Materials News

Food fills the appetite of biobased solutions Food need not go to waste. Today, with technology getting more sophisticated, even common food sources and scraps can be turned into plastic material! Considering the prevalence of food shortages, repurposing it into something practical, yet highly valuable, is a virtuous move.

N

ew technologies on bioplastics, materials that are derived from renewable biomass, are lifting the burden on petroleum as the chief resource for producing plastics. When landfilled, food wastes release greenhouse gases, alleged to be 25 times more harmful than carbon dioxide. Thus, bioplastics not only lend the opportunity to tap into food to develop a high-value raw material but also to produce material with lower carbon footprint and lower toxicity.

The advantage of PHA is that it naturally degrades in marine and terrestrial ecosystems, unlike petroleum-based plastics like PE and PP, plus it caters to broad commercial application potential, including commercial food-grade packaging and agriculture films. FCB, which works with waste producers and licenses its technology, is seeking partners with experience compounding PHA and other bioplastics such as PBS, PBAT, PLA and starches.

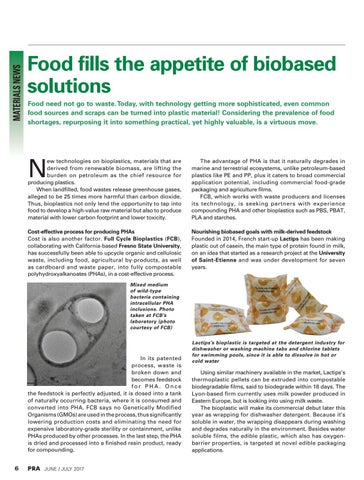

Cost-effective process for producing PHAs Cost is also another factor. Full Cycle Bioplastics (FCB), collaborating with California-based Fresno State University, has successfully been able to upcycle organic and cellulosic waste, including food, agricultural by-products, as well as cardboard and waste paper, into fully compostable polyhydroxyalkanoates (PHAs), in a cost-effective process.

Nourishing biobased goals with milk-derived feedstock Founded in 2014, French start-up Lactips has been making plastic out of casein, the main type of protein found in milk, on an idea that started as a research project at the University of Saint-Etienne and was under development for seven years.

Mixed medium of wild-type bacteria containing intracellular PHA inclusions. Photo taken at FCB’s laboratory (photo courtesy of FCB)

In its patented process, waste is broken down and becomes feedstock for PHA. Once the feedstock is perfectly adjusted, it is dosed into a tank of naturally occurring bacteria, where it is consumed and converted into PHA. FCB says no Genetically Modified Organisms (GMOs) are used in the process, thus significantly lowering production costs and eliminating the need for expensive laboratory-grade sterility or containment, unlike PHAs produced by other processes. In the last step, the PHA is dried and processed into a finished resin product, ready for compounding.

6

JUNE / JULY 2017

Lactips’s bioplastic is targeted at the detergent industry for dishwasher or washing machine tabs and chlorine tablets for swimming pools, since it is able to dissolve in hot or cold water

Using similar machinery available in the market, Lactips’s thermoplastic pellets can be extruded into compostable biodegradable films, said to biodegrade within 18 days. The Lyon-based firm currently uses milk powder produced in Eastern Europe, but is looking into using milk waste. The bioplastic will make its commercial debut later this year as wrapping for dishwasher detergent. Because it’s soluble in water, the wrapping disappears during washing and degrades naturally in the environment. Besides water soluble films, the edible plastic, which also has oxygenbarrier properties, is targeted at novel edible packaging applications.