West Coast Edition For: WA, OR, and CA Vol. 13, No. 2 APR / MAY ’23 BUYER’S GUIDE PAGES 32-45 a2zMFG.com a2zMFG.com Born Out Of A Belief In The Excellence Of Craft

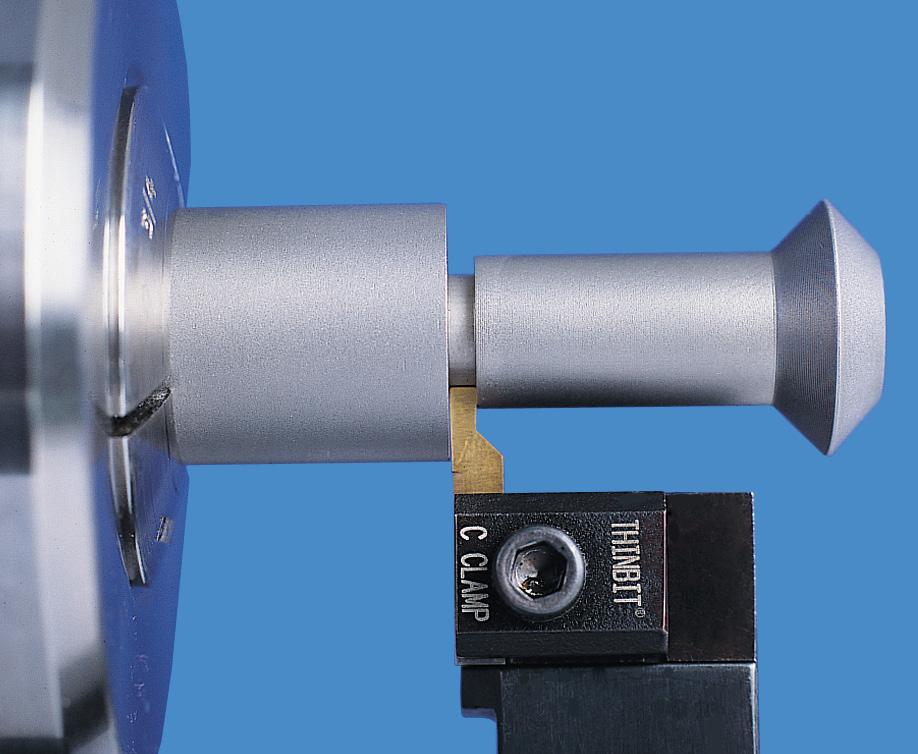

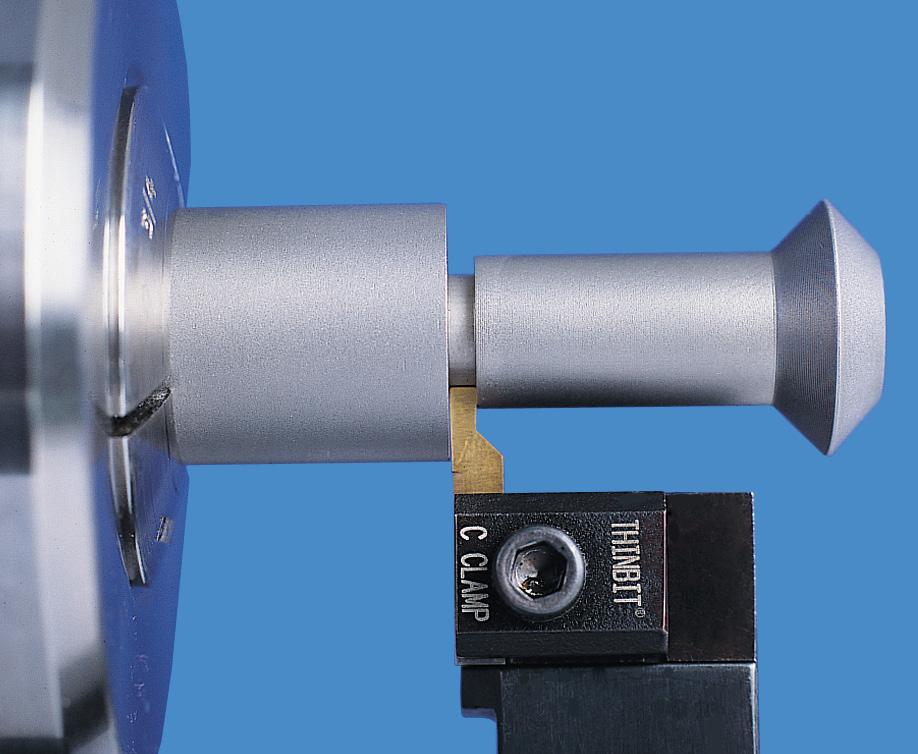

GROOVING THREADING PARTING BORING TURNING FACE GROOVING CUSTOM TOOLING FORM TOOLING MILL TOOLING Follow us on: 888-THINBIT | WWW.THINBIT.COM

J.K. Rowling, Harry Potter and the Goblet of Fire

The republic we call America was founded on strong beliefs that were tested during the Revolutionary war.The common belief was the idea that all people are created equal, regardless of their origin, color of skin, and belief system of religion. These pioneers of the new world believed all people have fundamental rights, like liberty, free speech, freedom of religion, due process of law, and freedom of assembly. Many Americans saw a powerful federal government as a threat to individual liberty. The first 10 amendments to the constitution, the bill of rights, limited federal power by protecting citizens’ freedoms and promoting a “We The People” government.

In recent decades, the United States has seemed in danger of losing its position as a worldleading manufacturing economy. While absolute output has grown during the 21st century, the US shares of global manufacturing GDP and gross sales have fallen. In real value-added terms, growth in the sector has slowed dramatically over the past three business cycles, from 4.9 percent in the 1990s to 1.4 percent in each of the past two decades. And much of that recent growth has been driven by design, services, and software activities, rather than by physical production.2 The number of manufacturing firms and manufacturing plants in the United States has fallen by roughly 25 percent since 1997, reflecting an increase in closures and a slowdown in start-ups.

A strong manufacturing economy unlocks important employment and advancement opportunities—a factor set to grow in significance if current job market pressures ease. Manufacturing is the main economic engine and primary employer in around 500 US counties today, and in those communities, the industry employs a broader-than-average swath of the overall population and does so more inclusively. In most cases, employees don’t need fouryear degrees, and they can earn twice as much as those holding equivalent service-sector jobs, as employers invest in up skilling and reskilling their current workers by offering expanded learning opportunities. Our analysis suggests that reviving manufacturing could add up to 1.5 million jobs, particularly among middle-skill workers, which would help recalibrate the US labor market and bolster the middle class.

Strengthening the sector could also address the supply chain issues that have been wreaking economic havoc over recent years, easing disruptions caused by the pandemic while improving global competitiveness in the mid to long term. Between 2010 and 2019, the US trade deficit in manufactured goods more than doubled, reaching $883 billion. The country currently meets 71 percent of its final demand with regional goods, trailing Germany (with 83 percent), Japan (86 percent), and China (89 percent). Increased import dependence has left some key US manufacturing supply chains exposed to greater global risks.3 The supply chain shocks of the past three years have pushed those risks to the top of the corporate agenda: in surveys, more than 90 percent of senior executives tell us that increasing the level of resilience in their supply chains is a priority.

Manufacturing offers high-skill, high-wage jobs for American workers and could do so even more as the industry becomes more digitized and automated.With existing worker shortage and rapidly evolving skill requirements, employers can become skill builders and develop the workforce needed to remain competitive while helping people access meaningful and lasting employment.

In closing I would like to thank all of you that call US manufacturing their home. We make things, fix things, and help reinvent a better way of life for the world.

Kim Carpenter

Born Out Of A Belief In The Excellence Of Craft Portland Japanese Garden

Published by: A2Z Manufacturing West Coast

PUBLISHERS/EDITORS

Kim Carpenter & Linda Daly

Kim@A2ZManufacturing.com

Mail Address: 1538 E. La Vieve Ln. Tempe AZ 85284

Telephone: (480) 773-3239

Website: www.A2ZManufacturing.com

CONTRIBUTORS

Linda Daly, Eugene Wirth, Stephen Hannemann, Hugh Taylor

Published

contracts,

and

supply a viable supplier source for the industry.

Circulation: A2Z Manufacturing West Coast maintains a master list of over 14,000 decision makers consisting of fortune 1000 companies, small manufacturing companies, engineering firms, DOD & Scientific Lab facilities, machine shops, fab-shops, and secondary source businesses. It has an estimated pass on readership of more than 25,000 people. The majority of our readers are based in CA, OR, WA area!

Advertising Rates have remained the same since 1999, deadlines and mechanical requirements furnished on our website at: www.a2zManufacturing.com.

All photos and copy become the property of A2Z Manufacturing.

The Publisher assumes no responsibility for the contents of any advertisement, and all representations are those of the advertiser and not that of the publisher.

The Publisher is not liable to any advertiser for any misprints or errors not the fault of the publisher, and in such event, the limit of the publisher's liability shall only be the amount of the publishers charge for such advertising.

bi-monthly to keep precision

of

manufacturers abreast

news,

trends,

to

Cover

E-mail:

Announcements/Releases ................... 6-14 Feature Articles ........................... 1,10, 20-21 Buyers Guide Equipment Services ..... 32-38 Buyers Guide Processes ...................... 39-45 Card Gallery ........................................ 32-45 Index Of Advertisers ............................... 46 Editorial .................................. Throughout A2Z MANUFACTURING WEST COAST • 4 • APR - MAY ’23

Kim@A2ZManufacturing.com

“We are only as strong as we are united, as weak as we are divided.”

