APRIL 2023

AIP: PEAK PROFESSIONAL BODY FOR PACKAGING EDUCATION & TRAINING IN AUSTRALASIA

inside this BUMPER 2023 PIDA Award Issue...

2023 Australasian Packaging Innovation & Design (PIDA) Awards winners announced

2023

DESIGN OF THE YEAR

WINNERS

POSITIONS VACANT

Page 2-5

BEYOND

4x Job Vacancies Available

NEW

MEMBERS

The AIP would like to welcome the following new Members...

NAME GRADE STATE/COUNTRY

Angela Colafella Associate (AAIP) VIC

Ron Adrian Dionaldo Member (MAIP CPP) International

Ombeline Even Associate (AAIP) NSW

Angela Hanson Associate (AAIP) QLD

Peter Horvat Associate (AAIP) ACT

Angela Jones Member (MAIP) NSW

Col Kavanagh Associate (AAIP) VIC

NAME GRADE STATE/COUNTRY

Vicki March Associate (AAIP) NSW

Phil May Member (MAIP) WA

Hemalekha Nagulan Associate (AAIP) NSW

Anantha Alaganan Sankaranarayanan Member (MAIP) VIC

Russell Saunders Member (MAIP) VIC

Mark Wood Member (MAIP) VIC

Page 29

AIP

NEWS

MEMBER FULL MEMBER SUPPORTING SIGNATORY CORE PARTICIPANT FOUNDING PARTNER SUPPORTER

&

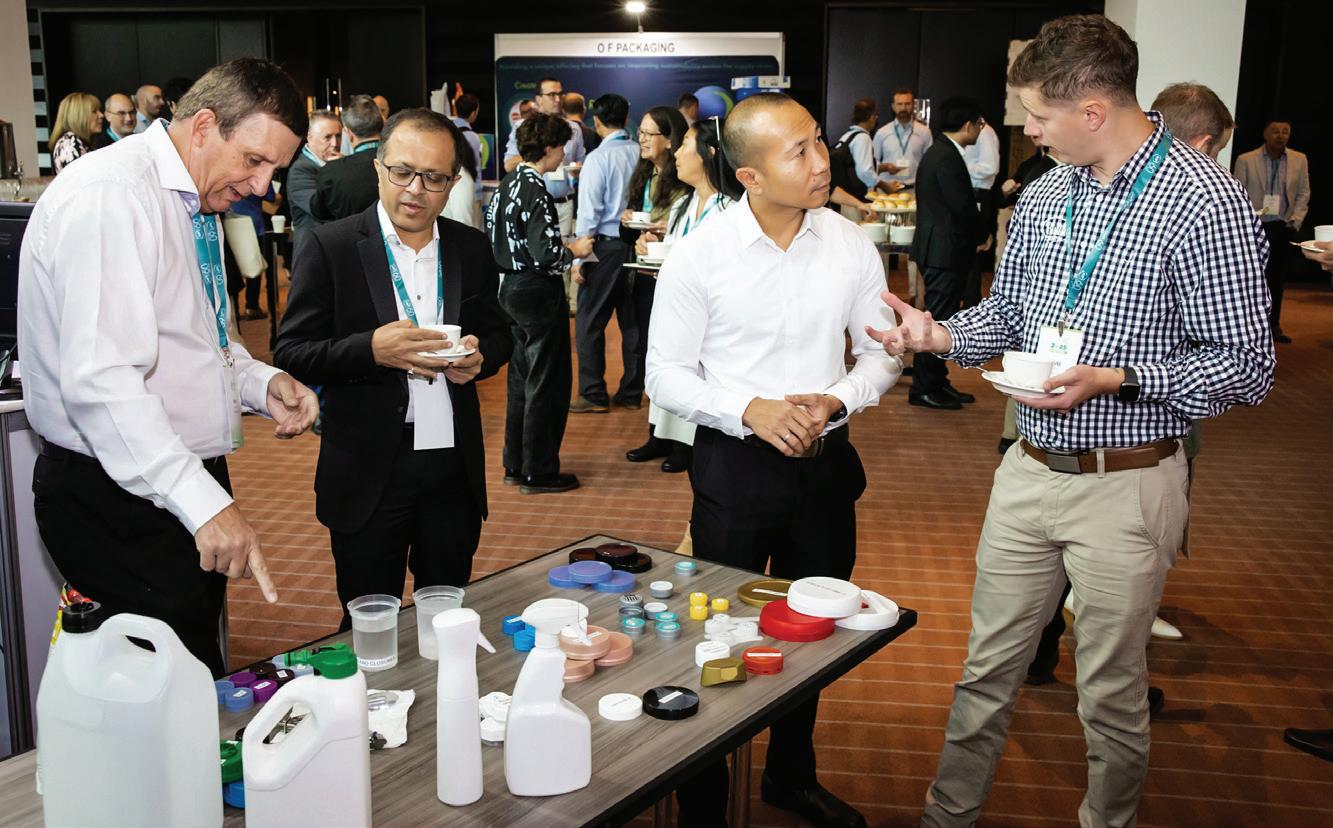

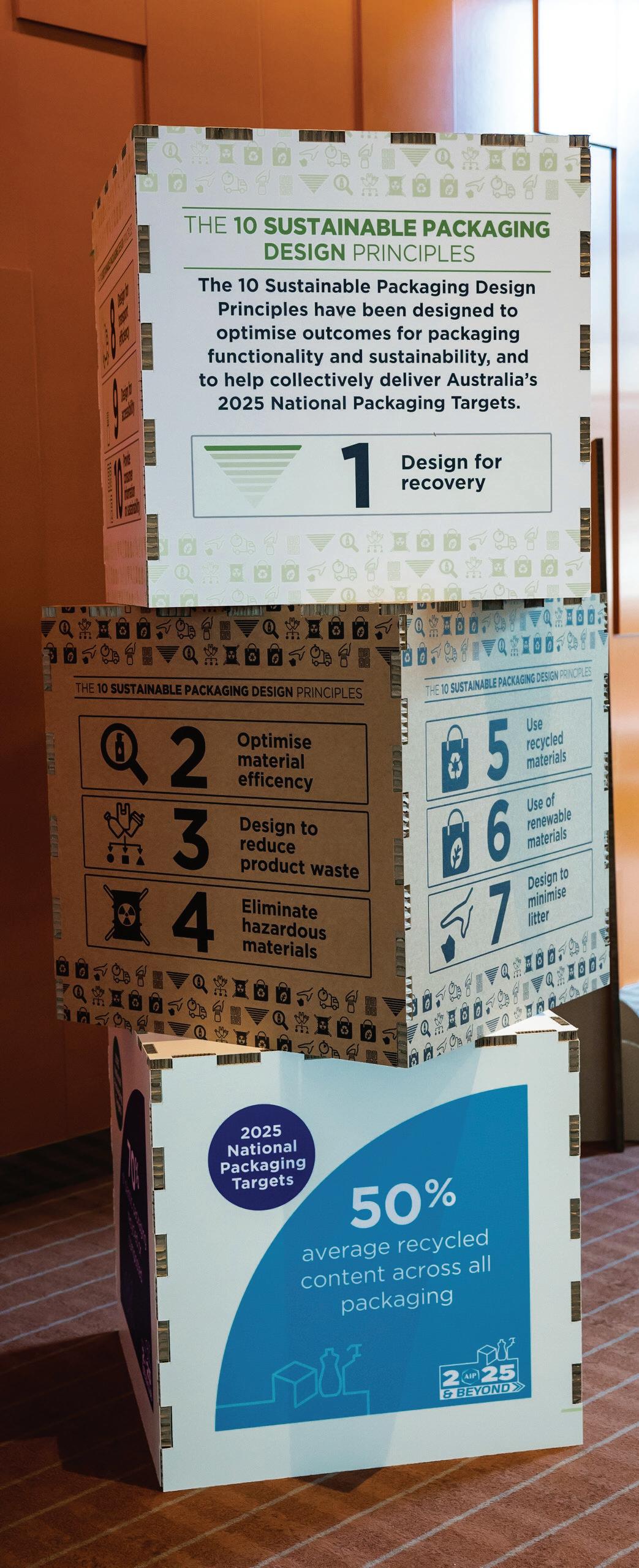

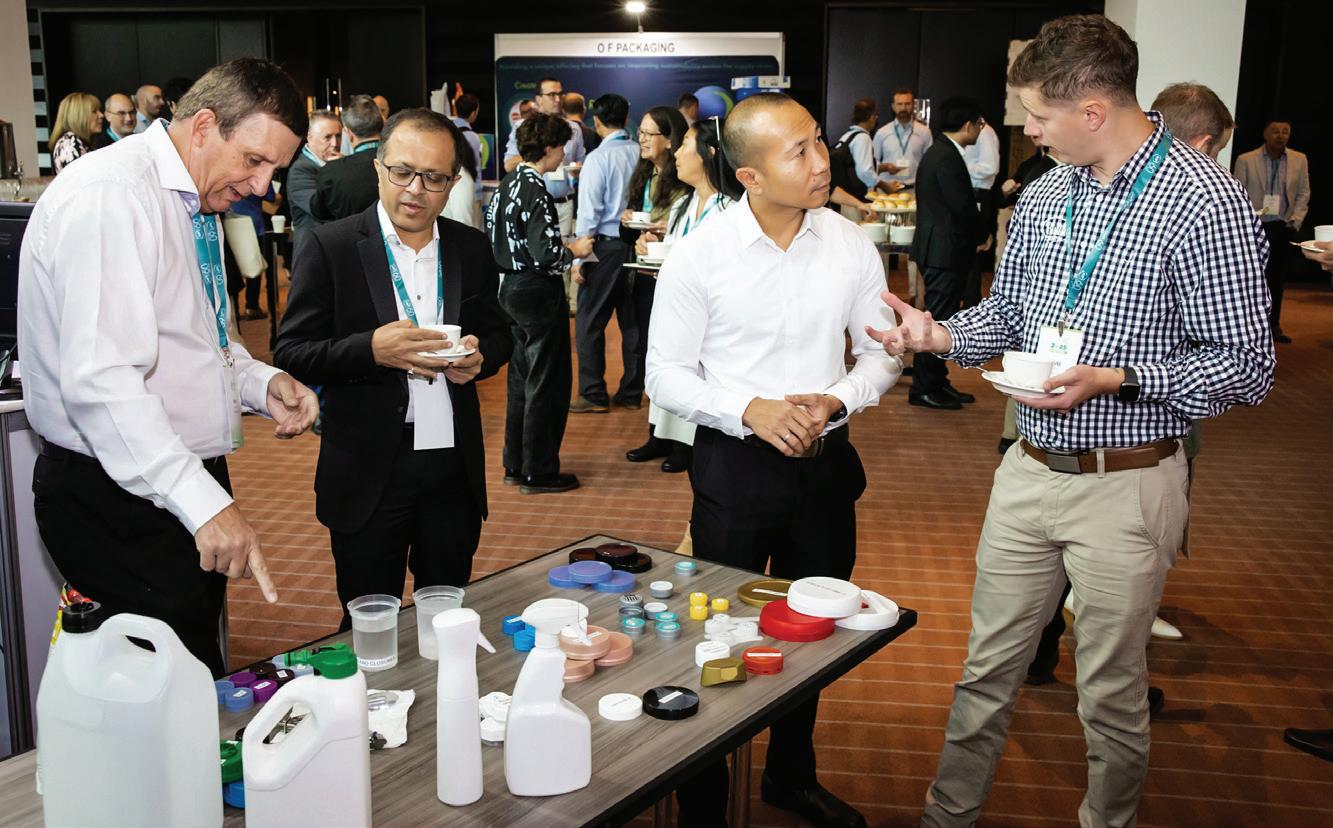

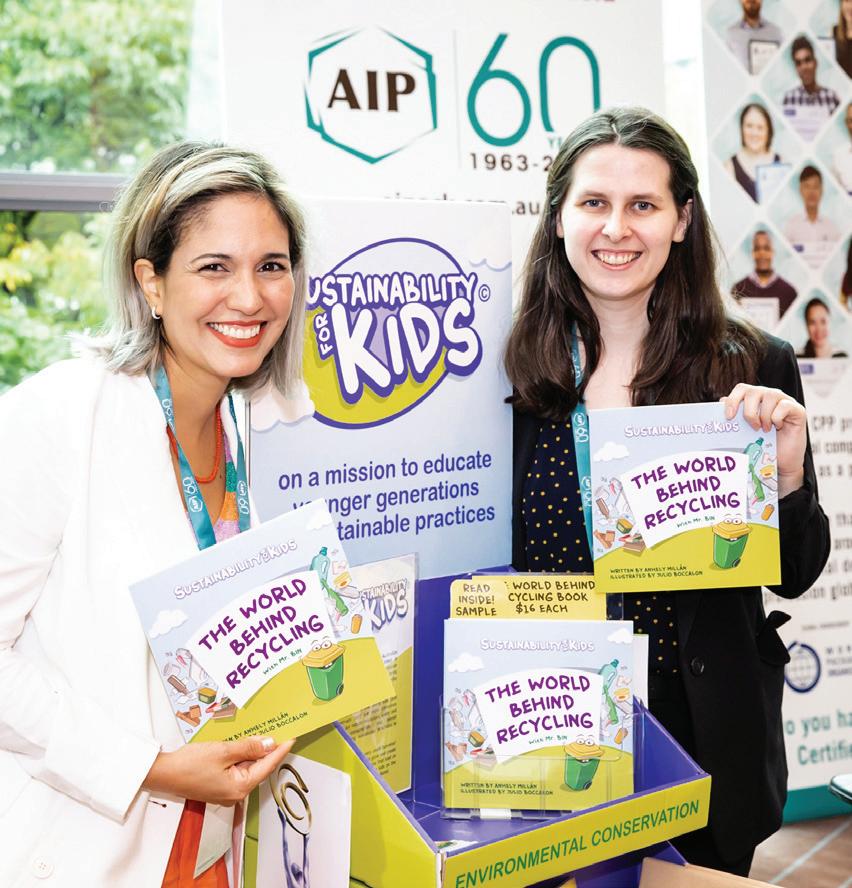

AIP Australasian Packaging Conference WRAP UP Page 91

Position Vacant Fonterra: Packaging Technologist

Your Purpose

At Fonterra, they ensure that all their value adding production packing lines are consistently meeting product food safety, regulatory, quality & efficiency standards and therefore meeting and exceeding their customer and stakeholder expectations. Hence this exciting opportunity for a Packaging Technologist based at their Richmond office, on a hybrid model.

The Insight & Innovation team is focused on maintaining the growth trajectory of the business. As a key part of this team, the Packaging Technologist’s responsibility is to deliver both new product and packaging projects from ideation to launch. The role will encompass packaging development, artwork workflow, value engineering, quality improvement and cost optimisation projects. It requires strong project management and stakeholder engagement skills as you will engage with a cross functional team to deliver initiatives collaboratively. You will be working closely with manufacturing, engineering, procurement, technical and quality.

Reporting to the NPD Manager – Cheese, Spreads, Beverages and Milk Powders, this role will expose you to a very exciting innovation agenda and pipeline, in a time where Fonterra are investing significantly on their capabilities, as well as having a front row seat on their sustainability program. Your responsibilities will include but not limited to the following:

• Contribute to the production of sustained significant commercial value for Fonterra Australia through delivering packaging solutions for NPD, cost optimisation and business support projects.

• Execute the technical packaging delivery of projects for the Fonterra Australia business, particularly for projects supporting the Cheese, Spreads, Beverages and Milk Powders team strategy.

• Applying sound packaging development principles to participate in taking a scoped concept through to launch.

• Leading the handover and introduction of any changes to packaging specifications through New Product Development projects.

• Creation and validation of changes to packaging material specifications through implementing packaging initiatives.

