) Theoretical output Displacement Max. pump speed Continuous Limited Max. working pressure Weight Dimensions Tare-weight torque Direction of rotation 108 54 108 162 108.0 1800 2300 400 13.9 1 18.0 090 500 1000 1500 P M l/min 45.0 90.0 135.0 90.0 1500 2000 300 9.8 3⁄4 11.5 SAPT 090, 130 DIN TIPPER PUMP rpm cm3/rev. rpm bar kg ISO G Nm left (L) or right (R), exchangeable Theoretical output Displacement Max. pump speed Continuous Limited Max. working pressure Weight Dimensions Tare-weight torque Direction of rotation 130 65.0 130.0 195.0 130.0 1500 2000 300 13.9 1 18.0

SAP-084L-V-DL4-L35-S0S-200

PRODUCT NUMBER 23211.HS 23212.HS 23219.HS 23220.HS PRODUCT

SAP-084R-V-DL4-L35-S0S-200 SAPT

SAPT 130L-N-DL4-L35-SOS-000

Sunfab SCPD twin flow pumps

Sunfab SCPD 56/26 DIN is a twin flow pump with two separate flows of different sizes. Can be mounted directly on the vehicle’s power takeoff. See the installation instructions starting from page 50.

Dual by-pass valves

HAWE Finland Oy Koskelontie 15 | 02920 Espoo | Finland | Tel. +358 (0)10 82126 00 | sales@hawe.fi | www.hawe.fi 9

rpm 600 1000 1200 1500 1800 56.0 + 26.0 1850 1850 2200 2700 400 18 22.5 21 25.5 rpm 600 1200 1800 PUMP SCPD 56/26 DIN BY-PASS cm3/rev. rpm rpm rpm rpm bar kg kg Nm Nm left (L) or right (R), not exchangeable Theoretical output A+B Displacement A+B Max. pump speed A+B Max. working pressure A Maximum speed B Maximum speed, released Max. working pressure Weight with valve Weight without valve Tare-weight torque with valve Tare-weight torque without valve Theoretical power at pressure and pump speed Theoretical torque on pump shaft at different pressures Direction of rotation l/min 33.5 + 15.5 = 49 56.0 + 26.0 = 82 67.0 + 31.0 = 98 84.0 + 39.0 = 123 100.5 + 46.5 = 147 200 Bar 11.2 + 5.2 = 16.4 kW 22.4 + 10.4 = 32.8 kW 33.6 + 15.6 = 49.2 kW 200 Bar 178 + 83 = 261 Nm 300 Bar 16.8 + 7.8 = 24.6 kW 33.6 + 15.6 = 49.2 kW 50.4 + 23.4 = 73.8 kW 300 Bar 267 + 124 = 391 Nm 200 Bar 22.4 + 10.4 = 32.8 kW 44.8 + 20.8 = 65.6 kW 67.2 + 31.2 = 98.4 kW 400 Bar 265 + 165 = 521 Nm

24 V SCPD-56/26 20536

SCPD-56/26L-V-DL4-L35-S0S-200 SCPD-56/26R-V-DL4-L35-S0S-200 SCPD

SCPD 76/76

PRODUCT NUMBER 20534.HS 20535.HS 23333.HS 23334.HS PRODUCT

76/76 L-N-DL4-35-SOS-200

R-N-DL4-35-SOS-200

By-pass valve makes adjusting the volume flow easy!

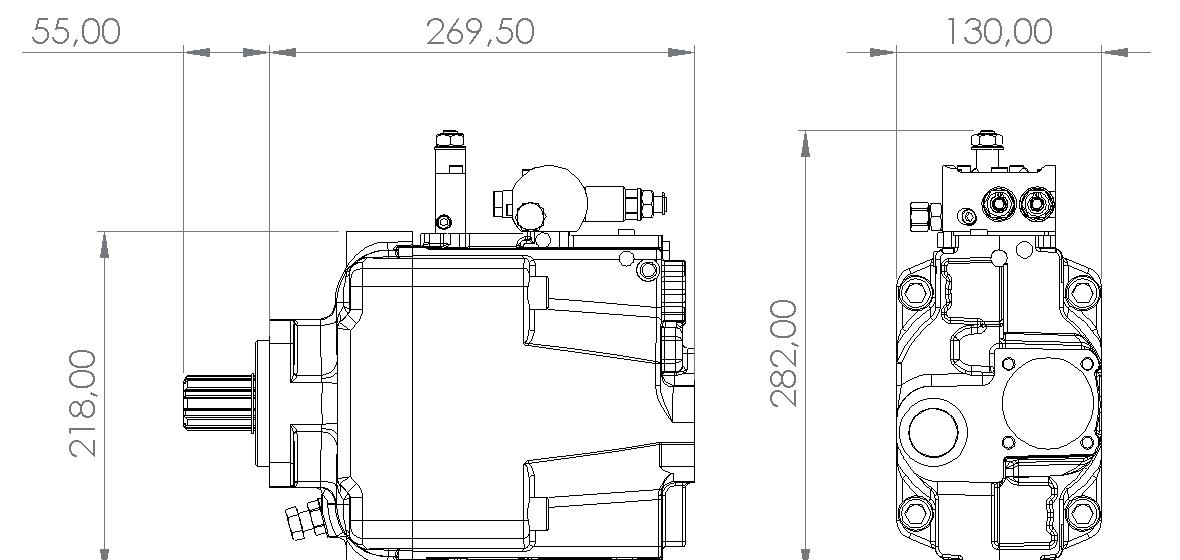

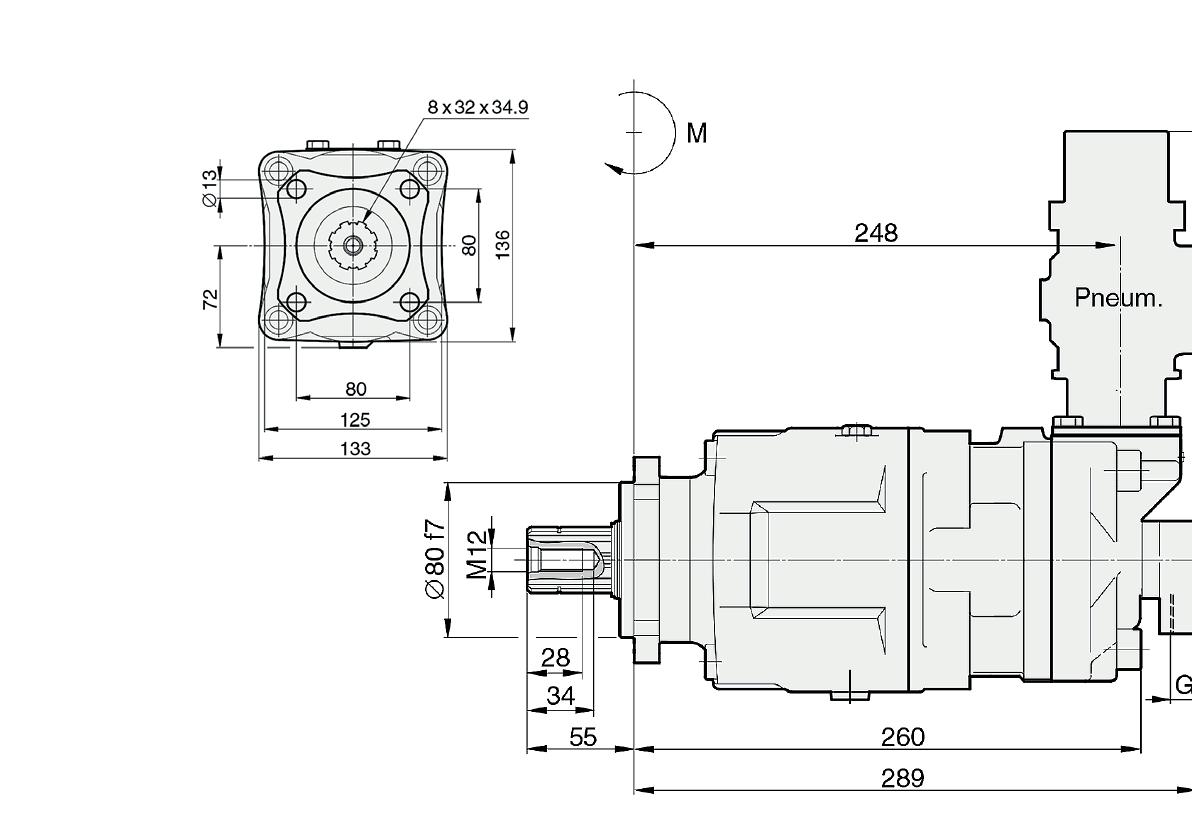

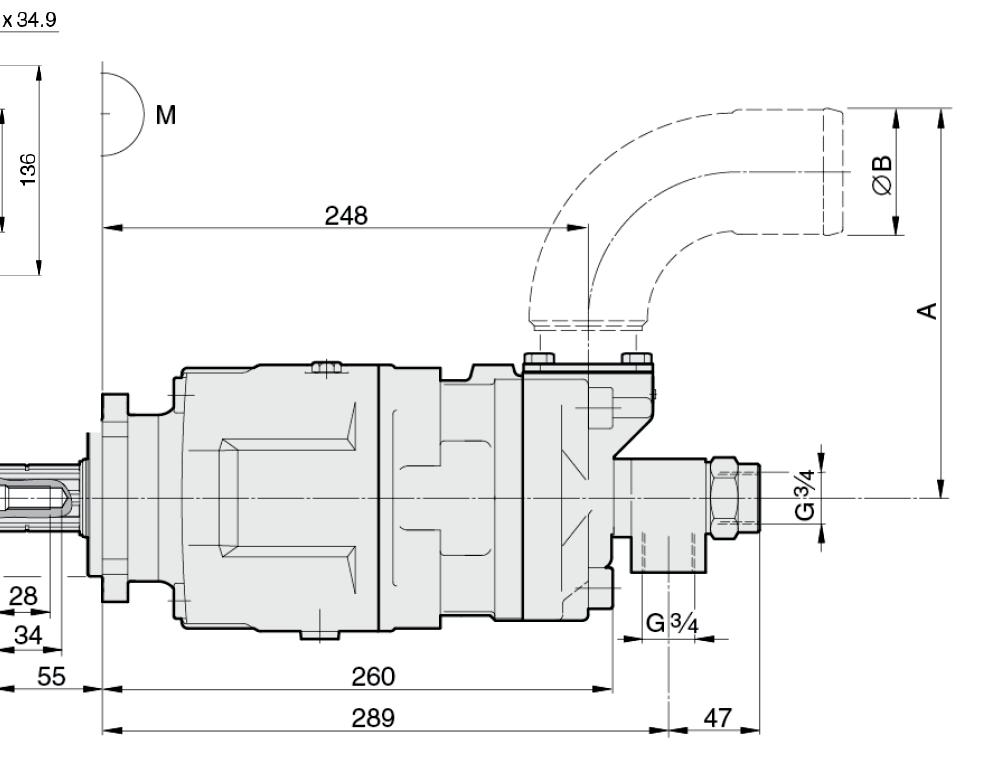

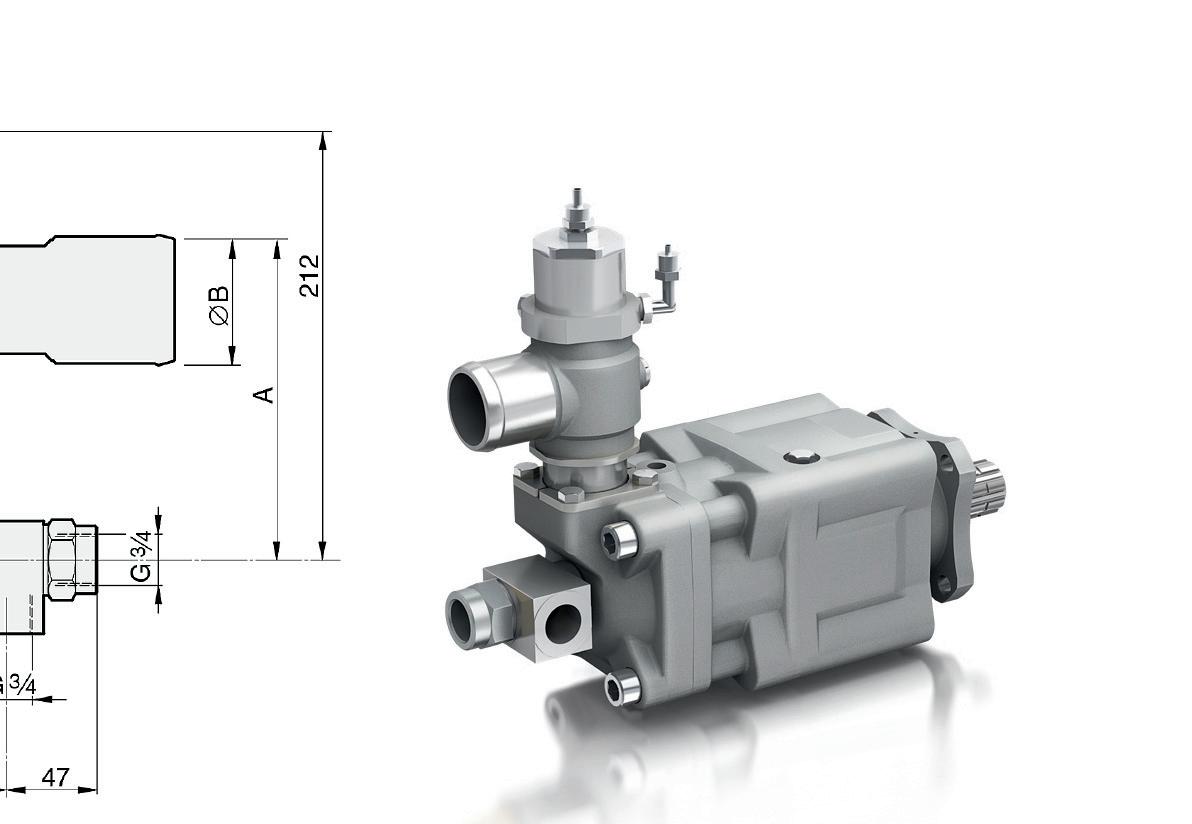

Sunfab SLPD pumps

Sunfab SLPD is an in-line twin flow pump with extremely low noise level for demanding mobile hydraulics. Can be mounted directly on the vehicle’s power take-off. The SAVTEC model can also be mounted directly on the engine's power take-off. See the installation instructions starting from page 50.

SLPD-28/28W-V-DL4-L34-S4S-4

SLPD-35/35W-N-DL4-L35-S4S-0

SLPD-46/46W-N-DL4-L35-S4S-0

SLPD-53/53W-N-DL4-L35-S4S-0

SLPD-64/32W-V-DL4-L35-S4S-4

SLPD-46/46W-N-DL4-L35-S4S-4

SLPD 53/53W-V-DL4-L35-S4S-4

SLPD 35/35W-N-SC4-C14-S4S-0

HAWE Finland Oy Koskelontie 15 | 02920 Espoo | Finland | Tel. +358 (0)10 82126 00 | sales@hawe.fi | www.hawe.fi 10

13.7 +13.7 27.5 + 27.5 41.3 + 41.3 27.5 + 27.5 1800 350 22.0 133 50 26.5 PUMP SLPD 20/20-64/32 DIN rpm 500 1000 1500 cm3/rev. rpm bar kg A B Nm optional Theoretical output Displacement Max. pump speed Max. working pressure Weight Dimensions Suction coupling dimensions Tare-weight torque (M) Direction of rotation 28/28 20.3 +10.1 40.7 + 20.3 61.0 + 30.4 40.7 + 20.3 2200 350 22.0 133 50 26.5 40/20 l/min 16.9 +16.9 33.9 + 33.9 50.8 + 50.8 33.9 + 33.9 2200 330 22.0 133 50 26.5 35/35 27.4 +13.7 54.9 + 27.5 82.3 + 41.2 54.9 + 27.5 1800 350 22.0 166 64 26.5 56/28 22.9 + 22.9 45.8 + 45.8 68.7 + 68.7 45.8 + 45.8 1800 330 22.0 166 64 26.5 46/46 26.2 + 26.2 52.5 + 52.5 78.7 + 78.7 52.5 + 52.5 1600 330 22.0 166 64 26.5 53/53 31.5 + 15.7 63 + 31.5 94.5 + 47.2 63.0 + 31.5 1600 350 22.0 166 64 26.5 64/32 13.7 +13.7 27.5 +27.5 41.3 +41.3 27.5 + 27.5 1800 2500 350 24.5/23.5 133 50 32.5/29.5 PUMP SLPD 20/20-64/32 DIN SAVTEC rpm 500 1000 1500 cm3/rev. rpm rpm bar kg A B Nm optional Theoretical output Displacement Max. pump speed Max. pump speed, idling Max. working pressure Weight Dimensions Suction coupling dimensions Tare-weight torque (M) Direction of rotation 28/28 20.3 +10.1 40.7 +20.3 61.0 +30.4 40.7 + 20.3 2200 3000 350 24.5/23.5 133 50 32.5/29.5 40/20 l/min 16.9 +16.9 33.9 +33.9 50.8 +50.8 33.9 + 33.9 2200 3000 330 24.5/23.5 133 50 32.5/29.5 35/35 27.4 +13.7 54.9 +27.5 82.3 +41.2 54.9 + 27.5 1800 2500 350 24.5/23.5 166 64 32.5/29.5 56/28 22.9 +22.9 45.8 +45.8 68.7 +68.7 45.8 + 45.8 1800 2500 330 24.5/23.5 166 64 32.5/29.5 46/46 26.2 +26.2 52.5 +52.5 78.7 +78.7 52.5 + 52.5 1600 2500 330 24.5/23.5 166 64 32.5/29.5 53/53 31.5 +15.7 63 + 31.5 94.5 +47.2 63.0 + 31.5 1600 2500 350 24.5/23.5 166 64/32 13.1 + 10.1 20.3 +20.3 30.4 +30.4 20.3 + 20.3 1800 3000 350 24.5/23.5 133 50 32.5/29.5 20/20

10.1 +10.1 20.3 + 20.3 30.4 + 30.4 20.3 + 20.3 2200 350 22.0 133 50 26.5 20/20

PRODUCT NUMBER 50426.HS 18657.HS 18658.HS 18659.HS 18680.HS 18682.HS 18683.HS 18728.HS PRODUCT SAVTEC Equipped with a pneumatic SAVTEC valve. 18600.HS Hose diameter mandatory. fi|hfi 5 32.5/29.5 Quiet dual hydraulicsflow for property management! 64

HAWE Finland Oy Koskelontie 15 | 02920 Espoo | Finland | Tel. +358 (0)10 82126 00 | sales@hawe.fi | www.hawe.fi 11

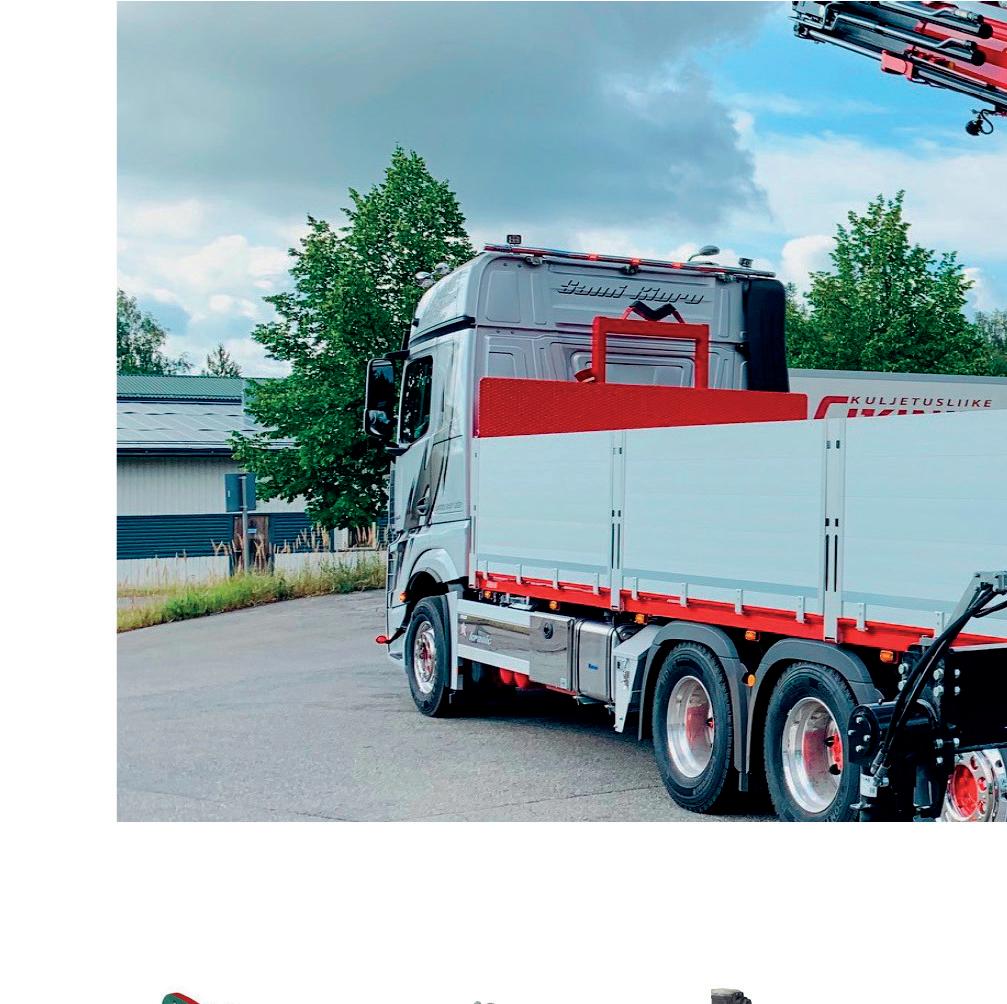

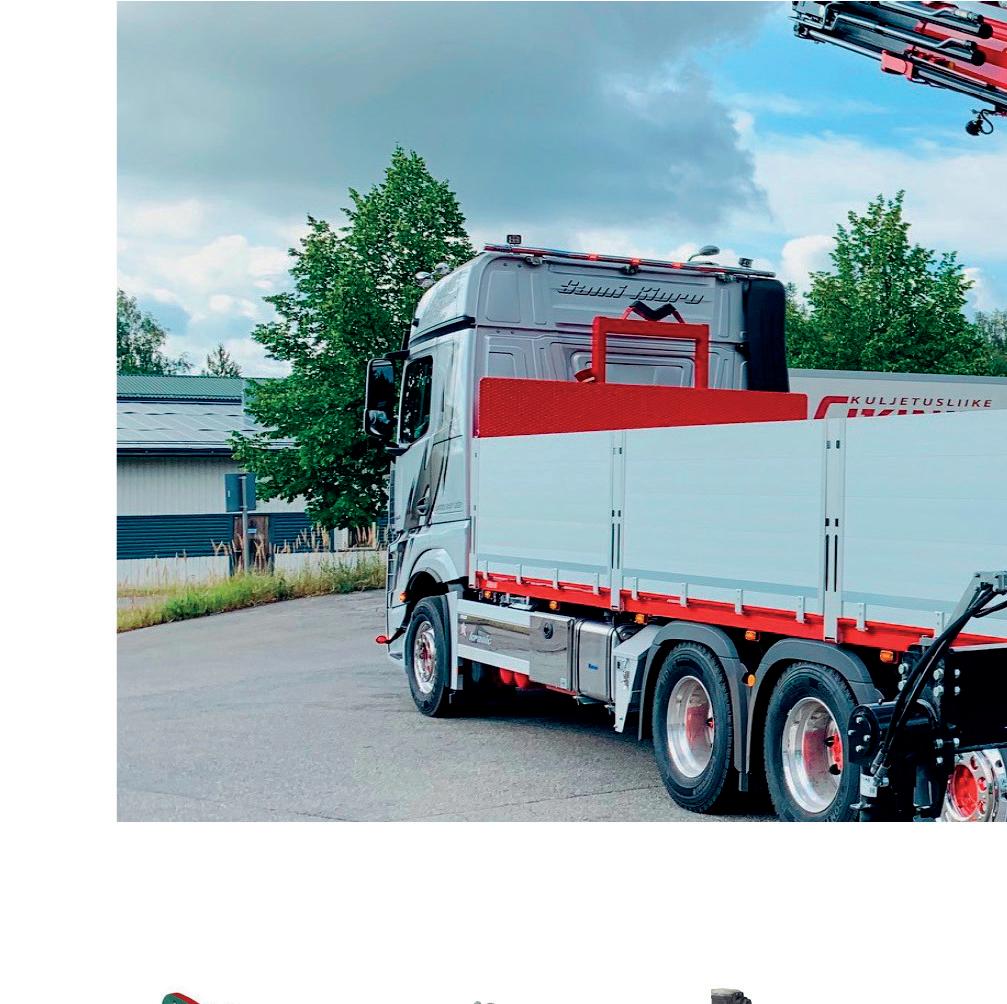

vehicleGreatmulti-purpose byTyllisOy. Theentirehydraulicsystem isfromHAWE.

Compact medium pressure pumps

HAWE C40V

High rotation speed – up to 3,300 rpm!

Compact and light structure

LS, power and electrical controllers available

HAWE C40V code key

Load-sensing controllers

LS0DA Load-sensing pressure controller without signal pressure relief

LS1DA Load-sensing pressure controller with integrated signal pressure relief

pressure relief

pressure relief Pressure controllers Mechanically adjusted pressure controller Flow controllers Proportional flow controller with increasing characteristic Flow controllers LR Power controller Coil voltage and type

1 Increasing characteristic, 24V, Deutsch connector

2 Descending characteristic curve, 24V, Deutsch connector

3 Increasing characteristic, 12V, Deutsch connector

4 Descending characteristic curve, 12V, Deutsch connector

5 Increasing characteristic, 24V, AMP connector

6 Descending characteristic curve, 24V, AMP connector

7 Increasing characteristic, 12V, AMP connector

8 Descending characteristic curve, 12V, AMP connector Only rising options available for controller VE.

Gaskets

Special versions and accessories

G Suction pump function Stroke limitation

0 No control

5

Thru-shaft

See the installation instructions starting from page 50.

