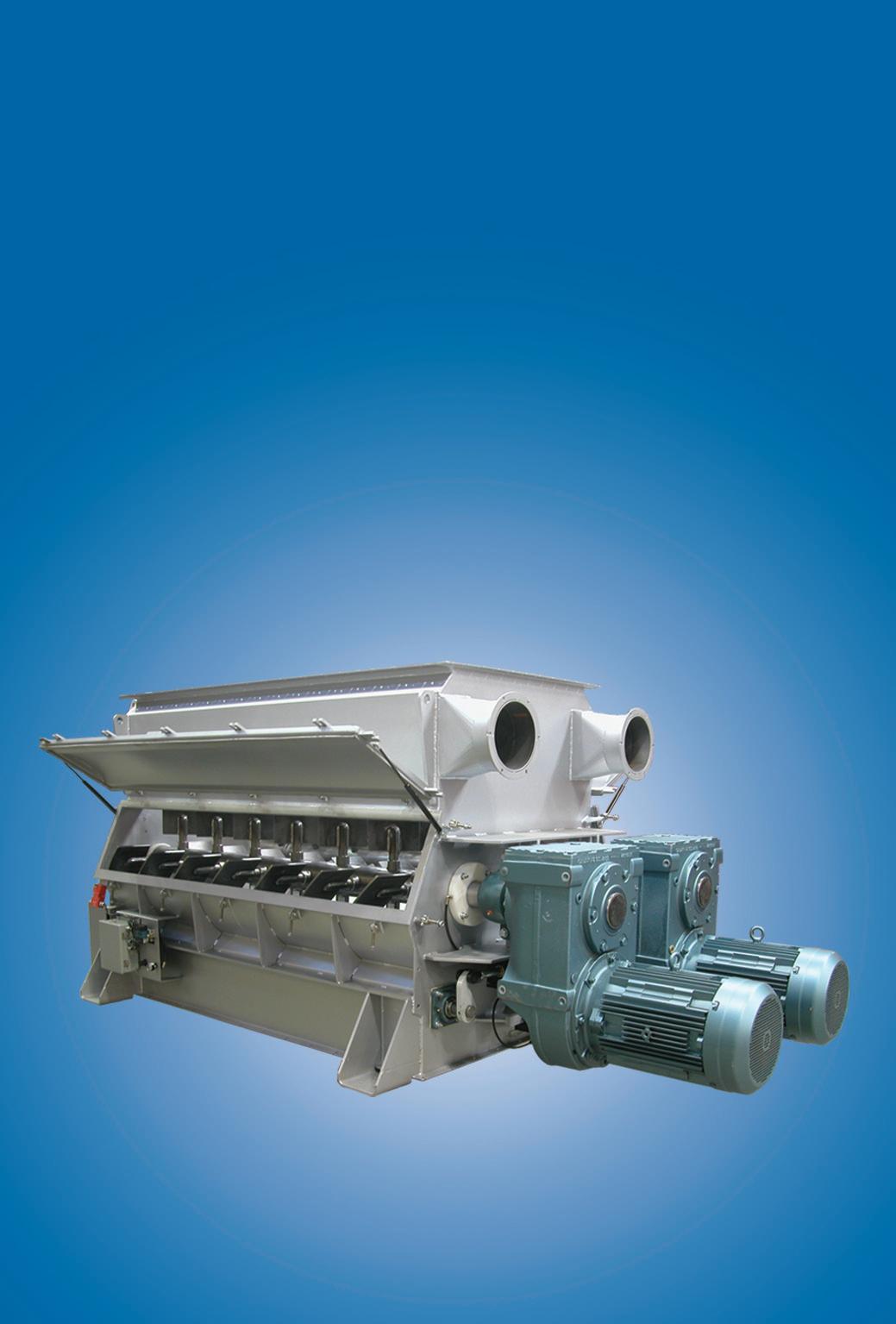

We are a leading provider of custom solutions for the handling of bulk materials for processing businesses across various industries. Dynamic Air has over five decades of expertise in designing and manufacturing pneumatic conveying systems and equipment for handling dry bulk solids.

At Dynamic Air, we set the standard for excellence in bulk solids handling. With a relentless focus on quality, reliability, and customer satisfaction, we deliver reliable, high-quality pneumatic conveying systems, equipment, and custom solutions that exceed expectations. BULKBUSTERTM

We never take a cookie-cutter approach just to cut costs up front; we know that the right solution will save you money in the many years to come. Our tailored solutions involve thoughtful planning, meticulous engineering and precise manufacturing that optimize efficiency and productivity.

Sales Director: James Scrivens

Production: Sarah Daviner

Accounts Manager: Avery Hudson

Office Manager: Katie Brehm

BULK SOLIDS TODAY is published 6 times a year by Abbey Publishing Ltd

ADVERTISING & EDITORIAL

Please contact us at:

Tel: 01933 316931

Email: editorial@bulksolidstoday.co.uk advertising@bulksolidstoday. co.uk

Web: www.bulksolidstoday.co.uk

Twitter: www.twitter.com/ BulkSolidsToday

CIRCULATION

To receive a copy free of charge, please send your details to subs@bulksolidstoday.co.uk

No part of this publication may be reproduced by any means without prior permission from the publishers. The publishers do not accept any responsibility for, or necessarily agree with, any views expressed in articles, letters or supplied advertisements.

ISSN: 1365/7119 All contents © Abbey

Eriez®, the global leader in separation technologies, announces its participation at the upcoming NPE2024: The Plastics Show. The event will be held at the Orange County Convention Center in Orlando from May 6-10 and is seen as a premier gathering for industries worldwide to promote plastics, innovation and sustainability.

Eriez will showcase cutting-edge products at NPE2024 booth W5588, including an Eddy Current Separator, metal detectors, grate magnets and highdeflection feeders.

