12 minute read

design

Moving beyond conceptual design with simulation

Using multiphysics simulation to understand the interaction between environmental, geometrical, and structural variables, engineers at Newtecnic ensure that innovative building façades are both beautiful and buildable

Simulation software has become a key tool for Newtecnic’s façade design work, which includes Federation Square in Melbourne, Australia, and more recently, the Heydar Aliyev Cultural Centre in Baku, Azerbaijan.

Bespoke is the norm for these iconic building projects and each one requires thinking that goes beyond conceptual design alone. Architects provide an artistic view and perhaps surface modelling of a building design, then engineers build up the façade in layers, making sure that the design retains its creativity while also ensuring its structural integrity.

“A key aspect of our work is to describe the physical behaviour of the façade systems we design,” explains Carmelo Galante, head of research and development at Newtecnic.

From solar studies that allow optimisation of the shading design in order to reduce cooling loads and maximise visual comfort, to the way in which fixing brackets for rainscreen cladding affect the integrity of the insulation, there are numerous challenges that can be resolved with the help of simulation.

Newtecnic uses Comsol Multiphysics for its façade design and analysis work. It is used to study the 3D thermal bridging effect — the way in which highly conductive materials penetrate insulation — on the overall energy efficiency of the buildup, evaluate the maximum temperature of components, and suggest the most suitable product or material. “I can evaluate cladding pressures on the building structure for schematic design stages and study more complex façades in which mechanical and natural ventilation are present at the same time. I can evaluate how different design configurations would affect the hygrothermal performance of a façade system,” says Mr Galante.

Mr Galante imports complex geometries from Autodesk AutoCAD and Rhino. Autodesk Revit is being used more and more at Newtecnic, including a new addon that allows users to interface Comsol simulations with the Revit environment. Galante also combines the use of simulation with parametric design tools, such as the programming language Grasshopper, which is used to build and analyse complex geometries by means of generative algorithms.

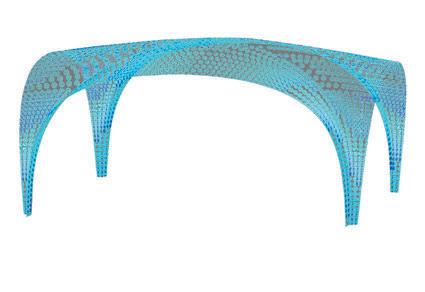

A current project involves designing the façade system for a high-profile private building comprising a series of self-supporting concrete shells ranging from 10m to 80m in length and reaching heights of up to 30m (Figure 1).

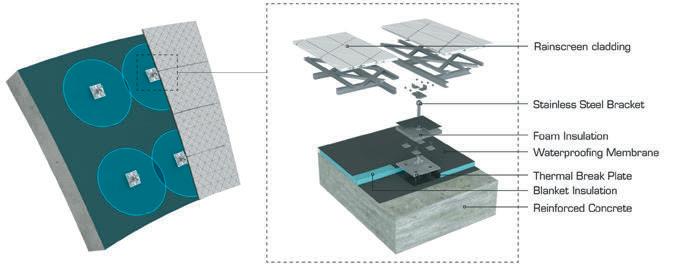

The concrete shells are clad with a rainscreen façade system made out of ceramic panels that are doubly curved in order to accurately reproduce the building geometry. Each panel is supported at its corners by adjustable fixing brackets made out of stainless steel. The brackets are attached to the concrete structure through four post-drilled anchorages (Figure 2). As the brackets penetrate the insulation layer and have a much higher thermal conductivity than the concrete structure, they create thermal bridges through the façade envelope, significantly reducing its thermal performance.

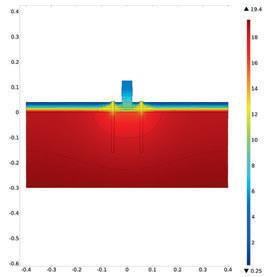

By conducting a simplified 2D simulation study, engineers were able to look at how the thermal bridge effect created by the brackets influenced the temperature distribution in the façade (Figure 3). The results from the simulation were entered into a Grasshopper script to evaluate three areas of interest: those influenced by one bracket, those influenced by two or more brackets, and those not influenced at all (Figure 4).