HAWE Finland Oy Koskelontie 15 | 02920 Espoo | Finland | Tel. +358 (0)10 82126 00 | sales@hawe.fi | www.hawe.fi 12

Controller

proportional

proportional

028 045 085 V

Direction

LAnticlockwise Mounting flange B2 SAE-B 2-hole J744 101-2 DIN 3019-1 (-028 and -045) C6 SAE-C 2- and/or 4-hole J744 127-2 and 127-4 DIN ISO 3019-1 (085) Production

Viton

of rotation R Clockwise

series

Stroke limitation, fixed. Include the control setting in your order!

versions 0000 No thru-shaft.

frames A3 and B3. K02G Thru-shaft compatible. Flange Shaft A11D SAE-A 2-hole J744 82-2 DIN ISO 3109-1 SAE-A J744 (16-4 DIN ISO 3019-1) 9T 16/32 DP A21D SAE-A 2-hole J744 82-2 DIN ISO 3019-1 19-4 DIN ISO 3019-1 11T 16/32 DP B11D SAE-B 2-hole J744 101-2 DIN ISO 3019-1 SAE-B J744 (22-4 DIN ISO 3019-1) 13T 16/32 DP B21D SAE-B 2-hole J744 101-2 DIN ISO 3019-1 SAE-BB J744 (25-4 DIN ISO 3019-1) 15T 16/32 DP C11D SAE-C 2-hole J744 127-2 DIN ISO 3019-1 SAE-C J744 (32-4 DIN ISO 3019-1) 14T 12/24 DP C21D SAE-C 2-hole J744 127-2 DIN ISO 3019-1 SAE-CC J744 (38-4 DIN ISO 3019-1) 17T 12/24 DP Frame versions A1 Radial inlet and pressure connections, with thru-shaft (085) A3 Axial inlet and pressure connections (085) B1 Radial inlet and pressure connections, with thru-shaft (028 and 045) B3 Axial inlet and pressure connections (028 and 045)

A2 SAE-B J744 13T 16/32 DP (028 and 045) A4 SAE-BB J744 15T 16/32 DP (045) A6 SAE-C J744 14T 12/24 DP (085) A8 SAE-CC J744 17T 12/24 DP (085)

Load-sensing

Only

Shaft type

Displacement Load-sensing pressure controller with electric

pressure controller with electric

Compact medium pressure pumps

HAWE HP5V

High rotation speed

Light and compact

HAWE HP5V code key

6cc gear pump Standard configuration with 10cc gear pump

Flange Shaft Pumps

Excavator applications. - Other mobile equipment, construction machinery and industrial applications

AMP Junior timer, 2-pin FKM (Viton)

DR Pressure control. S28-85

ER1 Electro-hydraulic pressure controller, increasing characteristic S28-45

ER2 Electro-hydraulic pressure controller, descending characteristic curve S28-105

L1 Load-sensing pressure controller S28-85

P0 Hydraulic remote control S28-85

Power controllers

L1/1 Load-sensing pressure controller and power control S28, 45-105

P0/1 Hydraulic remote control and power control S28, 45-85

L1/1-E0 Electr., descending char. + pressure control + power control S28, 76-85

L1/1-H0 Hydraulic control + pressure control + power control 76-85

LP1 Load-sensing pressure controller and power control 28

Connections (excl. inlet and pressure)

A UNC port, ISO 11926

G BSPP thread, JIS B2351

M Metric port, ISO 9974

Flange thread type

M Metric thread

Shaft type

SAE J744-22-1 B6.35×28 key slot

SAE J744-25-1 B6.35×32 straight shaft

SAE J744-32-1 B7.94×44 straight shaft

See the installation instructions starting from page 50.

HAWE Finland Oy Koskelontie 15 | 02920 Espoo | Finland | Tel. +358 (0)10 82126 00 | sales@hawe.fi | www.hawe.fi 13 Product line Displacement Production series V Applications Coil types 1 Thru-shaft Direction of rotation L Anticlockwise Mounting flange

S1

Controllers Pressure controllers

Clockwise Nitrile) Standard product line Compact product line A series Gaskets

S UNC thread

Hydraulic circuit Open hydraulic circuit No thru-shaft, standard No thru-shaft, SAE ports on the back No thru-shaft, threaded ports on the back Standard configuration with

Heavy duty pumps

HAWE V30E

95-270cc mobile pump

Broad selection of controllers

For demanding conditions

Quiet

For mobile equipment of all sizes

HAWE V30E code key

pressure controller

load-sensing controller

proportional pressure controller

power controller

proportional flow controller

Additional functions: angle indicator

0 no angle indicator

1 angle indicator

2 angle sensor (Hall)

Housing versions

1 No thru-shaft

2 Thru-shaft

See the installation instructions starting from page 50.

HAWE Finland Oy Koskelontie 15 | 02920 Espoo | Finland | Tel. +358 (0)10 82126 00 | sales@hawe.fi | www.hawe.fi 14 Type Displacement Direction of rotation L Anticlockwise R Clockwise Shaft type D K Mounting flange F N E C

V R D N

70

suitable

Controllers

Model Generation

Gaskets

for HFC. See document D 7960E-en.

Heavy duty pumps

HAWE V30G(L)

110–280cc heavy duty pump

High nominal pressure: up to 420 bar!

Broad selection of controllers

For demanding conditions

Integrated feed pump optional

Large mobile machines and industrial systems

HAWE V30G(L) code key

Power controllers

LR power controller, stable setting

L1 proportional power controller, overrides the stable setting

Pressure controllers

DR pressure controller, stable setting

DS load-sensing pressure controller

Flow controllers

S0 no output regulation

E1 proportional flow controller

The controllers are combinable: power controller + pressure controller + flow controller. Additional functions: angle indicator

See the installation instructions starting from page 50.

HAWE Finland Oy Koskelontie 15 | 02920 Espoo | Finland | Tel. +358 (0)10 82126 00 | sales@hawe.fi | www.hawe.fi 15 Type L=feed pump; no L=no feed pump Direction of rotation 110 Anticlockwise R Clockwise Shaft type Mounting flange Ø Ø Ø Ø V V no angle indicator angle indicator angle sensor 0 1 2 Displacement Gaskets L 0 No thru-shaft

Outlet flange Code Flange Shaft

Controllers

Heavy duty pumps

HAWE V80M

200cc mobile pump

High nominal pressure: up to 400 bar! Ideal for continuous operation in demanding conditions – e.g. crushers

HAWE V80M code key

Type

Displacement

200 Direction of rotation

L Anticlockwise

R Clockwise

Shaft type

D W50x2x24x9g DIN 5480 (V30E-160)

S SAE-F J 744 15T 8/16 DP, 50-4 DIN ISO 3109-1

U SAE-D J 744 13T 8/16 DP, 44-4 DIN ISO 3109-1

Mounting flange

G 180 B4 HW DIN ISO 3019-2

F SAE-E 4-hole J 744, 155-4, DIN ISO 3019-1

W SAE-D 4-hole J 744, 152-4, DIN ISO 3019-1

Gaskets

Controllers

P pressure controller

LSP load-sensing controller

L power controller

Model Generation

Additional functions: angle indicator

0

1 angle indicator

Housing versions

V proportional flow controller 1

See the installation instructions starting from page 50.

HAWE Finland Oy Koskelontie 15 | 02920 Espoo | Finland | Tel. +358 (0)10 82126 00 | sales@hawe.fi | www.hawe.fi 16

N

No thru-shaft

Thru-shaft V R N

2

no

angle indicator

HAWE Finland Oy Koskelontie 15 | 02920 Espoo | Finland | Tel. +358 (0)10 82126 00 | sales@hawe.fi | www.hawe.fi 17

innovationsdrillingrigsandtechnologyforsoilinvestigation, mineralprospectingandwell drillinginthemostdemanding conditionsintheworld.

Geomachine

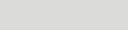

Pump–PTO gaskets

Flanges

Factory-approved pump assembly grease

Renolite LX PEP 2

HAWE Finland Oy Koskelontie 15 | 02920 Espoo | Finland | Tel. +358 (0)10 82126 00 | sales@hawe.fi | www.hawe.fi 18

108 - 130 G 1 ½” 57.15 58.72 66.68 69.85 27.76 30.18 31.75 35.71 FLANGES SCM Engine SCP ISO Pump 50513.HS 50939.HS 50431.HS 50431.HS 50644.HS 50512.HS 50513.HS 50939.HS SAE/M 6000 Psi 50938.HS 50435.HS 50645.HS 50940.HS SCP ISO 3000 Psi 50644.HS 50512.HS 50431.HS 50939.HS 6000 Psi Product RENOLIT LX-PEP 2 400 g assembly grease RENOLIT LX-PEP 2 18 kg assembly grease 24 5001-21.HF 24 5002-21.HF Product code

CM3/rev 25 - 34 25 - 34 40 - 64 40 - 64 84 - 130 84 - 90 84 - 130 108130 G ½” G ¾” G ¾” G 1” G 1” G 1 ¼” G 1 ¼” G1½” 40 49 47.63 50 80 52 37 58 72 66 68 69 85 18.24 22.23 23 80 26 19 30 18 FLANGES SCM 50512.HS 6000 Psi 50432.HS ISO/UN 6000 Psi 50432.HS SAE/UN 6000 Psi 50644. 50512. 50513. 50939. 6000 P

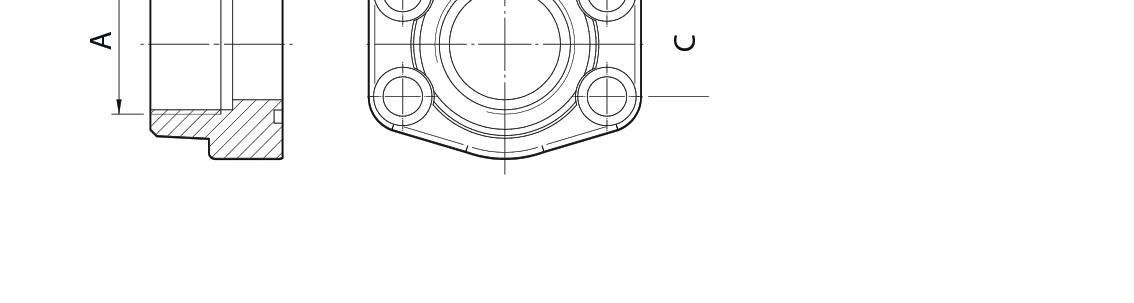

ØE (4x) A D B C ØE (2x) A D B C FLANGE DIN 4 SAE-B 4 SAE-B 2 SAE-C 4 81 102 102 128 O ABCDO EProduct number 80 146 146 114,5 106 114 175 145,5 106 144 122 114,5 13 13 14 14 61077.HS 18244.HS 61178.HS 61177.HS

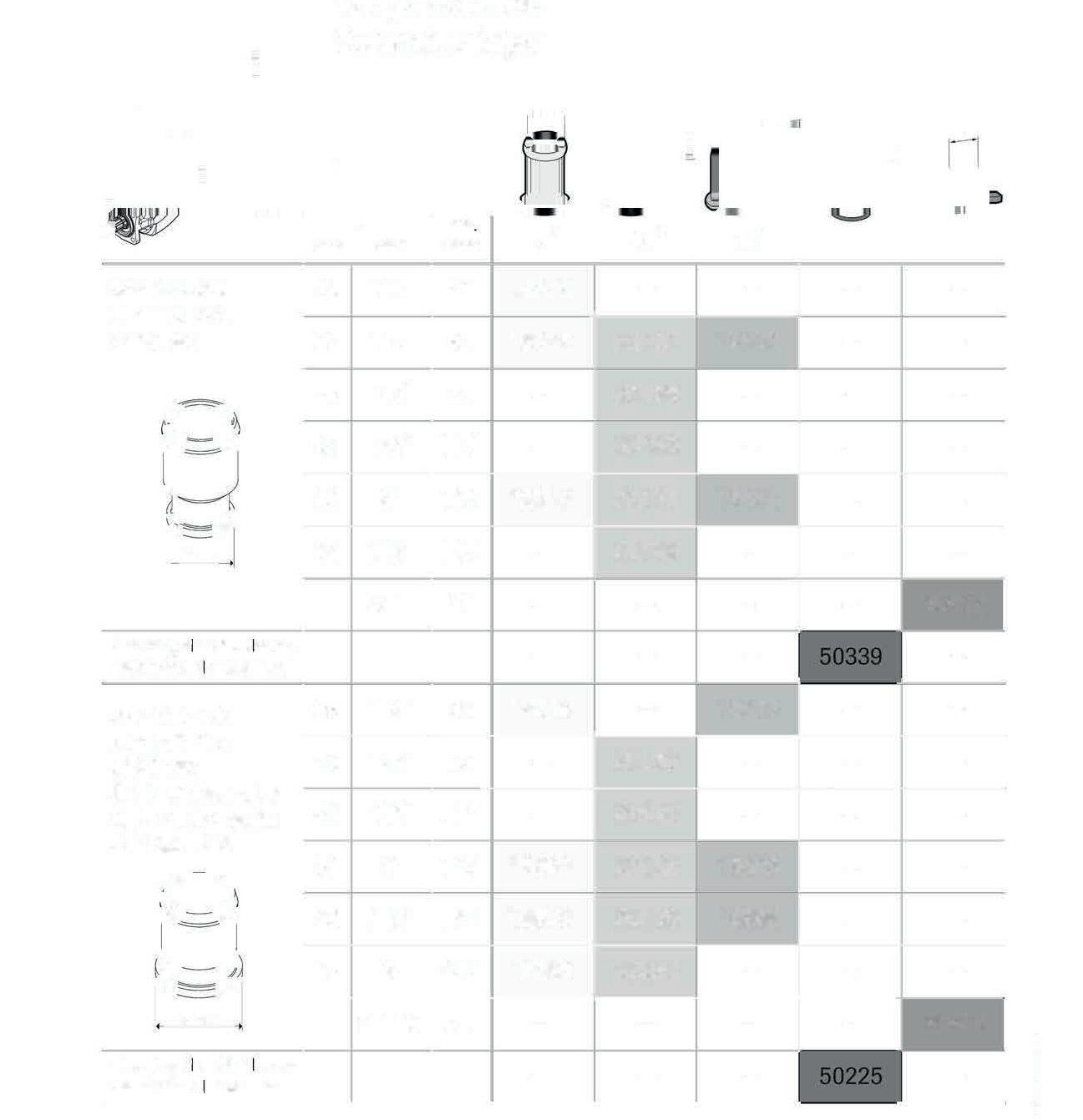

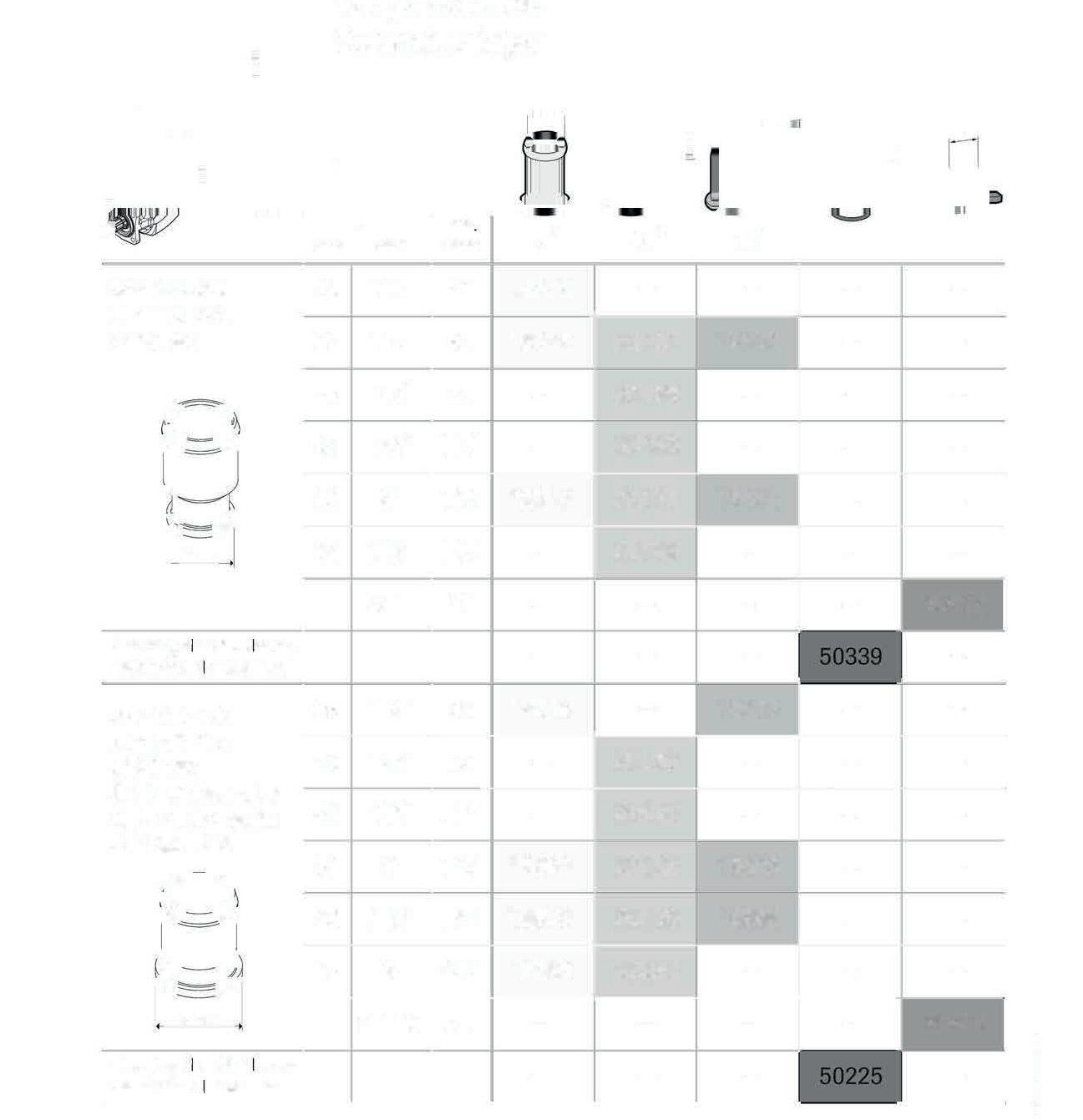

Suction connectors

System sizing guide

Check the suction connector size!

Suction connectors in stock!

HAWE Finland Oy Koskelontie 15 | 02920 Espoo | Finland | Tel. +358 (0)10 82126 00 | sales@hawe.fi | www.hawe.fi 19

Suction connector flange set Suction connector flange set <90 50 32 19 19 Output l/min Suction line (mm) Return line (mm) Pressure line (mm) Housing flushing <120 50 32 25 19 <160 63 38 25 19 <220 75 45 32 19 HAWE Finland Koskelontie 15 02920 E et t Suction connector se

