Thermal system design and simulationeBook PDF

Visit to download the full and correct content document: https://ebooksecure.com/download/thermal-system-design-and-simulation-ebook-pdf/

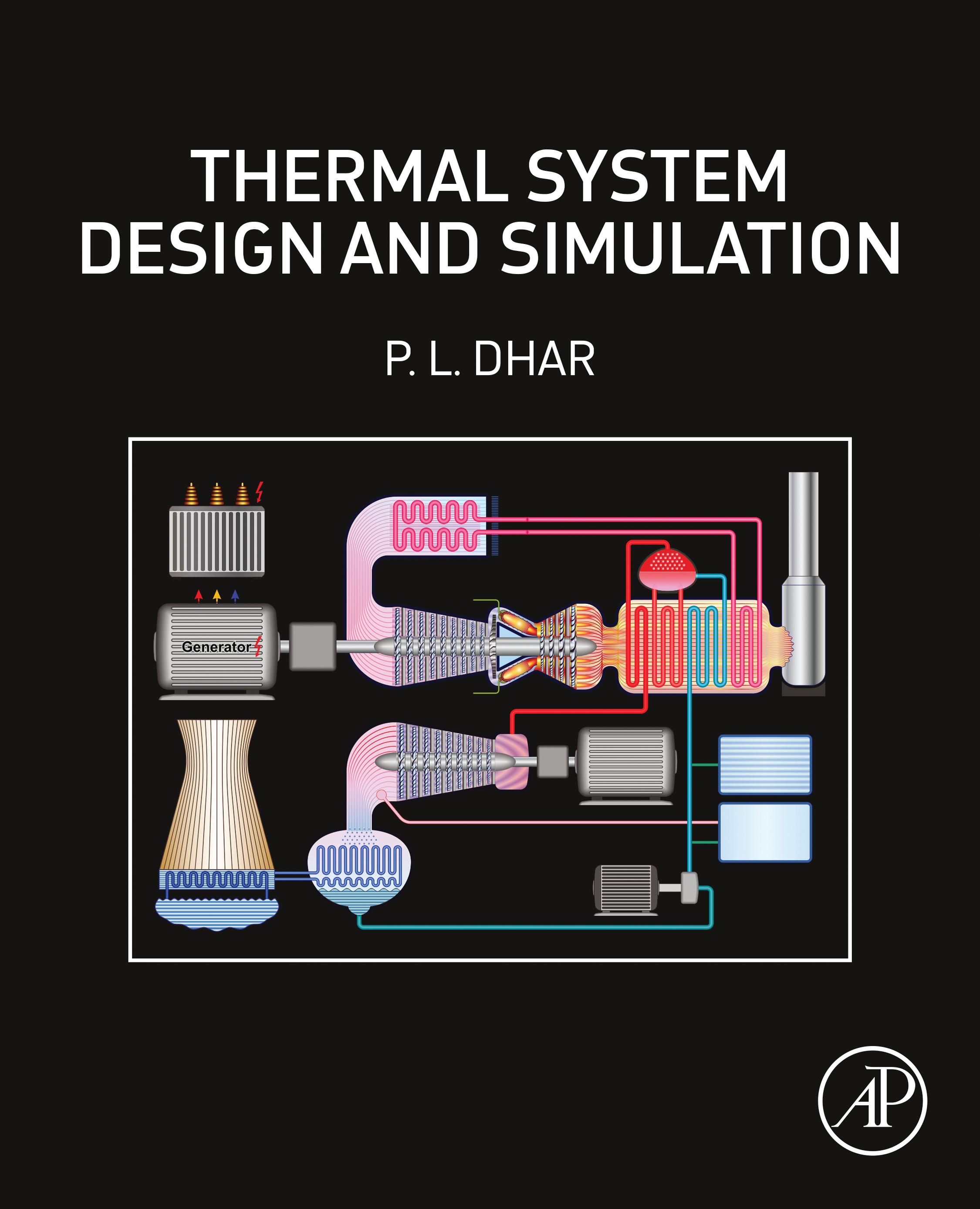

THERMALSYSTEM DESIGNAND SIMULATION

THERMALSYSTEM DESIGNAND SIMULATION

P.L.DHAR

AMSTERDAM • BOSTON • HEIDELBERG • LONDON

NEW YORK • OXFORD • PARIS • SAN DIEGO

SAN FRANCISCO • SINGAPORE • SYDNEY • TOKYO

Academic Press is an imprint of Elsevier

AcademicPressisanimprintofElsevier

50HampshireStreet,5thFloor,Cambridge,MA02139,UnitedStates

TheBoulevard,LangfordLane,Kidlington,OxfordOX51GB,UnitedKingdom ©2017ElsevierLtd.Allrightsreserved.

Nopartofthispublicationmaybereproducedortransmittedinanyformorbyanymeans,electronic ormechanical,includingphotocopying,recording,oranyinformationstorageandretrievalsystem, withoutpermissioninwritingfromthepublisher.Detailsonhowtoseekpermission,further informationaboutthePublisher’spermissionspoliciesandourarrangementswithorganizations suchastheCopyrightClearanceCenterandtheCopyrightLicensingAgency,canbefoundatour website: www.elsevier.com/permissions

ThisbookandtheindividualcontributionscontainedinitareprotectedundercopyrightbythePublisher (otherthanasmaybenotedherein).

Notices

Knowledgeandbestpracticeinthisfieldareconstantlychanging.Asnewresearchandexperiencebroaden ourunderstanding,changesinresearchmethods,professionalpractices,ormedicaltreatmentmaybecome necessary.

