9771445115000 01 MAY/JUNE $8.95 including GST TRUCK OF THE YEAR AUSTRALASIA RURAL TRANSPORT RISING STAR TWO NEW ELECTRIC TRUCKS TRUCKS ON TEST AND THE WINNER IS….

If you’re ready to get serious about tackling bigger jobs, grab yourself an NLR 45-150 AMT SWB Traypack from the Ready-to-Work range for $62,990† drive away. And to prove we aren’t playing, buy any NLR Traypack before June 30 and you’ll get $3,500* to spend on genuine accessories or a service agreement. So, now’s the time to trade up from your ute. Head to isuzu.com.au or visit your nearest Isuzu Truck Dealer now.

†O er One: NLR 45-150 AMT SWB Traypack (Promotion Truck) drive away between 1 April 2024 – 30 June 2024. Drive away price of $62,990 for the Promotion Truck includes GST, or a service agreement. Non-transferable or redeemable. Fleet and Government purchasers are not eligible. Visit isuzu.com.au for terms and conditions. FSA/ISZS2047 READY-TO-WORK NLR TRAYPACK RANGE Playtime’s over, get $3,500* to spend on extras. NLR 45-150 AMT SWB TRAYPACK

DRIVE † AWAY

$62,990

registration, government and statutory charges, and dealer delivery costs. *O er Two: Buy any Ready-to-Work NLR Traypack vehicle and receive $3,500 value for genuine accessories or a service agreement.

Versatility that’s good for business

DAF is a versatile all-rounder with the perfect combination of superior comfort and luxury for the driver and maximum vehicle efficiency for the operator. So, you need a truck for a hook lift system with excellent manoeuvrability and a high payload? There’s a DAF for that!

Whether your needs are distribution, long-distance haulage or construction, the versatility of DAF keeps you moving, and that’s good for business. DAF.COM.AU

SEE DAF VERSATILITY IN ACTION DAF PURE EXCELLENCE

A PACCAR COMPANY DRIVEN BY QUALITY

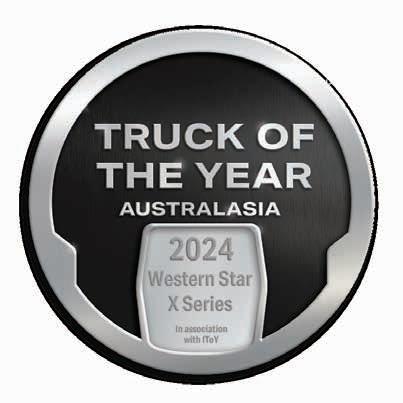

14 AND THE WINNER IS….

The winner of the Truck of the Year Australia was announced and presented at the Teletrac-Navman Technical Maintenance and Safety Conference, recently, on 13 March 2024 in Christchurch, New Zealand.

22 SMOOTH RIDE IN THE CITY

This first test drive of the second generation Fuso eCanter demonstrates how city delivery in the latest electric truck is going to give the driver a smooth ride in the city.

30 THE ECONOMICS OF TRUCKING’S CARBON ZERO

Looking at the realities which will face transport operations as they migrate across from fossil fuel dependency to the zero carbon economy, one of experts in the field examines some possible scenarios.

48 CLOSING LOOPHOLES EXPLAINED

In her report back to the Livestock and Bulk and Rural Carriers Association conference, the Executive Director of the Australian Livestock and Rural Transporters Association, Rachel Smith’s speech saw the recent act passed in Federal Parliament on closing loopholes explained.

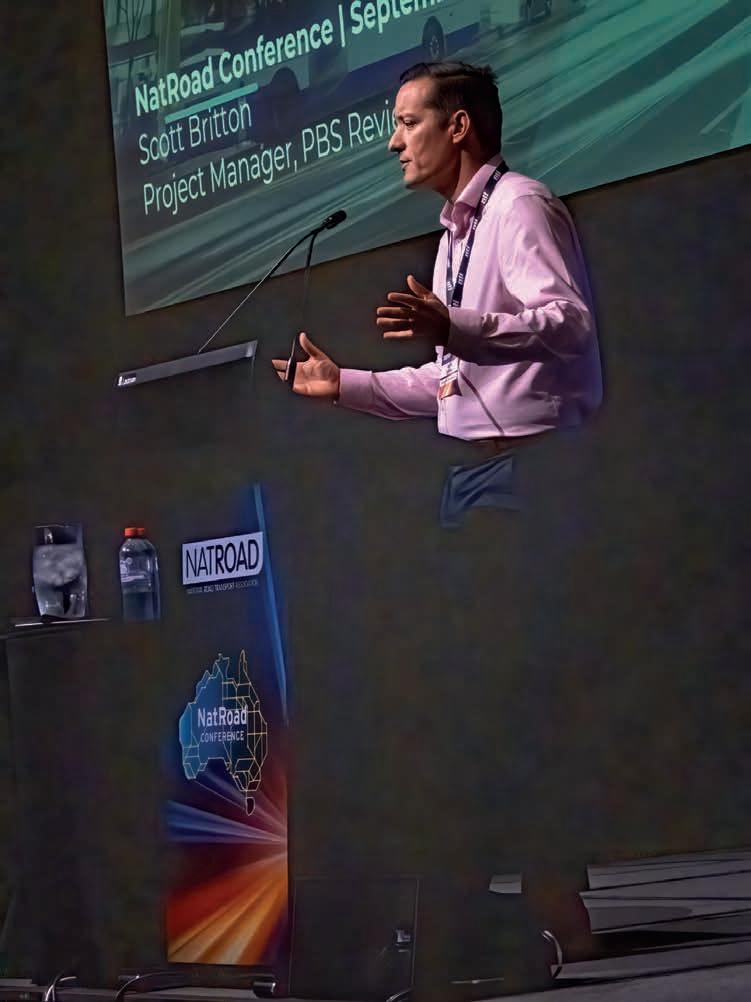

54 TAKING PBS FORWARDS

One of the most influential movers in the development of Performance Based Standards explains how the scheme is preparing for the next twenty years, taking PBS forwards and developing it further.

50 GETTING ALL THE ELECTRONICS TO TALK TO EACH OTHER

Trucking operators are now adding more and more electronic equipment to their combinations and need to ensure they can all talk to each other when needed, especially when they are used for compliance.

Contents ISSUE 140

ADELAIDE DARWIN PERTH MACKAY SYDNEY MELBO URN E BR IS BANE NEWCASTLE/HUNTER VALLEY TAMDELE, 21 Hakkinen Road, Wingfi eldSA 5013 Ph. 08 8347 1222 email sales@gitsham.com.au web www.gitsham.com.au Mobile Sales and Service Ph. 08 8927 0986 email info@isridarwin.com.au web www.isridarwin.com.au 408 Welshpool Road, Welshpool WA 6106 Ph. 08 9361 7646 email info@mmtisri.com.au web www.mmtisri.com.au 110-120 Maggiolo Drive, Paget QLD 4740 Ph. 07 4952 1844 email admin@isrimky.com.au web www.isriseatsmackay.com.au 510 Victoria Street, Wetherill Park NSW 2164 Ph. 02 9756 6199 email isri@isri.com.au web www.isri.com.au Unit 1/569 Somerville Rd, Sunshine West VIC, 3020 Ph. 03 9311 5544 email sales@isrisunshine.com.au web www.isri.com.au 3/120 Gardens Drive, Willawong QLD 4110 Ph. 07 3275 2044 email sales@isribrisbane.com.au web www.isribrisbane.com.au Unit 2/13 Hinkler Ave, Rutherford NSW 2320 Ph 02 4932 0600 email sales@hvss.com.au web www.isri.com.au ISRI: DEALERS

A NORMAL ELECTRIC TRUCK

The integration between the new technologies and the driver interface makes taking a trip in the new Mercedes Benz eActros more like driving a normal electric truck 38

A RISING RURAL STAR IS NAMED

In its second year, the Rural Transport Rising Star Award attracted another group of young people who are going to take the rural transport industry onwards and upwards into a, hopefully, bright future.

Standard Issue

46 ALRTA COMMITTED TO DRIVING CONTINUOUS IMPROVEMENT TO ANIMAL WELFARE STANDARDS

Driver and animal welfare continues to be a principal issue for the Australian Livestock and Rural Transporters Association and its members, writes Executive Director Rachel Smith.

49 NHVR TRANSITIONS INTO QUEENSLAND REGULATION

The NHVR is now seen across Queensland, following the transition of heavy vehicle safety services, writes Sal Petroccitto OAM, NHVR CEO.

68 CHARGING AHEAD

From my experience truck manufacturers overexaggerate the capabilities of their electric vehicles, reckons PowerTorque’s European Correspondent, Will Shiers.

72 HEADING INTO THE TRUCKING FUTURE

Industry stalwart, Bob Woodward, looks back on the developments in technology and wonders. Over the past 35 years there has been significant improvements in productivity longer combinations with heavier axle groups within the Australian road transport fleet. Increased axle group mass has been concurrent with developments in suspension systems, longer new combinations have resulted from research and broadened knowledge of vehicle dynamics.

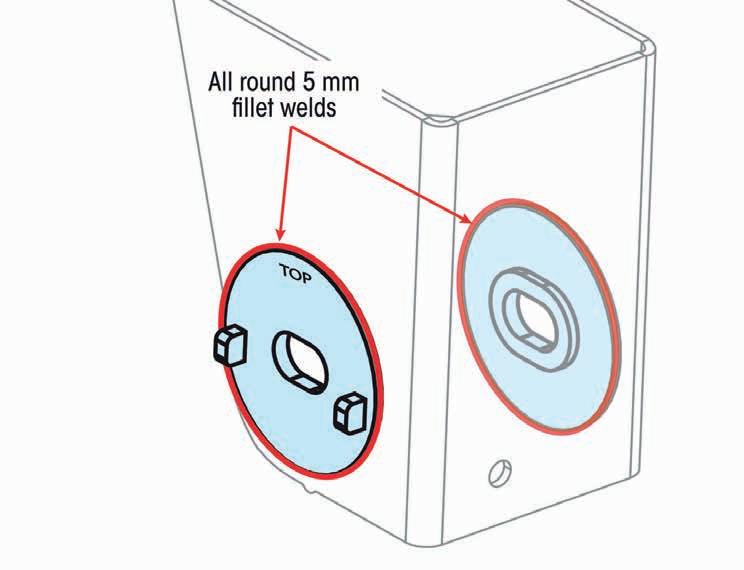

76 WORN HANGER REPAIR

Hangers are not an item that normally wear. However, they may become gouged or worn from a loose pivot bolt or wear washers that have worn through.