Editor’s Corner

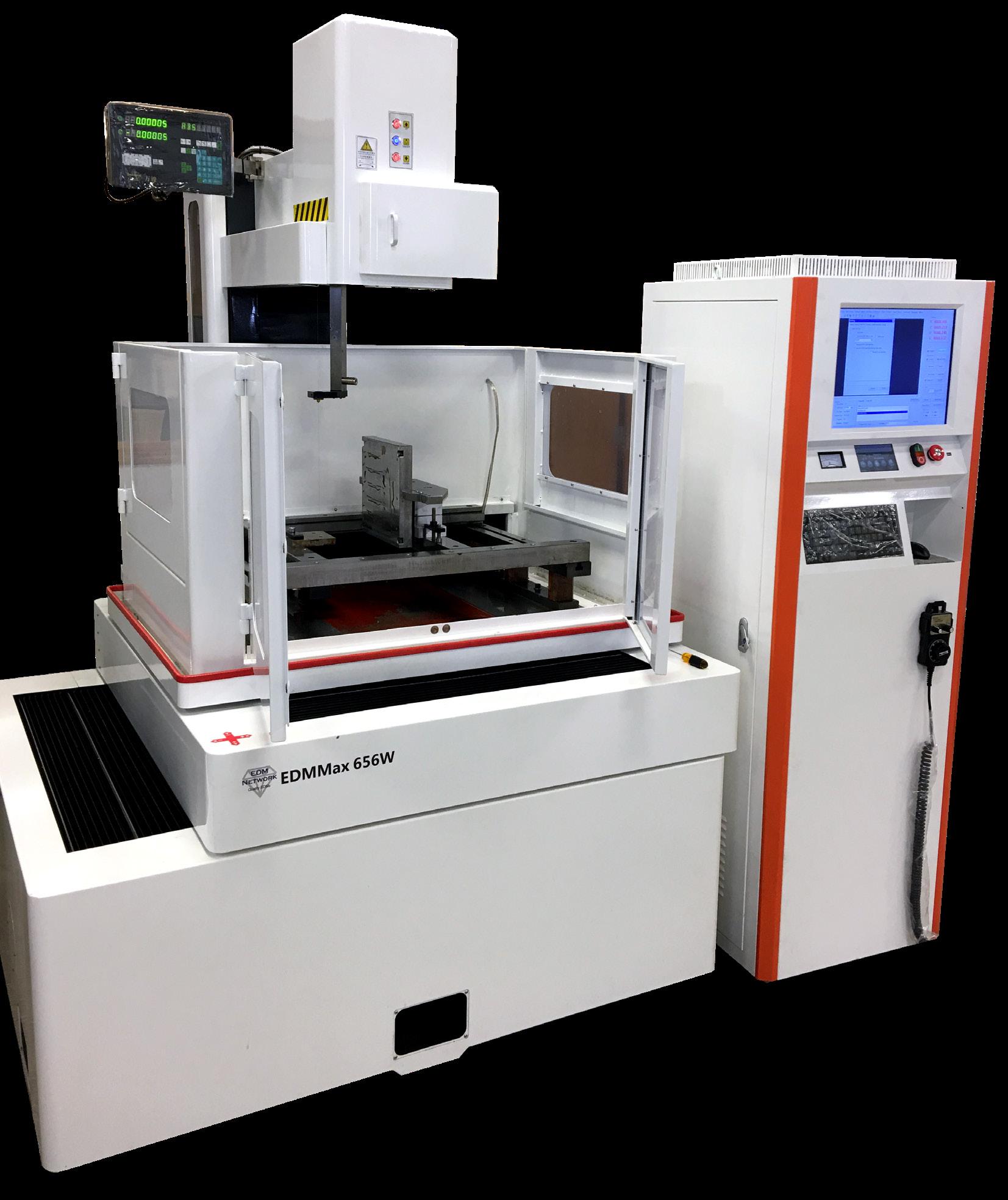

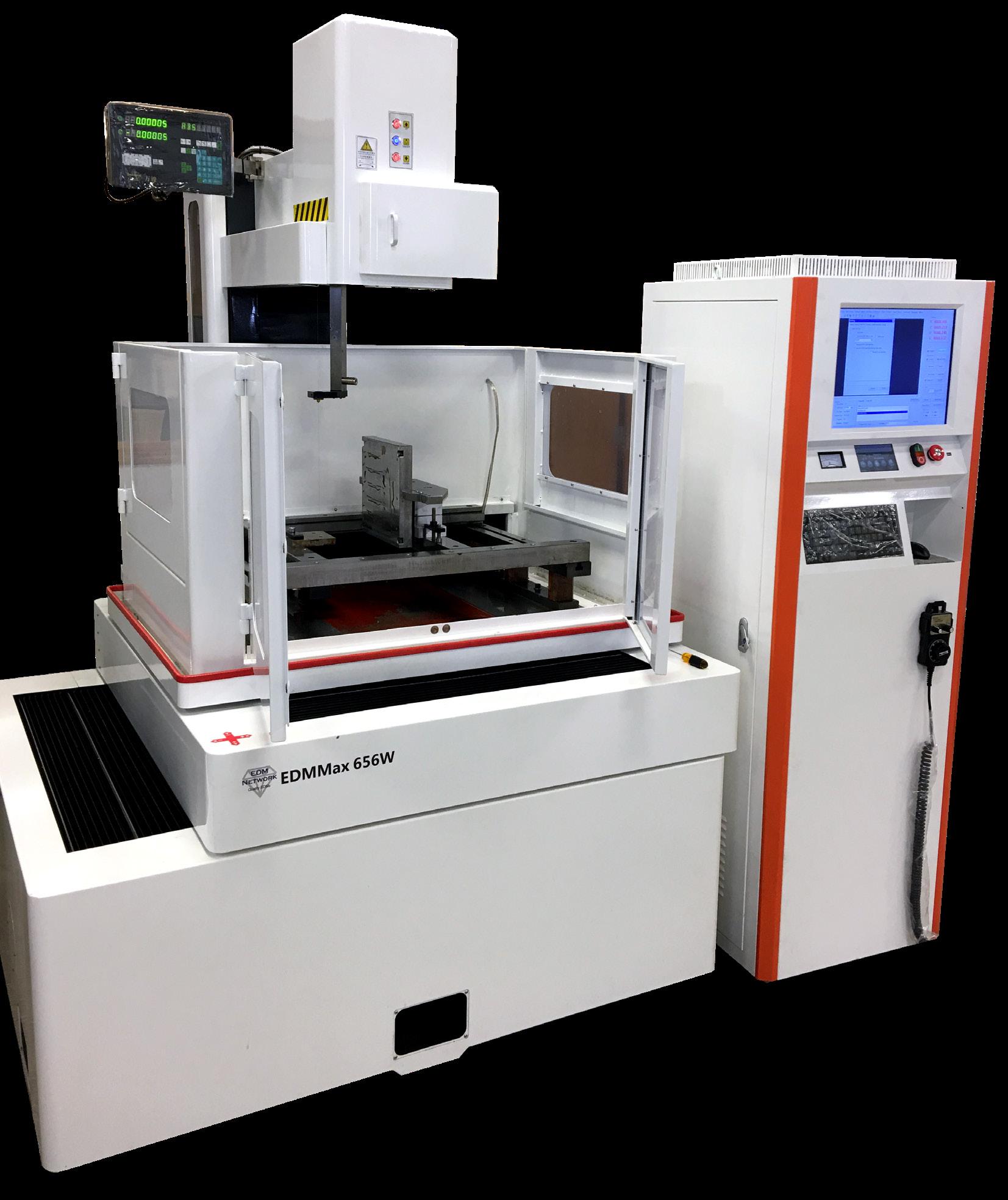

We have added a number of improvements over the standard Fast Wire Edms including:

• Cutting capacity of 625 x 625 mm

• Panasonic AC Servo motors and drivers

• Hiwin Linear Guideways

• Build in Cad System

• Two filters

• Increased height side walls to reduce splashing

• View windows to see the wire progress

• Automatic spent wire spooler

• Optional build plate support fixture

• Optional Anti Electrolisis (AE)

sizes available: • 400x320x410mm H

630x500x625mm H

1000x800x1050mm H

Horizontal Model 1000x1000x1000mm 1974 Bucktail Lane, Sugar Grove, IL 60554 1-888-289-3367 www.edmnetwork.com EDM Network provides “Everything in EDM”