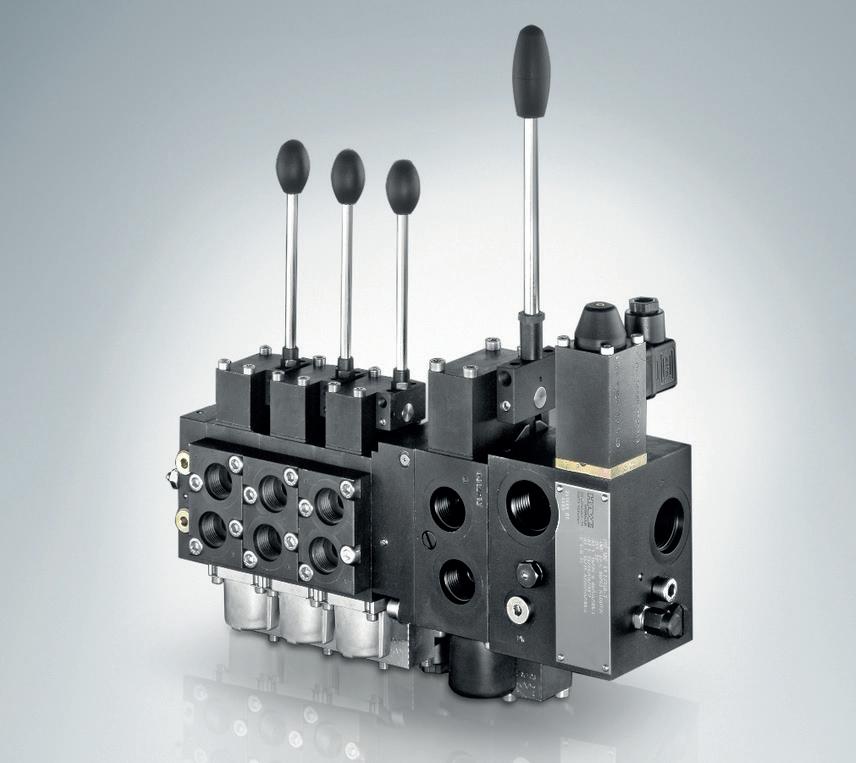

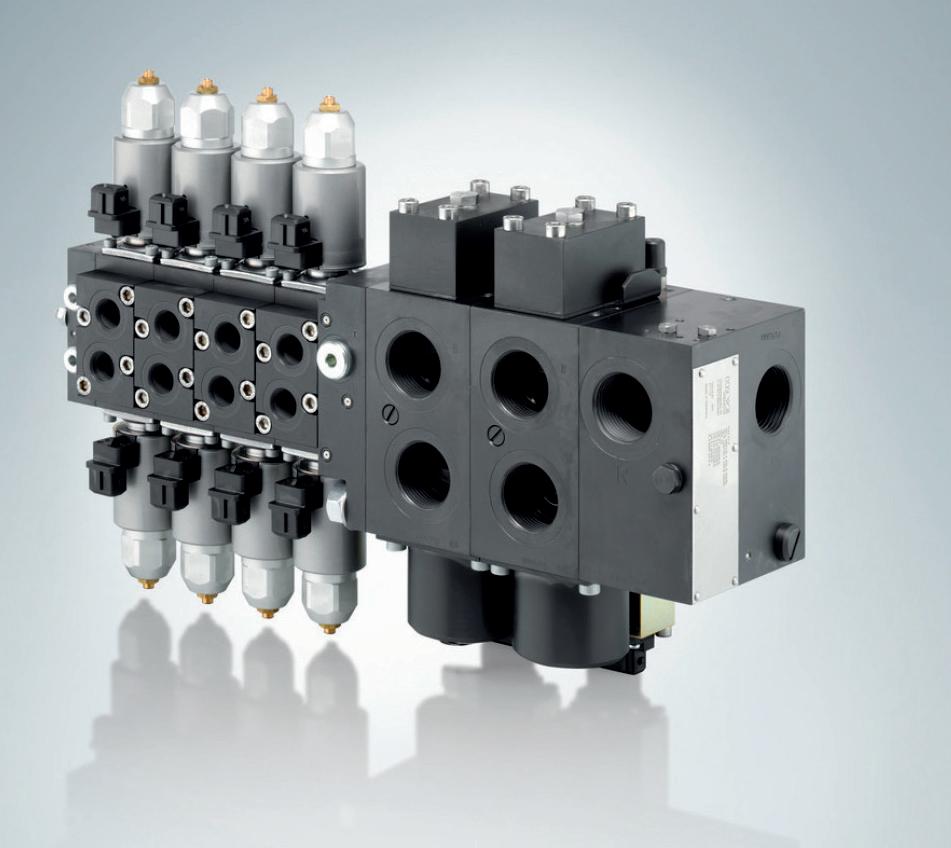

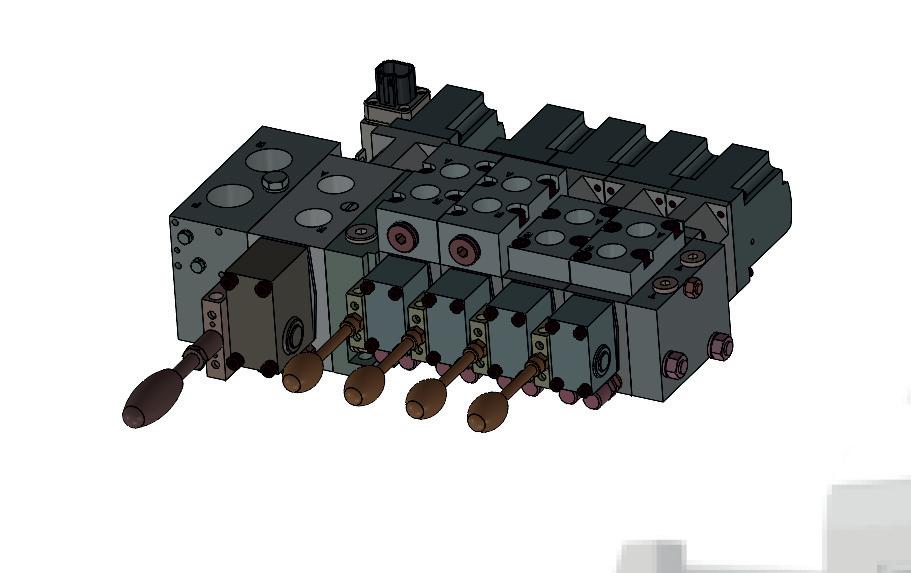

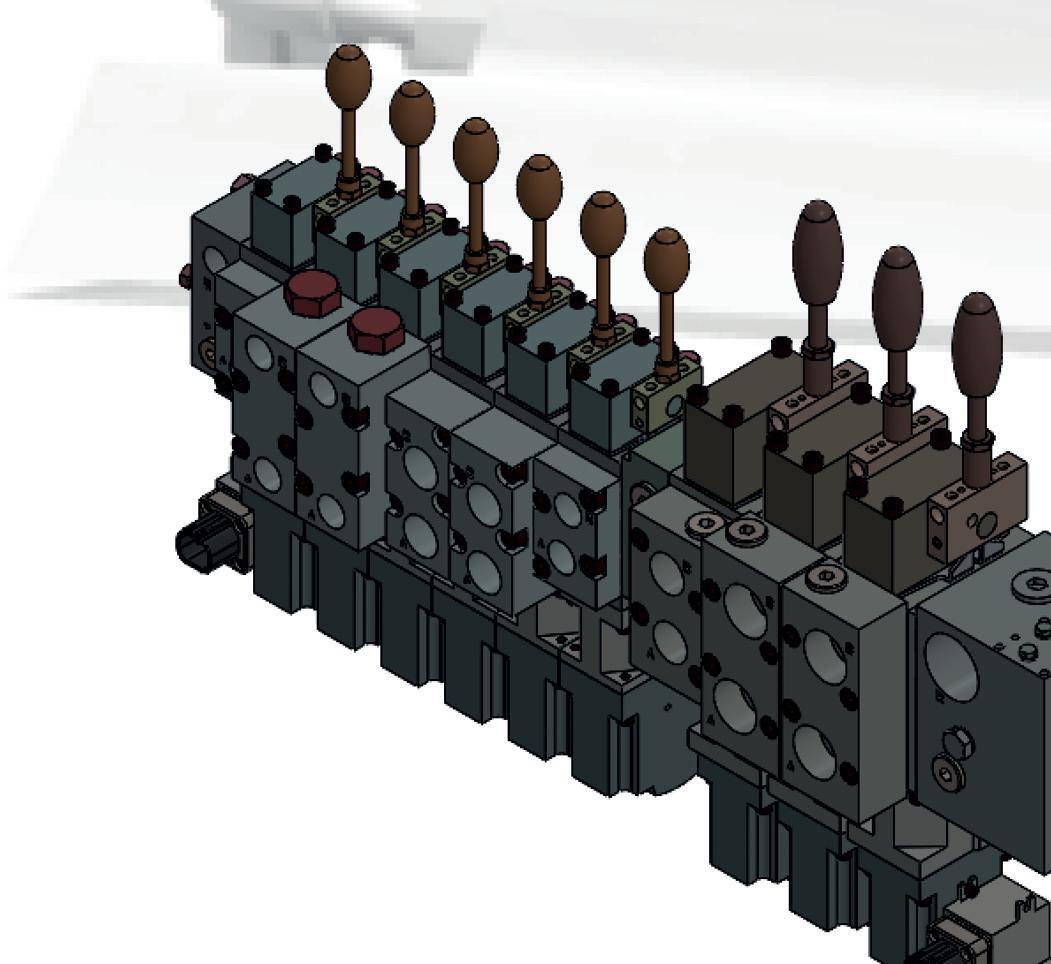

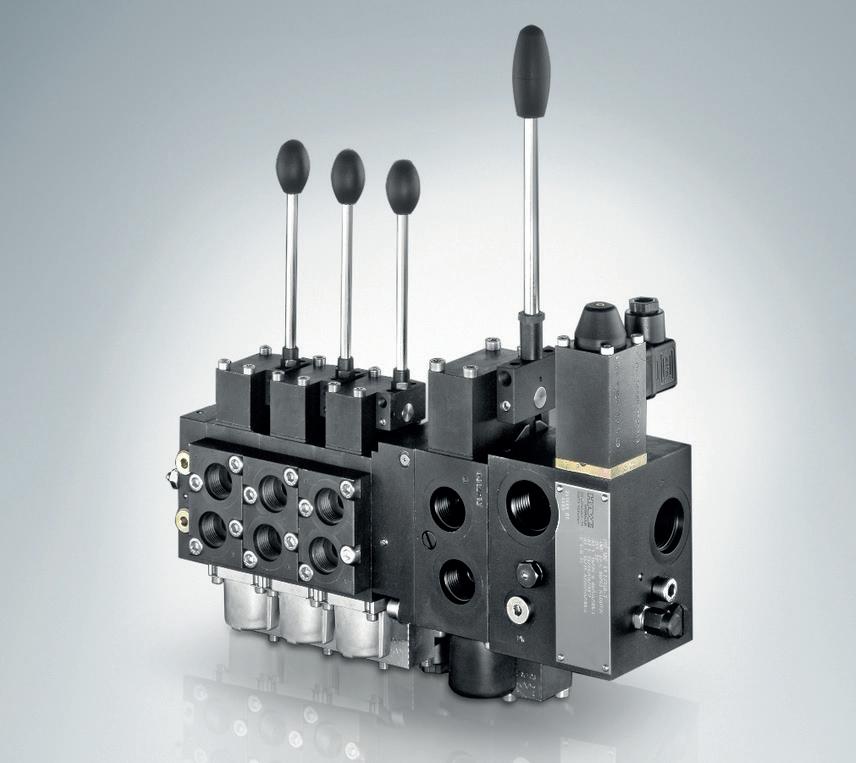

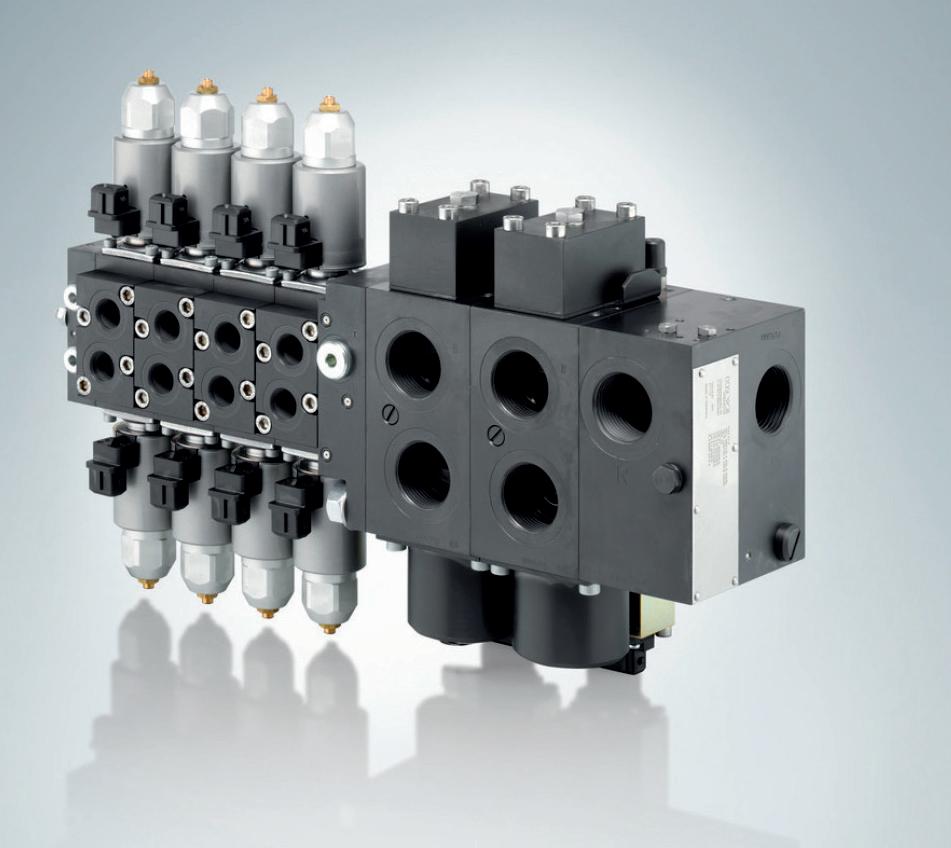

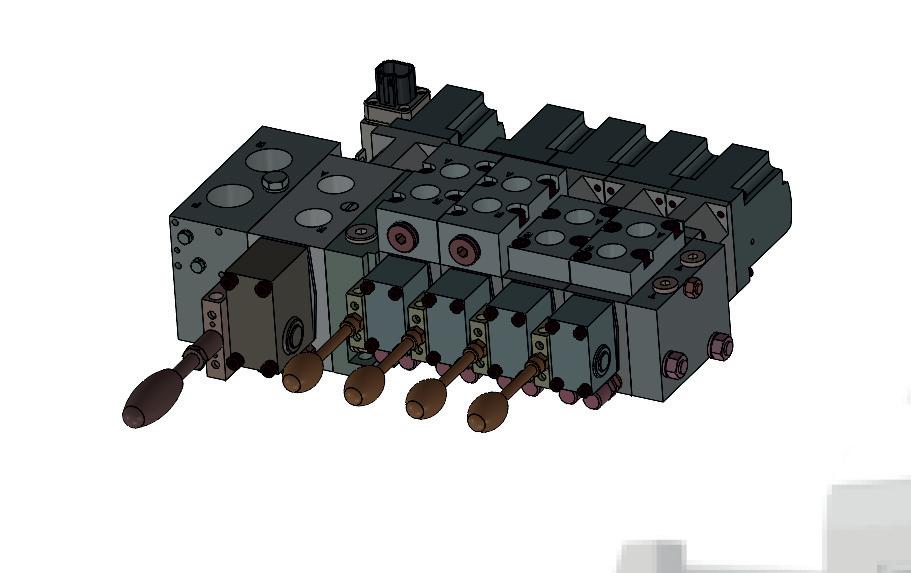

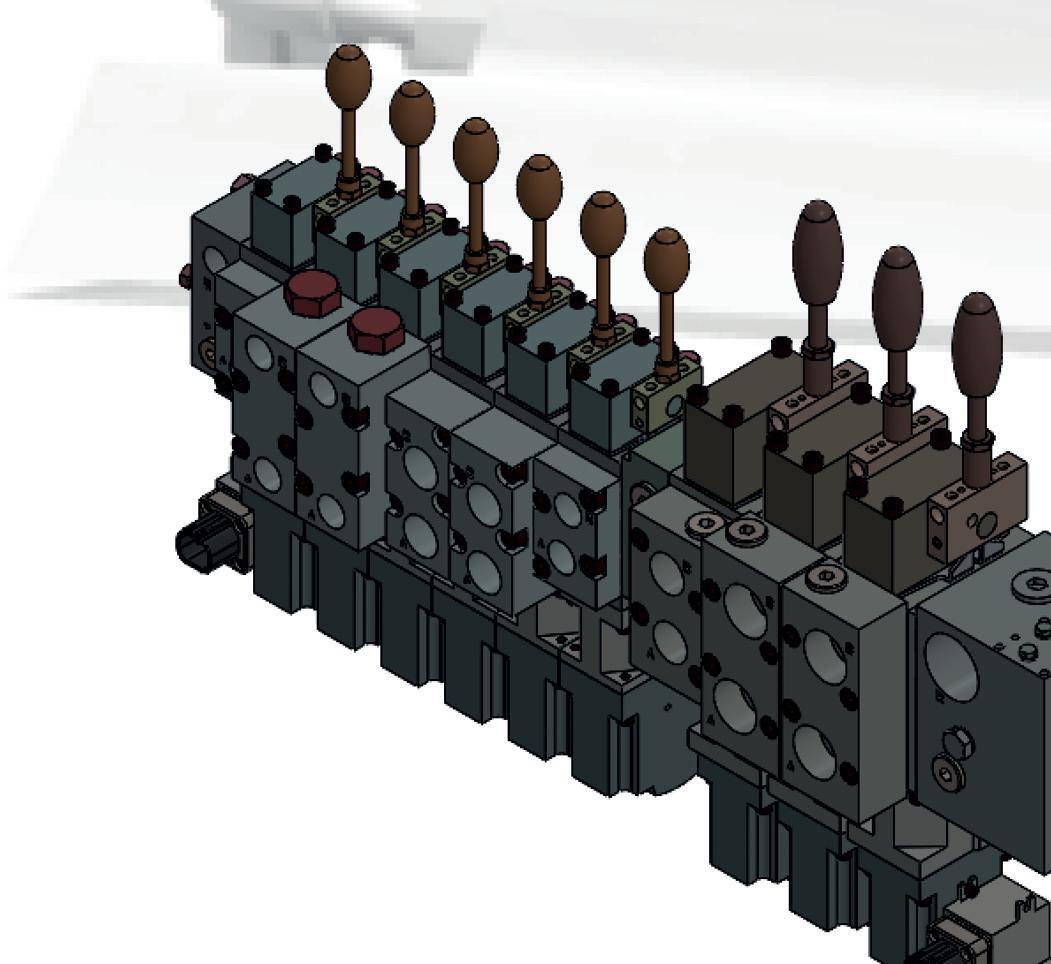

HAWE valves for mobile equipment

PSL is a robust and reliable directional control valve made of steel. The valve ensure precise and cost-effective operation. High modifiability makes the PSL valve an essential part of a smart hydraulic system.

PSL (V)

Modular size

Low pressure loss

Very compact

Additional functions are easy to integrate into the valve bank

PSL (V)-CAN lite

Easy wiring = four-pole cable

Quick start-up

Integrated electronics

CAN interface

Pre-set parameters

Built-in diagnostics

PSL (V)-CAN

In addition to the PSL (V)-CAN lite features:

Comprehensive monitoring

Precise proportional flow adjustment = precise movements

No hysteresis

Valves to your needs with fast delivery!

HAWE Finland Oy Koskelontie 15 | 02920 Espoo | Finland | Tel. +358 (0)10 82126 00 | sales@hawe.fi | www.hawe.fi 20

CWS is an competitive price sandwich-type on/off directional control valve. High modifiability makes the valve suitable for a wide range of applications.

CWS

Various integrated by-pass valves

Multiple spool options

Additional functions available for ancillary blocks, e.g. load-holding valves

CLHV load-holding valves

EDL

Modular system

Multiple spool options

Compatible with PSL spool section

Competitive price proportional valve alve, CLHV

CLHV load-holding valves are suitable for various applications. Combined with a PSL directional control valve, CLHV ensures controlled and precise operation.

CLHV

Maximum pressure 350 bar

Four sizes (max. 320 l/min)

Multiple housing options

HAWE Finland Oy Koskelontie 15 | 02920 Espoo | Finland | Tel. +358 (0)10 82126 00 | sales@hawe.fi | www.hawe.fi 21

valvesLoad-holdingalsoforT11A,T2AandSAE housings!

holding AandSAE

Auxiliary valves

Check valves

HAWE’s high-quality RK, RB, RC check valves are durable and reliable.

Leakproof valve

Ideal for the most demanding applications thanks to its uniform quality.

Check valves RHC, RH, HRP are available as pipe-installation-type and cartridge-type models.

Flow control cartridges SB, SQ

Wide flow area, (max 400 l/min)

Precise load-independent flow control valve

g and durable origina WE valve

andHigh-quality leak-proofcompactvalves from HAWE! lea

HAWE Finland Oy Koskelontie 15 | 02920 Espoo | Finland | Tel. +358 (0)10 82126 00 | sales@hawe.fi | www.hawe.fi 22

f

Pressure limiting valves MV, MVE, SV, SVC, MVP Used as a pressure limiting valve and sequence valve

Low hysteresis

Minimal impact of oil viscosity

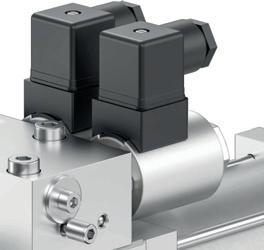

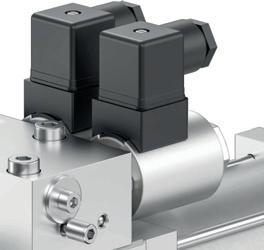

HAWE ROLV and other CETOP valves

Solenoid valve

All control options available

Leak-proof CETOP seat valve, floating

WiderangeofATEX, iderange ofATEX, IECEx and MSHA valves.

HAWE Finland Oy Koskelontie 15 | 02920 Espoo | Finland | Tel. +358 (0)10 82126 00 | sales@hawe.fi | www.hawe.fi 23

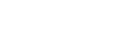

HAWE EV2S - DIN connector

HAWE EV2S - DIN connector

Compact and affordable programmable connector

User-friendly

Programming with eDesign and parametrisation with the Visual Tool software or BT smartphone version, 1–2 sensor inlets depending on the configuration

Ask more about different versions!

sk more

HAWE electric control systems

HAWE’s electric control systems are cost-effective, flexible and reliable. We deliver control logic solutions as pre-programmed or ready for programming. Can be integrated into existing systems.

HAWE CAN I/O 14+ control system

IP67: heavy outdoor use

Compact and affordable

Four dual-function movements per unit

Multiple control units can be connected to one system

As a main unit in small systems or an expansion unit in larger systems

Programming with eDesign or by parametrisation

HAWE Finland Oy Koskelontie 15 | 02920 Espoo | Finland | Tel. +358 (0)10 82126 00 | sales@hawe.fi | www.hawe.fi 24

t

t

Co Us Pr th 1–As A

l

Easy Weprogramming!turnkeyalsooffer packages.

HAWE PLVC8

IP67: heavy outdoor use

Fast control logic

Precise operation and extensive adjustment options

For demanding control systems

Programmable twin plug for double-acting coil with Bluetooth

Programmable plug, two-branched

Programmable logic

Cable CAN I/O+

USB CAN adapter, PC and CAN bus connection

Starter kit

Programming interface for CAN I/O and PLVC controls, FREE

Programmable logic

Programmable logic

Cable PLVC 8

Programmable logic

Cable 3CM 3XL-3XM-3CM-Typ A

Programmable logic

Programmable logic with Ethernet connection

Cable (1.7 m +/-50 mm)

Programming interface for CAN I/O and EV2S controls, FREE

Programming interface for PLVC 8 controls, FREE

HAWE 3CS and 3CM

IP67: heavy outdoor use

Fast control logic

Precise operation and extensive adjustment options

For demanding control systems

With safety-rating, optional

HAWE eDesign programming interface

HAWE eDesign programming interface

FREE, no licence required easy to use, no programming skills required visual programming interface for CAN I/O and EV2S controls

HAWE Finland Oy provides user training

HAWE Finland Oy Koskelontie 15 | 02920 Espoo | Finland | Tel. +358 (0)10 82126 00 | sales@hawe.fi | www.hawe.fi 25 Hysteresis under control! Hy

c

Programming

Product EV2S-BT-G-M EV2S-CAN-DG-L3K CAN-I0 14+ CAN-IO 14+: Cable 2.5 m PCAN-USB ADAPTER CAN-IO 14+ Starter Kit HAWE Visual Tool PLVC 8X2-G PLVC 8X2-X-EW PLVC 8 Cable 2.5m 3CM 3CM Cable 1.7 m 3CS 3CS Ethernet 3CS Cable eDesign Open PCS LogiCAD Product description IP 65 IP 65 IP 68 IP 20 IP 67 IP 67 IP 67 IP 67 IP 67 Protection class 4 (14) 11 (6) 11 (6) 28 16 16 Input 4 + 4 16 16 28 15 15 Output (PWM) 170 g 2.4 kg 2.5 kg 1.3 kg 0.6 kg 0.8 kg Weight -40…+70°C -40…+80°C -40…+85°C -40…+80°C -40…+80°C -40…+85°C -40…+85°C -40…+85°C Temperature range 6964 0013-84 6964 0005-73 6962 9454-00 6219 3002-00 6964 0021-72 6964 0023-10 www.hawe.fi 6964 0049-62 6964 0049-61 6217 2042-00 6964 0035-22 6219 3720-00 6964 0034-43 6964 0035-23 6219 3721-00 www.hawe.fi www.hawe.fi www.hawe.fi Product code

interface

HAWE joysticks

HAWE joysticks

analogue or CAN bus version high-quality and durable for professional use wide selection

CAN Joystick, 3 buttons CAN Joystick, 4 buttons + mini joystick Versatile seat structures

Ask more about different options!

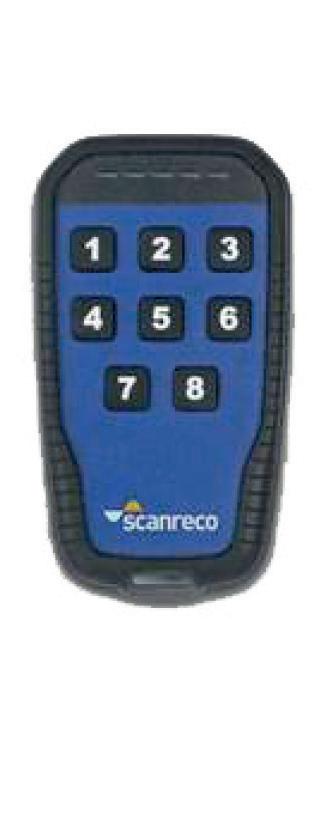

HAWE radio control systems – Scanreco

HAWE radio control systems

On/off and proportional versions Can be connected to another control system

HAWE Finland Oy Koskelontie 15 | 02920 Espoo | Finland | Tel. +358 (0)10 82126 00 | sales@hawe.fi | www.hawe.fi 26

Product V28B33 V28B32 KST31 Product description IP 67 IP 67 Protection class 9…32 V DC 9…32 V DC Voltage CANopen CANopen Output signal CAN CAN Type -40°C…+85°C -40°C…+85°C Temperature range DEUTSCH DTM04-4P DEUTSCH DTM04-4P Connector 11 1003-22.HF 11 1002-22.HF Product code

Product 1618 CU CAN Open G5 2.4 GHz RCS G3B Spec 2748 crane radio kit 49283 HCU Pocket-06 G5 P6A IP67 IP67 Protection class 12/24 Voltage CAN Output (PVM) 2.4 GHz 2.4 GHz 2.4 GHz Frequency 23 1003-20.HF 23 1001-19.HF 23 1002-20.HF Product code -25°C…+70°C -25°C…+70°C -25°C…+70°C Temperature range

MORE INFORMATION FROM THE SALES TEAM

HAWE displays

Pre-programmed

HAWE pressure transmitters

mitters

Hydraulic solutions and packages and all Scanreco products and spare parts!

HAWE pressure transmitters (auxiliary electronics)

HAWE provides various sensors and transmitters

Durable and reliable

Ask HAWE Finland about other signal options

HAWE Finland Oy Koskelontie 15 | 02920 Espoo | Finland | Tel. +358 (0)10 82126 00 | sales@hawe.fi | www.hawe.fi 27

0... 100 BAR 0... 250 BAR 0... 400 BAR 0... 600 BAR Product DT 2-1 DT 2-2 DT2-4 DT2-6 Product description IP 67 IP 67 IP 67 IP 67 Protection class 4…20 mA 4…20 mA 4…20 mA 4…20 mA Signal 70 g 70 g 70 g 70 g Weight -30°…+100°C -30°…+100°C -30°…+100°C -30°…+100°C Temperature range MSD-T7 MSD-T7 MSD-T7 MSD-T7 Connector 6217 7201-00.HW 6217 7202-00.HW 6217 7203-00.HW 6217 8102-00.HW Product code

HAWE displays

programming

screen available 5” touch screen 7” touch screen Foot+adapter Display Display Foot+adapter Foot+adapter 1m cable for all OPUS displays Product Product description IP 65 IP 65 IP65 IP65 Protection class 8…36 V DC 8…36 V DC 9…36 V DC 9…36 V DC Voltage CAN CAN CAN CAN Output -30°C…+75°C -30°C…+75°C -30°C…+75°C -30°C…+75°C Temperature range 13 3018-22.HF 13 3016-21.HF 13 3017-21.HF 13 3004-11.HF 13 3015-17.HF 13 3012-15.HF 13 3008-12.HF 13 3013-15.HF Product code Best buttons and displays fromHAWE! Bes and from OPUSB3EN1CANT000 OPUSB4EN1CANT000 OPUS B RAM-JALKA OPUSA3SL1CANB0005 OPUSA6SN2CANB000 OPUSBERM004 A3 OPUSBERM006 A6 OPUSKAAPELIFIN

or ready for

Touch

Example of a road maintenance truck’s hydraulics ics rucks hydrauli

HAWE Finland Oy Koskelontie 15 | 02920 Espoo | Finland | Tel. +358 (0)10 82126 00 | sales@hawe.fi | www.hawe.fi HAWE Finland Koskelontie 15 02920 Espoo Finland sales@hawe.fi www.hawe.fi

HAWE Finland Oy Koskelontie 15 | 02920 Espoo | Finland | Tel. +358 (0)10 82126 00 | sales@hawe.fi | www.hawe.fi HAWE Finland

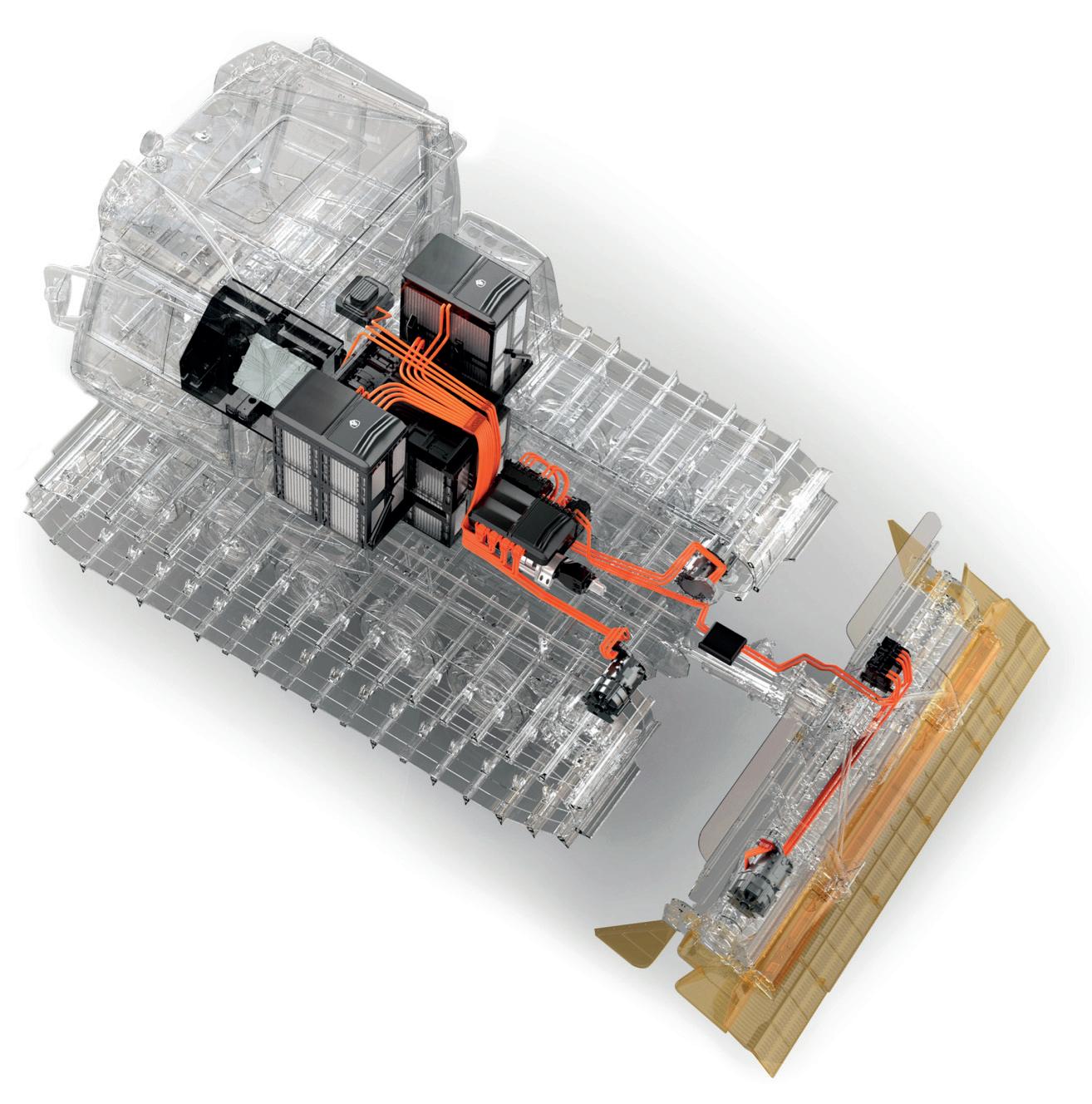

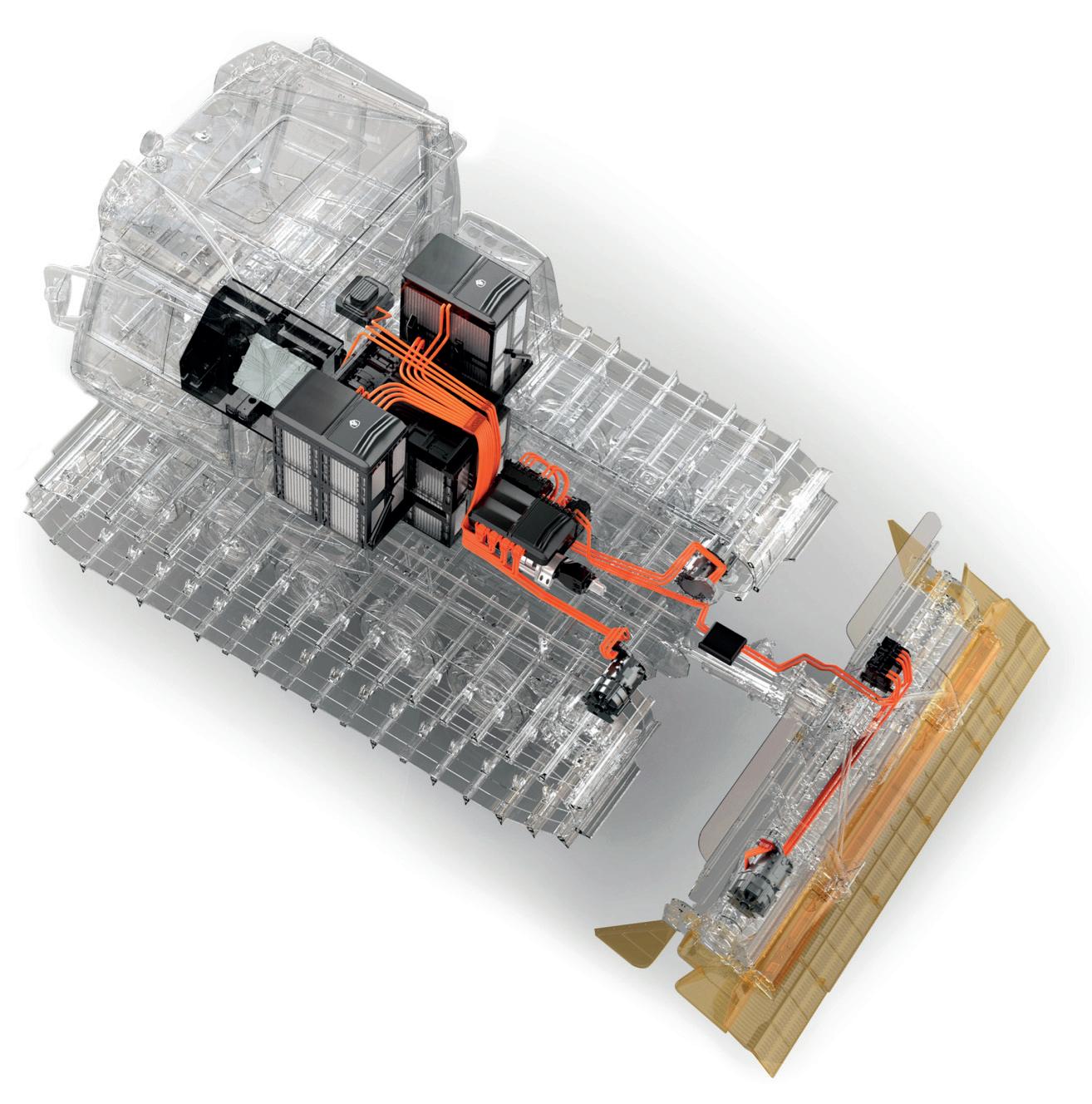

HAWE electric drives for mobile equipment

HAWE electric drives for mobile

Hybrid or electric?