• Understanding of APCO and the ARL guidelines, implement on pack to help consumers to recycle correctly and supporting Brand owners and packaging suppliers to design packaging that is recyclable at end-of-life.

• Strong written and oral communication skills.

• Self-motivated, with the ability to work both as an active team member and independently.

• At least 3 years’ experience in a sustainability focussed role or organisation.

• Experience in supporting members or customers, including delivery of training programmes, workshops and event management.

• Tertiary degr ee in environment, sustainability or management.

You will play an integral role in many of their key business initiatives and will develop effective working relationships with stakeholders at all levels of the organisation. Some travel to their Operations sites, located across VIC and TAS, will be required.

What you will bring

Fonterra are looking for someone bright and driven with a passion for the packaging space, ideally with good mechanical aptitude. You will have several years’ experience as a packaging technologist having worked with a wide range of food packaging solutions.

A clear and natural communicator, you will easily be able to share practical and theoretical knowledge about packaging formats and show demonstrated ability to drive change.

In addition, you will have:

• Packaging Technologist degree or other relevant packaging related tertiary qualification.

• Strong analytical and problem-solving skills, with the ability to think creatively and identify opportunities for process improvement.

• The ability to work autonomously, but also to be comfortable asking questions when required.

• Strong Project Management and prioritisation skills

• Good computer literacy skills, with SAP experience being a bonus.

• Proven practical packaging technologist experience, preferably within the dairy or food industries.

• Proven history of effective contribution as a member of a multi-disciplinary team.

• Proven knowledge of cross functional specification and regulatory requirements.

• Robust organisational ability and attention to detail

• Effect change and build relationships through problem-solving abilities.

About Fonterra

Fonterra is a global nutrition company owned by 10,000 farming families in New Zealand. They employ 20,000 people around the globe and offer amazing opportunities for people who want to join their team.

In Australia, they take the milk they collect from their farmers, and their eight manufacturing sites across Victoria and Tasmania turn this into dairy foods that generations of Australians have grown up with and love, including Perfect Italiano™, Mainland™, Western Star™, and Bega™. At Fonterra, they understand that to attract top talent they need to have the jobs that will make you want to get out of bed in the morning. Diversity, inclusion, and flexibility are a big part of their business, and with a collaborative culture, inspiring leaders and passionate people, this is a great place to work.

AIP NEWSLETTER APRIL 2023 2

PLEASE APPLY TODAY

Position Vacant Fonterra: Packaging Technologist – Sustainability

About Fonterra

Fonterra is a global nutrition company owned by 10,000 farming families in New Zealand. They employ 20,000 people around the globe and offer amazing opportunities for people who want to join their team.

Your Purpose

This is an opportunity to be part of something truly special. Fonterra are seeking an experienced Packaging Technologist with a passion for sustainability to lead the packaging development, execution, and implementation of Fonterra’s Sustainable Packaging goal of 100% Recyclable, Compostable or Reusable by 2025. Based at their modern Richmond head office and working within a hybrid model with WFH flexibility, this role will see you understand Fonterra Australia’s sustainability plan and work closely with the Project Manager – Sustainability to plan, develop, trial, and implement all required packaging changes to meet Fonterra’s 2025 targets.

As the Packaging Technologist – Sustainability, you will be responsible for leading the development and execution of a robust technical trial plan to ensure successful implementation of any required packaging changes to their existing portfolio.

Operating within a cross functional environment, you will work closely with the NPD, Operations and Procurement functions to identify any synergies with NPD and Operations packaging projects.

You will also:

• Deliver all the required packaging technical documentation as part of the Sustainability program.

• Develop and maintain strong relationships with existing and new packaging suppliers to brief and develop the packaging solutions required to achieve Fonterra’s sustainability targets.

• Work closely with the Specifications team to develop and deliver all necessary administration changes as part of the sustainability program such as SAP Material Master Data changes, and Specification updates in Hamilton Grant.

• Develop and maintain strong relationships at relevant manufacturing sites to ensure successful handover and commercialisation of all changes to packaging through the sustainability program, in particular with the production & quality functions.

You will play an integral role in many of their key business initiatives and will develop effective working relationships with stakeholders at all levels of the organisation.

Some travel to their Operations sites, located across VIC and TAS, will be required.

What you will bring Fonterra are looking for someone bright and driven with a passion for the packaging sustainability space, ideally with good mechanical aptitude.

You will have several years’ experience as a packaging technologist having worked with a wide range of food packaging solutions.

A clear and natural communicator, you will easily be able to share practical and theoretical knowledge about packaging formats and show demonstrated ability to drive change.

In addition, you will have:

• Degree qualifications in Science, Technical or Engineering discipline. Food Science, Food Technology, Packaging technology is preferred.

• 5+ years’ Food/Packaging Technologist experience within Manufacturing/FMCG.

• Packaging sustainability experience will be highly advantageous.

• Demonstrable ability to work cross functionally including machine operators, line leads and senior managers.

• Excellent planning and organisation skills.

About Fonterra

Fonterra is a global nutrition company owned by 10,000 farming families in New Zealand. They employ 20,000 people around the globe and offer amazing opportunities for people who want to join their team.

In Australia, they take the milk they collect from their farmers, and their eight manufacturing sites across Victoria and Tasmania turn this into dairy foods that generations of Australians have grown up with and love, including Perfect Italiano™, Mainland™, Western Star™, and Bega™.

At Fonterra, they understand that to attract top talent they need to have the jobs that will make you want to get out of bed in the morning. Diversity, inclusion, and flexibility are a big part of their business, and with a collaborative culture, inspiring leaders and passionate people, this is a great place to work.

AIP NEWSLETTER APRIL 2023 3

PLEASE APPLY TODAY

Position Vacant Patties Foods: Senior Packaging Technologist

• Varied & challenging role.

• Pakenham based, with travel between sites required.

• Growing food manufacturing company.

Are you ready for a change of scenery? To say goodbye to peak hour traffic each day? Here is your opportunity to work for an iconic organisation situated in Pakenham, Victoria. As one of the largest Australian food manufacturing companies, Patties Foods owns iconic brands such as Four’N Twenty, Patties, Herbert Adams and Nannas. Making food Australians love isn’t just about creating great recipes, choosing the perfect ingredients or using the best measures or mixers, it’s also about cooking with heart. Passion and pride are their key ingredients, and they never forget to add a generous serve of care.

Patties Foods values of courage, trust, integrity and ownership reflect their origin as a family-owned company. They are the custodians of a unique portfolio of brands that have become household names across the nation. Of course, along with Great Brands, and Great Assets, the other vital ingredient in their recipe for success is – GREAT PEOPLE!

They currently have an exciting opportunity for a Senior Packaging Technologist to join their Marketing & Innovation Team. The role is located in Pakenham but will require travel. This is a great opportunity to work with packaging across the baked, frozen and chilled environments.

Reporting into the Senior Packaging Manager, the role will be responsible for:

• Introducing innovative packaging designs and formats.

• Leading and executing packaging projects across multiple production sites.

• Develop relevant packaging specifications and knowledge management systems (Inc. reporting).

• Highly cross-functional role, across multiple departments and factory sites.

• Engaging with suppliers of packaging material and equipment to autonomously deliver on projects.

• A focus on improving efficiencies across the packaging spectrum, including supply chain.

• A keen priority on optimising (minimising) the impact of their business on the environment.

• Direct input into and approval of artwork.

The role is located at the Pakenham manufacturing site, with regular project-based travel between production sites and head office.

The successful candidate will be passionate about all things packaging related! You will champion the packaging function across the group, with an enthusiastic and pro-active attitude, excellent organisational skills and attention to detail, and the ability to problem solve and provide solutions. Your strong communication skills and drive to make a positive contribution will ensure your success in the role.

FMCG manufacturing experience is required, with a technical understanding of the various packaging streams/formats and their manufacturing processes. A degree or diploma in Packaging Technology / Food Technology / Food Engineering or similar will be highly advantageous.

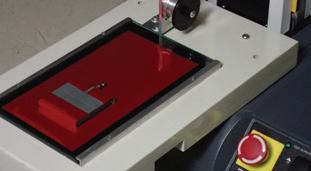

Evidence is Confidence

• Oxygen Transmission & Water Vapour Transmission Rate

• Analysis of plastic materials & Multilayered Structures

• Tensile Strength, Tear, Impact & Puncture Resistance

• Investigation of plastic materials & supply consistency

www.gunnlab.com

AIP NEWSLETTER APRIL 2023 4

PLEASE APPLY TODAY Independent

impartial testing of plastics and packaging

www.gunnlab.com

We’ve got the tools for the job.

Our reputation comes from over 30 years of technical expertise, backed up with modern laboratory equipment.

Position Vacant Diageo: Packaging Technologist

About Diageo

With over 200 brands sold in more than 180 countries, Diageo are the world’s leading premium drinks company. Every day, over 27,000 dedicated people come together at Diageo to create the magic behind our much-loved and timeless brands including Baileys, Guinness, Gordon’s and Smirnoff.

Join them, and you will collaborate with hard-working people from all corners of the world. You will innovate and push boundaries, shaping a sustainable and more inclusive future that we can all be proud of.

With diversity at their core, they celebrate their people’s individual passions, commitments and specialist skills. In their supportive culture, your voice will be heard and you’ll be empowered to be you. Just bring your ambition, curiosity and ideas, and they will celebrate your work and help you reach your fullest potential.

About the role

As a Packaging Technologist you will oversee packaging development related activities for all assigned Innovation, Renovation and Promotion projects. This role includes technical support to the manufacturing sites through collaboration with the Procurement team for supplier development and identifying cost savings and efficiencies. The role holder is also expected to contribute to the Diageo Society 2030 Sustainable targets.

This position is responsible to design, develop, validate and implement new packaging for Innovation, Renovation, Imports and Cost initiative projects. It will also render technical support to the Huntingwood and Bundaberg supply sites regarding all packaging related issues.

What does this role look like for you?

Are you an innovative individual who would like to design and develop new and improved packaging for a world leading alcoholic beverage company? They are looking for someone with a comprehensive understanding of packaging development as well as a person who can provide technical support to the wider team. You will also be passionate about sustainability and will work closely with the packaging manager on the Diageo Society 2030 projects.

Responsibilities:

• Design, develop and implement packaging for new, changed or promotional products in line with marketing requirement and sustainable guidelines to meet launch dates.

• Provide technical guidance for the application and approval of artworks to packaging components within Diageo formal process to meet mandatories and technical standards.

• Conduct trials and provide technical support to Huntingwood and Bundaberg sites to validate new packaging and processes.

• Liaise with suppliers on alternative packaging materials and technologies for innovative solutions and/or cost saving opportunities.

• Create, document and maintain packaging trial reports, packaging materials specifications and business critical data with SAP.

So, what about you?

• Understanding of packaging materials – preferably glass, cans, labels, paperboard and corrugate.

• Sound understanding of Packaging Development process and Sustainable Packaging Guidelines

• Good knowledge of project management processes and practices and continuous improvement principles.

• 5+ years’ experience in packaging development preferably in consumer goods and high speed production environment.

What are the benefits?

Diageo are an organisation that creates products that are part of celebrations, and their culture reflects this. At Diageo, you will have the ability to work flexibly to ensure you can unlock your own potential through creating bold plans and driving your vision. You will also be rewarded through competitive salary and monetary benefits including bonus, flexible leave entitlements and product allowance as well as being supported via non-monetary benefits including an industry leading parental leave policy, volunteering days and workplace giving, and subscriptions to mental health and fitness platforms.

Diversity Statement

Celebrating their inclusive and diverse culture is core to Diageo’s purpose of “celebrating life every day everywhere”. This purpose is, in itself, inclusive in nature, as it values everybody irrespective of background, disability, religion, gender identity, sexuality or ethnicity. They know that for their business to thrive and for Diageo to realise its ambition, they depend on having diverse talent with a range of backgrounds, skills and capabilities in each of the 180 countries in which they operate and to reflect their broad consumer base. They view diversity as one of the key enablers that helps their business to grow and their values, purpose and standards set the conditions for them to respect the unique contribution each person brings.

Flexibility is key to success in their business and many of their staff work flexibly in many different ways, including part-time, compressed hours, flexible location. Please talk to them about what flexibility means to you and don’t let anything stop you from applying.

AIP NEWSLETTER APRIL 2023 5

PLEASE APPLY TODAY

Elevate your Packaging Career

Do you have what it takes to become a Certified Packaging Professional?

The Certified Packaging Professional CPP ® is the premier designation in the industry globally, signifying excellence as a packaging professional with the most recent IoPP salary survey revealing that CPPs ® earn up to 10% more than their non-certified co-workers. Using the CPP ® program to assess and evaluate one’s professional competency validates you as internationally proficient as a packaging professional; a cut above your peers.

Isn’t it time that you joined recognised packaging experts from around the world with the industry’s leading professional designation and elevate the packaging profession globally?

AIP

6

NEWSLETTER APRIL 2023

AIP: PEAK

BODY FOR PACKAGING EDUCATION & TRAINING IN AUSTRALASIA WORLD PACKAGING ORGANISATION

PROFESSIONAL

Up-Coming Courses, Webinars & Tradeshows

MAY 2023

Interpack

WHEN: 4 - 10 May 2023

WHERE: Düsseldorf, Germany

WHAT: Interpack is far more than just a packaging show. As the world's leading trade fair, it is the major inspiration for the packaging industry and all related process technologies. 2,700 exhibitors from more than 60 countries will present their latest ideas, innovate concepts and technological visions at interpack - not only in equipment and machinery for packaging and processing, but also in production tools for packaging materials, materials themselves, and services for the entire industry.

Interpack

WHEN: 8 May 2023

WHERE: International Lounge, Messe Düsseldorf, Germany

WHAT: They exist - 'Women in packaging', but there are still too few women in the industry, and too few make it to the executive levels.

Especially in times of a shortage of skilled workers, valuable potential often remains untapped. Many women also seek contact with like-minded people. So there are many good reasons for a women's network.

This year, interpack is promoting an exchange for the first time with an event by women for women. Together with the WPO, it is hosting a panel discussion followed by networking on May 8. Female participants have the opportunity to expand their professional network, get inspired by other women and share experiences.

All women who are already working in the industry as well as interested junior staff, trainees and students are invited.

2023 WorldStar Global Packaging Awards 19 Australian Companies to receive awards

WHEN: 6 May 2023

WHERE: Dusseldorf, Germany

WHAT: WPO is happy to announce that the upcoming WorldStar Award Ceremony for 2023 will take place physically on 6th May 2023, in Düsseldorf (Germany), during Interpack trade show (May 4-10 2023).

