YOUR MACHINE TOOL BANK BANTERRA.BANK | MEMBER FDIC Contact Us Today For Your Machine Tool Financing Needs Why Shops Choose Banterra Bank Loan products designed speci cally for machine shops World-class deposit products including Treasury Management Industry-leading service with local decisions Bank commitment to Made In USA and Made In Arizona values ARIZONA DIVISION 950 W. Elliot Rd., Suite 114 | Tempe, AZ 15100 N. 78TH Way | Scottsdale, AZ 480-645-9005 Banterramachinetool.com

BUILDING LOANS EQUIPMENT LOANS SBA LOANS DEBT CONSOLIDATION LINES OF CREDIT BUSINESS CHECKING AND CASH MANAGEMENT

Product Offerings

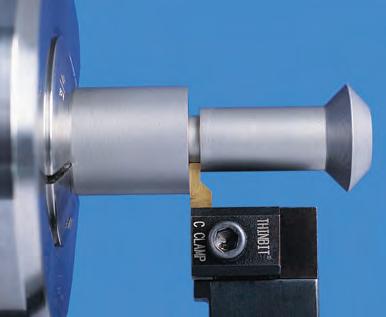

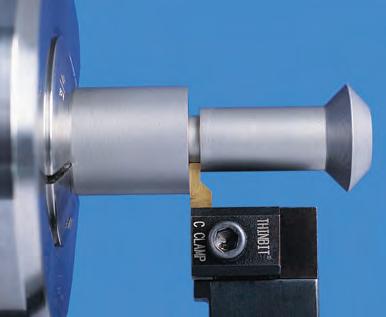

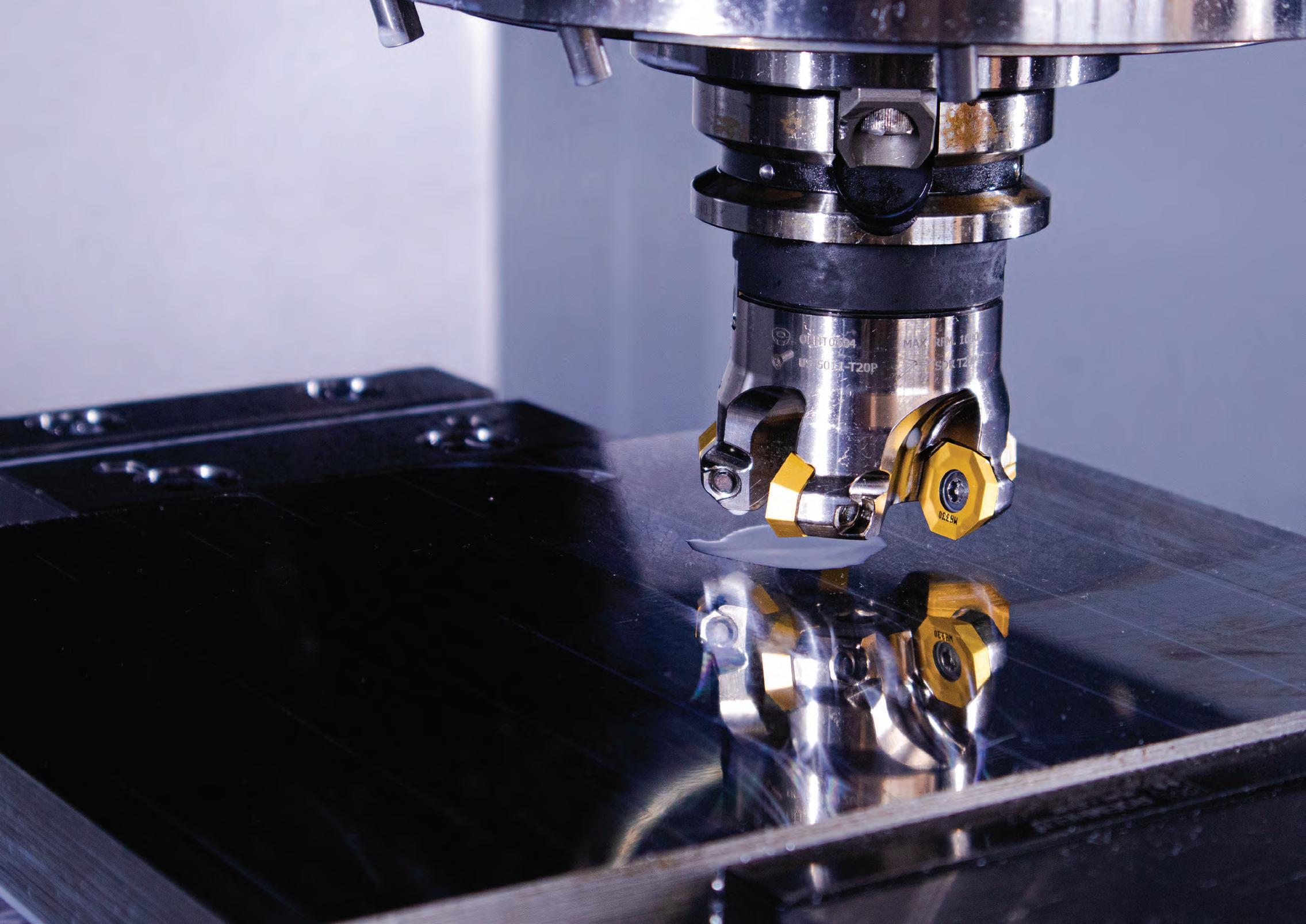

GROOVING THREADING PARTING BORING TURNING FACE GROOVING CUSTOM TOOLING FORM TOOLING MILL TOOLING Follow us on: 888-THINBIT | WWW.THINBIT.COM

Imagine if there were a place where management could go to discover ways to improve their business and the customer experience. A place where, just by visiting, the executives come away more energized and their employees become more engaged.

This place exists in your company. Likely, it’s just steps away from you – It’s the trenches of your organization – the frontlines, where the work gets done and the customer experience actually gets delivered.

A recent Wall Street Journal article shared a story just about this. Here is a synopsis. After 5 years running Uber Technologies, CEO Dara Khosrowshahi got behind the wheel himself. Using the alias ‘Dave K’ and a secondhand Tesla he purchased, the CEO made numerous trips as a rideshare driver over the next several months.

Dave K. learned much about his company during this process.

• It was difficult to sign up as a driver

• He witnessed first-hand ‘tip baiting’, which is when customers offer a large tip when placing the order, only to lower it once the food has been delivered.

• He was punished by the app for rejecting trips, though they couldn’t see drop off location or estimate pay before accepting the trip.

• Surprisingly hard to take, in his words, was the rudeness of some Uber riders. This was all part of a campaign to better understand and improve Uber’s drivers, since it was extremely difficult to sign up new drivers once life re-opened in the US post-COVID.

The campaign, code named ‘Project Boomerang’, helped spearhead one of the biggest makeovers of Uber’s business since its inception in 2009. The company woke up to the fact that everything starts with its drivers, “Having loyal drivers makes Uber more competitive and sets it up to expand into new categories”, Dara says. Interestingly, Uber’s lucrative bonuses helped bring on less loyal drivers than did their modifying areas of the business that made it difficult for the drivers to do their jobs well.

The result: Uber’s ride share revenue more than doubled in 2022, and their market segment share is estimated at 74% in the US, while its closest competitor, Lyft, has seen its market share shrink from 26% to 26% in this same time.

When was the last time you spent time sitting beside customer service employees, listening to incoming calls and watching the staff handle customer requests? Or seeing the hoops they jump through to get product out to a customer, on schedule? How about the last time you rode with a sales rep, observing their interactions with new prospects? Or shadowing a supervisor to better understand the decisions they need to make and the tools they possess to make them?

If you’re like many business leaders, it’s probably been a while since you did this. Likely you feel you don’t have the time. Just consider leaders who excel at it. Amazon founder Jeff Bezos, Southwest’s Herb Kelleher and Costco’s Jim Sinegal are among the very busy executives for whom visiting the trenches was a standard routine.

It makes sense. On a regular basis, visit areas where first line employees are doing their jobs. Ask questions and engage with them. You just might learn new ways to improve the business. In fact, try a campaign ‘Project Boomerang’ – it could well have results similar to Uber. In closing, God bless our troops and I wish you continued success.

Linda Daly,Publisher

GATEWAY COMMUNITY COLLEGE CONTINUES TO EXPAND ITS MANUFACTURING PROGRAM.

With New State of the Art Haas Machines.

Address: 1538 E La Vieve Lane

AZ 85284 Telephone: (602) 412-7696

Kim Carpenter Takashi Sato Gene Wirth

Published bi-monthly to keep precision manufacturers abreast of news and to supply a viable vendor source for the industry.

Circulation: The A2Z MANUFACTURING has compiled and maintains a master list of approximately 8500 people actively engaged in the precision manufacturing Industry. It has an estimated pass on readership of more than 19,300 people.

Advertising Rates, deadlines and mechanical requirements furnished upon request or you can go to A2ZMANUFACTURING. com.

The Publisher assumes no responsibility for the contents of any advertisement, and all representations are those of the advertiser and not that of the publisher.

The Publisher is not liable to any advertiser for any misprints or errors not the fault of the publisher, and in such event, the limit of the publisher's liability shall only be the amount of the publishers charge for such advertising.

CONTRIBUTORS

Announcements. 6-19 Feature Articles 1,36-37,42-43 Feature Articles.......................... 52,58-59 Buyers Guide Equipment...............73-81 Buyers Guide Processes 82-93 Card Gallery 73-93 Index of Advertisers

Editorial.................................Throughout Cover Published by: A2Z Manufacturing PUBLISHER/EDITOR Linda

94

Daly linda@a2zMANUFACTURING. com

Tempe,

A2Z MANUFACTURING SW • 4 • May / June 2023

Editors Corner

A2Z MANUFACTURING SW • 5 • May /June 2023 Designed and built for use with Haas ST and DS series CNC turning centers, the Haas Bar Feeder connects directly to the Haas control. YOUR ONE SOURCE FOR THE BEST SELECTION IN AUTOMATION SYSTEMS HAAS FACTORY OUTLET A Division of Ellison Machinery Co. LLC 1610 S. Priest Dr., Ste. 101, Tempe, AZ 85281 | HaasCNC.com | 480.968.5877 Sales & Service Scan for our complete line of integrated automation products. Haas Integrated Automation Systems. Making your job as a machinist easier. Optional Automation • 4th- and 5th-Axis Rotaries • Sub-Spindles • Parts Catcher System • Auto Door for Mills and Lathes • Automatic Coolant Refill Haas Bar Feeder All-inclusive design, with plug-and-play capabilities to Haas lathes Pallet Pool Systems • 3-Station for VF-2YT/SS, VM-2 • 6-Station for EC-400 • 6-Station for VC-400/SS • 6-Station for UMC-1250/SS • 10-Station for UMC-750/1000/SS • 10- or- 20-Station for UMC-500/SS Automatic Parts Loaders • Turning Center APL • VMC APL • Small UMC APL Robot Systems • HRP-1 System – 7 kg capacity • HRP-2 System – 25 kg capacity • HRP-3 System – 50 kg capacity

Haas Factory Outlet-Phoenix Invites Machinists to CNC Mill & Lathe G&M Code Programing Courses

Mill and lathe classes are scheduled every other month. Each course consists of 3 days of hands-on instruction led by a Haas Certified Instructor. Students will learn the basics of the Haas control, operation of machines, and Haas programming using G & M codes. Classes are free to all Haas CNC machine owners and operators. Classes are held Monday through Wednesday from 2:00 P.M. to 5:30 P.M.

Please join us for an upcoming session of the Haas CNC training. We recommend registering as early as possible as class sizes are limited.

Mill Training Class — 5/15 - 5/17

Lathe Training Class — 6/19 - 6/21

Training is held at Haas Factory Outlet- Phoenix, a Division of Ellison Machinery facility located at 1610 S Priest Drive, #101 Tempe, AZ 85281. To register and for additional information visit www.EllisonAZ.com or call 480-968-5877.