Practitionersandresearchersmustalwaysrelyontheirownexperienceandknowledgeinevaluatingand usinganyinformation,methods,compounds,orexperimentsdescribedherein.Inusingsuchinformation ormethodstheyshouldbemindfuloftheirownsafetyandthesafetyofothers,includingpartiesfor whomtheyhaveaprofessionalresponsibility.

Tothefullestextentofthelaw,neitherthePublishernortheauthors,contributors,oreditors,assumeany liabilityforanyinjuryand/ordamagetopersonsorpropertyasamatterofproductsliability,negligenceor otherwise,orfromanyuseoroperationofanymethods,products,instructions,orideascontainedinthe materialherein.

LibraryofCongressCataloging-in-PublicationData

AcatalogrecordforthisbookisavailablefromtheLibraryofCongress

BritishLibraryCataloguing-in-PublicationData

AcataloguerecordforthisbookisavailablefromtheBritishLibrary

ISBN978-0-12-809449-5

ForinformationonallAcademicPresspublications visitourwebsiteat https://www.elsevier.com/

AcquisitionEditor: LisaReading

EditorialProjectManager: MariaConvey

ProductionProjectManager: SusanLi

Designer: MarkRogers

TypesetbySPiGlobal,India

Themethodologyofdesignofengineeringsystemshas,overthelastthreedecades, undergoneamajorshift—fromanart,wheretheexperienceofthedesignerwasof paramountimportance,toasciencewithrigorousoptimizationprocedureschoosing thebestpossibledesignfromamongawidevarietyofdesignsgeneratedbyasoftware. Thermalsystems,becauseoftheircomplexity,badlyneededsuchatooltohelpthe designers.Thisbookdocumentstheproceduresthathavebeendevelopedoverthese yearstobringaboutthistransition.