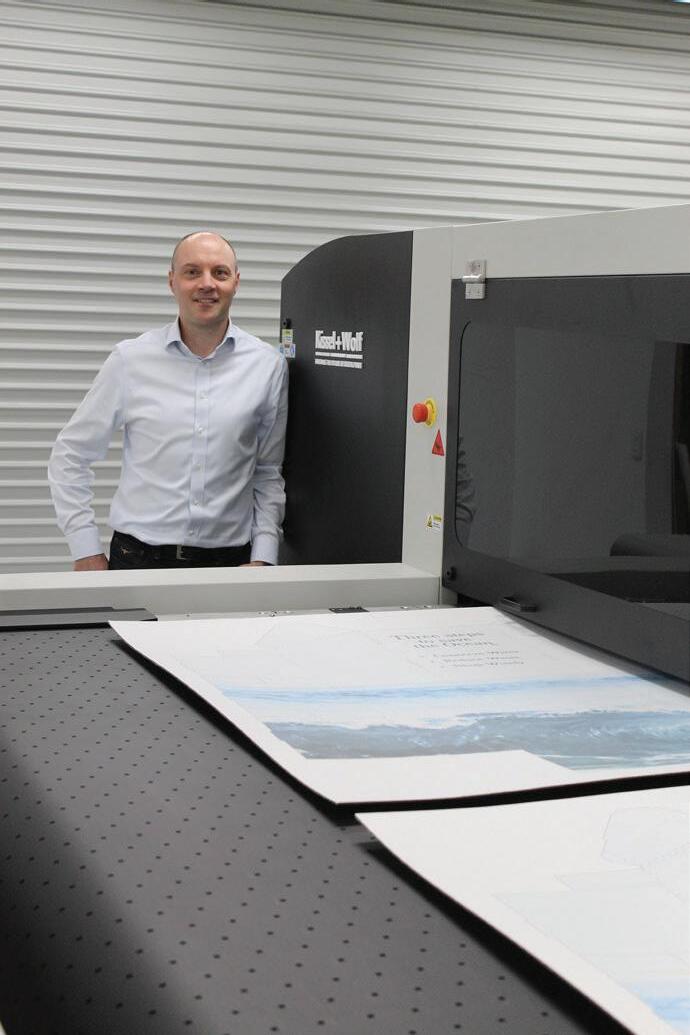

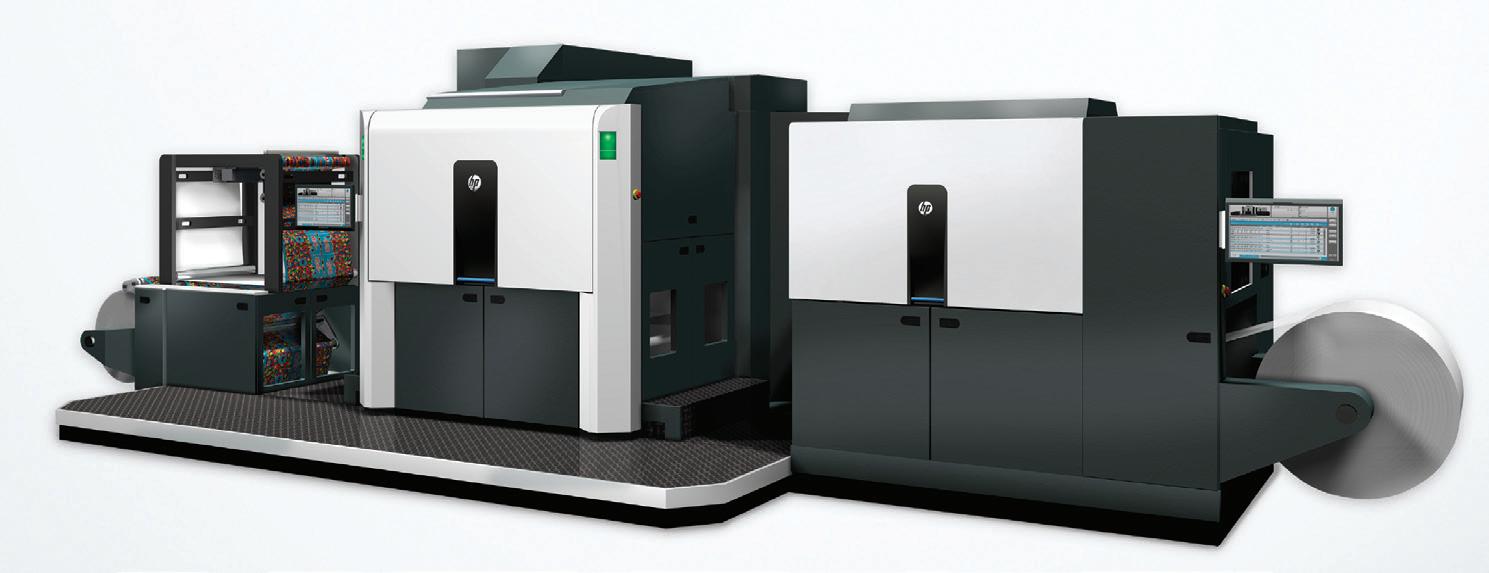

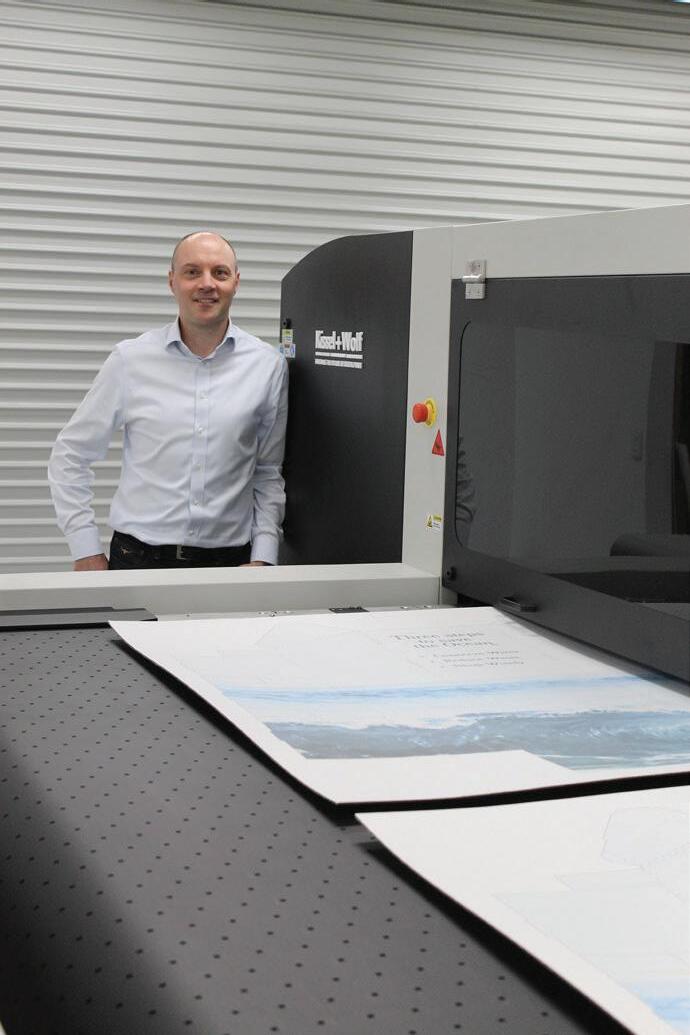

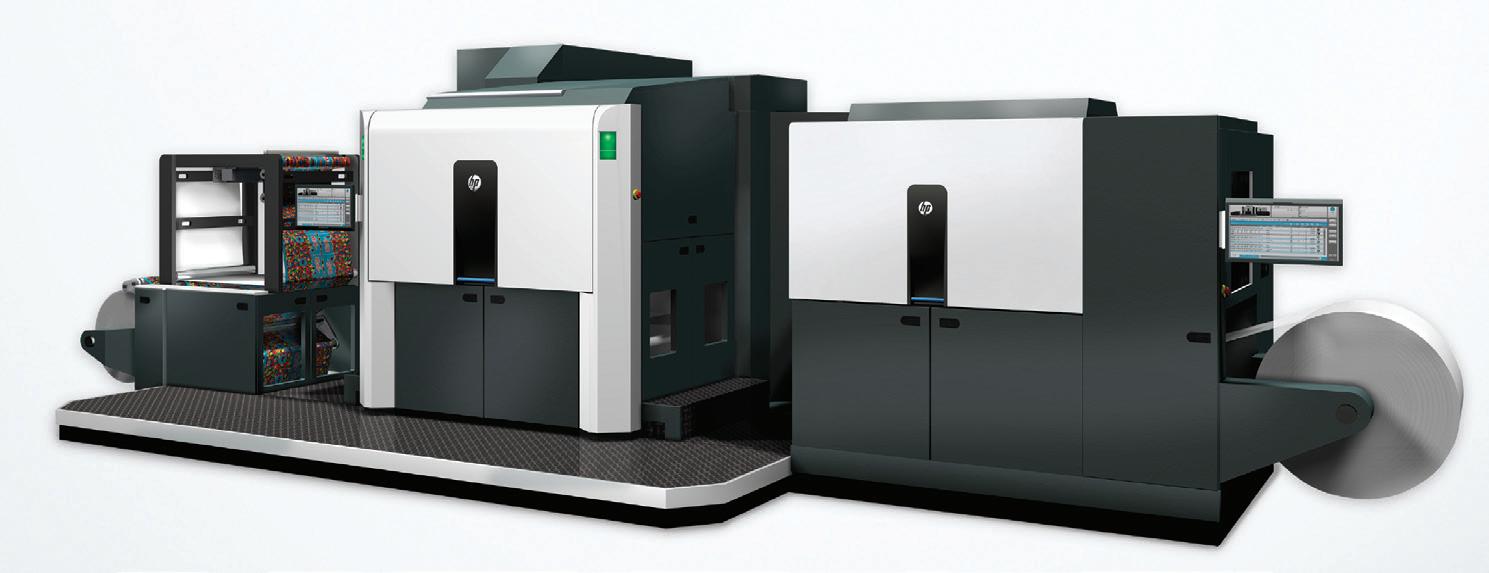

Packaging Open Day: Kissel + Wolf Australia

WHEN: 10 May 2023

WHERE: 26 Ovata Drive, Tullamarine VIC

WHAT: Kissel + Wolf are extending an invitation to all AIP Members to visit their Tullamarine premises on the 10th of May. If you are looking to stay ahead of the latest trends in the print and packaging industry and want to learn about innovative technology that contributes to a circular economy and meets the demands of e-commerce packaging then this open day is for you. The upcoming open house event by Kissel + Wolf Australia is a golden opportunity to stay ahead of the curve in the fast-evolving print and packaging industry.

AIP NEWSLETTER APRIL 2023 7

Eligible for CPP Points

= 1 CPP PTS

*

Up-Coming Courses, Webinars & Tradeshows

MAY 2023

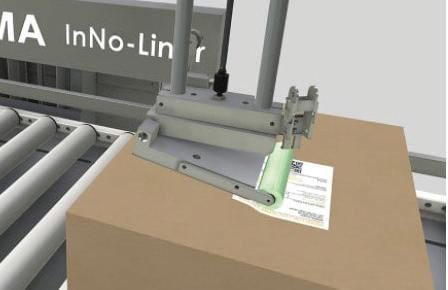

AIP Packaging Specifications Training Course: VIRTUAL REVISED EDITION

WHEN: 24 May 2023

WHERE: Via Zoom

WHAT: The packaging specification defines all the necessary packing levels for a product or transport the product. For a product, a packaging specification focuses on the packed product and which packaging materials are being used to ensure safe travels in the rigors of the supply chain. In the course we will cover aspects such as: Why have a specification, the management thereof, how to collect the data, and the fundamentals of drafting a specification. We will discus material types in packaging, as well as sampling plans, testing of packaging, and how best to incorporate all the data into one document. The course will address the importance of auditing suppliers of your packaging. After the course you will be able to know what is key to a packaging specification sheet. You will fully comprehend that the packaging specification is a technical document that contains a series of standard requirements for packaging a product. It includes size, dimensions, weight, materials, tolerances and load related information.

TRAINER:

JUNE 2023

ProPak Asia 2023 AIP to host training course & seminars alongside

WHEN: 14 - 17 June 2023

WHERE: BITEC, Bangkok, Thailand

WHAT: ProPak Asia 2023, the leading Processing & Packaging trade event for Food, Drink, Pharmaceutical, Cosmetics, and Consumer Products brings together exhibiting companies and buyers from around the world.

ProPak Asia is returning in its 30th installment as the Premier Processing & Packaging event of its kind in Asia and continuing in its commitment to provide the industries with the latest advancements in machinery, technologies and innovative solutions. This year, ProPak Asia offers its Hybrid exhibition presents both physical and virtual exhibitions together, where you can visit booths at BITEC and interact with exhibitors on the online platform at your convenience aiming to overcome global challenges and driving industry into the future that will require quality products and efficient solutions to feed a growing population and protect the environment digitally.

2023 Global Packaging Forum

WHEN: 14 June 2023

WHERE: Alongside ProPak Asia 2023, Bangkok, Thailand

WHAT: The Australian Institute of Packaging (AIP), in conjunction with Informa Markets, will be running the fourth Global Packaging Forum as an in-person event during day one (14 June) of ProPak Asia 2023.

Each session will bring together expert global presenters who will be discussing various topics within the packaging realm including circular and sustainable packaging design, designing out waste through packaging, the shift towards mono material recyclable materials and packaging, how to maintain a balanced approach between the environmental impacts of packaging and food and what is on the horizon for new innovations.

Speakers confirmed so far include Sealed Air, TetraPak, Plantic, Amcor Flexibles, Close the Loop Group, Contech and industry associations from across the globe including the World Packaging Organisation, PMMI, UCIMA and AIP.

All of industry is invited to attend, so book your place today. The seminar will be conducted in English and all attendees will attain 1.5 CPD points per session towards the global Certified Packaging Professional designation and a certificate of attendance.

AIP NEWSLETTER APRIL 2023 8

Eligible for CPP Points

2023 GLOBAL PACKAGING FORUM @ CO-ORGANISED BY * = 1 .5 CPP PTS PER SESSION

* = 12.5 CPP PTS

Prof Pierre Pienaar MSc, FAIP, CPP Education Director Australian Institute of Packaging (AIP)

Up-Coming

Courses, Webinars & TradeshowsPACKAGING OPEN DAY

Attention, packaging enthusiasts! Are you looking to stay ahead of the latest trends in the print and packaging industry? Want to learn about innovative technology that contributes to a circular economy and meets the demands of e-commerce packaging? The upcoming open house event by Kissel + Wolf Australia is a golden opportunity to stay ahead of the curve in the fast-evolving print and packaging industry.

At this event, you will get an exclusive chance to learn about the latest trends and developments in the packaging world, including cutting-edge technologies that can streamline your workflow, simplify your packaging artwork & prepress, and contribute to a circular economy.

The event promises to be an immersive experience, allowing you to collaborate with other industry professionals, build your network, and gain invaluable insights from the experts. You'll learn how to rethink your planning and imposition process with artificial intelligence, create packaging samples using digital cutting and creasing, take advantage of digital inkjet printers for corrugated packaging, and streamline your end-to-end workflow with web-to-pack for packaging converters.

Don't miss out on this exciting opportunity to learn from Kissel + Wolf Australia and other industry experts. Attend the open house to learn how to simplify your packaging artwork and prepress, rethink your planning and imposition process with artificial intelligence, create packaging samples using digital cutting and creasing, take advantage of digital inkjet printers for corrugated packaging, and streamline your end-to-end workflow with web-to-pack for packaging converters.

This is event is exclusive to AIP members and will be held on Wednesday 10. May from 12 – 3 pm, with light lunch served.

Register now and take the first step towards becoming a packaging industry leader!

AIP NEWSLETTER APRIL 2023 9

Up-Coming Courses, Webinars & Tradeshows

JUNE 2023

Flexible Packaging: Now & Into The Future: Training Course

WHEN: 14 June 2023

WHERE: Alongside ProPak Asia 2023 , Bangkok, Thailand

To be held alongside

WHAT: One of the fastest growing segments of the packaging industry, flexible packaging combines the best qualities of plastic, film, paper and aluminium foil to deliver a broad range of protective properties while employing a minimum of material. Typically taking the shape of a bag, pouch, liner, or overwrap, flexible packaging is defined as any package or any part of a package whose shape can be readily changed.

Leading the way in packaging innovation, flexible packaging adds value and marketability to food and non-food products alike. From ensuring food safety and extending shelf life, to providing even heating, barrier protection, ease of use, resealability and superb printability, the industry continues to advance at an unprecedented rate.

The life cycle attributes of flexible packaging demonstrate many sustainable advantages. Innovation and technology have enabled flexible packaging manufacturers to use fewer natural resources in the creation of their packaging, and improvements in production processes have reduced water and energy consumption, greenhouse gas emissions and volatile organic compounds.

The Flexible Packaging: Now & Into the Future training course will cover the basic fundamentals of flexible packaging, its benefits, how you chose the specific structures to match the product, its performance, marketing challenges and how the packaging is manufactured.