RM Garrison Machining Purchases Ilium Works And Adds New Equipment

RM Garrison Machining Inc. (RMG) is proud to announce its acquisition of Ilium

Works (IW). IW is a California manufacturer of aftermarket BMW Motorcycle parts. This acquisition will compliment the Accutronix Motorcycle Part division already under RMG ownership.

The acquisition will also add a Mazak HCN 5000 Horizontal Machine Center, a Mazak QTN 200 NY Lathe, (2) Haas VF4 Vertical Machining Centers and a compliment of secondary machining and fabrication equipment to its equipment lineup which will increase RMG’s capacity.

Contact: RM Garrison Machining, Inc. 1138 W Watkins St Phoenix, AZ 85007 (623) 582-6544

admin@rmgmachining.com

A2Z MANUFACTURING SW • 6 • May /June 2023 Announcements Con’t Next Page

Backed by Okuma’s Industry-Leading Warranty Program

Okuma’s MULTUS U3000 Multitasking Machine offers an ideal combination of power, speed, and process flexibility. A broad scope of machining functions and the ability to complete tasks in a single setup make this machine simple and efficient for producing a variety of parts. Combining powerful turning and milling capabilities, made possible with Okuma’s OSP-P300 control, equals one thing – increased production capacity.

Explore all of the powerful features of the MULTUS U3000, including:

• Full 5-axis contouring (available as an option)

• New compact B-axis spindle

• 240-degree B-axis range

• 30 hp milling motor spindle

• 12,000 RPM H1 milling spindle

• Wide range of ATC configurations available (40 to 180 tools)

A2Z MANUFACTURING SW • 7 • May /June 2023 A2Z MANUFACTURING SW • 9 • March / April 2022

Okuma. Welcome to open possibilities.

IS

CALLING ALL MULTITASKERS MORE

POSSIBLE

To

To

1205

Tempe, AZ 85281 www.arizonacnc.com 480-615-6353

learn more, visit: okuma.com/products/multus-u3000

inquire, visit: okuma.com/distributors Arizona CNC Equipment, LLC

S Park Lane, Suite 2

Praxis Precision Specializes In Quick Turn Machined Large Parts; Welcomes Prototype And Production Work

Praxis Precision, founded by Michael Yellowhair, Journeymancaliber machinist with more than 3 decades of experience, specializes in machining large parts, particularly for R&D / prototype work.

Michael says, “We have 5 axis capabilities, and are well equipped for inspecting our customers parts, with our Mitutoyo CRYSTA-Apex S CMM. It is a high precision CMM featuring MSCOSMOS 2 which allows the company to import solild models for quick programming along with reliable accuracy, just what we need for our customers’ precision tooling and machined parts.”

One of the company’s latest machine tool acquisitions was the Takumi V11 4-axis box way, 50 Taper, geared head vertical machining center. Michael says it offers the perfect combination of heavy cutting and high stability. Other machine tools at

Praxis Precision include Doosan and Haas machines, including a 5 axis machining center.

In addition to milling and turning, the company offers surface grinding. Their expertise in Mastercam and Solidworks makes it easy for customers to send solid models that can easily be imported.

Michael says that many customers come to his company when they need precision parts manufactured quickly. “We can machine a majority of our parts in a few weeks”, Michael says, adding that Praxis Precision can comfortably turn parts up to 22” in diamter x 41”long, but can swing up to 28” if needed and mill parts with machine travels of 43” x 26” x24”.

To learn more about how Praxis Precision, conveniently located in Mesa, Arizona, can help you with your machining and grinding

A2Z MANUFACTURING SW • 8 • May /June 2023 Announcements & Releases Continued Announcements Continued Page 10

Register today!

3 Companies Under 1 Roof

Family Run For 35 Years

Family-Run For 34 Years

Competitive Pricing

3 Companies - 1 Ownership

11 CNC Swiss Screw Machines

First Light F-35 Helmet Test A Success

Announcements & Releases Continued

needs, contact them at: 480-833-1444 or email sales@ praxisprecision.com

Okuma America Launches New Business Segment Focused on Automation Solutions for Manufacturers

The first test of a new, lightweight F-35 helmet was successful, according to the prog ram office, a promising sign that the Pentagon can qualify and implement all three fixes to the jet’s escape system by the end of the year.

Recently, at Holloman Air Force Base, New Mexico, Lockheed Martin’s F-35 conducted the fir st test combining all three solutions designed to reduce the r isk of neck injury to F-35 pilots during ejection, according to spokesman Joe DellaVedova. Once the full gamut of testing is completed, hopefully by the end of the summer, the JPO can beg in implementing the two modifications to the ejection seat and issuing the new Generation III “light” helmet to the fleet, he said

The recent sled test, conducted with a 103-pound mannequin, is the latest sign that the JPO can make good on its promise to finish the three design fixes by November, allowing the military services to lift restrictions on lightweight pilots flying the F-35 Last year, Defense News first repor ted that pilots under 136 pounds were barred from flying the fifth-generation aircraft after testers discovered an increased r isk of neck damage to lightweight pilots ejecting from the plane. The US Air Force has also acknowledged an “elevated level of r isk” for pilots between 136 and 165 pounds.