EDMMax 656W 37 min TIME TO CUT

Four

•

•

•

The new model

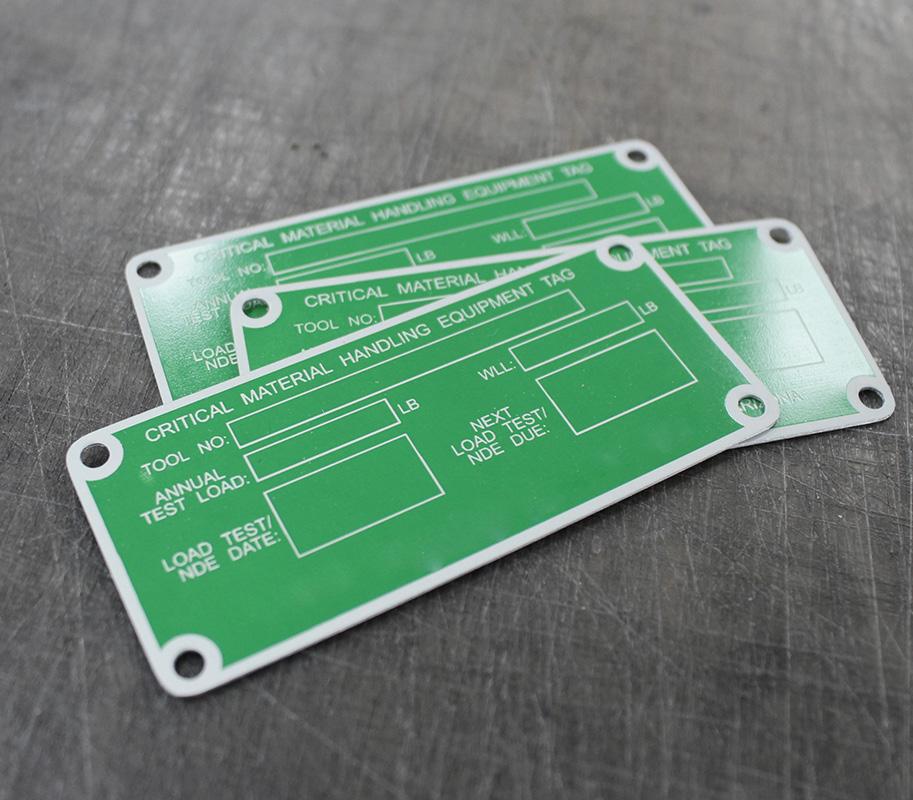

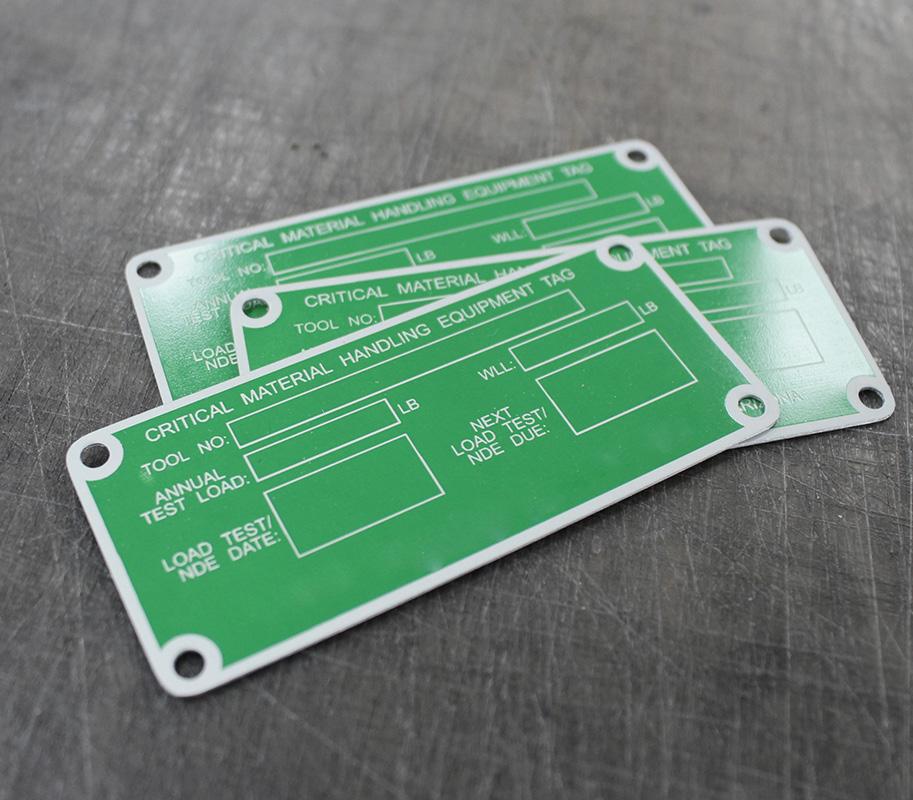

AB Finishing Tech

The Northwest Black Oxide Leader

By Stephen Hannemann

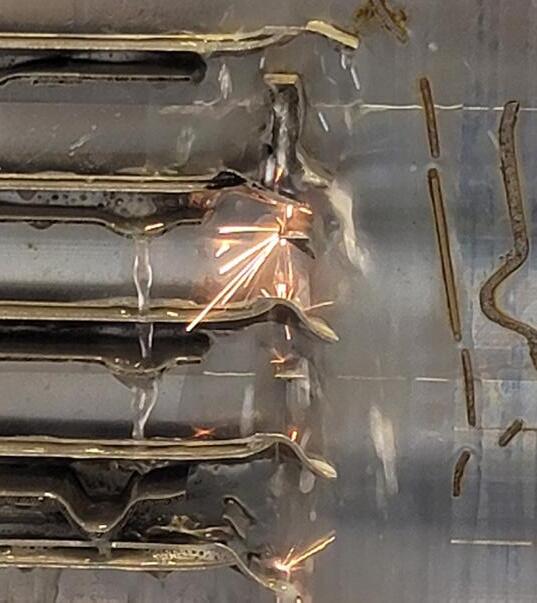

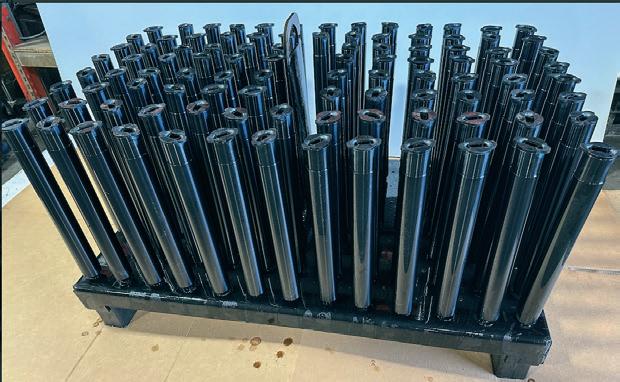

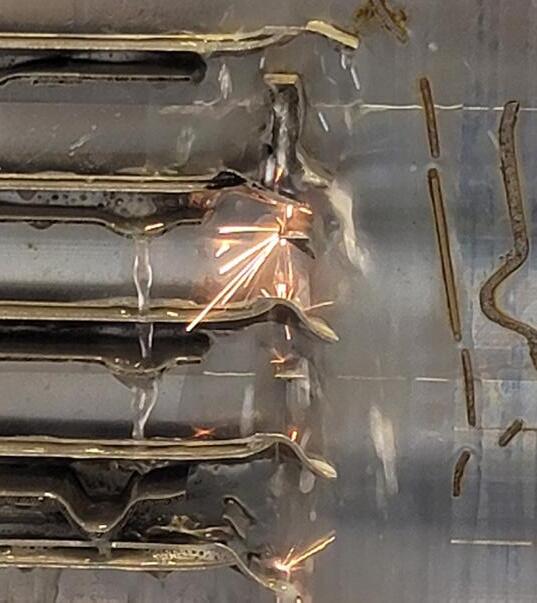

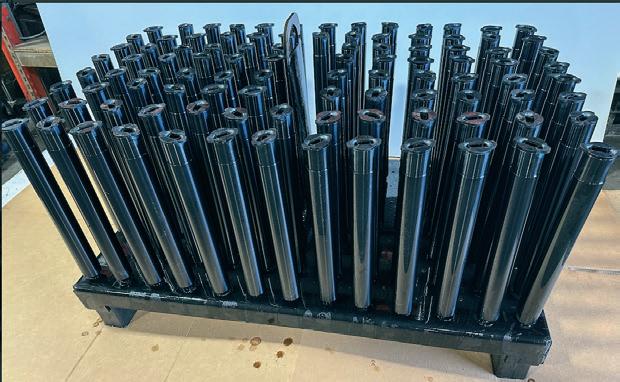

AB Finishing Tech, with 87 years of history and the largest black oxide tanks west of the Mississippi, continues to set the gold standard for black oxide conversion coating in the Northwest. With endless types of industrial metal surface finishes available, only a few can claim being ahead with black oxide.

AB Finishing Tech specializes in black oxide treatment of steel, stainless steel, and iron components, transforming their surfaces to a lustrous black. The process provides dimensional stability, corrosion resistance, and exceptional lubricity characteristics. The applications for this process are endless for a myriad of industries, from large exercise equipment and automotive components to small parts used in medical devices, and everything imaginable in between. The list is limitless.

AB utilizes a hot process forming a black oxide coating by immersing components in an oxidizing salt bath at an elevated temperature. The parts are then rinsed and dried. The Impressive results are evident in the included photos.

AB Finishing Tech’s capabilities are nearly limitless both for quantity of product shipped and part size. With their large 4’x6’ black oxide tank,

and depending upon configuration, they can comfortably accommodate 5’plus parts, as well as the smallest size fasteners and ancillary components. Additional companion services offered include shot peening and sandblasting. AB sports one of the largest wheelabrators in the Northwest. In addition to a peerless surface preparation, shot peening relieves stress, increases part strength, and reduces metal fatigue under use.

An all-important bonus to entrusting your parts to AB is their stellar quality and ontime delivery record. It is a 100% win-win!

Visit our ad on page 18 of this publication. Learn more at www.abfinishingtech.com.

AB Finishing Tech, 6724 NE 46th Ave., Portland, OR 97218 or call (503) 282-7239.

Email: info@abfinishingtech.com.

Cybersecurity

Six Ways To Make Sure Your Manufacturing Business Is Cyber-Secure

By Thomson Mathew—ANCA Software Product Manager

While smart factories are revolutionizing the manufacturing industry through innovation, being connected comes with new risk factors that must be addressed. A Deloitte study revealed that 48% of manufacturers identified operational risks—including cybersecurity—as the greatest danger to their factories.

Manufacturing can be a lucrative ‘get’ for cyberattackers, targeting your intellectual property or blocking production. Businesses risk financial, time and productivity losses if they don’t get the balance right. So, how can you make sure your business is safe?

1. Understand your security requirements and risk

The cloud offers manufacturers an unprecedented level of flexibility, from lights-out manufacturing to remote real-time data. But this level of connection can expose your business to attack.

While it may be your first concern, the risk isn’t limited to connected machines. Manufacturers can also be vulnerable to phishing attacks, ransomware and internal breaches, among others. This means company phones, email addresses and laptops should all be protected. Relying on supply chains also means manufacturing can be disrupted by attacks on suppliers and distributors. Having a clear picture of risk areas is the first step to creating a secure network.

2. Document your policies and processes

A false sense of security can be devastating to a manufacturing business if a cyberattack eventuates. Even if you’re on top of what needs to be done, you must ensure everyone in the business understands the risks—human behavior is a significant factor in compromised systems!

• Clearly document your security measures.

A2Z MANUFACTURING WEST COAST • 6 • APR - MAY ’23

Announcements & Releases

• Implement a policy of regular security reviews.

• Apply software updates as they’re made available.

• Teach staff about the benefits of strong passwords and two-factor authentication.

• Ensure new employees are educated as part of their induction.

• Introduce a “principle of least privilege”—give employees the minimum permissions they need to perform their duties.

3. Choose secure machines

Operational technology, including tooling machines, creates endless opportunities for manufacturers. In the past, these machines had no external links to networks and so weren’t vulnerable to digital attacks. Running machines 24/7 means relying on the network to remain secure even when you’re not there. Because of these risks, ANCA machines have been designed to use whitelisting to ascertain networks can only be accessed by predetermined parties. That means new software and devices must be authorized before they can be added, massively reducing the risk of introducing viruses, malware or weak points. Each piece of software has been thoroughly assessed for vulnerabilities before being whitelisted, so manufacturers can be assured of their machines’ security.

4. Get a clear picture of your whole network

If you’re using a tooling machine, you’re exposing your systems to external third parties.The potential consequences are that you could lose data, you could lose productivity time, or you’ll have ongoing maintenance.You’re putting your machine at risk.

Your manufacturing business isn’t just the machines in your factory. It includes other businesses— like material suppliers, logistics companies and even accountants—and all of their extended networks. Any vulnerability they have can affect your business outcomes.

Speak to each of your stakeholders about what they do to protect their networks.You may not be able to change their approach, but it’ll help you to mitigate the risk at your end, for example, by choosing a more secure supplier or looking into vertical integration.

5. Make regular offline backups

Even the most secure cloud and digital systems can fail. To ensure your IP is as robust as possible, and to limit the impact on your productivity, you should be performing regular offline backups away from your network. It’s best to be overcautious. Store multiple backups in different places to better distribute the risk of further data loss—and make sure those locations are secure, too.

Automating this process eliminates the need to remember to do it (often until it’s too late) but performing periodic manual backups will give you the best coverage.

6. Be ready to adapt as things change

Cybercrime is big business—some reports suggest it’s the equivalent of the world’s third-largest economy, inflicting damages in the trillions of dollars every year. Globally, spending on cybersecurity is expected to grow to

almost U.S. $350 billion by 2026. ,

State Of The Manufacturing Economy

Chris Frans, CLFP (President, Epic Finance)

A question that I am often asked is “what are you seeing out there?”, which ultimately leads to a discussion about the economy from both a macro and micro perspective.

From my view (of financing manufacturing equipment all around the US), the larger companies are continuing to increase machining capacity with new machine orders, but the relatively smaller companies are showing increased hesitation in recent times.This is displayed in the accompanying graph (estimated figures for display purposes).

The bad: The majority economic indicators within the manufacturing market are pointing to some degree of a recessionary period that should be felt in late Q3/early Q4.

The good: This will be the most foreseen and anticipated recession in history. If we do enter a recessionary period, it should be relatively short term (versus a standard 18-month recession) and easy to weather. If we do not enter a recession, we will more than likely experience lack-luster production for that period.

The better:The forecast for late 2023 is positive and appears even stronger as we look at 2024.

The best: The US economy is extremely resilient and historically bounces back the year proceeding a recessionary period. We have the highest GPD in the world and manufacturing will always be a significant contributor.

Whether we enter a slow period or not, now is a great time to take advantage of Epic Finance’s 120-day payment deferral program. With this program, your first monthly payment isn’t due until 120 days after the equipment has been fully installed. This program, combined with our aggressive rates, speed of approval, and fearless customer service is what makes us your best option for all types of equipment financing.

Please feel free to reach out directly to discuss your goals and find out how Epic can help achieve them.

Chris Frans, CLFP President chris@epicapprovals.com, 303-261-8200

A2Z MANUFACTURING WEST COAST • 7 • APR - MAY ’23

Re-Energizing American Manufacturing:

Lux Precision Manufacturing

From its humble roots on a college campus, Lux Precision Manufacturing (Lux) is a premiere manufacturing company that has a mission to reenergize American manufacturing.With the unique operating location on the campus of Grand Canyon University (GCU), Lux serves the medical device, aerospace, semiconductor, and defense industries with precision machined parts. Lux, however, has a unique business model that is reenergizing American manufacturing by introducing college students to precision manufacturing and giving them an opportunity for educational immersion in manufacturing.