With the latest challenges facing us regarding sustainability in packaging the course will discuss the options, pros and cons of Compostability vs Recyclability, moves to mono material recyclable packaging to meet CEFLEX standards and other innovative alternative materials now available. As an add on, the course will be looking at the future plans for flexible packaging and available closed loop collection programs, kerbside collection development, advanced recycling options for circular design and many others to meet Packaging and Food Waste Targets.

Course Objectives:

The objectives of the course are to provide participants an understanding of:

• A good broad understanding of the benefits of Flexible packaging.

• The process of manufacturing.

• Where the future lies with flexible films and the changes ahead.

• Snap shot of some of the latest packaging trends and what are the driving forces.

• Understanding the challenges facing us with the sustainable packaging race toward.

LECTURER:

Joe Foster FAIP Education Team Australian Institute of Packaging (AIP)

ProPak Asia 2023: Fibre and Flexibles Workshops

WHEN: 15 June 2023

WHERE: Alongside ProPak Asia 2023, Bangkok, Thailand

WHAT: The Australian Institute of Packaging (AIP), in partnership with Informa Markets, will be running two interactive workshops on the 15th of June that will be discussing the Future of Flexibles & soft plastics and the Future of Fibre and Renewable Materials. The workshops will bring together leading experts in these materials in a panel discussion format with interaction from the attendees. All of industry is invited to attend, so book your place today. The seminar will be conducted in English and all attendees will attain 2 CPD points per session towards the global Certified Packaging Professional designation and a certificate of attendance.

* = 12.5

CPP PTS

To be held alongside

* = 2

CPP PTS PER SESSION

AIP NEWSLETTER APRIL 2023 10

Up-Coming Courses, Webinars & Tradeshows

JULY 2023

Foodpro 2023

WHEN: 23 - 26 July 2023

AIP to host training course & more alongside

WHERE: Melbourne Convention & Exhibition Centre

WHAT: foodpro, Australia's most trusted and proven trade event in the food manufacturing industry, is back for the first time in 6 years.

Returning 23-26 July 2023 at the Melbourne Convention & Exhibition Centre, foodpro provides the first opportunity for the industry to celebrate the contribution of Australian food producers, distributors, and manufacturers. Showcasing the latest packaging and processing solutions, foodpro is where the food industry gathers to make big business deals, network and explore ways to create an efficient future for manufacturing. Generate leads and close deals at an action packed four day gathering attracting premium and qualified buyers.

AIP Sustainable Packaging Session for the Meat & Proteins Industry

WHEN: 23 July 2023

WHERE: Smart Food Lounge, Foodpro 2023, Melbourne Convention & Exhibition Centre

WHAT: AIP Sustainable Packaging Session for the Meat Industry: Showcasing innovative award-winning sustainable and circular packaging solutions that have won PIDA Awards and WorldStar Packaging Awards for the meat/proteins side of the industry. This session will bring together a number of experts in this field that have recently been recognised for their unique, innovative and sustainable packs.

Active & Intelligent Packaging: Training Course NEW COURSE

WHEN: 24 July 2023

WHERE: Alongside Foodpro 2023, Melbourne Convention & Exhibition Centre

WHAT: Printed Packaging will NEVER be replaced even though nearly every other printed medium has shifted to digital and now sits on a smartphone or PC. Likewise, email and social media platforms are a crowded space where it is difficult to stand out.

To be held alongside

To be held alongside

We use smartphones and smart appliances, drive smart cars, and we increasingly purchase consumer goods that are supplied and transported in smart packages. So, what makes all those things ‘smart’ and how can 'smart packaging' be implemented?

This course is designed to assist anyone who is responsible for packaging, marketing, operations, logistics in the consumer goods and broader supply chain seeking to stay relevant in their consumers lives by using smart packaging solutions that offer out-of-the-box business value.

The course will provide attendees with a better understanding of the smart packaging solutions currently available to transform the way they package, deliver and market their products and connect directly with consumer or offer value that will ensure customers ‘come back for more’. Best Practice examples of award-winning packs from the PIDA awards and WorldStar Awards across Active & Intelligent Packaging will also be discussed in the course.

Discussions will cover Active & Intelligent Packaging in easy to understand terms, and will highlight applications being embraced by brands across various industries who are trying to leverage the benefits of smart packaging solutions to enhance their operations whilst at the same time providing an unparalleled customer experience. Is your business prepared for such transformations?

Course Objectives:

• Develop a better understanding of Active & Intelligent Packaging solutions and the core technologies involved in their delivery.

• Understand the global standards the underpin the smart packaging revolution

• Learn how various smart packaging solutions could be implemented and developed

• Understand applications and use case examples of active and intelligent packaging from inventory management, to customer interaction as well as recycling, brand protection and product recall

• Learn how reducing food waste is possible via smart packaging

• Understand how to use data for insights and increased sales for your products

• Learn how to utilise smart packaging platforms to stay relevant in consumers lives and increase sales

• Learn how smart packaging can help mitigate loss events in the supply chain

LECTURER:

Michael Dosser MAIP Education Team Australian Institute of Packaging (AIP)

* = 12.5 CPP PTS

AIP NEWSLETTER APRIL 2023 11

Eligible for CPP Points

* = 1 CPP PT

Up-Coming Courses, Webinars & Tradeshows

JULY 2023

Flexible Packaging: Now & Into The Future: Training Course

WHEN: 24 July 2023

WHERE: Alongside Foodpro 2023, Melbourne Convention & Exhibition Centre

WHAT: One of the fastest growing segments of the packaging industry, flexible packaging combines the best qualities of plastic, film, paper and aluminium foil to deliver a broad range of protective properties while employing a minimum of material. Typically taking the shape of a bag, pouch, liner, or overwrap, flexible packaging is defined as any package or any part of a package whose shape can be readily changed.

Course Objectives:

The objectives of the course are to provide participants an understanding of:

• A good broad understanding of the benefits of Flexible packaging.

• The process of manufacturing.

• Where the future lies with flexible films and the changes ahead.

• Snap shot of some of the latest packaging trends and what are the driving forces.

• Understanding the challenges facing us with the sustainable packaging race toward.

LECTURER:

Joe Foster FAIP Education Team Australian Institute of Packaging (AIP)

AIP Sustainable Packaging Session for the Food Industry

WHEN: 25 July 2023

WHERE: Smart Food Lounge, Foodpro 2023, Melbourne Convention & Exhibition Centre

WHAT: This session will showcase innovative packs that have recently award-winning PIDA Awards and WorldStar Packaging Awards including certified compostable packs, fibre based packs, packs made out of renewable materials and smart packaging. This session will bring together a number of experts in this field that have recently been recognised for their intuitive packaging that can potentially save food loss and waste across a value chain and also are more sustainable.

Australasian Waste & Recycling Expo (AWRE) 2023

WHEN: 26 - 27 July 2023

WHERE: International Convention Centre, Sydney

AIP packaging sessions alongside

WHAT: The waste, recycling and resource recovery industry is continuing to transform and has quickly become the nucleus for driving Australia towards a cleaner, more sustainable future. AWRE is THE premier national platform for waste professionals to join forces and work towards this common goal. The event will include three exciting elements for visitors and exhibitors alike.

AIP AWRE Sustainable Packaging Design Session

WHEN: 26 July 2023

WHERE: Alongside AWRE 2023, International Convention Centre, Sydney

WHAT: The AIP will be running a session at AWRE that will be focussed on how to design out waste, create more circular and sustainable packaging with lower environmental impacts. The unique innovations that will be discussed in the session will be award-winning PIDA and WorldStar examples. The Sustainable Packaging Design session is free for all of industry to attend so book your place today. All attendees will attain 1 CPD point per session towards the global Certified Packaging Professional (CPP) designation.

AIP NEWSLETTER APRIL 2023 12

Eligible for CPP Points

* = 12.5 CPP PTS

* = 1 CPP PT * = 1 CPP PT To be held alongside

be held alongside To be held alongside

To

Up-Coming Courses, Webinars & Tradeshows

JULY 2023

AIP AWRE Sustainable Packaging Design Session #2

WHEN: 27 July 2023

WHERE: Alongside AWRE 2023, International Convention Centre, Sydney

WHAT: The AIP will be running a session at AWRE that will be discussing the balance required between the environmental impacts of food waste vs packaging waste. The session will discuss the trade-offs, unintended consequences and also showcase award-winning best practice examples of intuitive and innovative Save Food Packaging Design that can minimise food loss and waste across the value chain. Speakers will be recognised designers in the field and will be discussing their most recent PIDA and WorldStar award winning packs. This Food Waste vs Packaging Waste session is free for all of industry to attend so book your place today. All attendees will attain 1 CPD point per session towards the global Certified Packaging Professional (CPP) designation.

SEPTEMBER 2023

AIP 60th Anniversary Dinner

WHEN: 1 September 2023

WHERE: Aviary, Crown Promenade, Melbourne

Save the date

PACK EXPO Las Vegas 2023

WHEN: 11 - 13 September 2023

WHERE: Las Vegas Convention Center, Las Vegas, Nevada

WHAT: Every two years, PACK EXPO Las Vegas brings together all packaged goods and life sciences industries for the most productive week of the year. This is where suppliers showcase their latest innovations and end users discover game-changing solutions to packaging and processing challenges. With thousands of solutions on display, PACK EXPO Las Vegas 2023 is the one show in North America where consumer packaged goods and life sciences companies can count on finding the right solutions for their next project.

AIP NEWSLETTER APRIL 2023 13

* = 1 CPP PT To be held alongside sustainable insulated packaging to grow your online business? PlanetProtectorPackaging.com During these COVID times, you can rely on WOOLPACK to keep your products cool, sustainably.

offer a wide range of industry specific solutions for Ecommerce, Seafood and Pharmaceuticals.

We

AIP NEWSLETTER APRIL 2023 14 Melbourne Convention & Exhibition Centre 23 26 JULY 2023 foodproexh.com Where big business deals happen Running for over 50 years, Australia’s largest event for food and beverage manufacturing is back. With a whole host of new additions, including Networking Drinks, an exclusive Business Lounge, an exciting new Sensory Experience Zone and product sampling opportunities, there has never been a better time to get involved. Secure a premium stand today Book your stand AIP to have a Stand, run 2x training courses and 2x packaging forums alongside FoodPro

26-27 July 2023

ICC SYDNEY

AIP to have a stand and run 2x packaging forums alongside of AWRE

Driving a World of Solutions

The waste, recycling and resource recovery industry is continuing to transform and has quickly become the nucleus for driving Australia towards a cleaner, more sustainable future.

AWRE is THE premier national platform for waste professionals to join forces and work towards this common goal. Discover the latest innovations and solutions and connect with like-minded experts as we propel Australia to lead the charge to global and national waste targets – together.

AIP NEWSLETTER APRIL 2023 15 Up-Coming Courses, Webinars & Tradeshows Find Out More AWRE.COM.AU #AWRE2023

FoodTech PackTech 2023

WHEN: 19 - 21 September 2023

WHERE: Auckland Showgrounds

Up-Coming Courses, Webinars & Tradeshows

SEPTEMBER 2023

AIP to host training course & more alongside

WHAT: New Zealand’s foremost food and packaging technology exhibition where New Zealand’s food manufacturing sector encounters new materials, processes and technology from the world’s top suppliers. FoodTech PackTech (FTPT) is New Zealand’s largest food manufacturing, packaging and processing technology trade show. Running strong for over 20 years this free to attend event brings industry professionals and decision makers together providing a forum for education, discussion and the sharing of knowledge and expertise, critical in the sustainability and growth of the industry.

The AIP are a supporting association of the FoodTech PackTech New Zealand again this year and as a part of the partnership the Institute will be hosting four hours of packaging sessions on Day One, a training course on the Future of Flexible Packaging on Day Two and an exhibition stand.

We hope that you will join us as this will be our first time in New Zealand since the pandemic started..

AIP & FoodTech PackTech Sessions

WHEN: 19 September 2023

WHERE: Alongside FoodTech PackTech 2023, Auckland Showgrounds

WHAT: The AIP will be running a series of packaging sessions which will be designed as panel discussions covering a broad range of topics including packaging targets, waste directives, Sustainable & Circular packaging innovations and designs, incorporating recycled content into packaging, the future of soft plastics and flexible packaging, how to embed the 10 Sustainable Packaging Design Principles into your business, the role that packaging plays in minimising food waste, the future of fibre and renewable materials, the important role that the Australasian Recycling Labelling program plays across ANZ and updates for ANZPAC. The speakers will also include a number of our NZ winners of the ANZ PIDA Awards and the WorldStar Packaging Awards.

Flexible Packaging: Now & Into The Future: Training Course

WHEN: 20 September 2023

WHERE: Alongside FoodTech PackTech 2023, Auckland Showgrounds

WHAT: The Flexible Packaging: Now & Into the Future training course will cover the basic fundamentals of flexible packaging, its benefits, how you chose the specific structures to match the product, its performance, marketing challenges and how the packaging is manufactured.

With the latest challenges facing us regarding sustainability in packaging the course will discuss the options, pros and cons of Compostability vs Recyclability, moves to mono material recyclable packaging to meet CEFLEX standards and other innovative alternative materials now available. As an add on, the course will be looking at the future plans for flexible packaging and available closed loop collection programs, kerbside collection development, advanced recycling options for circular design and many others to meet Packaging and Food Waste Targets.:

Course Objectives:

The objectives of the course are to provide participants an understanding of:

• A good broad understanding of the benefits of Flexible packaging.

• The process of manufacturing.

• Where the future lies with flexible films and the changes ahead.

• Snap shot of some of the latest packaging trends and what are the driving forces.

• Understanding the challenges facing us with the sustainable packaging race toward.

LECTURER:

Joe Foster FAIP Education Team Australian Institute of

Packaging (AIP)

* = 12.5

CPP PTS

AIP NEWSLETTER APRIL 2023 16

Eligible for CPP Points

To be held alongside To be held alongside * = 1 CPP PT per session

Up-Coming Courses, Webinars & Tradeshows

19 - 21 September 2023

Auckland Showgrounds

New Zealand’s foremost food and packaging technology exhibition where New Zealand’s food manufacturing sector encounters new materials, processes and technology from the world’s top suppliers

See us at stand 160

The AIP will have a stand, run multiple packaging sessions and a training course alongside FoodTech PackTech.

AIP NEWSLETTER APRIL 2023 17

Up-Coming Courses, Webinars & Tradeshows

OCTOBER 2023

thinkfood LIVE AIP & AIFST Content Partners

WHEN: 25-26 October 2023

WHERE: Carriageworks, Sydney

WHAT: Introducing thinkfood LIVE, ‘the food NPD event’, showcasing the ideas, ingredients and innovation of the food manufacturing, retail and FMCG industries. An exhibition and conference established specifically to support the new product development cycle, the event will cover everything from consumer insights and packaging, to design agencies and test kitchens. There will be a key focus on ingredients and flavour houses, who can help emerging and established businesses curate the perfect launch pad for their new product or brand. An independent event, aiming to deliver innovative solutions and novel ingredients alongside an unrivalled education program – thinkfood connects select vendors, content creators and service providers with the professionals that bring new food products to life. Stand bookings are also now open.

Waste Expo Australia

WHEN: 25-26 October 2023

WHERE: Melbourne Convention and Exhibition Centre

WHAT: Waste Expo Australia is the country's largest gathering of waste management and resource recovery professionals. Alongside our largest ever conference program, running across 4 different tracks with 60+ individual sessions and over 100 leading national and international experts, Waste Expo Australia will feature 100+ brands with presence from both local and international exhibitors, providing a platform to discover the latest breakthrough innovations shaping the future of the waste, recycling and resource recovery industry. Attracting more than 6,000 industry professionals, Waste Expo Australia is a must-attend event in the industry's calendar. Be part of this free-to-attend exhibition and conference from 25-26 October 2023 at the Melbourne Convention and Exhibition Centre.