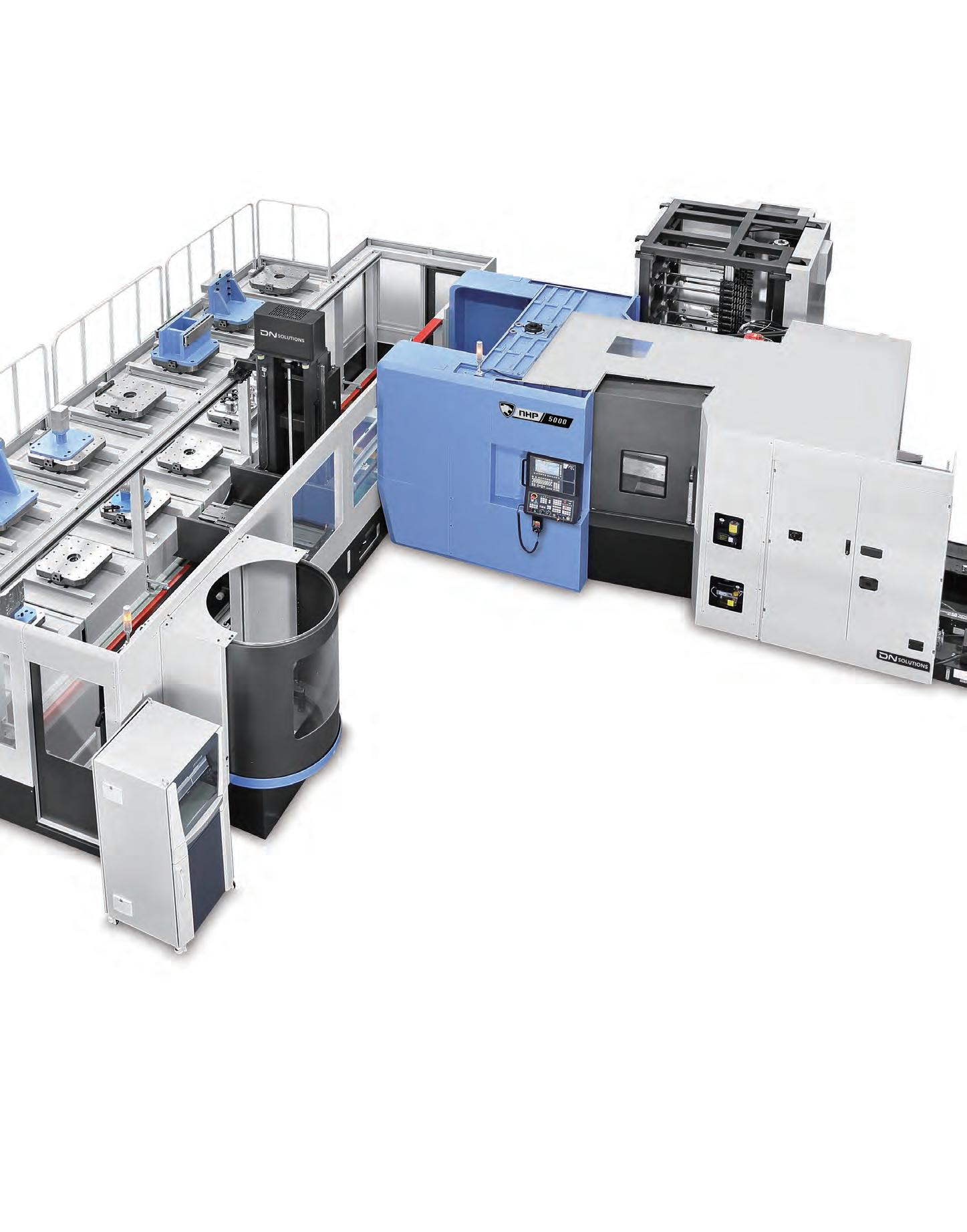

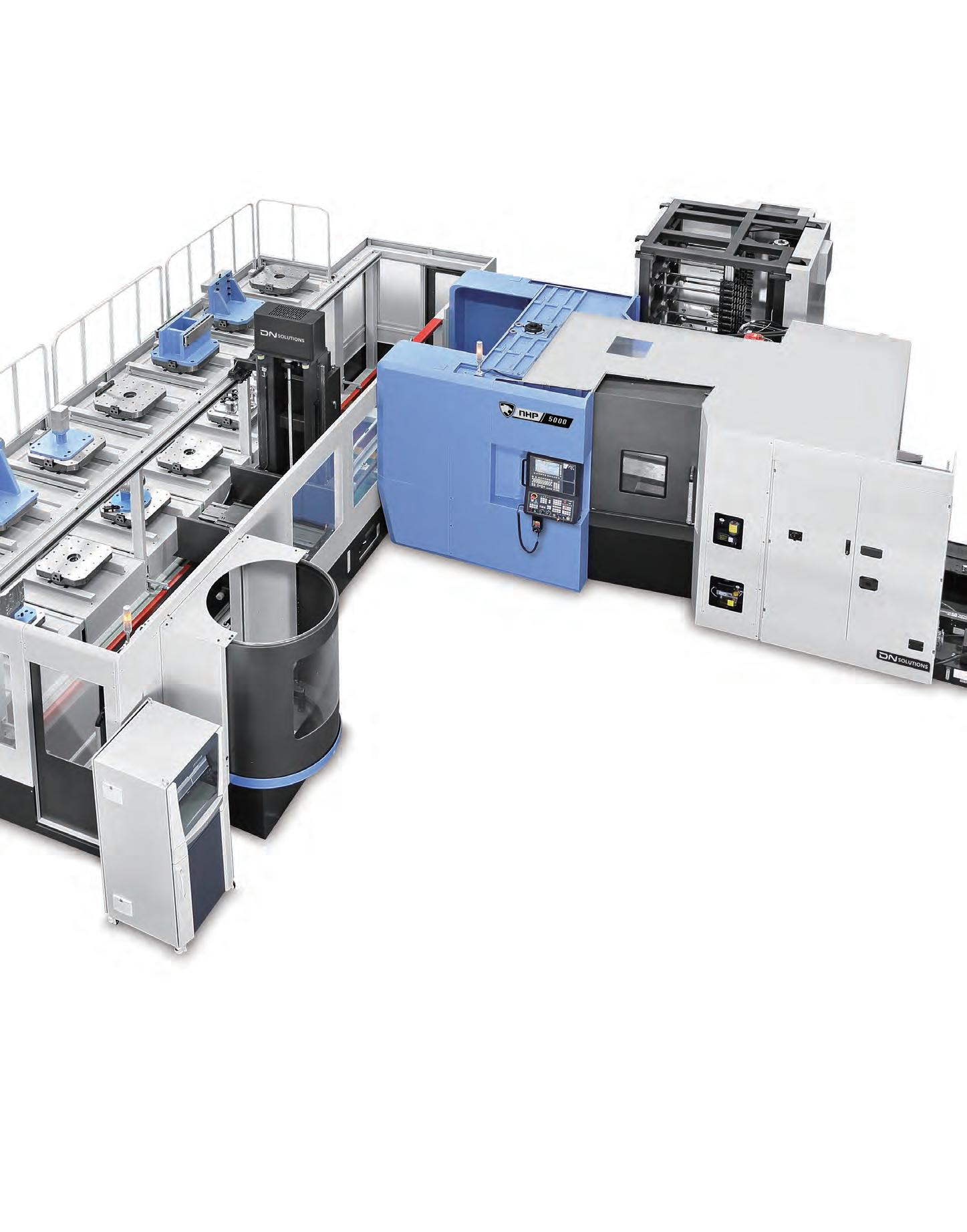

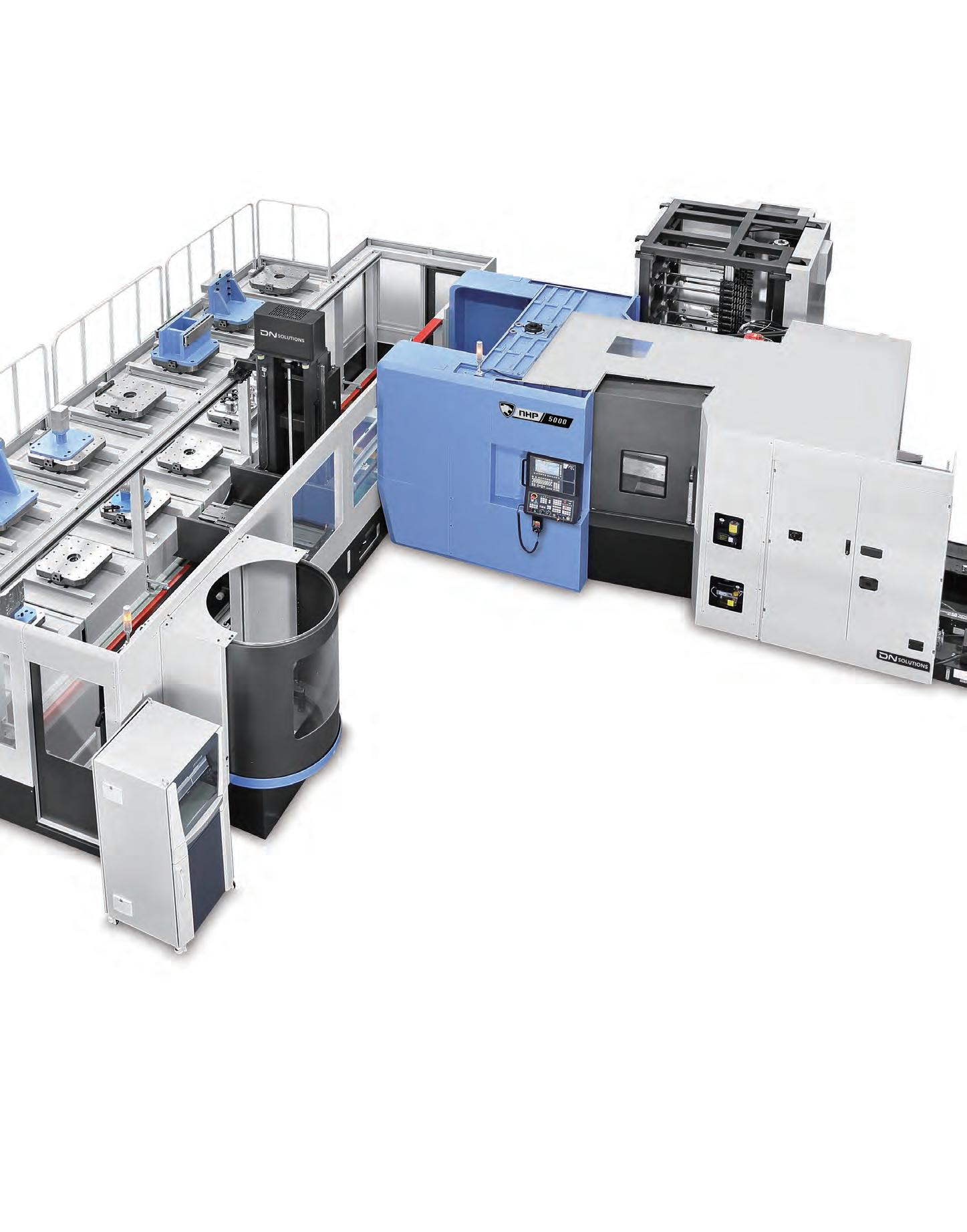

Senior executives at Okuma America Corporation, a global leader and builder of computer numeric control (CNC) machine tools, controls and automation systems, are pleased to announce the launch of a new business segment created to recommend, sell and support manufacturing production line systems comprised of Okuma CNC machine tools and integrated automation technologies. The new division will be based at the Okuma America Corporation headquarters in Charlotte, North Carolina, USA.

systems including automated material loading and unloading systems, machine tending and industrial robotics, automated work piece pallet changers (APC), flexible manufacturing systems (FMS), smart manufacturing systems and beyond.

To support the new business segment, company leaders have appointed Wade Anderson as the division’s new General Manager. Mr. Anderson has worked for Okuma for 17 years in a variety of roles including engineering, technical sales, sales leadership, product management, and technology partner relationships. Additional organizational resources will be appointed to support the division’s infrastructure and customer applications.

The prototype helmet tested weighs about 4.63 pounds, approximately 6 ounces lighter than the orig inal Gen III helmet, and is designed to ease some strain on smaller pilots’ nec ks during ejection

The decision to launch the Okuma Factory Automation Division was in direct response to increased demand from manufacturers seeking automated machining systems and cells for their operations to address labor shortage issues and to increase production capacities. With the launch of this new division, Okuma will be optimally positioned to offer customers a broad range of Okuma machine tools and automation system pairings. Solutions will include both proprietary and seamlessly-integrated automation

Although the test was the fir st test of the new helmet, the JPO, Loc kheed Mar tin and seat-maker Mar tin Baker have conducted at least seven other tests with the latest version of the seat, which is equipped with two modifications designed to reduce r isk to pilots.The fixes to the ejection seat itself include a switch for lightweight pilots that will delay deployment of the main parachute, and a “head support panel,” a fabric panel sewn between the parachute r isers that will protect the pilot’s head from moving backward dur ing the parachute opening.

Landmark Solutions Receives Next Generation Award from Pat Mooney Saws

Landmark Solutions has proudly entered the Pat Mooney Saws 2022 Legacy Club, having received the Next Generation Level Award for their contribution to a recordbreaking year in Pat Mooney’s history. Dealer Development Manager, Dave McCallen, presented the award to Landmark VP, Chad Mooneyham, and Regional Sales Manager, Chris

The prog ram office has about another 10 tests planned, which will use a mix of low-, middle- and high-weight mannequins.

“This initial test had promising results and the F-35 enterpr ise is on a path to qualify the helmet . by the end of this summer,” DellaVedova told Defense News. “The lighter helmet expected to be fielded by the end of the year is in line with the seat timeframe as well.”

Announcements Continued Page 12 A2Z MANUFACTURING SW • 10 • May / June 2023

A 2 Z MANUFACTURING SW 41 EDM Wir e/ Sinker Sma ll Hol e 14 Machines WATERJET CUTTING UP T O 6 ’ X 12’ 2 Mach ine s LASER NTC 2500 Watt DIE REPAIR & METAL STAMPING SCREW MACHINING Up To 32 M M whitleym achine.com www.s tp-az.com 4801 S 35 St, Phoenix Ar izona 8 5040 Tel 602-323-5550 Fax 602-323-9950 Em ail C liff@whitleym achine.com √ √ √

ISO 9001: 2015 Certified √

SPECIALTY

PRODUCTS

TURN

√ ISO

√

√

√

√

9001: 2015 Certified

AS9100 Revision D Certfied

Competitive Pricing

“Simply effective.”

We’ve developed our B-Cool MC 600 to help you minimize your process costs. Whether you produce large or small series, this water-miscible coolant with its economical formulation ensures stable and robust performance in universal machining applications. It keeps workpieces and machines clean and is gentle to people and the environment.

Test us. It‘s worth it. blaser.com/bcoolmc600

www.magnumprecisionmachines.com PHOENIX OFFICE P: 602-431-8300 F: 602-431-8301 E: sales@magnumaz.com EL PASO OFFICE P: 915-856-7900 F: 915-857-4700 E: sales@magnumep.com ALBUQUERQUE OFFICE P: 505-345-8389 F: 505-344-7167 E: magnumalb@magnumabq.com

Dr. Olivia Bossart and Stefan Freudiger R&D Chemist and Product Manager Blaser Swisslube AG

Announcements & Releases Continued

Roberts, at Landmark’s facility in Southern California in late February. Landmark has expressed their gratitude and excitement for their long-term partnership with Pat Mooney Saws and looks forward to another great year in 2023.

Latitude Machinery, LLC, Announces The Machinery Lines It Carries

Latitude Machinery, LLC, a new and used machinery distributor based in Mesa, AZ serving AZ, NM, CO and UT is proud to announce its association with the following machinery manufacturers:

• ESAB - XXL plasma/oxy-fuel water jet and CO2 laser products. ESAB also recently purchased Swift Cut, a UK based company manufacturing entry level plasma and water jet tables.

• Cutlite Penta – The new king in high power fiber lasers. This Italian manufacturer imports 2d and tube lasers from 4-40kw with optional bevel head and automation.

• Bendmak USA – Offering structural fabrication machinery that includes Beam Lines, Angle Lines, Plate Rolls, Section

Rolls and weld positioners.

• Cosen Saws – Horizontal Miter, Scissor and Contour Saws, Vertical Contour, Plate and Tilt Frame Saws.

• V irtek Vision International – Laser Inspection Equipment and Virtek Vision Iris 3d and LTG Laser Template Generator that eliminates the need for weld fixtures.

• MSS Nitrogen – Nitrogen Generators, Compressed Air Systems and Gas Mixing Systems for lasers.

Please visit our website at www.latitudemachinery. com or contact us at sales@latitudemachinery.com for more information.

Mazak Brings SYNCREX Swiss-Style Machines to PMTS 2023

During the Precision Machining Technology Show (PMTS) 2023, Mazak will showcase several models from its new SYNCREX Series of Swiss-style machines in booth 3053. Among them will be the SYNCREX 38/9 that accommodates bar stock up to 1.5” (38mm), and incorporates a removable guide bushing adapter that allows operators to preset

A2Z MANUFACTURING SW • 12 • May /June 2023

Announcements Continued Page 14

CUSTOM-BUILT BUSINESS SUCCESS.

BANK WITH PURPOSE.

Member FDIC ALERUS.COM/BUSINESS

COMMERCIAL BANKING

Our

SPECIALTY TURN PRODUCTS

3020 South Park Drive ,Tempe, AZ

sales@stp-az.com • Tel: 602-426-9340

STP-AZ.COM

We Manufacturing Complex Intricate Parts Requiring Extreme Precision And Quality

We Are Built For High Production Parts And Can Handle Extremely Tight Tolerances

High Precision Swiss Lathe Machining 24x7

New State-of-the-art 12,500 square foot facility

ISO 9001: 2015 & AS9100D Certified

CNC Swiss screw machines

run lights out 24 x 7 Subsidiary of Whitley Machine

can

Industrial Production Returns to Growth After February’s Storms Subside

The Federal Reserve reported that industrial production in March rose 1.4%, returning to growth after an unseasonably stormy February knocked it down 2.6%. The report shows total industrial production rose 2.5% at an annualized rate during the first quarter of 2021 despite the losses endured in February by manufacturing, mining, and utilities companies.

Announcements & Releases Continued guide bushings outside of the machine. The SYNCREX 38/9 is also convertible and can be quickly changed over to run in chucker mode for added part processing flexibility.

Mazak’s SYNCREX Swiss-style Series encompasses models featuring seven, eight and nine-axis configurations and are optimized for precision high-production of small parts. SYNCREX “9X” models deliver added part processing flexibility as they are capable of full 5-axis contouring while using the B-axis tool post.

tools and prepare the machine for automatic cycle. Spending less time setting up the machine and more time in production.

Motor vehicles and parts production, which fell 10% in February, rose 2.8% in March but remained depressed by a persistent shortage of semiconductors. Most durable goods indexes rose between 2% to 3%.

Like all Mazak machine tools, SYNCREX machines are backed by Mazak’s comprehensive 2-year warranty, industry-leading MPower complete customer care service and support program, and lifetime parts availability.