During NPE2024, Eriez’ plastics industry experts will be on-site to engage with attendees, providing valuable insights into the company’s comprehensive solutions and offering advice tailored to address operators’ specific application challenges.

For more information about Eriez products for the plastics industry, visit eriez.com/ NA/EN/Industries/Plastics-Rubber.htm.

Established in 1942, Eriez is a global leader in separation technologies. Our commitment to innovation has positioned us as a driving market force in several key technology areas, including magnetic separation, flotation, metal detection, and material handling equipment. The company’s 900+ employees are dedicated to providing trusted technical solutions to

the mining, food, recycling, packaging, aggregate, and other processing industries. Headquartered in Erie, Pennsylvania, USA, Eriez designs, manufactures, and markets on six continents through 12 wholly owned international subsidiaries and an extensive sales representative network. For more information, visit eriez. com.

As part of its ongoing commitment to sustainability Toyota Material Handling Europe has announced the creation of an Environmental, Social and Governance (ESG) committee.

The new team will help shape Toyota’s strategy and decision making as the company continues its progress towards becoming a highly sustainable organisation Directors from every business function within TMH Europe will make up the ESG team and together they will tackle a full range of sustainability issues, such as climate change, diversity and health & safety.

Tom Schalenbourg, Director

- Sustainable Development at Toyota Material Handling Europe, commented: “Every sustainability challenge is inherently cross-functional, so it makes sense to put together a team of directors representing each TMH Europe business function. The formation of the ESG Committee will help us to support our management and gain momentum as we continue transitioning to a more sustainable business.”

ESG is a set of standards measuring a business’s impact on society and the environment. The standards cover areas such as how transparent and accountable companies are in terms of their

leadership, executive pay, audits, internal controls and shareholder rights.

According to the CBI, In the UK ESG is considered an increasingly important component for business growth, while research by McKinsey found that customers in a range of industries are more willing to buy brands that they perceive to be ethical.

Toyota Material Handling Europe has been one of the material handling industry’s sustainability frontrunners for more than 10 years. The latest edition – the sixth – of the company’s Sustainability Report was published recently.

McCulla Ireland, the coldchain storage and transport specialist, has bolstered its fleet with the addition of 33 new S.KO COOL SMART refrigerated semitrailers.

The final reefers from the order hit the road in recent weeks, cementing a partnership between the two businesses that is now into its second decade.

Brian Beattie, Operations Director at McCulla Ireland, says: “We took our first two semitrailers from Schmitz Cargobull in 2008 having been exclusively with another manufacturer before. The trailers we’ve had in the years since have all proved to be robust products with great longevity and build quality.”

Family-owned McCulla Ireland is celebrating 55-years of trading this year and has built its business by cultivating longterm relationships with clients, an approach it is utilising with Schmitz Cargobull too.

“We had an issue a few years back and they fixed it very quickly. The customer service

they provide is excellent, and the level of attention you receive from their team throughout the process is impressive. It really is a partnership,” he says.

Supplied by Kevin Wynd, Regional Sales Manager at Schmitz Cargobull, the latest order comprises single and multi-temperature trailers and a specification honed over many years to meet McCulla Ireland’s exacting requirements.

McCulla Ireland, which has its headquarters in Lisburn, near Belfast, operates three coldstores across the island of Ireland with a combined capacity to house 15,000 pallets. It also provides value-added services, including blast freezing and tempering.

Its operation, which sees it moving everything from frozen chips to high-end pharmaceuticals, involves sending unaccompanied trailers across the Irish Sea.

On the occasions that damage does occur, during sea crossings for example, the

ability for its in-house technicians to simply replace the affected panels rather than the whole side of the trailer thanks to a segmented design, is yet another reason the percentage of Schmitz Cargobull products in the McCulla Ireland fleet continues to grow.

Its latest semi-trailers all feature Schmitz Cargobull’s TrailerConnect® telematics system and are built on a galvanised MODULUS bolted chassis. The chassis has been designed for both strength and durability and comes with a 10-year warranty against rustthrough on all galvanised parts.

The partnership will begin a new chapter later this year, with the arrival of a new ‘pharmaceutical specification’ S.KO trailer, which features advanced load security.

It will be fitted with a double deck loading beam system, which will allow 66 pallets to be transported per load to service the requirements of a specific McCulla Ireland customer.

EFFECTIVE AUGUST 1, 2024, THE COMPANY WILL OFFICIALLY TRANSITION ITS NAME UNDER COPERION

Following its September 2023 acquisition by Hillenbrand (NYSE: HI), Schenck Process Food and Performance Materials (FPM) is transitioning its name and brand to Coperion. The full legal change to Coperion will be completed by August 1, 2024.

Coperion is an operating company of Hillenbrand with 140 years’ experience in some of the world’s most critical processing industries. Schenck Process FPM has contributed an integral part to its divisions, which support processing solutions for manufacturing in polymers/performance materials, food, health & nutrition and aftermarket sales & services.

Schenck Process FPM expertise, team members, manufacturing sites, test and innovation centers, and technologies remain in place. This includes flagship brands such as RBS, Stock, Baker Perkins, Kemutec and Mucon. Customers can experience a seamless transition bolstered by more resources and broader technology capabilities available through Coperion.

“The acquisition of Schenck Process FPM in 2023 has been an essential step for the development of Coperion toward a more diversified company and an expanded footprint. With the transition of the FPM brand name under Coperion, we take the next step in our journey,” said Ulrich Bartel, President of Coperion.

“Aligning more closely with Coperion reflects a significant opportunity for us to combine our strengths and offer customers access to a broader portfolio of solutions, technologies and services,” said Matthew Craig, Vice President and General Manager, Schenck Process FPM. “This wider range of complementary technologies and increased scale makes us even more capable of delivering value.”

The evolution to the Coperion name and brand begins with the schenckprocessfpm.com digital domain shifting to coperion.com. The company’s website and emails, including those from technology brands such as Baker Perkins, will change. The new website can be found at coperion.com/fpm.