78 REFRIGERATION TRANSITION PART THREE

In this final instalment of our three part series of articles exploring the transition of refrigerated transport across to zero emission running, we will explore some of the solutions we will see on our roads in the near term.

the brand behind the brands

• Supporting drivers for more than 50 years

• Seating – on a higher level

0297566199 isri@isri.com.au

www.isri.com.au

ISRI SEATS 44

ATA CALLS FOR FWC FOCUS

The Australian Trucking Association has called on the federal government and the Fair Work Commission to ensure that truckies are getting a fair go in the new laws included in the Closing Loopholes Bill.

ATA Chair David Smith raised concerns over payment terms and fuel surcharges in its road transport contract chain orders. The FWC now has powers to make decisions on such matters.

The call arrived after the ATA’s February meeting.

“Payment terms and fuel surcharges are a longstanding problem for trucking businesses,” he says.

“We believe the industry and the TWU should be able to achieve a common position on these issues for the commission to consider.”

TWU National Secretary Michael Kaine supports David’s notion.

“Dangerous practices such as elongated payment times that push unsustainable financial risk onto transport operators and owner drivers on wafer-thin margins will be first cab off the rank,” he says.

The ATA and TWU will work together to ensure the FWC sets fair guidelines on these issues, as well as employees’ ‘right to disconnect’ when not on the job.

PAVING THE WAY FOR THE FUTURE OF HEAVY ELECTRIC VEHICLES

Queensland is paving the way for the future of heavy electric vehicles with the recent announcement of the state government’s next step in its Zero Emission Heavy Vehicle Network Map.

Heavier electric vehicles are set to be allowed to drive on certain freight routes in the state – predominantly in South East Queensland – with an eye on the further distribution and manufacturing of bigger and more powerful electric trucks in the state. State transport minister Bart Mellish says that Queensland wants to become a nationwide and global leader in the uptake of heavy electric trucks.

“This announcement will put Queensland on the map as a leader in future electric truck manufacturing,” he says.

“As transport is one of the main contributors to Queensland’s emissions, zero emission heavy vehicles can make a significant contribution to meeting Queensland’s targets to reduce emissions by 30 per cent below 2005 levels by 2030 and achieving net zero emissions by 2050.” There are risks that have to be considered regarding the additional mass of these vehicles, but the state

government reaffirms that zero emissions heavy vehicles are the future of the state.

This will allow electric vehicles with a steer axle mass of up to eight tonnes on freight roads in Queensland.

This has already allowed a company like Followmont Transport, a Brisbanebased organisation, to take delivery of the country’s first Volvo FH Electric.

The FH Electric prime mover only arrived in Australia a week before the handover in anticipation of the changing of the heavy electric vehicle rules.

It will be tasked with shuttling trailers between Followmont’s Eagle Farm depot, servicing major accounts around Brisbane and running overnight linehaul to the company’s Toowoomba and Sunshine Coast depots.

The 540kWh, 666hp FH Electric prime mover is currently rated to 44 tonnes and has a range of up to 300km on a single charge. A 60kW charger has been installed on site at Followmont’s head office for overnight charging, with plans to install charging solutions further afield as the company seeks to increase reach and range.

8 NEWS & VIEWS POWERTORQUE May/June 2024

IMAGE: VOLVO GROUP AUSTRALIA

EFFECTS OF ROAD TOLL PRIVATISATION

The effects of toll road privatisation in New South Wales have come to the forefront after the release of the Independent Toll Review interim report by Professor Allan Fels on March 11.

According to the review, significant reform is needed after damage across a number of years and various legislation which has failed to ease the burden on motorists.

The review first began in the first half of 2023 when Professor Fels and Dr David Cousins were asked to independently assess the efficiency, fairness, simplicity and transparency of tolls.

The NSW government says that the price of tolls in NSW are simply too high, which discourages the efficient use of toll roads. Toll prices have been locked in for decades with a system that was designed with financial returns back to toll road operators in mind rather than managing traffic in the most efficient way.

Reforming Sydney’s vast road toll network will be a complex task, the government adds, spanning 13 different toll roads and 10 individual contracts, with two more toll roads under construction.

The range of the review’s

recommendations include a unified, network-wide price structure that is charged on a declining distancebased method to assist people who must travel further – specifically the millions of motorists in western Sydney who currently carry the largest burden and have the fewest public transport alternatives.

It also recommends creating a stateowned special purpose entity to set toll prices and improve competition, legislative changes to allow toll prices to be set independently of individual contracts, and engaging the Independent Pricing and Regulatory Tribunal (IPART) in oversight of toll price setting.

The review’s results, however, has spurred the Transport Workers Union (TWU) to label Sydney’s toll road system as an “out-of-control” crisis, with motorists to pay an estimated $195 billion in tolls between now and 2060.

TWU NSW/Qld state secretary Richard Olsen says the tolling system has spiralled out of control, placing an unbearable burden on road transport, becoming “highway robbery for transport workers”.

“It’s high time for major reforms that prioritise the livelihoods of owner-

MITSUBISHI FUSO AND HINO PROVIDE MERGER UPDATE

Mitsubishi Fuso and Hino Motors have provided an update on the advanced technology development collaboration between Daimler Trucks, Mitsubishi Fuso and Toyota Motor Corporation.

The vehicle manufacturer says the merger between itself and Mitsubishi Fuso has been extended after originally targeting March 2024.

Hino says the extension is due to the ongoing process of obtaining the necessary regulatory clearances and approvals.

Since May 2023 the four manufacturers have collaborated

on achieving carbon neutrality and strengthening the commercial vehicle business on a global scale based on a Memorandum of Understanding (MoU).

The MoU also outlines a plan between Mitsubishi Fuso and Hino to merge on an equal footing and collaborate in commercial vehicle development, procurement and production.

Hino says the companies have been discussing how it can work with Mitsubishi Fuso to improve business efficiency and enhance competitiveness.

They have also discussed

drivers over corporate profits. The New South Wales Government must step up and take decisive action to rein in the exorbitant toll costs,” Richard says.

“The current trajectory is unsustainable and unjust and the tolling companies’ exploitation of drivers must end. We demand immediate action to overhaul the system and better the well-being of transport workers.”

Despite Prof Fels last year stating that the review would not recommend ways to override long-term contracts to toll companies like Transurban, the TWU says the finances of private companies are being prioritised at the cost of drivers.

The TWU says the ongoing increases in the costs of toll roads creates an enormous financial burden for all transport workers. It adds that while just about every operating cost for owner-drivers has steadily increased over the years, none has increased more than toll roads.

The union points to Prof Fels statements, who made it clear “tolls need a big shake up. Major reforms, no holds barred and the New South Wales Government needs to take back control of tolls.”

how Daimler and Toyota can collaborate on further enhancing their technology development capabilities and promote Connected-Autonomous and Automated/Shared/Electric (CASE) technology across Japan and Asia.

Hino says merger discussions are progressing on a positive note and that the strategic objectives and logic of the proposed transaction continues to be valid, with the timing of the business integration set to be announced as soon as a reliable timeline for the pending investigations is available.

9 www.powertorque.com.au NEWS & VIEWS

NATROAD WELCOMES CALL FOR MORE REST AREAS

A Parliamentary committee has recommended that the NSW Government build more heavy vehicle rest areas in the state after an inquiry into the pressures on truck drivers.

The NSW Legislative Council Committee on Transport and the Arts released the report in February, which also called for an education program for motorists on the importance of rest areas to heavy vehicle drivers.

The inquiry made a number of recommendations for how the government can ease pressures on truck drivers, and also welcomed Austroads’ licence changes.

NatRoad CEO Warren Clark says the association is supportive of the inquiry’s recommendations.

“It is a big issue with our members, and we advocated strongly on their behalf,” he says.

“I’m happy to say the committee members got our message.

“Rest areas may not be the sexiest of topics to anyone outside our industry, but they are a preoccupation for many drivers for reasons of safety and complying with the rules.

“It’s not good enough that someone moves up the licence ladder on the basis of how long they’ve held a qualification.

“We have long held the view that drivers issued with a heavy vehicle licence must have the skill sets and experience needed to drive a heavy vehicle.

“We welcome the committee’s concurrence with that view and look forward to continuing to work with all governments towards a national competency-based licencing system,” says Warren.

NHVR TAKES OVER IN QUEENSLAND

The National Heavy Vehicle Regulator will begin the transition to take over road regulation in Queensland, following in the wake of the Queensland Department of Transport and Main Roads.

This will see the regulator become fully responsible for on-road compliance and enforcement in the state starting from April 20 this year.

NHVR CEO Sal Petroccitto says the organisation hopes to create consistent regulation for heavy vehicles nationwide to provide safer roads and work for drivers.

“The transition of heavy vehicle services in Queensland will complete our National Service Transition (NST) program – a huge accomplishment for our organisation,” he says.

“I am thrilled we are a step closer to achieving our aim, of having a consistent approach to compliance and enforcement from the roadside to interventions, borderless operations and delivering timely, national responses to critical

compliance issues.

“The transition will result in a more streamlined approach to how heavy vehicles are regulated across Australia, a journey that will have taken the NHVR almost 10 years to achieve.

“From April 20, on-road compliance, investigations, prosecutions and programmed heavy vehicle inspections will be some of the services currently provided by TMR to transfer across to the NHVR.

“This exciting milestone will see 165 roles added to the NHVR as part of our Northern Region, many of which will transfer across from TMR.”

The NHVR is also launching a new operation to improve safety in the construction industry.

It will be an on-road targeted operation, focused on mechanical safety and compliance with mass, dimension and loading requirements of heavy vehicles operating in support of the construction sector.

DAIMLER PUSHES AHEAD WITH NEW SAFETY SYSTEMS

Stricter safety regulations for trucks are set to come into effect as of July 2024 in Europe, and Daimler Truck is preparing accordingly with its latest safety systems.

All new vehicles introduced since July 2022 have had to comply with these new standards, which requires driver assistance systems on truck and bus models.

“The EU General Safety Regulation is an important step towards accident-free driving – our ‘Vision Zero’,” says Rainer Müller-Finkeldei, Head of Mercedes-Benz Trucks Product Development.

“We have been consistently pursuing this path for decades and are now setting new standards with

our enhanced safety assistance systems. And this with a view to the best possible accident prevention to protect drivers and all road users.”

