Energy Efficiency pumpindustry

FEATURES:

• Import & export update

• Fire pump standards

• Water industry advocate

• History: Bob Moore interview

Meet the pump people

PIA Exhibition & Seminar 9-10 October 2012

Visit the exhibition for free, or register today for the seminar Register at www.pumps.asn.au

When?

Tuesday 9 October

Exhibition trade day and seminar (advance registration required) 9:30am - 5pm

Wednesday 10 October

Exhibition open to trade and public, 9:30am - 4pm

Where?

The Whitehorse Centre

397 Maroondah Highway Nunawading, VIC (At rear of Civic Centre)

The venue is within easy reach of the Eastern & Eastlink Freeways and there is ample free parking available.

Pump Industry Australia Incorporated

Kevin Wilson – Secretary PO Box 55, Stuarts Point NSW 2441 Australia

Ph/Fax: (02) 6569 0160 pumpsaustralia@bigpond.com

Harry Katunar – President KSB Australia

Ron Astall – Vice President Astech Consulting Services & United Pumps Australia

Brad Antrim – Councillor Grundfos Pty Ltd

Michael Bauer – Councillor Dynapumps

Geoff Harvey - Councillor Davey Products Pty Ltd

John Inkster – Councillor Brown Brothers

John Link – Councillor Link Pumps

Alan Rowan – Councillor Life Member

Keith Sanders – Councillor Australian Industrial Marketing & Life Member

President’s welcome

Iwould like to welcome all readers to the first edition of the pump industry magazine. It’s great to see that our industry has attracted enough interest to have its own dedicated magazine.

We need to remind ourselves that the Australian pump industry is a significant contributor to the Australian economy, with an annual market for pumping equipment estimated at $1,000 million annually, and over 2,500 people employed in manufacturing and distribution. We make an impact in many areas across the community from delivering drinking water, irrigating our crops, fire protection for our property, airconditioning for our buildings, enabling our power stations to deliver electricity, and helping our miners and oil and gas producers to process their export orders or ensuring your backyard swimming pool or domestic water supply runs smoothly.

Our proud history in Australian manufacturing goes back to the gold rush era in the 1870s. Although there has been major change over past decades with the introduction of new technology, removal of trade protection and globalisation, we still make a wide range of pumps here in Australia that are exported worldwide. Many of our local companies have been acquired by international operators; this has provided new opportunities for employees in the industry to develop their technical and professional skills, as well as ensuring we keep pace with latest manufacturing technology and design.

Our association now represents not only manufacturers but distributors, resellers, agents and other businesses supplying products and services to our market. Many of our smaller members are value adding by packaging pumps with ancillary equipment to supply innovative total package solutions to

their customers. There is a growing trend for pump users to seek out end to end total package solutions, with single point responsibility for delivering a fluid at the required capacity and pressure for an application. This presents opportunities and challenges for our industry, as does the focus on energy efficient pumping systems and fast tracking of projects and increasing demand for faster deliveries and a fiercely competitive market place.

Our vision is for PIA to play a leadership role in the growth of the Australian pump industry. The PIA offers our members, big and small, a voice to the market place, a way of showing our capability to general industry and consulting with government, providing education to industry and student, and a great way to network and learn from peers.

Our PIA executive officers are currently working in 3 main areas:

1. Publications; Alan Rowan is working on an update of our popular Pump Handbook and Friction Loss Book.

2. Standards; Ken Kugler is working with Standards Australia to amend the Fire Pump Standard AS 2941 We are also working with Sustainability Victoria and the E3 Committee in developing a minimum efficiency standard for pumps.

3. Marketing & Media; Keith Sanders produces our regular PIA newsletter, and our market research & statistics.

Upcoming PIA events include our pump exhibition in Melbourne on 9th & 10th of October and the AGM on November 22.

For more information on our activities and upcoming events, please turn to pages 10-11 or visit our website www.pumps.asn.au