Ihadtheprivilegeofintroducinganewcourse“ThermalSystemSimulationand Design”forpostgraduatestudentsofThermalEngineeringatIITDelhiabout25years ago.Itwasprimarilyasharingofmyownresearchwork,andofmyotherresearch studentsatIITDelhi.Graduallyasthecoursetookshape,itsscopewaswidenedbased onthefeedbackfromthestudents.Atthattimetherewasjustonebookavailableon thistopic,namely“DesignofThermalSystems”byProf.W.F.Stoecker.Thisexcellent bookwastherecommendedtextbookforthecourse.Asthecoursedevelopeditwas noticedthatmanyoftheconceptsthatwehaddeveloped,likeuseofinformationflow diagramstosimplifythesimulationprocedures,noveloptimizationmethodssuitable forthermalsystemsimulation,etc.,werenotadequatelycoveredinthisoreventhe othertext“DesignandOptimizationofThermalSystems”byProf.Y.Jaluria,which waspublishedin1998.Duringthecourseofourresearchworkwehaddevelopedthe detailedsimulationproceduresforvariousequipmentusedinrefrigerationsystems,in thermalpowerplants,andnoveldesiccant-basedcoolingsystems.Theonlyreferences availablewiththestudentsforstudyingtheseweretheoriginalresearchpapersorthe PhDthesesandtheresearchmonographon“ComputerSimulationandOptimization ofRefrigerationSystems”writtenbymeandmyformerresearchstudentDrG.R.Saraf. Assimilarcourseswereintroducedatmanyotherinstitutes,theneedaroseforanupto-datetextwhichincorporatedallthetopicsdiscussedinthesecourses.Thisbookis writteninresponsetothatneed.

Ihadgotthefeedbackthatmyearliermonographonrefrigerationsystemsdesign wasbeingreferredbythedesignersintheindustry,andsothepresentbookhasbeen writtenkeepingtheirneedsalsoinview.

Thebookhasbeenenrichedbythefeedbackofhundredsofstudents—manyofthem professionalengineersfromtheindustry—whotookthiscourse.Myformercolleagues Prof.M.R.RaviandProf.SangeetaKohli,whohavealsotaughtthecoursemanytimes overtheseyears,gavemanyvaluablesuggestions.Manythankstoallofthem!Thanks

arealsoduetoMr.HarshSharmawhopainstakinglytypedthefirstdraftofthebookin LaTeXsoftware.

Ihopethebookwillbeusefultoboththestudentsandthepracticingengineers interestedinthisexcitingfieldofgreatpracticalimportance.Anysuggestionsforits improvementwouldbegratefullyacknowledged.

P.L.Dhar

Introduction

Thedesignofthermalsystems—bethesepowerproducingsystems,likeathermal powerplant,orpowerabsorbingsystems,likeacentralair-conditioningplant—has traditionallybeencarriedoutusingthumbrulesbasedlargelyonexperience.Overthe years,consortiumsofexperiencedengineershavebeenformedbyreputedpublishers, aswellaswell-establishedprofessionalsocietieslikeASMEandASHRAE,toproduce authoritativehandbookstohelpdesignsafeandfunctionalsystems.Thesehandbooks givevaluableinformationonthelikelyrangeofvaluesofimportantdesignparameters, butthefinalchoiceofthevaluesofvariousdesignparametersforatypicalapplication stillrestswiththedesignengineer.Anyengineerwouldnaturallywishthathischoiceof designparametersshouldresultinan“optimumdesign”—thatwhichbestsatisfiesthe requirementofhisclients—beitminimizationofthecost,weight,orfloorarea,orthe maximizationoftheefficiency,coefficientofperformance,etc.Thisdemandsthatalarge numberofalternativedesignsbeobtainedandevaluatedwithrespecttotheoptimization criterion.Traditionallyeventoarriveataworkabledesignofathermalsystem,withits numerousinterconnectedcomponents,hasbeensuchalaborioustaskthatrarelyany attemptwasmadetoarriveatthe“optimumdesign.”Manycompaniesdidmodifytheir equipmentdesignsprogressively,onthebasisoftheperformanceofearliermodels,and thusslowlythedesignswereimprovedovermanygenerationsof“models.”However, overthelastthreedecades,thepossibilityofdoinghighspeedcomputationthrough desktopcomputershasmadecomputer-aideddesigncommerciallyviable.Thedesigners canthusaimatobtainingoptimumdesignsofthermalsystems.Increasingcompetition andrapidlyincreasingcostsofenergyhave,infact,madethistaskimperative.