In 2017,Weston Smith founded Lux out of a dorm room on the campus

of Grand Canyon University originally as an electric longboard rental company. He grew up on a horse ranch in Flagstaff and never tried skateboarding until his freshman year on campus and waited until he was a sophomore to purchase his first electric longboard. Mind you, 2017 was the same year that all the hoverboard batteries were catching on fire. “It completely transformed how I got around campus,” he said. “I had so many students stop me and say they want one – that sparked my entrepreneurial instincts.” So, Weston started renting out electric longboards to college students. Nine months after buying an electric longboard fleet, there was a 90% battery failure rate in the electric longboards.

As a mechanical engineering student,Weston started innovating and developed a solution for the massive battery failure rate in the rental fleet; a flexible battery that uses the same battery technology found in Tesla cars. With this technology development, Weston decided to shift the business model of Lux from electric longboard rentals, to electric manufacturing. Over the course of two years, Lux Longboards launched three different board lines. The last and most innovative board line launch was the Lux LX, which was an Offroad electric longboard that went over 30mph on a range up to 19 miles.

In 2020, covid hit and the supply chain for Lux Longboards was decimated due to shortages and importing issues. With the supply chain in shambles, Weston made an executive decision to onshore as much of the manufacturing for Lux Longboards as possible. Luckily at that time, Lux owned a Kitamura Mycenter Zero Vertical CNC Mill that was used for light production and prototyping. Lux began machining as many parts as possible for the longboards. “I had so many contacts in industry that constantly were asking if we had capacity to make parts for them.”Weston then started contract manufacturing for Lux. As industry demand grew for precision manufacturing, Lux scaled its machine shop capabilities and discontinued electric longboard manufacturing in 2022 to focus its growth in CNC machining.

In August of 2023, Lux Precision Manufacturing will be expanding to a new 12,000 sqft facility on GCU’s campus with a mixture of 16 CNC mills and lathes. While still serving the medical device, aerospace, semiconductor, and defense industry with precision manufactured parts. Lux has partnered with GCU to impact the manufacturing workforce. With an estimated 2.1 million unfilled manufacturing jobs by 2030, GCU is launching a manufacturing certificate program with an emphasis in CNC

A2Z MANUFACTURING WEST COAST • 8 • APR - MAY ’23

CNC AND MANUAL MACHINERY SINCE

New - Used -Appraisals

Auctions Our Showroom At: 3305 Edison Way, Fremont, CA 94538 Is Open Monday - Friday From 8am To 5pm BOB KROHA ROB KROHA CONTACT US TODAY: 510-249-1000, PERMACH.COM

1979

-

machining. In this immersive educational environment, GCU certificate students and 4-year degree engineering students will have an opportunity to work for Lux in manufacturing operations where they will gain hands-on manufacturing experience. Lux Precision Manufacturing mission is to re-energize American manufacturing by producing quality, precise parts for industry and by partnering with GCU to impact the manufacturing workforce.

For more infomation on Lux Precision Manufacturing Contact them at: weston@ luxprecisionmfg.com, (602) 633-5662.

Paperless Parts Strengthens Manufacturers’ IT Security

Job shops and other manufacturers using the online quoting platform will gain a layer of security control when enhanced visibility and access rights management are required, particularly for orders linked to DoD programs.

With its chief technology officer noting that manufacturers are “major target for cybercrime,” Paperless Parts is introducing data-security capabilities for the job shops and contract manufacturers using its quoting platform. The new Paperless Parts IT Module will help users ensure that sensitive data, especially Controlled Unclassified Information (CUI), is handled appropriately during quoting.

MILL S & THRILL S

S

DNM: global best seller

BVM: premium powerhouse

The new capability is particularly suited to operations working in the defense manufacturing supply chain, who frequently handle sensitive intellectual property (IP) and high-security information.

“The U.S. invests more than $100 billion dollars into defense research and development annually. In the private sector, companies spend billions each year developing their intellectual property. Protecting the IP of these organizations is a matter of national security, and maintaining American competitiveness on a global scale,” according to Paperless Parts co-founder and CEO Scott Sawyer.

U.S. DoD contract manufacturers are required to adhere to strict security standards, including multi-factor authentication, tight access control, and detailed audit capabilities. As early as May 2023, such manufacturers will

SALES (866) 567-2580

SERVICE (800) 994-0146

PARTS (888) 207-2787

be subject to third-party audits to ensure compliance with the standards outlined in the Cybersecurity Maturity Model Certification (CMMC) 2.0. Individual shops will have to ensure that all of their security and IT control processes are CMMC-compliant.

Boston-based Paperless Parts is a Cloud-based estimated and quoting software that supports a broad range of manufacturing functions, including milling and machining, sheet metal fabrication, and additive manufacturing.The ITAR-registered site is hosted on Amazon GovCloud (also used by DoD), and leverages in-transit data encryption using TLS v1.2 with modern ciphers, at-rest data encryption using AES-256, 100% US-based system administrators and support team, a System Security Plan based on the FedRAMP Moderate baseline (NIST 800-53), nightly data back-ups, and more.

Continued Page 10

A2Z MANUFACTURING WEST COAST • 9 • APR - MAY ’23

D o os a n M a c h i n e To o l s i s n ow

t s

Get your ideal VMC

ready for the ver tic al

your

or visit dn-solutions

The lineup of ver tic al machining center s at DN Solutions is ver satile, compac t and born to make incredible

par

for as long as you need them to

, then get

leap. Talk to

loc al DN dis tributor

com

DEM: entr y-level par t producer

VM: swif t and s trong

The versatile VMC lineup at DN Solutions is enough to get anyone excited.

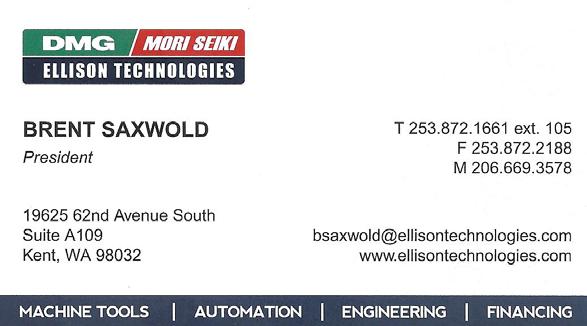

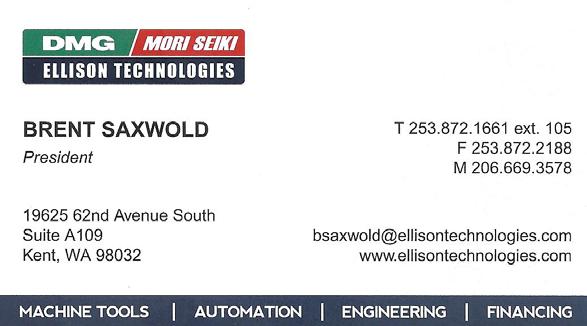

www.ellisontechnologies.com |

The new Paperless Parts IT Module introduces a layer of security control for shops that require enhanced visibility and access rights management, or any shop bidding for orders connected to DoD programs. With the IT Module, users will be able to use Single Sign-On (SSO) to centralize login and session management via third-party identity providers (including Microsoft Azure Active Directory, Okta, and OneLogin.)

Also, they will be able to restrict users’ ability to access CUI based on individual intelligent permissionsor type of role, so that CUI can only be viewed, downloaded, or shared by authorized users. Permissions are enforced at the User Interface, API, and database level.

Additionally, they’ll be able to flag files that contain CUI data so that access is limited to designated users, restrict other users, or set or remove CUI flags. And IT Module users will be able to track who is accessing CUI and create audit reports by downloading an audit log of all access to or modification of data that could potentially contain CUI.

“As critical national infrastructure, manufacturing is a major target for cybercrime, and the average cost of a data breach to a U.S. small enterprise is over $8 million,” Sawyer continued. “We want to arm our customers with the tools they need to ensure that the data they are entrusted with is as secure as possible.”

Airlines, Pilots Disagree on Pilot Shortage

by Kerry Lynch

Wednesday’s testimony in the U.S. Congress reflected differences in opinion on the existence of a pilot shortage.(Photo: Pixabay)

The state of pilot supply came under scrutiny in the House Aviation Subcommittee on Wednesday as industry stakeholders who testified disagreed about whether a shortage exists and whether measures such as raising the mandatory retirement age for airlines would help.

Regional Airline Association president and CEO Faye Malarkey Black in testimony called the situation “devastating” and said that despite soaring passenger demand, the shortage is decimating small community air service. She said the shortage has been growing for decades, with a chief issue stemming from the FAA’s slow action on advancing pilot training standards.

“The impacts of the pilot shortage are real,” she said. “Currently, more than 500 regional aircraft are parked, and those aircraft remaining in service are underutilized. The impact has been felt by 308 airports or almost 72 percent of all U.S. airports.”

A2Z MANUFACTURING WEST COAST • 10 • APR - MAY ’23

Calling the situation particularly acute among airline captains, she said the fact that 50 percent of the pilot workforce would be forced to retire in the next 15 years will exacerbate the problem.

“Thousands of willing, healthy, and skilled pilots who would like to continue working are being forced out of the profession at age 65, to the detriment of air service across the country,” said Black. Despite the increase in pilot certificates, there still are not enough qualified and interested people to hire, she added.

Last year marked a record for new pilots qualified—9,491—but the number “fell far short of the 13,128 hired by just one subset of the airline industry last year,” she stressed. “It is vitally important that pilot production in 2022 be put in the proper context.”

The Air Line Pilots Association (ALPA) released data in advance of Wednesday’s hearing showing that the FAA has certified 2,658 new airline pilots in just the first three months of this year and 63,932 since 2013, when stricter qualification rules took effect (the so-called 1,500-hour rule). The airlines filled about 40,000 positions at the same time.

“Over the past 10 years, the United States has not only reduced airline passenger fatalities but also produced more than enough pilots to meet airline hiring demand,” said ALPA president Jason Ambrosi. “The groups that continue the flood of misinformation and misleading data are only interested in one thing: manufacturing a crisis to lower aviation safety standards and increase their bottom line.”

ALPA blames the decision of the airlines to bump to smaller equipment, park aircraft, and furlough pilots during the pandemic for creating the current situation.When demand returned and airlines rehired pilots, they needed retraining, creating a backlog. Ambrosi told lawmakers he believed enough supply exists to satisfy demand and

cautioned against raising the pilot age on the grounds that it would put the U.S. out of sync with international standards.

Heather Krause, director of physical infrastructure for the Government Accountability Office (GAO), noted that the number of individuals qualified to become airline pilots increased between 2017 and 2022 and enrollments in training schools likewise increased. Forecasters project an increase in pilot supply, she testified, but “the extent to which projected supply would exceed or fall short of industry’s demand for pilots is unknown, given uncertainties surrounding future demand.”

Hiring and wage data indicate a strong demand for pilots, and regional airlines in particular have faced difficulties meeting that demand. Airlines have increased pay and the FAA is taking steps to support workforce development, she noted, but it is unclear whether these steps will be enough.