Harry Katunar President, Pump Industry AssociationEnergy Efficiency pumpindustry

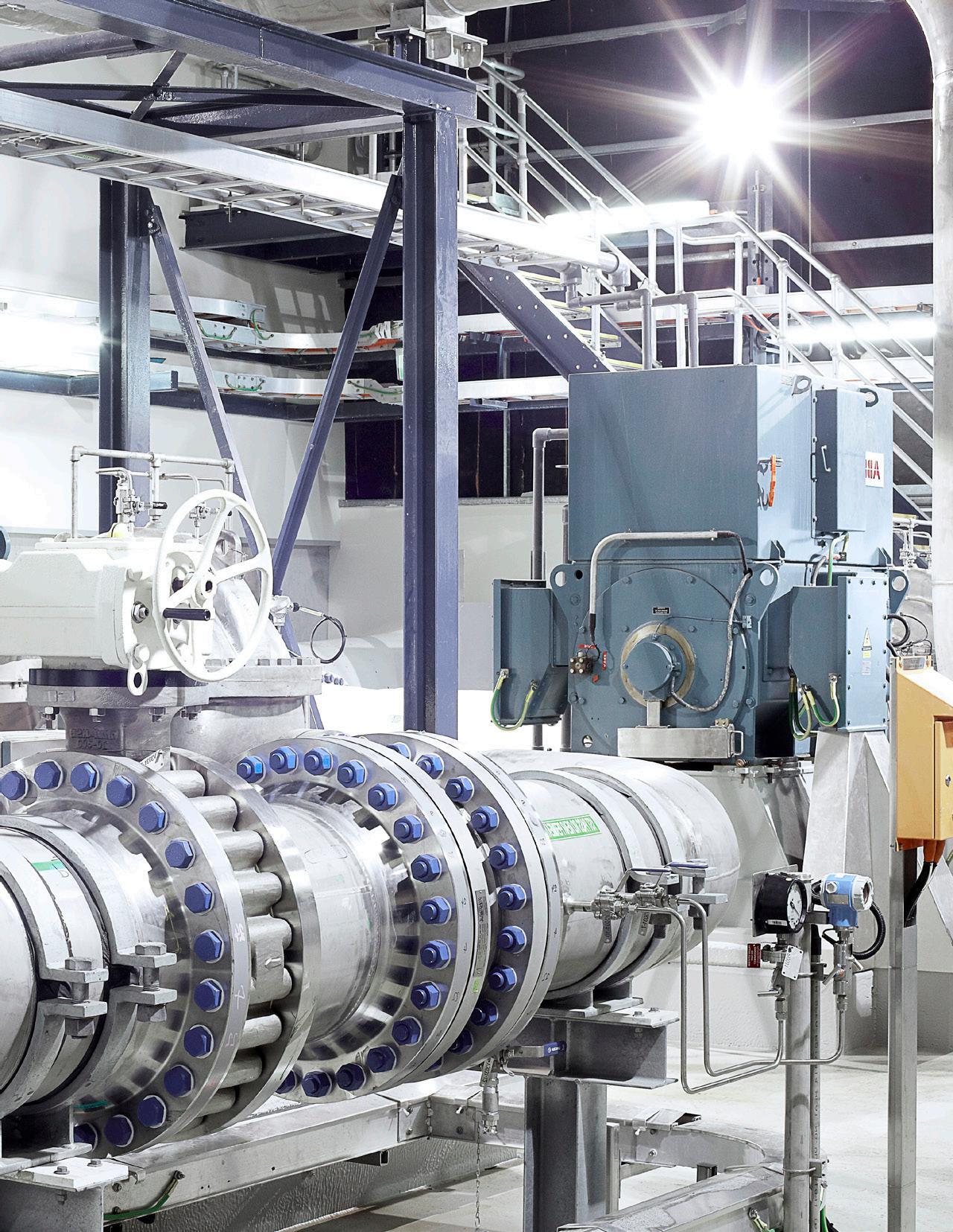

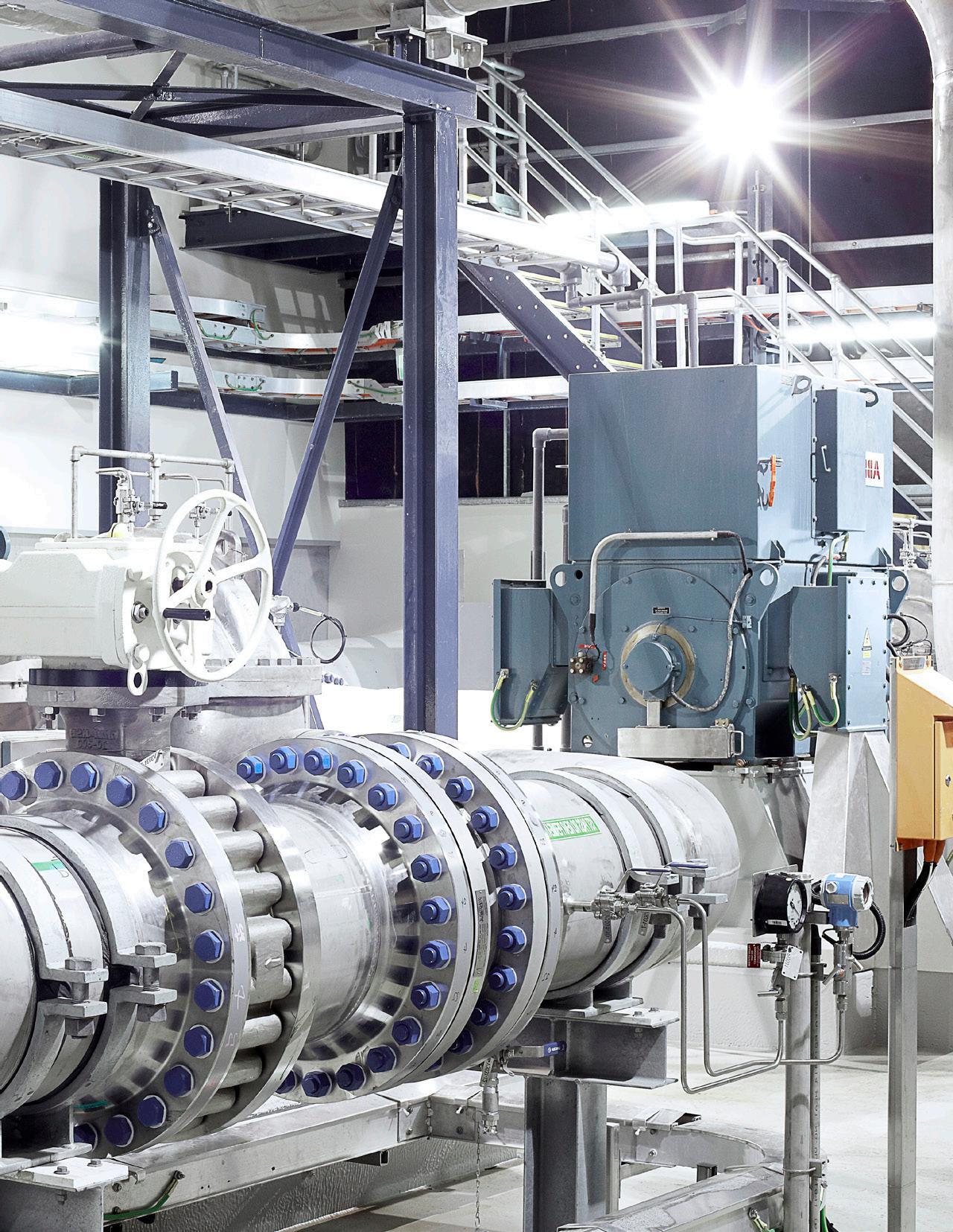

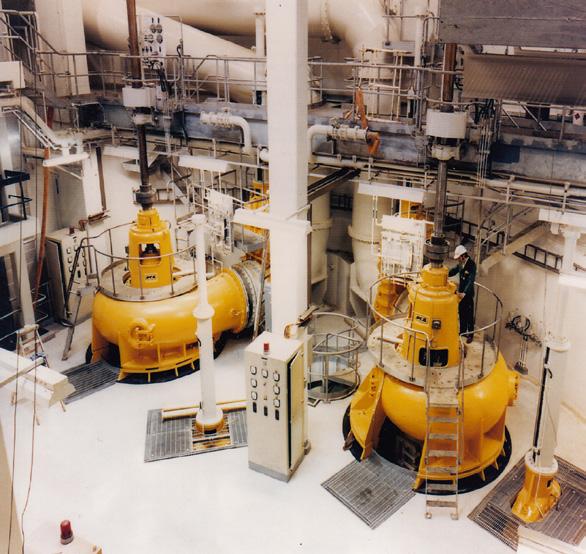

Cover shows pump, pipework and motor on the WA Water Corporation’s new Southern Seawater Desalination Plant

This magazine is published by Monkey Media in co-operation with the Pump Industry Association (PIA). The views contained herein are not necessarily the views of either the publisher or the PIA. Neither the publisher nor the PIA takes responsibility for any claims made by advertisers. All communication should be directed to the publisher.

The publisher welcomes contributions to the magazine. All contributions must comply with the publisher’s editorial policy which follows. By providing content to the publisher, you authorise the publisher to reproduce that content either in its original form, or edited, or combined with other content in any of its publications and in any format at the publishers discretion.

Published by Monkey Media Enterprises

ABN: 36 426 734 954

GPO Box 93, Melbourne VIC 3001

P: (03) 9440 5721

F: (03) 8456 6720

monkeymedia.net.au

info@monkeymedia.net.au pumpindustry.com.au magazine@pumpindustry.com.au

Design by Linda Tucker Happy Places Design www.happyplaces.com.au

ISSN: 2201-0270

Editor’s welcome

Welcome to the first edition of pump industry magazine. This is a magazine by the pump industry and for the pump industry and I thank the PIA for the opportunity.

As I’ve worked on this magazine, the one statistic I’ve heard again and again is that pumps are the second most common type of machinery in the world, so it is only right that they have their own magazine in Australia.

Of course, it’s a changing industry, as industry stalwart Bob Moore points out later in this issue. The industry has shifted from manufacturing to a larger number of importers. On the positive side this has resulted in many small-medium enterprises specialising in various areas and providing a high standard of technical expertise and service. As such, the Australian pump industry is in good health.

The users of pumps are as diverse a group as any, and this magazine is aimed at reaching a wide range of these end-users, communicating useful information about pump applications and being seen as a one-stop shop and trusted source for all pump informationwhatever industry you are in.

Pumps do not operate in isolation, and pump systems include a range of other equipment, such as motors and drives, valves and monitoring equipment. This magazine will seek to cover the full range of products and equipment used in pump applications. The editorial schedule on the second-to last page should give you some indication of the planned scope of future editions.

Many of the people I have spoken with have wondered why I would choose to publish a pumps magazine. For those who don’t know me, I have spent the last decade in trade publishing and have launched many successful industry titles. I have seen how an industry magazine can draw businesses together and grow the industry and the association, creating new opportunities by improving communication in and about the industry

The pump industry deserves a high quality magazine to showcase its capabilities, and this is what I hope to deliver. Any modern magazine must of course have a strong online component as well, and pump industry will be simultaneously published as a digital edition, as well as being supported by a website and newsletter containing exclusive online-only content.

I would like to thank all the members of PIA for their co-operation. I have spoken with virtually all members and I appreciate your time and ideas and have taken action on your input. I would particularly like to thank those who stepped up and backed this first issue with advertising and editorial.

The response has been overwhelmingly positive, and I’m very pleased to say the magazine is going ahead and we are here for the long haul, with your ongoing support and feedback.

Chris Bland Publisher and Editor

Acromet (Aust) Pty Ltd design and manufacture innovative solutions for a wide range of system applications.

• Customised Design

• Detailed Manufacturing

• Comprehensive Factory Testing

• Professional Installation

• Reliable Service

Acromet’s extensive experience and proven track record, delivers a cost e ective solution to meet the client’s operational demands.

pumpindustry 6

All the latest news

The Hydraulic Institute (HI) has recently updated two pump standards, covering allowable operating region for centrifugal and vertical pumps and submersible pump tests.

Plus a look at the latest projects and industry developments, both locally and internationally.

14

Energy efficiency

An update from Sustainability Victoria on the progress towards MEPs for pumps, as well as a look at optimising overhauls to save energy from Ray Beebe and a project update from KSB.

Import and export update

PIA has been routinely conducted an analysis of the import and export activity of commonly used pumps in the Australian market. This has been achieved by monitoring ABS Import and Export Statistics over the period 2003 – 2011.

32

Advocating for industry

The Australian Government’s Water Supplier Advocate, Bob Herbert AM, is leading a strategy to develop, improve and promote the Australian water industry and champion the firms in this vital sector.

34

Fire pump standards

A look at the requirements for fire pumpsets in new buildings in accordance with the Building Code of Australia and maintenance of existing fire pumpset installations. Fire pumpsets are critical infrastructure installations in many buildings and facilities throughout the world. The efficiency of water as a fire suppression agent is well recognised however water’s suppression qualities are often measured by the quantity and speed by which it can be applied to a fire.

PUMP PIONEERS

40

MAIN FEATURES 24 43

Robert J “Bob” Moore

Robert J “Bob” Moore is a Life Member of PIA and one of the true elder statesmen of the industry, having started working in pumps in 1955, and regarding himself as a lifelong pump-man. Chris Bland recently had the chance to ask Bob, now 85 and still going strong, to reflect on his life and career.

Acromet - Celebrating 50 year s of service

October 2012 marks 50 years since Acromet was founded, we take this opportunity to speak to General Manager Keith Gardner.

Balance matters

Imbalance of rotating components is one of the most common sources of machine faults in rotating assemblies, pumps and fans, and is a major cause of complete equipment failure.

COVER STORY

Converting the Indian ocean into drinking water

26

Most states in Australia have recognised the importance of purifying seawater using reverse osmosis technology and have desalination plants either operating or under construction in an effort to drought-proof our nation.

PROJECTS

Sewer bypass success

28

In August, Pump Affinity performed a key role in the 450mm rising main valve replacements from Wyong Shire Council’s Sewer Pumping Station (SPS) T22. SPS T22 receives sewage flows from 8 other sewage pumping stations, two private pumping stations and has over 4400 Equivalent Tenements in its catchment. The Peak Wet Weather Flow is up to 190L/sec.

Sweet upgrade

30

Recent negotiations between Sugar Australia and Stevco Seals & Pumps Victoria has resulted in Stevco Vic being awarded a tender to supply and commission a second replacement pumpset to upgrade the 100 year old water injection system.

TECHNICAL

36

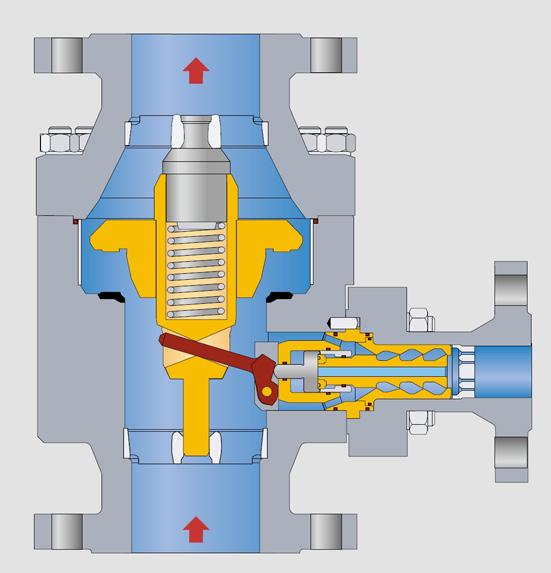

ARC valves - best practice

Centrifugal pumps are one of the most common pieces of process equipment. In modern process systems there is a requirement for multiple flow conditions to meet process requirements. In times of start-up, shutdown or abnormal process conditions system flow can be greatly reduced and flows through centrifugal pumps may fall below the pump’s minimum flow value.