AIP NEWSLETTER APRIL 2023 18

Eligible for CPP Points Eligible for CPP Points AIP to Partner

AIP NEWSLETTER APRIL 2023 19 Apply to Exhibit 25 - 26 October 2023 Carriageworks Sydney The Food NPD Event Ideas. Ingredients. Innovation. Meet the brightest minds in food and beverage manufacturing and product development. Connect with creatives and industry professionals looking for trusted suppliers to bring their next bestsellers to life thinkfood.com.au

Australian Institute of Packaging

Helping small to medium-sized enterprises adopt the Australasian Recycling Label

The AIP is proud to be partnering on a new campaign helping SMEs to put the ARL on their packaging.

Small businesses can access:

The ARL Marketplace: new educational hub featuring free AIP training videos and the Packaging Impact Calculator.

Expertise from four campaign partners: the Australian Packaging Covenant Organisation, the National Retail Association, and the Australian Food and Grocery Council.

Weekly ARL drop-in session: Register for the online sustainable packaging discussion.

COMING SOON: a new online directory of approved packaging that’s ready to label with the ARL.

To find out more register* today at arlmarketplace.org.au

AIP NEWSLETTER APRIL 2023 20

1. 2.

*Please tick the AIP from the drop-down box when you indicate where you heard about this program on the registration link.

3. 4.

Unique Women in Packaging forum at interpack 2023 - 8 May

By women for women: interpack will be launching a new Women in Packaging event for the first time on the 8th of May and everyone is invited to attend.

interpack is proud to support women with their own event, and within the framework of the trade fair, to contribute to a diverse industry, to provide opportunities for more young talent to come in to the industry and for better chances for developing a long term career in a global community.

Under the title 'Women in Packaging', interpack will be hosting an inaugural event on the 8th of May explicitly designed to learn more about the women in the wider packaging and processing industries and Nerida Kelton , Vice President Sustainability & Save Food, World Packaging Organisation will be the moderator for this exciting panel discussion.

Historically the packaging and processing industry has been predominantly shaped by men and until the last few decades women in leading positions are especially rare across the globe.

Globally we are seeing a scarcity of trained professionals in the industry and the 'Women in Packaging' forum at interpack will draw attention to barriers, challenges and opportunities for all women across the world to see the industry as an attractive place to establish a long-term career.

The five panelists are Unique Women in Packaging that are internationally successful, pioneers in their areas, marketing experts and founders of companies, role models and inspirations for others in this exciting industry we all work in.

This event will allow attendees to not only learn from the panelists successes, challenges and career pathways but you will also be able to profit from their advice, learnings and recommendations.

Sharing their experiences on the panel are Valentina Aureli , CEO of Aetna Group in Italy, Dr. Afsaneh Nabifa r, Group Leader for the global market development of biopolymers at BASF, Australian Nadia Taylor , co-founder and Director tna solutions, Marjo Halonen , Vice President Communications at Metsä Board Corporation in Finland and Gabi Bauer , Head of Marketing & Communications at Uhlmann Pac-Systeme.

The 'Women in Packaging' forum will take place at interpack on 8 May at 12:00 h in the International Lounge on the ground floor of the trade fair skyscraper and all of industry is invited to attend this very important inaugural event for the global processing and packaging industries.

The event is supported by the WPO – World Packaging Organisation.

Click here for free registration. Book your place today!

AIP NEWSLETTER APRIL 2023 21

UltraGuard™ Solutions for improved barrier properties in polyethylene

UltraGuard™ Solutions by Milliken is a line of performance additives that brings value to polyethylene parts by improving barrier properties. It can be used in films, and in injection molded, compression molded, and blow molded parts.

These additives cut by up to 50% the transmission rate of any substance (such as moisture or oxygen) that passes through the polyethylene bottle.

White opaque HDPE bottles are commonly used for OTC (over-the-counter) drugs, prescription drugs and nutraceutical products because they have good moisture barrier and light protection properties. Barrier enhancement in HDPE pharma bottles is particularly valuable because it can help to extend the potency of drugs toward the end of their shelf life.

As an added benefit, UltraGuard Solutions also provide sustainability benefits. To meet the barrier requirements, pharma bottles typically have much thicker walls than needed from a purely functional point of view. PE resin formulated with these additives enables bottle makers to reduce the weight of these bottles by up to 20% while still providing enhanced barrier properties. These lighter-weight bottles, therefore, use significantly less material and lessen their overall impact on the environment.

Polyethylene with UltraGuard Solutions provides controlled crystallization allowing for enhanced properties.

up to 60% improved barrier downgauging increased shelf life

For more details and information please contact us at asiachem@milliken.com or visit us online at chemical.milliken.com

AIP NEWSLETTER APRIL 2023 22 WVTR of HDPE Bottles Original Wall Thickness HDPE HDPE with UltraGuard 0.00173 0.00114 0.00229 0.00154 WVTR ( g/ pack. day ) -33% -34%

© Copyright 2022 Milliken & Company. All rights reserved. Milliken™ and Ultraguard™ are trademarks of Milliken & Company.

Milliken presents

Reduced (20%) Wall Thickness

Celebrating the barcode's 50th birthday with next-gen promise

The BBC has called the barcode “one of the 50 things that made the modern economy”, and rightfully so. Since its creation in 1973, the symbol is now present on over 1 billion products, and the ‘beep’ at the checkout counter of every store is instantly recognisable worldwide.

The barcode has changed the way we have shopped over the past 50 years. Although all barcodes may look pretty similar, the power lies inside, with a simple scan connecting a physical product to digital information that flows across the entire supply chain thanks to global standards.

The organisation behind the barcode and its global standards — GS1 — has evolved over the last five decades from a standards organisation towards a standards and services organisation currently present in 116 markets.

As the barcode turns 50, GS1 is now launching a global transition from traditional barcodes to next-generation barcodes that may once again change our lives in new ways.

“As consumers rightly demand more and better product information, and the planet requires us all to maximise the power of data for smart and efficient decisions, we are now launching a global transition from traditional barcodes to next-generation barcodes and we welcome everybody on board for this journey,” a GS1 spokesperson said.

Next-generation barcodes

Next-generation barcodes, such as two-dimensional QR codes, can capture large amounts of data for businesses, regulators, consumers and patients, offering more than just links to web pages. They may tell a product’s story, its origins, if it contains allergens, if it is organic, how it can be recycled and what its environmental footprint is. This transparency will help people make decisions about what they buy and use.

GS1 is building a coalition of industry leaders to deploy next-generation barcodes globally, putting technology at the service of efficient trade, more sustainable shopping and patient safety.

It launched a global initiative to transition from traditional to next-generation barcodes with key players in the retail sector at the end of 2020. Over 20 countries and districts, including Australia, China and Brazil, have already started successful pilots. In 2021, GS1 China promoted 2D barcodes and 20 major key branches, including the Zhejiang Branch of GS1 China (Zhejiang Institute of Standardisation), joined the project. In Australia, a 2D program designed to increase awareness, capacity and adoption is in full execution.

“The GS1 barcode is globally recognised and ready for new business. We have experienced 50 years of the barcode transforming how we buy and sell things. As consumers rightly demand more and better product information, and the planet requires us all to maximise the power of data for smart and efficient decisions, we are now launching a global transition from traditional barcodes to next-generation barcodes and we welcome everybody on board for this journey.”

Image credit: iStock.com/LadadikArt

This article was published with permission by foodprocessing.com.au

AIP NEWSLETTER APRIL 2023 23

AIP NEWSLETTER APRIL 2023 24

WPO launches latest Sustainability Perspectives position paper

The WPO (World Packaging Organisation) is pleased to announce that the new Position Paper ‘Sustainability perspectives across the globe is available for free download on the website https://worldpackaging.org/resources/28/ or via the PDF link https://worldpackaging.org/Uploads/2023-02/ResourcePDF51_1675967696.pdf

“Looking through the lens of WPO members, sustainability is ever-evolving, dynamic and in a flux of change”, states Nerida Kelton, WPO Vice President Sustainability & Save Food. She explains the document is the result of recent discussions among 21 countries, WPO members (Finland, Austria, Italy, Poland, Ireland, Wales, Scotland, England, United States of America, South Africa, Ghana, Kenya, Vietnam, United Arab Emirates, Israel, India, China, the Philippines, Thailand, Australia and New Zealand), about the latest trends, barriers, challenges and initiatives within their country and region.

”What is interesting is that the sentiment is the same in every corner of the globe. Whilst a lot is happening in circular and sustainable design, a lot more needs to be done to realistically be able to meet packaging and waste targets globally, regionally and locally”, adds Nerida.

“The common themes are designing out waste at the start, eliminating problematic materials, phasing out single use plastics, incorporating more recycled content into products, and ensuring that the materials and packaging that is put out into the market is in fact capable of being collected, sorted, recycled, reprocessed and put back into other solutions.”

Key initiatives and programs that are being developed across the WPO member countries include:

1. Moving soft plastics and flexible packaging to mono material formats that can be recycled and/ or reprocessed through Advanced Recycling facilities, Kerbside collection or Return to Store programs.

2. Developing Extended Producer Responsibility (EPR) Regulations.

3. Establishing Plastics Pacts and roadmaps for the country or region.

4. Creating Deposit Return Schemes/Container Deposit Schemes.

5. Building facilities for recycled content.

6. Establishing Single Use Plastics (SUP) Regulations.

7. Improving Materials Recovery Facility (MRF) capabilities and technologies.

8. Building Advanced/Chemical Recycling facilities.

9. Developing Consumer Education for Recycling.

10. Creating on-pack labelling programs to help guide consumers to recycle correctly.

“With so much happening across the world, WPO offers a unique platform to be able to bring developed and developing countries together, in one room, to regularly and openly discuss what is happening globally, regionally and locally”, celebrates Prof Pierre Pienaar, CPP, WPO President.

According to Pierre “The Sustainability & Save Food working group is a strong and passionate team of packaging experts from across the world who are all working towards circular design. The group learns from one another, and we hope that members take some of the ideas and programs back to their own country to implement. WPO recognises that no country can do this by themselves. By sharing knowledge, on not only the positive sides of sustainability, will enable all of us to have a clearer view on what needs to be done in our own regions to meet global, regional and local packaging and waste targets.”

“Everyone has a role to play to ensure that packaging is being designed to provide the lowest environmental impacts wherever possible and that the materials and formats are fit-for-purpose, functional and truly capable of being collected, sorted, recycled and reprocessed in the country that it is sold in”, ends Nerida.

AIP NEWSLETTER APRIL 2023 25

Positi on Pape r Susta i nability persp e cti ves across th e glob e Click here to see the full paper

www.worldpackaging.org

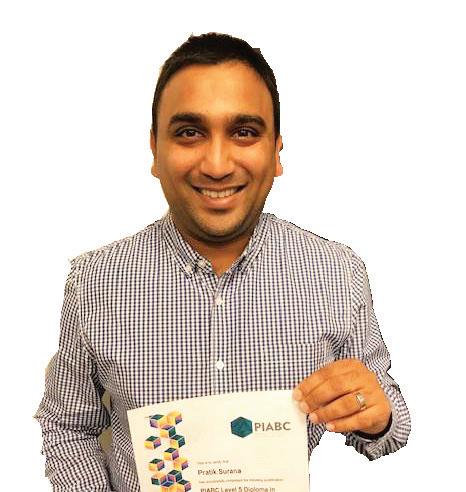

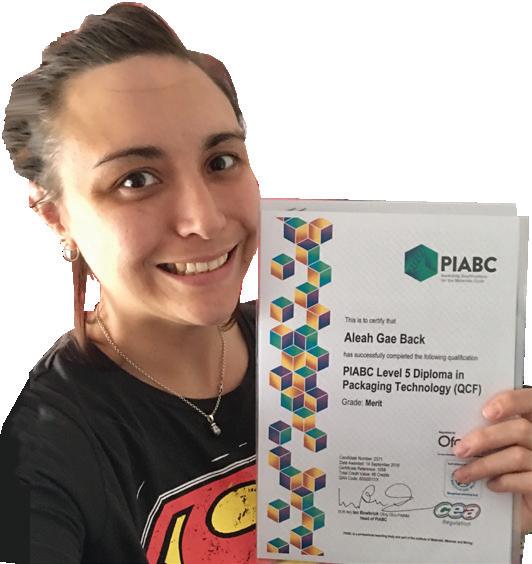

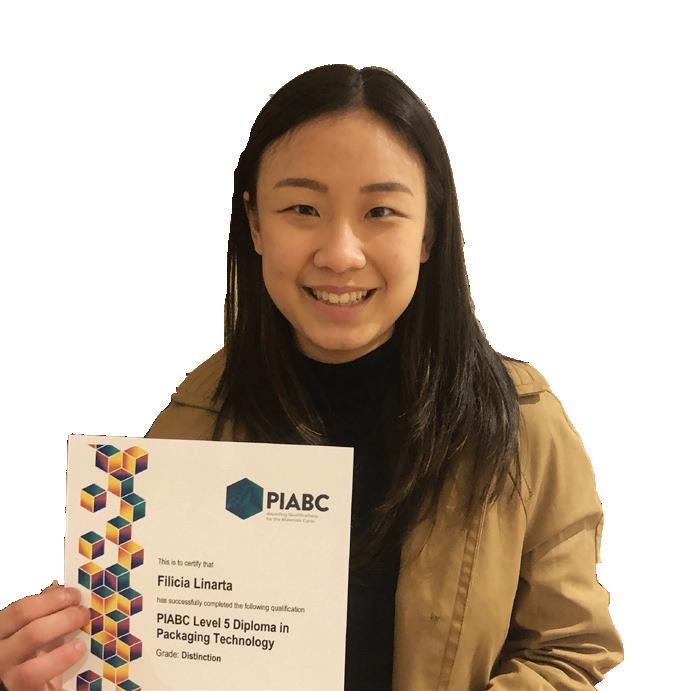

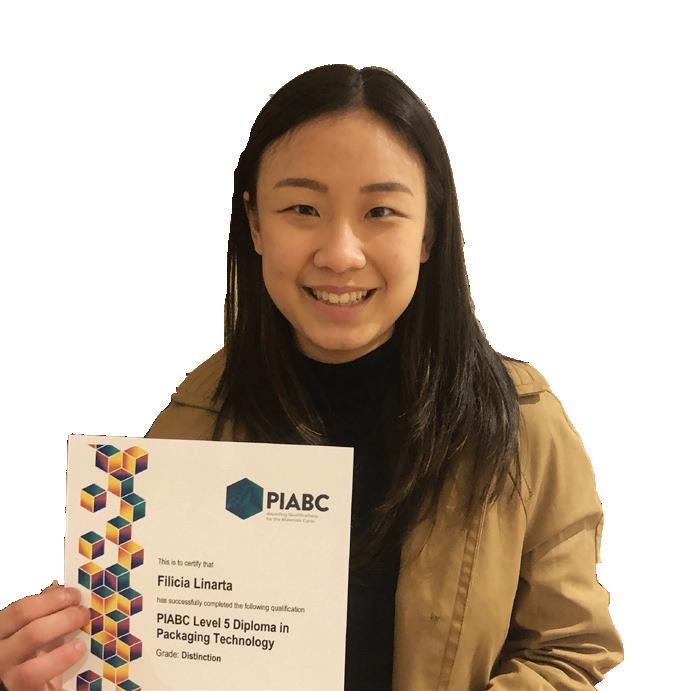

DIPLOMA IN PACKAGING TECHNOLOGY

Internationally recognised as the premier qualification in the packaging industry.

The Diploma in Packaging Technology is a Level 5 PIABC, 51-credit foundation degree-level qualification that prepares students to take responsibility for packaging operations at any level through the supply chain and can also lead to higher level study.