A2Z MANUFACTURING WEST COAST • 11 • APR - MAY ’23

ChatGPT Is Changing Manufacturing... Here’s How To Use It

“The chatbot can provide quick responses for common issues that customers have, enable faster diagnosis and suggest personalized recommendations.”

ChatGPT is making headlines. OpenAI recently released its latest version of ChatGPT, which can provide “human-level performance” on many professional tests, such as the bar exam and the SAT.

But what can it do in the industrial space? Here we chat with Mikaela Pisani, head of data science for Rootstrap, about the newest version of ChatGPT and how manufacturers can actually use the ongoing development of new AI technology to improve business outcomes. Take a look…

ChatGPT might change the manufacturing industry in many ways, creating optimizations plans, predictive-maintenance schedules, mitigating risks, improving communications (making them faster and more efficient), as well provide quality control-detecting anomalies in the available information.

Manufacturers using this tool would be able to make better decisions, reduce costs, improve quality and, as a consequence, have a greater customer satisfaction.

The chatbot can provide quick responses for common issues that customers have, enable faster diagnosis and suggest personalized recommendations. Therefore, it can optimize time in responses giving the user useful information helping manufacturers to build stronger relationships with their customers by providing better service, personalization and responsiveness.

Smart Industry: What concerns/challenges does this tool present?

Mikaela: While ChatGPT and other AI technologies offer significant benefits for the manufacturing industry, they also present several concerns and challenges. AI systems might be vulnerable to cyberattacks, compromising sensitive information. It is manufacturers´ responsibility to ensure security over AI systems.

Also, there is a trend that more and more AI is replacing automated tasks, and without a human in the loop there might be ethical concerns regarding decisions made with these tools. Therefore, manufacturers should consider introducing humans to validate and correct AI results in order to provide a secure service.

In addition, a big challenge for manufactures is the integration of AI systems into the common workflow and processes.The use of AI should be done by steps, enabling compatibility with other systems.

A2Z MANUFACTURING WEST COAST • 12 • APR - MAY ’23

The workforce is not familiar with this technology, so owners need to invest money and time into training workers to integrate the tool in their job. On the other hand, there might be a reduction of personnel, since AI can automate many tasks and processes that are currently being done by people; it might be better for the company to hire trained people rather than wait for the current workforce to be ready for the job. This may lead to job displacement.

Smart Industry: What limitations exist with ChatGPT for application in the industrial space and how long will these limitations exist?

Mikaela: The limitations that ChatGPT have are the following:

1. The lack of actual information.This fact is a problem when you need updated information, and also this model is not very useful when you need to validate the source. In the short term this won´t be a problem, since Microsoft and Google are realizing search engines connected with a language model like this.Therefore, the mix of a search engine and a chatbot will be really powerful tool for searching information fast and getting a summarization.

Phoenix Heat Treating Phoenix Heat Treating

2. It does not have any real-world experience, so the understanding of certain situations might be limited.This might be a problem because in some cases, practical knowledge and skills are essential for success in the field.This limitation will persist for a long time, because it is one of the elements that separates us from machines. It is true that machines can have certain memory and learn from the experience and simulation, but their experience is more limited than ours. It may not have the same level of intuition and creativity that a human would bring to a problem. So it is unlikely to fully replace the benefits that come from hands-on experience in the industrial space.

3. Bias: AI models present bias inferred from training data or patterns that they learned. Bias can affect the responses and decision-making. Bias will be always present since it is impossible to remove it; even when we think that bias is zero, there will be bias. This fact is not that fatal since we already have human bias; maybe with the help of AI we are able to reduce it.

Smart Industry: What does the use of this tool look like five years down the road?

Mikaela: I feel that this tool is revolutionizing our way of work. We will

need it to make our work faster and keep up with market expectations. In the near future, AI might be used on every step of manufacturing process, in this way manufacturers will exponentially improve use of resources and time, focusing on providing better quality and freeing more time for working on creative ideas that deliver innovation.

Mikaela: In my opinion, there are a huge amount of opportunity to take advantage of this tool in the manufacturing area—think automating communications, optimizing costs and resources, providing opportunities for workers to focus on more strategic tasks rather than repetitive tasks, to detect errors and predict maintenance, as well as provide useful insights for decision-making and sharper recommendations.

ChatGPT can streamline this process by interpreting large volumes of data coming from a variety of sensors and metrics to get to the key findings that enable teams to pinpoint where a failure is likely to show up and act before shutdowns are needed.

A2Z MANUFACTURING WEST COAST • 13 • APR - MAY ’23

G E T T O K N O W U S Servicing our industry and trade

in intelligence heat treating for

60 years. www phoenix-heat-treating com 602-258-7751 cs@phxht com Established in 1963 Real Time Live Job Tracking 10+ Processes Performed 50+ Furnaces AOG and Line Down Services Over 10+ Prime Approvals 24/7 Processing

customers

over

Contracts

FLIR Unmanned Aerial Systems, Hvalstad, Norway, was awarded a $93,889,000 firm-fixed-price contract for Black Hornet 3 unmanned aerial systems, spare parts and ancillary services. Bids were solicited via the internet with one received. Work locations and funding will be determined with each order, with an estimated completion date of April 11, 2028. U.S. Army Contracting Command, Aberdeen Proving Ground, Maryland, is the contracting activity (W91CRB-23-D-0008).

Lockheed Martin Corp., Lockheed Martin Aeronautics Co., Fort Worth,Texas is awarded a $172,100,266 modification (P00001) to a cost-plus-fixed-fee, firm-fixed-price order (N0001920F0002) against a previously issued basic ordering agreement (N0001919G0008). This modification definitizes the order and adds scope to provide special test/tooling equipment for increasing Block 4 manufacturing capacity, as well as procures material modification kits in support of removing life limits, correcting deficiencies, and retrofitting aircraft to incorporate Next Gen Distributed Aperture System hardware and associated Power and Thermal Management System modifications efforts.These modifications are in support of F-35 aircraft for the Air Force, Marine Corps, Navy, Foreign Military Sales (FMS) customers, and non-U.S. Department of Defense (DOD) participants.Work will be performed in Fort Worth,Texas, and is expected to be completed in December 2030. Fiscal 2023 aircraft procurement (Navy) funds in the amount of $208,445; fiscal 2022 aircraft procurement (Air Force) funds in the amount of $67,568,935; fiscal 2022 aircraft

procurement (Navy) funds in the amount of $53,866,743; fiscal 2021 aircraft procurement (Navy) procurement funds in the amount of $6,792,712; fiscal 2021 aircraft procurement (Air Force) funds in the amount of $5,148,444; FMS funds in the amount of $1,044,729; and non-U.S. DOD participants funds in the amount of $37,470,258 will be obligated at the time of award, $11,941,156 of which will expire at the end of the current fiscal year. The Naval Air Systems Command, Patuxent River, Maryland, is the contracting activity.

Bell Textron Inc., Fort Worth, Texas, has been awarded an estimated $7,960,693 modification (P00043) against a five-year contract (SPE4AX-17-D-9410) with one five-year option period for H-1 consumables. This is a firm-fixed-price requirements contract. The performance completion date is April 13, 2025. Using military service is Marine Corps.Type of appropriation is fiscal 2023 through 2025 defense working capital funds. The contracting activity is the Defense Logistics Agency Aviation, Philadelphia, Pennsylvania.

Textron Systems, Hunt Valley, Maryland, is awarded an $18,675,412 fixed-price incentive (firm target) modification to previously awarded contract N00024-14-C-6322 for retrofit of the Unmanned Influence Sweep System (UISS) Unmanned Surface Vehicle (USV). Work will be performed in Hunt Valley, Maryland (70%); and San Diego, California (30%), and is expected to be completed by June 2024. Fiscal 2023 other procurement (Navy) funds in the amount of $18,675,412 will be obligated at time of award and will not expire at the end of the current fiscal year. The Naval Sea Systems Command,

A2Z MANUFACTURING WEST COAST • 14 • APR - MAY ’23

Washington, D.C., is the contracting activity.

Vigor Marine LLC, Portland, Oregon, is awarded a $29,181,598 firm, fixed-price contract (N3220522C4211) for a 110-calendar day Regular Overhaul Dry Docking availability of Military Sealift Command’s fleet oiler USNS PECOS (T-AO 197). This contract includes a base period and four unexercised options, which if exercised, would bring the cumulative contract value of this contract to $30,552,590. Work will be performed in Portland, Oregon, beginning May 19, 2023, and is expected to be completed by Sept. 5, 2023. Working capital funds (Navy) in the amount of $29,181,598 are obligated for fiscal 2023, and will not expire at the end of the current fiscal year. This contract was competitively procured via the sam.gov website and one offer received. The Navy’s Military Sealift Command, Norfolk, Virginia, is the contracting activity (N3220522C4211).

The Survice Engineering Co. LLC,* Belcamp, Maryland, is awarded an $8,359,234 firm-fixed-price contract for the production and delivery of 21 TRV-150C Tactical Resupply Unmanned Aircraft Systems and 12 months of Systems Engineering Program Management services in support of the Navy and Marine Corps Small Tactical Unmanned Aircraft Systems program office. Work will be performed in Churchville, Maryland, and is expected to be completed in March 2024. Fiscal 2023 procurement (Marine Corps) funds in the amount of $6,363,065; and fiscal 2023 operation and maintenance (Marine Corps) funds in the amount of $1,996,169 will be obligated at the time if award, $1,996,169 of which will expire at the end of the current fiscal year. This contract was not

competitively procured pursuant to 10 U.S. Code 4022(f). The Naval Air Systems Command, Patuxent River, Maryland, is the contracting activity (N0001923C0033).

The Boeing Co., St. Louis, Missouri, was awarded a $1,170,768,698 undefinitized modification (P00001) to a firm-fixed-price order (N0001922F0030) against a previously issued basic ordering agreement (N0001921G0006). This modification procures 400 RGM-84L-4 Harpoon Block II Update (HIIU) Grade B canister tactical missiles, four RTM-84L-4 Block II HIIU Grade B canister exercise missiles, 411 containers, four blast test vehicles, two Harpoon Weapon System (HWS) Joint Common Test Sets (JCTS), Harpoon Coastal Defense System (HCDS) spares, weapon station support equipment, JCTS spares, missile spares, HCDS training equipment, integrated logistics support and technical publications, field service representatives and training.Work will be performed in McKinney,Texas (24.43%); Pontiac, Michigan (12.93%); Annapolis, Maryland (9.20%); Pine Brook, New Jersey (4.96%); St. Louis, Missouri (3.49%); Randolph, Vermont (2.83%); Galena, Kansas (2.7%); Huntsville, Alabama (2.21%) Grove, Oklahoma (2.05%); Chandler, Arizona (1.80%); Setauket, New York (1.51%); Enumclaw, Washington (1.37%); Minneapolis, Minnesota (1.24%); St. Charles, Missouri (1.22%); Federal Way, Washington (1.15%); Union, Missouri (1.14%); and various locations within and outside the continental U.S. (25.77%), and is expected to be completed in March 2029. Foreign Military Sales funds in the amount of $629,776,662 will be obligated at the time of award, none of which will expire at the end of the current fiscal year. The Naval Air Systems Command, Patuxent River, Maryland, is the contracting activity.

