Solid start to Fonterra’s financial year. PAGE 5

ADAPTING, EVOLVING

Return to spring calving. Page 12

STACK IT UP Eltham cheese’s big move Page 6

Solid start to Fonterra’s financial year. PAGE 5

Return to spring calving. Page 12

STACK IT UP Eltham cheese’s big move Page 6

Whakatane farmer Gerard Van Beek’s 20-year crusade for lactose payment pays off. PAGE 4

SUDESH KISSUN

sudeshk@ruralnews

SUDESH KISSUN

FOR OVER 20 years, Whakatane farmer

Gerard Van Beek has been attending Fonterra annual general meetings with the same message – it’s time to include lactose into the co-op’s farmgate milk price model.

His persistence is paying off with Fonterra announcing that from 1 June 2026, its milk price payments to farmers will start to be split into fat, protein and lactose rather than just the current fat and protein.

Van Beek told Dairy News that he was relieved that a lactose payment will be introduced in the new season.

“I thank Fonterra staff who prepared the first principles financial model used in this milk payout evaluation cycle.

“They were able to break away from the existing model dominated by a historic genetics’ paradigm centred on milk fat and protein rather that trueful valuation of all milk components.”

A Fonterra spokesman told Dairy News that the addition of lactose from the 2026-27 season is about fine tuning the framework that’s used to distribute the farmgate milk price so that it’s more precise and fairer in terms of recognising

the underlying value of the different components of milk supplied to the co-op.

About 85% of milk is composed of water. Approximately 5% is lactose, with fat constituting approximately 5% and protein about 4%. The rest is minerals and vitamins. These percentages are based off co-op averages over recent seasons.

He says the variability of lactose content across different milk profiles is relatively limited, and this tight range makes it the least variable of all the solids within milk.

“Because of the limited variability of lactose across milk profiles, for the vast majority of farms there will only be a small impact or no impact from this change.”

Preparing for the inclusion of lactose in the milk payment, New Zealand Animal Evaluation has amended economic values (EVs) as part of the December 2025 Animal Evaluation run, ensuring the breeding worth (BW) index continues to reflect current farm conditions and milk payment structures.

Each year, the EVs that underpin BW are reviewed to ensure they capture the latest on-farm costs and returns New Zealand dairy farmers face. The updates, which went live last week, help maintain

the accuracy and relevance of BW – the index used to rank cows and bulls on their ability to breed efficient and profitable replacements.

NZ Animal Evaluation Manager Andrew Fear says the annual update process keeps BW aligned with changing market realities.

“Breeding Worth is a vital tool for farmers, providing an independent measure of genetic merit that links directly to farm profit. These annual updates ensure it remains current and

Whakatane farmer Gerard Van

has been pushing for a payment for the lactose component in milk for over 20 years.

GERARD VAN Beek says that in 1980 the New Zealand Dairy Board coined the term milksolids which incapsulated milk fat and protein.

He says this formed the basis of the ‘A+B-C milk payout’ model that has been used by most dairy companies ever since.

When the current Breeding Worth model was introduced in 1996, it calculated the efficiency of farmers converting feed energy to farmer profit.

“Because lactose did not form part of the payout model, it was determined that it had no economic value at the farm gate,” he says.

“This led to lactose feed energy being lumped in with the volume economic value. This ignored that lactose revenue was lumped in with the protein payout value. This led to a gross under allocation of feed energy to the overvalued protein economic value and a massive penalty in volume economic value.

In 1999 the CODEX for the manufacture of milk powders changed and allowed milksolids (lactose and minerals) to be added to the solids, not fat part and standardise the protein content to 34%.

“This shifted lactose from a waste product into a valuable ingredient that effectively has the same value as milkfat or protein in Fonterra’s reference basket of commodity products.

“An analysis of the composition of Fonterra’s reference commodity products shows that lactose and minerals make up 43% the mass of product sold.”

robust, helping farmers make confident, futurefocused breeding decisions,” says Fear.

“For farmers, these updates ensure that the BW rankings they use to guide breeding are grounded in the most up-to-date economic conditions and milk payment structures. This helps with herd profitability, resilience and efficiency, as the market evolves.”