We provide all components from accumulators to power transmission solutions and electrification of hydraulics. We help you with the electrification of your vehicle from initial design to prototype production.

Wedesign,build andtestelectricdrives formobile equipment.

HAWE Finland Oy Koskelontie 15 | 02920 Espoo | Finland | Tel. +358 (0)10 82126 00 | sales@hawe.fi | www.hawe.fi 30

HAWE electric drives for mobile equipment

HAWE’s team electrifies your special vehicle, self-propelled machine or hydraulic system!

The HAWE Mattro battery pack is designed for use in off-high machines or as traction batteries. Compared to other products on the market, it offers a very high energy density, which makes it a problem solver in space-critical electrification projects. An intelligent battery management system (BMS) is integrated to protect and monitor the battery and communicate with the higher-level controller or the charger. It can control an integrated heater or communicate status-dependent current recommendations to the vehicle.

HAWE does not design the battery system as an individual component, but as an important part of a larger system. Our design team is happy to help you with the design of the entire system – from the traction motor and energy storage systems to hydraulics. You get everything from one place.

HAWE Finland Oy Koskelontie 15 | 02920 Espoo | Finland | Tel. +358 (0)10 82126 00 | sales@hawe.fi | www.hawe.fi 31

Example of a HAWE crane configuration

PTO and adapters, cardans, shaft flanges

HAWE Finland has a broad range of power take-offs (PTO) and gearbox and motor adapters.

Available for many pump mounting types, including: ISO 4-hole DIN 5462, SAE (A, B, BB, C), UNI 3 (21 UNI 222)

Switch options: mechanic, pneumatic, vacuum, electric and electro-hydraulic

Only high-quality PTO materials and components are used. Suitable for demanding conditions.

HAWE has PTOs for these makes: Allison, Eaton, Hino, Hyundai, Isuzu, Iveco, Mercedes Benz, Mitsubishi-Fuso, Nissan, Renault, Scania, Toyota, Volvo and ZF, Aisinamong.

Prior to assembly of the pump, the shaft/hub connection must be adequately greased with a high-temperature grease as per MAN works standard MAN 284 Li-H2. No pastes containing metal (copper, aluminium, etc.) must be used.

Tipping valves

Tipping valves available for various systems on demand

Compressed-air control or electrical control

HAWE Finland Oy Koskelontie 15 | 02920 Espoo | Finland | Tel. +358 (0)10 82126 00 | sales@hawe.fi | www.hawe.fi 32

SCANIA

VOLVO ZF

Product Scania Pto GR 900 double power take-off Scania Engine Pto Ed-120 Scania Engine Pto Ed-160 092403.HF 7022204.HF 7021104.HF Product code Product Volvo Engine Pto D13,D16 Volvo Adapter kit Dt-2412c Volvo Adapter Kit. R1000 7022904.HF 116504.HF 110304.HF Product code Product ZF Base Pto Kit Vb 1:1-32 Full adapter kit ZF. Traxon 1010K03.HF 1028804.HF Product code

Product HF Base Pto Kit Vb 1:1 Central Piston Adapter 125 mm 1015K03 703204.HF Product code

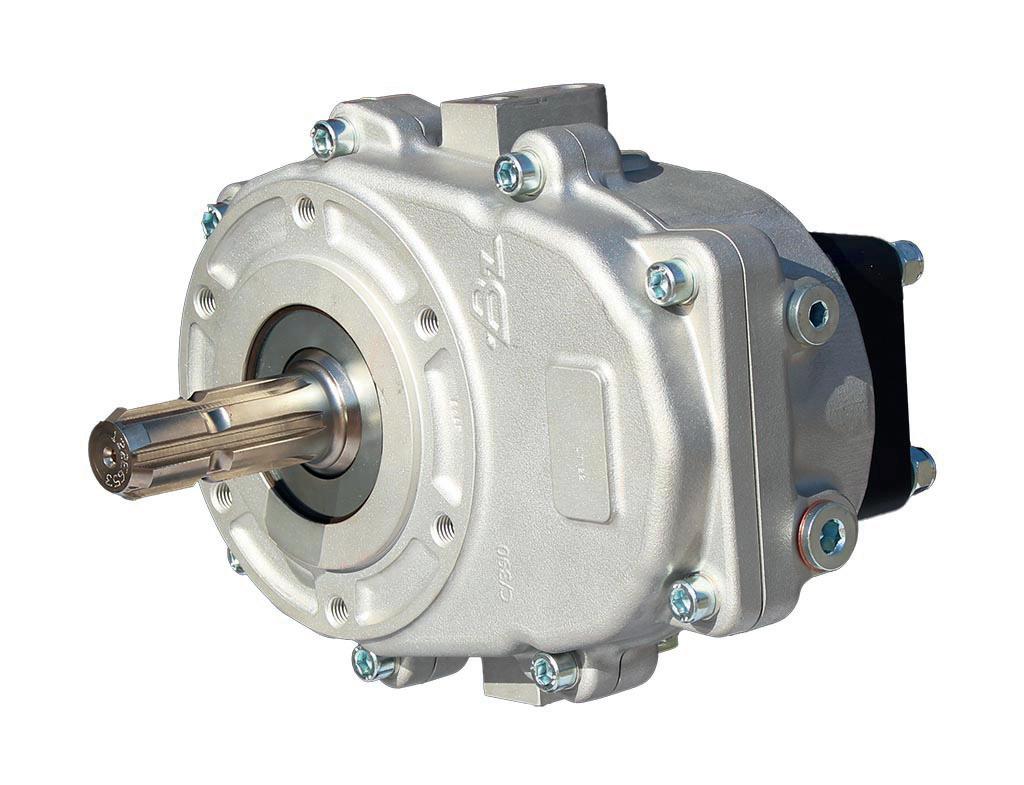

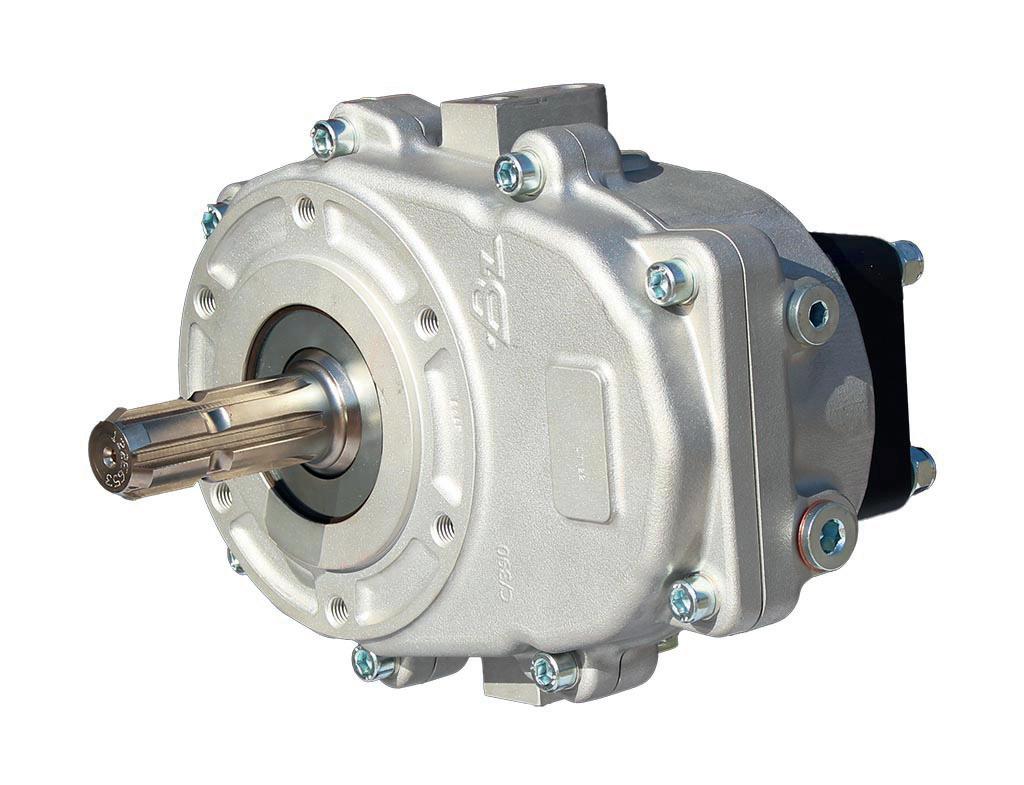

TRACPOWER trackpower gear boxes

HAWE Finland Oy Koskelontie 15 | 02920 Espoo | Finland | Tel. +358 (0)10 82126 00 | sales@hawe.fi | www.hawe.fi 33

69,9 79,4 95,3 74,5 84,0 Product Cardan 1100 (B1) Cardan 1300 (B2) Cardan 1400 (B3) DIN 4- bolt DIN 6- bolt A mm 16643.HS 17335.HS 18150.HS 17010.HS 901215.HF Product code 57,2 60,3 69,9 47 57 B mm All pumps

Cardan flanges

Ask your HAWE distributor about options! Take-off-powered trackpower gear box for tractors All PTOs and accessories from HAWE

Filters

Pressure filter <420 bar Product description

SF-030-G-10-B-T-G12-IB-A/4 SF-045-G-10-B-T-G20-IB-A/4 SF-070-G-10-B-T-G20-IB-A/4

SF-090-O-O-B-T-G24-B-A

filter

max.

By-pass valve standard. Available with flange unions and various indicators and gasket materials

Glass fibre Glass fibre Glass fibre Glass fibre Glass fibre Glass fibre Glass fibre Glass fibre Glass fibre Glass fibre Glass fibre Glass fibre Flow l/min 110 110 160 160 240 240 330 330 500 500 >200 >200 Filter material 5 μ 10 μ 5 μ 10 μ 5 μ 10 μ 5 μ 10 μ 5 μ 10 μ 5 μ 5 μ Filtration NBR NBR NBR NBR NBR NBR NBR NBR NBR NBR NBR NBR Gaskets RE-030-G-05-B/4 RE-030-G-10-B/4 RE-045-G-05-B/4 RE-045-G-10-B/4 RE-070-G-05-B/4 RE-070-G-10-B/4 RE-090-G-05-B/4 RE-090-G-10-B/4 RE-130-G-05-B/4 RE-130-G-10-B/4 SE-090-G-05-B/4 SE-160-G-05-B/4 Product description Filter elements return filter max. 16 bar Available with different gasket materials 04 1083-21.HF 04 1084-21.HF 04 1085-21.HF 04 1086-21.HF Product code 04 1087-21.HF 04 1088-21.HF 04 1121-22.HF 04 1122-22.HF 04 1123-22.HF 04 1124-22.HF 04 1069-21.HF 04 1125-22.HF 04 1065-21.HF 04 1126-22.HF 04 1067-21.HF 04 1071-21.HF Product code 04 1072-21.HF 04 1073-21.HF 04 1074-21.HF 04 1075-21.HF 04 1066-21.HF 04 1070-21.HF Product code 04 1076-21.HF 04 1077-21.HF 04 1078-21.HF 04 1079-21.HF 04 1080-21.HF 04 1081-21.HF 04 1067-21.HF 04 1082-21.HF Product code HF HF HF HF HF HF HF HF e We have a wide range of filtration products!

HAWE Finland Oy Koskelontie 15 | 02920 Espoo | Finland | Tel. +358 (0)10 82126 00 | sales@hawe.fi | www.hawe.fi 34

Glass fibre Glass fibre Glass fibre Glass fibre Glass fibre X Flow l/min 110 160 240 330 330 660 Filter material 10 μ 10 μ 10 μ 10 μ 10 μ X Filtration NBR NBR NBR NBR NBR FPM Gaskets BSPP BSPP BSPP BSPP BSPP BSPP Connection type 3/4” 1 1/4” 1 1/4” 1 1/2” 1 1/2” 1 1/2” Thread size Visual Visual Visual Visual Visual Visual/electronic 24V Indicator

SF-090-G-10-B-T-G24-B-A

Return filters SF-160-O-O-V-T-G24-B-P024

Pressure filter max. 420 bar

Glass fibre Glass fibre Glass fibre Glass fibre Glass fibre Glass fibre Glass fibre Glass fibre Flow l/min 110 110 160 160 240 240 330 330 Filter material 5 μ 10 μ 5 μ 10 μ 5 μ 10 μ 5 μ 10 μ Filtration NBR NBR NBR NBR NBR NBR NBR NBR Gaskets SE-030-G-05-B/4 SE-030-G-10-B/4 SE-045-G-05-B/4 SE-045-G-10-B/4 SE-070-G-05-B/4 SE-070-G-10-B/4 SE-090-G-05-B/4 SE-090-G-10-B/4 Product description Filter elements

420 bar

Glass fibre Glass fibre Glass fibre Glass fibre Flow l/min 160 240 330 500 Filter material 10 μ 10 μ 10 μ 10 μ Filtration NBR NBR NBR NBR Gaskets BSPP BSPP BSPP BSPP Connection type 1 1/4” 1 1/2” 2” 2” Thread size Visual Visual Visual Visual Indicator RF-045-G-10-B-G20-V RF-070-G-10-B-G24-V

By-pass valve standard. Available with different connectors, filter materials, indicators and gasket materials

pressure

Available with different gasket materials

RF-090-G-10-B-G32-V RF-130-G-10-B-G32-V

Product description

Return filter max. 16 bar

HAWE Finland Oy Koskelontie 15 | 02920 Espoo | Finland | Tel. +358 (0)10 82126 00 | sales@hawe.fi | www.hawe.fi 35 All tank fromaccessories HAWE! A acce from

Tank accessories

HAWE power packs

Tank size 0.1–5000 l. Electricity 12–400 V.

HR mini power packs

For additional functions and distributed systems in mobile or industrial use

Reversible direction of rotation

Integrated check valves

Voltage 12V... 400V, depending on the model

HICON – Seawater-proof IP67 compact power pack of stainless steel

CAN control optional

Reversible direction of rotation

For 12–24V systems

HAWE Finland Oy Koskelontie 15 | 02920 Espoo | Finland | Tel. +358 (0)10 82126 00 | sales@hawe.fi | www.hawe.fi 36

KA compact power packs

Very compact, integrable valves

Pressure up to 700 bar

Internal condition monitoring optional

Optimised thermal management

INKA

Compact structure, integrable valves

Pressure up to 700 bar

Vertical and horizontal models with a 4–31 l tank

Fan optional

Wewill

FXU

Pressure up to 700 bar

Compact structure saves space

Easy configuration

Piston and accumulatorsdiaphragm

HAWE has a wide range of piston and diaphragm accumulators.

with r es space

i stalled

Industrial power packs with preinstalled valves and sensors

Hand pumps

High-quality hand pumps 30–800 bar from HAWE.

Single- and double-acting pumps + tanks

HAWE Finland Oy Koskelontie 15 | 02920 Espoo | Finland | Tel. +358 (0)10 82126 00 | sales@hawe.fi | www.hawe.fi 37

customise apowerpack foryou!

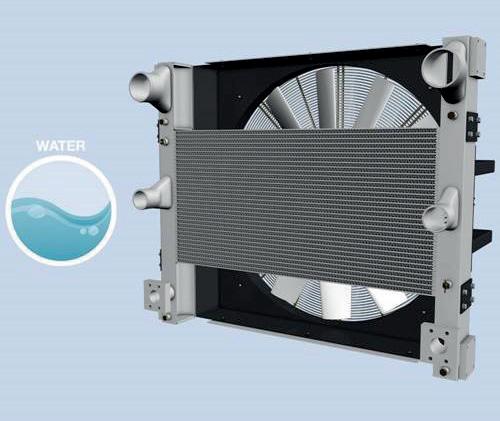

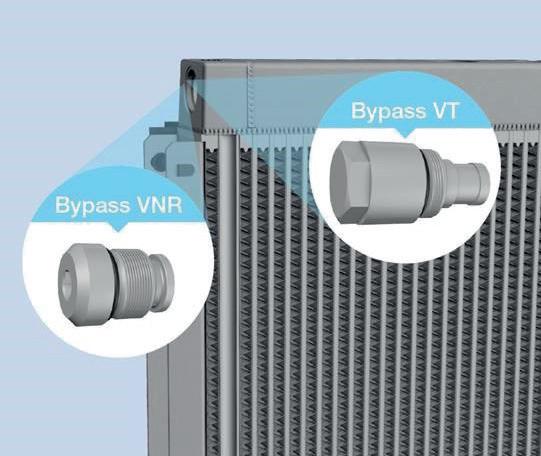

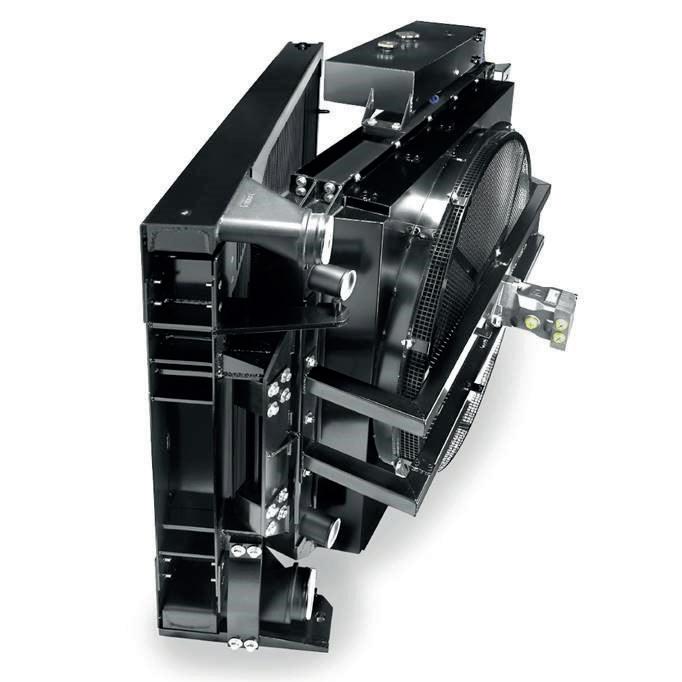

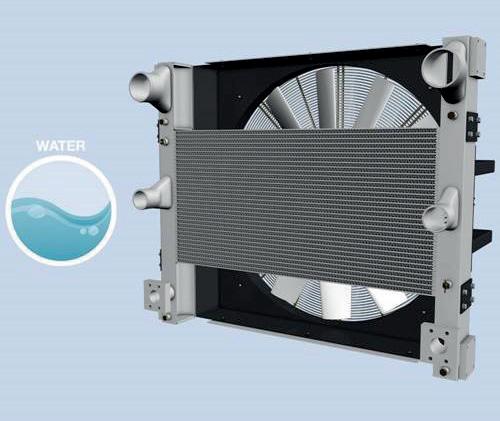

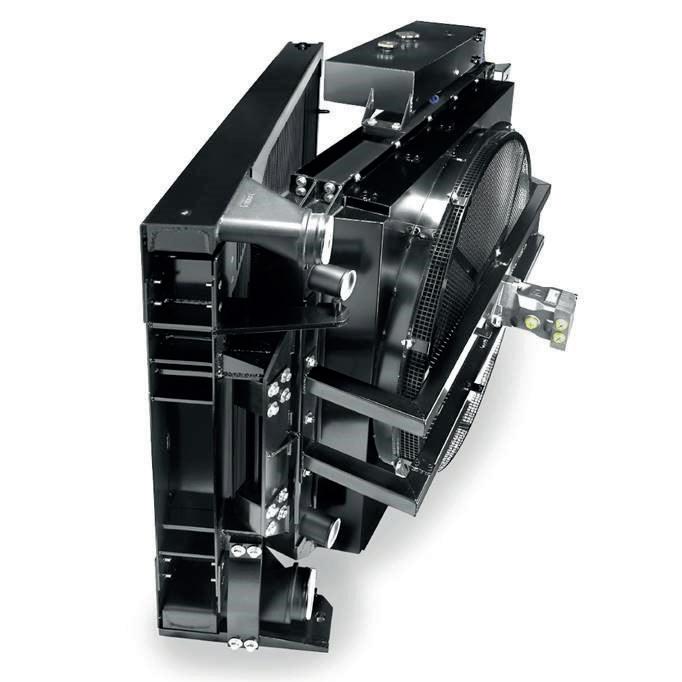

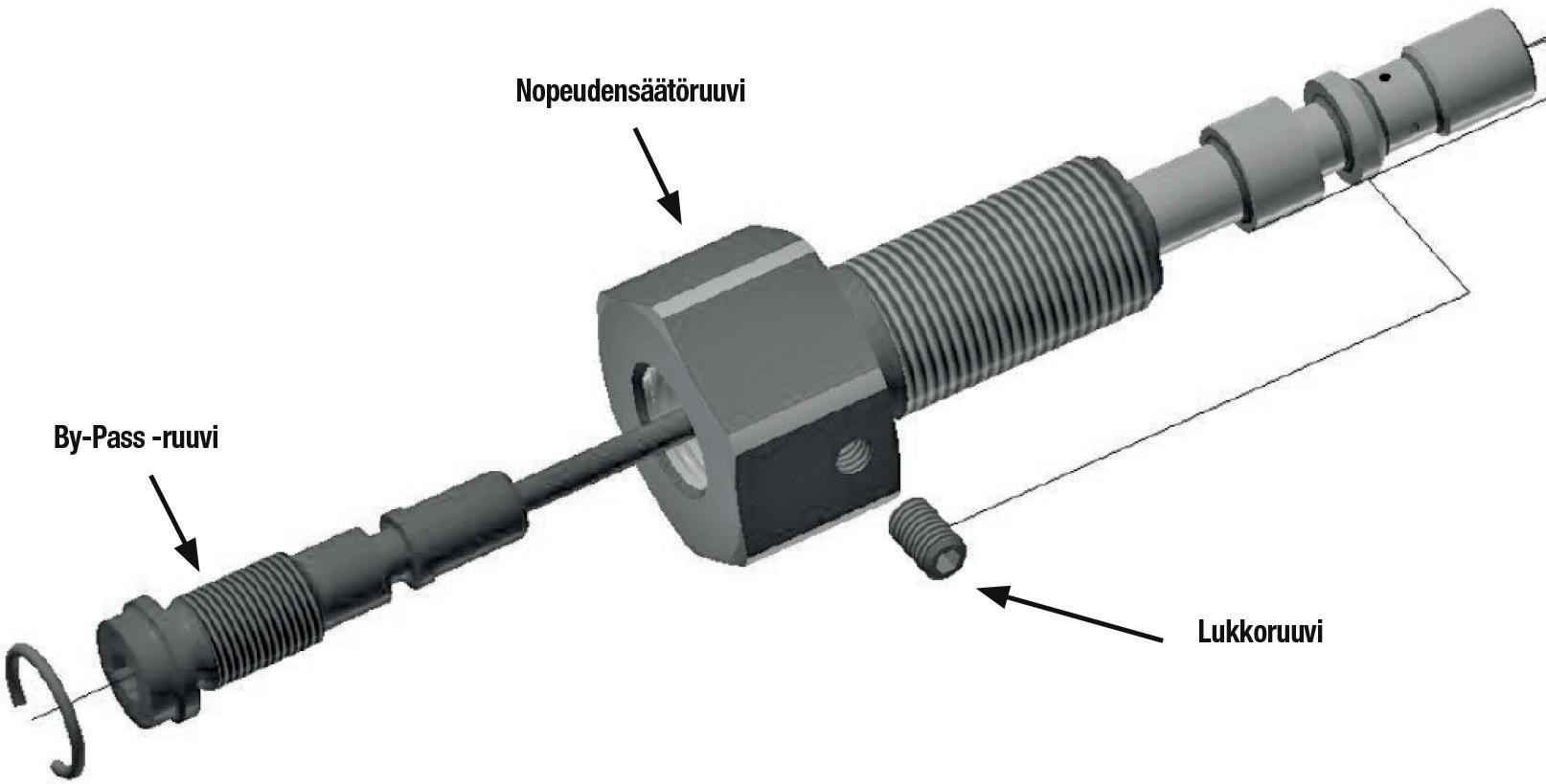

Coolers

HAWE Finland has a broad range of coolers. In addition to standard products, we provide cooling solutions customised to our customers’ needs.