A2Z MANUFACTURING WEST COAST • 15 • APR - MAY ’23

Contracts

Kratos Unmanned Aerial Systems Inc., Sacramento, California, is awarded a $9,156,552 modification to a previously awarded, costplus-fixed-fee contract. This modification adds scope to provide non-recurring engineering, integration, and installation of a sensor payload, as well as provides for associated labor and material for Unmanned Aerial Systems (UAS) mission systems and subsystems integration. Additionally, this modification adds scope to provide for the development and testing of autonomy and pilot vehicle interfaces, UAS ground and flight operations, as well as flight test events for the Navy. Work will be performed in Sacramento, California, and is expected to be completed in September 2023. Fiscal 2022 research, development, test and evaluation (Navy) funds in the amount of $8,572,892 will be obligated at the time of award, all of which will expire at the end of the current fiscal year. The Naval Air Warfare Aircraft Division, Patuxent River, Maryland, is the contracting activity.

Raytheon Missiles and Defense, Andover, Massachusetts, has been awarded a maximum $14,422,046 firm-fixed price delivery order (SPRRA2-23-F-0054) against a 10-year indefinite-delivery/ indefinite-quantity contract (SPRBL1-15-D-0017) for Patriot missile parts. This was a sole-source acquisition using justification 10 U.S. Code 2304 (c)(1), as stated in Federal Acquisition Regulation 6.302-1. This is a three-year contract with no option periods.The performance completion date is Feb. 17, 2026. Using military service is Army. Type of appropriation is fiscal 2023

through 2026 Army operations and maintenance funds. The contracting activity is the Defense Logistics Agency Aviation, Redstone Arsenal, Alabama.

Honeywell International Inc., doing business as Honeywell Aerospace, Deer Valley, Phoenix, Arizona, has been awarded a maximum $12,207,394 firmfixed-price, firm-fixed-quantity contract for B-1B air data computers. This was a sole-source acquisition using justification 10 U.S. Code 2304 (c)(1), as stated in Federal Acquisition Regulation 6.302-1 (a)(2). This is a three-year, two-month contract with no option periods. The performance completion date is May 1, 2026. Using military service is Air Force.Type of appropriation is fiscal 2023 defense working capital funds. The contracting activity is the Defense Logistics Agency Aviation, Tinker Air Force Base, Oklahoma City, Oklahoma (SPE4A1-22-G-0015).

Global Military Products LLC,Tampa, Florida, was awarded a $431,007,300 firm-fixed-price contract for the procurement and delivery of ammunition. Bids were solicited via the internet with two received. Work locations and funding will be determined with each order, with an estimated completion date of Jan. 31, 2024. U.S. Army Contracting Command, Rock Island Arsenal, Illinois, is the contracting activity (W519TC-23-F-0196).

Lockheed Martin, Rotary and Missions Systems, Liverpool, New York, is awarded a $63,270,853 firm-fixed-price modification to previously-awarded contract N00024-20-C-5503 for option exercise of full rate production Surface Electronic Warfare Improvement Program AN/SLQ-32(V)6 and AN/SLQ-32C(V)6 systems.Work will be performed in Liverpool, NewYork (78%); and Lansdale, Pennsylvania (22%), and is expected to be completed by February 2025. Fiscal 2023 other procurement (Navy) funds in the amount

A2Z MANUFACTURING WEST COAST • 16 • APR - MAY ’23

of $43,721,001 (70%); fiscal 2022 shipbuilding and conversion (Navy) in the amount of $9,774,926 (15%); and fiscal 2023 shipbuilding and conversion (Navy) in the amount of $9,774,926 (15%) will be obligated at time of award and will not expire at the end of the current fiscal year. The Naval Sea Systems Command,Washington, D.C., is the contracting activity.

Tomahawk Robotics Inc.,* Melbourne, Florida, is being awarded a $55,013,768 firm-fixed-price, indefinite-delivery/indefinite-quantity contract for production and post-production support of the Flexible Cyber-Secure Radio (FlexCSR) Systems. This contract includes options, which if exercised, would bring the cumulative value of this contract to $58,506,352. Work will be performed in Melbourne, Florida, and is expected to be completed by April 2028. No funds are being obligated at the indefinite-delivery/indefinite-quantity contract level.This contract was not competitively procured in accordance with 10 U.S. Code 3204(a) (1) (only one responsible source and no other supplies or services will satisfy agency requirements). The Naval Surface Warfare Center Indian Head Division, Indian Head, Maryland, is the contracting activity.

Raytheon Co., Tucson, Arizona, is awarded a $7,985,181 cost-plus-fixedfee modification to previously awarded contract N00024-17-C-5410 to exercise options and incrementally fund existing contract line items for engineering and technical support of Standard Missiles 2 and 6 (SM2/6). Work will be performed in Tucson, Arizona, and is expected to be completed by March 2024. Fiscal 2023 research, development, test and evaluation (Navy) funds in the amount of $7,684,181 (96%); and fiscal 2023 weapons procurement (Navy) funds in the amount of $301,000 (4%) will be obligated at time of award and will not expire at the end of the

current fiscal year. The Naval Sea Systems Command, Washington, D.C., is the contracting activity.

Northrop Grumman Systems Corp., Dulles, Virginia, has been awarded a $45,959,668, firm-fixed-price and cost-plus-fixed-fee modification (P00005) to contract FA8814-22-C-0004 for the Rapid On-orbit Space Technology Evaluation Ring 4 (ROOSTER-4), a self-propulsive secondary payload adapter for deploying small satellites. The contract modification incorporates effort required to develop, deliver, launch, and perform initial on-orbit support for ROOSTER-4. The total cumulative face value of the contract is $62,008,243.Work will be performed in Dulles,Virginia, and is expected to be completed by May 29, 2026. Fiscal 2023 research, development, test and evaluation funds in the amount of $29,132,816 are being obligated at the time of award. The modification brings the total cumulative face value of the contract to $62,008,243. The U.S. Space Force, Space Systems Command, El Segundo, California, is the contracting activity.

General Dynamics - Ordnance and Tactical Systems, Scranton, Pennsylvania (W15QKN-23-D-0025); and IMT Defense Corp.,* Westerville, Ohio (W15QKN-23-D-0026), will compete for each order of the $344,220,000 fixed-price with economic price adjustment contract for the manufacture, test, packaging and delivery of 155 mm M1128 artillery metal parts assembly. Bids were solicited via the internet with two received. Work locations and funding will be determined with each order, with an estimated completion date of April 13, 2028. U.S. Army Contracting Command, Newark, New Jersey, is the contracting activity.

A2Z MANUFACTURING WEST COAST • 17 • APR - MAY ’23 (800) 481-6271 www.pmplating.com We Are The Noble Partner With The Personal Touch! Precious Metals Plating Co., Inc + Gold Plating + Silver Plating + Nickel Plating + Electroless Nickel Plating + Tin Plating + Heat Treat With Plate + Nadcap Approved Processes + Boeing Approved Processes + Expedited Turnaround + X-ray Fluorescence Thickness Verification + In-House Laboratory With Atomic Absorption (AA) + Expanded Capacity In Vibratory Plating

Innovation Never Ends: As GE Turns 131, The Company’s Creative Minds Haven’t Run Short On Big Ideas

Chris Norris

Chris Norris

In 1876, a 28-year-old Thomas Edison came up with what may be his most underrated innovation: a laboratory and machine shop inside a single two-story building in Menlo Park, New Jersey. It’s a place he called his “Invention Factory,” and one that history calls the first R&D facility in the world. While the Menlo Park model was soon adopted by governments, universities, and rival companies, its DNA proved as distinct as it was world-changing, and it led to the birth of GE in Schenectady, New York, in April

1892. Over the following 131 years, that idea factory bloomed into a global company powered by teams of people who theorize, experiment, and put their results directly into commerce on a daily basis, pursuing real-world impact with a kind of optimistic humility. While much has changed since GE’s founding, its leaders now bring this same grounded ethos to technologies ranging from increasingly efficient jet engines to lower-carbon power plants, super-powerful wind turbines, and integrated, self-repairing digital grids.

In 2024, the current incarnation of GE will branch into two independent public companies: GE Aerospace and GE Vernova. As standalone entities, both will be better aligned and more focused, providing optimal lab conditions in which GE’s legacy — and its future — will be secured by ongoing generations of innovators like the ones highlighted below, as they transform and sustain a world Edison illuminated well over a century ago.

Catching Wind

At GE Vernova, one team is already bringing a powerful, real-world dedication to the world of wind energy. Partnering with the MIT-formed wind turbine tower manufacturing startup Keystone Tower Systems, GE Renewable Energy’s Onshore Wind “towers team” — including Technical Leader Greg Cooper, Senior Product Manager Neil Eveld, and Senior Sourcing Manager for North America Towers Carlos Roman — worked with Keystone to commercialize its spiral-welding tower technology and make the fabrication process more efficient.The process renders the same intricacies found in the construction of a paper straw, instead using the spiral-welded technology to build wind turbine towers with meters-wide steel, tapered and in variable lengths. The first one went into operation at a GE customer site this past October in Minnesota.

Greg Cooper and Eric SmithGreg Cooper, tower technical leader at GE Renewable Energy, and Eric Smith, founder and former CEO of Keystone Tower Systems. Credit: GE Renewable Energy. Top: Thomas Edison and legendary GE engineer Charles Steinmetz examine pieces of wood and porcelain insulators damaged by Steinmetz’s million-volt

Call Now! (503) 282-7239 info@abfinishingtech.com www.abfinishingtech.com 6724 NE 46th Ave. Portland, OR 97218 Quality and Service Since 1936 ON TIME, EVERY TIME! AB Finishing Tech prides itself on setting the standard for: • black oxide finishing • shot peening • sandblasting A2Z MANUFACTURING WEST COAST • 18 • APR - MAY ’23

lightning generator during Edison’s visit to Schenectady. Credit: Museum of Innovation and Science Schenectady.

Keystone referred to this process as the “automation of an art,” says Cooper, 46, “because there’s an art form to getting these towers right.” An engineering organizer at GE for 23 years, based at GE’s Schenectady mother ship, Cooper explains that this partnership is beneficial to both parties: “Now we have much better insight into this specific manufacturing process, and really understand what we’re getting.”

Just as Edison set out to improve existing solutions, the towers team pursues small improvements in ground-floor technology — charting the course for the industry alongside a broad team of GE colleagues, including design engineers, chief engineers, managers, and executives. All have made contributions to the effort with operational success in mind: “These tower innovations are a step in the evolution of an entire technology that we’re helping develop,” Cooper adds.

The collaborative partnership between Keystone and GE brings matched dedication and shared goals for the future as they work to automate the manufacturing process to build bigger — better, and faster. “This may look like just another tower supplier,” says Cooper, “but as we improve the technology, we’ll unlock other benefits; we’ll eliminate trucks and improve logistics, reduce costs for turbine fleets across the country, and contribute to larger sustainability goals.” Taller, higher-yield onshore wind turbines will become a possibility for vastly more customers, without compromising quality.

Eveld, 32, didn’t show up for his first day with a passion for sustainability. “When you’re coming out of undergrad, it’s more like ‘GE! They make cool things!’” says the Chicago-based product manager. “As I worked through different roles within GE, I found what I’m passionate about and what’s important.” Eveld now aligns with both Cooper and the Greenville, South Carolina–based Roman, 34, whose yen to figure out innovative new ways to reduce carbon output

sparked his interest in renewable energy systems.