Understanding pump curves

38

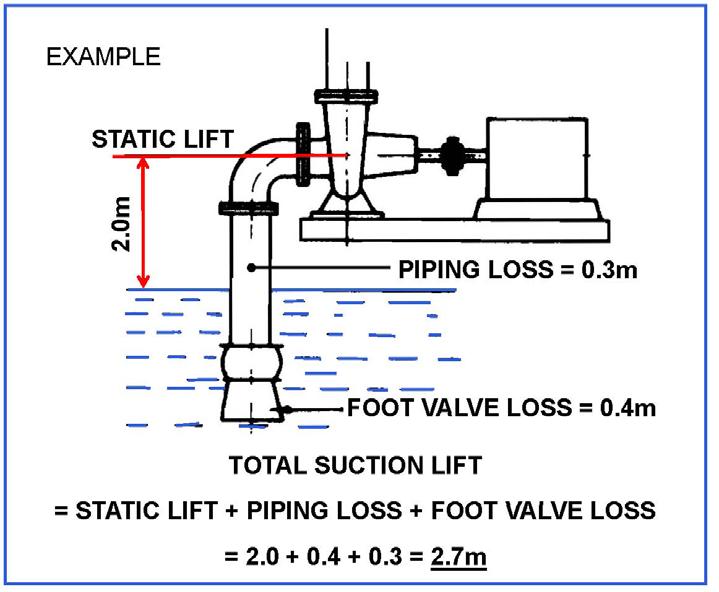

This edition, we look at Net Positive Suction Head Required (NPSHR) versus suction lift and self priming capability.

PUMP SCHOOL

Net Positive Suction Head (NPSH)

Many people are of the belief that a pump “sucks”. While not entirely incorrect, it’s easy to see why so many operators still struggle with pump problems.

Hydraulic Institute updates standards

The Hydraulic Institute (HI) has recently updated two pump standards, covering allowable operating region for centrifugal and vertical pumps and submersible pump tests.

HI updated the 1997 edition of the ANSI/HI standard on allowable operating region for centrifugal and vertical pumps and published ANSI/HI 9.6.3 – 2012 Rotodynamic (Centrifugal and Vertical) Pumps –Guideline for Allowable Operating Region.

The updated guideline discusses the effects of operating a rotodynamic pump at rates of flow greater than or less than the rate of flow at the pump’s best efficiency point (BEP). These effects influence the power consumption and life of pump components and, therefore, considering the operating rate of flow is essential to reliable, efficient pump operation.

The preferred operating region (POR) and the allowable operating region (AOR) are defined for rotodynamic pump types and related to specific speed. Factors that affect AOR are discussed and NPSH margin versus rate of flow is presented.

The guideline also indicates when stable or unstable operation may be expected based on typical system head curves, for pumps exhibiting a drooping head curve or a head curve with a dip. Considerations such as the robustness of a pump are also discussed.

HI has also updated the 2001 edition of

the ANSI/HI standard on submersible pump tests and published ANSI/HI 11.6 – 2012 Rotodynamic Submersible Pumps for Hydraulic Performance, Hydrostatic Pressure, Mechanical, and Electrical Acceptance Tests. The updated standard applies to customer acceptance testing of submersible pumps driven by induction motors, unless otherwise agreed or specified.

ANSI/HI 11.6 – 2012 provides uniform procedures for performance, hydrostatic, net positive suction head required (NPSHR), submersible motor integrity, and vibration testing of submersible pumps; and data recording and reporting of the test results. It is intended to define test procedures that may be invoked by contractual agreement between a buyer and manufacturer. It is not intended to define a manufacturer’s standard practice.

A submersible pump is defined as a close-coupled pump/motor unit designed to operate submerged in the pumped liquid. This definition includes submersible pumps operating in either a wet-pit or dry-pit environment. A standard test measures pump

performance from suction flange to discharge flange and electrical input power. It does not include accessory items, such as discharge elbows, suction fittings, or valves, unless specified by a contractual agreement.

The following submersible pump designs are covered in the 2012 edition of the standard:

• Semi-permanent/pull-up/wet-pit types

• Dry-pit/dry-installed types

• Portable/flexible discharge types

• Chopper/cutter/grinder types

• Close-coupled types

• Integral electric motor types

Information in the standard may be applied to pumps of any size and to any pumped liquids behaving as clean cold water. This standard does not deal with the structural details of the pump or with the mechanical properties of their components.

ISO 9001 CERTIFIED

AS2417 ISO9906 API 610 Hydraulic Institute

Coliban Water pumps water out of tourist attraction

Coliban Water is installing pumps to remove water from the Central Deborah Gold Mine, while they look into longer term solutions to Bendigo’s rising water table.

The water authority is in communications with two other local agencies for a solution, which may involve releasing water into the sewerage system.

In the meantime, the popular tourist attraction will have the water pumped out to ensure the site remains operational.

New pumping stations in Tasmania

Tasmania’s Southern Water is replacing a 108-year old pump station in Salamanca Place in Hobart, as well as pumping stations in Glenorchy and Clarence.

The upgrades form part of a $180 million, three year project to overhaul the city’s waste and wastewater systems.

“The existing pump station was never designed to cope with the amount of wastewater which comes from all the venues in the area,” Southern Water executive manager Russell Fox said.

Geelong Water Plant starts pumping

Commissioning has begun on Barwon Water’s Northern Water Plant in Geelong.

The $94 million project is located adjacent to the Shell Geelong Refinery and will produce around 2 billion litres of high quality class A recycled water.

Construction began on the plant in March 2011 and the plant will be fully operational in early 2013. John Holland is the principal contractor.

This major water-saving initiative will produce Class A recycled water suitable for industrial and community use in Geelong’s northern suburbs.The plant will use cutting-edge treatment technologies including biological treatment, ultrafiltration, and reverse osmosis.

Queensland Resources Council calls on government to help pump water from Queensland’s flooded mines

QRC Chief Executive Michael Roche used the recent Coaltrans conference in Brisbane to call for government help in solving the problem.

Roche said that while the industry was “on track to export more than 200 million

tonnes of coal in 2010-11...extensive flooding across our main coal-producing regions – the Bowen and Surat Basins –cost some 40 million tonnes in scheduled production and exports” which translated in $7 billion dollars in lost sales.

He cited the “cumbersome environmental processes under the previous state government” as having prevented the opportunity to pump out the pits while local rivers and streams flowed strongly, resulting in mines still holding around 250 to 300 gigalitres of water. some 19 months later.

The QRC is seeking a transition program from the state government to start shifting water this wet season and over subsequent wet seasons. According to Roche, “this is not about compromising environmental standards, but taking advantage of the heavy rainfall that nature traditionally throws at central and north Queensland over summer. In this case, dilution is the solution.”

Coal companies are reportedly investing strongly in preparation for the wet season including the construction of additional on-site water storages, pipelines, pumps and water treatment plant.

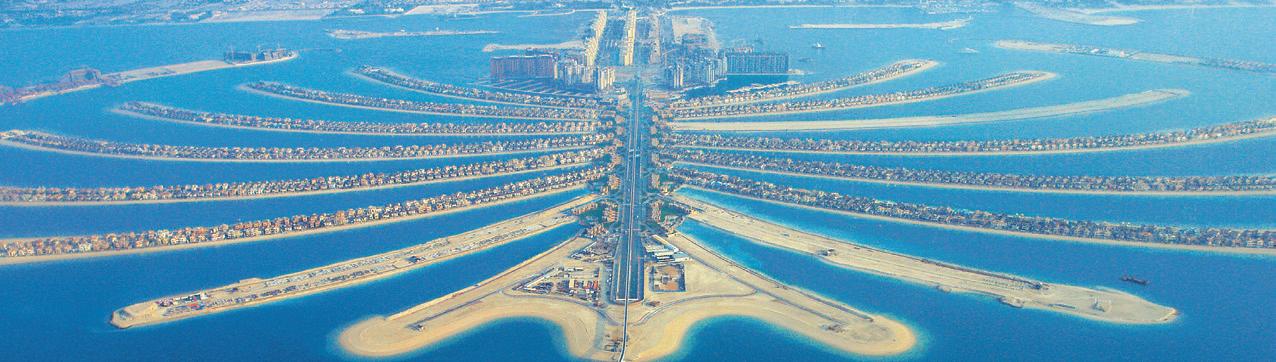

Reliable, long-term supply of drinking water.

As one of the world’s largest artificial islands, “Palm Jumeirah” in Dubai must rely on high performance pumps to meet its enormous demand for drinking water. The developers of this highly ambitious project put their trust in KSB to provide solutions which are extremely energy-efficient and easy to maintain. HGM – RO high pressure and Omega water transport pumps from KSB help to reliably produce 32,000 m3 of pure water every day and keep life cycle costs as low as possible. KSB is one of the world’s leading manufactures of pumps, valves and systems.

Franklin Electric acquires Cerus Industrial

Franklin Electric Co has acquired Cerus Industrial Inc. Based in Oregon, USA, Cerus designs, manufactures, and distributes motor controls, motor starters, contactors, protection devices, and variable frequency drives to a wide range of distributor and original equipment manufacturers in North America who serve three primary markets: HVAC, industrial motor sales and service, and pumping systems. Founded in 2003, Cerus has 65 employees and totalled $US14 million in sales last year.

Scott Trumbull, Franklin Chairman and Chief Executive Officer, said, “Cerus has deep technical and manufacturing strengths in several areas that are of strategic interest to Franklin Electric including variable frequency drives, starters, and control panels.

“The demand for electronic drives and controls for pumping applications is growing rapidly because these devices allow our customers to reduce energy cost, increase system life, and manage system parameters such as pressure and flow. While Franklin has been a leader in applying drive and control technologies to groundwater pumping systems, we believe that the Cerus acquisition will enable us to further accelerate our growth by increasing our technical and product development capacity, broadening our

product line, reducing our manufacturing costs and moving us into adjacent market areas.”