Fonterra strategic

advisor Malcolm Ellis says the co-operative’s decision to add lactose into the framework that’s used to distribute the Farmgate Milk Price is about recognition of value.

“The value assigned to each component of milk is largely driven by supply and demand dynamics, with fat and protein continuing to contribute the vast majority of a farmer’s milk revenue,” says Ellis.

FONTERRA SAYS the planned addition of a payment for the lactose component of milk from next season is not intended to encourage the production of milk with higher or lower lactose content.

While it is acknowledged that lactose has a value, fat and protein continue to contribute the vast majority of a farm’s milk revenue, the co-op says.

“Fat and protein should remain the

“Lactose also has a value, and Fonterra is fine tuning its parameters from the 2026/27 season to reflect this – where milk price payments will start to be split into fat, protein and lactose. For most farms, there will only be a small impact or no impact from this change due to the limited variability of lactose across milk profiles.”

@rural_news

facebook.com/ruralnews

key focus for farmers as they have the biggest impact in terms of generating improved farmer returns.”

It says preparations for the introduction of a lactose parameter from the 2026/27 season are ongoing.

Further information, including how the value is to be applied, will be shared with farmers in advance of next season.

PETER BURKE peterb@ruralnews.co.nz

GOVERNMENT PLANS to get rid of regional councillors shows a lack of understanding of the fundamental problem affecting all of local government – poor governance.

This from newly elected Waikato Regional Council member and former Federated Farmers provincial president Keith Holmes. He says unless government deals properly with the

governance issue, any move forward will simply be a case of rearranging the deck chairs. He says what’s come out in the past week is a Trump-like disruptive event and is based on the hope that something good will happen.

“But getting a better system of governance is at the heart of the problem,” Holmes told Dairy News

“The way we elect our governors /councillors is flawed because what happens is you get a mix of singleissue people and dreamers and few pragmatists there. The single-issue

KEITH HOLMES says everyone is touting the concept of unitary authorities (UAs) as a replacement for regional councils. But he says such a move would need to be handled carefully to ensure that, in places such as the Waikato and Canterbury, the cities don’t dominate the decision-making process if the voting rights are based on a population basis.

“For example, in the Waikato region, Hamilton City could absolutely dominate our region, yet these people have no idea of what’s happening in Tokoroa or Waitomo or places like that. So, the structuring of unitary authorities must be done in a way as to give plenty of room for issues to be dealt with at a

people and the dreamers have no understanding of the key ingredients of governance, which is taking a holistic and regional approach to decision making. A lot of people just don’t have enough experience to do that,” he says.

Holmes says the single most important thing that government must do is to get the governance of councils right.

The other problem he identifies is the staff of regional councils. He says many are out of control and that a totally risk-averse attitude has been

local level, in a sensible manner,” he says.

Holmes says any splitting up of existing regional councils into UAs has to be done very carefully, sensibly and sensitively. Finally, he questions whether handing oversight of regional council functions to district and city mayors will work.

“The poor mayors are already under pressure and haven’t got the time or the ability to provide oversight on what is a regional requirement, as opposed to a local requirement, because each little community has enough of its own problems to deal with. Giving them this task is too big an ask,” he says.

FONTERRA’S 2025/26 financial year is off to a strong start, with a first quarter group profit after tax of $278 million- up $15m on the previous year.

When excluding the costs associated with the consumer business divestment, Fonterra’s normalised earnings per share are 18 cents, up slightly on last year, according to its first quarter results released last week.

Chief executive Miles Hurrell says

continuing operations delivered a profit after tax of $158 million, equivalent to 9 cents per share, slightly down on the same period last year reflecting differences in sales phasing.

“We maintain our full year earnings range for continuing operations of 45-65 cents per share,” says Hurrell.

The co-op continues to make good progress on implementing its strategy, to grow value as a global business-tobusiness (B2B) dairy provider.

built up in councils, whereby few senior staff take responsibility for their actions and bring in lawyers and consultants to cement this process. At the same time, Holmes believes this has led to a build-up in the bureaucracy and a rise in staff numbers.

“There is no ruthlessness and no incentive to trim costs in local government because they can just

put up the rates. If I was chair of the regional council, I’d tell the staff to make the decision – no more consultants – no more peer reviews.