Unlike other valves that seal with friction, Posi-flate’s unique butterfly valve uses an inflatable seat to seal with air pressure. Thus it requires less torque and a smaller actuator, resulting in lower cost. Plus, the seat automatically compensates for wear, providing longer life. Some users have reported over six million cycles and the valves are still going strong.

Less friction

Low torque

Low maintenance

Lower actuator costs

Longer valve life

More reliable

Brixworth Engineering, manufacturer of the globally renowned Benco engine stands, has produced its largest-ever sidemounting turnover stand. Supplied to the Croydon facility of leading power transmission specialist Voith Turbo, the Benco 1050 (an upgrade to Brixworth’s standard Benco 1000 engine stand) is helping this progressive plant to inspect and service a variety of engines and transmissions.

With a load capacity of 5000 kg (at 500 mm from the mounting spindle) and a turning capacity of 10,000 Nm, the Benco 1050 supplied to Voith Turbo facilitates the manipulation of complete engines for inspection, repair or modification. Moreover, it is a mobile version featuring a motor drive to deliver rotational speed up to 4 rpm, although customers can opt for floor mounting and manual operation if preferable.

Control of the Benco 1050 at Voith Turbo is via a fixed pushbutton station, with pendant control available as an option. As a further point of note, Brixworth designed and manufactured additional mounting arms to minimise deflection throughout the loading and rotation process.

Rugged, cost-effective Benco engine stands are ideal for undertaking a whole host of newbuild, repair and refurbishment operations quickly and easily. With these popular engine stands, users can rotate or horizontally and vertically manipulate engines

with ease to minimise the dangers of personal injuries associated with the manual handling of heavy loads. An adjustable column facilitates working at a convenient height while maintaining access to all aspects of the operation.

Although a comprehensive range of standard models is available, Brixworth has considerable experience in the design and manufacture of bespoke engine stands to suit individual customer requirements. The company can undertake site surveys and provide engineers to evaluate any special demands, ensuring the supply of a safe, effective and cost-competitive solution.

Bulk Solids Today is the bi-monthly digital journal covering the storage, processing and handling of materials ranging from fine powders to the heaviest raw materials. To subscribe to Bulk Solids Today magazine or for more information, please feel free to visit www.bulksolidstoday.co.uk

Developed over many years, Benco engine stands today enjoy a worldwide reputation for simplicity and reliability in the rotational handling of heavy, out-of-balance loads with the added benefit of near backlashfree movement. The stands, more than 5000 of which have been produced for use in over 20 countries, can reduce man hours by up to 50% through the elimination of non-productive handling procedures. They fully comply with all current working practices and safety regulations, and come with an extensive guarantee for complete peace-ofmind.

If you would like to subscribe to receive a regular copy of the digital edition of Bulk Solids Today magazine, you can subscribe on our website - www.bulksolidstoday.co.uk

If you are interested in advertising within Bulk Solids Today magazine or supplying editorial content, please feel free to get in touch using the details on our website or below.

Bulk Solids Today is sent to our digital readership of over 9,000 Chief Engineers, Operations Managers and Technical Managers from within sectors including Chemicals, Food & Drink, Mining, Quarrying, Transport/Distribution, Recycling & Waste Management and more.

www.bulksolidstoday.co.uk

The Screencore range of Orbiter trommels is available in a variety of sizes, encompassing features making them ideal for construction, demolition, recycling and aggregates applications. Mobility, productivity and fuel efficiency have been inbuilt into the expanding range, with Orbiter trommels now found throughout the world working on a variety of materials.

Screencore has since its inception used its extensive expertise to develop and introduce a range of modern, mobile crushing, screening, stockpiling and pugmill solutions. The range has in a relatively brief period developed a reputation that its modern productivity and environmentally friendly attributes are highly suited to aggregate production on a truly global scale. In addition to the processing of virgin rock and the recycling of construction materials, members of the Screencore ranges have also proved to be ideal processing organic materials for composting and other green waste schemes.

“Screencore continuously engages with our dealers and end-users to innovate and refine our products,” explains company director Ciarán Ryan. “As a result, we have developed a range of crushers,

screens, pugmills, stockpilers, and now trommels, that are specifically designed for the efficient handling and processing of a variety of materials. The new Orbiter trommels, for instance, are particularly adept at producing accurately sized aggregates from primary and secondary sources. Like all our products, the new Orbiter trommels prioritize ease of transport and user-friendliness, ensuring that they meet the practical needs of our customers while setting new standards in the industry.”

The Screencore Orbiter trommel range, as well as other members of the Screencore product range, has rapidly gained recognition globally, particularly Australasia, Africa, Europe and the United States. For example, in France, an Orbiter 237 trommel, distributed by Screencore’s partner Starloc Auvergne, has been instrumental in processing various materials at a specialized recycling site. This model is particularly suited to large scale operations with its +7m (23’) drum length and radial fines stacker. Additionally, the Orbiter 237 features a 12m³ (18yd³) dump hopper and is tailored for the largest operators

in the industry. “The 1,200mm (48”) wide feed belt connects to a load sensing drum, ensuring that the machine maximizes productivity autonomously,” explains Ciarán Ryan. “Each element of the Orbiter 237 is specifically designed to ensure continuous operation without the need for constant operator input.”

The Screencore range of Orbiter trommels consists of three models, ranging from the powerful yet compact 125, to the 237, which is aimed at the larger producers. The Orbiter 125 is designed for work sites where space is at a premium and ideal for a contractor who needs to relocate quickly and often. The Orbiter 175 delivers high productivity from a compact chassis and features hydraulic folding conveyors and drum angle adjustment with a large infeed hopper and a Cat 130hp engine.