Edison’s foundational focus on real-world impact forms a similar future-oriented pragmatism in the leaders of the towers team and the engineering organization that they are a part of. While they work to extend customers’ reach into the sky, this team’s feet are planted firmly on the ground. “The future of energy is so much more complex than most people understand,” Eveld says. “And I think GE Vernova is positioned to be a real player in all its systems, with an emphasis on sustainability, both now and into the future.”

Internal Combustion

Internal Combustion

More than a century after Edison built his Menlo Park factory, and nearly 900 miles from there, high school junior Jamielee Buenemann

Continued Page 22

A2Z MANUFACTURING WEST COAST • 19 • APR - MAY ’23

A2Z MANUFACTURING WEST COAST • 20 • APR - MAY ’23 A2Z MANUFACTURING SW • 33 • May /June 2023 SOUTHWEST EDM Who Better To EDM Your Parts Than The #1 Fanuc EDM Expert in North America! 1125 W Pinnacle Peak Rd, Phoenix, AZ 85027 (623) 826-1025 southwestedm.com steve@southwestedm.com Wire EDM Job Shop With Full CNC Machining And Turning Capabilities... MANUFACTURING Capabilities 6 Matsuura Horizonal Machining Centers • Up to 80 Tools • 4-axis with Dual Pallets 8 Haas Vertical Machining Centers • Travels up to 60” • 4th and 5th Axis 2 Fanuc Wire EDMs • .004” - .012” Diameter • Up to 12” Thick Full Inspection / CMM Capabilities Engineering and Assembly Debur, Tumble, Media Blast, & Coating Type 7 FFL ITAR Registered “In conjunction with DillonAero Manufacturing, we offer EDM plus so much more in machining.” Steve Raucci, Owner Southwest EDM MANUFACTURING CAPABILITIES 6 Matsuura Horizontal Machining 8 Haas Vertical Machining 2 Fanuc Wire EDMs Full Inspection & CCM Capabilities Up to 80 Tools 4-axis w/ Dual Pallets Travels up to 60” 4th & 5th Axis .004”-.012” Diameter Up to 12” Thick Engineering & Assembly Deburr, Tumble, Media Blast, Type 7 FFL Contact: steve.raucci@dillonaero.com jay.goodrich@dillonaero.com

One of the 8 Haas VMCs

Our

Inspection/CMM Partnering with NEWS

Row of Matsuuras

Newest Machine:

Ocean EDM Hole EDM

Z MANUFACTURING WEST COAST • 21 • APR - MAY ’23 MAY 10-11, 2023 OREGON CONVENTION CENTER PORTLAND, OR INNOVATION. TECHNOLOGY. PRODUCTIVITY. OWNED & PRODUCED BY: FOR EXHIBITING INFO, CONTACT JOYCE LORTZ: JLORTZ@FACILITIESEXPO.COM | (410) 598-3535 REGISTER FOR FREE AT: MACHINETOOLEXPOS.COM

Continued From Page 19

set up her own R&D facility in the backyard of her parents’ Missouri house. Eager to apply her innate passion for problem-solving to her burgeoning interest in renewable energy, she gathered up some PVC pipes and old conveyor-belt motors and set to work building a wind turbine — an experiment that was partly about wind energy and partly about herself.

“Honestly, I was hoping to figure out whether I truly liked engineering, outside of just the math and science classes you’re taking in high school,” says Buenemann, 26. “And like I’m sure a lot of engineers do, once I started down the process, I kind of got addicted to working through the problems.”

This addiction, certainly the best kind to have, led Buenemann to a co-op at GE Aerospace and the Edison Engineering Development Program. After completing the Edison program, the Ohio State University graduate continued building her own technical depth while developing leadership skills, and now she represents a bold new chapter in GE’s odyssey.

“I love the community here and the overall atmosphere of continuing education and learning,” Buenemann says. “I find we’re always trying to improve at every level of the company. GE Aerospace invests in its employees, and I really saw that during my co-op.” Through this and other co-ops, Buenemann

Are you ready to implement or upgrade your Quality Management System to the new ISO 9001:2015 or AS9100D / ISO 9001:2015 Standard, AS9110C or AS9120B?

Special Packages available, take advantage of 20 plus years’ experience implementing and auditing quality management systems for commercial and aerospace companies!

Bretta Kelly, President and Owner of BMSC, LLC www.businessmsc.com has proven, copy written templates for ISO 9001:2015, AS9100D / ISO 9001:2015, AS9110C / ISO 9001:2015 and AS9120B / ISO 9001:2015 Standards with more than 30 companies upgraded and certified with zero to one finding results to date in their upgrade audits!

Packages Available:

Complete Electronic QMS System/Templates and 4 hours consulting – Manual, Policy, System Procedures, Work Instruction / Flow charts for some processes, internal audit program, management review program (including forms), competency / training program, objectives training template, risk training and how to document a corrective action training PowerPoint’s - $3,500

Complete Electronic QMS System/Templates and online webinar of how to complete –Manual, Policy, System Procedures, Work Instruction / Flow charts for some processes, internal audit program, management review program (including forms), competency / training program, objectives training template, risk training and how to document a corrective action training PowerPoint’s - $2,500

Do you need Quality Management System Software? Bretta Kelly is also President of CIS WWSG, LLC and is now offering the $3,500 Templates for FREE with purchase of CIS Software! www.cissoftware.com. CIS Software costs $5,000 upfront (one time) and $385/month license and server fees for UNLIMITED users, request a demo today! Testimonial from BMSC Clients featured in the A2Z Manufacturing Magazine who have taken advantage of the BMSC Templates for successful upgrades:

Bretta, I wanted to email you and let you know that because of the help of yourself and Debbie we completed our audit to the new revision with no findings! :) We very much appreciate all of the help that you both did for us and will recommend your company to anyone looking to get certified. Your system really makes it easy for companies like ours to stay organized and compliant to the guidelines. Kristie McKee, Gibbs Precision Machine

gained technical research experience in piezoelectrics and in mechanical systems by engineering locomotive trains, eventually finding a place at GE Aerospace in Cincinnati, Ohio, where she can indulge her passion for big, complex technologies like hybrid electric flight.

The path from a DIY wind turbine to a megawatt-class, multi-kilovolt hybrid electric propulsion system is less circuitous than it might seem. Like the GE Vernova spiral-welded tower team, Buenemann and her team have a goal of reducing CO2 emissions. That’s why NASA and Boeing have teamed with GE Aerospace to tackle hybrid electric commercial flight through the Electrified Powertrain Flight Demonstration project. What motivates her to get out of bed each morning is knowing her team is advancing technology that will have an impact decades down the road.

Indeed, 131 years on, GE is poised to take another major leap in its constant pursuit of innovation. Heading into the planned separation early next year, each company will remain laser-focused on its mission — to invent the future of flight and lead the energy transition. At GE Aerospace, the team is intent on meeting an unprecedented ramp in engine production as travelers return to the skies, delivering critical capabilities to the next generation of U.S. military aircraft, and developing more sustainable technologies that will push the airline industry to new heights. And with electric power generation needs projected to grow 50% by 2040, and interest in new decarbonization technologies on the upswing, GE Vernova is uniquely positioned to work with its customers to supply more sustainable, affordable, reliable, and secure solutions for years to come.

GE’s ultimate goal is to create a world that works.With the help of curious, tireless innovators like Cooper, Evald, Roman, and Buenemann, it’s set to do that well into the future.

A2Z MANUFACTURING WEST COAST • 22 • APR - MAY ’23

www.techfin.net

are committed to providing:

Equipment Financing

Approval Process

Financing Structures and Terms

Industry Knowledge

Tech Financial has been providing best-in-class financing to the Machine Tool Industry across the USA and Canada for over 20 years!

We

•Hassle-Free

•Fast

•Flexible

•Unmatched

Isaac Leman, CLFP 541-360-1318 isaacl@techfin.net

Contact our sales team today so we can help you get the equipment you need, when you need it

Kobe Knaak 414-213-2261 kobek@techfin.net

Sara Charlton, MBA 262-844-7571

sara@techfin.net

3,000+ Waterjet Parts Are Just a Click Away

We are an authorized distributor of genuine OEM parts from Flow, H2O Jet and KMT

From cutting heads, on/off valves, and orifices to ROCTEC nozzles and more, most parts are in stock, and ordering is fast and easy. Visit store.barton.com or call (800) 741-7756 to speak with a parts expert.

FREE SHIPPING EVERY DAY on qualifying online orders at store.barton.com

Any reference to the original manufacturer is for identification purposes only.

BARTON INTERNATIONAL USA/Canada 800-741-7756

518-798-5462 • info@barton.com • barton.com • store.barton.com

BARTON is a trademark of BARTON Mines Corporation.

International Travel Demand Is Growing At Twice The Domestic Rate, According To United Airlines Executives.

By Ben Miller

In a quarter when the airline announced a $256 million pre-tax loss, executives at United Airlines were quick to point out the positive things it sees on the horizon.

The Chicago-based carrier (Nasdaq: UAL) on Tuesday reported firstquarter revenues increased more than 51% to $11.4 billion from $7.6 billion a year earlier and announced an adjusted loss per share of 63

cents per share, an 85% improvement from a first-quarter 2022 loss of $4.24 per share.

Looking ahead, United said that it should report positive earnings per share of between $3.50 and $4 for the second quarter, and earnings of between $10 and $12 for the fiscal year.

That’s because United said it sees strong international travel demand in the second quarter and beyond.

“Demand remains strong, especially internationally, where we are growing at twice the domestic rate,” said CEO Scott Kirby, in a statement.

International travel demand caused United to add new direct flights from Los Angeles to Brisbane, Australia, and Auckland, New Zealand, as well as increasing flights from San Francisco to the area in what the airline called this week the “largest South Pacific expansion in aviation history.”

The South Pacific flight additions come after United said earlier this month that it’s adding more than a hundred international flights this summer from several U.S. markets, including Chicago, Los Angeles and NewYork.

And in February, United said it signed a new enhanced transborder agreement with Air Canada that will see the two airlines adding more flights at important hubs such as Chicago, Newark and Los Angeles.

A2Z MANUFACTURING WEST COAST • 24 • APR - MAY ’23 OIL MIST AND SMOKE IN YOUR SHOP? Low-Cost, Highly Efficient Mist and Smoke Collectors Designed Specifically for the Metalworking Industry www.mistcollectors.com 1-800-645-4174

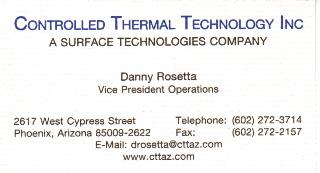

CONTROLLED THERMAL TECHNOLOGY (CTT) AND TS WEST

2617 West Cypress Street Phoenix AZ

602-272-3714

A Heat-Treating Company OFFERING

Salt Bath

Serving the Aerospace/Aircraft, Military, and Commercial Industries Other Services;

• GASEOUS CARBURIZING

• GASEOUS NITRIDING

• VACUUM HEAT TREATING

• HEAT TREATING

• NORMALIZING, ANNEALING, HARDENING, COLD TREATMENT STRESS RELIEVING, PRECIPITATION

Siemens Mobility, Whose Main North American Factory Is In Sacramento, To Build Plant In North Carolina

Department of Defense (DoD) Awards

North Carolina, and the city of Lexington come to another $16 million, according to sister Business Journal publications in Charlotte and the Triad area of North Carolina.