Hurco North America Announces Third Offering of Apprenticeship Program

The industrial production gauge includes productivity in three sectors: manufacturing, mining, and utilities. Manufacturing production (which excludes mining and utilities output) rose 2.7% in March after falling 3.7% the month before. Mining production improved 2.7%, while utility output fell 11.4% thanks to unseasonably warm March temperatures. Manufacturing output rose 1.9% at an annualized rate.

Like all models in the series, the SYNCREX 38/9 is a sliding headstock machine constructed on the Mazak High Damping Composite Casting (HDCC). This unique high rigidity base provides greater vibration damping characteristics, less thermal growth and greater part surface capabilities when compared to a cast iron base machine.

In nondurable manufacturing, the index for the chemicals industry rose 4.1%, and petroleum and coal products rose 5.7%, although neither sector has fully recovered from severe weather damage—the Federal Reserve noted that some chemicals factories remain offline thanks to damage sustained from February’s winter storms. Most nondurable goods indexes rose between 0.9%

Capacity utilization in manufacturing rose by 1.9 points, also reversing February losses.

Almost all market groups saw improvements in March, despite lingering challenges. The Federal Reserve’s index for other manufacturing, which includes publishing and logging, remained the same, but durable goods and nondurable goods indexes rose 3.0% and 2.6%, respectively.

Mazak SYNCREX machines sport the new MAZATROL SmoothSt and MAZATROL SmoothSt5 controls. Both controls feature the optional Mazak Swiss Setup Assist (MSSA) for fast and easy job setups along with the optional Mazak Dynamic Chip Control (MDCC) functionality. With Mazak’s intuitive and user friendly screens, the customer can quickly and easily touch off

Hurco North America announced it will open applications for the third class of its apprenticeship program April 1.

The Field Service

Apprenticeship (FSA) is a 2-year program that starts with a 12-week immersive introduction to the industry that merges hands-on training and

If February was notable for its storminess, March was notable for its heat. The unseasonably warm month coincided with a roughly 10% drop in consumer energy products, and the 11.4% drop in utilitie s utilization was the largest recorded in the history of the index’s 48-year history.

A2Z MANUFACTURING SW • 14 • May / June 2023 Announcements Continued Page 16

A2Z MANUFACTURING SW • 38 • May / June 2021

Tornos 6 axis Sigma

Tornos MultiSwiss 6x14

TheHurcoControlhastheflexibilityyouneedforthehighmixofpartsthatcomes throughyourshop.

EquallypowerfulforNCandConversationalProgramming(withtheaddedbonusof NC/ConversationalMerge),theHurcoControlreducessetuptimesoyoucanmake morechips.

Whetheryou’reababyboomer,amillennial,oraGenX-er,timeismoney.Eventhough Bob(left)andCharley(right)arefromdifferentgenerations,theyarebothmachinists whoappreciatetheimportanceofCNCtechnologythat’sdesignedtomakeshopsmore productiveandmoreprofitable.Checkouttheirvideoseries.

Hurco Companies, Inc. | One Technology Way | Indianapolis, IN 46268 | 800.634.2416 | info@hurco.com | HURCO.com | Machines shown with options. Information may change without notice. Double Column Boring MillsHorizontals3-Axis Vertical5-AxisDouble Column BridgeTurning Centers A CONTROL FOR EVERY GENERATION.

Watch the series at Hurco.com/mygeneration (303) 466-3777 FoothillsMachinery.com » Integrated

path simulation » No

click and

» Transform

created automatically for easy 5-sided conversational programming

data entry

Hurco’s 3D Import feature includes 3D DXF technology that now displays all CAD geometry, including splines and Z-depths. Go from “solid to part” seamlessly. Eliminate extra steps. Introducing 3D Import Hurco Companies, Inc. | One Technology Way | Indianapolis, IN 46268 | 800.634.2416 | info@hurco.com | HURCO.com | Information may change without notice. Find out more at HURCO.com/3DImport Contact your local distributor to find out which one of our 65+ models powered by WinMax® will make your shop more profitable D&R Machinery (480)-775-6462 dandrmachinery.com

CAD/CAM and tool

need to enter feature dimensions – simply

cut

Planes

no

required

repair of CNC machines with classroom training.

personal use, and business accounts. With the addition of Arizona Iron Supply, we can accommodate even larger industrial accounts and offer even more equipment and metal inventory to choose from.

While candidates with a degree or working toward one are encouraged to apply, candidates who are mechanically inclined with no industry or engineering experience are also encouraged to apply for the FSA.

We feel privileged to continue to serve Phoenix and surrounding areas. We can’t wait to show you how this development will improve your metal purchasing, metal recycling, and Rolloff Service experience.

The FSA program takes place at Hurco’s headquarters in Indianapolis, Indiana. To apply, please visit Hurco.com/FSA.

Visit one of our two locations to see how this exciting change will benefit you! Davis Metals: (602) 267-7208 / 3322 E. Washington Street, Phoenix, AZ 85034 Arizona Iron Supply: (602) 244-9649 / 130 S 23rd St, Phoenix, AZ 85034

“We know there are people outside our industry who would excel at a career as a service engineer for machine tools, but might not have been exposed to our industry. We believe the FSA will be important to bridge the skills gap and introduce more people to the machine tool industry, which benefits the industry as a whole,”said Cory Miller, General Manager for Hurco North America.

Re-Energizing American Manufacturing: Lux Precision Manufacturing

Landmark Hosts Open House At Metzfab Industries

Field service engineers will ultimately be ambassadors for Hurco Companies, Inc.—working to provide technical support, training, and service of state-of-the-art CNC machines at customers’ facilities across the country. Continuous training on emerging technologies in CNC controls, robot integration, 5-axis machine and multi-spindle lathe installation, repair, and applications will also be provided long after completion of the apprenticeship.

“If you have a strong work ethic, like to learn how things work, like hands-on training, and want a career instead of a job, this apprenticeship is for you,”said Mark Gilmore, Service Manager for Hurco North America.

L andmark Solutions held an Open House event at Metzfab Industries in Phoenix earlier this month.

Metzfab recently installed a new OMAX 80x 5 axis waterjet, a Bystronic Tube Laser system, a Bystronic ByStar Fiber Laser with full automation, multiple large high performance press brakes, and a fully automated robotic press brake. Installing soon is a new material finishing machine also coming from the Landmark Team.

From its humble roots on a college campus, Lux Precision Manufacturing (Lux) is a premiere manufacturing company that has a mission to reenergize American manufacturing. With the unique operating location on the campus of Grand Canyon University (GCU), Lux serves the medical device, aerospace, semiconductor, and defense industries with precision machined parts. Lux, however, has a unique business model that is re-energizing American manufacturing by introducing college students to precision manufacturing and giving them an opportunity for educational immersion in manufacturing.

Metzfab’s facility was chosen due to their company growth, and the addition of several new state of the art pieces of equipment. Metzfab is always pushing technology and equipment limits in an effort to build and deliver the best parts to their customers.

In 2017, Weston Smith founded Lux out of a dorm room on the campus of Grand Canyon University originally as an electric longboard

The Landmark Solutions open house event was a success, and we are all excited to continue our long term partnership with Metzfab. Everyone attending the event were impressed with the new equipment and technology, and how this has helped Metzfab grow and diversify their business.

A2Z MANUFACTURING SW • 16 • May / June 2023 Announcements & Releases Continued Announcements Continued Page 18 A2Z MANUFACTURING SW • 16 • July / Aug 2022 Announcements Continued Page 18

INNOVATION • DESIGN • PROTOTYPE • PRODUCTION

BYSTRONIC XPERT 80 PRESS BRAKE

FLOW

IBF 4020 WATERJET

Industries Served: Aerospace Military Defense Construction Automotive Marine Oil/Gas Mining Waste Water Metal Fab Hobbyist Heavy Equipment • Quick Turnaround (5-7 Days Typical) • Family-Owned & Operated Since 1981 • 3-D Scanning (Faro Arm Scan & Probe) • Cutting Capability Up” to 6’x12’

BYSTRONIC 3015 BYSMART LASER

PHOENIX WATERJET & LASER 602-484-9393 WWW.PHXWATERJET.COM 2518 North 35th Ave, Phoenix, AZ 85009 I N N O V A T E D E S I G N P R OTOTY P E • P R O DUCTI O N P H O E N X E S T 2 0 0 7

The Ugalde Family

Serving the Aerospace/Aircraft, Military, and Commercial Industries Quality System is Certified ISO 9001:201 15 and AS9100" "D"

FULL 5-AXIS CAPABILITIES

EQUIPMENT CAPACITIES RANGE UP TO:

HR-4R HAAS 4-Axis Horizontal Milling Center @ 150” x 66” x 48”

Ikegai VTL CNC Lathe @ Ø 55” Diameter

OKK VP9000-5-Axis Vertical Milling Center Ø 800 mm x 630 mm

Dynamic Machine & Fabrication Corp .

3845 East Winslow Avenue, Phoenix, Arizona 85040 Fax:602-437-8947

602-437-0339

WE'RE LOOKING FORWARD TO MEETING AND EXCEEDING YOUR EXPECTATIONS

Announcements & Releases Continued

rental company. “I had so many students stop me and say they want one – that sparked my entrepreneurial instincts.” So, Weston started renting out electric longboards to college students. Nine months after buying an electric longboard fleet, there was a 90% battery failure rate in the electric longboards.

As a mechanical engineering student, Weston started innovating and developed a solution for the massive battery failure rate in the rental fleet; a flexible battery that uses the same battery technology found in Tesla cars. With this technology development, Weston decided to shift the business model of Lux from electric longboard rentals, to electric manufacturing. Over the course of two years, Lux Longboards launched three different board lines. The last and most innovative board line launch was the Lux LX, which was an Offroad electric longboard that went over 30mph on a range up to 19 miles.

In 2020, as industry demand grew for precision manufacturing, Lux scaled its machine shop capabilities and discontinued electric longboard manufacturing in 2022 to focus its growth in CNC machining.

In August of 2023, Lux Precision Manufacturing will be expanding to a new 12,000 sqft facility on GCU’s campus with a mixture of 16 CNC mills and lathes.

While still serving the medical device, aerospace, semiconductor, and defense industry with precision manufactured parts, Lux has partnered with GCU to impact the manufacturing workforce. With an estimated 2.1 million unfilled manufacturing jobs by 2030, GCU is launching a manufacturing certificate program with an emphasis in CNC machining. In this immersive educational environment, GCU certificate students and 4-year degree engineering students will have an opportunity to work for Lux in manufacturing operations where they will gain hands-on manufacturing experience.

Lux Precision Manufacturing mission is to re-energize American manufacturing by producing quality, precise parts for industry and by partnering with GCU to impact the manufacturing workforce.

A2Z MANUFACTURING SW • 18 • May / June 2023 Announcements Continued Page 20

In Our 5th Decade of Manufacturing in Arizona

602-483-4414

Manual Lathes, Tool Room CNC Lathes, Big Bore Lathes, 2-6 Axis CNC Lathes, 7-16 Axis Mill/Turn Centers, Swiss CNC Lathes, Large Capacity VTL ’s

Manual Mills, Tool Room CNC Mills, 3 -5 Axis CNC Mills, VMC’s, HMC’s, Automation, FMS Systems, Large Capacity HBM’s

3-5 Axis Laser Solutions, Bending Solutions, Workholding, Quick Change Fixtures, Probe Integration, Inspection/Measurement Equipment, Machine Monitoring, Robotic Integration, Saws, Tombstones.

CNC PROS HAS PARTNERED WITH THE RIGHT SOLUTIONS TO ENSURE OUR TEAM OFFERS YOUR TEAM THE RIGHT TOOL FOR THE JOB.

CONTACT US FOR MORE INFORMATION

WWW.CNC-PROS.COM

economy from both a macro and micro perspective.

From my view (of financing manufacturing equipment all around the US), the larger companies are continuing to increase machining capacity with new machine orders, but the relatively smaller companies are showing increased hesitation in recent times. This is displayed in the accompanying graph (estimated figures for display purposes).

The bad: The majority economic indicators within the manufacturing market are pointing to some degree of a recessionary period that should be felt in late Q3/early Q4.