A new, but yet to be released development, is the Orbiter 206. “The 206 is the very latest Screencore trommel, and we are genuinely excited about it. It will deliver high levels of mobility, cost effectiveness and, ultimately, profitability for its users. It encompasses all the latest Screencore developed and patented features and will be released in Europe over the coming months,” explains Ciarán Ryan. “Its 20’ x 6’ drum is interchangeable with all other similar models, meaning it can seamlessly fit into an existing fleet and enable the utilization of any existing stock of spare drums.”

Often working alongside the Orbiter trommels, Screencore’s stackers also come with power solutions to suit various customer requirements. Now

further aiding customers, Screencore has further added to the potential of its flexible cost-effective environmentally friendly trommel range as both its 470 and 480 stockpilers come with an electric motor and can be run attached to an Orbiter trommel. With this Dual-Power, the trommel itself supplies the power to drive the machine. This means that the screening and stockpiling operation is significantly less expensive and more environmentally friendly as only one power source is being used. Furthermore, if the trommel is powered from the mains or a gen-set, or is electric powered for example, then emissions are negligible and operating costs are a fraction of a traditional set-up.

“With their sturdy construction, accurate sizing, and penny pinching running costs, Screencore’s Orbiter range – and accompanying stockpilershas proved on numerous occasions to be the ideal solution for recycling and processing of primary and secondary aggregates. In addition to flexible power solutions, including Dual-Power, we also offer a complete range of bespoke electric trommel systems for indoor operations,” concludes Ciarán Ryan .

Liebherr, in collaboration with Krank technology, has announced the launch of its own hosted digital platform, the Used Equipment Marketplace, specifically tailored for selected product segments. This initiative is a first for a major global OEM and marks a significant advance in the disposal of used equipment, focusing on construction and material handling machines.

One of the largest construction equipment manufacturers, Liebherr, has launched its own digital Used Equipment Marketplace. The new online platform is underpinned by Krank technology and provides a secure and user-friendly method to dispose of the thousands of used machines that Liebherr acquires as part of operations annually. Liebherr’s Used Equipment Marketplace is the latest example of Krank technology in action, demonstrating the platform’s robustness, scalability and ability to cater to businesses of all sizes with used equipment to dispose of.

Daniel Hecker, Business Development Sales at Liebherr-EMtec GmbH, commented on selecting Krank as the development partner: “We were looking for an expert in creating marketplaces for used construction equipment – and Krank is the standout partner. With the launch of this marketplace, focused on our specific product segments, we provide a central platform for our global used equipment business. Customers are able to independently search our virtual marketplace for the used equipment they need, while our sales partners register and manage their listings via the platform and its associated apps.

“The marketplace brings together on a single platform the entire supply and demand sides of our used equipment business,” Hecker continues. “It combines Liebherr’s strengths of personal advice and customer relationships with the much greater visibility a global digital marketplace offers.”

The Krank platform has been tailored specifically to meet Liebherr’s precise needs, upgrading and replacing existing systems to enhance service delivery. Designed with the user in mind, Liebherr’s Used Equipment Marketplace provides a wide selection of the company’s pre-owned machinery, including

wheel loaders, tracked and wheeled excavators, as well as attachments and spare parts from Liebherr’s sales and service partners. With its advanced search and filtering tools, users can easily find what they need. The platform supports global accessibility and promotes sustainability by extending the operational life of equipment, offering cost-effective, resourceconserving solutions.

The marketplace is accessible through a website and will soon be available via a mobile application. This app will feature personalized watch lists, realtime notifications, and direct seller communication, simplifying the equipment purchasing process. By selling directly through its platform, Liebherr maintains complete control over profitability, and eliminates the need for intermediaries in the sale process. This approach preserves against margin erosion for Liebherr and offers buyers the assurance of purchasing at the best price directly from the owners of the equipment.

“Our collaboration with Liebherr, one of the world’s largest and most respected manufacturers, is reshaping how companies manage their equipment lifecycle,” said Mark Turner, CEO of Krank. “Liebherr taking charge of selling its own used equipment shows how digital transformation is empowering companies to move away from traditional disposal routes. We are pleased to have our technology underpin Liebherr’s new digital marketplace.”

If you would like to subscribe to receive a regular copy of the digital edition of Bulk Solids Today magazine, you can subscribe on our websitewww.bulksolidstoday.co.uk

If you are interested in advertising within Bulk Solids Today magazine or supplying editorial content, please feel free to get in touch using the details on our website or below.

Bulk Solids Today is sent to our digital readership of over 9,000 Chief Engineers, Operations Managers and Technical Managers from within sectors including Chemicals, Food & Drink, Mining, Quarrying, Transport/ Distribution, Recycling & Waste Management and more.

www.bulksolidstoday.co.uk bst@abbeypublishing.co.uk

Tuf-Lok ring grip pipe and tube couplings are rugged, heavy duty, self-aligning and self-grounded couplings with a high end pull. They can be used for almost any application where pipe or tube ends need to be connected. The Tuf-Lok self-aligning couplings install quickly and easily with little effort.

Features

• Self-aligning

• Self-grounding

• High pressure rated

• Full vacuum rated

• Stainless or mild steel

• Usable on thin or thick wall pipe or tube

• Low cost

• Reusable

• Absorbs vibration

• Externally leakproof

GEODIS has recently commissioned an AutoStore system provided and installed by Dematic, a global leader in automated solutions and software for warehouses and distribution centres.

GEODIS, a leading global supplier of transport and logistics services and headquartered just outside Paris, entrusted Dematic with installing a stand-alone system for its customer, Nexter, which is now part of KNDS Group. This organisation is one of the leading European manufacturers of military land systems based in Germany and France. The solution has been installed in a fully automated warehouse in Moulins, France.

For this new automated facility, Dematic has supplied an AutoStore system with 12,500 bins, four R5 robots and two conveyor ports installed within the 22,000 square-metre (236,000 square feet) warehouse. Nexter, which designs and integrates land defence equipment systems, plans to use the warehouse for maintenance and operational

services and can stock around 32,000 items on-site.