World’s largest lumping station planned for Abu Dhabi

Abu Dhabi Sewerage Services Company (ADSSC) is constructing what is expected to be the world’s largest pumping station. Located in the Emirate of Abu Dhabi, United Arab Emirates, the pumping station will be over 100m deep and approximately 40m in diameter and will have an ultimate peak pumping capacity of approximately 3.3 million cubic metres per day.

ADSSC is the service provider for sewerage services and currently owns and operates the sewerage network and treatment plants throughout the Emirate of Abu Dhabi. To address projected growth within the Emirate, ADSSC has developed a comprehensive plan to increase system capacity. The cornerstone of this plan is the Strategic Tunnel Enhancement Programme (STEP).

Mott MacDonald has been appointed by ADSSC to provide contract administration and site overview services for the development of one of the world’s largest underground pumping stations.

The focus of STEP is a deep 41km long tunnel sewer and several systems of link sewers which will collect and transport wastewater to a main pumping station for onward treatment at the Al Wathba

Independent Sewage Treatment Plants (ISPTs). The link sewers will intercept the flows from existing gravity sewers upstream of the existing pumping stations, both on Abu Dhabi Island and the mainland. These flows will be channelled by gravity into the deep tunnel. At the downstream end of the deep tunnel, in the AI Wathba area, an underground pumping station will be built to lift the sewage to the surface, and into newly constructed ISTPs.

The pumping station will be housed in a large deep structure at one end of the tunnel. The facility will also accommodate electrical and power generation facilities, operations and maintenance facilities, standby power fuel storage and pumping and a flow distribution facility.

Mott MacDonald will undertake the role of engineer for the contract administration and construction oversight. This will involve project, design, cost, contract and health, safety and environment management.

Peter Hall, Mott MacDonald’s project director said,“the UAE is the third largest consumer of water in the world after Canada and the USA. There is a daily water consumption rate of nearly 550 litres per person in a region that receives less than 1cm of rain per year. Therefore, management and reuse of wastewater is a critical component to Abu Dhabi’s longterm sustainability.”

• Motor or wall mountable

• Fully programmable on site

• Software specifically designed for pump operation, control and protection

• High level hardware design

• More flexibility and cost savings

• Energy savings up to 70%

• Simple mounting “clip and work”

• Multi-pump capability up to 8 pumps

Monitoring of Yallourn Mine water continues

The EPA continues to monitor the flood waters being pumped from the Yallourn Mine, with early results indicating there have been no harmful levels of contaminants such as heavy metals or hydrocarbon.

TRUenergy’s Yallourn Mine in the Latrobe Valley was flooded on June 6 this year after the collapse of an artificial river bank constructed to carry the Morwell River across the middle of the mine. The flooding limited the operation of Yallourn power station that generates 22 per cent of Victoria’s electricity. TRUenergy applied to EPA for emergency approval to pump flood water from the mine.

In an emergency, a company can apply to EPA for approval to discharge waste to the environment. EPA may grant its approval if the company can demonstrate that the discharge will not cause any long-term negative impacts on the environment. An emergency discharge approval can only be issued for 120 days, after this time, the company must reapply for approval to discharge.

The discharge approval granted to TRUenergy requires the company to monitor the impact of the discharge on the river using an independent laboratory with a

NATA accreditation (National Association of Testing Authorities) to take and test the samples.

The results do indicate the discharge of water from the mine has increased turbidity levels (cloudiness due to silt) in the Latrobe River and there have been traces of some naturally occurring compounds, such as iron.

Zenit ECO pumps have been approved for Class 1 Zone 2 hazardous areas since 1998.

Due to regulatory changes in 2008 regarding certification standards, both White International and ZENIT have obtained the higher international standard IECEx, rather than only the ANZEx certification applied for in the past.

PIA Events

Event Calendar Opportunities in the resource sector

PIA held a successful seminar in Brisbane on August 29 which focused on pumping equipment for the resource sector.

The program was chaired by PIA Vice President Ron Astall, and included a range of pump companies and endusers presenting papers on the latest applications in pump technology in the resources sector.

The day opened with a presentations from Frank Passmore from Fire by Design discussing maintenance of fire pumps in remote locations. Gareth Munro of Weir Minerals demonstrated how operational costs of slurry pumping could be reduced and Jeremy Tuerlings of Flowseve demonstrated the latest monitoring equipment for pumps.

The afternoon included an interesting look at permanent magnet motors from

Rajan Tulasi at ABB, as well as a look at using model motor analysis to monitor driven machine condition from Mike Davis of Machine Monitor, a division of GE Energy. The day was rounded out with Marty Williams of BP Kwinana discussing pump reliability improvements and Andrew Nicolin from John Crane looking at diamond faces for mechanical seals.

The seminar followed the PIA General Meeting on the previous day, also held in Brisbane. The General Meeting included an address from Dugald Anthony from Austrade and export opportunities and support and a presentation from Ivan Hernandez from Frost & Sullivan about pump industry statistics. The general meeting was followed by casual drinks.

PIA Seminar and Exhibition

Whitehorse Centre, Whitehorse Rd, Nunawading,VIC

Tuesday & Wednesday, 9- 10 October, 2012

PIA Annual General Meeting & Dinner

Graduate House, University of Melbourne, Parkville, VIC Thursday, November 22, 2012

For more information or to register for PIA events, visit pumps.asn.au or email pumpsaustralia@bigpond.com

Other Events

All Energy

Melbourne 10-11 October, 2012 www.all-energy.com.au

Australian Pipeline Industry Assoc. (APIA)

Brisbane 13-16 October, www.apia.net.au/events

Fire Australia

Melbourne 14-16 November, 2012 www.fpaa.com.au/events/

2013

Australasian Oil & Gas (AOG)

Perth 20-22 February, 2013 www.aogexpo.com.au

OzWater

Perth 7-9 May 2013 www.ozwater.org

National Manufacturing Week

Melbourne 7-10 May 2013

www.nationalmanufacturingweek.com.au

APPEA

Brisbane 26-29 May, 2013 www.appea.com.au

Auspack Plus

Sydney 7 - 10 May 2013 www.auspackplus.com.au

Meet the pump people

Pump Industry Australia is pleased to invite pump users, consulting engineers, university and TAFE students to attend our exhibition & seminar program to be held at the Whitehorse Centre, Nunawading, Victoria on 9 & 10 October 2012.

The Exhibition will feature some of Australia leading Pump Suppliers and will focus on SME’s with particular expertise in applications and technologies that are leading edge. Many of us need to use our time wisely these days and this is an opportunity

When, where and how?

Tuesday 9 October - Exhibition trade day and seminar (advance registration required) 9:30am - 5pm

Wednesday 10 October - Exhibition open to trade and public, 9:30am4pm

The Whitehorse Centre, 397 Maroondah Highway Nunawading, VIC (At rear of Civic Centre)

The venue is within easy reach of the Eastern Freeway and there is ample free parking available

Register at www.pumps.asn.au

to“meet and learn” from some of Australia’s most experienced Pump People.

The Exhibition will be conducted in a relaxed atmosphere and will lead in to 6 stimulating seminars that will help to explain the black art of Pump Technology. Attend one that is of particular interest to

you or register for all, if you wish.

The general theme will be “environmental protection and energy efficiency”, but with pumps as the main focus of attention.

Seating will be provided for up to 60 participants and there will be time for Q&A. Register now to ensure you have a seat!

Seminar program - Tuesday October 9

Time Topic Presenter

10.00 – 10.30 Are you running your pumps too slowly?

11.00 – 11.30 ErP directive on MEPS for pumps in Europe

12.00 – 12.30 MEPS for Pumps in Australia

1.00 – 1.30 Developments in small pumping systems

2.00 – 2.30 Innovative vacuum pumping systems

3.00 –3.30 VSD’s in pumping systems

Ron Astall, Astech

David Kerridge, Wilo Australia

Ian McNicol, Sustainability Victoria

Ashley White, Davey Water Products

David Hobson, Emtivac Engineering

Bou Spithoven, CAP Industries

Join Pump Industry Australia

There are many worthwhile benefits you’ll receive from becoming a member of Pump Industry Australia Incorporated. Membership of the Association is available to the following types of persons or organisations:-

Member Qualifications

• Pump manufacturers.

• Pump importers

• Pump wholesalers

• Pump retailers

• Pump repairs & maintenance

• Pump consultants

• Pump training or education

• Suppliers to the pump industry

Membership Benefits

• Regular general meetings held at a members’ facilities provide the

opportunity to see different aspects of the industry, and to formally discuss current market conditions and other issues.

• Occasional Technical Seminars with presentations by specialists on the latest technology in pumping equipment and systems.

• Informal networking within the association with customers, suppliers and competitors.

• Discounts off retail prices when purchasing PIA publications.

• Annual Dinner with partners and guests.

• Opportunity to lobby government on issues important to the Industry.

• Discussion groups on marketing, statistics and training.

Annual Membership Fees

• Private Member $80 + GST

• Company Member less than 10 employees $150 + GST

• Associate Member (for large companies who are not participating directly in the pump industry however do have a strong interest in the industry eg. a motor supplier $250 + GST

• Company member (10 to 25 employees) $300 + GST

• Company member (25 to 100 employees) $600 + GST

• Company member (over 100 employees) $1,200 + GST

Celebrating 50 years of service to the industry

October 2012 marks 50 years since Acromet was founded, we take this opportunity to speak to General Manager Keith Gardner.

Congratulations on reaching 50 years - how did Acromet get started?

Acromet (Aust) Pty Ltd commenced operations in October of 1962 as a wholly Australian-owned company with Australian distribution agreements for American and Canadian equipment for the water supply and treatment industries. The initial product range specialised in gaseous Chlorination and Metering Pump Chemical feeding equipment.

How innovative were Acromet’s products at the time?

At this time, Acromet was the first company to introduce the then unique All Vacuum Chlorination system into the Australian market – a system now adopted by all major manufacturers.

Our beginnings were based on innovative equipment for its time, designed by our founder who has a passion for providing robust and reliable products with the highest accuracy possible.