What’s in it for me?

Completion of the Diploma in Packaging Technology demonstrates your commitment to your career and to the industry. Students who successfully complete the course and achieve the qualification are equipping themselves for senior positions within the packaging industry.

AIP NEWSLETTER APRIL 2023 26

AIP: PEAK PROFESSIONAL BODY FOR PACKAGING EDUCATION & TRAINING IN AUSTRALASIA

CERTIFICATES OF MERIT (listed by country)

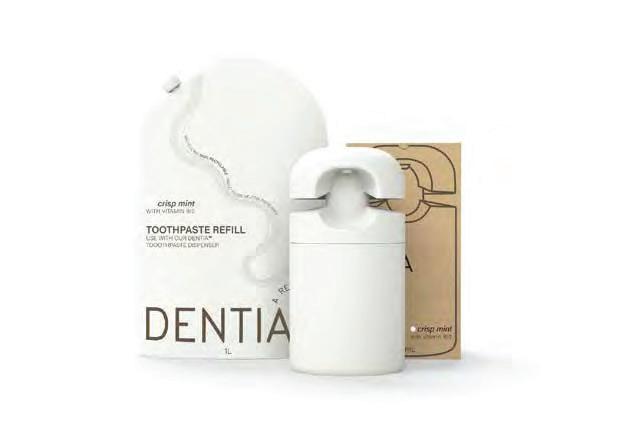

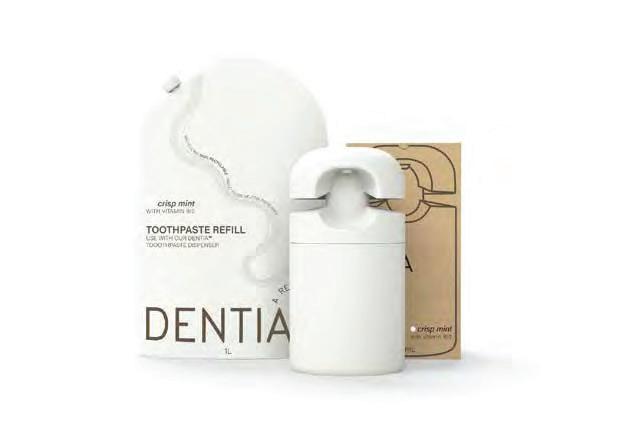

ENTRY ENTERED BY Dentia

Josephine Collins

University of New South Wales

2022 WorldStar Student Award Winner

ENTRY ENTERED BY Dentia

Josephine Collins

University of New

ENTRY ENTERED BY Packaging Design of a Fast Single Drug Delivery Bottle

LianKai Sun

Hunan University of Technology

This is a packaging design of quick single drug delivery bottle.The bottle bodyis made of medical high-density polyethylene. The structure comprises a medicine bottle shell, an internal medicine storage screw, a rotating shaft, a

Dentia is a refillable and recyclable toothpaste system. Consumers press the large, accessiblepump head to dispense the recommended amount of a low viscosity toothpaste through the mono-material pump. Users can refill the dispenser when needed by purchasing the recyclable bulk sized refill pouch.

I am honoured to have been awarded a Certificate of Merit for the 2022 WorldStar Student Awards. As a starting Industrial Designer, it is not only a wonderful international platform to showcase my work and skills, but a way to celebrate innovative and environmentally conscious design practices amongst up and coming designers. I would like to thank my teachers at UNSW for their guidance and encouragement, and I am grateful for the opportunity to have participated in an internationally recognised program. I am excited to see what doors this can open and where this takes me in the field of packaging. Thank you!

ENTRY ENTERED BY Packaging Design LianKai Sun

Hunan University EDUCATIONA L IN S TITUTIO N

This is a packaging design of quick single drug delivery bottle.The bottle bodyis made of medical high-density polyethylene. The structure comprises a medicine bottle shell, an internal medicine storage screw, a rotating shaft, a fixed shaft, a three-layer rotary table, etc.

AIP NEWSLETTER APRIL 2023 27

EDUCATIO NAL INSTIT U TIO N Australia COUNTRY

EDUCATIONA L IN S TITUTIO N China COUNTRY NO Let´s embrace packaging!

Josephine Collins

UNIVERSITY CERTIFICATE OF

Dentia

MERIT

CERTIFICATES OF MERIT 2022 International Packagi St udent OW R LDSTARSTUDENTFORPACKA G I GN

EDUCATIO

NAL INSTIT U TIO N

2023 AUSTRALASIAN PACKAGING INNOVATION & DESIGN ( PIDA ) AWARDS GALA DINNER

28th March 2023

AIP NEWSLETTER APRIL 2023 29 PACKAGIN G GOLD PARTNERS PLATINUM PARTNER COORDINATED BY MEDIA PARTNERS WINNERS DESIGN OF THE YEAR

2023 Australasian Packaging Innovation & Design (PIDA) Awards winners announced

AIP NEWSLETTER APRIL 2023 30

2023 Australasian Packaging Innovation & Design (PIDA) Awards winners announced

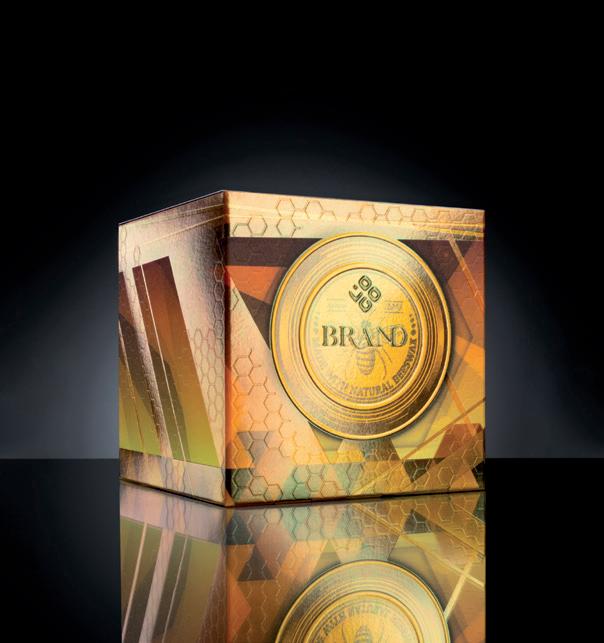

Winners for the 2023 round of the annual Australasian Packaging Innovation & Design (PIDA) Awards have been announced in front of 330 people at a gala awards evening at the Crown on the 28th of March.

Coordinated by the Australian Institute of Packaging (AIP) the PIDA awards are designed to recognise companies and individuals who are making a significant difference in their field across Australia and New Zealand.

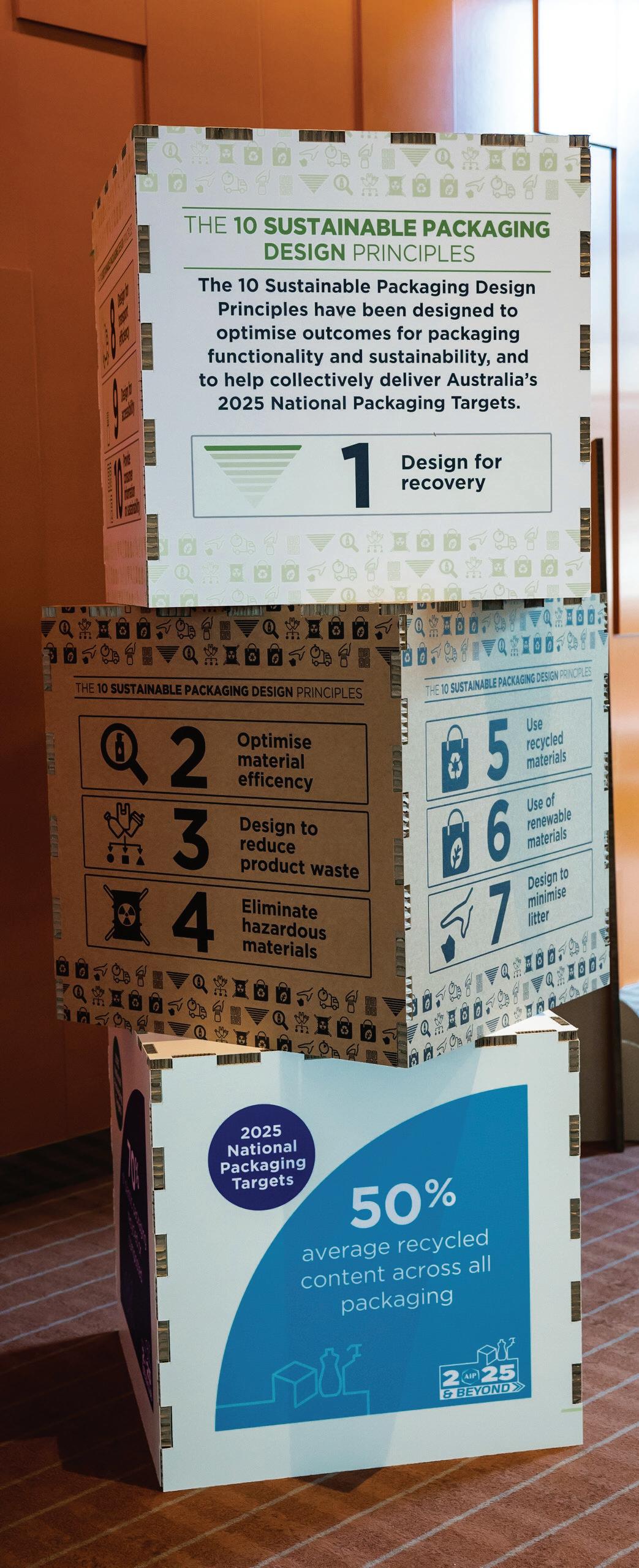

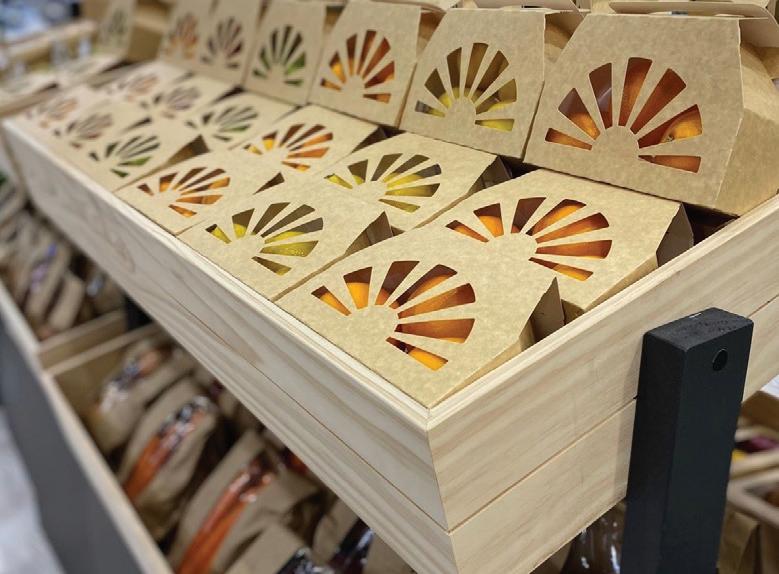

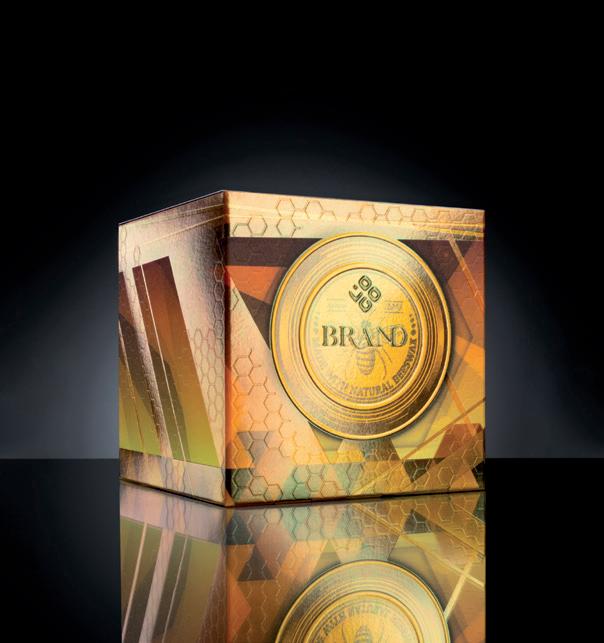

The Packaging Innovation & Design of the Year company awards recognise organisations that have designed innovative packaging within six categories:

1. Food Packaging Design of the Year

2. Beverage Packaging Design of the Year

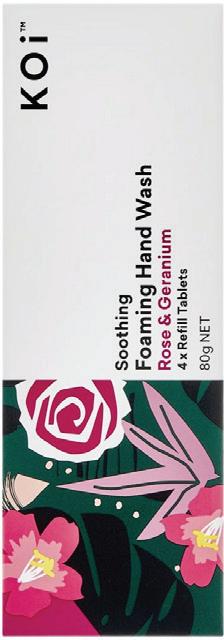

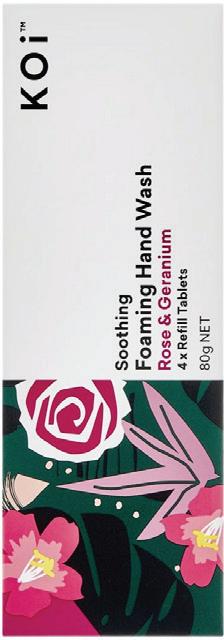

3. Health, Beauty & Wellness Packaging Design of the Year

4. Domestic & Household Packaging Design of the Year

5. Labelling & Decoration Design of the Year

6. Outside of the Box Design of the Year

There are five special awards also available:

1. Marketing Design of the Year

2. Sustainable Packaging Design of the Year

3. Industry Packaging Professional of the Year

4. Young Packaging Professional of the Year

5. ABA Scholarships

The PIDA Awards are also the exclusive feeder program for Australia and New Zealand for the prestigious WorldStar Packaging Awards run by the World Packaging Organisation. All 2023 PIDA winners will be automatically eligible for entry into the 2024 WorldStar Packaging Awards competition.

AIP NEWSLETTER APRIL 2023 31

2023 Australasian Packaging Innovation & Design (PIDA) Awards winners announced

AIP NEWSLETTER APRIL 2023 32

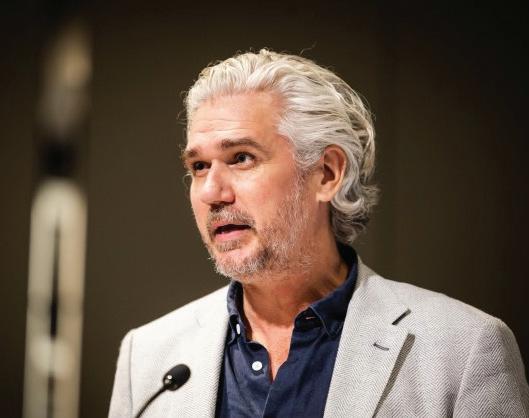

Winners crowned at PIDA 2023 night of nights

It was an evening to remember for the 350 packaging professionals gathered at the Crown Promenade in Melbourne for the long-awaited in-person gala dinner presentation of the Australasian Packaging Innovation & Design Awards. PKN was there.

The awards evening followed a successful first day at the AIP's Australian Packaging Conference, where many of the ideas shared on sustainable design and innovation were reflected in the winning entries.

MC for the night was Damian Walsh, with co-host Lindy Hughson, publisher of PKN Packaging News and Food & Drink Business, the exclusive media partners for the awards since the programme's inception. The duo presented the winners and category commentary in tandem, with presentation of special prizes made by senior AIP board members, Jason Fields FAIP, CPP, Pierre Pienaar FAIP, CPP and Ralph Moyle FAIP, CPP.