The good: This will be the most foreseen and anticipated recession in history. If we do enter a recessionary period, it should be relatively short term (versus a standard 18-month recession) and easy to weather. If we do not enter a recession, we will more

and historically bounces back the year proceeding a recessionary period. We have the highest GPD in the world and manufacturing will always be a significant contributor.

Whether we enter a slow period or not, now is a great time to take advantage of Epic Finance’s 120day payment deferral program. With this program, your first monthly payment isn’t due until 120 days after the equipment has been fully installed. This program, combined with our aggressive rates, speed of approval, and fearless customer service is what makes us your best option for all types of equipment financing.

Please feel free to reach out directly to discuss your goals and find out how Epic can help achieve them.

A2Z MANUFACTURING SW • 20 • May /June 2023

Chris Frans,

303-261-8200 WWW.NORTHSOUTHMACHINERY.COM | (800) 460-9014 | CA • OR • WA • AZ • NV LEAN. MEAN. 100% GREEN! • 100% Electric Precision Press Brake • 110 US Tons x 10.2’ • EC10 Touch Screen Control (EC20 Optional) • CNC X-Axis, R-Axis, Y1/Y2-Axis • Manual Z1/Z2-Axis (CNC Optional) • Mechanical Tool Clamping (Hydraulic Optional) • Tool Lighting on Front • 2x Front Support Arms • 2x Backgauge Stops • Installation & Training Included SAFANDARLEY E-BRAKE STANDARD FEATURES:

CLFP; President chris@epicapprovals.com

AZ US A SINCE 201 1

Businesses Struggling To Hire Might Get Some ShortTerm Relief. Here’s Why.

The historically tight labor market is showing some signs of loosening as companies throttled back on job openings, according to new data from the Bureau of Labor Statistics.

The number of job openings plummeted below 10 million at the end of February for the first time since May 2021. Despite a surge in “loud layoffs” for prominent companies, the data suggests companies are being more cautious about hiring rather than cutting jobs at this point. The layoff rate actually inched down in February to 1%, compared to 1.1% in January. The quit rate ticked up

to 2.6%, suggesting turnover remains a challenge.

Add it all up and the result is more mixed signals for employers already coping with significant uncertainty on several fronts. But even a slight loosening of the labor market could help businesses that have been struggling to hire workers since the pandemic recovery ramped up.

Of course, it should be noted that any relief is relative to the frantic hiring pace of the past two years. Experts still project companies will face long-term hiring challenges due to the nation’s shifting demographics.

A Federal Reserve survey of nearly 8,000 small businesses found the top operational challenge was hiring or retaining qualified staff, ahead of growing sales and reaching new customers. About 40% of businesses said they attempted to hire new workers and it was very difficult — far more than the 27% of businesses that said the same thing in 2018.

Overall, about 72% of firms facing hiring challenges said they had too few applicants, while 62% said the applicants they did get lacked job-specific skills or experience.

The historically tight labor market, brought on in part by demographic changes and exacerbated by the Covid-19 pandemic, has been the focus of efforts by the Federal Reserve to tame inflation by going after higherthan-normal wage growth.

As recently as February, Fed Chairman Jerome Powell called the labor market extremely tight and “out of balance,” with unemployment at 50-year lows, job vacancies near historic highs and wage growth still above where it was before the pandemic. The Federal Reserve has also explicitly planned for higher rates of unemployment and, in 2022, forecasted it could grow to 4.5% this year, essentially putting hundreds of thousands of Americans out of work. By Andy

Medici – Senior Reporter, The Playbook

A2Z MANUFACTURING SW • 22 • May /June 2023 MORE SATISFIED CUSTOMERS

Locations in AZ, NC, TX, FL, WI, MN Arizona Facility: 1310 N. Hobson Street Gilbert, AZ 85233 (480) 892-7800 Email: wricoazjb@wrico-net.com We specialize in: • Custom Metal Stamping • Precision Sheet Metal • Laser Cutting • Press Brake Forming • Deep Draw Stamping • Mig & Tig Welding • CNC Machining • Wire EDM • Tube Bending • 5 Axis Laser Cutting • Wire Forming • Spot welding • Mechanical Assembly • Engineering Assistance

WORLDWIDE

A GRIFFITHS COMPANY

FINANCIAL SOLUTIONS FOR YOUR BUSINESS

Working Capital

is the perfect product when your business has a project or additional expenses. Simple application process and funds up to $250,000. Capital intended to grow your business.

Equipment Finance

up to $500,000 (without financial review) for your new or used equipment acquisitions. With 100% financing and terms up to 84 months, it allows you to reserve cash in your bank account.

A2Z MANUFACTURING SW • 23 • May /June 2023

offer fast and simple financing solutions for businesses with an opportunity for growth and a need for capital. To learn more, contact: Chris Frans, CLFP 303-261-8200 chris@epicapprovals.com Denver, Colorado Credit approval required.

We

FINANCING FOR: Expansion/RemodelsInventory Equipment; New or Used Marketing/ Website Refresh Strengthen Cash Flow

CONTROLLED THERMAL TECHNOLOGY (CTT) AND TS WEST

2617 West Cypress Street Phoenix AZ

602-272-3714

A Heat-Treating Company OFFERING

Salt Bath Nitride-MELONITE®- Per AMS2753

Serving the Aerospace/Aircraft, Military, and Commercial Industries

Other Services;

• GASEOUS CARBURIZING

• GASEOUS NITRIDING

• VACUUM HEAT TREATING

• HEAT TREATING

• NORMALIZING, ANNEALING, HARDENING, COLD TREATMENT STRESS RELIEVING, PRECIPITATION

For More Info: Contact Danny Rosetta; 602-272-3714; drosetta@cttaz.com

For More Info: Contact Tim Johnston; 602-272-3714; tjohnston@cttaz.com

Department of Defense (DoD) Awards

Nikola Corp. Outlines Plans For New Hydrogen Hub In West Valley

Phoenix-based Nikola Corp. has submitted plans to the city of Buckeye for its new hydrogen manufacturing plant in the southern part of the city.

The company has been working on building a new hydrogen production hub, dubbed Project H20, across hundreds of acres in Buckeye just west of State Route 85 near the Arizona Department of Corrections Lewis Prison at 28702 W. Patterson Road.

Nammo Defense Systems Inc., Mesa, Arizona, was awarded a $498,092,926 firm-fixed-price contract for the full rate production of M72 Light Assault Weapon variants and components for shoulderlaunched munitions training systems. Bids were solicited via the internet with one received. Work locations and funding will be determined with each order, with an estimated completion date of Dec. 19, 2026. U.S. Army Contracting Command, Newark, New Jersey, is the contracting activity.

The plant is part of Nikola’s plans to build out a large-scale hydrogen supply and dispensing infrastructure business for its trucks as well as for industrial, residential and commercial heating and for decarbonizing natural gas and power generation.

Nikola said it will first build a nearly 160-acre liquid hydrogen production facility at the southeast portion of its property and eventually expand onto the remaining acres it owns as demand increases. Its hydrogen facility is expected to use clean manufacturing practices such as liquification and electrolysis, project documents said.

Raytheon Co., Tucson, Arizona, is awarded a $55,121,826 costplus-fixed-fee modification to a previously awarded contract (N0002421C5434) for engineering and technical services in support of the Evolved Seasparrow Missile and NATO Seasparrow Missile Sys-tems programs. This contract combines purchases for the U.S. govern-ment (99%); and the governments of Japan and United Arab Emirates (1%) under the Foreign Military Sales (FMS) program. Work will be performed in Tucson, Arizona (82%); Portsmouth, Rhode Island (17%); Andover, Massachusetts (less than 1%); San Jose, California (less than 1%); Aranjuez, Spain (less than 1%); Brisbane, Australia (less than 1%); and Koropi Attica, Greece (less than 1%). Work is expected to be com-pleted by December 2022. The Naval Sea Systems Command, Wash-ington, D.C., is the contracting activity.

Its current goal for the facility is to produce between 150 and 300 metric tons of liquid hydrogen daily to store on site before distribution. The plant will comprise two administrative buildings, a 7.3-acre liquification package, 7.4-acre electrolyzer package and water treatment facility.

Honeywell International Inc., Phoenix, Arizona, is awarded a $22,467,124 cost-plus-fixed-fee contract for the development, build and demonstration of the Compact Rubidium Extended

About 20 permanent jobs will be created for skilled plant operators and technicians over three rotating shifts and about 150 construction jobs will

also be created to build the facility. Project documents said the median hourly wage will be approximately $40 hourly. Construction is also expected to occur over 14 to 16 months.

Stability Timing (CREST) — a ruggedized atomic clock module with a unique combina-tion of performance and size, weight and power, capable of the abso-lute accuracy of a commercial cesium beam clock in a VPX-card-like form-factor. The CREST module will be designed to provide uninter-rupted Global Positioning System (GPS)-quality timing holdover in challenging military environments. Work will be performed in Phoenix, Arizona, with an expected completion date of Dec. 21, 2026. This contract was competitively procured under long range broad agency announcement (BAA) N00014-21-S-B001. The Office of Naval Research, Arlington, Virginia, is the contracting activity).

Nikola claims that its new hydrogen hub will expand the current network of hydrogen production, distribution and dispensing planned for North America.“This expanded network will further support the increasing demand for Nikola’s commercial vehicle leases and allow for future expansion into hydrogen powered infrastructure solutions for the city of Buckeye and the surrounding area,” Nikola said.

The Boeing Co., Mesa, Arizona, was awarded a $239,590,243 cost-plus-fixed-fee contract for the Apache Improved Turbine Engine Inte-gration Phase II. Bids were solicited via the internet with one received. Work will be performed in Mesa, Arizona, with an estimated comple-tion date of Dec. 31, 2026. Fiscal 2021 and 2022 research, develop-ment, test and evaluation, Army funds in the amount of $18,000,000 were obligated at the time of the award. U.S. Army Contracting Com-mand, Redstone Arsenal, Alabama, is the contracting activity.

The plant is expected to use existing private well water, which Nikola said is “sufficient” to meet the proposed level of development, demand and use.

Plans for the new hydrogen facility come as the company launches a new brand called HYLA to represent its hydrogen business. HYLA comprises the company’s energy products for producing, distributing and dispensing hydrogen to fuel its electric trucks. By Audrey Jensen – Phoenix Business Journal

A2Z MANUFACTURING SW • 24 • May /June 2023 A2Z MANUFACTURING SW • 44 • March / April 2022

D

LG Energy Solution To Invest $5.5 Billion To Build Battery Manufacturing Complex In Queen Creek

LG Energy Solution (LGES), a leading global manufacturer of lithium-ion batteries for electric vehicles, mobility, IT, and energy storage systems, announced it will invest a total of $5.5 billion to build a battery manufacturing complex in Queen Creek, Arizona. The complex will consist of two manufacturing facilities – one for cylindrical batteries for electric vehicles (EV) and another for lithium iron phosphate (LFP) pouch-type batteries for energy storage systems (ESS). The investment represents the largest single investment ever for a stand-alone battery manufacturing facility in North America.

The $5.5 billion is nearly four times the initially-announced investment of $1.4 billion. The company plans to invest $3.2 billion to build a cylindrical battery manufacturing facility for EV with a capacity of 27 GWh. LGES also plans to invest $2.3 billion in a LFP pouchtype battery facility for ESS with a capacity of 16 GWh. Both facilities, totaling 43 GWh, are expected to break ground this year and lead to the creation of thousands of new jobs.

“Our decision to invest in Arizona demonstrates our strategic initiative to continue expanding our global production network, which is already the largest in the world, to further advance our innovative and top-quality products in scale and with speed,” said Youngsoo Kwon, CEO of LG Energy Solution. “We believe it’s the right move at the right time in order to empower clean energy transition in the U.S.”

The new cylindrical battery manufacturing facility aims to start mass production of 2170 cells in 2025, mainly for EV makers in North America. It is the first-ever U.S. cylindrical battery manufacturing facility solely invested by a Korean battery manufacturer.

The company’s new manufacturing facilities will utilize a state-of-the-art smart factory system

that carries out all decision making on machine-produced data. By implementing this key measure to enhance product quality, the Arizona facilities will aim to increase yield, improve manufacturing processes, and boost productivity to better respond to the ever-rising battery demands in the region.