What have been some of the key turning points in the company’s history?

In 1969 Acromet increased its expansion in the industrial market with the introduction of an All Australian designed and manufactured range of Diaphragm and Plunger Metering Pumps and accessories. This range of pumps, known as the 900 Series, became the chemical metering work-horse for many industries throughout the late 1960’s, 1970’s and early 1980’s where some are still in operation today.

During this early period, the company also established a technically strong engineering division, responsible for the introduction of newly developed process pump technology into the general and Petro-Chemical industries.

The product range was further extended with the addition of Electro-magnetic Metering Pumps, Gear Pumps and Motor Driven Sealless and Specialized Centrifugal Pumps.

In 1982, after considerable investment in design and development, the company released a range of Dry Material Feeders that now cater for an extensive market in the Bulk Materials Handling industries.

During this period the 900 Series metering pumps were redesigned to incorporate a wider range in the performance envelope that increased the number of liquid heads that could be fitted to a single unit. The new pump was released in 1983 as the Acromet 3000 Series that has become a dominant player in the market and remains in production today at our Clayton, Victoria manufacturing facility.

What happened once the 900 series was discontinued?

Although 900 Series metering pumps were discontinued from production, our spare parts, factory service and repair support were maintained for 17 years. This philosophy is rarely seen in the industry today, yet still continues with all our manufactured products. This level of commitment is one of the reasons that Acromet is the only Australian manufacturer of metering pumps. This has

assisted us with the expansion of our extensive and satisfied customers around the world who use our Australian-made products.

What hasn’t changed over the years?

Throughout the years, product design and development has always been a priority on Acromet’s agenda with further development culminating in the release of the Acromet robust 2000 and 2500 Series metering pump along with the Acroflex flexible dry powder screw conveyor and our expansion into the Bulk Materials Handling systems. This principle continues our founder’s philosophy of a robust, reliable and accurate range of metering equipment.

In 2012 Acromet remains a fully Australian-owned and operated business proudly celebrating its fiftieth year of operation. The momentum of growth has been maintained in the past decade with a continuing emphasis on new product design and development positioning Acromet as a leading Australian manufacturer of Metering Pumps and Dry Material Feeders.

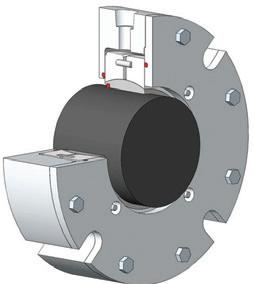

Balance matters

Imbalance of rotating components is one of the most common sources of machine faults in rotating assemblies, pumps and fans and is a major cause of complete equipment failure. Most people’s awareness of balancing is limited to knowing a car’s wheels and tyres that must be balanced, to avoid steering-wheel shudder and uneven tyre wear.

Equipment failures can have dramatic impact on a plant’s production and manufacturing commitments. If there is a grumble or a groan, a banging or shaking, or if things just don’t seem right it may be time to get it checked out. This can be critical especially as up to half of electric motor breakdowns are caused by damaged bearings, due mostly to the vibration occurred by the rotor’s imbalance.

Industrial balancing and vibration analysis on rotating machinery enables the early detection of faults before breakdown, and assists commercial and industrial facilities reduce their maintenance costs and unscheduled downtime. Dynamic Balancing of this rotating equipment offers many benefits, including:

• Increasing equipment’s performance and longevity, ensures optimum performance of machinery

• Improves running conditions to reduce ongoing maintenance costs and maximise return on investment, improving equipment operating costs and economy

• Lengthens service life. Bearings, suspensions, housings and foundations can be subjected to very high stresses caused by vibration resulting from unbalance and these result in greater wear.

• Products with unbalanced parts often have a shorter service life.

• Decreasing breakdowns and unscheduled downtime. Vibrations can reduce the frictional grip of screwed and clamped connections. Electric switches can be destroyed by vibration, pipes and cables can fracture at the connections.

• Reduces chances of equipment failure, vibration and imbalance can lead to catastrophic failure.

Note in these photographs the damage imbalance can cause.

Industrial balancing is the procedure where the mass distribution of a product, be it a pump, roller, impeller or the like, is accurately measured and suitably adjusted. This will ensure that the forces on the bearings, at a frequency corresponding to the devices operational speed, are within limits as specified in International Standards, such as ISO 1940-1:2003 Mechanical vibration (Balance quality requirements for rotors in a constant rigid state).

Precision Balancing has been offering in house and on site dynamic balancing and vibration analysis services since 1989 and have the equipment, skills and experience to satisfy your industrial balancing requirements. Owned and operated by qualified mechanical engineers, members of the Australian Institution of Engineers, with years of experience in mechanical engineering and industrial balancing. Precision Balancing has been offering a range of specialised balancing services for pump impellers since the company began, and has worked on a huge range of models and sizes. Precision Balancing offer personalised service including on site balancing, and quick turnaround or emergency after hours breakdown services. For more information on how industrial balancing can help you in achieving machine harmony visit www.precisionbalancing.com.au.

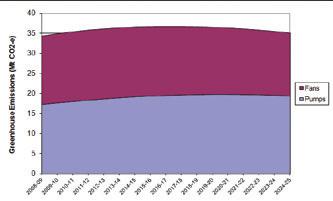

An efficient future for pumps and fans

Fans and pumps used in the commercial, manufacturing and mining sectors are a very significant source of energy use and greenhouse emissions. The Pump Industry Association and the Fan Manufacturers Association of Australia and New Zealand have been working with Sustainability Victoria to improve standards.

The energy used by pumps and fans is a significant part of total energy consumption as the below figures demonstrate, and this consumption is expected to increase.

The International Energy Agency (IEA) estimates that there is the potential to achieve across the board savings of 20 to 25% from ‘motor systems. This translates to around $1 billion in energy bill savings for pump and fan systems.

A number of key approaches can be taken, including the correct sizing of motors to match load requirements, use of variable speed drives where the load is variable, use of high efficiency components such as motors, couplings and end-use equipment. Optimisation of downstream distribution system, and elimination of losses and leaks as well as proper maintenance and repair all can contribute as well.

Barriers to saving energy

Of course, there are many barriers to achieving this. Firstly there are split incentives, such as the party which specifies the equipment is not directly responsible for paying the energy bills. Additionally, risk minimisation in the supply chain can mean like is replaced with like, or standard equipment is specified. A lack of information may also exist where equipment is not ‘energy rated’.

Further, the availability of information is not always enough. Energy costs are small percentage of total business costs and energy is not a ‘core business’, the focus is often on keeping the production line going, and on upfront cost and not lifecycle cost.

Energy costs can be a significant proportion of lifetime operating costs; up to 85 per cent for pump systems and 67 per cent for fan systems. Paying more upfront for a more efficient system can be a classic “win – win” situation for both the end use customer and the supplier

Energy efficiency regulations

In Australia, the Equipment Energy Efficiency (E3) Program coordinates the regulation of appliance and equipment energy efficiency. The main policy tools are Minimum Energy Performance Standards (MEPS) and Energy Labelling. They currently regulate around 20 types of equipment for MEPS and seven appliances for labelling

Industrial equipment

Regulation is expanding into industrial equipment. 3-Phase electric motors (0.75 to 185 kW) have been subject to MEPS since 2001. In July 2009, COAG agreed to implement the National Strategy for Energy Efficiency (NSEE). Measure 2.2.1 called for the expansion of MEPS significantly into the industrial sector to cover off-the-shelf products. A discussion paper on Industrial Equipment was released in September 2010 which identified pumps, fans and boilers as a key priority.

Key international developments

The EU’s Framework Directive on EcoDesign of Energy Using Products (2005) has been progressing work in four areas relevant to motor systems; electric motors, water pumps, circulator pumps in buildings and ventilation fans.

Forthcoming EU Regulations will commence for pumps in 2012 and be made more stringent in 2014. It covers

clean cold water pumps (0.75 kW to 150 kW) and building circulator pumps. ISO9906 sets the test standard. Similar regulations for fans are also being implemented in the EU.

Australian developments

Since the PIA workshop on pumps in 2011, work on both non-domestic fans and non-domestic pumps has proceeded, although the work on fans has been given a higher priority. A Product Profile Discussion Paper on Non-Domestic Fans was publicly released by the E3 Committee in May 2012, and consultation workshops held for industry stakeholders in both Melbourne and Auckland. Comments on this Product Profile have now closed, and the E3 Committee will consider the responses before deciding on a way forward.

A Product Profile on Non-Domestic Pumps is in the final stages of preparation and is expected to be released for public consultation by October 2012. The Profile will look at the markets for pumps in both Australia and New Zealand, will look at what is happening internationally to improve the efficiency of new pumps sold, and will consider a range of options which could be implemented in Australia and New Zealand to drive improvements into the efficiency of new pumps. As with

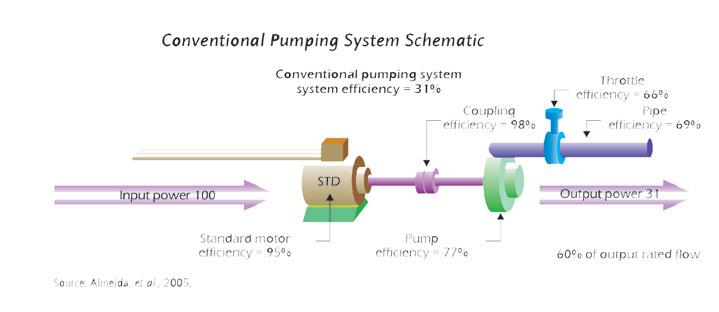

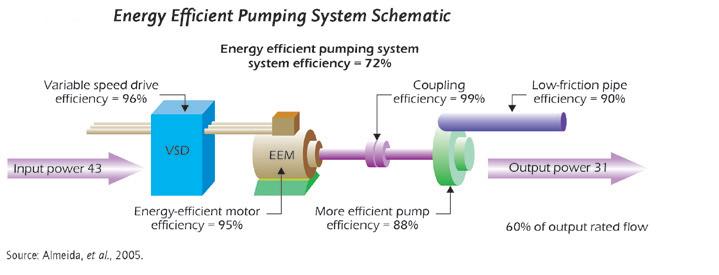

The above figures show how pump systems efficiency can be increased from 31 per cent to 72 per cent.

the fan profile, it is likely that consultation workshops will be held in both Australia and New Zealand to discuss the Profile with interested stakeholders and written submission on the Profile will also be considered.