“Make one mistake, okay, we will live with that, but make two and you’re gone, and suddenly you have changed the whole culture of local government behaviour because these people would own the decisions,” he says.

In October, farmer shareholders voted to approve the divestment of Mainland Group to Lactalis for $4.22 billion.

“This is a significant milestone and we’ve received a strong mandate from farmer shareholders on our strategy,” says Hurrell.

“We are firmly focused on delivering the commitments we’ve made, not least our target to lift earnings back to FY25 levels by

FY28, offsetting the impact of the divestment of Mainland Group.

“To support this goal, we are progressing with plans to invest up to $1 billion over the next three to four years in projects to generate further value and drive operational efficiencies,” he says.

In September, Fonterra announced a $75 million expansion of butter production at its Clandeboye site to help meet growing global demand and

improve product mix. Construction is nearing completion on the $75 million investment in the Studholme protein hub, with the first products expected in early 2026 and construction continues on the $150 million investment in a new UHT cream plant at Edendale, which is expected to be complete in the second half of 2026.

“We look forward to sharing further progress updates during the year,” says Hurrell.

WEDNESDAY 18th & THURSDAY 19th FEBRUARY 2026

8.30am - 3pm BEDFORD

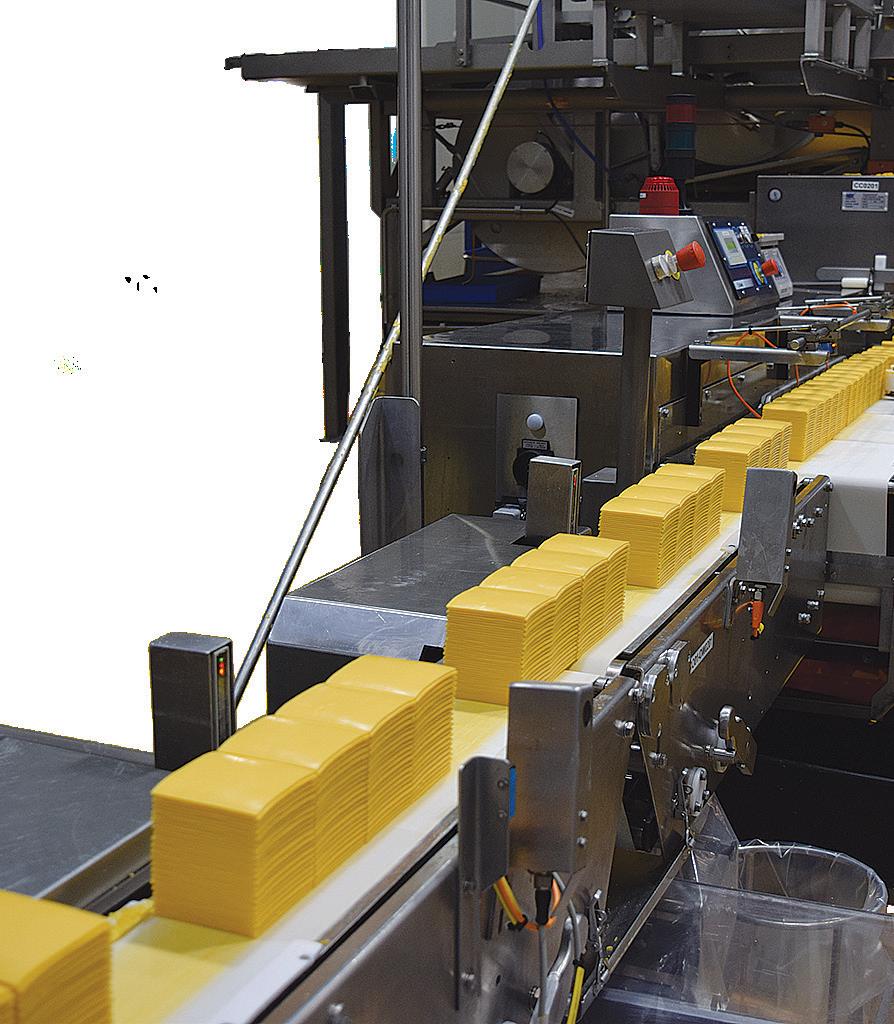

FONTERRA’S ELTHAM site in Taranaki is stepping up its global impact with an upgrade to its processed cheese production lines, boosting capacity to meet growing international demand.