The addition of systems including Active Brake Assist 6, Active Sideguard Assist 2, Front Guard Assist, Active Drive Assist 3 and Traffic Sign Assist have become standard on a number of models including the Actros model series, the new generation of the Actros L, the Arocs, Atego and Econic model series and Mercedes-Benz Special Trucks.

This all aims to lower the road toll on European roads, and eventually see these systems rolled out in all Daimler models across the world.

10 NEWS & VIEWS

POWERTORQUE May/June 2024

LBRCA ANNOUNCES 2024 YOUNG DRIVER OF THE YEAR

The Livestock, Bulk and Rural Carriers Association (LBRCA) has announced the winner of the 2024 LBRCA Young Driver of the Year award.

Charlie Pittman of Pittman Transport received the award at the LBRCA annual conference on February 23 to 24 which was held in Wagga Wagga.

Hailing from Orange, NSW the 25-year-old was recognised for his outstanding dedication to safety, excellence in best practices, and notable contributions to the road transport industry, earning him the much sought after accolade.

Growing up in a family immersed in the transport business for over a century, Charlie’s journey into the industry began after completing a business degree. He embraced the family legacy by actively engaging in the transport of livestock and bulk commodities throughout Australia.

“The job is really exciting as you

can be your own boss behind the wheel, and the opportunity to travel is also quite attractive,” he says.

“In the last three years, I have travelled through most of NSW and as far as Far North Queensland and Tasmania.”

Award initiator Lynley Miners congratulated Charlie on his outstanding best practice approach and commitment to driving and safety.

displays an exemplary work ethic, a proactive approach to safe work practices, and is a brilliant role model for the rural transport industry.

“The professionalism and leadership qualities Charlie possesses are a real win for our industry.

“He is hungry to learn and absorb every detail of the industry to be the best at what he does.”

HYUNDAI AND IVECO JOIN FORCES

A supply agreement has been reached between two major vehicle manufacturers as Hyundai and Iveco join forces. An Iveco-badged all-electric light commercial vehicle will become available in Europe, based on Hyundai’s eLCV.

The new vehicle will join Iveco Group’s electric light commercial vehicle lineup, enhancing its LCV portfolio alongside the widely sold Iveco Daily.

There was an agreement ceremony, held at Hyundai’s Seoul headquarters, which was attended by Jaehoon Chang, President and CEO of Hyundai Motor Company, Ken Ramírez, Executive Vice President and Head of Global Commercial Vehicle & Hydrogen Business at Hyundai Motor Company, Gerrit Marx, CEO

of Iveco Group, and Luca Sra, President, Truck Business Unit, Iveco Group.

Luca Sra says that the agreement is an exciting move for both companies.

“The unique partnership between Iveco Group and Hyundai Motor Company is making another significant step forward,” he says.

“The introduction of this new all-electric vehicle is particularly exciting for the European market, where urban and suburban distribution and delivery are crucial missions for logistics operators.

“We are confident that this agreement will not only strengthen our product offering but will also deepen our relationship with Hyundai, paving the way for continued collaborative projects that advance a more sustainable society.”

Hyundai and Iveco have been working in partnership since 2022, in which time they have developed and distributed a number of hydrogen-powered vehicles. This included the co-development of the eDaily FCEV and the launch of the E-Way FCEV city bus.

Under the partnership, Hyundai will manufacture and supply the Iveco-badged chassis cab for the European market and Iveco Group will locally customise and distribute the complete vehicles exclusively through its sales channels.

Iveco Group’s new product based on Hyundai’s Global eLCV platform will have its launch at this year’s IAA Transportation 2024, planned to be held from September 16–22, 2024, in Hannover, Germany.

11 www.powertorque.com.au NEWS & VIEWS

IMAGE: LBRCA

MITSUBISHI FUSO

LAUNCHES LIGHT-DUTY CANTER MODEL

The Japanese market has a new truck to look forward to, with the release of the light-duty Canter. It is the diesel model of the popular current eCanter model, which has enjoyed strong sales in the past year.

The new Canter will be available through MFTBC dealers and regional sales centres across Japan starting in February.

Mitsubishi Fuso says the new Canter model includes a redesigned interior for the first time in 14 years, with new design and functionality including a new dashboard and exit grips.

There is also a new 10-inch LCD panel, easy-to-use steering wheel switches, and a centre display that allows for operation of both navigation and radio via touch panel.

This Canter model also includes Fuso’s Active Sideguard Assist to help prevent collisions with pedestrians and cyclists, Active Brake Assist 5 and Active Attention Assist.

Its specs are as follows:

• Engine: 4P10+ 96kW(130PS)

• Transmission: 6-speed Duonic 2.0

• Standard Cab

• Wooden standard body

• All low floor

NEW CO2 FLEET EMISSION STANDARDS FOR EUROPEAN TRUCKS

Members of the European Union have reached an agreement on new CO2 fleet emission standards for trucks and buses across Europe.

These new standards will set figures for the allowable future emissions of CO2 from heavy vehicles. Emissions from trucks over 7.5 tons are required to be reduced by 45 per cent by 2030 – an ambitious goal.

Continuing into the coming decades, these emissions will then need to drop by 65 per cent by 2035, and 90 per cent by 2040 compared to a 2019 baseline.

Any trucks powered exclusively by e-fuels – be they electric or hydrogen – will be granted indefinite approval from the emissions requirements.

After EU state negotiators agreed in January that stricter emissions requirements would be necessary, this measure aims to provide legal certainty for both vehicle manufacturers and alternative fuel providers.

Currently, there are an estimated 921 hydrogen fuelling stations operating worldwide, with 37 new stations opening in Europe in 2023. This makes for a total of 265 stations across the continent, with Germany leading the way with 105.

According to H2stations.org, 92 per cent of the stations built

across the last 12 months in Europe are able to refuel heavy vehicles, making hydrogen trucking significantly more viable internationally.

Across the rest of the world, an additional 12 stations opened in Japan in 2023, 29 in South Korea, and seven in North America.

Australia’s first hydrogen refuelling station for trucks – located in Port Kembla in Wollongong, NSW – opened in July 2023, putting Australia on the map.

Most of the new hydrogen stations in Europe are designed to fuel heavy-duty vehicles, reflecting a shift in focus from fuel cell passenger cars to commercial vehicles, according to H2stations. Germany is also upgrading existing stations to serve heavyduty vehicles. Internationally, East Asia and the US are leading in the number of hydrogen fuelling stations.

ON BOARD ON SITE ON DEMAND

NEWS & VIEWS

LEFT HAND PAGE

IMAGE: AA+W/STOCK.ADOBE.COM

ALLISON EXPANDS SERVICE NETWORK

Global manufacturer of automatic transmissions systems Allison says its service network is continuing to expand as its list of customers continues to grow.

Australia is a major market for Allison. Its three local distribution and service partners include the likes of Heavy Automatics, Penske Australia and Transdiesel.

“While our distribution partners are increasing their service capabilities to support the growing number of Allison-equipped vehicles in Australia, our customers will continue to see value over the lifetime of their vehicles as Allison transmissions are more cost-effective due to lower maintenance,” said Robert Cavagnino, Head of Australia Sales at Allison Transmission.

“We design and manufacture a quality product and work very closely with our customers to be able to articulate what is needed for the harsh Australian environment, aiding resilient vehicles to overcome myriad challenges.”

Heavy Automatics, which has more than 100 Allison-trained staff working across Australia, recently opened a new 1,500 square metre service centre in Wacol, Queensland in June. Located within close proximity to vehicle equipment manufacturers, this presents even further expansion opportunities.

Penske Australia also opened a new site near the Gold Coast in September, while Transdiesel has also settled into its new flagship servicing centre, a 5500 square-metre facility in Epping, Victoria.

“Allison Automatics allow fleets to have drivers with varying levels of experience and with the drivetrain doing the work there’s less fatigue for the driver and more precise operation ability. This allows drivers to focus of the task at hand,” Robert said

“Allison’s superior performance encompasses startability, gradeability and steady acceleration, covering duty- cycles at higher average speeds.”

FUEL DELIVERY DRIVER LEADING THE WAY FOR INTERNATIONAL WOMEN’S DAY

Lowes Petroleum’s Alicia Waddingham may not be the typical image of a truckie – a 33-year-old single mother – but she’s breaking down walls and living her dream in the transport industry.

She’s been a driver for Lowes for a year now, making fuel deliveries anywhere within 100km of the depot. Having driven trucks for 13 years, Alicia says it’s like no other job in the world.

“What I like best about being behind the wheel is the freedom,” she says.

“Being out on the road and very much in control of my own day, listening to my own music. It’s like my own personal little office but on wheels – a moving office.

“Driving trucks is really like nothing else. It’s such a great job, because you’re not going to work and sitting in an office that doesn’t change. Even if you are seeing the same landscape every day it’s still somewhat different.”

Being a single mother has its challenges, but Alicia says Lowes has been very understanding and flexible with her hours.

She’s behind the wheel three days a week, and has the freedom to get home every night to her young daughter, which she says makes the job suit her life well.

“Clara is five years old, so it’s important I have a work life balance,” Alicia says.

“The hardest thing for any single mum is having a job and a child and trying to juggle the two. My knock off time can be anywhere from 2pm or 5pm so it’s very manageable and that my schedule allows me to be home every night is amazing.

“I am seeing more women drivers on the road these days as well as driving headers on the farms, so the word is getting out that this is a good career for women.”

NEWS & VIEWS

ALEMLUBE DIESEL FUEL

DISPENSING &

you

way. Available in capacities of 100L, 200L, 400L, 450L, 600L, 800L, 1,000L, 1,200L www.alemlube.com.au

STORAGE,

METERING KITSwith

all the

AND THE WINNER IS…

The winner of the Truck of the Year Australia was announced and presented at the Teletrac-Navman Technical Maintenance and Safety Conference, recently, on March 13 2024 in Christchurch, New Zealand.

Truck of the Year Australasia (ToYA) is judged by a jury consisting of the PowerTorque Editor, Tim Giles, New Zealand Trucking Media Editorial Director, Dave McCoid, FOCUS on Transport & Logistics Editorial Director, Charleen Clarke, long-time Australian trucking industry stalwart, Bob Woodward (who recently retired as the Australian Trucking Association’sChief Engineer), and Randolph Covich, Publisher of Deals on Wheels (New Zealand).

The new Western Star was in competition with two other contenders, in the form of the Volvo F-Series Electric and Scania’s Super Series. Any truck receiving a nomination as a ToYA candidate is being recognised for its

contribution to the standards of safety and efficiency of transport of goods by road in Australasia.