The AIP presented a surprise award on the night, which brought the audience to their feet in a standing ovation for Nerida Kelton, as they recognised the significant contribution the Institute's executive director has made to the AIP and the wider industry.

Nerida Kelton was recognised as a Fellow of the Institute, joining a special group of AIP leaders and contributors, many of which were in attendance on the night.

Kelton, who was overcome by emotion, said she was humbled and honoured to be made a Fellow.

AIP NEWSLETTER APRIL 2023 33

This article was published with permission by PKN Packaging News

Nerida Kelton, the newest AIP Fellow, with PKN publisher Lindy Hughson.

PIDA 2023 celebrates: A wonderful night for winners.

Lindy Hughson co-hosted with MC Damian Walsh.

2023 Australasian Packaging Innovation & Design (PIDA) Awards winners announced

AIP NEWSLETTER APRIL 2023 34

2023 Australasian Packaging Innovation & Design (PIDA) Awards winners announced

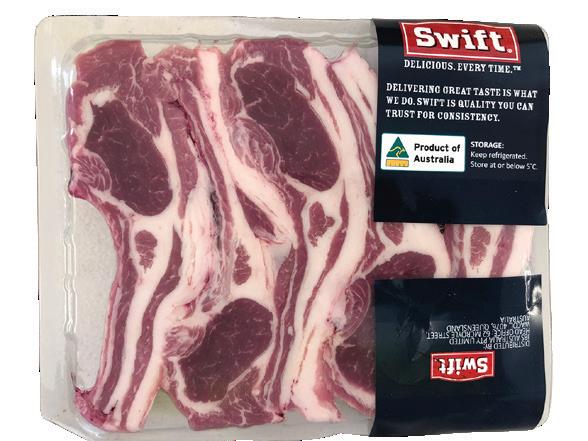

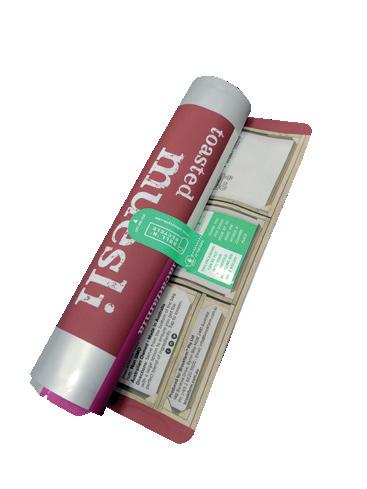

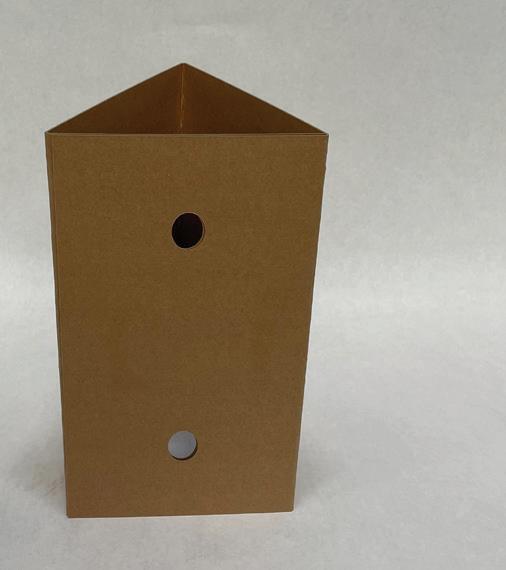

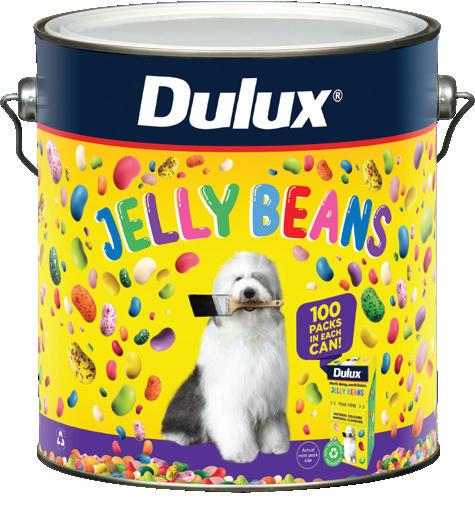

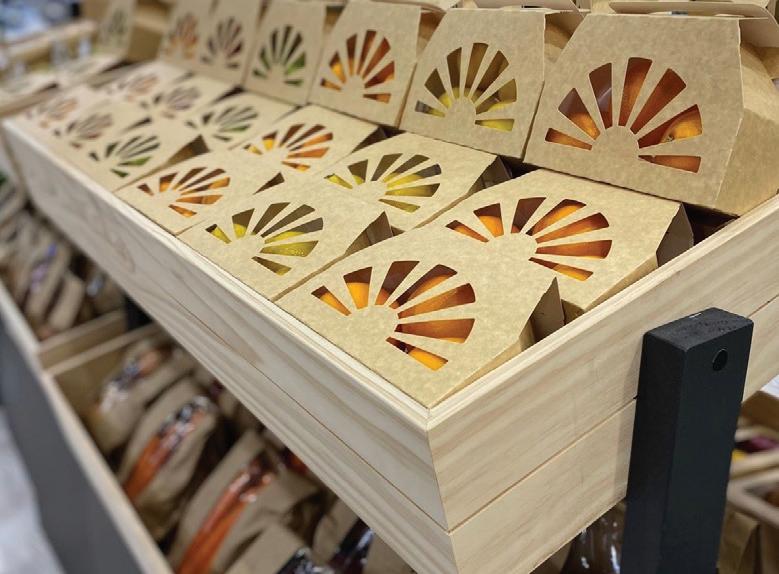

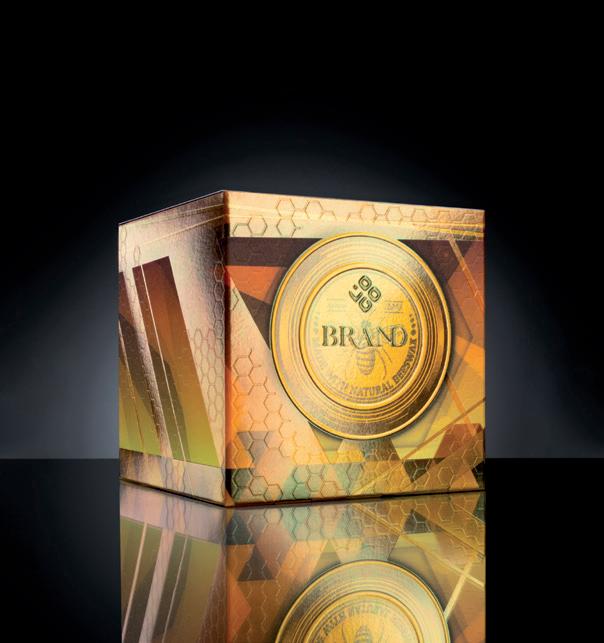

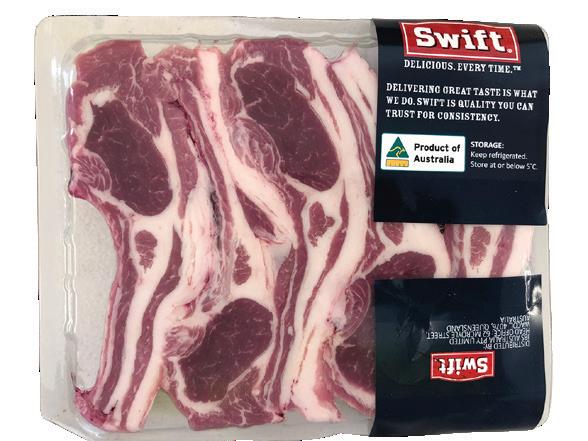

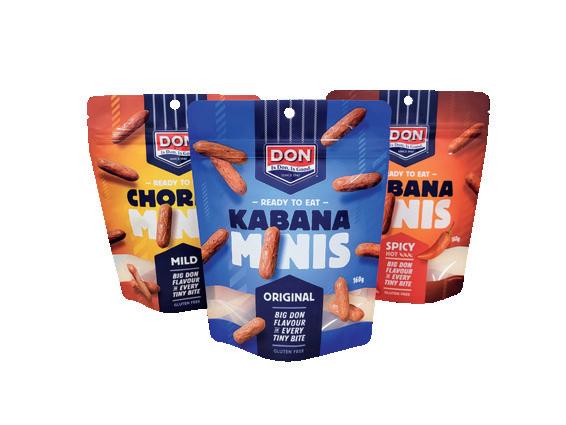

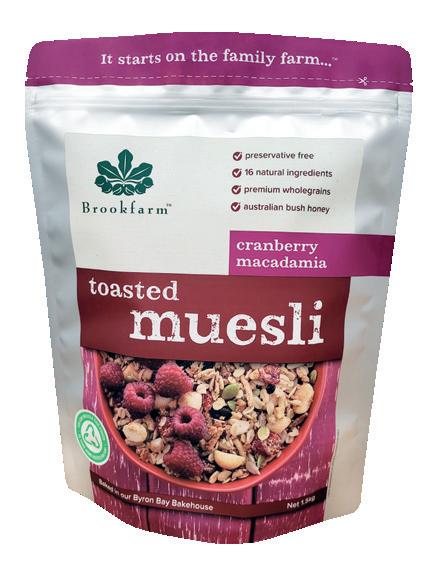

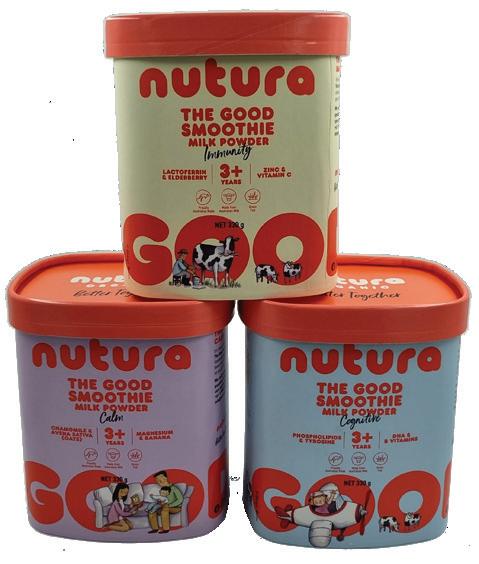

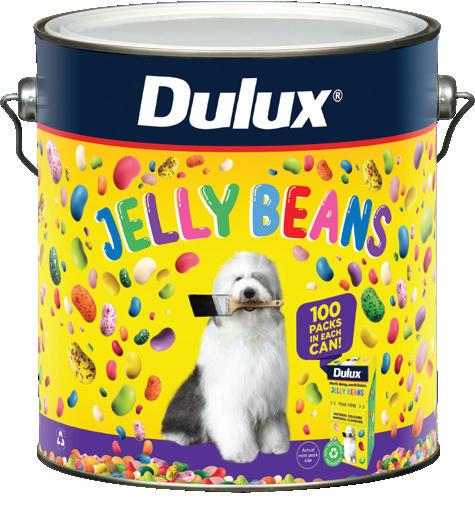

FOOD PACKAGING DESIGN OF THE YEAR

The Food Packaging Design of the Year award recognises organisations that have designed innovative packaging and/or materials, within food packaging and processing including fresh, frozen or other.

GOLD WINNER

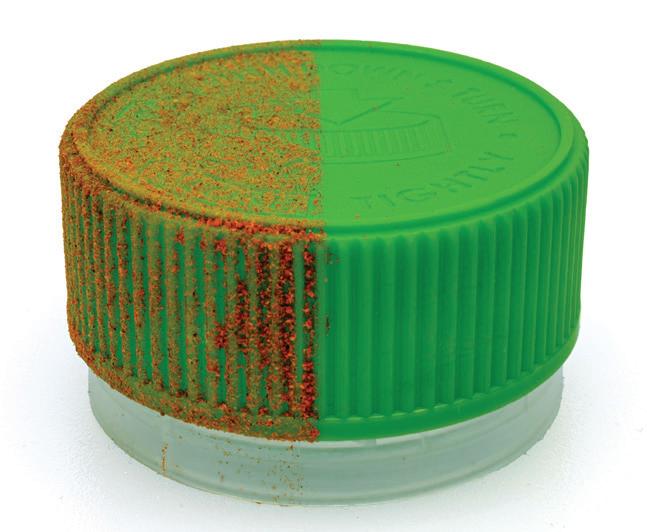

Gold award winner is JBS Swift Lamb Cutlets CRYOVAC Darfesh Mono-PET rollstock (Sealed Air)

GOLD WINNER

AIP NEWSLETTER APRIL 2023 35

2023 Food Packaging Design of the Year

FULL

HERE

READ THE WINNER'S

STORY

SILVER WINNER

2023 Food Packaging Design of the Year Silver award winner is EarthPouch High Barrier Quad Seal (Mikro Coffee Roasters & TCL Hofmann)

2023 Australasian Packaging Innovation & Design (PIDA) Awards winners announced

FOOD PACKAGING DESIGN OF THE YEAR

Australian

Watch the FOOD PACKAGING DESIGN OF THE YEAR winning video here.

AIP NEWSLETTER APRIL 2023 36

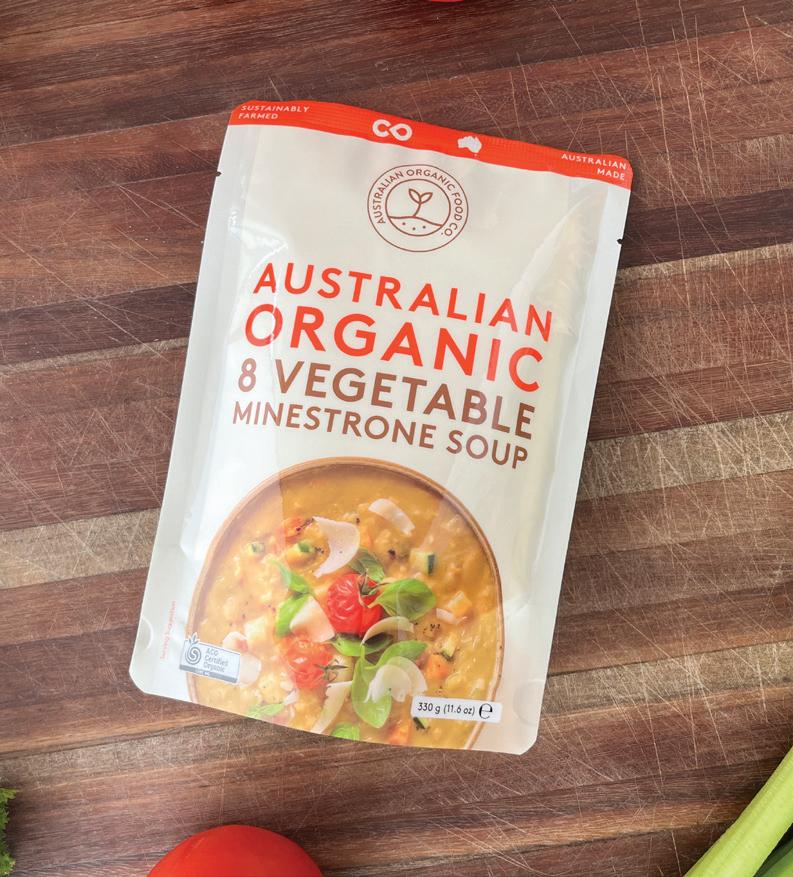

HIGH COMMENDATION WINNERS

2023 Food Packaging Design of the Year High Commendation award winners

DualPakECO compostable food trays (Confoil & BASF)