An efficient future?

Electricity prices will continue to increase in real terms; generation and distribution costs are the key driver and the implementation of the carbon tax will add to this. Energy costs account for the majority of lifetime operating costs. Any future MEPS regulations will drive some improvements to the new pumps and fans installed, but much bigger savings are possible. Upgrading the efficiency of pump and fan systems is a “win-win” situation for end users and suppliers.

More information

If any pump industry stakeholders have questions concerning the E3 Committee’s work on non-domestic pumps, they should contact Ian McNicol at Sustainability Victoria on (03) 8626 8772. Ian is leading the non-domestic pump work on behalf of the E3 Committee.

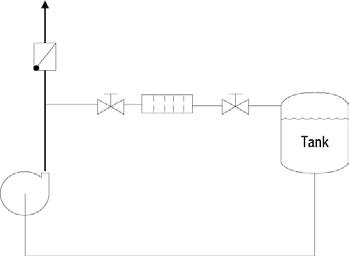

Optimise overhauls of pumps to save energy

Ray Beebe, DipMechE, MEngSc, FIEAust, CPEng(ret)Pumps are arguably the most common machine in power and process industry, and major consumers of energy, yet relatively little information is available on the application of predictive maintenance/condition monitoring to them. When deterioration in performance of a centrifugal pump causes a drop in plant production, overhaul is readily justified, as its cost is usually small in proportion. When the effect of deterioration is only to increase power consumption, the time to overhaul for minimum cost can be calculated from test results. This article describes some basic condition monitoring tests for pumps, and how to use these condition monitoring methods to estimate the increased power consumption caused by pump wear.

The extent and effects of internal wear in centrifugal pumps vary with the nature of the liquid pumped, the pump type and its operating duty. Some pumps last for years, others for only months.

Overhauling of pumps on a fixed time or breakdown basis is rarely the most costeffective policy. Use of condition monitoring ensures that pump overhauls to restore performance are performed when they are really necessary. There may of course be other factors to consider, such as field or OEM experience. However, despite the many excellent pump textbooks until recently there was little information available on how to apply conditionbased maintenance to pumps (ANSI/HI, 2000 and Beebe, 2004).

Monitoring methods should be chosen where justified that will detect each of the degradation modes which are experienced or expected:

• Vibration monitoring and analysis (probably the most widely applied method of condition monitoring for rotating machines in general, and suited to detect such faults as unbalance, misalignment, looseness),

• Sampling and analysis of lubricants for deterioration and wear debris (relevant for bearings/lubrication system faults),

• Electrical plant tests (relevant for motor condition),

• Visual inspection and Non-Destructive Testing (particularly relevant for casing wear),

• Performance monitoring and analysis (relevant for pump internal condition).

For critical machines, more than one method of condition monitoring may be justified. This Note will demonstrate use of performance analysis with some examples of condition monitoring in practice.

An understanding of basic pump performance characteristics is assumed, as is how to measure test data repeatably, as for condition monitoring, repeatability is more important than absolute accuracy.

The Head-Flow method shows pump wear

The most useful condition monitoring method is by Head-Flow measurement, because as well as pump deterioration, it detects any changes in system resistance. The method can be used for all pumps where flow, or a repeatable indicator of it, can be measured

Throttling the pump to obtain points over the full flow range is not necessary for monitoring. Some points near the normal operating duty point are sufficient to reveal the effects of wear, usually shown by the head-flow curve moving towards the zero flow axis by an amount equal to the internal leakage flow. (See “Test points-worn pump” on Figure 3).

A series of test readings at steady conditions at about 15 second intervals is sufficient, taking the average values to plot. Speed must also be measured for variable speed pumps, and the head-flow data corrected to a standard speed using the affinity laws.

Field tests sometimes give results slightly different from the manufacturer’s works tests because site conditions for flow and pressure measurement are rarely available as required by the various Standards for pump testing. However, note again that for monitoring it is relative changes we are seeking rather than absolute accuracy.

Non-intrusive ultrasonic flowmeters are applicable in many cases. A permanent flowmeter installed as part of a pump’s minimum flow protection or for process measurement can be used, provided its long-term condition is considered to be constant, or it can be inspected regularly.

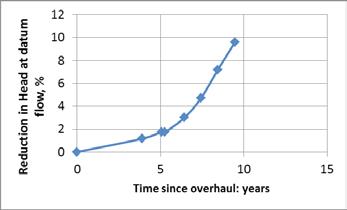

Figure 1 shows the trend in degradation of two pumps over some years. Wear amplitude is expressed at duty point flow as the percentage reduction in Total Head compared with the new datum condition. This is usually derived from Head-Flow tests near duty point, but can also be obtained using the shut-off head test where this is allowable.

Where a plant has a DCS, then regular interrogation of the plant historian can be used, as shown for the multistage boiler feed pump in Figure 1. Data points are extracted each six months from a run of ten days at steady load. (Constant speed pump, 4 stage, 5853 r/min, 5744kW, 171kg/s @20.4MPa)

Such performance information can show the extent to which a pump has deteriorated, and pumps can be prioritised for

overhaul on the basis of their relative wear. But, is the overhaul of the worst pump justified economically? A method for helping this decision is given later.

Figure 1: Degradation of pumps shown by Head-Flow testing (top) 230kW, (bottom) 5744kW

The shut-off head method for PdM of pumps

Measuring the Head at zero flow is a simple test. It is only possible where it can be tolerated, which is not so for high energy pumps nor for pumps of high specific speed where the power at shutoff is greater than that at duty point. Some pumps have exploded from built-up pressure when left running at zero flow!

With the discharge valve closed fully for no longer than 30 seconds or so, suction and discharge pressures are read when steady. The liquid temperature is also needed to find the density, which is used to convert the pressure readings into head values.

Wear of vane outer diameters will show readily, as the head-flow curve of a worn pump moves towards the zero flow axis. To show sealing ring wear, the pump head/flow curve needs to be relatively steep. (Note that if the pump has a rising curve, internal leakage will initially give an increase in shutoff head).

The thermodynamic method for PdM of pumps

Another method of pump monitoring is to measure the temperature rise of the liquid through the pump. This reflects the inefficiency of the pump. As the differential temperature is very small,

great care is required to measure it. Any effects of recirculation at pump inlet and outlet must be eliminated, and tests are not possible at very low flows or zero flow. The efficiency can be calculated from the measured data of inlet temperature, differential temperature and head. Comparisons if it changes with time can be made on plots of Efficiency vs Head. For high head pumps, an allowance must be made for the isentropic temperature rise which occurs as a result of pressure increase (Beebe, 2004).

Commercially available devices are widely used, especially in the water industry (Robertson, 2007). Tappings at suction and discharge are required to be two diameters away from pump flanges, for the installation of pressure/ temperature probes. Tong-type detectors are placed to measure motor power.

Pump efficiency is then found from the precise measurement of the head and temperature rise through the pump. From assessment of motor losses, the power absorbed by the pump is computed. From all this data, the pump flow can be found.

For condition monitoring, tests at around normal operating point are usually sufficient. The thermodynamic method would be more attractive economically if no special tapping points were required. Research at Monash University on high head pumps using special semi-conductor temperature probes on the outside surface of the piping, covered with insulation, gave usable results, provided the pump is allowed to run at steady operation conditions for 30 minutes in order for the piping temperature to stabilise (Beebe, 2002).

Percentage efficiency for pumps on water at up to 54°C is given by this empirical formula, which includes a correction for the isentropic temperature rise (Total Head is in kPa, temperatures in °C) (Whillier, 1972)

Measurement of balance flow for PdM of pumps

Multi-stage pumps with the impellers facing in the one direction usually have a balance disc or drum arranged such that final stage discharge pressure counteracts the axial thrust on the shaft line. Another method for condition monitoring is to measure the leakoff from the balance device (Karassik, 2001). The basis is that if there is increased wear in the annular space to the balance device which is evident from increased leakoff flow, then the interstage clearances are also worn. As the leakoff line is quite small compared to the pump main flow piping, a permanent flowmeter is relatively inexpensive.

At one power station, for some years overhauls have been scheduled on this basis on some boiler feed pumps. Flows are read manually, and trends plotted using a database program (Figure 2). Note that here the balance flow of 15 L/s corresponds to about 10 per cent of the duty flow, and consumes about 250kW of extra power. When added to the likely internal recirculation, this would mean an even larger proportion of the power absorbed being wasted. These pumps are variable speed and other tests show that the measured flows must be corrected in direct proportion to the speed.

On a set of pumps of another design elsewhere, both head-flow and balance flow were measured for some years, but no correlation was found between the two.

On yet another pump type, of 11 stages, the head-flow performance was tested as well below the datum curve. As the pump was dismantled, measurements showed that the interstage clearances were not worn. A condition monitoring credibility crisis was averted when the balance seat area was reached and found to be severely eroded from water leaking past the valve seat. Balance flow had obviously been very high. For the best monitoring, it is therefore considered that both head-flow and balance flow should be measured, particularly if the balance area can be separately dismantled in the field.

Figure 2: Condition monitoring of a high energy multi-stage pump by measurement of balance device leakoff flow. (Note: flows are corrected to a standard pump speed)

How to calculate the optimum time for overhaul

The most economic time to restore lost performance by overhaul will vary with the circumstances.

If the deterioration is constant over time, then a cash flow analysis can be done to ensure that the investment in overhaul will give the required rate of return. This is the same process as used in deciding on any investment in plant improvement.