Engineers were then able to prepare an accurate geometry for the system, including all the components of the build-up. “It is a real advantage to be able to combine two tools,” says Mr Galante. “Grasshopper allows me to investigate the geometry on a very large scale — that of the entire building — then I move back to the simulation software with this information and create a detailed 3D model to capture the real physics of the system.”

Using this approach, engineers could conduct a 3D analysis to study the thermal bridge effect in the bracket and surrounding building and compute the global heat transfer coefficient (U-value) of the façade.

“Using multiphysics simulation allows me to develop a better understanding of the real situation,” explains Mr Galante. “I

can combine fluid flow with heat transfer by conduction, convection, and radiation, meaning that I can thoroughly evaluate the interplay of different physical effects and confirm the performance of different structures and materials.” Responding to design changes Newtecnic’s engineers have to respond to continually changing designs, and need to be able to validate any design updates. “Simulation allows us to do that,” observes Galante. “We can demonstrate exactly what effect a design change will have, whether it relates, for example, to energy efficiency, structural performance, corrosion, or the lifecycle of a component.”

For Newtecnic director Andrew Watts, it is all about answering questions such as “Is it worth changing this to make something else work?” or “If we have to change it, how much do we have to change it by?” He comments: “With simulation, we can move away from the traditional building philosophy of studying individual components that only perform one function and can instead think in terms of multi-functional components, and of the building as a whole.”

Simulation is used to conduct analyses for every component of a building, and these results are fully integrated with drawings so that budget estimates are both clear and comprehensive. Fabio Micoli, associate director at Newtecnic, notes the value of delivering live feedback to clients.

“Simulation minimises construction costs by allowing contractors to see exactly what they are required to build, thereby reducing the need for contingency budgets or time for unresolved design issues and allowing the construction team to concentrate on meeting project deadlines.” Continuing improvement “The digital tools that we use, such as simulation software, enable us to explore new possibilities and improve our design processes,” Mr Galante says. He can see potential for expanding the use of simulation in the organisation, including using the new Application Builder, part of Comsol Multiphysics version 5.0.

As Mr Micoli notes, “We could, for example, enhance communication with clients by creating an application that allows an architect to modify different parametres and see exactly how changes would affect their design without knowing the underlying multiphysics simulation details.”

With simulation, a better understanding of building performance can be delivered, ensuring that an innovative architectural design puts its best face forward.

1

2

3 4

1. Rendering of a single shell shown from two different angles, many of which will be part of the building. 2. Highlighted view of the rainscreen system with fixing brackets. 3. Simulation results showing isotherms and temperature profile in oC of a section taken through a bracket. 4. Model of one of the shells shown in Figure 2 with areas highlighted that are influenced by one bracket, two brackets, or not influenced by any bracket.

The concept of a fabric weave within the coloured segments of the elevations was created using a cladding system that allowed the builders to achieve water-tightness more quickly

Bradford College

Bond Bryan Architects delivers an award winning addition to Bradford College, using Graphisoft’s ArchiCAD to integrate data from the design with contractors, consultants and clients.

The Bradford College David Hockney Building, was designed by Bond Bryan Architects and delivered using an open BIM process, which incorporated COBie deliverables. The eco-friendly building has a light and airy feel and is sympathetic to the large-scale mill and warehouse buildings that characterise parts of Bradford. It is centred around the college’s vision of creating a space that encourages and supports innovative forms of teaching and learning.

In 2008, the college embarked upon a comprehensive redevelopment strategy funded by the Learning and Skills Council. In 2009, the LSC withdrew the funds and the college was forced to reconsider its strategy with a majority self-funded project within a volatile and challenging marketplace. With assistance from Bond Bryan Architects, it devised a reduced scale development that, at its core, retained the original aims of embracing educational transformation within a flexible environment, while realising efficiencies in space utilisation and providing flexible-use spaces to accommodate changing learning methods.

The development is approximately 24,000 m sq with a construction cost of approximately £38m. This represents outstanding value for money. At the outset of the construction works, the team were challenged to save £2m of Value Engineering. Neither quality nor vision was diluted thanks to a strong team approach, with elements of the project being enhanced collaboration on value engineering. The exceptional quality and workmanship achieved by the subcontractors throughout is indicative of this process. Design concept Externally, the development draws upon the historic precedents set by the mill buildings situated within Bradford, while seeking to create an economic solution with locally sourced (Brighouse) natural sandstone. It pays homage to the textile industry of Bradford by replicating the concept of a fabric weave within the coloured segments of the elevations. This was created using a cladding system that allowed the builders to achieve water-tightness more quickly and was less labour intensive on site.