BRONZE WINNER

2023 Food Packaging Design of the Year Bronze award winner is Vitor Grapes ‘hippie punnet’ (NAVI Co Global)

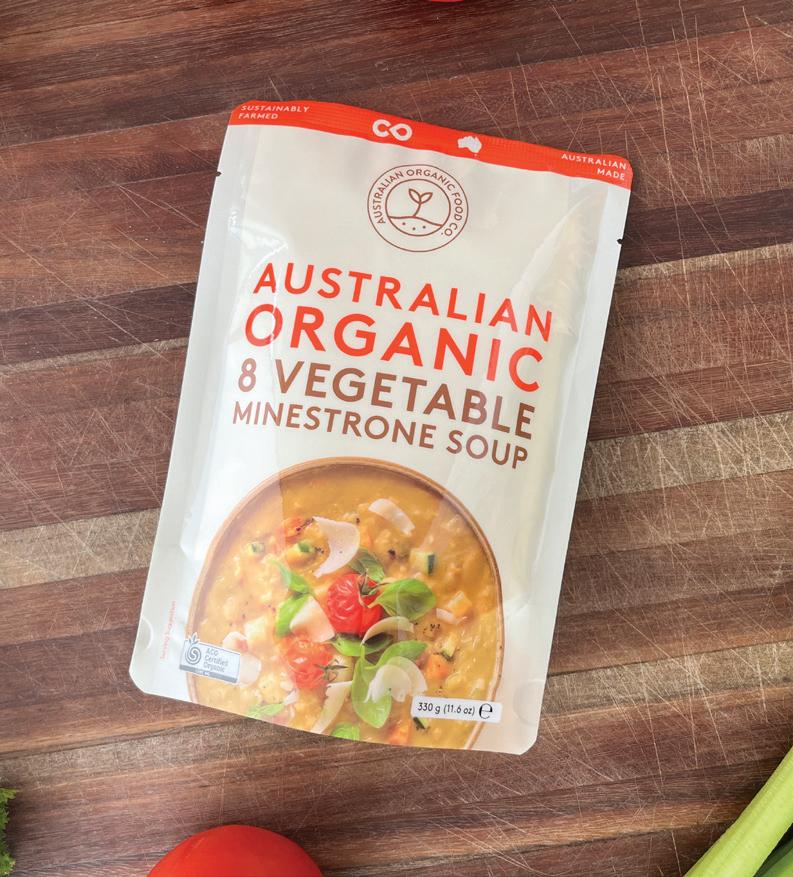

Organic Food Co. Minestrone Soup mono material retort pouch (Flavour Makers & Toppan Inc)

PIDA 2023: Food Packaging Design of the Year

The Food Packaging Design of the Year award recognises organisations that have designed innovative packaging and/or materials, within food packaging and processing including fresh, frozen or other categories.

"The food manufacturing sector is one of the biggest end users of packaging, accounting for over 70 per cent of all converted packaging," said PKN managing editor & publisher Lindy Hughson, who was co-host of the 2023 PIDA awards.

"It's also a highly competitive sector, where trends are a moving feast, and a constant stream of product innovation is required to feed consumer’s changing tastes and maintain shopper interest, and thus market share.

"But the biggest demand driving packaging design comes from the requirement to package food in sustainable materials - which includes designing for recyclability and compostabitlity, while also designing to prevent food waste.

"As a result, we're seeing a rise in new sustainable, high barrier structures, across fibre-based; compostable; and monomer plastic materials, as well evidenced in this year's selection of finalists."

And the winners are...

There were two High Commendations awards for the category: Australian Organic Food Co. Minestrone Soup mono material retort pouch by Flavour Makers and Toppan Inc. ; and DualPakECO compostable food trays by Confoil and BASF

The Bronze winner was Vitor Grapes ‘hippie punnet’ by NAVI Co Global , while the Silver winner was EarthPouch High Barrier Quad Seal by Mikro Coffee Roasters and TCL Hofmann .

Topping the category with the Gold was JBS Swift Lamb Cutlets Cryovac Darfesh Mono-PET rollstock by Sealed Air

About the Gold winner:

JBS Foods Australia is Australia's largest meat and food processing company, and its Swift brand of quality lamb products have been enjoyed by families since 1855.

The winning innovation is described as a "purposefully simple design where less is more". On retail shelves dominated by printed or black

packaging formats, the clear recyclable pack allows the product to be the hero and allows consumers to see both sides of the product. This, the company believes, is another reason consumers have come to trust this 168-year-old global brand. "What you see is what you get", and there's no need to dispose of a soaker pad that can commonly be found in fresh lamb retail packs.

Cryovac Darfresh mono-PET vacuum skin pack offers the combination of high barrier (low oxygen environment) together with the top web contouring the protein allowing for extended shelf life. An 18day fresh-chilled shelf life was achieved with this pack, which equates to less product waste across the value chain.

For processors, it means efficient batch manufacturing, further product distribution and enhanced sales. For retailers, it means longer merchandising periods, less retail markdowns and less waste. While for consumers, it means a longer window to consume product as the product can be frozen.

While this pack is designed to protect against food waste, it also offers sustainable packaging principles such as optimising material efficiency and design for material recycling. JBS switched to a mono-PET rollstock to address both recyclability and material efficiency. The company says the new design has proven to deliver the optimum level of protection against abuse and spoilage, without compromising product quality or safety.

AIP NEWSLETTER APRIL 2023 37

This article was published with permission by PKN Packaging News

PIDA 2023 Food Packaging Design of the Year: The Gold winner is JBS Swift Lamb Cutlets Cryovac Darfesh Mono-PET rollstock by Sealed Air.

AIP NEWSLETTER APRIL 2023 38

2023 Australasian Packaging Innovation & Design (PIDA) Awards winners announced

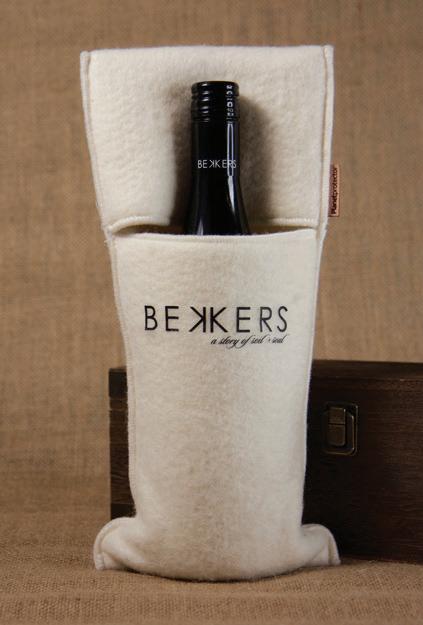

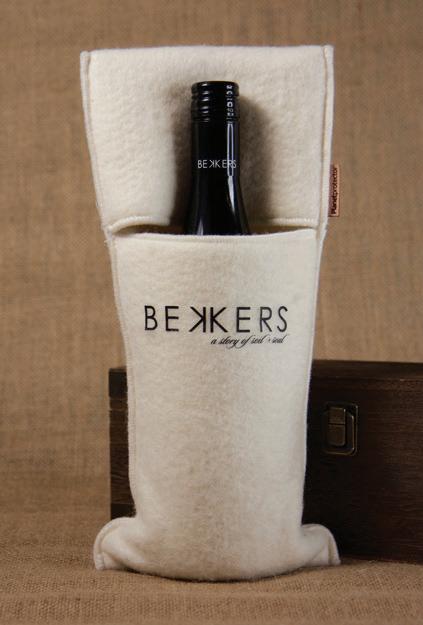

BEVERAGE PACKAGING DESIGN OF THE YEAR

The Beverage Packaging Design of the Year award recognises organisations that have designed innovative packaging and/or materials, within packaging and processing for liquid or dry tea, coffee, water and soft drinks including wine, beer and spirits.

GOLD WINNER

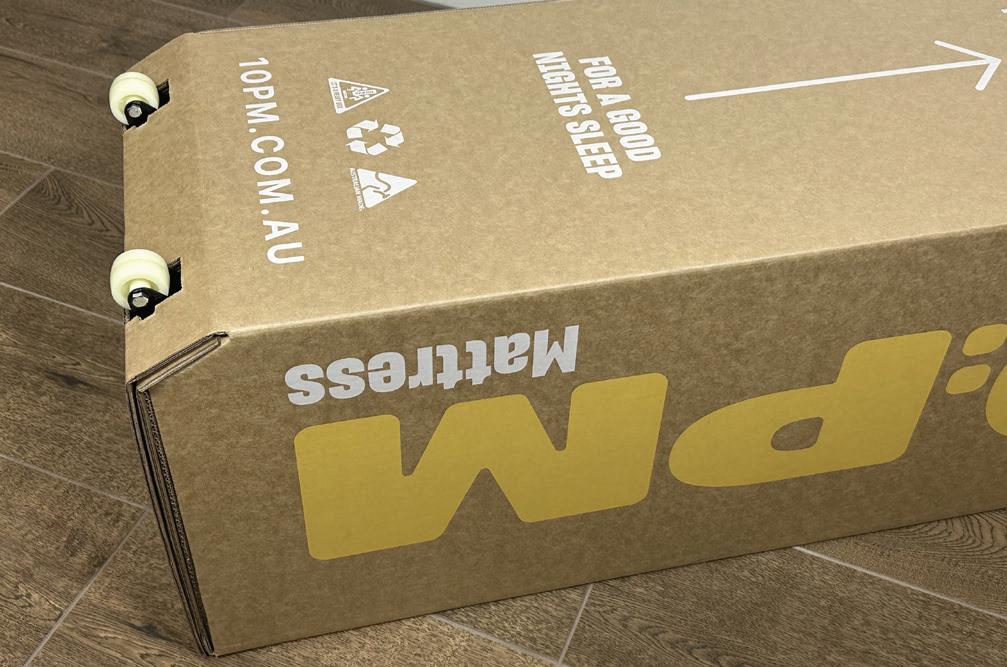

2023 Beverage Packaging Design of the Year Gold award winner is Banrock Station Eco Bottle (Accolade Wines)

GOLD WINNER

READ THE WINNER'S FULL STORY HERE

Watch the

BEVERAGE PACKAGING DESIGN OF THE YEAR winning video here.

AIP NEWSLETTER APRIL 2023 39

2023 Australasian Packaging Innovation & Design (PIDA) Awards winners announced

BEVERAGE PACKAGING DESIGN OF THE YEAR

SILVER WINNER

2023 Beverage Packaging Design of the Year Silver award winner is Penley Sustainability Range (Cutler Brands)

BRONZE WINNER

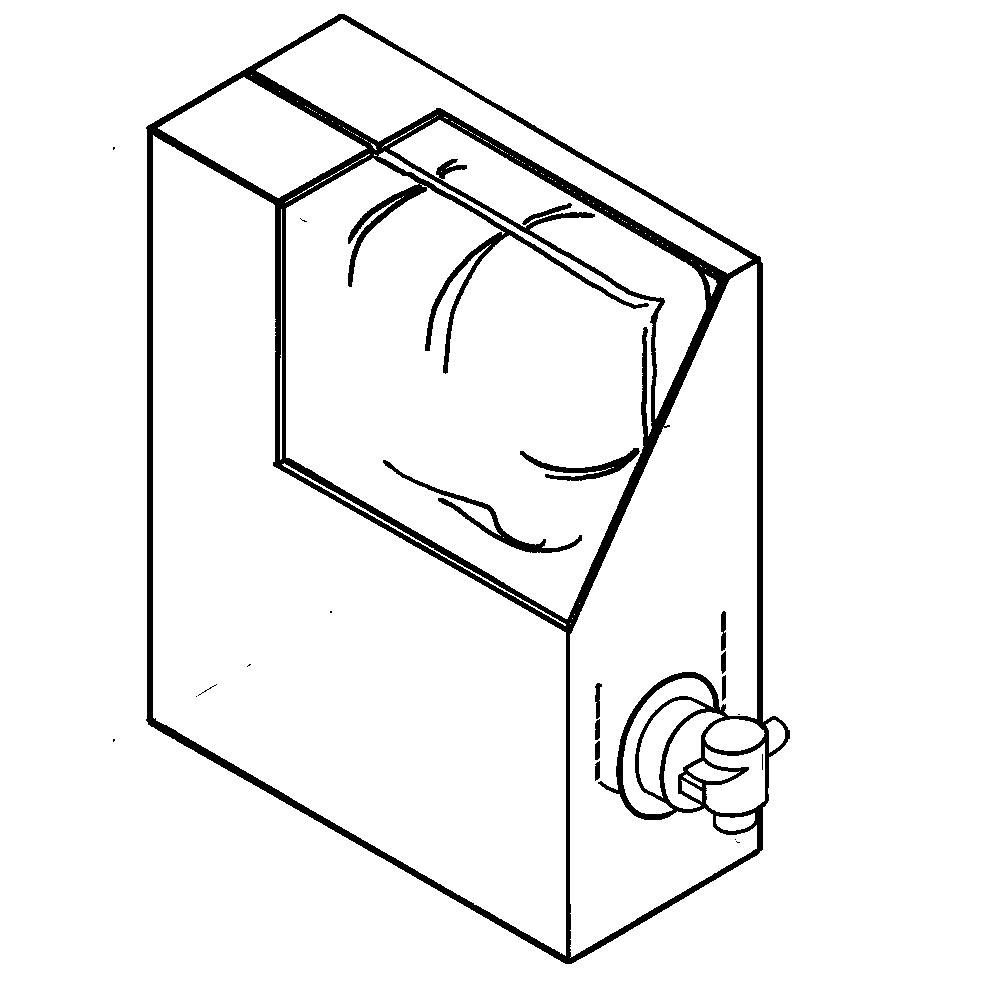

2023 Beverage Packaging Design of the Year Bronze award winner is Wine Protector (Planet Protector Packaging)

AIP NEWSLETTER APRIL 2023 40

PIDA 2023: Beverage Packaging Design of the Year

The Beverage Packaging Design of the Year award recognises organisations that have designed innovative packaging and/or materials, within packaging and processing for liquid or dry tea, coffee, water and soft drinks including wine, beer and spirits.

"Next to food, the beverage category has to be one of the most visibly creative in its presentation of packaging design, both in labels and primary containers, again with a strong focus on sustainability," said PKN managing editor & publisher Lindy Hughson, who was co-host of the 2023 PIDA awards.

"The designs moving successfully from shelf to trolley are those combining sustainability with functionality, visual appeal, clear on-pack messaging and smart packaging utility - thus engaging consumers in a crowded category where there is a veritable proliferation of new products, both in the alcoholic and non-alcoholic sector.

"The ground has certainly shifted for beverage bottlers in terms of consumer pushback on singleuse plastic, leading to a strong drive toward the use of post-consumer recycled plastic, a growing uptake of aluminium, and innovation in paper-based containers."

And the winners are...

The Bronze winner was Wine Protector by Planet Protector Packaging , while the Silver winner was Penley Sustainability Range by Cutler Brands

Topping the category with the Gold was Banrock Station Eco Bottle by Accolade Wines

About the Gold winner:

The Banrock Station bottle shape has taken a smart cross sectional design of a traditional Bordeaux wine bottle. This means that the bottle has the silhouette of a Bordeaux wine bottle face on, however, when turned to its side, it is flat. This innovative change in shape allows the same volume of wine (750ml) to be packed into a bottle that is 30 per cent more spatially efficient than it’s round, glass predecessor.

By being flat, and having a long neck, the bottle stands tall and proud on retail shelves. Banrock Station’s eco wine bottle is in fact slightly taller than round glass wine bottles when placed side-by-side.

The eco bottles are made from 100 per cent recycled PET (which is sourced in Australia) making them 84 per cent lighter than the average Australian round glass bottle.

In addition, the bottle has a key call out on the front of pack says 'Hey! I'm a 100 per cent recycled bottle'. The bottles use an active oxygen scavenger barrier technology to offer advanced shelf-life performance (19 to 21 months based on real-time and modelled data) over PET with no barrier.

The design offers significant lightweighting - the new pack is 63g, which is 84 per cent lighter than the average 400g glass bottle.