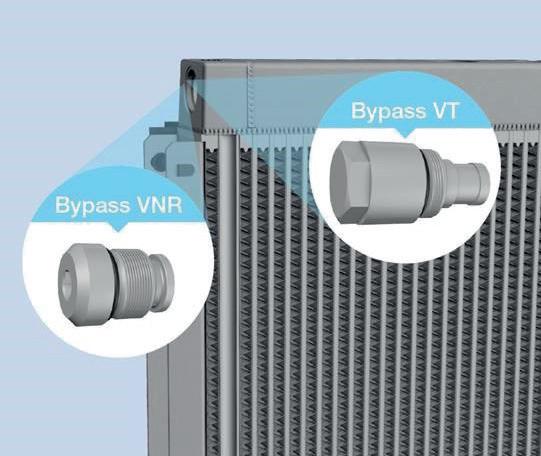

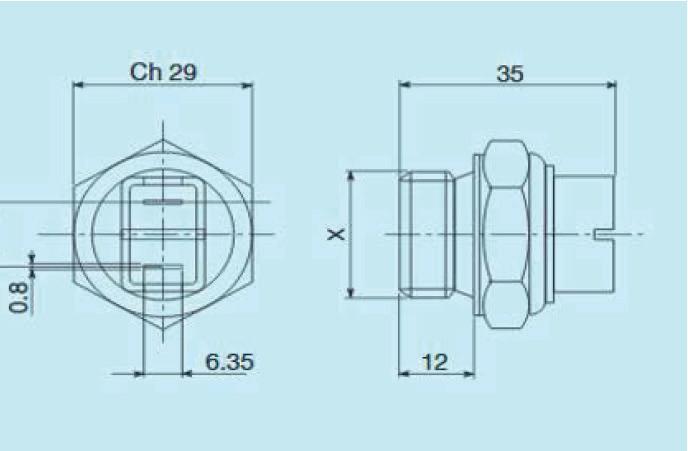

VNR 4.5 bar

Left supporting foot Right supporting foot

FR633110013.HF

FR633130013.HF

FR633060013.HF

FR633220013.HF

FR633110003.HF

FR633130003.HF

FR633060003.HF

FR633220003.HF

FR633113113.HF

FR633111013.HF

FR633133116.HF

FR633131015.HF

FR633063115

FR633061015.HF

FR633223115.HF

FR633221015.HF FR290000023R

HAWE Finland Oy Koskelontie 15 | 02920 Espoo | Finland | Tel. +358 (0)10 82126 00 | sales@hawe.fi | www.hawe.fi 38

225 280 280 385 225 280 280 385 225 225 280 280 280 280 385 385 Product SCM A 22 1EAP 24 V SCM A 26 1EAP 24 V SCM A 35 1EAP 24 V SCM A 56 1EAP 24 V SCM A 22 1EAP 12 V SCM A 26 1EAP 12 V SCM. A 35 1EAP 12V SCM A 56 1EAP 12V SCM A22 1EAP 24V bypass T15 V.T. 3 bar 60°C SCM A22 1EAP 24V bypass T15 VNR 4.5 bar SCM A26 1EAX 24V bypass T15 V.T. 3 bar 60°C SCM A26 1EAX 24V bypass T15 VNR 4.5 bar SCM A35 1EAX 24V bypass T15 V.T. 3 bar 60°C SCM A35 1EAX 24V bypass T15 VNR 4.5 bar SCM A56 1EAX 24V bypass T15 V.T. 3 bar 60°C SCM A56 1EAX 24V bypass T15

Blower diameter mm

FR290000024R Product code 980 1580 1580 1410 920 1570 1570 1260 980 980 2500 2500 2500 2500 3070 3070 Airflow m3/h 4.1 3.5 3.5 4.2 4.1 6.9 6.9 7.4 4.1 4.1 7 7 7 7 10 10 Current A 5.5 7 14.5 15.5 5.5 7 14.5 15.5 5.5 5.5 7.8 7.8 15.5 15.5 16.5 16.5 Weight kg 1.7 2.3 4.8 7.5 1.7 2.3 4.8 7.5 1.7 1.7 2.3 2.3 4.8 4.8 7.5 7.5 Capacity l

Thermostatic switches for coolers

integrated by-pass valve available customisable to your needs

12/24V, 220V or hydraulic motor drive the most common 24V models are always in stock

HAWE also delivers entire cooling systems

HAWE Finland Oy Koskelontie 15 | 02920 Espoo | Finland | Tel. +358 (0)10 82126 00 | sales@hawe.fi | www.hawe.fi 39

45–35 60–50 80–70 82–68 85–76 Opening temperature °C M22x1.5 M22x1.5 M22x1.5 M22x1.5 M22x1.5 Thread FR361104535R FR361106050R FR361108070R FR361108268R FR361108576R Product code

Smart FAN DRIVE controlsystem available!

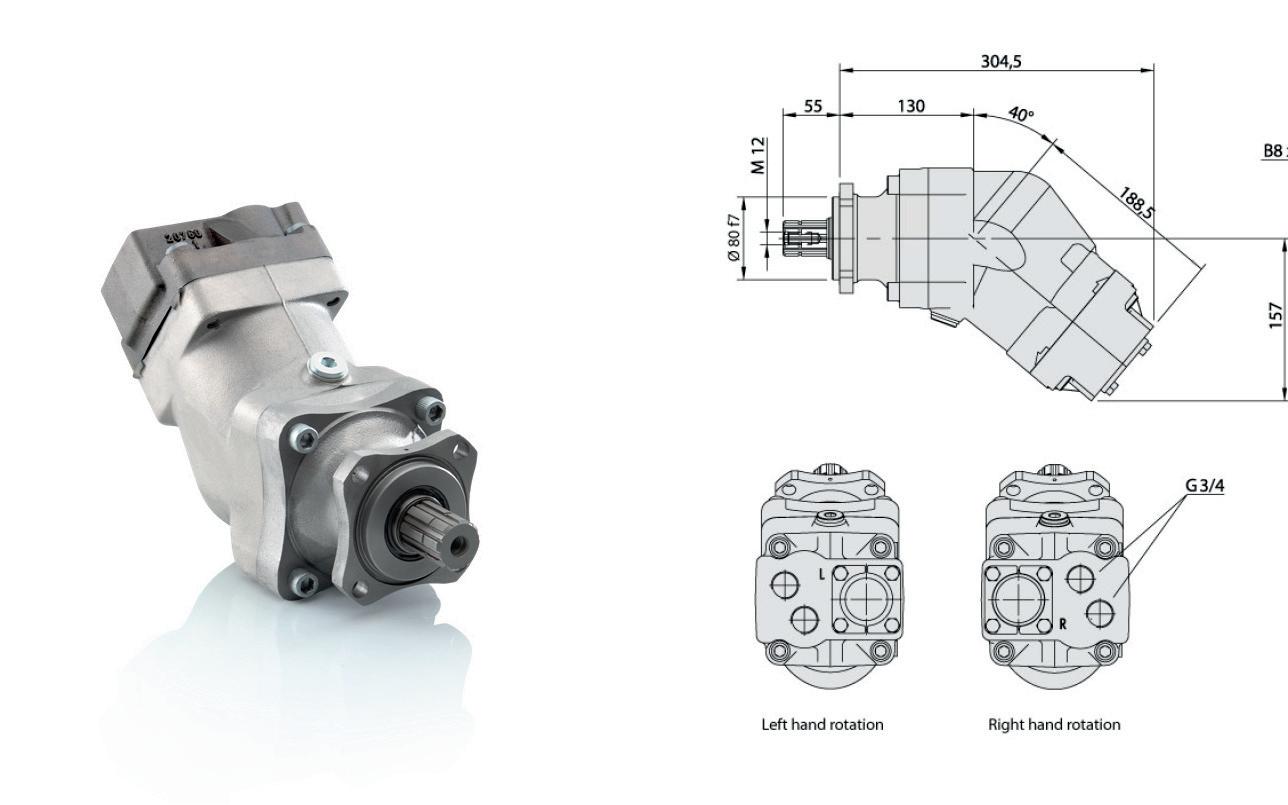

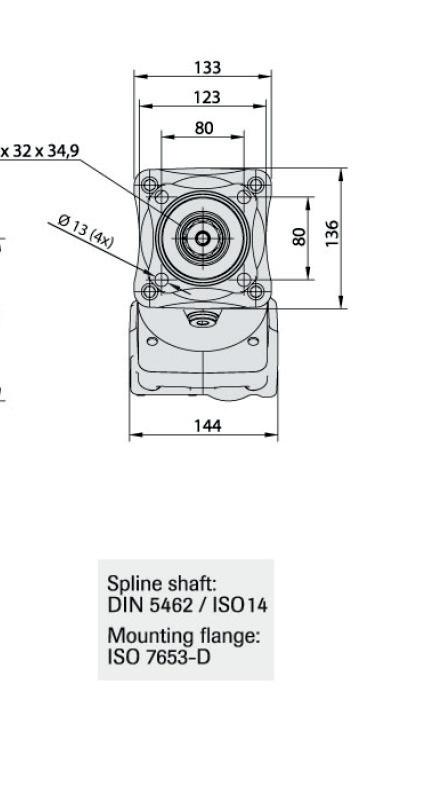

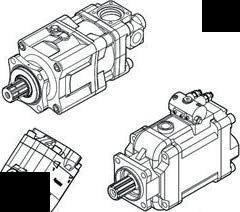

Hydraulic motors

HAWE Finland Oy’s selection also includes Sunfab’s fixed axial piston motors. The reliability of Sunfab products is based on the use of high-quality materials, tempering methods and surface treatment, and quality-certified manufacturing processes.

SCM 010-130 ISO

A series of robust axial piston motors with ISO shafts and flanges, ideal for applications of mobile hydraulics.

High reliability and durability thanks to high-quality materials, tempering methods and manufacturing processes.

SCM 010-130 SAE

A series of robust axial piston motors with SAE shafts and flanges, ideal for applications of mobile hydraulics.

High reliability and durability thanks to high-quality materials, tempering methods and manufacturing processes.

SCM 025-108 M2

Robust axial piston motors with a cartridge flange. Especially suitable for winch, slewing, wheel and track drives.

SAM 010-130 DIN

Light-weight casing axial piston motors, particularly suitable for mobile hydraulics. Corrosion-proof metal housing!

Sunfab motors ISO, SAE, M2 and DIN with multiple shaft options sizes 10–130 cm applications: chippers, crushers, water pumps, vibrators, drivetrains, winches, conveyors, etc. a reliable and compact motor with minimal moving parts and a high starting torque various valves and speed sensors available

HAWE Finland Oy Koskelontie 15 | 02920 Espoo | Finland | Tel. +358 (0)10 82126 00 | sales@hawe.fi | www.hawe.fi 40

S ns -

a All motors from HAWE. Contact us!

Sunfab piston motor code key

SC M - 064 W - P - I34 - W35 - S2 M - 1 00

Model

SC Sunfab Compact SA Sunfab Aluminium

Type

M Motor

Displacement

010 - 130

Direction of rotation

W

both directions

Shaft seal

P FPM (SCM)*

N NBR (SAM)

* below -25°C, contact HAWE

Mounting flange

I41 ISO 3019-2 4-h Ø80 (010-017)

I42 ISO 3019-2 4-h Ø100 (025-034)

I43 ISO 3019-2 4-h Ø125 (040-064)

I44 ISO 3019-2 4-h Ø140 (084-090)

I45 ISO 3019-2 4-h Ø160 (108-130)

DL4 DIN 4-h ISO 7653-D (012-130)

Shaft

Spline DIN 5480 (SCM ISO M2)

W20 W20x1.25x14x9g (010-017)

W25 W25x1.25x18x9g (010-025)

W30 W30x2x14x9g (025-064)

W32 W32x2x14x9g (040-064)

W35 W35x2x16x9g (040-108) 1

W40 W40x2x18x9g (084-130)

W45 W45x2x21x9g (108-130)

Key DIN 6885 (SCM ISO)

K20 ø 20 k6 (010-017)

K25 ø 25 k6 (010-025)

K30 ø 30 k6 (025-056)

K35 ø 35 k6 (040-064)

K40 ø 40 k6 (084-090)

K45

1

ø 45 k6 (108-130)

108 only SCM M2

SB2 SAE B2 J-744 (010-034)

SB4 SAE B4 J-744 (010-034)

SC4 SAE C4 J-744 (025-108)

SD4 SAE D4 J-744 (084-130)

M21 Plug-In Ø135 (025-034)

M22 Plug-In Ø160 (040-064)

S1

Rotation speed sensor

for a sensor

sensor, PNP Speed sensor, NPN

Additional function

Connections

G 2, 5 ISO G (010-130)

M 3 Metric (010-034)

Back-end connection SCM ISO 6162-2/SAE

0° Flange mounting, vertical (084-130)

40° Flange mounting, horizontal (040-064)

40° Female fitting (010-034)

90° Flange mounting, vertical (084-130)

90° Flange mounting, horizontal (025-130) Flange mounting, side (025-130)

Combicover 90° female fitting, side (010-034)

Back-end connection SCM M2 ISO 6162-2

Spline SAE J498b 30° Class 5 (SCM SAE)

(010-034)

(025-084)

(040-108)

(084-130) Key SAE J744 (SCM SAE)

(010-034)

DIN 5462 / ISO 14 (SAM DIN)

8x32x34.9 (012-130)

V1

V2

S3

2 3 4

90° Flange mounting, vertical (084-108)

90° Flange mounting, horizontal (025-108)

Back-end connection SAM DIN

40° Female fitting (010-130)

Only female fitting Only flange mounting Only S back-end 040-130 only SAM DIN

All gerotor motors from HAWE HMOMM, HMOMP, HMOMR, HMOMH, HMOMS, HMOMV, HMOMT Hydraulic brake for motors HMOMP/HMOMR/HMOMH also available

HAWE Finland Oy Koskelontie 15 | 02920 Espoo | Finland | Tel. +358 (0)10 82126 00 | sales@hawe.fi | www.hawe.fi 41

1 External drain line 00 P1 S1 S2 No sensor

Ready

Speed

13T

14T 12/24

C21 21T 16/32

D13 13T

B25

C32

D44

B13

16/32

C14

8/16

ø 25.4

ø 31.7 (040-064)

ø 44.45 (084-130)

L35

M23 Plug-In Ø190 (084-108) S2 S3 V1 V2 R1 K3

5

U 4 UN (025-130)