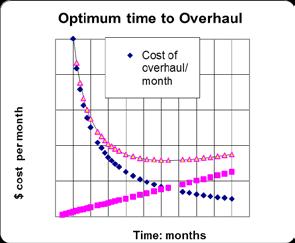

If the deterioration rate is increasing with time, then the optimum time for overhaul will be when the accumulated cost of the increased electricity consumption equals the cost of the overhaul.

The method is now described for some of the situations which occur.

Pump deterioration results in a reduction in plant production

Where the cost of overhaul is insignificant in proportion to the cost of lost production, prompt overhaul is usually simply justified at a convenient “window”.

Pump which runs intermittently to meet a demand

In a pumping installation such as topping up a water supply tank or pumping out, deterioration will result in the pump taking more time to do its duty. The extra service time required therefore results in increased power consumption which can be related to the cost of overhaul.

Pump deterioration does not affect plant production, at least initially: constant speed, throttle valve controlled pump

The internal wear does not cause any loss in production from the plant, as the control valve opens more fully to ensure that pump output is maintained. Eventually, as wear progresses, pump output may be insufficient to avoid loss of production, or the power taken will exceed the motor rating.

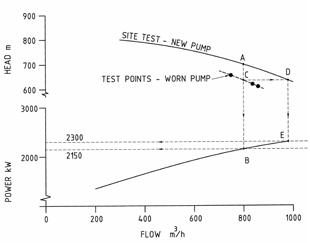

Figure 3 shows the Head-Power-Flow site test characteristics of such a pump. Its output is controlled using a throttle control valve. The duty flow is 800 m³/h, and the duty point in the new condition is A. The power absorbed by the pump is read off the Power-Flow curve as 2150kW: B. The power-flow curve should ideally be found on site, but the works tests information may have to suffice.

After some service, the “Test points -worn pump” plotted indicate that internal wear has occurred. When worn to this extent, the operating point moves to C, as the system resistance curve lowers when the throttle valve is opened further.

Figure 3: Head-flow-power characteristics of new pump, and head-flow points from worn pump.

The increased power required in the worn condition can be estimated by extending from the Head-Flow curve at constant head from the operating point to D, and then dropping to intersect the Power-Flow curve for new condition at constant flow: E. Follow the arrowed line in Figure 3. This assumes that the original curve still represents the flow through the impellers, of which less is leaving the pump to the system due to internal wear. (If the pump was motor-driven, the actual power may be able to be measured on test at extra expense).

In our example, the power required for this duty in the worn condition is shown in Figure 3 by the projection from the duty flow of 8003/h to the test curve to find 640m head, then across to the “Site test - new pump” curve, then down to the power curve, to find 2300 kW.

The extra electricity consumption is therefore 2300 - 2150 = 150kW ÷ motor efficiency (here it is 90%), to obtain 167kW.

If the sealing clearances are known, by previous experience of correlation with measured performance, or if the pump is opened up already, the extra power consumed likely to be saved by overhaul can be estimated (Stepanoff, 1957, and HI).

Finding the optimum time for overhaul from Head-Flow data

For this example, the test points were obtained following 24 months of service since the pump was known to be in new condition; an overhaul would cost $50,000; electricity costs 10c/kWh; and the pump is in service for 27 per cent of the time on average. The increased power consumption is estimated at 167kW (motor efficiency included).

Our test shows that the rate of increasing cost/month has reached 167 × 0.10 × 0.27 × 720 = $3240/month (taking an average month as 720h).

As the time now is 24 months, $3240 ÷ 24 gives the average cost rate of deterioration as $135/month/month.

The optimum time for overhaul can be calculated (Haynes and Fitzgerald, 1986) from

which is at 27.2 months. If plotted as cost/month against time, the resulting curves will show the cost per month of overhaul dropping with time, with the cost of lost energy increasing with time.

(The time value of money could also be taken into account if required). Usually the total cost curve is fairly flat for ± 20% or so. The calculations can be easily set up using a spreadsheet).

If the overhaul was delayed until, say, 30 months, then the accumulated cost of lost energy would have reached $135 × ½ × 30² = $60 750. At 27.2 months, the cost is $135 × ½ × 27.2² = $49939. The cost of delaying overhaul is thus the difference, $10811.

wear state than for a constant speed pump.

To estimate the power required in the worn state, the Head-Flow curve must be drawn for the current higher speed in the new condition. Select a Head-Flow point on the original new condition curve, and correct it to the higher speed: multiply the Flow by the speed ratio, multiply the Head by the (speed ratio)². Repeat this for some other points at flows above duty flow to draw the new condition HeadFlow curve.

where: O = cost of overhaul

C = cost rate of deterioration

giving here T = 27.2 months, but it is better to calculate and plot the average total cost/month values for a range of times. Seen clearly will be the cost impact of doing the repairs at some other time, such as at a scheduled plant shutdown.

Figure 4: Spreadsheet used to show the optimisation point graphically

How to calculate the total average cost per month, month by month

For example, take the time as 22 months:

The average cost of overhaul is now $50 000 ÷ 22 = $2273/month

The average cost of extra energy is now $135 × ½ × 22 = $1485/month

The total average cost/month is now the sum of these two figures = $3578/ month.

Repeat this calculation for several months, perhaps using a spreadsheet, and look for the minimum total cost,

Note that this calculation is only correct if the wear progresses at a uniformly increasing rate with time, but as Figure 1 shows, this is not unusual. Information may not be available to make any other assumption, but decision makers have to start somewhere! Other formulae apply for rates of change which are not linear (Haynes & Fitzgerald, 1986).

Note:

• Some relatively small pumps may never justify overhaul on savings in energy use alone, but may be justified on reduced plant production rate.

• The method does not apply to pumps of high specific speed that show little change, or even a reduction, in power with increased flow.

• If a pump varies in its duty, then the energy usage would be corrected in proportion.

• The cost of electricity to be used here may vary with the power supplier’s tariff structure. The cost may be less in stepped blocks with higher consumption levels for the plant, or a peak demand charge may apply

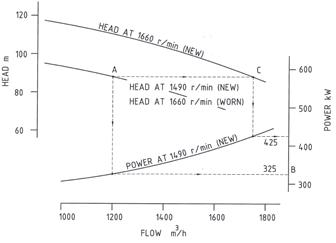

Pump deterioration does not affect production, at least initially: variable speed controlled pump

For a pump where the speed is varied to meet its desired duty, the effect of wear on power required is much more dramatic than for the case of a constant speed throttle controlled pump. This is because the power usage increases in proportion to the speed ratio cubed.

Unless the pump output is limited by the pump reaching its maximum speed, or by its driver reaching its highest allowable power output, then no production will be lost. However, power consumed will increase more dramatically for a given

Follow the same method and calculations as before to find the time for overhaul for minimum total cost. The operating point is projected from the worn curve to the new curve at the same speed as the worn curve. Figure 4 shows the performance of a variable speed pump. When new, operation at 1490 r/min meets the desired duty flow, at operating point A, requiring 325 kW power: point B.

After some time in service, internal leakage has increased such that the pump must run at 1660 r/min to meet the required duty - still point A.

To estimate the power required now, the Head-Flow curve must be drawn for the higher speed in the new condition. Several Head-Flow points are selected and corrected to the higher speed: multiply each Flow by the speed ratio, and multiply each matching Head by the speed ratio squared. This will result in the Head-Flow curve @ 1660 r/min in the new condition.

Project across from the Head at the duty flow - point A –to meet the head-flow curve @ 1660 r/min (new condition). (Line C in Figure 5). Projection downwards at constant flow leads to the increased power required at 425 kW. The extra power is 31 per cent more! (This pump is driven by a steam turbine, so power consumption cannot be measured).

The same calculations as before are followed to find the time for overhaul for minimum total cost.

Figure 5: Head-flow-power characteristics of new variable-speed pump, and headflow points from worn pump.

Optimisation using shut-off head test results

The shut-off head test information can also be used to estimate power used in the worn state and do the optimisation calculations as explained in the above section

Head-Power-Flow characteristics in the “new” state are needed as before, and the operating point must be known. Note the power required at operating point as before.

Make an overlay trace of the Head-Flow curve in the new condition. Place it over the “new” curve and move to the left horizontally until the curve cuts the Head axis at the value of shut-off head obtained on the test. The trace is now in the position of the “worn” HeadFlow curve which is being experienced. Exactly the same process can be followed as explained above.

Conclusion

A method of determining the optimum time for overhaul of a pump based on energy savings has been given. It is hoped that this valuable tool will help asset managers and engineers in their role of managing assets to provide capacity for production, and to improve energy efficiency and minimise greenhouse impact. This optimisation approach can also be applied to any item of plant where deterioration results in loss of efficiency and energy consumption can be measured or estimated.

About Ray Beebe

References

ANSI/HI 9.6.5-2000 American National Standard for Centrifugal and Vertical Pumps for Condition Monitoring

Beebe, R S (2004) Predictive maintenance of pumps using condition monitoring Elsevier, London

Beebe, R S (2002): Thermometric testing of high energy pumps using pipe surface measurements 3rd ACSIM (Asia-Pacific Conference on Systems Integrity and Maintenance), Cairns, Australia (2002)

Haynes, C J and Fitzgerald, M A (1986): Scheduling Power Plant Maintenance Using Performance Data ASME Paper 86-JPGC-Pwr-63

Karassik, I J et al (Eds) (2001) Pump Handbook McGraw-Hill

Robertson, M et al (2007) Continuous Pump Performance Monitoring and Scheduling IMechE Symposium - Energy Savings in Pumps and Pumping, London

Stepanoff, A J: Centrifugal And Axial Flow Pumps Wiley (1957), and Figure 1-77A of the PDF figures on www.pumps.org

Whillier, A (1972): Site testing of high-lift pumps in the South African mining industry IMechE paper C155/72 Conference on Site testing of Pumps London (1972) pp209-217 (I attended this while working in the UK 1971-73)

Ray Beebe, DipMechE, MEngSc, FIEAust, CPEng(ret) followed 28 years in power generation with 20 years at Monash University, based in Australia. He led the postgraduate programs in maintenance and reliability engineering for 15 years, with students all around the world studying by off-campus learning. His commitment to sharing knowledge and experience has led to writing and presenting at many conferences and conducting training courses in condition monitoring around the world. His second book gained the George Julius Medal of Engineers Australia for the best publication in mechanical engineering in 2004. His third book, on condition monitoring of steam turbines, will be published later this year. He is an active volunteer in Rotary and Scouting.