“The Dematic solution is proving to be extremely robust and has fully met our expectations in terms of efficiently utilising our floor space. It supports the ramp-up of Nexter activities within KNDS, aimed at maintaining land equipment in operational condition,” explains Thierry Schnepp, the director of business expertise capabilities at GEODIS.

“With the integration of automated and robotic equipment, we are fully supporting the growth strategy of GEODIS. We can also demonstrate our capacity to provide solutions adapted to the needs and constraints of modern logistics while establishing a third-party value chain based on customer experience and trust. It clearly opens the door for new collaboration,” notes Alain Bussod, the president at Dematic France.

The system operates on GEODIS’ own warehouse management software platform, Altesse.

For more information on Dematic, visit dematic. com and follow us on LinkedIn, Facebook, and X.

Using a combination of GPS technology, sensors and the vehicle’s electric motor or ic-engine performance information, telematics systems deliver the vital statistics that every warehouse or distribution centre manager needs to understand precisely how productive and cost-efficient their materials handling equipment (MHE) is and, arguably most importantly of all, how safely it is being operated.

For example, it is generally understood that getting the best value from any material handling budget means constantly reviewing intralogistics systems to make certain that each truck is being used safely and effectively throughout every shift. Truck-connected telematics technology will flag-up any under-used vehicles within the fleet - regardless of whether a company has several hundred units or one or two machines in operation.

The data generated by telematics to highlight trucks with lower-than- expected usage rates could prompt users take the necessary action to drive down their monthly MHE running costs. For instance, trucks might be switched to other areas of the business where they can be more productive or, in some cases, equipment may even be removed from the fleet altogether if the figures fed back by the telematics system demonstrate that usage rates consistently fall below what is forecast.

But, of course, efficient forklift fleet utilisation is about more than just knowing how often a truck is used: managers need to consider how operators are performing too. For example, how busy are they during their working day? Could they be more helpful if they were reassigned to undertake alternative tasks during their shift? Are more drivers needed to run the operation smoothly or is the opposite the case? Are drivers operating the trucks safely? By tracking individual driver activity, telematics delivers the kind of actionable data that will answer these questions and plenty more.

On-site safety is another cornerstone of costefficient materials handling that can be improved by the data gathered by telematics systems. With losses incurred because of accidental damage to either the goods, building or the truck itself typically representing 5-15%of a forklift’s operating expenses, if on-site safety is considered in pure monetary terms alone the benefits of operating a safe site are obvious.

Telematics systems, such as Toyota’s I_Site, can help safety conscious companies reduce the potential for accidents in several ways. These include pinpointing precisely where forklift mishaps take place. If the data indicates that a certain location within the warehouse is something of an accident ‘black spot’, management will be alerted and, if necessary, additional safety measures can be introduced to cut the likelihood of further incidents in and around the area.

Some telematics systems require each operator to use their own PIN code or smart access card to operate a truck. This feature not only restricts non-

qualified personnel from operating the machinery but the fact that it makes operators accountable for their actions during a shift means that they should take far more care when going about their daily routine. Naturally, this results in a safer environment and reduced product, truck or building infrastructure damage.

A significant percentage of a company’s MHE budget can be taken up by the efficiency – or otherwise – of the battery changing and recharging process but, by using data supplied by on-truck telemetry to monitor battery and charger performance, potentially costly problems can be avoided. Failure to properly oversee the critically important recharging regime could also damage the environment and will certainly result in higher than necessary operating costs.

Companies want to collect as much data about their business processes as they can get and there is almost no limit to the type of information that can be supplied by telematics-connected trucks. But if the statistics can’t be harnessed because they are presented in a way that only a professional data scientist could understand they will be of little or no value. In fact, having plenty of data can become more of a liability than an asset if users feel overwhelmed by it or have no idea how to use the figures in ways that will benefit their company. And, if that happens, the data tends to be left to gather dust!

Toyota is a market leader in telematics and introduced its I_Site MHE telematics technology more than 20 years ago. From the outset, I_Site has been designed to deliver valuable business insights, rather than simply supply users with figures and statistics. The system gives logistics professionals knowledge that they can use for the benefit of their businesses by presenting data as meaningful, helpful and actionable Information.

But by presenting a crystal-clear overview of everything users need to measure, analyse and improve their material handling operation I_Site allows logistics managers to take the sometimes-difficult decisions that are needed to keep full control of the intralogistics processes that they oversee. And by doing so, their companies will experience the true value of telematics.

I_Site is factory fitted as standard on all Toyota warehouse trucks and the latest version of the system will receive its UK launch this summer.

The compact but powerful characteristics of the ElectroMax Overband Magnet are highlighted on Bunting’s stand C9 at the Hillhead quarrying, construction and recycling show (25-27 June, 2024). The ElectroMax is accompanied on the stand by the TN77 and meTRON 05D metal detectors, and a permanent suspension magnet.

Bunting is one of the world’s leading designers and manufacturers of magnetic separators, eddy current separators, metal detectors and electrostatic separators. The Bunting European manufacturing facilities are in Redditch, just outside Birmingham, and Berkhamsted, both in the United Kingdom.

Magnetic separators and metal detectors operate in most quarries and mines, removing and identifying tramp metal that could damage process plant such as crushers and screens. In recycling operations, magnetic separators operate alongside eddy current separators, recovering both ferrous and non-ferrous metals. With decades of experience and a wide range of equipment designs, Bunting’s engineers assess the site conditions and the potential installation prior to recommended the optimum solution.

For ferrous metal separation, the ElectroMax and ElectroMax-Plus range of electro overband magnets separate the heavier and more awkwardly shaped tramp metal frequently missed by other designs of overband magnet. The lightweight, compact but powerful electromagnet is easily installed onto new and existing conveyor systems and is ideal for applications where space is limited or when extra separation power is required.