“I am thrilled to receive the 2024 Truck of the Year Australasia award on behalf of our Australia and New Zealand Western Star teams,” said Christie-Johnston. “Since we launched the all-new X-Series in late 2022, we’ve received outstanding feedback from everyone who has driven the trucks. From customers to media personnel, the response has been unanimous that the X-Series is a seriously premium package.”

Tim Giles talked about the way all the contenders brought major strengths to the competition. He ran through their strengths and the reasons for them being included in the short list.

“When it comes to pure engineering, the way Scania took what was an excellent and a frugal driveline and redesigned all of the components, taking them to another level, is very impressive. Volvo needed an electric alternative in the prime mover department, and came up with a solution which turned a good to drive, well-designed truck into a good to drive, well-designed truck that also achieves zero emissions,” said Tim at the TMS event.

“In the new X Series from Western Star, we see a completely different truck from its predecessor; the design brings the Western Star brand bang up to date. The X Series includes all of the latest goodies like the Detroit DT12 AMT, which has performed well from

14 TRUCK OF THE YEAR AUSTRALASIA

POWERTORQUE May/June 2024

the word go. For the traditionalist, there is still a Roadranger available, just to reassure us that the dying art of the truck driver is still with us.”

Looking into the Australasian truck market from a overseas perspective, Charleen admitted that this year’s competition was particularly challenging to judge. She was unable to attend the presentation, but sent her comments online.

“All three contenders are superb trucks,” said Charleen. “On the one hand, there was the Scania Super, a brilliant truck that proves the potential for the internal combustion engine. It does everything exceptionally well, but the potential for fuel savings is hugely appealing. This would definitely resonate with each and every transport operator.

“Then there was the Volvo. The company has done an astounding job of bringing e-mobility to truckers around the world. The FH is sublime in

that a driver can just hop into it, drive the truck, and save the planet at the same time (yes, I know that’s a slight exaggeration).

“Finally, there was the Western Star X-Series. With its powerful driveline, better-than-ever safety features, comfortable and ergonomic cab, we all knew that the X-Series had to be in with a shot. The X-Series got the nod from me because it’s a huge leap forward for the brand. It’s

also probably the ultimate truck for Australasian transport operators, and it can be rolled out right now.”

Competition host for 2024, Dave McCoid felt the competition was really interesting this year, and had given the jury some difficult decisions to make, due to the fact that each truck was innovative in a different way.

“After a couple of difficult rounds of discussion all five of us involved in the selection process were unanimous the

15 www.powertorque.com.au

AUSTRALASIA

TRUCK OF THE YEAR

IMAGE: WESTERN STAR TRUCKS

L to R, Dave McCoid, Hamish Christie Johnston, Kurt Dein and Tim Giles.

IMAGE: NZ TRUCKING

TRUCK OF THE YEAR AUSTRALASIA

Western Star X-Series was this year’s winner,” said Dave. “The X-Series circumvents several steps in what would normally be the evolutionary path for a truck at the stage the previous model was at, but being able to tap into the Daimler Truck North America platform has catapulted the X-Series to the pointy end of the market.

“The result not only increases choice in the marketplace for those whose customers have stringent safety requirements, but also raises the industry sector bar for the average level of capability. It also extends the challenge to competitors whose premium bonneted products might not match the X-Series in some core capabilities. In terms of the New Zealand market, offering an 8x4 and the 450kW engine hits the nail on the head.

“And lastly, there’s also that

are, being proud and honouring it, and knowing there’s still an active market. Yes, I’m talking gauges, gear levers, and grain on the dash. The sun is most definitely setting on that era in the industry, but not just yet, if that’s what you want in your big, new, shiny Star. This is a well thought through marketwide offering.”

THE WINNER

For a fuller profile of the winning truck range, see the following article on page 18.

THE RUNNERS UP VOLVO F SERIES ELECTRIC

When looking at the contenders for the Truck of the Year Australasia, it was important to look at some of the new technologies coming through and see if there are any, which have reached the point where they look like they are going to be effective and have arrived

With the launch of the Volvo, heavy duty electric truck range late in 2023, the Australasian transport industry could see a viable alternative option on a model which is already one of the top selling trucks. The Volvo heavy duty range has been effective and grown in Australasian markets, now the company is offering a zero carbon emissions alternative to the current diesel range.

Two members of the ToYA jury, Tim Giles and Dave McCoid, got a chance to test drive a Volvo FH Electric at the end of 2023. This is a fully electric truck and one which will effectively change the emissions effect of the freight task, but it is an interim technology. This is not going to be the final product which Volvo will be offering to the market in the long-term as a zero carbon emissions alternative.

This first iteration of the Volvo heavy duty electric truck is a relatively small

16 POWERTORQUE May/June 2024

Kurt Dein, Head of Western Star Trucks

IMAGE: NZ TRUCKING

No offer of shares in Capricorn Society Limited (ACN 008 347 313) is made in this promotion. ALL THE PARTS YOU NEED IN THE ONE PLACE.

Generous

Find out more about the benefits of belonging to Australia’s largest coop for automotive.

One trade account Quick access to parts & services

Rewards Program No joining fee At Capricorn, we’ve done the hard work for you. With one consolidated trading account across thousands of suppliers, we’ve got all the parts and services you need to run a successful heavy vehicle business. It takes the hassle out of managing multiple payments – plus you’ll earn Capricorn Rewards Points for every dollar you spend, putting cash in your back pocket.

TRUCK OF THE YEAR AUSTRALASIA

put, the Volvo engineers have looked at the current diesel Volvo FH, and removed the engine and associated accessories, then replaced them with all of the equipment required to create an electric driveline.

Having driven quite a few electric trucks in test drives in the last couple of years, it has become clear that one of the differentiating elements between trucks, is the way that the software and computers on board control the application of power through the driveline. Without this control the acceleration can be too quick and the driver’s head will smack into the headrest of the driver’s seat.

This system shows its quality in the fact that pressing the accelerator, simply enables the vehicle to move off in a controlled manner, gradually picking up speed until reaching the desired velocity. This truck moves with the smoothness and effortlessness we have come to associate with Volvo in recent years..However, the electric version of the FH does take this to another level.

SCANIA SUPER

In a truck test drive, PowerTorque took two Scania Super models out for a quick run. There was a Scania 460P Super pulling a single trailer and a Scania 560R Super pulling a fully loaded B-double set.

The return of the Super name is

a logical choice, it has been used historically by the brand when new engines were introduced and was often written somewhere on the front of the truck, in the past. The 13 litre engine in the two trucks tested is an all-new engine for Scania. This test drive included the 460hp version and the 560hp version, which taking the 13 litre into unknown territory.

There’s no EGR, but a two-stage SCR, the main dose is injected just after the turbocharger exhaust outlet near the exhaust brake flap where the exhaust gas is hot and turbulent. This better atomises the AdBlue for a more efficient clean up of NOx.

High compression engines tend towards higher ignition temperatures, in cylinder, leading to higher NOx

the point at which the power curve flattens out before rising slowly to maximum power between 1700 and 1800rpm.

On the 560hp version of this engine the torque maxes out at 2800Nm (2065ft lb) which is up there, in terms of torque, with many of the 15 and 16 litre engine available.

In a change which took many by surprise Scania have broken with a very long tradition and developed an AMT without any synchros. Opticruise has been though many iterations, always with synchros, but this new box is a revolutionary and not evolutionary step-up.

As part of the fuel saving design the AMT will only go up to 12th

18 POWERTORQUE May/June 2024

L to R, Dave McCoid, Hamish Christie Johnston, Kurt Dein and Tim Giles.

IMAGE: NZ TRUCKING

IMAGE: NZ TRUCKING

IMAGE: WESTERN STAR TRUCKS

A CLOSER LOOK AT THE TOYA WINNER

Launching a new truck range for a brand like the Western Star X Series can be a tricky task. Any renewal has to balance the need to retain the traditional strengths of a good-looking dependable robust truck, with the requirements to include all of the latest technology, in terms of driveline, electronics and comfort. This can be achieved by getting the small details right as well as the headline items. PowerTorque looks at the fine detail put into the Truck of the Year Australasia’s design and runs through the features drivers will notice.

There are a number of changes in the X Series that are unique to the Western Star brand in the Australian market. The truck which emphasises this point the best is the 48X a truck, which doesn’t exist anywhere else in that world.

When it comes to the 49X, it’s got the power hood, a larger bonnet with more internal volume than anything used in the US. The design includes a lot of features and improvements underneath which are needed for our higher temperatures and increased GCM which 49X will run at here in Australia, plus coping with the rougher roads.

20 TOYA WINNER

POWERTORQUE May/June 2024

IMAGES: WESTERN STAR TRUCKS

The bonnet is now made from a moulded resin instead of the previous fibreglass design. This makes it more flexible, and is claimed to be more durable and impact resistant than the previous model.

As a power plant, there’s the Detroit DD engine range, coupled with a choice of Allison auto, Eaton Roadranger and the Detroit DT12 AMT. The truck is a completely 12-volt system, as you would expect from a North American truck.

The larger cabins now available have come from the Daimler (Freightliner) catalogue, but when fitted, to retain durability, there are steel crossbeams fitted to maintain rigidity. These are exclusive to Western Star.

Climbing up into the new cabin the first thing you notice is the ’70 degree ingress’ which describes the way the aluminium steps are set back so that it’s not a vertical climb up into the cabin, it’s more like a set of stairs. There are five points of contact when you’re getting into the truck.

Of course, it would not be a new modern truck without the full multifunction steering wheel, with which we are becoming more and more familiar.

21 www.powertorque.com.au

TOYA WINNER

Looking at the dash it is a well laid out, but a standard looking array. To the driver’s left, on the binnacle, there are dials, radio and aircon controls. One step to the right is the customisable area. This is where operators can put any sets of controls they want or leave it blank. This will be the home of the screen for the entertainment system which will follow later.

SMOOTH RIDE IN THE CITY

This first test drive of the second generation Fuso eCanter demonstrates how city delivery in the latest electric truck is going to give the driver a smooth ride in the city.