By Mark Anderson

A Sacramento Regional Transit District light rail car is being completed at the Siemens Mobility train factory in Sacramento.

Nammo Defense Systems Inc., Mesa, Arizona, was awarded a $498,092,926 firm-fixed-price contract for the full rate production of M72 Light Assault Weapon variants and components for shoulderlaunched munitions training systems. Bids were solicited via the internet with one received. Work locations and funding will be determined with each order, with an estimated completion date of Dec. 19, 2026. U.S. Army Contracting Command, Newark, New Jersey, is the contracting activity.

Siemens Mobility announced it will build an East Coast rail car manufacturing center in Lexington, North Carolina, investing $220 million in the region between Charlotte and the Triad area.

Siemens’ Sacramento train factory has delivered more than 3,000 locomotives, passenger coaches and light rail vehicles.

The company has been building light rail and trains in Sacramento since 1984, and it has been at French Road since 1992.The Sacramento factory has been busy in recent years with a series of record orders for new vehicles.

Siemens Mobility is calling the new North Carolina factory a sister plant to its 31-year-old Sacramento train and light rail factory at French Road.

“This is a pure growth story. We’ve invested $150 million in our Sacramento facility over the past 15 years and will continue to invest,” said Kara Evanko, Siemens spokeswoman, via email.

“While now was the right moment in time to find additional space on the East Coast, where we can also grow in close proximity to our East Coast customers, Sacramento will continue to be our North American Rolling Stock headquarters and our light rail service center hub,” she said.

Raytheon Co., Tucson, Arizona, is awarded a $55,121,826 costplus-fixed-fee modification to a previously awarded contract (N0002421C5434) for engineering and technical services in support of the Evolved Seasparrow Missile and NATO Seasparrow Missile Sys-tems programs. This contract combines purchases for the U.S. govern-ment (99%); and the governments of Japan and United Arab Emirates (1%) under the Foreign Military Sales (FMS) program. Work will be performed in Tucson, Arizona (82%); Portsmouth, Rhode Island (17%); Andover, Massachusetts (less than 1%); San Jose, California (less than 1%); Aranjuez, Spain (less than 1%); Brisbane, Australia (less than 1%); and Koropi Attica, Greece (less than 1%). Work is expected to be com-pleted by December 2022. The Naval Sea Systems Command, Wash-ington, D.C., is the contracting activity.

Siemens said it will invest more than $220 million to create more than 500 jobs in North Carolina. The effort there will receive a North Carolina Economic Investment Committee incentives package totaling about $16.8 million. Additionally, incentives from Davidson County,

Stability Timing (CREST) — a ruggedized atomic clock module with a unique combina-tion of performance and size, weight and power, capable of the abso-lute accuracy of a commercial cesium beam clock in a VPX-card-like form-factor. The CREST module will be designed to provide uninter-rupted Global Positioning System (GPS)-quality timing holdover in challenging military environments. Work will be performed in Phoenix, Arizona, with an expected completion date of Dec. 21, 2026. This contract was competitively procured under long range broad agency announcement (BAA) N00014-21-S-B001. The Office of Naval Research, Arlington, Virginia, is the contracting activity).

The French Road plant is the region’s second-largest manufacturer with about 2,500 employees, according to the Sacramento Business Journal’s most recent list. The Sacramento plant builds equipment for Amtrak and private and public rail companies all over the U.S. and Canada. The Sacramento factory is now building new low-floor light rail cars for the Sacramento Regional Transit District.

It’s common for reasons of supply chain and customer service for companies to want to have West Coast and East Coast operations, said Michelle Willard, chief public affairs officer with the Greater Sacramento Economic Council, which recruits companies to develop jobs in Sacramento.

The French Road factory had 600,000 square feet of buildings in early 2019. It passed 1 million square feet at the end of last year. The factory has a testing track on site.

Honeywell International Inc., Phoenix, Arizona, is awarded a $22,467,124 cost-plus-fixed-fee contract for the development, build and demonstration of the Compact Rubidium Extended

The Boeing Co., Mesa, Arizona, was awarded a $239,590,243 cost-plus-fixed-fee contract for the Apache Improved Turbine Engine Inte-gration Phase II. Bids were solicited via the internet with one received. Work will be performed in Mesa, Arizona, with an estimated comple-tion date of Dec. 31, 2026. Fiscal 2021 and 2022 research, develop-ment, test and evaluation, Army funds in the amount of $18,000,000 were obligated at the time of the award. U.S. Army Contracting Com-mand, Redstone Arsenal, Alabama, is the contracting activity.

A2Z MANUFACTURING WEST COAST • 25 • APR - MAY ’23 A2Z MANUFACTURING SW • 44 • March / April 2022

Nitride-MELONITE®- Per AMS2753 D

tjohnston@cttaz.com

For More Info: Contact Tim Johnston; 602-272-3714;

Adapting to New Possibilities

Christopher Dawson takes over for Interim CEO Jesse Fittipaldi, who will become Arcimoto president, reporting to Dawson.

Dawson joined the Arcimoto board last summer shortly after founder Mark Frohnmayer’s abrupt exit as CEO. That began a period of turmoil as a collapsing stock left Arcimoto (Nasdaq: FUV) without a funding source that had carried it through disappointing sales growth since going public in 2017.

Mounting losses forced deep layoffs and furloughs and pushed Arcimoto to the brink of bankruptcy in January before it eked out a $12 million stock sale and landed a $6 million loan.

But Dawson, citing his tenures at Tesla and other EV startups and Arcimoto’s “good bones,” said he was confident a leaner Arcimoto can survive and claw its way toward profitability.

“There’s enough potential economic energy in what we have in the factory to keep Arcimoto moving throughout the year and increase our sales, delivery and output by Q4,” he said. “We can do it without raising additional funds. (But) we will absolutely raise additional funds because it allows us to move more quickly to that target.”

Seven years at Tesla

Arcimoto Appoints Tesla Veteran Christopher Dawson As

CEO

Pete Danko | Portland Business Journal

“There’s enough potential economic energy in what we have in the factory to keep Arcimoto moving throughout the year and increase our sales, delivery and output by Q4,” Christopher Dawson, the new Arcimoto CEO, said.

Arcimoto, facing grave financial circumstances, has tapped a board member with Tesla experience as its new CEO, the Eugene electric vehicle maker said Thursday.

Dawson spent two years as a contractor at Tesla (Nasdaq: TSLA) beginning in 2012, then five years on staff, eventually becoming senior manufacturing engineer and maintenance manager, according to Arcimoto. An MBA and Navy veteran, he has also held executive positions at startups Nikola Tesla Co. and Atlis Motor Vehicles, an Arizona company that is facing its own difficulties.

After halting production in January, Arcimoto restarted production in March. It is making three vehicles per day now, Dawson said, ready to scale up as sales dictate. A daily workforce that once topped 300 is now at about 110, the new CEO said.

The company sold 228 vehicles last year, up from 192 in 2021 and 117 in 2020. It had revenue of $6.6 million in 2022 and a bottom-line loss of $62.9.

A2Z MANUFACTURING WEST COAST • 26 • APR - MAY ’23

1.800.281.5734 Germantown, WI USA www.hainbuchamerica.com

n Change from O.D. to I.D. to jaw clamping in < 2 minutes

n Use the same adaptations on your HAINBUCH turning or stationary chucks

n Keep the basic clamping device mounted on the machine

Chucks and adaptations are available in round or hexagonal configurations

“I think we can sell in excess of 400 units this year if we execute on all our marketing,” Dawson said. “That’s the bottom end. To be frank, I would be disappointed if we only did 400.”

Announcements & Releases Continued

Narrowly targeting its efforts at likely buyers will help boost sales, he said, describing that demographic as upper-middle-class people with second homes looking for a vehicle for running quick errands and getting around town.

from outside North America to North America. Reshoring includes work that is produced either in-house or outsourced. A complete definition of “reshoring” is available here. Applications must be submitted by June 30. To view award details and enter to win, visit this webpage.

“There’s some basic kind of housecleaning that can happen at the manufacturing level to really help drive” efficiency, he said, adding: “When I say there’s massive potential in that factory, it comes from 10-plus years of experience of automating specifically electric vehicle processes.”

“From 2010 to 2020, more than one million jobs were announced as coming to the United States from offshore. This is a tremendous achievement, and we seek to motivate and honor the companies that have made reshoring a reality,” said Harry Moser, founder and president of the Reshoring Initiative.

materials and services to the industry.

The Association For Manufacturing Technology (AMT) represents U.S. builders and distributors of manufacturing technology – the advanced machinery, devices and digital equipment that U.S. manufacturing relies on to be productive, innovative, and competitive.

Arcimoto put 144 vehicles into rental operations the past two years, a significant deployment of capital, but in the fourth quarter last year the number dropped to zero. Trials at rental can lead to sales, Dawson said, but the company needed to continue to be careful about the assets it sends into that channel. It has moved some vehicles out of rental and put them up for sale, and could do more of that, he added.

Questions about the National Metalworking Reshoring Award can be directed to Harry Moser at 847-867-1144 or harry.moser@ reshorenow.org. For more information on AMT’s efforts on reshoring and supply chain efforts, visit IMTS.com/supplychain.

In a news release, Frohnmayer, who remains chairman of the Arcimoto board, lauded Dawson’s appointment.

NTMA is the voice for the precision manufacturing and tool and die industries in the United States. Backed by nearly 1,300 member companies, representing more than $30 billion in sales, NTMA provides an array of benefits to members and the industry including advocacy in Washington, training and education programs and networking events nationwide.

“I’ve had the pleasure of witnessing his no-nonsense, roll up the sleeves style, and appreciated his intentional approach since his appointment to the board of directors last summer,” Frohnmayer said. “His extensive experience and laser focus on efficiency is essential in accelerating Arcimoto’s next phase of growth.”

The Reshoring Initiative, founded in early 2010, helps manufacturers realize that local production, in some cases, reduces their total cost of ownership of purchased parts and tooling. The Initiative also trains suppliers how to sell against lower-priced offshore competitors.

‘Product profitability’ in fourth quarter

Meanwhile, Arcimoto will continue to find efficiencies in its factory, Dawson said. Arcimoto’s cost of goods sold was nearly four times its revenue in 2022. In other words, it lost big on each FUV sale. Dawson said the company would achieve “product profitability” in Q4 by improved processes and also because it already has “tons of parts on the shelf” ready to use.

PMA, an inaugural sponsor of the National Reshoring Award, is the full-service trade association representing the North American metalforming industry — the industry that creates precision metal products using stamping, fabricating, spinning, slide forming and roll forming technologies, and other value-added processes. Its

The Benefits Of Worki ng With P4Swiss / Lindel CNC Machining

Along with the Dawson, Fittipaldi and Campoli moves, Arcimoto said Thursday that Dwayne Lum, previously chief product officer, will replace Terry Becker as chief operating officer as Becker moves to lead Arcimoto’s Tilting Motor Works Division.