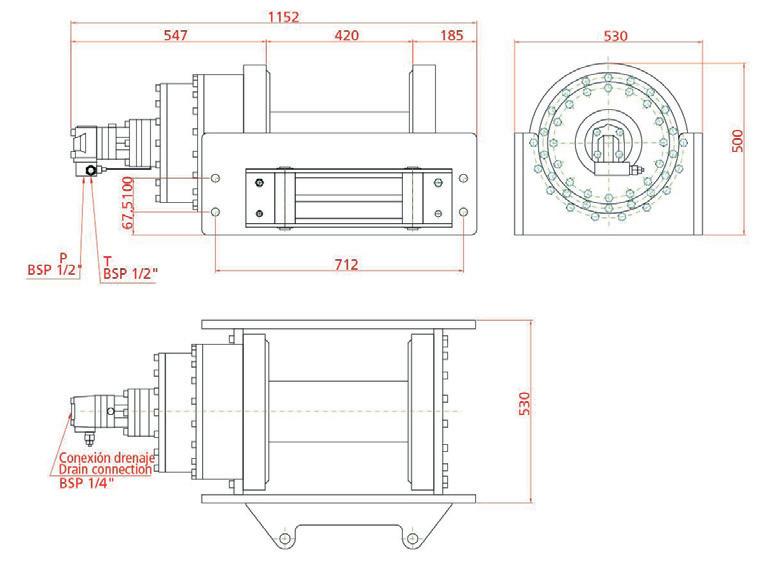

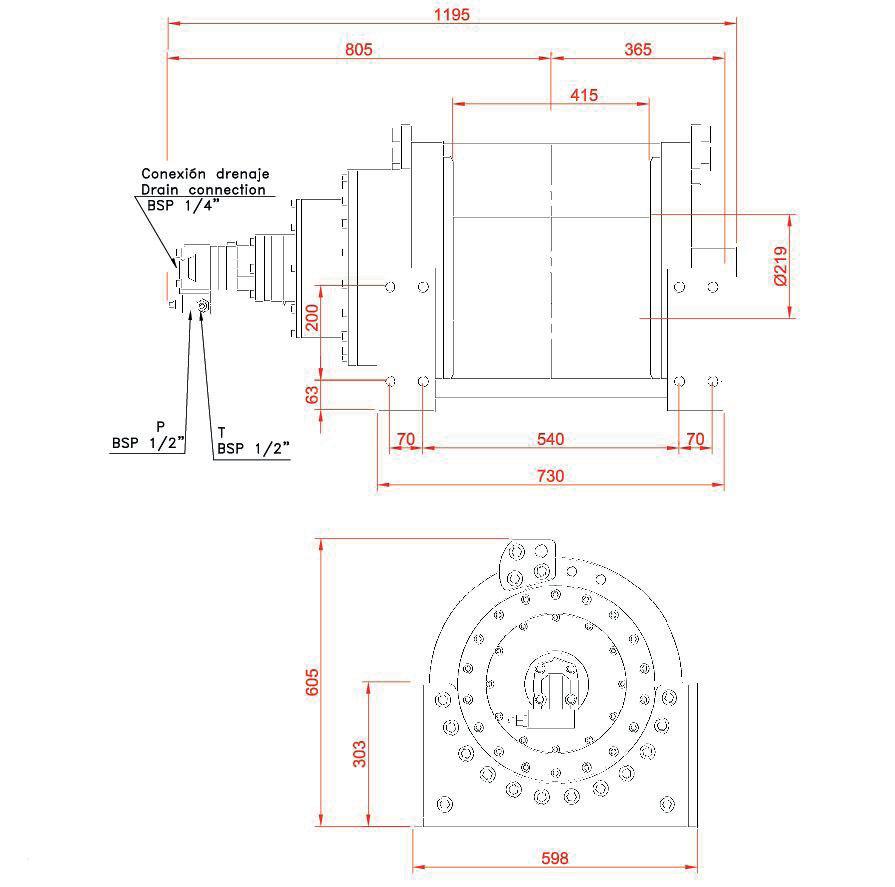

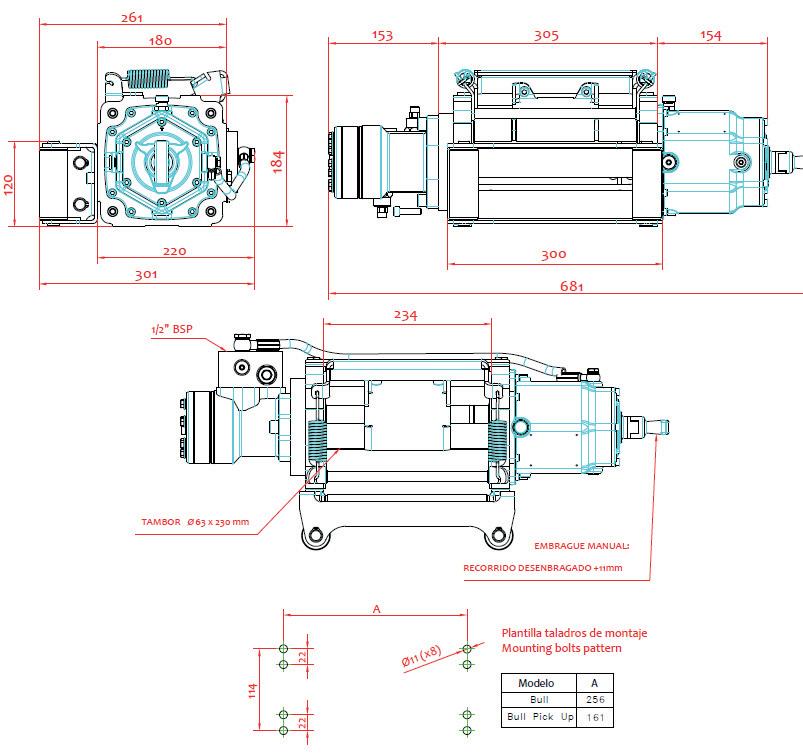

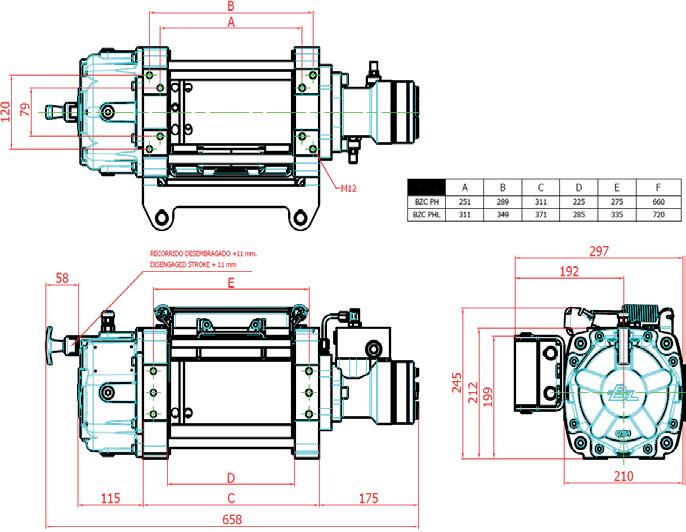

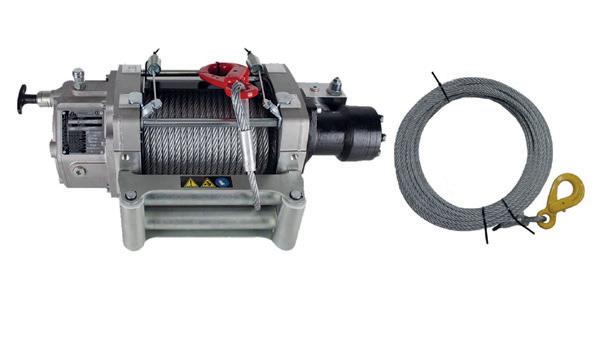

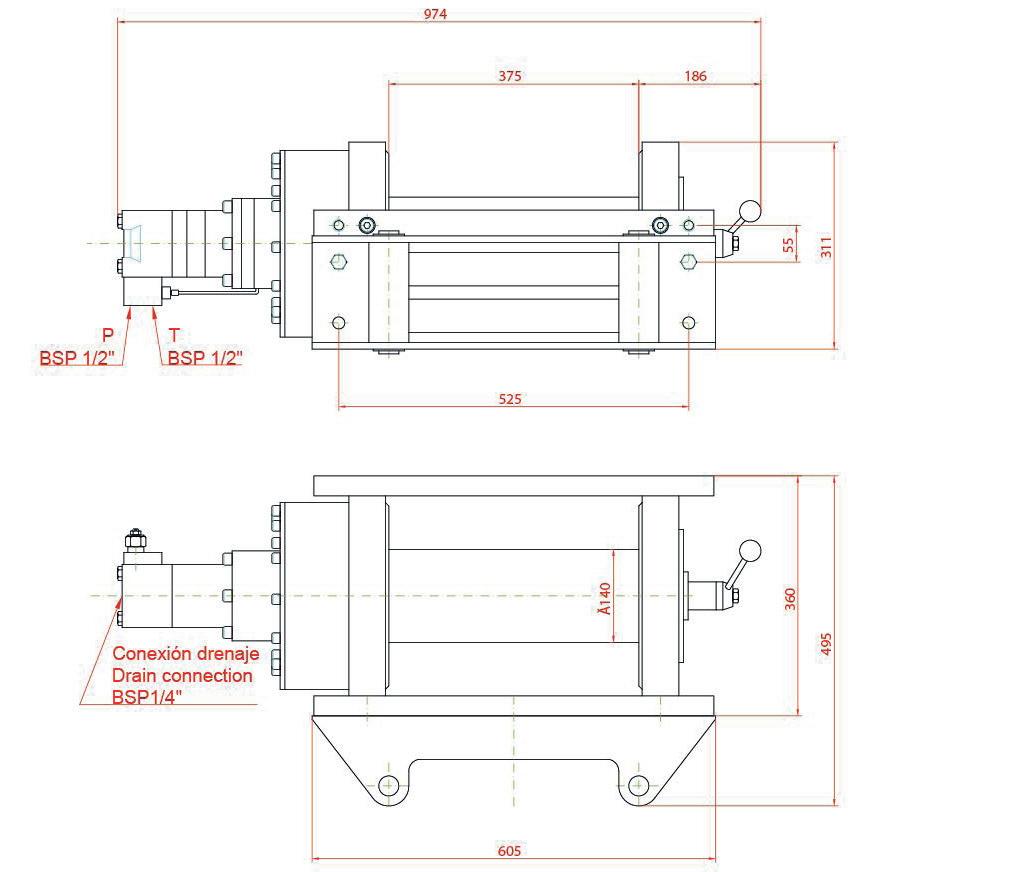

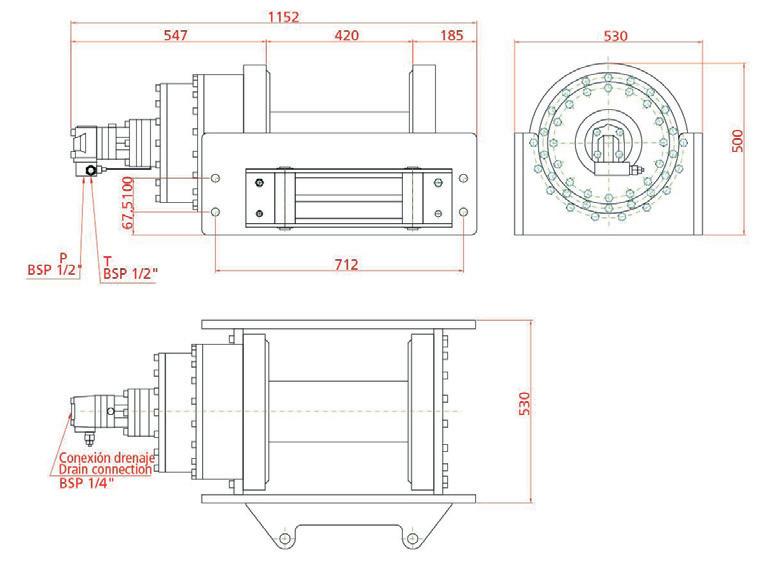

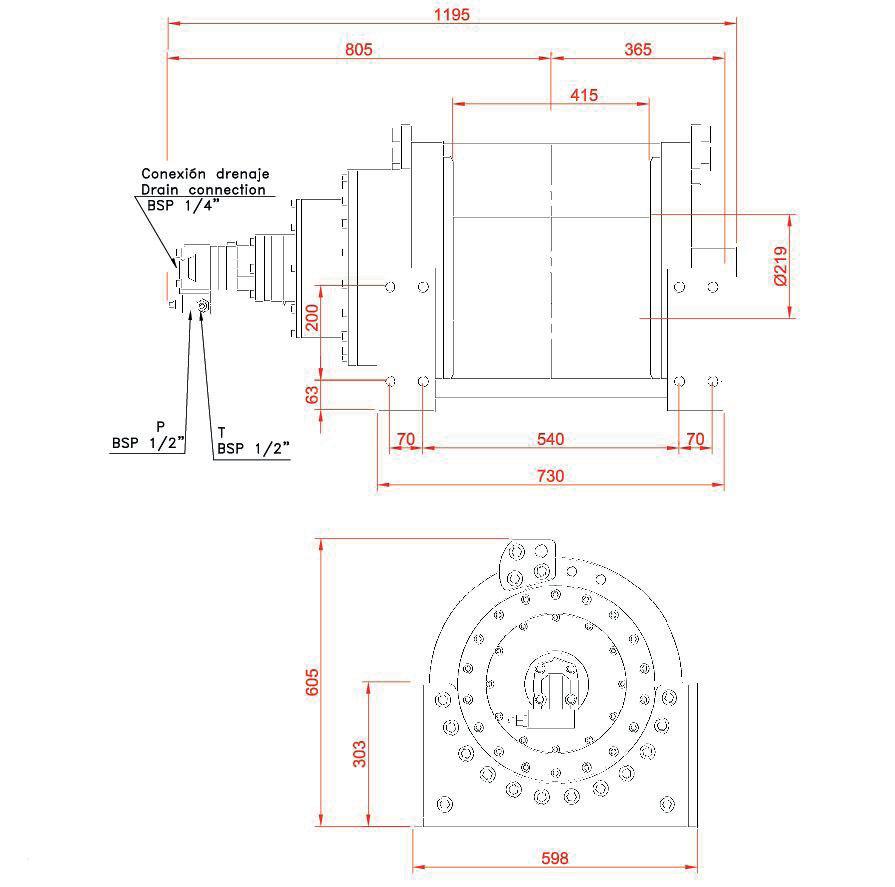

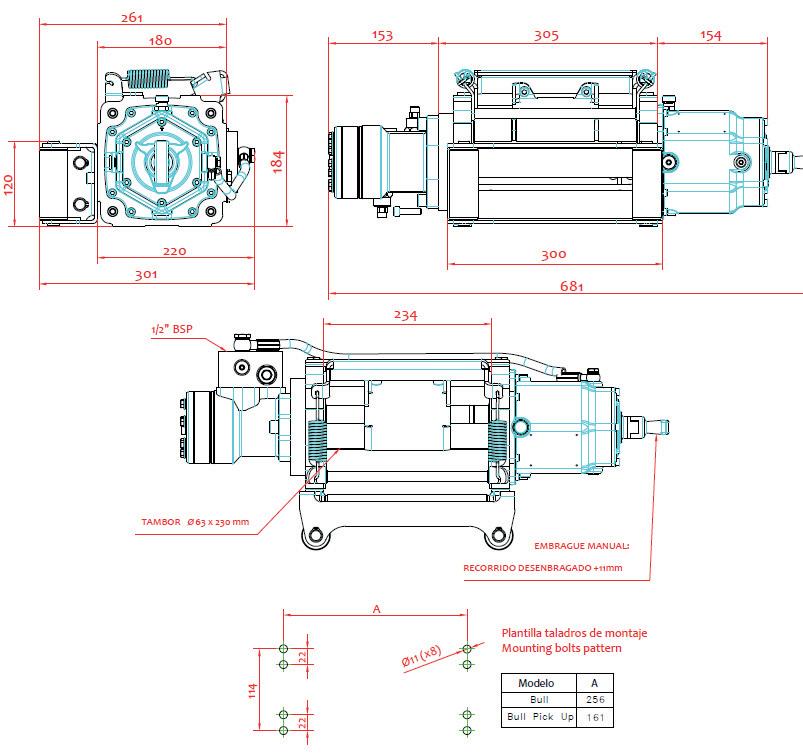

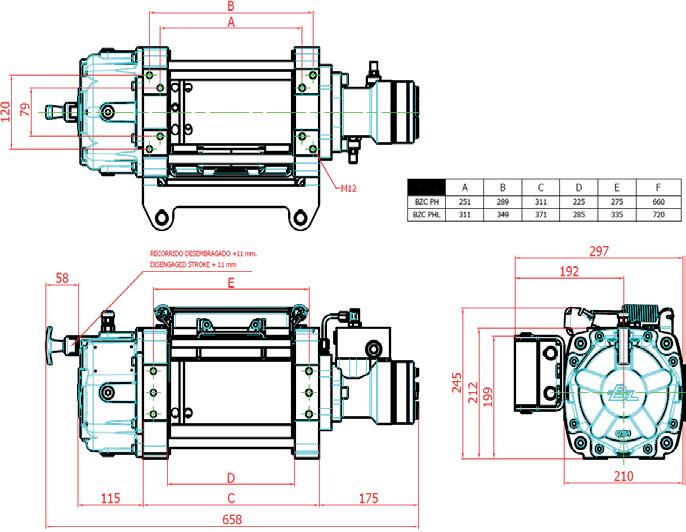

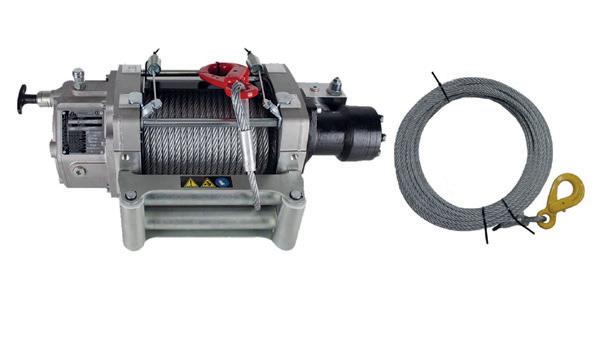

Winches

High-quality and durable hydraulic winches 3,500–30,000 kg from HAWE

HAWE Finland Oy Koskelontie 15 | 02920 Espoo | Finland | Tel. +358 (0)10 82126 00 | sales@hawe.fi | www.hawe.fi 42

9028625 9028825 9017725 9029625 9031625 3500 4600 6800 10000 15000 20000 30000 Model BZC-3500 BZC-4600 BZC-6800 GT-10000 GT-15000 GT-20000 GT-30000 Max. traction kg 25/30 21 16 18 12 22 6 Max. speed m/min 9029625.HS 9017825.HS 9020025.HS 9028625.HS 9028725.HS 9028825.HS 9031625.HS Product code HAWE

also has other test products, including acid-proof solutions

Gauge fittings and instruments

High-quality

SMK-20-G1/8-B-C-KK-W3

SMK-20-G1/8-B-C-W3

SMK-20-G1/4-B-C-KK-W3

SMK-20-G1/4-B-C-W3

SSV-20-W3

SMS-20-400-A-W3

SMS-20-1000-A-W3

SMS-20-1500-A-W3

SMS-20-2000-A-W3

SMS-20/M1/4-B-OR-500-B-W3

SMS-20/M1/4-B-OR-1000-B-W3

SMS-20/M1/4-B-OR-1500-B-W3

SMS-20/M1/4-B-OR-2000-B-W3

Digital Stauff test sets and particle analysers

HAWE Finland Oy Koskelontie 15 | 02920 Espoo | Finland | Tel. +358 (0)10 82126 00 | sales@hawe.fi | www.hawe.fi 43

Test products

1/8” BSPP 1/8” BSPP 1/4” BSPP 1/4” BSPP M16x2/M16x2 M16x2/M16x2 M16x2/M16x2 M16x2/M16x2 M16x2/M16x2 M16x2/G1/4 M16x2/G1/4 M16x2/G1/4 M16x2/G1/4 Product Gauge fitting Gauge fitting Gauge fitting Gauge fitting Intermediate adapter M16x2/ M16x2 Test hose M16x2/M16x2 Test hose M16x2/M16x2 Test hose M16x2/M16x2 Test hose M16x2/M16x2 Test hose M16x2/G1/4 Test hose M16x2/G1/4 Test hose M16x2/G1/4 Test hose M16x2/G1/4 Thread ED/NBR ED/NBR ED/NBR ED/NBR---Gasket Plastic Metal Plastic MetalPlastic Plastic Plastic Plastic Plastic Plastic Plastic Plastic Protective cap Zn/Steel Zn/Steel Zn/Steel Zn/Steel Zn/Steel Zn/Steel/PA Zn/Steel/PA Zn/Steel/PA Zn/Steel/PA Zn/Steel/PA Zn/Steel/PA Zn/Steel/PA Zn/Steel/PA Material

code

fittings and instruments DN2 DN2 DN2 DN2 DN2 DN2 DN2 DN2 Size

Product

Gauge

00|l@hfi|hfi

us about other test products!

Stauff gauge fittings and hoses from HAWE.

Ask

HAWE Finland solutions – components, programming and systems

HAWE Finland Oy Koskelontie 15 | 02920 Espoo | Finland | Tel. +358 (0)10 82126 00 | sales@hawe.fi | www.hawe.fi 44

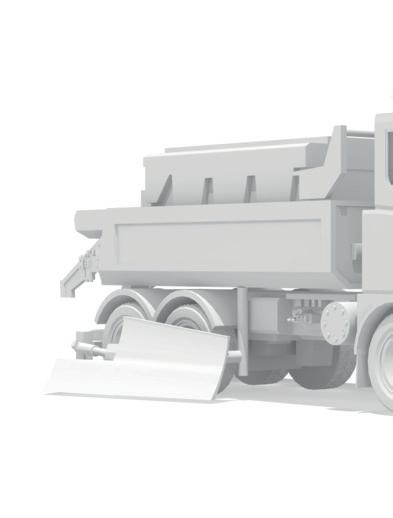

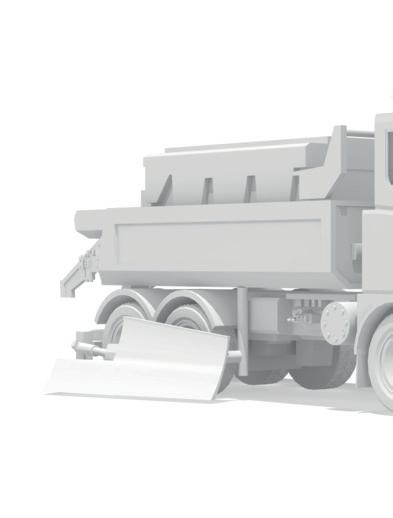

Gravel hopper trailer truck

HAWE V60N variable displacement pump does NOT REQUIRE a by-pass valve!

Fixed Sunfab pumps with or without a by-pass valve. Remember the tank’s by-pass valve flushing line.

HAWEFinlandOy Koskelontie15|02920Espoo|Finland|Tel. +358(0)108212600|sales@hawe.fi|www.hawe.fi

HAWE V60N variable pump does NOT REQUIRE a valve!

Fixed Sunfab pumps with or without a valve. Remember the tanks valve line.

Road maintenance truck

HAWE Finland solutions – components, programming and systems

Forest machine

Gravel spreader

HAWE Finland Oy Koskelontie 15 | 02920 Espoo | Finland | Tel. +358 (0)10 82126 00 | sales@hawe.fi | www.hawe.fi 45

HAWE V30E pumps and PSV valve banks and CLHV load-holding valves.

HAWE V30E pumps and PSV valve banks and CLHV valves.

HAWE PSL/PSV valve banks.

HAWE Finland solutions – components, programming and systems

Timber truck

HAWE V60N130 and 110 variable with new controllers! Make sure the are clean.

HAWE V60N130 and 110 variable displacement pumps with new controllers! Make sure the quick couplings are

Refuse truck

HAWE V60N variable pump does NOT REQUIRE a valve!

HAWE V60N variable displacement pump does NOT REQUIRE a by-pass valve!

HAWE Finland Oy Koskelontie 15 | 02920 Espoo | Finland | Tel. +358 (0)10 82126 00 | sales@hawe.fi | www.hawe.fi 46

HAWE Finland solutions – components, programming and systems

Lorry crane truck

Power

standard in

variable pumps, for other sizes!

standard in V60N-130 variable displacement pumps, optional for other sizes!

Fixed Sunfab with or without a valve. Remember the tank’s valve line.

Fixed Sunfab pumps with or without a by-pass valve. Remember the tank’s by-pass valve flushing line.

HAWE V60N variable displacement pump does NOT REQUIRE a by-pass valve!

HAWE V60N variable pump does NOT REQUIRE a byy-pass valve!

HAWE Finland Oy Koskelontie 15 | 02920 Espoo | Finland | Tel. +358 (0)10 82126 00 | sales@hawe.fi | www.hawe.fi 47

controller

HAWE Finland Koskelontie 15 02920 Espoo Finland Tel. +358 82126 00 sales@hawe.fi www.hawe.fi

Power controller

V60N-130

Hook lift truck

HAWE Finland solutions – components, programming and systems

HAWE Finland Oy Koskelontie 15 | 02920 Espoo | Finland | Tel. +358 (0)10 82126 00 | sales@hawe.fi | www.hawe.fi 48

your cooler from HAWE! Make sure to keep the tank clean.

Semi-closed hydraulic system with a fixed pump or variable displacement pump!

Get

Chipper truck

Concrete mixer truck

HAWE Finland solutions – components, programming and systems

Safety-rated components and solutions.

HAWE Finland Oy Koskelontie 15 | 02920 Espoo | Finland | Tel. +358 (0)10 82126 00 | sales@hawe.fi | www.hawe.fi 49 HAWE Finland Koskelontie 15 02920 Espoo Finland sales@hawe.fi www.hawe.fi

Semi-closed hydraulic system with a fixed pump or variable displacement pump! We carry ATEX products.

Tank truck

Fire fighting truck

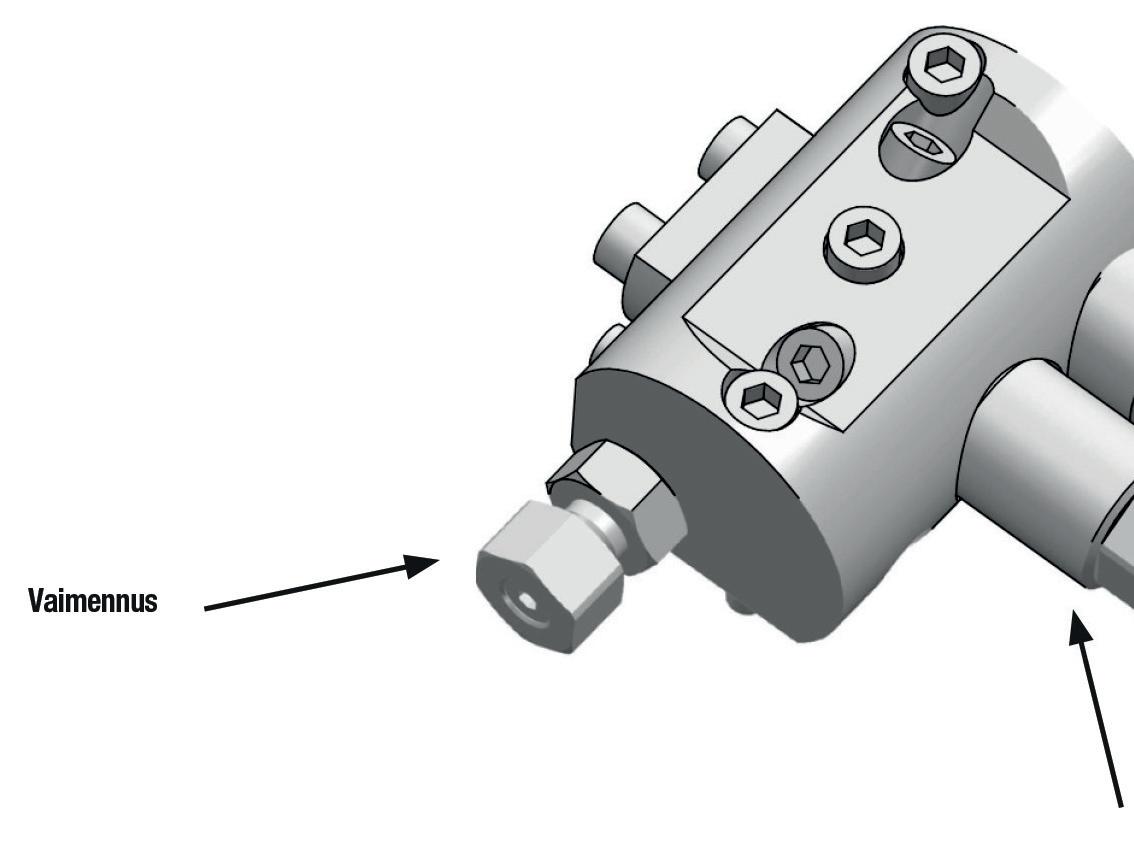

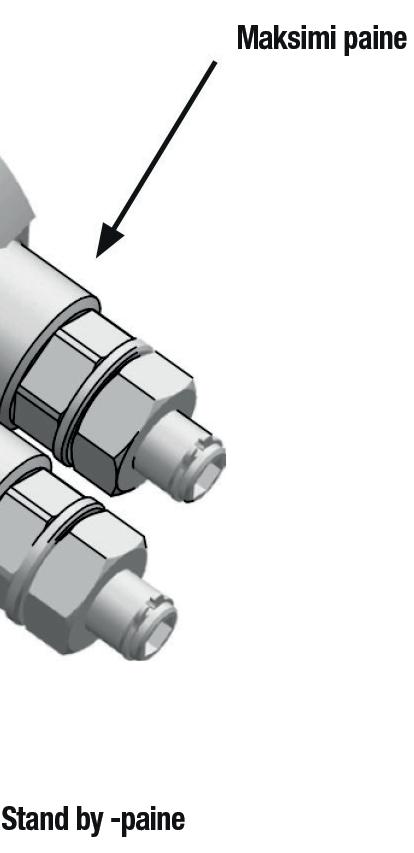

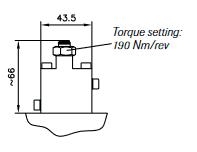

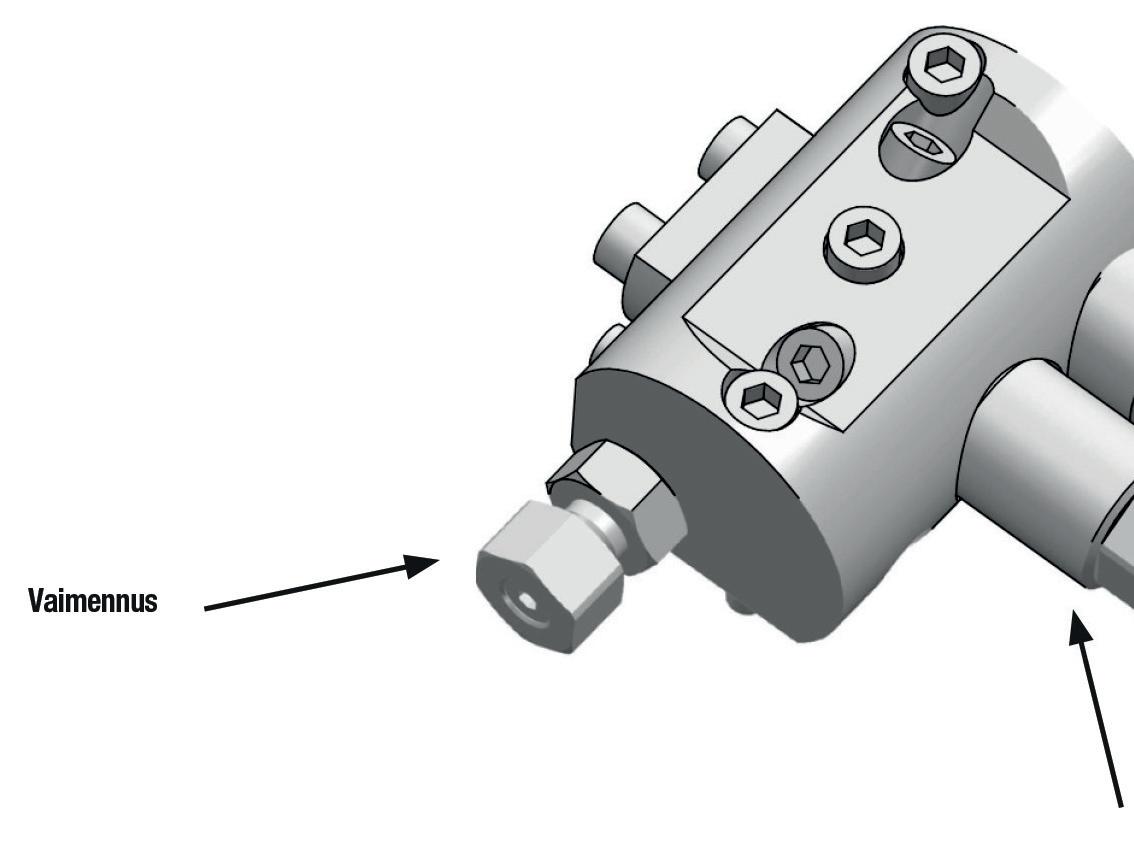

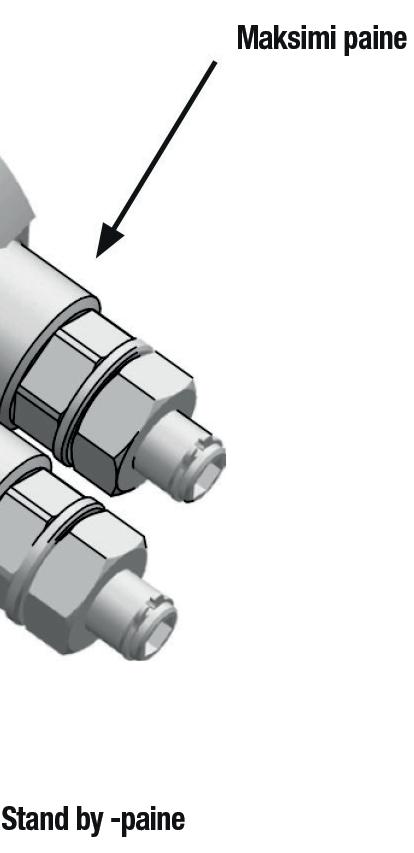

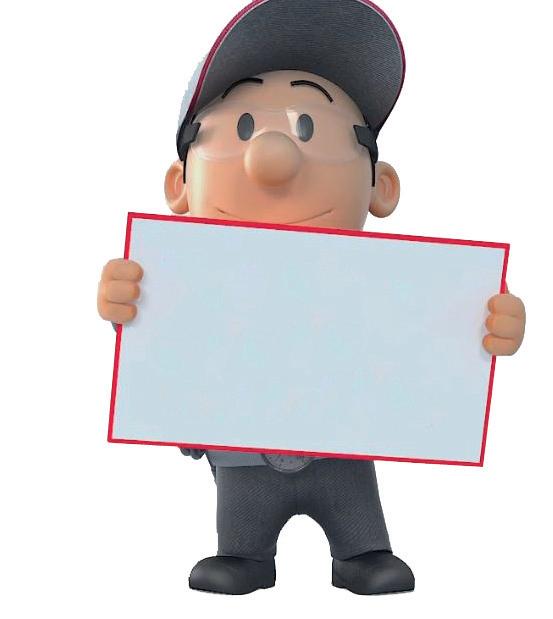

HAWE Finland Oy Koskelontie 15 | 02920 Espoo | Finland | Tel. +358 (0)10 82126 00 | sales@hawe.fi | www.hawe.fi 50 Pump installation instructions –HAWE variable displacement pump V60N - LSP V60N 130 - tehonsä Remember return line to tank! Dynamic screws Stand-By pressure 10 bar/rev. Maximum pressure 50 bar/rev. 22. Speed control screw 22 Damping screw 23 Lock screw Dynamic screw functions LSP controller 12 V60N 130- Power control V60N 060-110 - Power control Torsion: 190 Nm/rev. Torsion: 190 Nm/rev.