22 TRUCKS ON TEST

POWERTORQUE May/June 2024 IMAGES:

DAIMLER TRUCKS

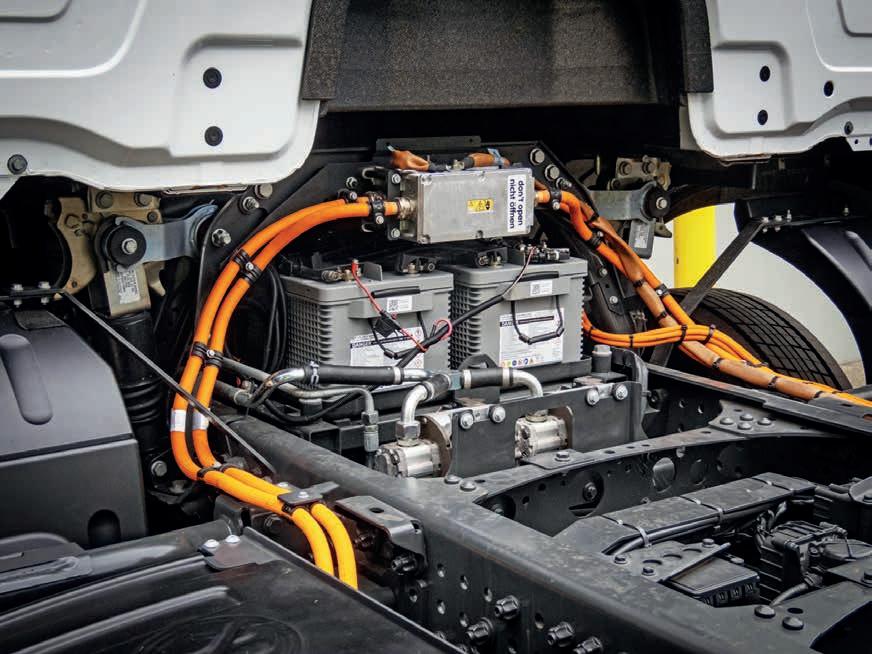

Driving and then running a Fuso eCanter will be many truck operators first contact with electric truck technology. Running a truck powered by batteries and being charged, either en route, or back at the depot, plus the importance of cooling systems, modularity, and weight distribution.

The development of this next generation of electric vehicles from Fuso, has taken key learnings from the earlier generations, and this is the third iteration of the eCanter which PowerTorque has had a chance to drive, and the major steps forward at each step are very clear.

The first prototype we saw was a novelty, but a bit rough when it came to accelerating. The progress made on the first eCanter to be sold here, three years ago, was striking, with the computer controlling the application of power through the drivetrain to such degree that driving it felt smooth. This was Australia’s first taste of an electric truck from a major manufacturer and there are now around 50 on Australian roads

The arrival of the second eCanter may not be so strikingly different, but it does demonstrate a genuine level of sophistication in electric truck design. The addition of the eAxle means this is the finished article, with the emphasis now on improving the communication and integration between the batteries, electric motor and final drive. On the evidence of this test drive, the engineers have done an excellent job. As the cost calculations change over time, we can expect to see many more appearing on our roads in the next few years.

Advanced safety features in these new truck models includes side guard assist with active braking, stopping the vehicle to prevent accidents with people, vehicles or objects on the nearside of the truck.

Operators do now understand the need for advanced systems to stop vehicles in emergency situations. Concerns about the reliability of these systems, potential benefits. the effectiveness of audible warning systems and the challenges of

norm in our fleets.

“All of our experience with the first generation eCanter, with the first generation OEM electric vehicle (EV) into the market has informed this new eCanter,” said Romesh Rodrigo, Head of Vehicle Homologation, Regulatory Affairs and Future Mobility at Daimler Truck Australia Pacific. “It was also very evident about its first mover advantage, and the fact that we only offered it in one variant shows how much effort went into the vehicle itself. The first generation units have clocked up over 8 million km, globally. There’s a lot of key learnings come out of that and fed into the next generation eCanter.”

“It’s been really interesting hearing the feedback around the applications where they have targeted, saying, this is where it’s at, this is what does the job and some of them have had carved out a special job for it.

“The good thing about eCanter having been introduced into our market for a period of time is the fact that our dealers have had experience

23 www.powertorque.com.au

TEST

TRUCKS ON

TRUCKS ON TEST

comes in, it’s not going to be foreign to the network.”

Fuso has confirmed the next generation all-electric eCanter will be launched in Australia this May with a full model line-up consisting of 14 variants.

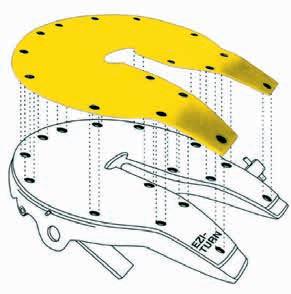

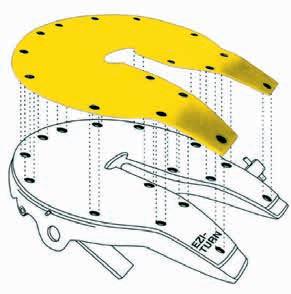

SPECIFYING AN ECANTER

The basic specifications of the eCanters includes all of those, outside of the driveline, offered in the existing fossil fuel vehicles that are on the market. Nothing has been subtracted from the specification purely because it is a different powertrain.

The payload available on the eCanter varies from 500kg with one battery on the lightest truck up to a 4.5 tonne GVM with a body where the payload is around 600-700kg. When you go up to six tonne GVM, there’s a payload of around 2.5 tonnes. Each battery weighs roughly 500kg, so moving from two to three batteries will reduce payload by around 500kg.

The other side of a payload calculation is the fact that the range is changing as you add each battery (there’s a choice between one and three). Each extra battery will increase range by, at least, 100km. As a rough rule of thumb one battery limits range to just over 100km, with two batteries that’s 200km and with three, 300km.

The caveat here is, of course, driving style. A smooth and frugal driver will get much further and someone who goes hard and is constantly on and off the brakes, is going to get no more than the projected range.

Fuso expect the eCanter sweet spot will be around the six tonne GVM model, which offers enough payload to make it more viable and also offers

the choices around batteries. An operator can choose to go with one battery and get more payload, if they concentrate on city centre deliveries and only need 100km plus range.

If they want more range the second battery doubles that range, but knocks off 500 kg of payload and a third battery gets a much better range but further compromises payload. You pays your money and takes your choice.

The big ticket item in the move to this second generation of eCanter is the inclusion in the design of the eAxle concept. This is a technology which makes logical sense and we can expect it to roll out across all truck designs into the future. However, currently Fuso and Mercedes Benz are the only brands offering this kind of technology in Australia. The eAxle is, of course, heavier than a conventional differential, but does allow for more flexible weight distribution towards the front of the vehicle.

Because this removes the need for a drive shaft from the motor/engine under the cab, chassis real estate becomes available allowing the batteries to be mounted well within the perimeter of the vehicle. This mitigates the safety scenario where there is a danger of a battery cell being ruptured in a side-on collision, and a risk of fire. The extra space available on the chassis is also going to give bodybuilders more room to bring a design down beneath the main body level if required.

The eCanter is fitted with thermally controlled battery packs, with cooling liquid lines in the battery pack itself, integral in the structure of the battery packs.

One of those topics which will

be front of mind will be the safety features of a new vehicle, and battery safety and their protection from impact and fire will be high on the agenda. Around the batteries are mounted deceleration sensors, which will detect any side impact and immediately kill the high voltage system, reducing the risk of fire.

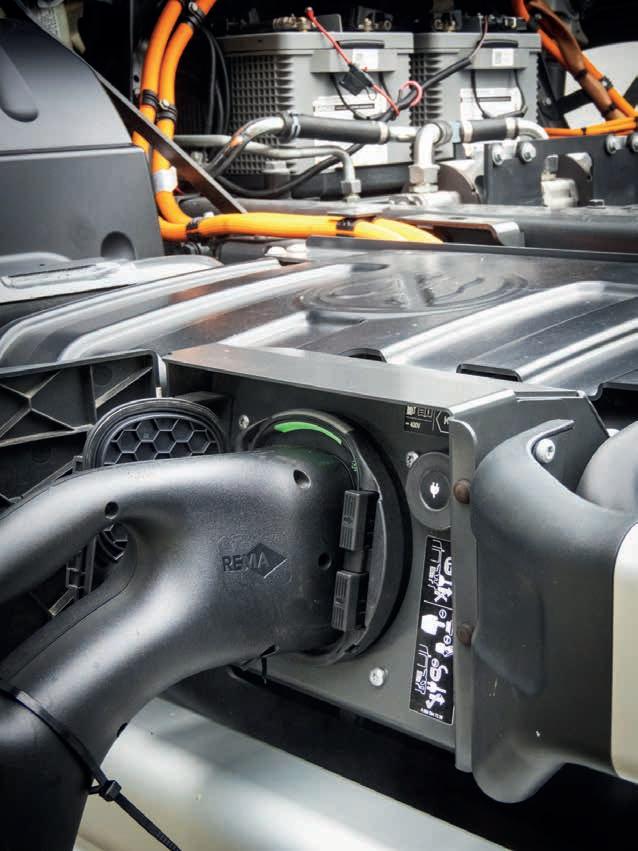

In terms of charging, Fuso covers all of the bases, it can use both AC charging, from a three phase socket and DC charging, which is much quicker, but requires the right electric infrastructure on site. This means that it can be used in a back-to-base scenario and charge up overnight on AC, which is generally available. However, when working in a more time pressured task it can use DC charging, which would enable a truck to work shifts, but comes with expensive infrastructure.

These new eCanter models have independent front suspension(IFS) on both narrow cab and wide cab, but not on the heavier 7.5 and 8.5 tonne GVM models. These revert to the typical Fuso beam front axle. Driving the eCanter on some the the wonderful(?) Melbourne roads sees the IFS smooth out the worst of the bumps and adds to the serenity in a cab, which is already eerily quiet.

“What this new design has given us the ability to do, is offer 14 variants of the eCanter, and a lot of it comes down to this modularity,” says Romesh “Going all the way from four and a half ton from a single battery. You can run a dual battery at 4.5 tonne, but payload starts to come down. This is obviously a challenging segment, for, these trucks in general, all the way up to eight tonne.

“With all of these you have the ePTO option, which can be either

24 POWERTORQUE May/June 2024

Superior construction and performance; now with intelligent control.

Unlock your Ultima light bar’s full potential with a revolutionary new Ultima Connect+ Controller.* Featuring 3 customisable driving modes, boost mode and the ability to connect multiple lights, Connect+ gives you total beam control.

Ultima High Performance Light Bars are the first in Narva’s innovative Ultima Connect+ range.