The co-op says the investment is part of its strategy to scale up for long-term growth, make the best use of farmers’ milk, and focus on highvalue applications in foodservice. It says it also reflects the co-op’s commitment to strong partnerships with global customers like McDonald’s, and delivering consistent, high-quality dairy products to consumers around the world.

The site’s processed

“It’s not every day you see three slices of our cheese in one burger – it’s a great showcase of the skill and care that goes into what we do here in Eltham.”

cheese is now featured in McDonald’s newest burger – the Big Arch – which launched in Australia on 16 July and in New Zealand on 22 October, following earlier rollouts in Europe

and the US. The burger includes three slices of Eltham’s cheddar cheese.

Kelvin Gray, operations manager at Eltham, says the team is proud to see their product showcased in such a high-profile way.

“It’s not every day you see three slices of our cheese in one burger – it’s a great showcase of the skill and care that goes into what we do here in Eltham. Knowing that our work in Taranaki is being enjoyed by consumers around the world is incredibly rewarding.”

The Eltham site has been producing cheese for McDonald’s for decades, and today its white cheddar slices are used in McDonald’s restaurants across

Asia Pacific. This year, Fonterra has supplied millions of kilograms of cheese and other dairy products to McDonald’s, with New Zealand’s 170+ McDonald’s restaurants accounting for approximately 1.7 million kilograms.

Every batch of cheese undergoes around 100 rigorous quality tests to ensure it meets McDonald’s standards for taste and consistency – whether served in New Zealand, China or the Philippines. Last year, Fonterra was also awarded the McDonald’s ANZ Supplier Quality Management System Excellence Gold Award for scoring an A-grade for more than five consecutive years.

ANNOUNCED IN August 2025, Eltham is upgrading its processed cheese lines to increase capacity for slice-on-slice (SOS) cheese, in response to growing demand from global customers like McDonald’s. The upgraded Individually Wrapped Slice line will see a new grinder (the machine that grinds up cheese prior to it being cooked), new blender and new cooker. Alongside this, two new cheese grinders are being installed on each of the SOS lines. The upgrade and installations are running on track, with commissioning of the lines scheduled for February 2026.

The site also continues to scale up its operations to meet rising global demand for Individually Quick Frozen Mozzarella (IQF). This will see an increase of

approximately 7,000 metric tons in volume for the site once operational in June 2026. This expansion will enable the co-op to supply enough cheese for more than 40 million pizzas annually, reinforcing cheese as a key category in Fonterra’s high-value Foodservice channel.

Eltham’s cheese production is deeply connected to New Zealand’s dairy farming community. Milk from local farms is transformed into cheese that ends up in billions of meals globally.

With around 400 employees, Eltham is one of South Taranaki’s largest employers. Its expertise in processed cheese continues to evolve, helping shape the taste of global foodservice – one slice at a time.

THE FONTERRA divestment capital return should provide “a tailwind to GDP growth” next year, according to a new ANZ NZ report, but it’s not “manna from heaven” for the economy.

Writing in the latest ANZ NZ Agri Insight report, economists Matt Dilly and Matthew Galt said the $3.2b return, subject to regulatory approval, will be equal to about 0.7% of New Zealand’s GDP, averaging about $400,000 for each of Fonterra’s 8162 shareholders.

“The capital return will provide a tailwind to GDP growth through 2026,” the report says, “however, the boost to GDP is likely to be considerably smaller than 0.7% of GDP as only the portion spent domestically will add

directly to GDP.

“As such, the return is one tailwind to growth among a wider mix of tailwinds and headwinds and doesn’t change our view that GDP growth will pick up from 0.3% annual average growth in 2025 to a more robust 2.6% annual average growth in 2026.”

About 78% of New Zealand’s dairy farmers are Fonterra shareholders, and the report called the capital return “the icing on top of an already sweet farmgate milk price” for the year.

Discussing how farmers will likely spend their funds, the authors said “it will of course vary from farmer-to-farmer based on their personal circumstances”.

“Some combination of debt reduction, on-farm investment, off-

farm investment, and consumption are the main possibilities.