The ElectroMax and ElectroMax-Plus Overband Magnet uses a strong and deep electromagnetic field to lift and separate the ferrous metal out of conveyed materials such as waste, mined ore, and quarried rock. Unlike other designs of electro overband magnet, the electromagnet is cooled with air rather than oil. This significantly reduces the weight and size, whilst being environmentally friendly by not using oil.

The ElectroMax Overband Magnet is 185% stronger than equivalent permanent overband magnets and 25% lighter. The development was in response to customers’ requests for smaller, lighter, and more compact Electro Overband Magnets without compromising separation performance.

The ElectroMax-Plus has additional power and, at a suspension height of 500mm, is over 105% stronger (in terms of Force Index) than the equivalent ElectroMax.

Since April 2019, Bunting has built and shipped over 120 ElectroMax and ElectroMax-Plus Overband Magnets for a value exceeding £3 million.

Bunting’s range of magnetic separators extends to standard permanent overband and suspension magnets, oil-cooled electro overband and suspension magnets, drum magnets, and pulley magnets. The optimum design of magnetic separator depends on the installation and the metal separation objective.

Metal detectors commonly operate alongside magnetic separators, with the TN77 model being an industry standard. The TN77 Industrial Metal Detector detects damaging tramp metal present in conveyed materials such as aggregates, mined ore, and recycled materials. This includes identifying both tramp iron and low-grade manganese steel (e.g. digger teeth). Once detected, the problematic metal is removed either manually or automatically, preventing damage to screens, crushers and conveyors. The TN77 design is easy to install and simple to operate, making it one of Bunting’s most popular metal detectors.

The closed tunnel type meTRON 05 C Metal Detector provides high-sensitivity detection in rough industrial environments including encapsulated or loose tramp metal present in conveyed, vibratory chutes, gravity-fed and material-slide transported materials. Once detected, the problematic metal is removed either manually or automatically, preventing damage to processing equipment. The meTRON 05 C typically protects equipment including grinders, crushers, mills, chippers, and shredders.

For non-ferrous metal separation and recovery in recycling operations, Bunting has a range of Eddy Current Separators. With either concentric or eccentric magnet rotors, the eddy current separator separates small non-ferrous metals, such as aluminium, copper and zinc, down to 3mm in size.

“Hillhead is an important show for Bunting,” explained Bradley Greenwood, Bunting’s European Sales Manager. “Many of our existing and potential customers are either exhibiting or visiting. The show provides the ideal opportunity to help solve metal separation problems, whilst also displaying production scale equipment on the stand.”

For further information, please contact us on press@buntingmagnetics.com or visit our website: Bunting-Redditch – www.bunting-redditch.com

Develon, formerly known as Doosan Construction Equipment, has launched the new DX140RDM-7, the latest addition to the company’s successful range of demolition excavators. Like the three larger models from 31 to 61 tonne, the new DX140RDM-7 22.5 tonne demolition excavator offers multiple configurations to choose from, providing the customer with a range of solutions depending on the project to be completed, including a multi-purpose version that can be used for other applications on site as well as demolition.

In fact, the DX140RDM-7 offers even more choices, starting with a ‘Monolithic’ variant unique to this model that features only a demolition arm without any possibility of interchangeability. Alternatively, like the larger machines, the DX140RDM-7 is also available in a dual format utilising a modular boom design and hydraulic lock mechanism, allowing the user to change between different arms for demolition and digging using the same machine.

In the fixed ‘Monolithic’ version of the new DX140RDM-7, the impressive working range allows

the machine to work with a demolition attachment to a maximum height of 16 m. The recommended maximum tool weight in this mode is 1450 kg. In common with the other models in the demolition excavator range, the DX140RDM-7 offers high visibility and a tiltable cab, particularly suited to high reach demolition applications and providing a 30 degree tilting angle.

In the dual purpose version of the DX140RDM-7, the pin height and maximum tool weight are 14 m and 1450 kg, respectively (with a 2 m extension as an option). All the components such as the undercarriage, the tilting cab and the shoes remain the same as in the fixed version, only the modular boom design and hydraulic lock mechanism are different, allowing the user to swap between the demolition and digging arms.

The innovative design ensures it is a simple process to change between a demolition boom and an earthmoving boom to accomplish different types of work on the same project. A special stand is provided to facilitate the boom changing operation, which is based on quick-change hydraulic and mechanical coupler connections. A cylinder-based system is used to push the locking pins into place to help complete the procedure.

The multi-boom design also allows the earthmoving boom to be mounted in two different ways, which with the demolition boom, provides further flexibility with a total of three different configurations for the dual purpose base machine.

The DX140RDM-7 has a hydraulically adjustable undercarriage, which extends to a maximum width of 3.7 m to provide optimum stability when working on demolition sites. The width of the undercarriage can be retracted

hydraulically to 2.5 m in the narrow width position, which is ideal for transporting the machine. The mechanism is based on a permanently lubricated, internal cylinder design which minimises resistance during the movement and helps to prevent damage to the components.

Like all Develon demolition excavators, standard safety features on the DX140RDM-7 include a FOGS cab guard, safety valves for the boom, intermediate boom and arm cylinders and a stability warning system.

For more on Develon, please visit the website: https://eu.develon-ce.com/en/

Drydocks World today announced a series of significant enhancements to its Propeller Repair Services’ operational capabilities, solidifying its position as the one-stop solution for comprehensive propeller repair needs, catering to all sizes and types with unparalleled efficiency and precision.

The facility is uniquely equipped to handle insitu repairs for minor damages directly on the vessel without removing the propeller and more extensive repairs within its workshop, which includes a dedicated area and pit for propeller work. The provision of nickel aluminium bronze alloys for the fabrication of missing parts and a comprehensive suite of repair techniques, such as laser pitch checking and blade profiling, further underscore the yard’s expanded capabilities.