Pump installation instructions –

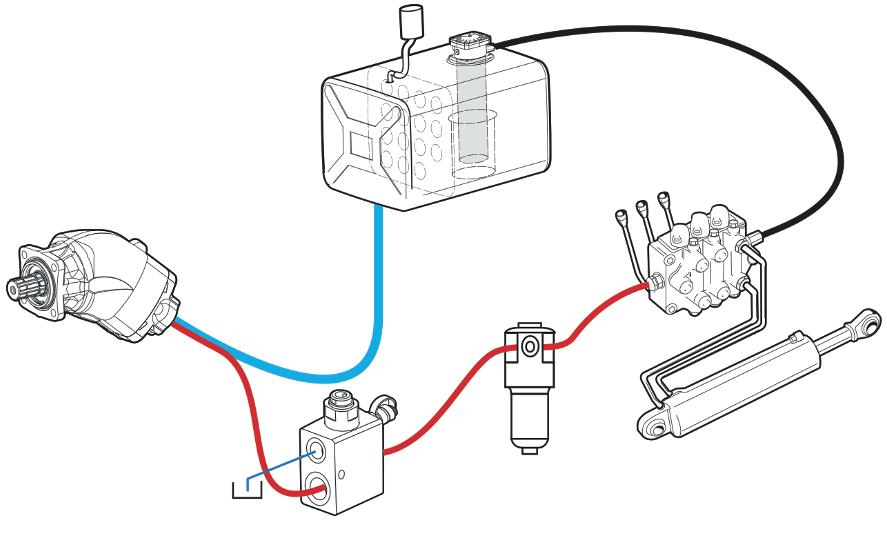

HAWE variable displacement pump V60N - LSP SYSTEM

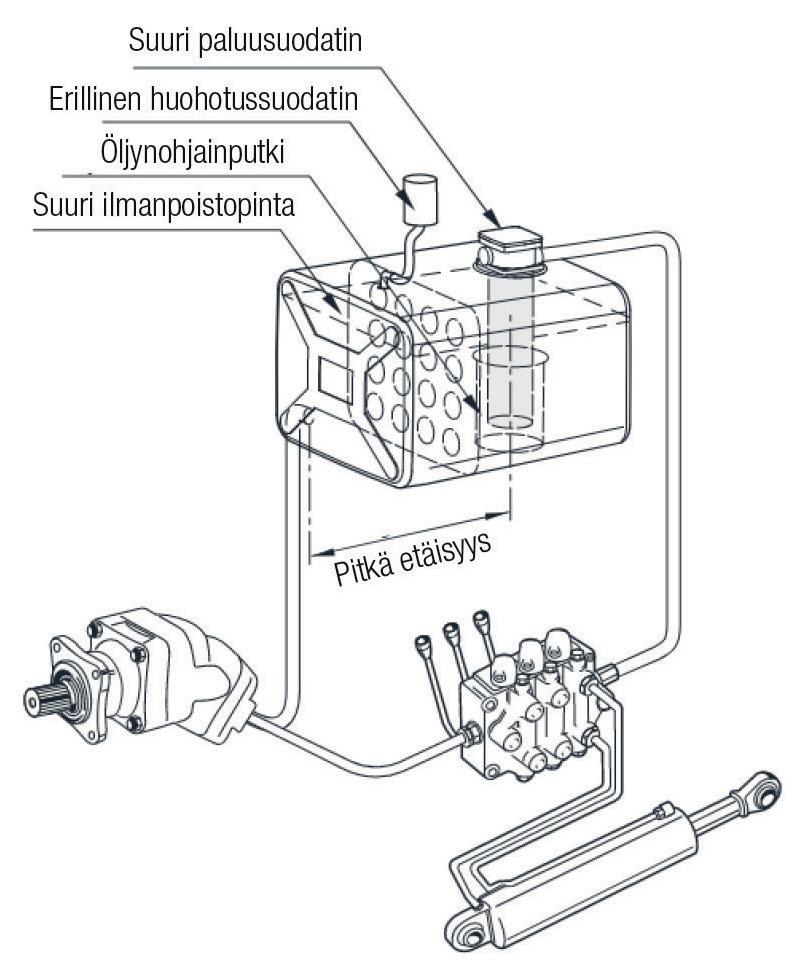

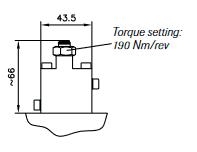

1. The oil tank’s capacity must be at least twice as high as the pump’s maximum output per minute.

2. Make sure the tank and the inlet hose are clean.

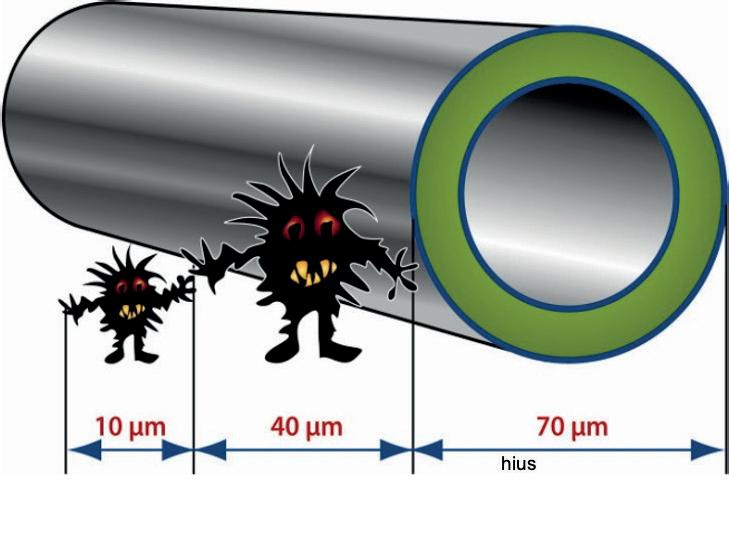

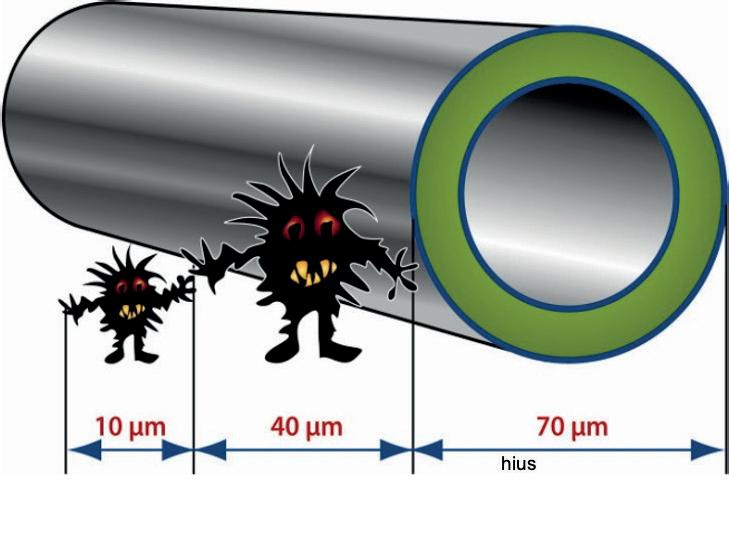

3. The return valve’s throughput capacity must be four times as high as the pump’s maximum output per minute with the filter’s filtration ratio being 10 μ.

4. Breather filtration ratio 10 μ.

5. It is recommended to install a pressure filter on the pressure line.

6. Install the tank as close to the pump as possible, so that the pump stays below the oil level.

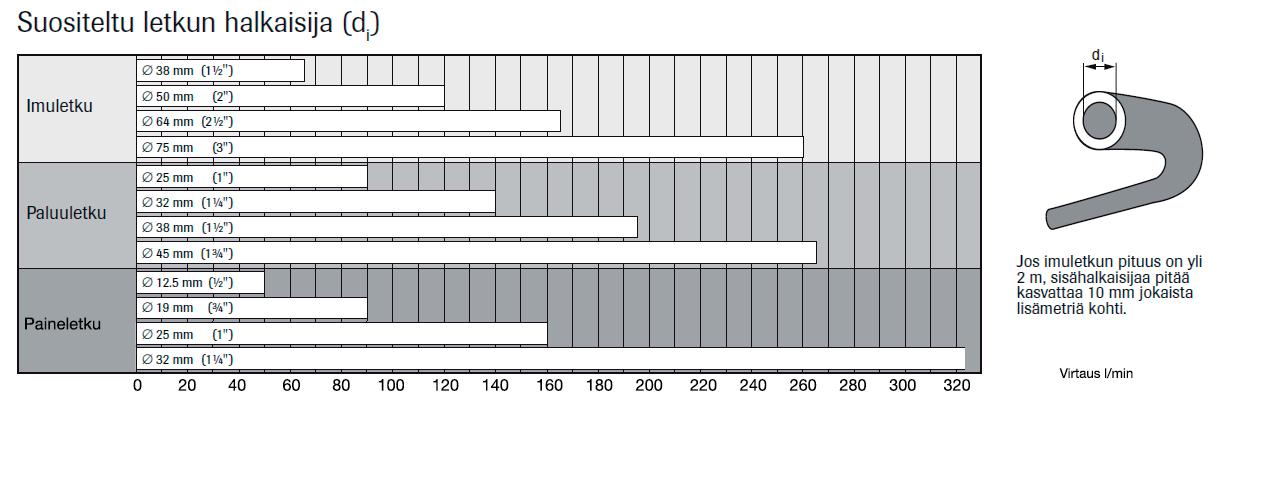

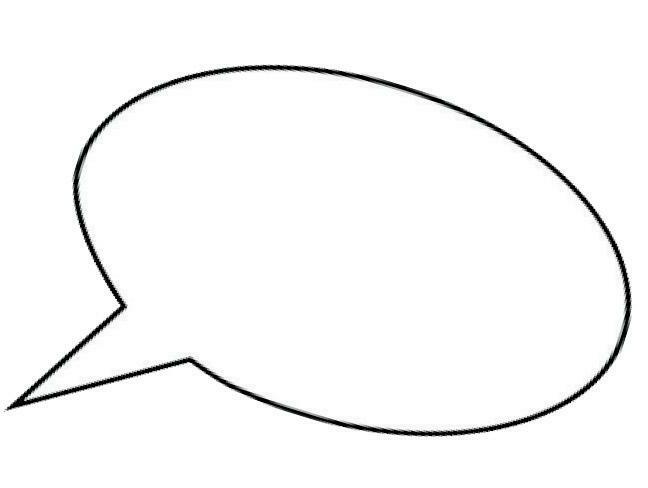

7. The system output determines the inner diameter of the suction line. See table.

8. The pump’s housing return line must be placed below the oil level and as far as possible from the tank’s suction outlet. The return line’s inner diameter is 19 mm (3/4” hose)

9. The pressure line must be equipped with a shock valve set to approximately 30 bar higher than the pump’s maximum pressure. See the table for the line’s inner diameter.

10. The LS line capacity must be 10% of the pressure line capacity. In other words, if the lines are of equal length, the inner diameter of the LS line must be 1/3 of the pressure line’s diameter.

11. Before installing the pump, make sure its direction of rotation is correct.

12. Fill in the pump housing with filtered oil. This also applies to vehicles with a rear mounting tank.

13. Use a manufacturer-recommended grease to lubricate the pump shaft. (Renolite LX PEP 2)

14. Do not install the pump shaft coupling by striking it.

15. Before use, make sure that the suction line and the pump are full of oil.

16. After installation, let the system run idle for 10 min (max. 50 bar).

17. When replacing the pump, the entire system must be emptied and cleaned, including the tank and hoses. Replace the filters after 50 hours of use.

18. If a pump of another make is being replaced, read step 8 carefully.

PUMP ADJUSTMENT

19. Adjust the pump pressure values as necessary.

20. Factory settings: standby pressure 28 bar and maximum pressure 300 bar, V60N 130 power controller L 700 Nm

21. The stabilisation of the system may require the adjustment of the dynamic screws on the side of the controller.

22. Use the speed control screw to adjust the pump’s reaction rate from zero angle to maximum angle. Screw fully loose -> maximum reaction rate. Factory setting: 1 1/2 turns loose.

23. Use the damping screw to adjust damping. Screw fully loose -> maximum damping. Factory setting: 1 turn loose.

HAWE Finland Oy Koskelontie 15 | 02920 Espoo | Finland | Tel. +358 (0)10 82126 00 | sales@hawe.fi | www.hawe.fi 51

Sunfab fixed displacement pump –installation instructions

1. The oil tank’s capacity must be at least twice as high as the pump’s maximum output per minute.

2. Make sure the tank and the inlet hose are clean.

3. The return valve’s throughput capacity must be four times as high as the pump’s maximum output per minute with the filter’s filtration ratio being 10 μ.

4. Breather filtration ratio 10 μ.

5. It is recommended to install a pressure filter on the pressure line.

6. Install the tank as close to the pump as possible, so that the pump stays below the oil level.

7. The system output determines the inner diameter of the suction line. See table.

8. The pressure line must be equipped with a pressure limiting valve. The pressure limiting valve must come before any quick couplings.

9. Before installing the pump, make sure its direction of rotation is correct.

10. Fill in the pump housing with filtered oil. This also applies to vehicles with a rear mounting tank.

11. Use a manufacturer-recommended grease to lubricate the pump shaft. (e.g. Renolite LX PEP 2)

12. Do not install the pump shaft coupling by striking it.

13. Before use, make sure that the suction line and the pump are full of oil.

14. After installation, let the system run idle for 10 min max. 50 bar

15. When replacing the pump, the entire system must be emptied and cleaned, including the tank and hoses. Replace the filters after 50 hours of use.

HAWE Finland Oy Koskelontie 15 | 02920 Espoo | Finland | Tel. +358 (0)10 82126 00 | sales@hawe.fi | www.hawe.fi 52

sure to check the pump rotation direction and speed! su pdire speed Large return filter Separate breather filter Oil control pipe Large venting area Recommended hose diameter (dr) Longdistance If the inlet hose is longer than 2 m, the inner diameter must be increased by 10 mm per extra metre. Flow l/mm Inlet hose Return hose Pressure hose

Make

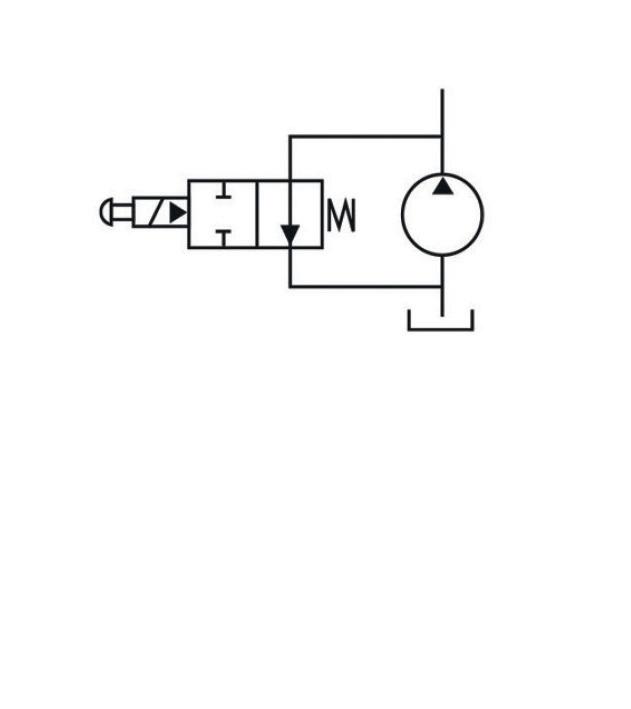

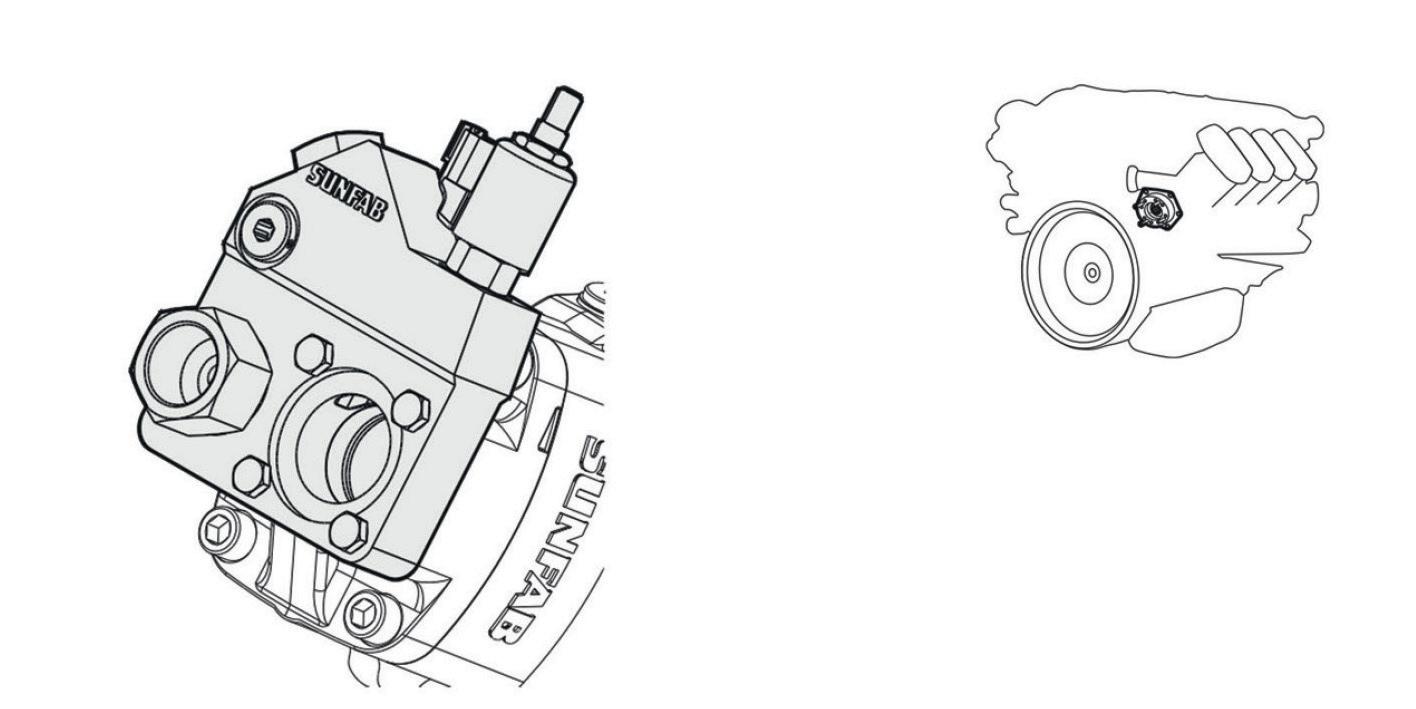

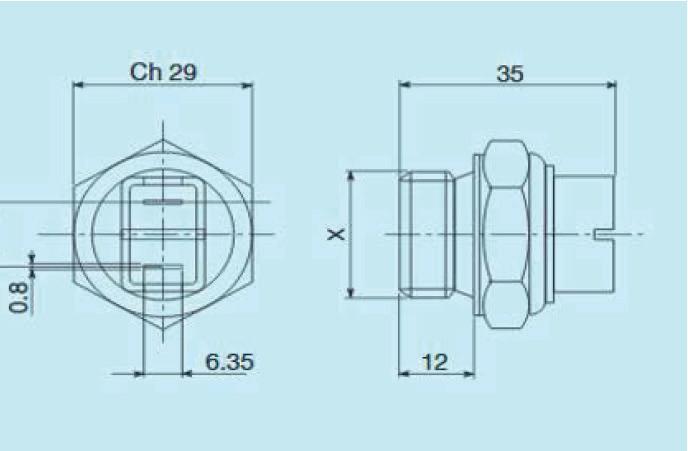

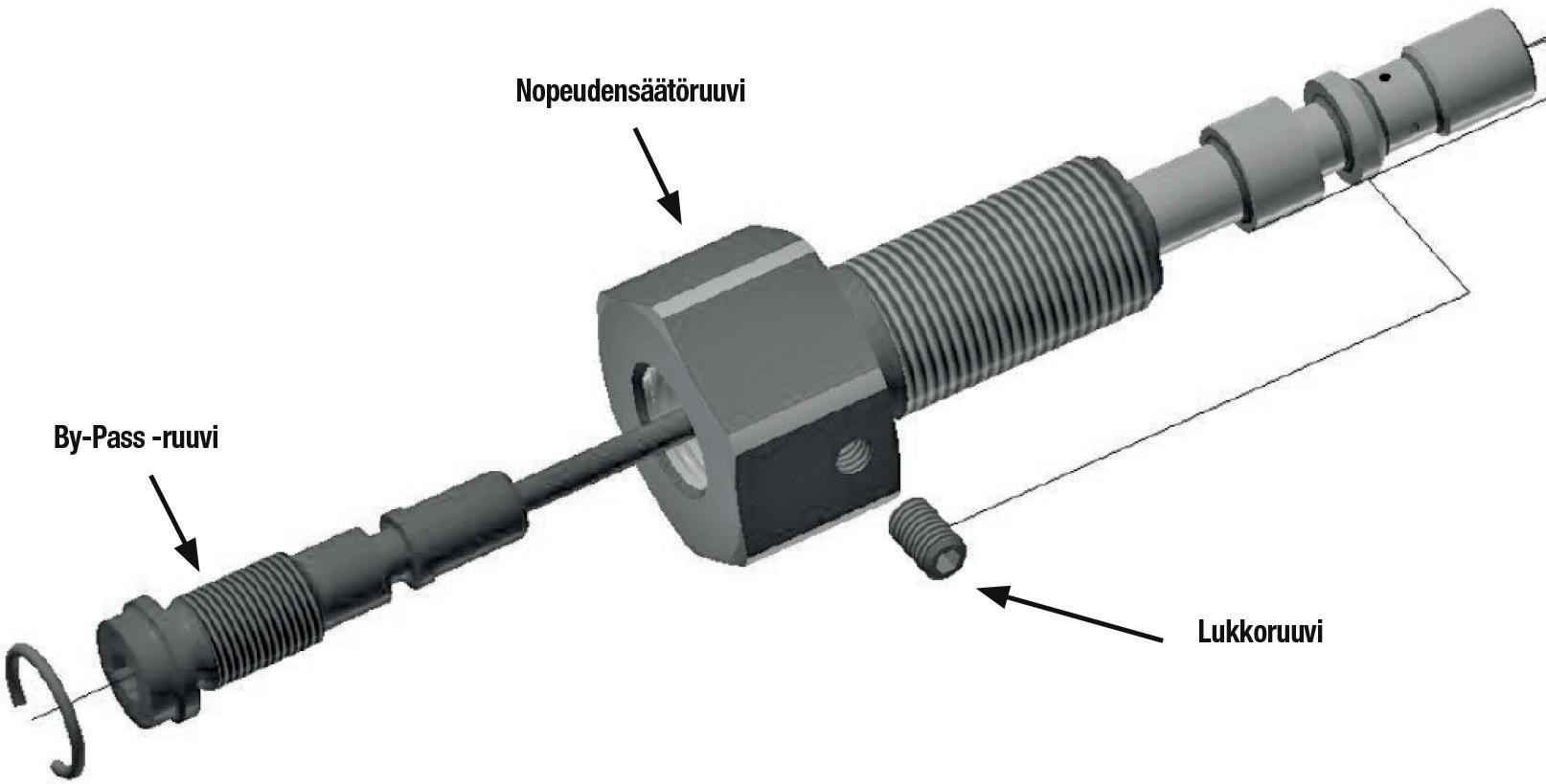

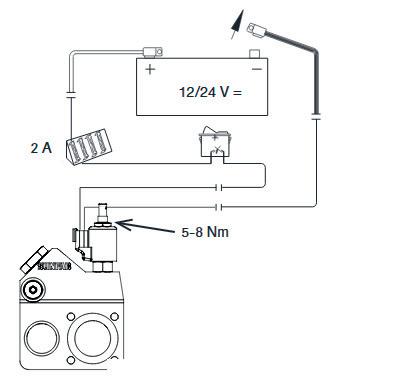

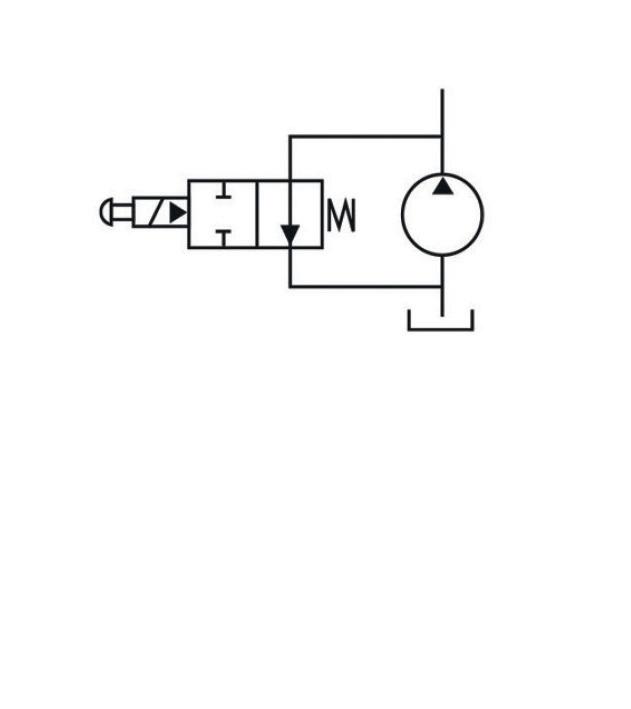

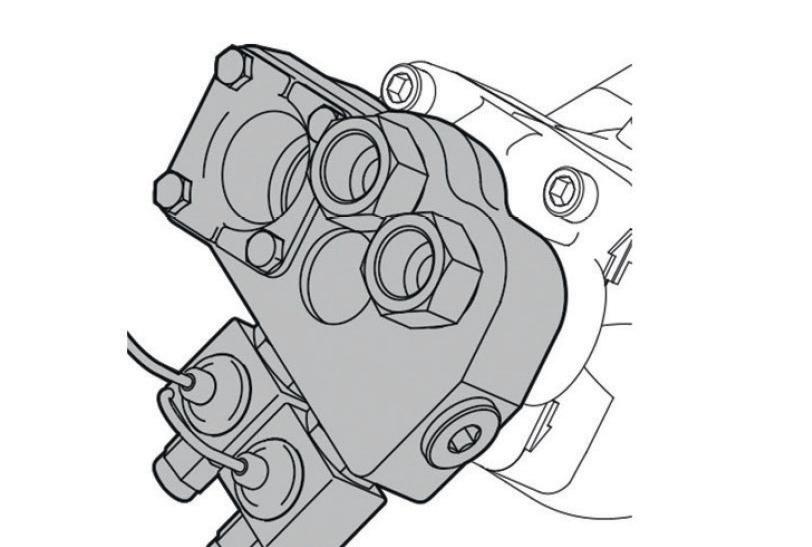

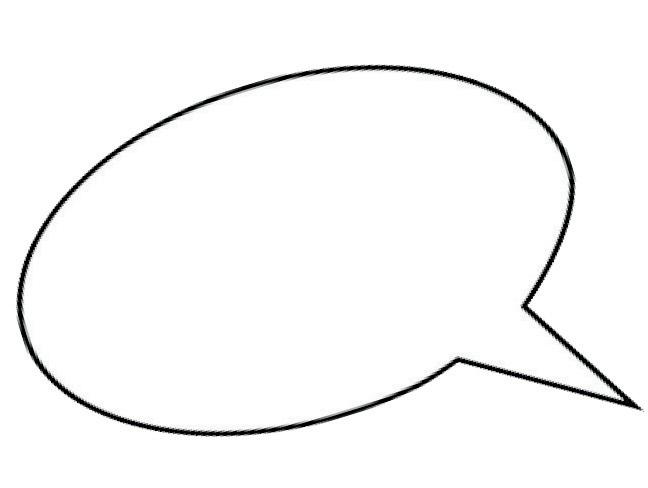

By-pass valve – installation instructions

The by-pass valve is designed for Sunfab fixed displacement pumps’ SAP and SAPT assemblies, where the power take-off is not switched off during operation.