Toappreciatethedifferencebetweena“feasibledesign”andthe“optimaldesign” letusconsiderasimple,commonlyencounteredproblem:designofaheatexchanger, say,forrecoveringwasteheatfromthefluegasesleavingadieselgenerator(DG)setto producesteamforuseinalaboratory.Thefirststepinthedesignprocesswouldbeto specifytheamount,thetemperature,andpressureofthesteamrequiredinthelaboratory. Letusassume,forthesakeofillustration,thatthelaboratoryrequires5kg/minofdry saturatedsteamatapressureof2bar.Knowingtheminimumtemperatureofwaterin winter,say10◦ C,wecancalculatetheamountofheattransferthatshouldoccurinthe heatexchanger.Themassflowrateandthetemperatureofthehotgasesexitingfrom ThermalSystemDesignandSimulation

Fig.1.1 FintubeheatexchangerforrecoveringheatfromDGsetexhaust.

theDGsetatthedesignconditionswouldbeknownfromitsperformancedata.Now, usingthisdataweneedtodesignasuitableheatexchangerforthisapplication.

Thefirststepindesignwouldbetochoosethetypeofheatexchanger,fromamong variouspossibilities[1].Thisisusuallydonebythedesignengineeronthebasisof hisexperience,keepinginviewvarioussystemicconstraints,likethetypeoffluids, theirfoulingpotentialandcleanability,thepermissiblepressuredrops,consequencesof leakage,etc.Inthiscase,say,wechoosetubefinheatexchangertominimizethepressure droponthegasside.Nextwehavetochoosethetubediameterandthefinheight.This isusuallydoneonthebasisofprevalent“goodindustrialpractices.”Supposewechoose tubesofbasediameter16mm,IDof14mm,withintegralfinsontheoutsideof 2mmheightspacedonthetubewithapitchof4mm.Wethenhavetodecideonthe configurationofthetubebank,thelongitudinalandlateralpitches, ST and SL ,andthe sizeoftheductthroughwhichthehotgaseswouldflow,asshownin Fig.1.1

Theseareagainchosenbasedonthepastexperiencewiththistypeofheatrecovery units.Thusthetwopitches ST and SL ,couldbechosen,typicallyas32and30mm, respectively.Thesizingoftheductwillhavetobedonetoensurethatthegasside velocityiswithinacceptablelimits1 andallthetubescanbeaccommodatedwithina reasonablelength.Wecouldchooseagasvelocityoverthetubebundle,sayof10m/s, anddesigntheexhaustgasductaccordingly.Wethenchoosea“reasonable”valueof velocityofwaterinthetubes,say1.5m/s(usuallywatervelocityislimitedto3m/sto minimizeerosion),anddecideonthenumberofthetubesneededinasinglepassofthe heatexchangertoachievetherequiredmassflowrateofwater.

Havingfixedthebasicconfigurationsandthecrucialdesignvariables,theheat transfercalculationscanbedone.Weestimatetheheattransfercoefficientofthegas

1 Ifitistoolow,thegassideheattransfercoefficientwouldbeverysmall,andifitistoohigh,thegasside pressuredropwouldbehighandthatwouldinfluencetheperformanceoftheICengineoftheDGset throughincreaseinitsexhaustpressure.

sideandthewatersidebyusingappropriatecorrelationsfromtheliterature;findthe overallheattransfercoefficientandtheeffectivemeantemperaturedifferencebetween thetwostreams,andthenestimatetheheattransferareaneeded.Thelengthofthe heatexchangertubescanthenbecalculated.Wethushaveafeasibledesignoftheheat exchangerwhichwilldelivertherequiredamountofsteam.