LGES’ expansion adds to a recent string of battery announcements in Arizona. In February, Ecobat announced plans to build a lithium-ion battery recycling facility in Casa Grande. In December, American Battery Factory announced it is investing $1.2 billion to build a lithium-ion battery manufacturing facility in Tucson, and Sion Power announced it is expanding its battery manufacturing operations in Tucson, creating over 150 jobs.

A2Z MANUFACTURING SW • 26 • May /June 2023 ,I NC. Equipment: Band saws Plate saws Shears Leveling Line Slitter Line Industries: Aerospace Semi-Conductor Medical Kitchen/ Restaurant Defense HVAC Automotive/ Racing Phoenix: Reno/Sparks NV Las Vegas, NV 602.278.5052 775.355.8100 702.719.6061 wwwCoastAluminum.com WHY SELECT COAST ALUMINUM? • ISO9001/AS9120 Certified • Offering Next Day Delivery • 80,000 sq. ft. Facility With Extensive Inventory • Stocking Stainless Steel, Aluminum Stock and Specialty Metals

A2Z MANUFACTURING SW • 27 • May /June 2023 Stay in Touch (714) 393-3783 Info@landmarksolutionscorp.com landmarksolutionscorp.com 925 N. Shepard Anaheim, CA 92806 Take your next step with us. Fiber Lasers • Press Brakes • Automation • Waterjets • Plate & Angle Rolling • Plasma & Oxy Cutting Deburring • Saws • CNC Machining • Nitrogen Generation • Robotic Welding Your Partner in Manufacturing Equipment Bringing over 100 years of industry experience Best Choice Parts, a Landmark company, stocks thousands of OMAX, AccuStream, and Hypertherm parts at our CA and AZ locations for immediate will-call or guaranteed same-day shipment. Now Offering Technical Service Best Choice Parts and Landmark Solutions are excited to announce the offering of local, factorytrained technical service and preventative maintenance on a wide range of equipment. EXCLUSIVE DISTRIBUTOR OF: Proud

ALL THE METAL YOU NEED UNDER ONE ROOF

which was announced in October.

O Analytics joined 17 other companies from New Mexico and across the country as part of the aerospace accelerator program. Many representatives from those companies traveled to Albuquerque from places such as Mountainview, California; Buffalo, New York; and Jacksonville, Florida, to take part in a pitch competition and meet local aerospace experts.

For Jones, the relationships she found by meeting other scientists, founders and industry experts in Albuquerque helped reframe how she wants to grow her company.

“What we’re finding is that there are a number of resources that are available in the state,” Jones said. “It’s not just funding per se. There are intellectual resources here in the labs at Sandia and also Los Alamos.

“Access to data and the imagery and the natural resources in New Mexico are equally as important to us as finance and the kind of ‘intelligentsia’ through the people who are here in New Mexico.”

Aerospace Companies Establish Mission Control At Newspace New Mexico’s Launchpad

Stacey Franklin Jones first heard rumblings of a new aerospace accelerator program last summer. Word of new opportunities spread quickly in what Jones, CEO of West Virginia-based aerospace company O Analytics, described as a tight-knit space startup community.

“From multiple sources, it sounded like it was going to be a really exciting program, and that it was going to be one that would be perfect for us in the stage that we were in,” she told Albuquerque Business First.

Her company applied to be a part of NewSpace New Mexico’s Ignitor program soon after, and O Analytics was accepted into the program’s first iteration of 18 participants

NewSpace New Mexico ran the inaugural Ignitor program out of its co-innovation workspace in Albuquerque, called the NewSpace New Mexico Launchpad. On any given day, you can find leaders and scientists from different companies using the slew of resources at the 8,700-square-foot facility, including a clean room, a thermal vacuum chamber, 3-D printers, soldering stations and individual work benches.

Casey Anglada DeRaad, the founder and CEO of NewSpace New Mexico, said much of the equipment at the Launchpad comes from the needs of young aerospace companies, which

A2Z MANUFACTURING SW • 28 • May /June 2023 800.528.9875 www.azironsupply.com 130 S. 23RD STREET PHOENIX, AZ 85034 OPEN: MON-FRI: 7:30AM-5PM /azironsupply /company/az-iron-supply /az_ironsupply /arizonairon • Bar, Flat, Sheet, Channel, Tube, Square, Rectangular Steel and more • Ornamental Metals • Delivery Across Arizona • Cutting Services • CNC Plasma Cutting • Custom Fence Pickets • Roll-o Container Services • Metal Recycling • Wiping Rags

often don’t have enough money and physical space to purchase and use their own equipment.

And the demand for equipment has grown as more companies look to utilize resources at the Launchpad, which is located at 2420 Alamo Ave. SE in Albuquerque. Scott Maethner, vice president of operations and integration for NewSpace New Mexico, said the nonprofit currently has 11 user agreements signed for companies to use the Launchpad.

That number has grown from only three agreements prior to the turn of the year, he said.

NewSpace’s Ignitor program, which was held in February, has been one driver of that increased demand.

“As they were here in town, a lot of them started talking to us about using our Launchpad and our facilities,” DeRaad said about representatives from the Ignitor companies who traveled to Albuquerque as part of the accelerator program. “And we can connect them even beyond the facilities we have here. We’re setting up a network of being able to get to other test equipment and lab equipment with the labs and other industry partners.”

In order to purchase more hightech equipment for aerospace companies to use, DeRaad said NewSpace is actively raising money. She said the nonprofit is targeting between $3 and $10 million.

While resources in New Mexico for growing aerospace companies extend beyond Albuquerque, DeRaad said NewSpace New Mexico’s Launchpad can act as a base for companies to turn their concepts into products, to

then eventually find more money and more customers. By Jacob Maranda -

Landmark Solutions Now Offering OnSite, Factory Trained Technical Service

Landmark Solutions and its sister company, Best Choice Parts, are proud to further support the fabrication community by offering on-site, factorytrained technical service on a wide array of equipment. Friendly, experienced, and efficient technicians are available for machine repairs and preventative maintenance throughout the region.

Service can be scheduled by emailing info@ landmarksolutionscorp.com or calling +1 (855)-WATRJET.

A2Z MANUFACTURING SW • 29 • May /June 2023 /davismetalsandsalvage /company/davis-salvage-co.-l.l.c. /davismetalsandsalvage /davissalvage YOUR ARIZONA METAL SUPPLIER & SCRAP METAL RECYCLING CENTER OPEN: MON-FRI: 7:30AM-5PM / SAT: 7:30AM-NOON 3322 E. WASHINGTON ST. PHOENIX, AZ 85034 602.267.7208 davismetals.com 3RD GENERATION FAMILY OWNED & OPERATED • Metal Recycling • Roll O Services • Used Metal Supply • New Metal Supply • Ornamentals • Wiping Rags • HVAC Equipment Recycling • Delivery Available • Corporate Accounts

New Mexico Inno Reporter

Mesa-based Rosotics Expands Footprint At

Falcon Field Airport

Rosotics is planning a major expansion at Falcon Field Airport in Mesa where it intends to create a manufacturing, research and development campus for its heavy metal 3D printing system that will hit the market later this year.

The Mesa-based startup has inked a lease for nearly 130,000 square feet in two hangars in the northwest section of Falcon Field, the company announced at a launch event. The company previously occupied 15,800 square feet of space in a hangar at the airport.

In addition to research and development operations at Falcon Field, Rosotics will test, assemble and manufacture the Mantis, a portable 3D printing machine with arms that unfold and stretch, allowing for large prints of aerospace-grade aluminum and steel.

“This is a machine that is designed to make it possible for any parts larger than a refrigerator to be built by 3D printing,” Rosotics founder and CEO Christian LaRosa said, referring to the Mantis. “Initially, our market is aerospace and that’s for a very important reason. Aerospace is held to arguably the highest performance standard in metallurgy in the U.S. This machine is designed to meet that standard.”

The Mantis leverages rapid induction printing that uses fewer material resources and is more energy efficient than typical 3D printing methods, while providing capability for larger prints that previously weren’t possible for the aerospace, construction, marine and energy industries, LaRosa said.

“This machine is designed to make it easy to print something as large as a rocket structure, a tank or an interstage of a launch vehicle,” he said.

The Mantis base model produces aerospace-grade aluminum and steel prints ranging from 5 to 30 feet in diameter and more than 20 feet in height. The machines, however, can be built to suit customers’ needs. The Mantis plugs into a 240 volt outlet typically installed in warehouses, LaRosa said.

Your one stop shop for 623.847.4028 - NEW 10KW BYSTRONIC FIBER LASER - NEW CNC PRESS BREAK - 5-AXIS WATERJET CUTTING (table 13’10” x 6’7”) - CERTIFIED MIG, STICK, & TIG WELDING - LASER CUTTING SERVICES - DEBURRING SERVICES - PUNCH & SHEARING - STAINLESS STEEL FABRICATION - PRECISION SHEET METAL WORK - GENERAL METAL FABRICATION & DESIGN - SAW CUTTING - TUBE BENDING SERVICES - PRODUCT MANUFACTURING & ASSEMBLY - PRODUCTION & PROTOTYPING - MOBILE FABRICATION & WELDING 623.847.4028 Address : 5815 W McLellan Rd Glendale, AZ 85301 Our Phone : 623.847.4028 Email : sales@azwelder.com QUICK TURNAROUND 1-2 Day Lead TIME

At its Falcon Field headquarters, Rosotics will test the machine’s limits to learn how fast it can print as well as how much stress the 3D printed material can withstand, LaRosa said.

There’s also potential for Rosotics to assemble parts at Falcon Field for delivery to customers upon request, LaRosa said.

“If they want, a fuselage section could be built here, loaded onto a truck and delivered. That could also be done,” LaRosa said. “The expansion at Falcon Field is instrumental in that.”

The company in November raised $750,000 in a seed funding round led by Draper Associates — an early-stage venture capital firm based in San Mateo, California — with participation from Correlation Ventures, Vibe Capital and Sequoia Capital.

Rosotics expects to launch the Mantis in October at an initial price of $95,000 with plans to offer monthly subscriptions that includes ongoing support, upgrades and maintenance.

The company operates a hardware-as-a-service business model, meaning as technology evolves, customers can take advantage of its latest developments.

Rosotics has been in discussions with several aerospace and helicopter companies about the Mantis and is in the process of booking deliveries for later in the year, LaRosa said.

The company, which AZ Inno recently named a ‘2023 Startup to Watch,’ is eager to expand in Mesa’s growing aerospace community. “Boeing is right across the street from us and Virgin Galactic’s next-generation

Phoenix Heat Treating Phoenix Heat Treating

vehicle is going to be built in the city of Mesa,” LaRosa said. “It’s just wonderful to be surrounded by a community of aerospace innovation.” By Amy EdelenReporter Phoenix Business Journal

As Intel’s Chandler Expansion Progresses, Sen. Kelly Says Company Should Have ‘Competitive Application’ For CHIPS Act Incentives

Intel Corp.’s Ocotillo campus in Chandler was buzzing with activity as construction workers transported materials and cranes hoisted steel trusses onto buildings that will soon become the company’s newest semiconductor factories.

U.S. Sen. Mark Kelly was onsite to view construction progress of the two factories — Fab 52 and Fab 62 — a $20 billion project that broke ground in 2021 and is expected to spur creation of more than 3,000 high-paying tech jobs.