BRAWN: Ultima Light Bars

• Market-leading beam performance

• 2 beam pattern options available

• Unprecedented 10-year warranty

BRAINS: Connect+ Controller

• Adjustable brightness

• Boost mode – 15% more power for 30 seconds

• Single unit to control all Connect+ enabled products

ULTRA-WIDE FLOOD BEAM PATTERN LONG & WIDE HYBRID BEAM PATTERN YEAR WARRANTY CONNECT+ IP68 IP69K CUSTOM TRIMS SCAN TO SEE THEM IN ACTION narva.com.au/Ultima

*Sold separately

a pulley drive, which is not a super high torque output more for refrigeration compressors, and then you also have direct close coupled which obviously increases the capacity a lot.”

ON THE ROAD

PowerTorque took both of the models available for testing for a drive of around 50 plus km route in and around the city in Melbourne, on roads which will probably be the kind of workplace these trucks will be handling day-in day-out when they

Sat in the driver’s seat, the driver does feel relaxed, due to low noise levels and the access to really powerful torque, under the right foot. This feel of the truck and the way it seamlessly accelerates when needed, will probably aid drivers in adopting a more relaxed style, and then be better able to get more range.

The design refresh retains a walk through cabin, the eCanter and Canter share a cabin design, so there is still the dash mounted gearstick for the diesel powered version. However, on the eCanter, that control

option. Position three regenerates the most and works very much like an engine brake or retarder on large diesels, it brings the truck up quite quickly.

The new generation eCanter comes with an active safety package, here we see the full Daimler safety suite included in one of the smaller members of the company’s wide ranges of trucks. Here is all of the fruit which is becoming common currency at the top end of truck ranges, but now available here on a truck you can drive with a car license.

There are cameras and radar enabling the automatic emergency braking with which truck owners are now becoming familiar. Out on the highway, the adaptive cruise control, which also relies on this system makes life easier for the driver to let the automated system navigate the stop-go traffic of suburban Melbourne.

The eCanter does also include, for the first time on any Canter, side guard assist, which is offered higher up in the weight range by Fuso and displays a tell-tale red triangle on the A pillar on the passenger side, if there is a vehicle in the blind spot. The system will actively intervene and actually stop the truck, if it

TRUCKS ON TEST

TRUCKS ON TEST

detects a major problem. It goes through iterations of warning before braking.

Again, the fact that the driver doesn’t have to concentrate hard on the stopping and going from traffic to traffic light, adds to the serenity induced by the relative silence in cab. The combination of low noise levels from the driveline, smooth acceleration and deceleration modulated by automatic systems, and the smooth ride from the IFS, makes running on these bustling road a much more relaxing and comfortable experience than it is for many drivers fighting with a manual gearbox and a diesel engine while travelling these same routes.

This next generation of the eCanter and new Canters includes an improved interior feature like Apple CarPlay, which is accessible on the central display.

The overall experience from behind the wheel is a relaxed one. The peaceful nature of the driving

is added to by the smart way the different aspect of the driving experience are integrated.

The calm way the truck goes about its work, while, at the same time getting the job gets done quickly, safely and efficiently adds to this impression. The various instruments and screens tell the driver what is going on and the quietness of the cab also means the instructions from Google maps don’t get lost in a gear change.

All of the controls become second nature once the driver works out how each of them functions. The only one which could be improved is the lever for activating and setting the regenerative braking levels. It is currently a repurposed gearstick on the dash, it would work much better as a button under the driver’s thumb on the steering wheel.

and less carbon emissions, at the same time as being a pleasant and relatively peaceful drive.

Outside of that minor criticism there is little to fault in the truck. We have seen the Canter develop over time to a solid performer.

This is the first entrant from a major truck manufacturer into the light duty zero emission market in Australia and it will set the benchmark which others will have to, at least, match going forward. It will come at a premium price, but we can be sure that this

28 POWERTORQUE May/June 2024 C M Y

THE ECONOMICS OF TRUCKING’S CARBON ZERO

Looking at the realities which will face transport operations as they migrate across from fossil fuel dependency to the zero carbon economy, one of experts in the field examines some possible scenarios.

Australian trucking operators are currently in various stages of decarbonising their businesses. Some are a taking the first few steps on the road to zero carbon, while others are looking at the options for the future, then some will wait on the sidelines and see how the radical changes in the industry play out.

The Alternative Fuel Summit, organised by the Victorian Transport

Association, was aimed at informing operators and suppliers participating in the industry, helping them to make informed decisions on the next step for their business. The process of decarbonisation needs to clearly defined, in order to give the business owner confidence to be able to make the first steps on the road financially sustainable.

Professor Russell Thompson is

and Department of Infrastructure Engineering at the University of Melbourne. His main research areas are city logistics, physical internet, resilient transport systems and Intelligent Transport Systems.

“I’m trying to outline some areas where I think there’s some opportunities for some of the work, that I’ve been involved in, to assist the trucking industry,” said Russell. “How we make decisions is very important and there’s a lot of decisions made by an industry, associated with trying to decarbonise. It’s good to reflect on who are the decision makers because they’re very complex systems, we’re talking about here.

“There’s a lot of different types of decision makers. We’ve got businesses, families, government, but I want to talk about how we can use computers. Being able to exchange our knowledge and learn from each other is important.

“There’s a lot of interest in alternative fuels, technologies and engineering, but I’m going to talk about networks and how networks can play a very important role, in this transition to net zero emissions. We’ve got a very dynamic mix of technologies and a very fast changing environment, a lot of uncertainty in terms of the future, a lot of automation opportunities, but also a lot of computer technology and a shared economy.”

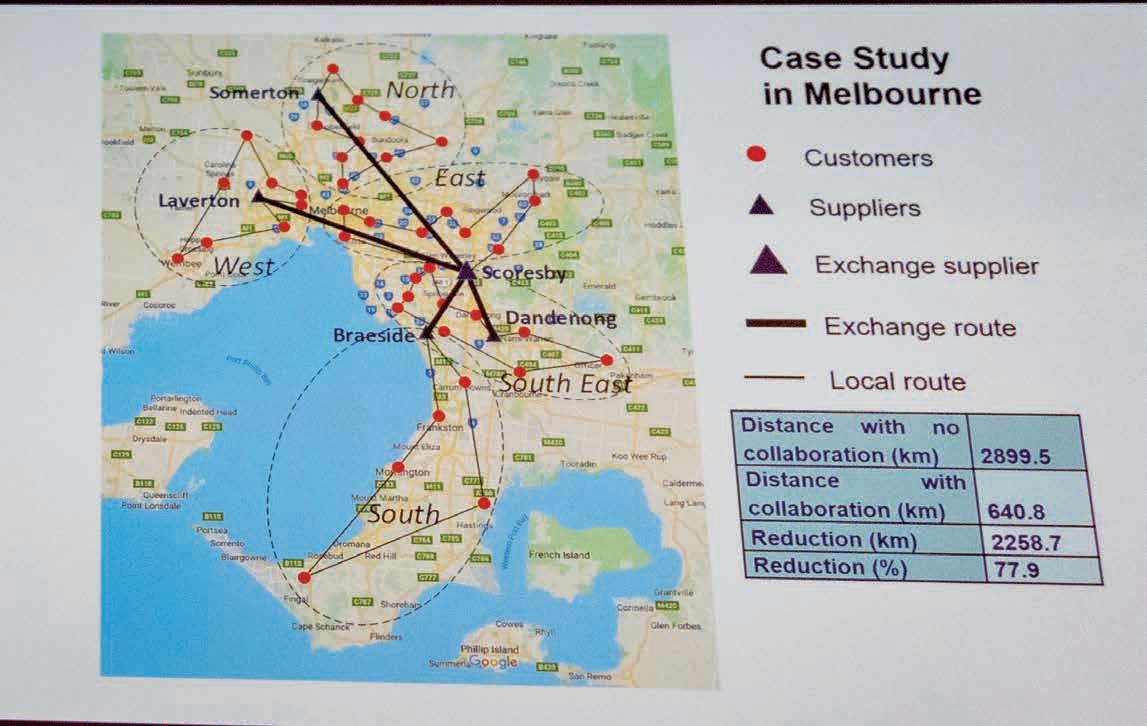

Russell done a lot of work in mathematical modelling about reducing total emissions. He has been working on a set of equations around emissions produced per vehicle kilometre. The distance the vehicles are travelling is a major influence on the total emissions.

His team has been studying networks and how they can be

30

ALT-POWER

POWERTORQUE May/June 2024

IMAGES: PRIME CREATIVE

Professor Russell Thompson, Professor of Transport Engineering and Department of Infrastructure Engineering at the University of Melbourne

transformed as part of the transition to net zero emissions. They have looked at the concept that it’s how far these vehicles are traveling and the nature of the networks that they’re operating on, which is important. Where the terminals are, where the warehouses are, where the customers are and where the demand is. He has also worked on utilisation of the vehicles, and thinks this is very important and can have a major role to play.

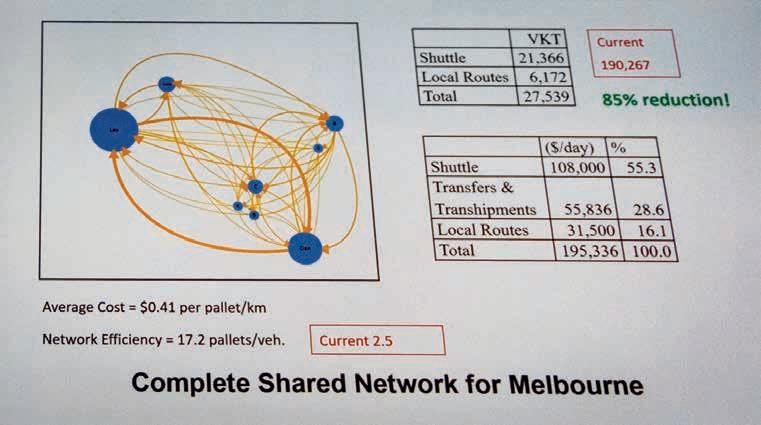

“I’ve only got one formula in this presentation, for the concept of network efficiency, tonne kilometres divided by the number of kilometres travelled,” said Russell. “Tonne kilometres represents demand, we move stuff and we move it over distances and this is not going to change. It’s actually increasing, we actually need more stuff and demand it should be transported. We get some scary predictions about how it’s going to grow dramatically and asking how

the industry is going to cope, and that’s the scary part.