Itisobviousfromtheabovedescriptionofthedesignprocessthatwecouldhave obtainedmanyother“feasible”designsbychangingthevaluesofthevariablesliketube diameter,finpitch,finheight,velocityofwater,velocityofhotgases,longitudinaland lateralpitchesofthetubebundle,etc.,assumedaboveonthebasisof“goodindustrial practices.”Foreachchangeinthevalueofadesignvariable,adifferentdesignoftheheat exchangerwouldbeobtained.Wecouldthenchoosebetweenthembasedonasuitable optimizationcriterion.Theoptimizationcriterioncould,forexample,beminimization oftheinitialcost,orofthepressuredroponthegasside(sincethatwouldinfluencethe performanceoftheICengineoftheDGset)orasuitablecombinationofthetwo.Thus wecould,forexample,apportionacosttothesteamproducedandtothereductionin DGsetoutputcausedbygassidepressuredropintheheatexchanger,andcombine thesesuitablywiththeinitialcostoftheheatexchangertoevolveacompositefunction whichgivesthenetincreaseinprofitduringtheentireprojectedlifeoftheDGset, duetoincorporationoftheheatrecoverysystem.Theheatexchangerdesignwhich maximizesthisprofitcouldbechosenasthe“optimumdesign.”Anotherapproach couldbetoconstrainthepressuredroponthegassidetobelessthanaspecifiedvalue andthenminimizetheinitialcostoftheheatexchanger;yetanotherapproachbeingto maximizethesecondlawefficiencyoftheheatexchanger.

Now,sincethenumberofpossiblefeasibledesignsisextremelylarge,weneedto devisesuitablestrategytonarrowdownthesearchdomaininconsonancewiththe chosenobjectivetoarriveatthe“optimumdesign”withminimumcomputational effort.Thisnecessitatesuseofmathematical/numericaloptimizationtechniquesto generatealternativedesignswhicharelikelytobe“better”thantheinitialdesign. Further,toassesswhetherthedesignsso“generated”arefeasible,weneedaprocedure todeterminetheperformanceofthesystembasedonsuchadesign.Thisrequires computer-basedsystemsimulationprocedures.Systemsimulation,inturn,needscomprehensiveprocedurestopredicttheperformanceofeachcomponentofthesystemand amethodologytointegratetheseproceduresintunewiththeiractualinterconnection inthesystem.Thusacomprehensivecomputerprogramtoobtainoptimaldesignofa thermalsystemwouldessentiallybeanoptimizationalgorithmtomaximize/minimize theobjectivefunctionsubjecttotheconstraintsthatitprovidestherequiredthermal performance2 withoutcompromisingonothernonthermalperformancemeasureslike 2

Whichispredictedwiththehelpofthesystemsimulationprogram.

longlife,safety,permissiblewearandtear,noise,etc.3

Moreoftenthannot,the optimizationalgorithmisasearchproceduretogenerateprogressively“better”designs, whichneedtobecheckedforfeasibilitybyusingthesystemsimulationprocedure.

Thesystemsimulationproceduresarealsoquiteusefulintheirownright.They enableustoassesstheinfluenceofvariousoperatingparametersontheperformance ofthesystemoritscomponentswithoutactuallyconductinglaboratorytestswhich areoftenveryexpensiveandtimeconsuming.Wecanthusdoasensitivityanalysisto identifytherelativeinfluenceofvariouscomponentsand/ortheoperatingconditions ontheoverallsystemperformance.Mostthermalsystemsrarelyoperateonthedesign conditions,andthesystemsimulationprocedurescanhelpuspredicttheir“off-design” performance.Thisisoftenofgreathelpindesigningsuitablecontrolstrategiestoensure safeand“optimal”operationevenunderoff-designoperatingconditions.

1.1OUTLINEOFTHEBOOK

Asindicatedbythetitleofthebook,itsfocusisonsimulationanddesignofthermal systems.Bytheterm“system”weimplyacollectionofcomponentswithinterrelated performance,andby“simulation”wemeanpredictingtheperformanceofasystemfor agivensetofinputconditions.Thermalsystemsgenerallyinvolvetransferofheatand work,oftenthroughfluidsmovingthroughvariouscomponents.Thusanalysisofthe performanceofthermalsystemsdemandsathroughknowledgeofthefundamentalsof thermodynamics,heatandmasstransfer,andfluidmechanics.Weshallreviewthesevery brieflyin Chapter3.