Less hot air in Canberra

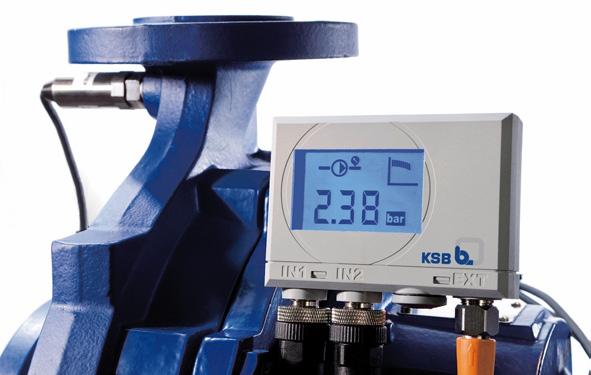

Australia’s Parliament House on Capital Hill is one of the main attractions in the nation’s capital, Canberra. Opened in 1988, the building is now 24 years old and has recently undergone some modernisation to ensure high standards of energy efficiency. During the city’s hot summers, KSB pump sets equipped with PumpMeters ensure temperatures stay comfortable.

Modernisation work in Parliament House sought to employ energyefficient and environmentally friendly technology, especially when it comes to the air-conditioning system. In keeping with this aim, KSB supplied pumps from the Etanorm series equipped with PumpMeter monitoring units. These ensure that the Etanorm pumps always run at the correct operating point, guaranteeing efficient operation.

Energy Efficiency

The system operation is demand driven and only operates at the required actual performance level to ensure the required optimum comfort level. The mode of operation is realised via the use of highly efficient and reliable Etanorm pumps, coupled with high efficiency electric motors and performance regulated via frequency controller.

Water Savings

As the system automatically adjusts to the required demand levels, it only ever pumps just the right amount of water required to meeting the cooling requirements.

Innovation

The automatic performance regulation from Etanorm, was only one aspect of the innovative solution. The incorporation of PumpMeter took innovation to a whole new level.

Parliament House facts

The building was designed by Mitchell/ Giurgola Architects and opened on 9 May 1988 by Elizabeth II.

At the time of the construction, it was the most expensive building in the world at more than A$1.1 billion.

The building itself is 300 m in length and width and contains 250,000 m2 of floor space and contains 4,700 rooms

Construction required 300,000 cubic metres of concrete, enough to build 25 Sydney Opera Houses and has a design life of at least 200 years.

About PumpMeter

PumpMeter continuously analyses the pump operating data and allows operators to see at a glance if they are operating economically. It won the prize for environmental contribution of the year at the Pump Industry Awards UK in 2011.

The state of the import and export market

PIA has routinely conducted an analysis of the import and export activity of commonly used pumps in the Australian market. This has been achieved by monitoring ABS Import and Export Statistics over the period 2003 – 2011. This provides some useful insights into the state of the industry and the level of manufacturing currently conducted in Australia.

Imports

Pump imports into Australia increased marginally in 2011 from 2010. Anecdotal evidence suggests bare pump production is decreasing in favour of imports. However the ability of the local industry to build pumping equipment for specific applications has increased and become more sophisticated to meet market demand.

The statistics show that growth in centrifugal pumps has been strongest, while the trend for rotary pumps has been flatter. The general growth trend of the past decade showed some drop off in 2010 but appears to be increasing again.

USA remains the main port of origin with 24 per cent of all pump imports to Australia originating in the US. China is in second place with 14 per cent, just ahead of Germany with 13 per cent. Other notable ports of origin are Japan, the UK, Sweden and Italy.

Exports

Pumps exports from Australia have shown a strong growth trend over the past decade and increased substantially in 2011, with pump parts showing the greatest improvement. Southeast Asia remains the main destination, with exports to Indonesia at 26 per cent in 2011. New Zealand is in second place with 9% and other notable destinations include PNG, China and the USA.

Considering the impact of the global financial crisis, the Australian pump market seems to have performed well and demand for pumping equipment is trending upwards

Pump types included:

The statistics are available by analysing the tariff codes applied to the goods. The following codes have been included in this analysis.

8413.50 – Other reciprocating positive displacement pumps. (diaphragm, “oil-cushion”, electro-magnetic pumps and machines using the suction or forcing action of two pistons)

8413.60 – Other rotary positive displacement pumps. (gear, vane, rotary piston, lobe type, helicoidal and peristaltic pumps)

8413.70 – Other centrifugal pumps

8413.81 – Other pumps (electro-magnetic, ejectors, emulsion, gas combustion, steam pulsators, compressed air chamber elevators and hydraulic ram pumps)

8413.91 – Pump parts

Pump types not included

Pumps for dispensing fuel or lubricants – used in filling stations, hand pumps, fuel lube or cooling medium pumps for internal combustion engines, concrete pumps, liquid elevators.

Full statistics are available to PIA members, see page 11 for more information on joining. Or for more details on the pump market, please contact pumpsaustralia@ bigpond.com

Exports by product

Pump parts

Other Pump Types

Centrifugal Pumps

Rotary PD

Reciprocating PD

Exports by country

All others, 24.99%

Russia 2.17%

UAE, 2.54%

Phillipines, 2.54%

New Caledonia 2.94%

UK, 3.46%

Singapore, 4.20%

China, 4.63%

Indonesia, 26.46%

New Zealand, 9.34%

USA, 8.55%

PNG, 8.19%

Converting the Indian Ocean into drinking water

We need fresh water to survive but two-thirds of our planet is covered with salt water so an obvious solution seems to be to remove the salt from the water that is readily available to make drinking water. Most states in Australia have recognised the importance of purifying seawater using reverse osmosis technology and have desalination plants either operating or under construction in an effort to drought-proof our nation.

ABB’s drives and motors surpass the energy efficiency requirements of Western Australia’s new Southern Seawater Desalination Plant whilst it pumps seawater which is converted into 50 billion litres of fresh drinking water for Perth residents annually. This, combined with the existing desalination plant based in Kwinana, ensures that more than 30 per cent of Western Australia’s water supply will come from climate independent sources.

The first stage of WA’s latest desalination plant was officially opened in September 2011, three months ahead of schedule and within the $955 million budget, ensuring an ongoing climate independent water source for West Australians. This new plant, the second for the west coast, is located between Binningup

and Myalup, south of Perth and the desalinated water will be fed into the existing Integrated Water Supply Scheme (IWSS). The IWSS pumps fresh water into Perth’s metropolitan dams which supply residents with high quality drinking water.

To achieve the optimum operating efficiencies, the Southern Seawater Alliance (SSWA) awarded ABB the contract to supply nine identical 800 kW 3.3 kV drives to power and control the main reverse osmosis (RO) and seawater intake pumps for the desalination plant following a competitive tender process.

SSWA are mindful of the ongoing environmental impact of a desalination plant on the local area and hence, all aspects of engineering design on the project required the highest possible

energy efficiency performance. This exacting standard also ensures the site will continue to have the lowest possible environmental impact into the future.

In order to prove the high levels of energy efficiency offered by ABB, the motors and ACS 1000i variable speed drives were thoroughly tested and achieved results which not only met, but exceeded the customer’s rigorous energy efficiency expectations.

John Kutniewski, medium voltage drives specialist for ABB in Australia said, “in our initial tender, we quoted an efficiency of 96.1 percent at maximum operating speed and the results of the testing carried out at our drives factory in Turgi, Switzerland revealed the efficiency was 96.4 percent.

ABB's motors and drives were thoroughly tested and achieved results which not only met, but exceeded the customer's rigorous energy efficiency expectations

“The ACS 1000i model is a fully integrated standard drive which includes an 11,000 volt input transformer. This combination is an unbeatable solution for pumping stations in the water industry. By employing our drives on the pumps instead of throttling, SSWA’s energy bill can be reduced by as much as 60 percent for the RO and seawater intake pumping applications.”

“In addition to being efficient, the drives include key interlocking to prevent

opening of the inverter power sections while the drive is energised. ARCGuard and output isolators were also included to address site operation and maintenance requirements without increasing floor space.”

The desalination plant has also ordered five ABB 750 kW motors to operate in conjunction with the ACS 1000i Drives and the pumps manufactured by FlowServe which will be operating on site. ABB has been working with FlowServe

Optimize process performance without compromising energy efficiency.

to test their drives and motors to ensure they will achieve maximum efficiency with the customers chosen pump supplier.

Additional to the drives systems provided on this project, ABB has also supplied low voltage switchboards, motor control centres, power factor correction equipment and transformers. All products have been designed with the aim of delivering reliability, lower operating costs and minimising life-cycle costs.

Water and wastewater utilities are facing many challenges from managing leakage and pressure, optimizing pump performance, improving potable water quality, reducing energy consumption and CO 2 emissions to lowering maintenance costs. ABB’s drives, motors and PLCs are designed to help motor-driven applications such as pumps, fans, compressors and conveyors, tackle these, and other, challenges.

To discover how to improve your utility’s energy efficiency and productivity, visit www.abb.com/water

Sewer bypass success

In August, Pump Affinity performed a key role in the 450mm rising main valve replacements from Wyong Shire Council’s Sewer Pumping Station (SPS) T22. SPS T22 receives sewage flows from 8 other sewage pumping stations, two private pumping stations and has over 4400 Equivalent Tenements in its catchment. The Peak Wet Weather Flow is up to 190L/sec.

Pump Affinity provide quality flow management and ground water solutions, including horizontal, wellpoint and well dewatering, pH dosing, pump project management, flow gauging, and pump hire.