The company has expanded its team of qualified and highly skilled professionals equipped to tackle the full spectrum of propeller repair needs and ensure adherence to the highest standards set by the International Society of Classification Societies (IACS).

Capt. Rado Antolovic, PhD, CEO of Drydocks World, said: “Our improved propeller repair services highlight our dedication to maritime excellence and leadership, with a focus on innovation ensuring unparalleled efficiency and quality.

Our unique in-house ability to provide immediate solutions for unforeseen propeller issues sets us apart, earning the trust of shipowners who value our swift and thorough responses to their repair needs.”

Over the past two years, Drydocks World has successfully repaired over 20 fixed pitch propellers and 50 CPP blades, contributing significantly to its revenue and underscoring the effectiveness and efficiency of its service. The achievement demonstrates the yard’s enhanced competency and commitment to meeting the evolving needs of the maritime industry.

In addition to the focus on propeller repair capabilities, Drydocks World has unveiled a new Cryogenic Pipe Shop, a cutting-edge Gasket Manufacturing Facility, and a new CNC Plate Cutting Facility, each designed to support the company’s vision of continuous improvement and technological advancement in maritime services.

The company has upgraded its capabilities with a new Cryogenic Pipe Shop to support the growing needs of the oil, gas, and renewable energy sectors. The facility, equipped with advanced welding and fabrication tools, is set to lead the region in exotic pipe fabrication, handling materials like stainless steel and titanium, with an annual capacity of nearly 350,000

inch dia of pipe.

Further enhancing its fabrication workshop, Drydocks World recently launched a new CNC plate-cutting facility, equipped with machines for enhanced plasma cutting, bevelling, and oxyfuel cutting. The addition of auto sensors and an inkjet printer for plate marking reflects the company’s commitment to technology and quality.

A Gasket Manufacturing Facility with fully automated CNC technology designed to streamline gasket production was also inaugurated to produce a versatile range of gaskets, operating 24x7 to support continuous operations across all production units.

Capt. Antolovic added: “ Our new facilities underscore our commitment to excellence and innovation, offering clients unmatched services that redefine industry standards through our investment in technology and talent.”

The Mechanical Department at Drydocks World also underwent various infrastructure and equipment enhancements to increase productivity and efficiency while generating additional revenue. The advancements complement the existing facilities and accommodate simultaneous project works, ensuring timely delivery with the highest quality and safety standards.

Drydocks World’s continued investment in its facilities and capabilities highlights its role as a pivotal player in the global maritime industry, dedicated to setting new standards in quality, safety, and service.

The Bella dryer/cooler offers thermal efficiencies to 80 percent or better because air flows around material while it is suspended in the weightless zone. The result is a more consistent material.

Flexicon’s PNEUMATICON® Pharmaceutical Grade Filter Receiver for medium- to high-throughput vacuum and positive-pressure conveying of extra-fine, difficult-to-handle and/ or contamination-sensitive bulk solid materials, features designs to readily change/inspect filter cartridges and sanitise the interior.

A gas-spring-operated lid provides access to a removable filter plate, allowing cartridge filters to be removed and inspected or cleaned from the top, eliminating product hold up points and cleaning difficulty associated with side access doors and bolted-in filter plates. Tri-clamp fittings additionally allow rapid disconnection and cleaning of all accessory parts and lines.

Constructed of #316L stainless steel to pharmaceutical standards, the receiver housing is devoid of interior ledges, cavities or recesses that could harbour contamination, and features three tapered filter cartridges that separate conveyed material from the air stream.

Automatic reverse pulse-jet cleaning of the pleated filter media maintains separation efficiency, while the tapered filter design improves material release.

Available in 450 and 610 mm diameters, the design can accommodate level sensors, pressure monitors, and other accessories.

Typical applications include separation of bulk pharmaceuticals, nutraceuticals, foods, and other contamination-sensitive materials being conveyed to tableting machines, packaging lines and other downstream processes.

Flexicon also manufacture complete pneumatic conveying systems, flexible screw conveyors, tubular cable conveyors, bulk bag dischargers, bulk bag

conditioners, bulk bag fillers, bag dump stations, drum/box/container tippers, weigh batching/ blending stations and plant-wide bulk handling systems. Contact Flexicon Europe Ltd, +44 (0)1227 374710, sales@flexicon.co.uk, www.flexicon.co.uk

Leading materials handling company, Cablevey Conveyors, operating as part of Automated Handling Solutions (AHS), has announced the launch of Cleanvey - a groundbreaking development in the automation of Clean-in-Place (CIP) processes for tubular drag conveyors. The solution is set to redefine standards in food safety and production efficiency within the food processing industry.

Cleanvey is engineered to automate the CIP process, allowing for efficient, thorough cleaning of tubular drag conveyors, crucial in maintaining sanitary compliance and ensuring the safety of food products. Designed with integrated water line hookups and pre-programmed cleaning options, this mobile unit simplifies the cleaning process, enabling a technician to initiate a comprehensive cleaning cycle with just the press of a button.

Tailored to meet the industry’s demand for a more streamlined, less labour-intensive cleaning process, Cleanvey significantly reduces the time and effort traditionally required for conveyor cleaning, offering a customisable, user-friendly approach that enhances productivity and minimises downtime. In addition to its cleaning capabilities, the solution offers advanced features such as optional sprayballs

for targeted cleaning of residues and a sanitary blower that drastically reduces drying times, both further accelerating the readiness of conveyors for subsequent use.

Chris Brennan, director of engineering - AMP/ AHS, said: “By automating the CIP process, we are not just improving efficiency, we are also enhancing the consistency and reliability of cleaning, which is vital for food safety. Cleanvey is designed to be easy to use, highly effective and adaptable to various cleaning needs, making it an essential tool for any food processing facility.”

