Advertorial

Emery Oleochemicals brings surface effects of plastics into focus

E

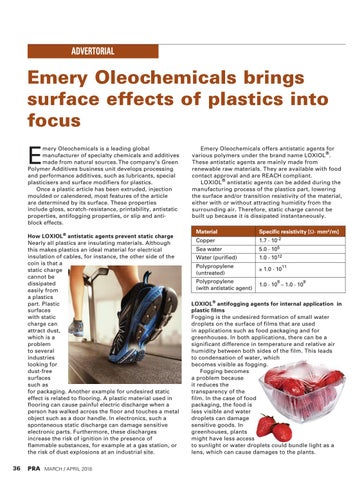

mery Oleochemicals is a leading global manufacturer of specialty chemicals and additives made from natural sources. The company’s Green Polymer Additives business unit develops processing and performance additives, such as lubricants, special plasticisers and surface modifiers for plastics. Once a plastic article has been extruded, injection moulded or calendered, most features of the article are determined by its surface. These properties include gloss, scratch-resistance, printability, antistatic properties, antifogging properties, or slip and antiblock effects. How LOXIOL® antistatic agents prevent static charge Nearly all plastics are insulating materials. Although this makes plastics an ideal material for electrical insulation of cables, for instance, the other side of the coin is that a static charge cannot be dissipated easily from a plastics part. Plastic surfaces with static charge can attract dust, which is a problem to several industries looking for dust-free surfaces such as for packaging. Another example for undesired static effect is related to flooring. A plastic material used in flooring can cause painful electric discharge when a person has walked across the floor and touches a metal object such as a door handle. In electronics, such a spontaneous static discharge can damage sensitive electronic parts. Furthermore, these discharges increase the risk of ignition in the presence of flammable substances, for example at a gas station, or the risk of dust explosions at an industrial site.

36

MARCH / APRIL 2018

Emery Oleochemicals offers antistatic agents for various polymers under the brand name LOXIOL ®. These antistatic agents are mainly made from renewable raw materials. They are available with food contact approval and are REACH compliant. LOXIOL® antistatic agents can be added during the manufacturing process of the plastics part, lowering the surface and/or transition resistivity of the material, either with or without attracting humidity from the surrounding air. Therefore, static charge cannot be built up because it is dissipated instantaneously. Material

Specific resistivity [Ω· mm²/m]

Copper

1.7 · 10-2

Sea water

5.0 · 105

Water (purified)

1.0 · 1012

Polypropylene (untreated)

≥ 1.0 · 10

Polypropylene (with antistatic agent)

1.0 · 10 – 1.0 · 10

8

11 9

LOXIOL® antifogging agents for internal application in plastic films Fogging is the undesired formation of small water droplets on the surface of films that are used in applications such as food packaging and for greenhouses. In both applications, there can be a significant difference in temperature and relative air humidity between both sides of the film. This leads to condensation of water, which becomes visible as fogging. Fogging becomes a problem because it reduces the transparency of the film. In the case of food packaging, the food is less visible and water droplets can damage sensitive goods. In greenhouses, plants might have less access to sunlight or water droplets could bundle light as a lens, which can cause damages to the plants.