“However, the denominator in terms of efficiency is the vehicle kilometres travelled, how far the vehicles are traveling to satisfy this demand. If we can start to think about our vehicles and their capacity, and how that capacity can be utilised more, and how these networks can be transformed, this provides a significant opportunity to lower our emissions.

“What we should think about is how we can deliver the same freight, but running over fewer kilometres. We can start thinking about how these networks are designed and configured and operated to reduce the amount of movement and the distances of overall travel. This is an important concept, I believe, and this introduces the physical internet.”

Russell has been involved in this area for over five years, and it’s an

emerging area of concepts, based on an analogy with the digital internet. He points out that we’re not worried about how the data is transmitted, and don’t care about where it goes, all we want is information that we can request quickly, fast and accurately.

This concept of a physical internet has been around for about 10 years, with the aim of trying emulate a lot of the characteristics of the digital internet in terms of the compatibility and integration into the physical world of road freight. Looking at the integration of the standards, to try and get that efficiency into the network. looking at open and shared networks, which are more collaboratively orientated.

“Things are going to have to be standardised because, there’s a lot more exchange and sharing of resources,” said Russell. “Compatibility of goods and load units are very important, and we’re

31 www.powertorque.com.au ALT-POWER

know where things are, and to know when things might be coming.

“This is a an advanced concept and an Australian company called GS1 Australia have developed some really good standards for allowing the information exchange necessary, for these exchanges and for this transparency to be implemented. We’re working with GS1, and they’ve really got some amazing standards to be able to track at low cost and to be able to share this information, to be able to get that confidence that the goods, when they are trans-shipped and are moving around with different vehicles, we know where they are and what’s going on.

“The concept of the physical internet is that we have got loads of different units and they need to be exchanged and transferred, so they need to be standard. We are moving to the concept of the right mode for the right load. The idea is to actually recognise that often this needs to involve multiple modes. We need to think about how much of this available capacity we’re using within our vehicles and the inevitability that we need to do this efficiently, revolves around exchanging our goods at hubs

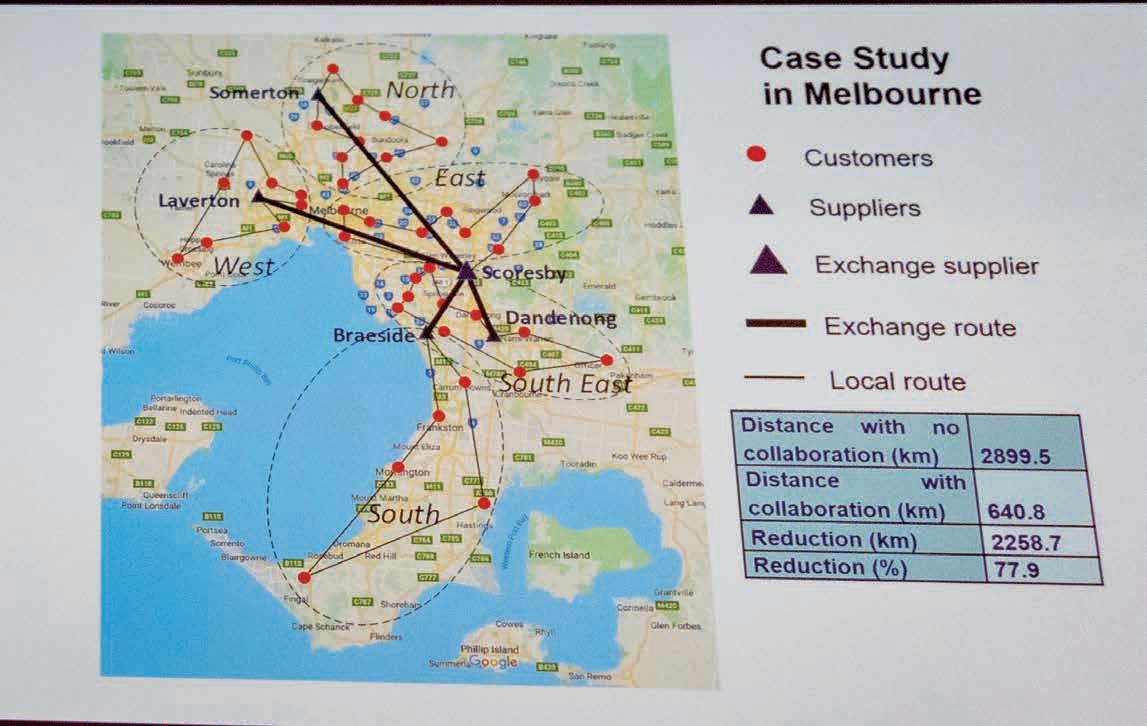

about a large urban area where they are distributing to a number of retail outlets across a metropolitan area. The example had 48 delivery points in the area and, typically, these deliveries would come from a number of depots warehousing to service these outlets.

The routes are quite efficient, independently, in their own right. However a more collaborative network with a compatible, integrated shipping concept, with transfers occurring between warehouses, with each warehouse receiving goods and

all the collections back to the local warehouse and later transferring the freight to the other other hubs in a consolidated form.

This shared network works out to create a 78 per cent reduction, in terms of transport distance travelled. This is gained just through the collaborative system. There are no new vehicles, no new facilities, the wholesalers and distributors simply agree to share the workload and achieve a significant reduction of 78 per cent.

“This result is quite remarkable

32 POWERTORQUE May/June 2024

ALT-POWER

and and of course, the network efficiency gain is quite a lot higher,” said Russell. “This is very good news for trying to promote the collaborative network in terms of the scale. Those costs in terms of distance, translate to emissions, and financial cost savings as well. No new facilities, no new technology, no new vehicles.

“In logistics we’re quite often criticised because we want to build new terminals, we want to have more fancy trucks, but in this case, we improve by using existing networks, just with sharing and collaboration.

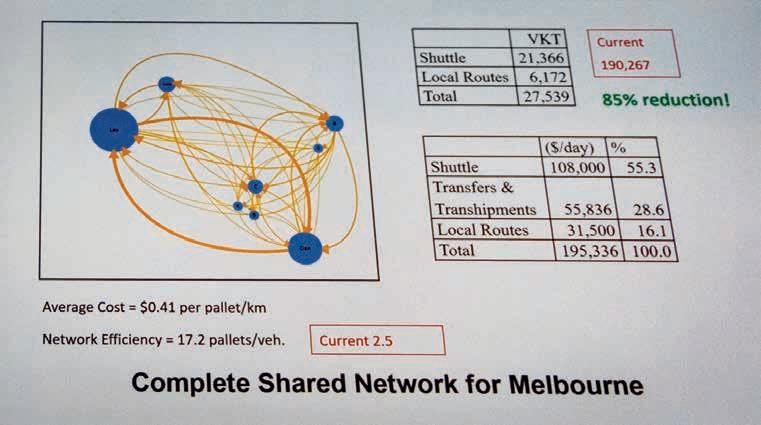

“Similarly, if we’ve got a lot of freight moving across between our production and warehousing areas, a lot of the trips are returning back to the depot or back to the plant empty, and going quite considerable distances. So we looked at how we might be able to use our high productivity freight vehicles, and to look at local pickups and local drop offs with shuttles between these different areas. So we did the modelling, we did this for Melbourne’s key freight areas, and we were able to design a collaborative shared network consisting of hubs with high capacity freight vehicles running between them.

“We looked at the number of movements, the frequency and the volume that they’re traveling. We were able to get the kilometre tonne number down, to 27,000km travelled, down from 190,000km. This is an 85 per cent reduction again, just by sharing, collaboration, hubbing and using those high capacity freight vehicles.”

Quite dramatic savings can be achieved, and these equate to major emission reduction within the supply chain. The key freight areas in Melbourne offer huge opportunities to reduce emissions. Also total cost of ownership is very important for the trucking industry, and the researchers did calculate these alternatives, the return on investment, the present values, the total cost of ownership, weighing up the variables, particularly with electric freight vehicles.

The number of variables make it difficult, no-one knows the price of energy in the future, whether electric or hydrogen or something else will dominate, or if any technology will do so. As a result, Russell is trying to work with mathematical methods which are able to encapsulate a lot of this variability, uncertainty, and can help the industry with its modelling, because it’s just so complex.

“We’re looking at a range of techniques, multi criteria analysis

looks at different attributes for the different alternatives and compares them and looks at the different preference weighting,” said Russell. “So we’ve done a lot of work in multi criteria analysis. We’ve also done a lot of work in robust optimisation, which tries to determine the best solutions when you acknowledge the variability and you can actually develop scenarios to look into the future, and see what these are likely to be”

33 www.powertorque.com.au

ALT-POWER

FINDING SUCCESS IN LEASING

Penske Leasing’s influx of new MAN models have proved popular with customers, and has launched the company strongly into 2024.

The last time PowerTorque spoke to Adrian Beach from Penske Leasing, the truck rental company was excited about its order of MAN TG3 models that were set to arrive on Australian shores last September.

Like many other sectors of the transport industry, the final quarter of the year is when business is busiest for leasing companies, and Adrian says 2023 was no different.

The new trucks came in at the perfect time for Penske Leasing. After continually facing shipping issues and factory shutdowns, the final months of 2023 have sparked massive growth leading into 2024.

“We usually like our brand new trucks to hit in the fourth quarter, where we kind of flex up to match the increased demand that comes in the fourth quarter with all the Christmas deliveries and stuff like that,” Adrian explains.

“I wanted to have some that were on the ground in operation, but they were still going through production, the build up and everything like that.

“The new TG3s coming in have been huge for business, and

customers love them. And with the lease business, now that we have this pipeline of inventory, we can really go after some of those lease deals.”

Adrian says that since the TG3 models joined the Penske Leasing rental fleet, demand for the trucks has increased massively.

“Now we’ve got people requesting TG3s, which is hard, because they still only make up 10 or 15 per cent of our fleet, we still have to replace our older models,” he says.

“When the drivers get dropped off to pick up their rental truck, they’re always asking if they can get one of the new ones.

“The TG3s are really easy to get in and out of, they changed the whole configuration of the door and the steps. Our GM cabs in the TGX 540s have got a flat floor and a really high roof, and a lot more room for the driver.

“They’ve brought the windscreen down and the window levels down.

34 TRUCK LEASING

POWERTORQUE May/June 2024

IMAGES: PENSKE LEASING

The visibility is really good.

“The TG3s have got everything that we loved about the TG2s, it’s the same engine and drivetrain, they’re just stiffening up the front suspension a little.

“They’re still just as reliable, and fuel economy is great. But now they have a really flashy interior, it looks a lot more like a premium truck on the inside now. We can’t get enough of them.”