Continued Next Page

A2Z MANUFACTURING SW • 31 • May /June 2023

GET TO KNOW US Servicing our industry and trade customers in intelligence heat treating for over 60 years. www.phoenix-heat-treating.com 602-258-7751 cs@phxht.com Established in 1963 Real Time Live Job Tracking 10+ Processes Performed 50+ Furnaces AOG and Line Down Services Over 10+ Prime Approvals 24/7 Processing

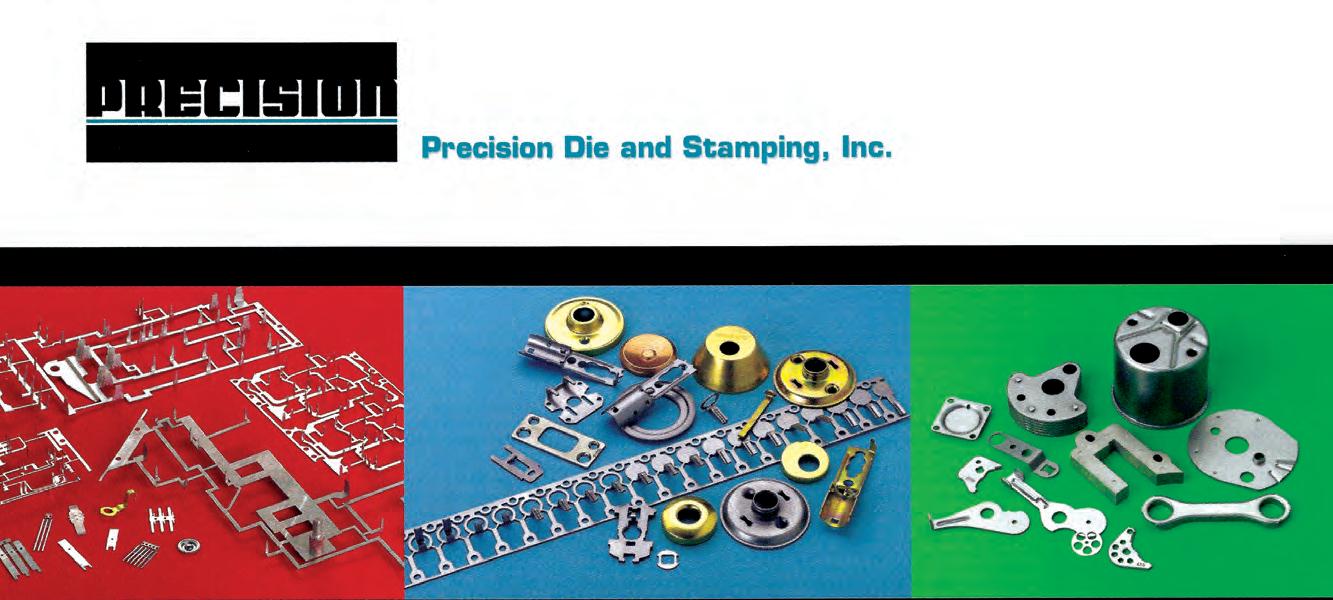

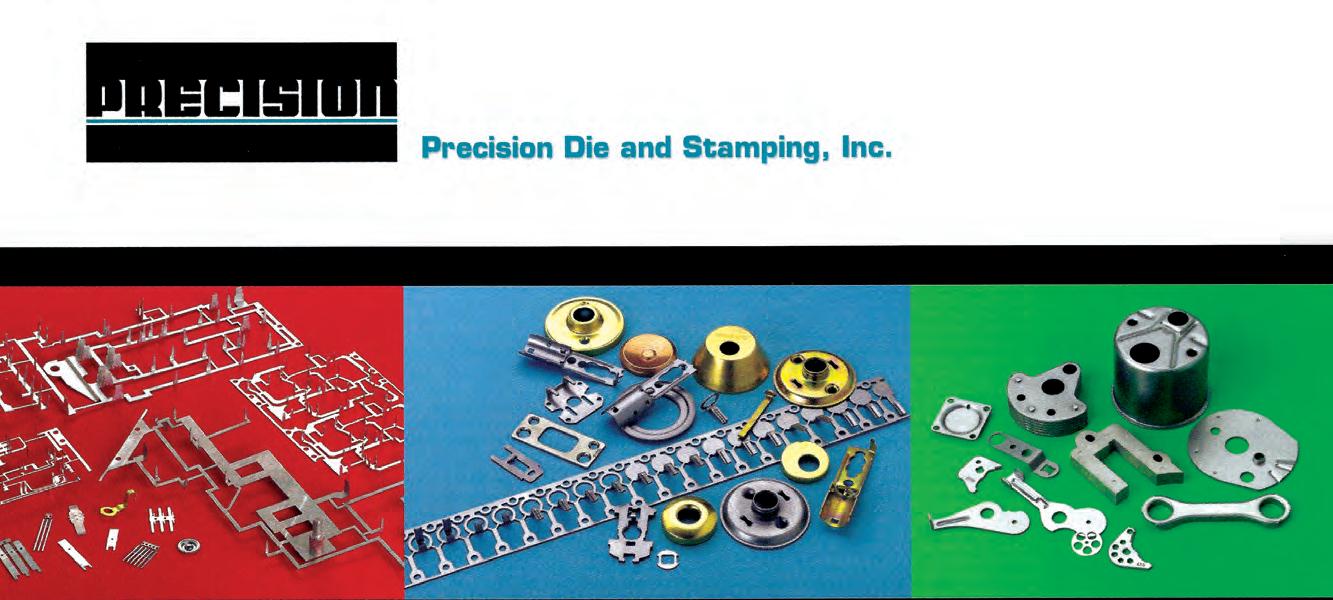

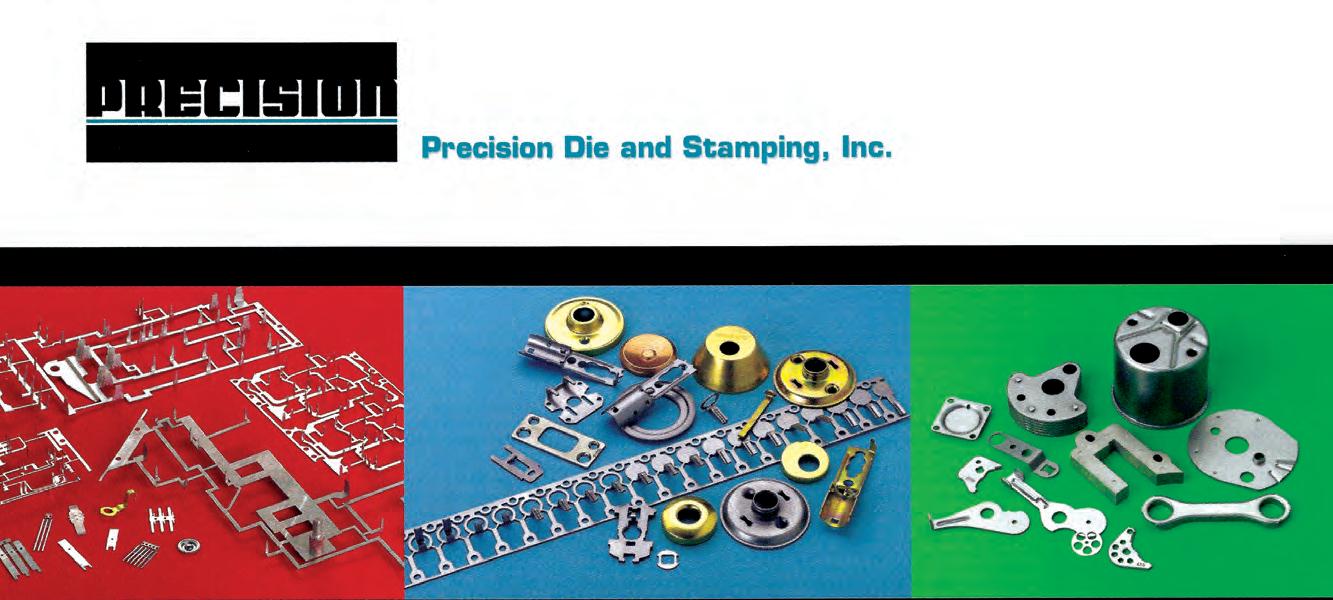

and dedication to customer service are number one priorities. This type of expertise and dedication has fostered a reputation of excellence in the tooling and stamping industry.

Located in Tempe, Arizona, our 100,000 Sq. Ft. Facility contains state of the art equipment , with production capabilities ranging from simple geometries to complex forms with intricate details. Precision enjoys a world-class reputation supplying a variety of OEMs, managing their inventory levels, and making certain product quality and timely delivery are NEVER compromised.

“This is going to be one of the premier facilities in the world, certainly here in the state of Arizona, bringing thousands of good paying jobs that you can actually raise a family on and that do not require a four-year degree,” Kelly said.

Intel spokeswoman Linda Qian declined to disclose whether the company is on track for meeting its previously announced timeline for opening the fabs in 2024.

She said Intel is making a “tremendous amount of progress” on the fabs, which will be complete within three to five years from the initial groundbreaking date.

The fabs will have more than 250,000 square feet of clean room space and will produce wafers, which are thin slices of semiconductor material used for fabrication of integrated circuits. Each wafer can hold hundreds or thousands of chips, depending on size.

Intel will send the wafers to an assembly testing center where they’ll be cut via lasers into individual chips, packaged and

shipped to customers, said Jason Bagley, government affairs director for Intel Corp.’s U.S. Southwest region.

The fabs will support growing demand for Intel’s products and be a provider for Intel Foundry Services. The two fabs, when complete, will bring the total to six fabs on Intel’s existing Ocotillo campus.

“I almost can’t stress enough how important these wafers are to our economy,” Kelly said. “Semiconductor chips go in everything from cellphones, vacuum cleaners and cars to the most sophisticated fighter jets in the world.”

The pandemic exacerbated a global shortage of semiconductor chips, most of which are produced in Asia.

“We’re at a point now where we need to change the balance of the semiconductor industry supply,” Bagley said. “We are actively working on these two new factories here as part of that strategy to shift some of that production capacity back to the U.S. and back to Europe, so we have more of a fifty-fifty division between Asia, the U.S. and E.U. These efforts are critical to the ability of this country to continue to innovate and continue being a global leader in the semiconductor space.”

By Amy Edelen – Reporter, Phoenix Business Journal

A2Z MANUFACTURING SW • 32 • May /June 2023

West 10Th St • Tempe, AZ 85281 Ph: 480-967-2038 • F: 480-829-0838 • www.PrecisionDie.com Automotive • Semiconductor • Lockset Hardware • Power Tools • Lawn & Garden Equipment • Aerospace

Precision Die & Stamping, Inc. 1704

A2Z MANUFACTURING SW • 33 • May /June 2023 SOUTHWEST EDM Who Better To EDM Your Parts Than The #1 Fanuc EDM Expert in North America! 1125 W Pinnacle Peak Rd, Phoenix, AZ 85027 (623) 826-1025 southwestedm.com steve@southwestedm.com Wire EDM Job Shop With Full CNC Machining And Turning Capabilities... MANUFACTURING Capabilities 6 Matsuura Horizonal Machining Centers • Up to 80 Tools • 4-axis with Dual Pallets 8 Haas Vertical Machining Centers • Travels up to 60” • 4th and 5th Axis 2 Fanuc Wire EDMs • .004” - .012” Diameter • Up to 12” Thick Full Inspection / CMM Capabilities Engineering and Assembly Debur, Tumble, Media Blast, & Coating Type 7 FFL ITAR Registered “In conjunction with DillonAero Manufacturing, we offer EDM plus so much more in machining.” Steve Raucci, Owner Southwest EDM MANUFACTURING CAPABILITIES 6 Matsuura Horizontal Machining 8 Haas Vertical Machining 2 Fanuc Wire EDMs Full Inspection & CCM Capabilities Up to 80 Tools 4-axis w/ Dual Pallets Travels up to 60” 4th & 5th Axis .004”-.012” Diameter Up to 12” Thick Engineering & Assembly Deburr, Tumble, Media Blast, Type 7 FFL Contact: steve.raucci@dillonaero.com

VMCs Row

Our Newest Machine: Ocean EDM Hole EDM Inspection/CMM Partnering with NEWS

One of the 8 Haas

of Matsuuras

Q2 Update to the 2023 Economic Outlook Forecasts 1.0% Expansion in Equipment and Software Investment

Equipment and software investment growth cooled in the early months of 2023, resulting in the Equipment Leasing & Finance Foundation lowering its annual forecast for investment growth to 1.0%, according to the Q2 update to the 2023 Equipment Leasing & Finance U.S. Economic Outlook. The report released today also predicts sluggish economic growth in Q1 as the economy edges closer toward recession, which the Foundation continues to expect will begin during the second half of the year. Overall, annualized economic growth is forecast to be 0.7% in 2023, largely driven by a solid jump-off point at the end of last year.