Mostoftheequipmentsusedinathermalsysteminvolveheatandmasstransfer. Forsuchheat/massexchangersitisoftenpossibletodevelopdetailedmodelsof processsimulation.However,forsomeimportantequipmentlikemultistageturbines andcompressors,detailedthermofluidmodelingisextremelycomplicated.Often,while simulatingthermalsystemsusingsuchturbomachines,andotherequipmentswhere processmodelswouldbetoocumbersometoincorporateinthesystemsimulation program,theperformancecurvesofsuchequipmentsaretakenfromthemanufacturer’s catalogs,andconvertedintoequationsforeaseofuseinthecomputerprograms.We alsoneedtofitsuitableequationsintothethermodynamicpropertydata.Equation fittingisusuallydoneusingthe“leastsquarestechnique.”Theartandscience(or rathermathematics!)offittingequationsintodataarediscussedin Chapter2,along withothermathematicaltechniquesneededinthermalsystemsimulation.Theseinclude commonlyusedmethodsforsolutionofsimultaneousalgebraicequations(bothlinear andnonlinear)anddifferentialequations,basicconceptsofLaplacetransformation,etc. Abriefdiscussiononengineeringeconomicsisalsoincludedinthischapter,focusing

3 Thesenonthermalconsiderationsareoftenincorporatedthroughconstraintsonvariables,seealso Chapter11

mainlyonthebasicprinciplesofconvertingcomplexoptimizationobjectives4 into financialterms.

Thedetailedprocessmodelsoftypicalequipmentusedinthermalsystemslike heatandmassexchangers,varioustypesofcompressors,gasifier,etc.,arepresentedin Chapter4.Mostthermalsystemsuseatmosphereasaheatsourceorasink.Sincethe environmentalconditions(liketemperature,humiditycontent,solarradiationintensity, etc.)areinherentlyuncertain,andcanonlybepredictedwithcertainprobabilities, arigorousstudyoftheperformanceofthermalsystemsshouldincorporatethis probabilisticdescription.Suchanapproachistermedasstochasticsimulation,andshall beonlybrieflydiscussedinthelastchapterofthebook.In Chapter4 thefocusis ondeterministicsimulation,whereitisassumedthattheinputvariablesareprecisely specified.Further,thoughthefocusofthebookisprimarilyonthermalsystemslike powerproducingsystems(ICengines,steampowerplants,etc.)andcoldproducing systems(likerefrigerationandair-conditioningequipment),inthischapterwehavealso illustratedtheapplicationofbasiclawsofthermodynamicsandheat-masstransferto developprocessmodelsforotherapplicationsinvolvingtransferofheatandmasslike coolingofelectronicequipment,manufacturingprocesses,heattreatment,dehydration offoods,etc.

Systemsimulationinvolvesintegrationofthemodels/equationsforpredictingthe performanceofvariouscomponentsintoacomprehensiveprocedurewhichensures thatvariousconservationequations(likethoseformass,momentum,andenergy conservation)aresatisfied.Fromamathematicalperspectivesystemsimulationinvolves solutionofsimultaneous“equations,”mostlynonlinear,representingtheperformance ofitscomponents.Manyatimesthese“equations”areactuallydetailedprocess modelsoftheequipmentwhereinvariousvariablesareintricatelyrelated,usually throughdifferentialequations.Toevolveasuitablesystemsimulationstrategy,the componentsimulationmodelsarerepresentedintheformofinformationflowdiagrams whichindicatetheminimuminputvariablesnecessarytoobtainthedesiredoutput information.Bysuitablychoosingtheinputandoutputvariables,andcombining theseinformationflowdiagramsjudiciously,itispossibletoevolvestrategieswhich significantlyreducethecomputationaleffortforsystemsimulation.Theconceptof informationflowdiagramanditsutilityinsystemsimulationarediscussedin Chapter5. Afewcomprehensivecasestudiesofsomecommonthermalsystems,illustratingtheuse ofalltheseconceptsarepresentedin Chapter6

Themainfocusofthebookisonoptimumdesignofthermalsystems.Asdiscussed brieflyabove,theobjectivesofoptimumdesign,theconstraintsandthedesignvariables, canallvarydependinguponthespecificrequirementsofthesituationandthe designer’spreferences.Thus,forexample,theobjectivefunctioncouldbeeconomic,like

4 Likeminimizationofthetotalcostofaplanttakingintoaccountboththeinitialcapitalcostandthe runningcostspreadoveritsentirelifetime.