Internally, the scheme was viewed as a single entity collaborative space, surrounded by specialist teaching zones. This required a move away from traditional, teacher-led styles of delivery in smaller cellular classrooms, and into larger, more flexible spaces that offer a range of potential learning environments. Materials Inherent sustainability was a key component of the design and the supply chain was involved from an early stage. Lean construction workshops helped create efficiencies but also fostered an environment of

Collaborative: larger, more flexible spaces offer a range of potential learning environments

collaboration. The traditional concrete frame was re-designed as a post-tensioned solution saving a third off the concrete. This reduced the amount of deliveries to the site.

All timber used was from registered sustainable sources where possible, including the plywood hoardings that enclosed the site. These were used for shuttering the retaining walls in the external works scheme. Other systems of construction were chosen with sustainability in mind.

The Building Research Establishment carried out a pre-demolition audit on the existing buildings in order to identify opportunities for recycling or re-using materials. Some 98% of these buildings were identified as re-usable or recyclable. OpenBIM approach Since 2012, Bond Bryan Architects has focused on using open rather than native data, as they see it as an important part of their future and the future of the construction industry as a whole. Open data will lead to greater consistency and quality.

Producing consistent, high quality models and data for others to use has been the company focus for the past several years. The real implementation was driven by the Bradford College project. The aim was to demonstrate open workflows on a live project as well as to establish more consistent data deliverables for use by contractors, consultants and clients. Working with the contractor BAM Construct UK, Bond Bryan Architects immediately identified a number of issues with model exchange using the IFC open format. Within the firm, the central BIM team supported the project team to initially find temporary solutions to these issues. This was followed up with more detailed research to understand and finally resolve them.

The architects collaborated with BAM and other vendors to find permanent solutions. Centering the approach around IFC also influenced the firms’ development plan for COBie, the UK Government’s data deliverable from 2016.

“Given the plethora of software available, the most logical way to deliver this data is using IFC,” Bond Bryan Architects BIM manager and Associate Director Rob Jackson says. “Throughout the Bradford College project we discussed with BAM their data needs and began to understand how COBie could be integrated. This has resulted in us building in data as a standard deliverable for all new projects rather than an added extra.

“There is still some way to go to fully integrate but we continue to work with vendors to further integrate the remaining requirements. We are now delivering 60%-70% of the requirements of COBie due to our commitment to IFC, and this is allowing us to show others how they can benefit from our data.”

Bond Bryan Architects integrated the lessons learned from Bradford College into the model authoring tool templates. Their knowledge has led to Mr Jackson being asked to join the buildingSMART Technical Group and the AEC (UK) BIM Committee, which helps develop technology implementation guidance.

The extra effort also led to the team assisting Graphisoft in the development of a UK&I specific Archicad template released in 2014. This work not only benefitted this project, but had wider benefits for the industry by sharing the knowledge and feedback to vendors and ultimately resulting in improvements in software solutions.

In 2014, it became evident that once outputs were standardised, it was also necessary to find a way to ensure the data was correct.

In September 2014, the firm introduced Model Checking for new projects. This validation has been built around IFC (ISO 16739:2013), COBie-UK-2012 and the Riba Plan of Work 2013. The firm is now updating this to incorporate further with the requirements of BS 1192-4:2014. Visualisation of Bradford College Bond Bryan Architects’ models use Graphisoft Archicad as well as a variety of software to produce digital visualisations including Autodesk 3ds Max, Lumion, Graphisoft BIMx, Graphisoft Archicad, Abvent’s Artlantis, and Maxon Cinema 4D.

The original visuals were produced inhouse between March 2012 and June 2013, while the photographs were taken, also inhouse, in August 2014. The original models were produced in Graphisoft Archicad 15 and visualisations were produced in Autodesk 3ds Max. Client satisfaction The design team, client team and main contractor adopted a pro-active approach to the project that resulted in very few issues arising during construction. An additional project, Bradford College Advanced Technology Centre, was subsequently awarded to the same design and delivery team.

The college occupied the building in September 2014, and have reported reduced staffing costs, improved team working and student supervision along with improved student achievement levels.

The project was not only highlighted as an example for innovation in education space but also as a pathfinder project for BIM for the entire team.