The Foundation’s report is focused on the $1.16 trillion equipment leasing and finance industry and highlights key trends in equipment investment.

Nancy Pistorio, Foundation Chair and President of Madison Capital LLC, said, “Despite the U.S. economy ending 2022 with healthy growth and maintaining some momentum into early 2023, equipment and software investment softened to 2% annualized growth in Q4 and remains under pressure. The economy is still above water, but most indicators point to slowing growth, and many economists continue to expect a recession to begin later this year. Should that come to

pass, I also expect the equipment finance industry will demonstrate its characteristic resilience, innovation, and resolve, and will continue to serve the financial needs of our customers regardless of the economic climate.”

Highlights from the Q2 update to the 2023 Outlook include: Equipment and software investment growth was sluggish in Q1 as the combined effects of a slowing industrial sector and higher interest rates weighed on equipment demand. While certain end-user markets may fare better in the months ahead, a broad economic downturn will drag on investment across the board, resulting in agrowth forecast for equipment and software investment of just 1.0%.

The U.S. economy is expected to continue to soften despite a healthy labor market, lower energy prices, and supply chain improvements. Stubborn inflation combined with rising consumer financial stress and a looming debt ceiling showdown will add to financial sector woes. Although a “soft landing” scenario is still achievable, a mild recession is likely, beginning during the second half of 2023.

The manufacturing sector has worked through much of its pandemic-era supply chain backlogs, but measures of supply chain health indicate the industrial sector is in the midst of a protracted slowdown. On the plus side, the sector’s jumping-off point was strong, so while demand is likely to continue to soften this year, the downturn may not be as severe as in past cycles.

A2Z MANUFACTURING SW • 34 • May /June 2023 OVER 26 PRIME APPROVALS OUR CAPABILITIES 3027 E Washington St, Phoenix, AZ 85034 • (602) 275-1917 Semiray a Division of Mistras Group www.semirayinc.com www.mistrasgroup.com *Penetrant *Magnetic Particle *Anodize Type I, II, III *ChemFilm Type II ROHS Compliant *Passivation *Pre Penetrant Tech *Pressure Test *Paint *Dry Film Lube *Flow Test / AF5333 *Borescope Inspection *Ultrasonic Cleaning *Millipore Clean & Inspection ...And Many Other Value Added Services

A2Z MANUFACTURING SW • 35 • May /June 2023

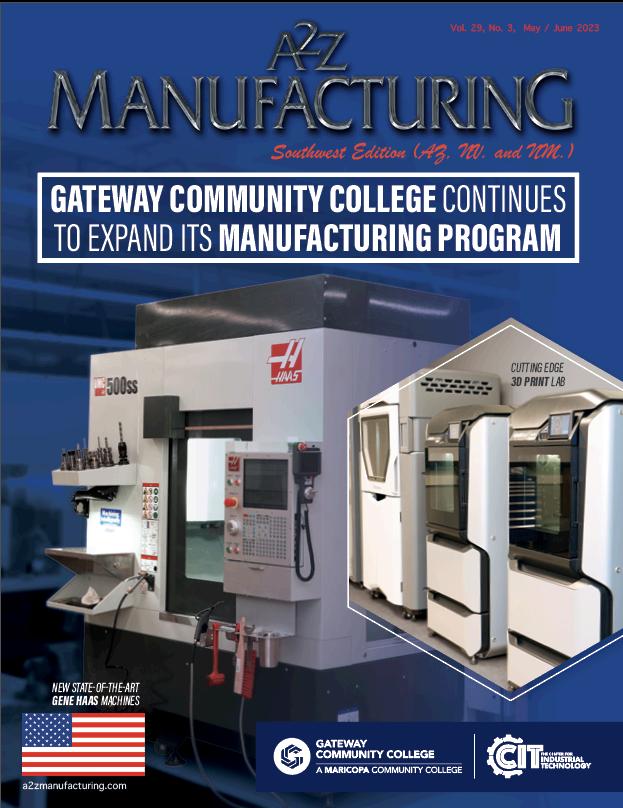

GateWay Community College Continues to Expand Its Manufacturing Program

As Arizona quickly becomes one of the country’s largest manufacturing states, suppliers have continued to turn to one of the premier workforce development colleges in the Valley, GateWay Community College.

GateWay recently announced significant upgrades to its manufacturing program, emphasizing its commitment to workforce development and new technology. The program continues to expand its focus and training on multi-axis machining and additive manufacturing with a full suite of digital inspection and reverse engineering using Geomagic, Design X,

“We’ve learned to change just as quickly as the industry,” said Dave Zamora, lead faculty for the program. “We know that when our graduates enter the workforce, they have trained on some of the latest and most advanced technology on the market.”

In addition to its state-of-the-art manufacturing lab, the college offers a fully equipped 3D printing lab, where students can experiment

with the latest 3D printing technology and gain hands-on experience with additive manufacturing. The lab is equipped with advanced technology, allowing students to explore a wide range of manufacturing techniques.

The college also recently partnered with HAAS, a leading manufacturer of CNC machines, to offer HAAS CNC operator certification. The certification program is designed to give students a comprehensive understanding

“The end result is our graduates earn more money, have more opportunities, and fill critical jobs for Arizona’s manufacturing industry,” added Zamora. “Our training provides our students with a broad perspective that opens even more doors for them.”

Beyond the equipment, the program also includes Mastercam Multi-axis CNC programming software, which is used to

A2Z MANUFACTURING SW • 36 • May /June 2023

of HAAS CNC machines, preparing them for careers in the manufacturing industry.

program live tooling lathe and simultaneous 5-axis CNC mill. This software is essential for precision manufacturing and will give students a competitive edge in the job market. Students are also exposed to digital design tools from Solidworks, with classes that train for five levels of professional certification. This can ultimately lead to an Expert Level Industry Certification in Solidworks.

“We’ve been a workforce development college for 55 years,” said Dr. Amy Diaz, president of the college. “These upgrades and advances in our program represent GateWay’s commitment to providing students with the latest technology and hands-on training in manufacturing.”

GateWay has emerged from the pandemic with momentum after launching its new Center for Industrial Technology. The center brought together five of the college’s existing programs: Industrial Design Technology, Automotive, HVAC, Water Resources and Environmental Science Technology, and Water

and Wastewater Treatment.

The college also recently announced that enrolled students in the CIT - Industrial Design Technology program at its Washington campus are eligible to apply for scholarships. A grant provided the funding for the scholarships through the Gene Haas Foundation.

For information on the program, visit gatewaycc.edu/cit or call (602) 2868000 for enrollment services.

A2Z MANUFACTURING SW • 37 • May /June 2023

### GATEWAY COMMUNITY COLLEGE MEDIA CONTACT: Lindsey Wilson lindsey.wilson@gatewaycc.edu 602-286-8229 direct line GateWay Community College Phoenix, Arizona https://www.gatewaycc.edu

Maker of blimp-like hybrid-electric cargo airship taps Honeywell Phoenix for generator

Phoenix-based Honeywell Aerospace will supply power for a blimp-like airship that is expected to handle heavy loads in less accessible areas for a variety of industries.

A 1-megawatt generator made by Honeywell was selected by Flying Whales Quebec — which is based in France and Canada — to be integrated into its new LCA60T hybrid-electric airship that is currently under development.

The Flying Whales craft is a 200-meter-long hybrid-electric vehicle able to carry 60 tons of cargo. It can load and unload from a stationary hovering position and was originally designed to carry renewable wood from remote areas. It is now conceived as a transport option that can move heavy loads at low cost with no ground constraints for a variety of logistical applications such as loading and unloading cargo ships or assisting in disaster zones.

Honeywell’s generator system was chosen for its power density and efficiency and its suitability for piloted and autonomous flight. It

can also be used as a motor without modifications for electric propulsion engines, Honeywell said.

In the Flying Whales craft, the generator will be integrated with a gearbox and a turbine that uses jet fuel and sustainable aviation fuel. The generator will supply power to the electric engines in a system that works similarly to one in a hybrid-electric automobile.

“Honeywell’s 1-megwatt generator is a perfect fit for a transformational aircraft like the LCA60T,” Dave Marinick, Honeywell Aerospace president of Engines & Power Systems, said in a statement. “Our generator is four times as powerful as any other generator flying today, and at unmatched power density. We believe in creating a more sustainable future for aviation, and our work with Flying Whales is helping bring that future to life.”

The Phoenix company said its generator passed its first round of testing in May 2022, and said that its results have been more impressive as testing has continued. The most recent tests in late 2022 revealed that the generator operated continuously at 1,000 kilowatts at 1.06 MVA (or 1MW) power levels, Honeywell said. The company said this means it has the high-power density and efficiency needed for hybrid-electric propulsion for aerospace and ground uses.

A2Z MANUFACTURING SW • 38 • May / June 2023 Continued Page 40

1.06 MVA (or 1MW) power levels, Honeywell said. The company said this means it has the high-power density and efficiency needed for hybrid-electric propulsion for aerospace and ground uses.

“This important collaboration completes and strengthens our Canadian consortium to develop and manufacture our high-power turbogenerator. Today, we are building in Canada the expertise and technological advancements for tomorrow’s aeronautics,” said Flying Whales CEO Arnaud Thioulouse in a statement. By Jeff Gifford – Digital Editor, Phoenix Business Journal

Boeing Will Be Building Dozens Of Apache Helicopters In Mesa

The Boeing Co. will be building 184 AH 64E Apache attack helicopters in Mesa under a $1.9 billion contract modification that brings the value of an existing deal with the U.S. Army to $2.1 billion.

The modification, which was awarded on March 17, can still increase to more than $3.8 billion in the future, Boeing said. Boeing was the sole applicant for the contract after bids were solicited via the internet, the Department of Defense said.

The Apaches are projected to be finished by the end of 2027. Of

the total number, 115 will go to the U.S. Army, with 15 more to be procured as options. In addition, 54 helicopters will go to partner nations as part of the Foreign Military Sales program — including the first Apaches ever to go to Australia.

“We are enhancing the U.S. Army’s attack fleet, while supporting additional partner nations and welcoming our newest Apache customer, the Australian Army,” said Christina Upah, vice president of Attack Helicopter Programs and senior Boeing Mesa site executive, in a statement. “This contract highlights the need for Apaches worldwide.”

Australia is the 18th nation to use Apaches. Egypt will be another recipient of the helicopters under the Boeing contract, the Defense Department said. More than 1,275 Apaches are in operation around the world right now, Boeing said, and the U.S. Army earlier this month clocked the 5 million flight-hour milestone with the aircraft.

“With more than five million flight hours, the Apache continues to be reliable, versatile and lethal,” said Katie Yursky, interim vice president of Attack Helicopter Programs and senior Mesa site executive, in a statement.

A2Z MANUFACTURING SW • 40 • May /June 2023

ALUMINUM,

1138 W Watkins St, Phoenix AZ 85007 623-582-6544 Sales@RMGMachining.com 602-254-4173 Sales@ValleyMachineWorks.com

STAINLESS, BRASS, PLASTIC, AND ALLOYS

BREAKDOWN, METAL SPRAYING WATERJET, PLASMA & LASER CUTTING STICK, MIG, TIG & PORTABLE WELDING FORKLIFT FORK STRAIGHTENING

CNC, SWISS, MILL & LATHE DESIGN, POLISHING, CAD, PACKAGING

Hunter Machine Moving, LLC offers machine moving, rigging and transport services, throughout Arizona.

Costello

The U.S. Army said the Boeing contract demonstrates the importance of the Apache program, which has been going since 1984, when the first AH64 took flight. The Army currently uses D-model Apaches as well as the AH-64E model.

“This multi-year contract is critical for the warfighter and the entire Apache team,” said Col. John (Jay) Maher, U.S. Army Apache project manager, in a statement. “It demonstrates the Army’s commitment to continue putting unmatched capability into the hands of our nation’s finest, while providing stability and predictability for the outstanding citizens and companies that pour their talent into producing the best attack helicopter in the world.”

Boeing signed the first multi-year Apache contract in 2017, and it resulted in 244 remanufactured Apaches for the Army and 24 new units for an international customer.

The Apaches are built at Boeing’s Arizona facility near Falcon Field Airport in Mesa. Boeing employs more than 4,400 people

Rigging & Storage &