Recycling

No-waste solutions for waste plastics This article by Angelica Buan provides a roundup of the latest technologies and processes that suggest landfills, incinerators and the curb side are no place for waste plastics.

R

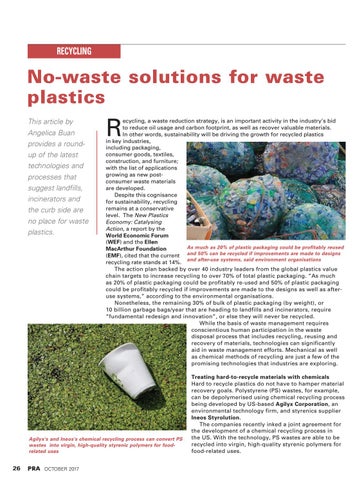

ecycling, a waste reduction strategy, is an important activity in the industry’s bid to reduce oil usage and carbon footprint, as well as recover valuable materials. In other words, sustainability will be driving the growth for recycled plastics in key industries, including packaging, consumer goods, textiles, construction, and furniture; with the list of applications growing as new postconsumer waste materials are developed. Despite this cognisance for sustainability, recycling remains at a conservative level. The New Plastics Economy: Catalysing Action, a report by the World Economic Forum (WEF) and the Ellen As much as 20% of plastic packaging could be profitably reused MacArthur Foundation (EMF), cited that the current and 50% can be recycled if improvements are made to designs and after-use systems, said environment organisations recycling rate stands at 14%. The action plan backed by over 40 industry leaders from the global plastics value chain targets to increase recycling to over 70% of total plastic packaging. “As much as 20% of plastic packaging could be profitably re-used and 50% of plastic packaging could be profitably recycled if improvements are made to the designs as well as afteruse systems,” according to the environmental organisations. Nonetheless, the remaining 30% of bulk of plastic packaging (by weight), or 10 billion garbage bags/year that are heading to landfills and incinerators, require “fundamental redesign and innovation”, or else they will never be recycled. While the basis of waste management requires conscientious human participation in the waste disposal process that includes recycling, reusing and recovery of materials, technologies can significantly aid in waste management efforts. Mechanical as well as chemical methods of recycling are just a few of the promising technologies that industries are exploring.

Agilyx's and Ineos's chemical recycling process can convert PS wastes into virgin, high-quality styrenic polymers for foodrelated uses

26

OCTOBER 2017

Treating hard-to-recycle materials with chemicals Hard to recycle plastics do not have to hamper material recovery goals. Polystyrene (PS) wastes, for example, can be depolymerised using chemical recycling process being developed by US-based Agilyx Corporation, an environmental technology firm, and styrenics supplier Ineos Styrolution. The companies recently inked a joint agreement for the development of a chemical recycling process in the US. With the technology, PS wastes are able to be recycled into virgin, high-quality styrenic polymers for food-related uses.