REFRESHING THE FLEET

With demand continuing to arise for the MAN TG3 models, it’s called for even more to be added to the fleet.

Fortunately for Adrian and the Penske Leasing team, the used truck market is probably stronger than its ever been. They work in conjunction with Penske Australia New Zealand to send models that have reached the end of their five-year leasing lifespans to used truck dealers, continually refreshing the fleet.

Germany.

“We’re having so much success with the lease product line lately, and some of that has to do with this pipeline of inventory we have.

It has paved the way for newer models to keep the Penske Leasing fleet fresh.

“I’ve got 100 TG3s on order. We’ve got some of them that are right here in the back, in Wacol, waiting to go through the process,” Adrian says.

“We’ll deliver to the dealership where they can do the final bits and pieces and retail them to us. And then we’ve got some that are already ordered that are on a boat in transit, and then we’ll have production slots.

“We don’t want to get them all at

“We can quote a customer, and we can say, ‘I actually have three of them in Wacol that match your spec’. So we can get those pulling trailers in service in just a couple of months.”

Adrian says that the TG3 models have seen so much success due to their versatility, able to service a range of different jobs for customers with various needs across the transport sector.

But for those in need of something heavier-duty, Penske Leasing is addressing that too.

“We do have some Western Star

before the launch because we just needed to get in line and get our slots. We’ve got a group coming in that are landing in July.

“They’re 48X models, with the 40 inch sleeper, the DD16, and then D12 automatic transmission. We’re looking forward to those.

“Those will be available in Brisbane, Adelaide and Perth. That’s where we kind of see the demand for big customers, road trains, a little higher weights, longer distances.

“Our South Australian customers, a lot of them service Darwin. So they’re going all the way up the middle and back. They’ll really love the bonneted truck, and the bigger cab and even more room for the driver.”

SERVING TO SUIT NEEDS

Another area where Penske Leasing has found recent success is in the type of customers they have been working with.

The rental market suits specific businesses better than others, Adrian explains, and they have been able to build working relationship with companies who aren’t as experienced in running their own fleets.

“We’ve really made progress with some manufacturing companies who aren’t necessarily transport companies,” Adrian says.

“We like transport companies, they use a lot of trucks and everything like that, but a bigger transport company has got fleet

35 www.powertorque.com.au TRUCK LEASING

TRUCK LEASING

experts and maintenance experts, and procurement experts. Because trucks and transport is kind of their core competency, there’s not as much value that we offer them.

“Whereas if we’re talking to a company that manufactures or produces something, processes something, they just need to have trucks, either as a customer service tool, to better service their customers to deliver equipment or tools or materials from one plant to the next. That’s where we really add a lot of value.

“A lot of those, fleet managers, there are operation managers, and they’re managing people and the plant equipment, and they got 20

different hats that they’re wearing in that company.

“With the lease deals we can offer them, we’re customising that program, it’s very bespoke.

“The base spec that we start with is maybe one of our five flavours of rental truck. If they want it blue, we’ll paint it blue. We put their livery on the side.

“If they want a different bull bar or a ballrace turntable, we can totally customise the spec. We structure the financing around how they’re actually going to use the truck.

“Our rental fleet reflects the fact that the needs are not the same in every location. The rental fleet in each location kind of reflects the

needs of the customers that are based out of there.

“That’s one of the things we like about the MAN TG3, and especially that 13 litre range that they have there. It’s a great little local truck for a customer.

“That’s one of the fun parts of the of the job is when you meet with a customer, and they’re not a truck expert.

“And you ask some questions about what they’re doing, where are they going? What’s the cargo? How is it secured, how they unload and unload?

“Then helping them pick the right tool for the job, that’s one of the fun parts of the job for me.”

36 POWERTORQUE May/June 2024

PERFORMANCE & ECONOMY

DD16

NO COMPROMISE 500-600 HORSEPOWER

@ 1,800 RPM

1,850-2 ,050 DIESEL ENGINE 15.6L INLINE 6 lb-ft @ 975RPM

Extreme duty and heavy hauling for your biggest jobs

Detroit’s most powerful truck engine ever, the DD16 boasts up to 600 horsepower and 2,050 lb-ft of torque. The big bore workhorse provides efficient and dependable power and performance without compromise.

Advanced combustion and aftertreatment technology exceed future emissions requirements whilst retaining exceptional fuel efficiency and uptime.

This power, performance, and efficiency are backed by the most comprehensive warranty and extended coverage packages, ensuring the highest level of support for our customers.

When you buy a Detroit product, you’re buying billions of miles of engineering excellence. Tried and true, Detroit engines are built to ride the roughest roads.

With Detroit, there’s no compromise.

detroitaustralia.com.au

detroitanz

COMPLIANCE 80/04 EMISSIONS ADR

A NORMAL ELECTRIC TRUCK

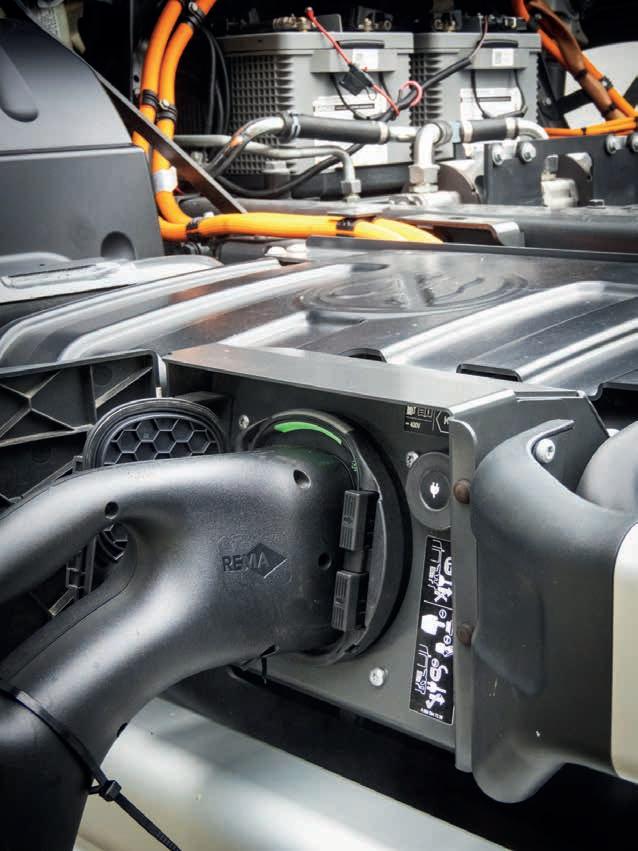

The integration between the new technologies and the driver interface makes taking a trip in the new Mercedes Benz eActros more like driving a normal electric truck

The first generation of the Mercedes-Benz eActros looks like it’s going to be the basis for the design for the next 20 or so years, in the development of the new line of trucks the German truck maker.

The eActros was previewed in 2022 at the IAA Exhibition in Hanover, Germany, and includes several aspects of its design that we can expect to see in virtually all of the electric trucks arriving in our market over the next decade or so.

New models that we have been discussing in the last few years are much simpler electric trucks. They have been, basically, a diesel truck, which had the diesel engine and tanks removed, and the space has been filled with an electric motor, control and cooling systems, and power batteries.

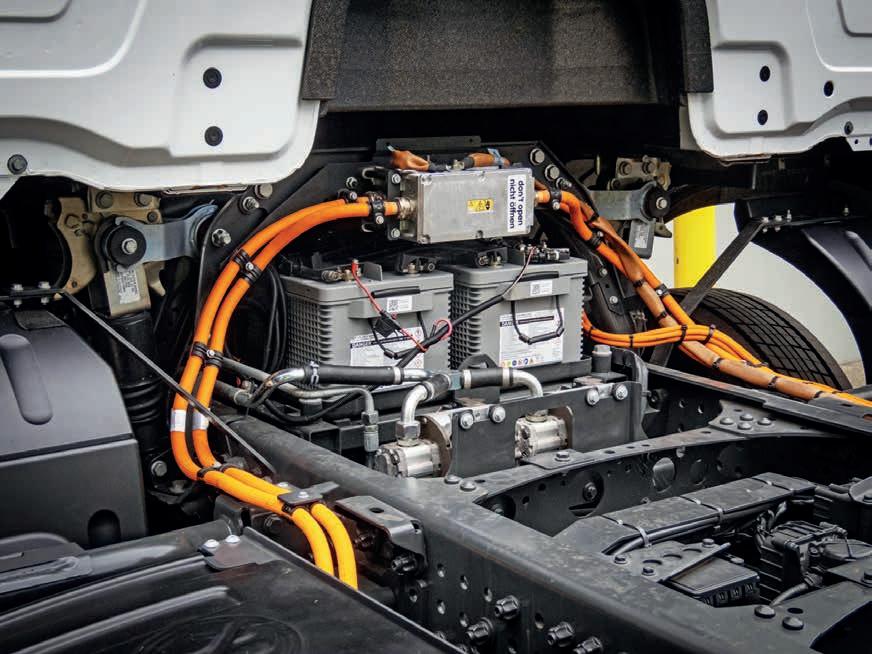

Where the eActros differs from most of these is that, like the eCanter third generation, being released by Fuso around the same time (another company in the Daimler truck group), this truck includes an eAxle.

Development of the eAxle is a weight and space-saving technology that replaces the rear differentials on the drive axles with a large unit containing electric motors, a transmission, and a differential. This innovation frees up much more

space for the truck manufacturer to fit more batteries and also enables them to distribute the weight in a better way within their existing design. We can expect almost every single truck manufacturer moving into the electric space to eventually adopt something

38 TRUCKS ON TEST

POWERTORQUE May/June 2024

IMAGES: PRIME CREATIVE

like an eAxle drive and differential, instead of using a drive shaft being driven by an electric motor in the position of the previous diesel engine.

The eAxle driven for this test has two electric motors, plus a two speed transmission and a planetary set to control and directly feed power into the drive axle. It still uses the original housing used before, but with different equipment inside. On trucks designed to run at higher masses the transmission will be a four speed.

FIRST EXPERIENCE

Looking at the eActros from the outside, it is almost impossible to tell that it has electric power. However, that is not the aim of exercise. The point is to demonstrate that MercedesBenz does have this technology and that it is capable of handling a variety of freight transport tasks in the future.

Signage on the trucks, the blue flashes of paintwork, which Daimler chooses to put on all of their electric vehicles, and the casing in which the batteries are held give away what type of truck this is.