Cablevey Conveyors is committed to innovation and customer support, providing a mobile, versatile and efficient solution to meet the evolving needs of the food processing industry. Cleanvey reflects the company’s commitment to advancing conveyor technology and upholding the highest standards of food safety and production excellence.

Customer demonstrations will be available at the new AMP/AHS facility in Darwen, Blackburn-Lancs, from early Summer 2024.

For further details on how Cablevey’s Cleanvey solution can transform your food processing operations, please visit Cablevey Conveyors.

Dehydrated fruit processor Zarecki has made a name for themselves across Europe since launching in 2017. Processing over 6,000 metric tons of fresh fruit every year, Zarecki brings together locally grown produce and modern technology to provide food manufacturers with top quality ingredients for their breakfast cereals, snack bars, confectionaries and more. In 2022, while expanding production with a new line that sweetens and dehydrates different types of berries, Zarecki turned to Key Technology and selected an integrated vibratory conveyor system with five Impulse™ shakers.

“The fruit on this section of our new processing line is as delicate as jellyfish, so our highest priority when choosing shakers was protecting the quality of these fragile berries,” said Marcin Sosnicki, Managing Director at Zarecki. “Our new conveyor system also needed to handle a wide variety of fruits – you’d be surprised how differently a cherry behaves from a blueberry, plus we handle our apple products on this line for part of the year as well. Versatility and fast changeover were important criteria during our selection process.”

“We knew Key was the ideal partner for this project because of their deep expertise with many kinds of food processing facilities worldwide. They bring creativity and ingenuity when identifying what will work best for unique applications like ours,” explained Sosnicki. “The Key team took extra steps to research and test our products before presenting us with their recommendations.”

Designed for processing and packaging lines that require precise metering and low maintenance drives, Key’s Impulse shakers are ideal for product mixing, ingredient feeding, scale feeding and more because they start and stop quickly, which helps maximize product quality, throughput and line efficiency. Impulse is equipped with dedicated solidstate controls that enable conveying pan amplitudes to range from zero to 100 percent for superior production versatility.

“The Key team visited us in Poland two or three times to fully understand our operations during the design process and tailor our conveyors to fit our existing layout. Then, a Key supervisor came out to oversee the line assembly, installation, commissioning and first production – we never felt like we were on our own,” said Sosnicki. “We had high expectations for Key’s customer service, and they exceeded them.”

Running at speeds of up to two metric tons of fruit per hour, Zarecki’s new line sweetens cherries, currants and blueberries with infusion tumblers, which discharge the syrupy product into a flume system.

From there, product is run through a series of three Impulse conveyors with specialized screens that desyrup and de-juice the fruit. Next, an Impulse transfer conveyor directs the product 90-degrees around a corner and feeds an Impulse spreading conveyor featuring custom-designed lanes, which perfectly spread the infused fruit for presentation to the dryer’s infeed system.

When this line is running apples, the product skips the de-syruping shaker and moves directly from a separate apple preparation line to the first Impulse de-juicing shaker, since the apples are not infused.

“One impressive aspect of this integrated conveyor system is it acts as a buffer between batch processing upstream and continuous processing downstream at the dryer, which needs to be fed constantly,” noted Sosnicki. “And since Impulse is equipped with electromagnetic drives, we can simply adjust the speed from the control panel when needed. This makes things easier for our operators at the same time it helps preserve our product quality and increase our line efficiency.”

Impulse’s magnetic drives also help minimize maintenance, with no sliding or rotating parts to wear and no belts or bearings to fail. Oil-free drives help protect food safety while rugged construction makes these conveyors ideal for 24/7 use in harsh environments. All units are dust- and moisture-resistant with an IP65-rated enclosure to ensure years of trouble-free operation. “Durability is a must-have in our processing facility to withstand our wet, hot environment and sticky, acidic products,” said Sosnicki. “Impulse fits our needs perfectly.”

“Overall, Key has been instrumental in helping us expand our business and provide the world-class dehydrated fruit that we are known for,” concluded Sosnicki. “We couldn’t have done this without Key and our Impulse shakers.”

Metso is launching productized FIT™ in-plant and Foresight™ overland conveyors for reliable material transportation in the mining industry. The standardized conveyor modules and premium components offer high capacity and layout flexibility as well as substantial savings in time and resources, from feasibility and design to implementation, thereby enabling higher lifetime productivity.

The high-capacity Metso Foresight™ overland conveyors are fixed or relocatable and connect the primary crushing station with the coarse ore stockpile. The Metso FIT™ in-plant conveyors are compatible with Metso FIT™ crushing plants that are designed for the most demanding mining applications.

“The modular FIT™ and Foresight™ conveyors take project ease, speed and productivity to the next level. We have designed these conveyors for easier planning, configuration, installation and maintenance with a wide range of modules and components. This enables our mining customers to get their in-plant and overland conveying systems up and running faster and brings a quicker return on investment,” says Guillaume Lambert, SVP, Crushing at Metso.

“Thanks to the standardized modular design of the conveyors, we have been able to shorten delivery time by up to 25% and set-up time by up to 15%. Metso premium components are used in the conveyors, and the use of ConveyInsights™ predictive maintenance and flow control technology can help our customers achieve their productivity targets. To improve the feasibility study process on Foresight™ overland conveyors, we developed the William Conveyor Explorer, an application software that is connected to our conveyor module range. It can be found in the new Metso Crush and Convey Resource Center. Our mining and EPC/M customers can enter their process and route data and then instantly assess multiple options and download the modules they need for efficient planning in their software environment. This development also supports mine electrification programs to reach fast decarbonization plans and targets,” notes Lambert.

To ensure continuous conveyor performance, Metso can provide a wide scope of services ranging from optimization and life-cycle services to premium wear and spare parts. Metso has installed over 1,000km of conveyors globally.

More information about Metso Foresight™ and FIT™ conveyors is available on our website.