1. Rotatable valve

2. Clean the pump connection surface.

3. Install the valve by using suitable gaskets and emergency screws.

4. An external 3/8"- ½" return line must be placed below the oil level and as far as possible from the tank’s suction outlet.

5. The by-pass valve must be protected with a fuse of 2 amperes.

By-pass valve – emergency use

1. If there is an interruption in power supply, the system can be pressurised using an emergency screw.

2. Turn the screw inwards until the valve spool hits the bottom.

3. At the end of emergency use, return the screw to its original position, secure it and replace the protective cap.

HAWE Finland Oy Koskelontie 15 | 02920 Espoo | Finland | Tel. +358 (0)10 82126 00 | sales@hawe.fi | www.hawe.fi 53

ed rn Assemble thesystem carefully! semble esystem Flushing port Emergency use

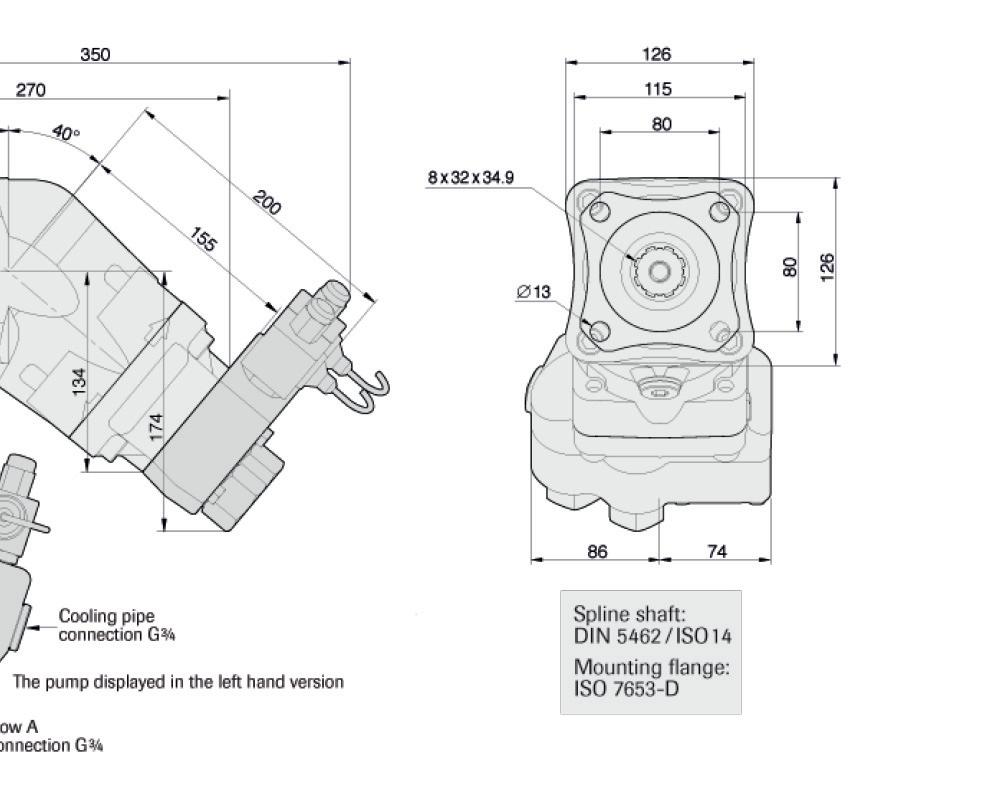

Dual flow Sunfab – pump installation instructions

(double pumps)

NB! SCPD 056/+26 and SCPD 076/076 pumps have their own values

1. The oil tank’s capacity must be at least twice as high as the pump’s maximum output per minute.

2. Make sure the tank and the inlet hose are clean.

3. The return valve’s throughput capacity must be four times as high as the pump’s maximum output per minute with the filter’s filtration ratio being 10 μ.

4. Breather filtration ratio 10 μ.

5. It is recommended to install pressure filters on the pressure lines.

6. Install the tank as close to the pump as possible, so that the pump stays below the oil level.

7. The system output determines the inner diameter of the suction line. See table.

8. The pressure lines must be equipped with pressure limiting valves. The pressure limiting valves must come before any quick couplings.

9. Before installing the pump, make sure its direction of rotation is correct. The direction of rotation cannot be changed.

10. Fill in the pump housing with filtered oil. This also applies to vehicles with a rear mounting tank.

ft. (e.g

11. Use a manufacturer-recommended grease to lubricate the pump shaft. (e.g. Renolite LX PEP 2)

12. Do not install the pump shaft coupling by striking it.

13. Before use, make sure that the suction line and the pump are full of oil.

line

Make sure to check the pump rotation direction and speed!

sur p dire speed

idle for system ng the ter 50

14. After installation, let the system run idle for 10 min (max. 50 bar).

15. When replacing the pump, the entire system must be emptied and cleaned, including the tank and hoses. Replace the filters after 50 hours of use.

HAWE Finland Oy Koskelontie 15 | 02920 Espoo | Finland | Tel. +358 (0)10 82126 00 | sales@hawe.fi | www.hawe.fi 54

120 l/min 1470 rpm 50 19 32 Maximum flow Maximum rotation speed Suction line mm Pressure line mm Return line mm SCPD 056 160 l/min 1850 rpm 64 19 38 SCPD 026 185 l/min 1230 rpm 64 19 38 Maximum flow Maximum rotation speed Suction line mm Pressure line mm Return line mm SCPD 076 255 l/min 1700 rpm 75 25 45 SCPD 076

g n

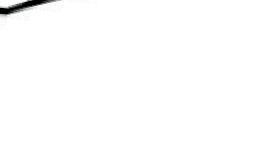

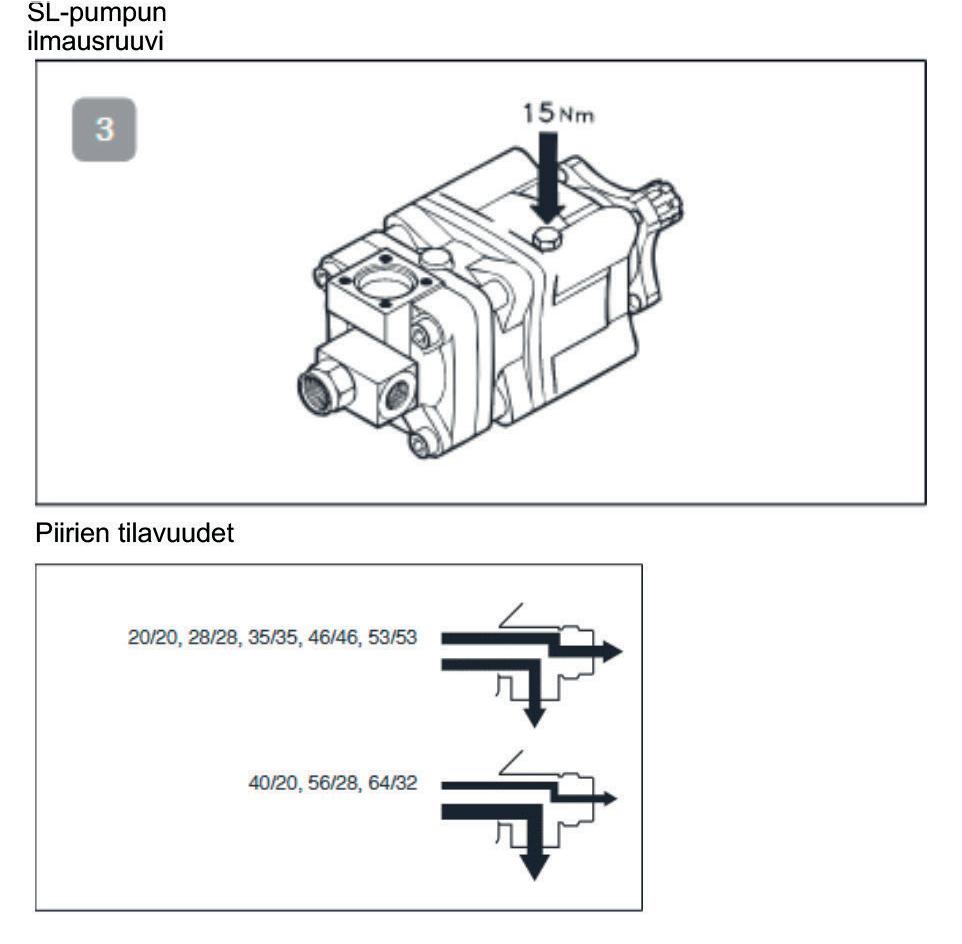

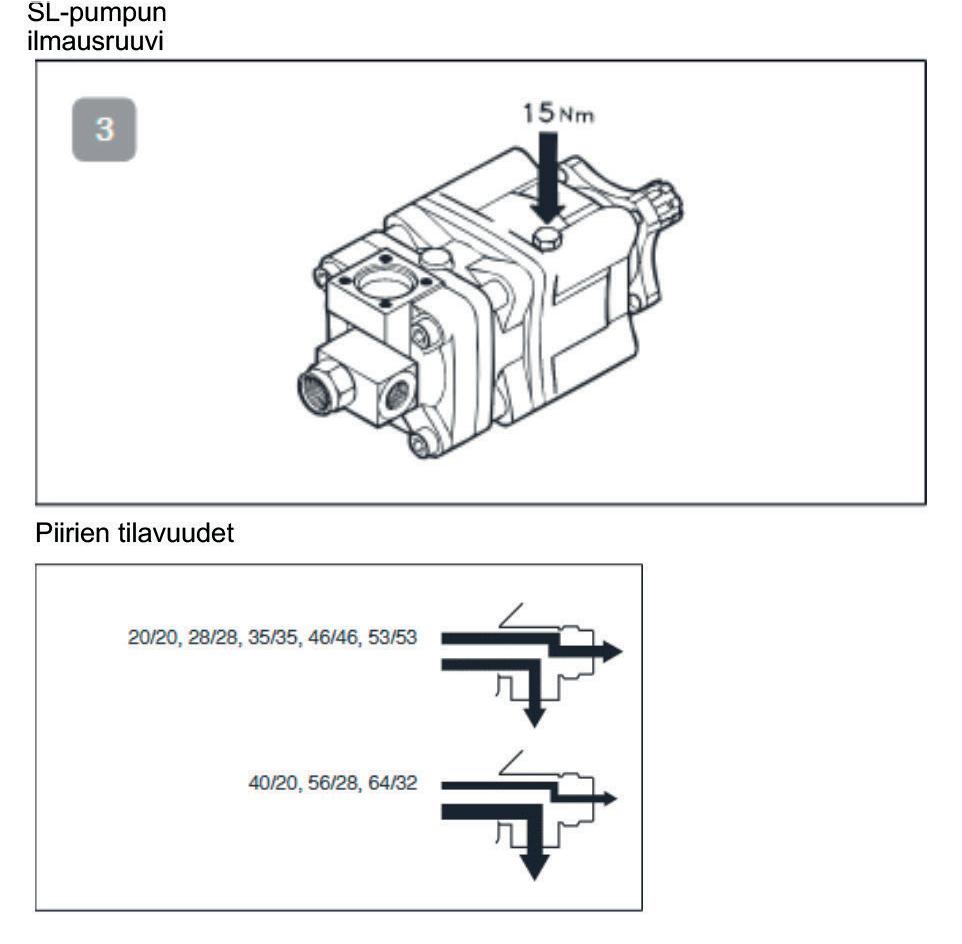

Sunfab SL – pump installation instructions

1. The oil tank’s capacity must be at least twice as high as the pump’s maximum output per minute.

2. Make sure the tank and the inlet hose are clean.

3. The return valve’s throughput capacity must be four times as high as the pump’s maximum output per minute with the filter’s filtration ratio being 10 μ.

4. Breather filtration ratio 10 μ.

5. It is recommended to install pressure filters on the pressure lines.

6. Install the tank as close to the pump as possible, so that the pump stays below the oil level.

7. The system output determines the inner diameter of the suction line. See table.

8. Do not turn the pump when the pump is full of oil.

9. Free direction of rotation

10. Use a manufacturer-recommended grease to lubricate the pump shaft. (Renolite LX PEP 2)

11. Do not install the pump shaft coupling by striking it.

12. Before use, make sure that the suction line and the pump are full of oil.

13. Bleed the pump before use.

14. After installation, let the system run idle for a few minutes.

15. If the pump output is pulsating, there is still air in the system. Switch the pump off and on for a few times to bleed the system.

16. When replacing the pump, the entire system must be emptied and cleaned, including the tank and hoses. Replace the filters after 50 hours of use.

HAWE Finland Oy Koskelontie 15 | 02920 Espoo | Finland | Tel. +358 (0)10 82126 00 | sales@hawe.fi | www.hawe.fi 55

SL pump SL pump bleeder screw

Circuit capacity

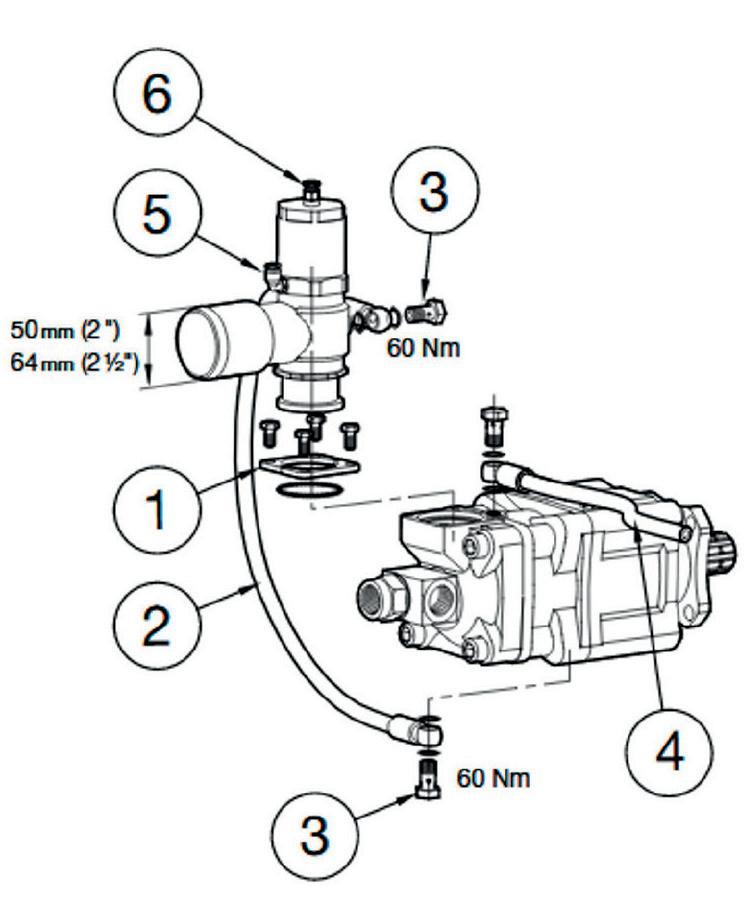

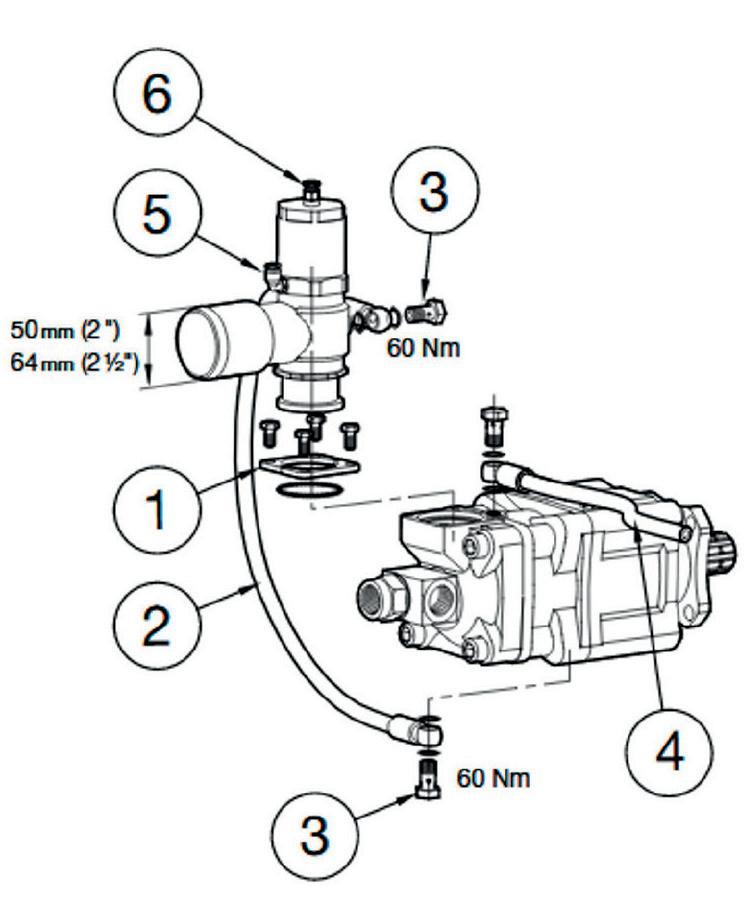

Sunfab SAVTEC – pump installation instructions

Savtec is the suction line shut-off valve for Sunfab SL pumps. Savtec is intended for assemblies where the power take-off is not turned off during operation.

1. The oil tank’s capacity must be at least twice as high as the pump’s maximum output per minute.

2. Make sure the tank and the inlet hose are clean.

3. The return valve’s throughput capacity must be four times as high as the pump’s maximum output per minute with the filter’s filtration ratio being 10 μ.

4. Breather filtration ratio 10 μ.

5. It is recommended to install pressure filters on the pressure lines.

6. Install the tank as close to the pump as possible, so that the pump stays below the oil level.

7. The system output determines the inner diameter of the suction line. See table.

8. Do not turn the pump when the pump is full of oil.

9. Free direction of rotation

10. Use a manufacturer-recommended grease to lubricate the pump shaft. (e.g. Renolite LX PEP 2)

11. Do not install the pump shaft coupling by striking it.

12. Hose number 4 (½”) is placed below the oil level and as far as possible from the tank’s suction outlet.

13. Angle nipple number 5 is the compressed-air connection of the valve opening. Straight nipple number 6 is the hose ventilation connection.

14. Before use, make sure that the suction line and the pump are full of oil.

15. After installation, let the system run idle for a few minutes.

16. If the pump output is pulsating, there is still air in the system. Switch the pump off and on for a few times to bleed the system.

17. When replacing the pump, the entire system must be emptied and cleaned, including the tank and hoses. Replace the filters after 50 hours of use.

HAWE Finland Oy Koskelontie 15 | 02920 Espoo | Finland | Tel. +358 (0)10 82126 00 | sales@hawe.fi | www.hawe.fi 56

HAWE Finland Oy Koskelontie 15 | 02920 Espoo | Finland | Tel. +358 (0)10 82126 00 | sales@hawe.fi | www.hawe.fi 57 Notes ____________________________________________ ____________________________________________ ____________________________________________ ____________________________________________ ____________________________________________ ____________________________________________ ____________________________________________ ____________________________________________ _______________________ _____________________ ____________________________________________ ____________________________________________

Hydraulic system – General troubleshooting

The most common malfunctions and troubleshooting.

No pressure in the system.

Check the pump’s direction of rotation

Check the oil level in the oil tank

Make sure the suction line’s ball valve is open

Check the pump oil level

The machine jerks/vibrates.

Check the suction line diameter and connections

Check the pump rotation speed

Check the pump’s distance from the tank

Check the oil viscosity

Check the oil level in the oil tank

Make sure the pump gets oil

Check the LS signal (V60N pump)

High oil temperature.

Check the return and pressure hose diameter and choking

Make sure the by-pass valve works properly

Check the oil tank size/oil level

Check the return and pressure filters

Check the system valves

The machine is slow when loaded.

Check the pressure limiting valves

Check the by-pass valve

Check the pump condition

Check the LS line

Oil leak.

High oil temperature

High ambient temperature around the pump

Cavitation

The machine is powerless.

Check the pressure limiting valves

The machine makes abnormal sounds.

Air or water in oil – cavitation

Check the oil level

Check the suction line

Identify the source of the sound

Most common reasons:

Dirty oil

Water or air in oil

Power and programming problems

tem d tear ect use

Reliable HAWE hydraulics with good maintenance!

HAWE Finland Oy Koskelontie 15 | 02920 Espoo | Finland | Tel. +358 (0)10 82126 00 | sales@hawe.fi | www.hawe.fi 58

p

HAWE Finland services

HAWE Finland Oy locations and sales representatives in Finland:

ESPOO

HAWE Finland Oy Koskelontie 15, 02920 ESPOO

Taneli Tuomas taneli.tuomas@hawe.fi

+358 50 5608 965

Tommi Strand tommi.strand@hawe.fi

+358 400 320 395

Tapio Kytömaa tapio.kytomaa@hawe.fi

+358 44 985 5365

Yury Moroz yury.moroz@hawe.fi

+358 44 4939 288

TURKU

helppoa HAWE hydrauliikkaa!

HAWE Finland Oy Tykistökatu 4 B, 20520 TURKU

Risto Suominen risto.suominen@hawe.fi

+358 10 8212655

OULU

HAWE Finland Oy Teollisuustie 1, 90830 Haukipudas

Tomi Kononen tomi.kononen@hawe.fi

+358 50 468 6012

Distributors in Finland:

ESPOO Maantec Oy, Muottipojankuja 1, tel. 0400 810 649 IISALMI LH-Osa Oy, Teräskatu 3, tel. 040 743 0946 JOENSUU Närhi Oy, Lentoasemantie 10B, tel. 0400 658 200

Fluiconnecto Oy, Itä-Päijänteentie 57, tel. 010 341 4000 KEMI Hydro-Kemi HK Oy, Autoilijantie 9, tel. 020 728 8520 LAHTI Fluiconnecto Oy, Jussilankatu 10, tel. 010 341 4000

OULU Fluiconnecto Oy, Voudintie 8, tel. 010 341 4000

| www.hawe.fi

PALOKKA Närhi Oy, Palokanorsi 12, tel. 045 3506 334 PIETARSAARI C&J Service Ab, Lostisbackavägen 3, tel. 0500 873 502

ROVANIEMI HydraSpecma Oy, Ahjotie 28 B, tel. 020 7509 332 SEINÄJOKI Lakeuden Hydro Oy, Rajatie 46, tel. 040 5212 001 TAMPERE Fluiconnecto Oy, Keskuojankatu 12, tel. 010 341 4000

TOIVALA LH-Osa Oy, Takojantie 10, tel. 040 4860 702 TURKU Fluiconnecto Oy, Ruunikkokatu 9, tel. 010 341 4000 TUUSULA Maantec Oy, Teollisuustie 1, tel. 050 3065 688

Hyvällä huollolla

Hyvällä huollolla

VAASA Lakeuden Hydro Oy, Laturintie 4, tel. 044 3433 454 VALKEALA Nappa Machine Oy, Teollisuustie 7, tel. 0400 762 047 VARKAUS Hydro Set

Hyvällä huollolla

helppoa HAWE hydrauliikkaa!

helppoa HAWE hydrauliikkaa!

helppoa HAWE hydrauliikkaa!

Distributors in Baltic region:

huollolla

helppoa HAWE hydrauliikkaa!

huollolla HAWE

HAWE Finland Oy Koskelontie 15 | 02920 Espoo | Finland | Puhelin +358 (0)10 82126 00 | sales@hawe.fi | www.hawe.fi 59

HAWE Finland Oy Kellonsoittajantie ·02770 ESPOO Kellonsoittajantie ·02770 ESPOO puh. (09)5712000

Kiertotie

Oy,

3, tel. 045 177 9880

sales@hawe.fi

HAWE Finland Oy puh. (09)5712000 syyt: ilmakuplia

öljyssä ohjelmointiongelmat suunniteltu järjestelmä kuluminen Hyvällä huollolla

ESTONIA BALTIC TREND OÜ Peterburi tee 69, 11415 Tallinn tel. +3725184204 Dido Hüdraulika Ringtee 43, 50105 Tartu tel. +372 5664 3687 Dido Hüdraulika Kesk tee 3, 75305 Jüri tel. +372 5309 9253 Eler Hydraulic Selja tee 11, 44105 Kunda tel. +372 327 0945 LATVIA Metsatek SIA ”Kaldari”, Ķekavas nov., Ķekavas pag., LV-2123 tel. +37126558666 LITHUANIA UAB ‘‘Domingos prekyba‘‘ Vilnius, Savanoriu 187B, LT-02300 Vilnius tel.+370 5243 22231 UAB ‘‘Domingos prekyba‘‘ Kaunas Elektrenu g. 1S, LT-51192 Kaunas, Lithuania tel. +370 614 28674 UAB ‘‘Domingos prekyba‘‘ Siauliai Zemaites g. 137 tel. +370 698 14821 HAWE Finland Oy puh. (09)5712000 ilmakuplia öljyssä ohjelmointiongelmat järjestelmä kuluminen Hyvällä

puh. (09)5712000 Yleisimmät syyt: Likainen öljy tai ilmakuplia öljyssä ja ohjelmointiongelmat suunniteltu järjestelmä Normaali kuluminen Käyttövirheet

huollolla helppoa HAWE hydrauliikkaa!

HAWE Finland Oy syyt: öljy ilmakuplia öljyssä ohjelmointiongelmat suunniteltu järjestelmä kuluminen Käyttövirheet

HAWE Finland Oy puh. (09)5712000 syyt:

öljyssä ohjelmointiongelmat suunniteltu järjestelmä kuluminen Käyttövirheet

ilmakuplia

puh. (09)5712000 ilmakuplia öljyssä ohjelmointiongelmat järjestelmä kuluminen Hyvällä

HAWE Finland Oy puh. (09)5712000 ilmakuplia öljyssä ohjelmointiongelmat suunniteltu järjestelmä kuluminen HAWE Finland Oy puh. (09)5712000 öljyssä ohjelmointiongelmat järjestelmä HAWE Finland Oy puh. (09)5712000 öljyssä ohjelmointiongelmat järjestelmä

HAWE Finland Smart Hydraulics. Easy Business! HAWE Finland Oy Koskelontie 15 | 02920 Espoo | Finland | Tel.+358 (0)10 82126 00 | sales@hawe.fi | www.hawe.fi We provide hydraulic components and systems as well as programming solutions. Your distributor: Copyright HAWE Finland Oy, 11 /2022