“With the special dividend coming on top of an already favourable backdrop for dairy farmers, some are likely to loosen the purse strings on household spending, whether that be an overdue holiday, home improvements, a new car, or just regular day-to-day spending.”

ANZ NZ’s managing director for business and agri Lorraine Mapu said the bank would be supporting farmers’ ambitions and plans, and that it’s important they take the time to consider what’s right for their business.

“Your proceeds, your plan – that’s our message,” Mapu said.

“We’re here to back what’s right for each

farm, whether that’s restructuring lending, investing in growth, or simply holding on to the funds.

“There’s no one-sizefits-all approach. Some may look to reduce

debt, others might invest in productivity or sustainability, and some may choose to hold a cash buffer for seasonal needs.

“For a small group of customers, repaying debt

will be the most sensible choice and we will be transparent about any such needs and why.” Mapu also noted some farmers may choose to use the funds outside their farming operations, including for family succession or other investments.

“This is a rare opportunity for shareholders to take stock and plan ahead with confidence,” she said.

layers of bureaucracy, but he adds that it will be some time before there is clarity around what the changes will look like.

FARMERS APPEAR to be cautiously welcoming the Government’s plan to reform local government, according to Ag First chief executive, James Allen.

He says, at a high level, most farmers seem to be comfortable with simplifying the burden of multiple

He says while regional councillors may disappear, the functions performed the regional councils won’t go away.

“At the end of the day, regional councils have a role to play in managing a whole lot of things, including environment, and that role

won’t go away,” he says.

Meanwhile, Allen says overall dairy production around the country is going well. He says the North Island is pretty good, with just a red flag around Hawke’s Bay which is experiencing very dry conditions.

“But in reality, there are not many dairy farmers in that area,” he says.

Allen says the storms in Southland did cause problems but overall the impact of these will not have a

massive effect on total production.

He adds however that some of the farms around Hurunui in Canterbury will have problems given the damage to their large irrigators.

“There will be isolated farms that will be severely impacted but it’s going to come down to the individual farm rather than total NZ dairy production,” he says.

Allen says the mood of most dairy farmers is still positive. He

says the drop in the milk price was not unexpected, most people saw it coming, so it came as no great surprise. He says overall farmers are in a good frame of mind and he notes that in the Waikato there’s been some good rain, so pasture growth rates are pretty good and so is the quality of the grass.

“What we are seeing is that a bit more late silage is being made, which is good sign,” he says.

• Ideal for Cattle Troughs

• High Flow

• Side/Bottom Mount

• Detach to Clean

• Compact/Robust

• Up to 50mm Inlet

• Flows up to 600L/min

• For Storage Tanks

• Easy Access to Valve

• Inlets Upto 50mm

• Avoids Starting & Stopping of Pump When Tank is Filling

PRIME MINISTER Christoher Luxon has been on a charm offensive with farmers.

Last week, he held several meetings with farmers – one in Hawke’s Bay and one in Waikato.

With a general election less than 12 months away, the fight for the rural vote is underway. Milking It understands in some parts of the country - like Southland – National is facing intense competition from none other than its two coalition partners – ACT and NZ First.

THE RURAL sector is set to receive some good news from the Government this week.

Details on a replacement for the Resource Management Act (RMA) will be released to the media this week.

Milking It understands a major announcement on consents and how they are handled by regional councils are also on the cards.

Farmers are unhappy with unnecessary cost, uncertainty and red tape required just to renew their existing resource consents, especially the need to spend hundreds of thousands of dollars on a piece of paper that may not be needed once the RMA is rewritten.

Tanker on the roll

SEEN A giant cheese roll rolling along Southland’s roads?

You aren’t seeing things: in fact, it’s just an Open Country milk tanker that’s had a tasty makeover.

The makeover is the brainchild of Brett Hamilton, the general manager for transport at Open Country’s Awarua depot.

Open Country then turned to the award-winning team at Invercargill’s Creation Signs, who worked on it “all day, all week” to get the cheese roll, also known as ‘Southland Sushi’, tanker finished.

PRESIDENT DONALD Trump’s decision to impose tariffs on imports into the US is doing good things for global trade, according to Agriculture and Trade Minister Todd McClay.

Speaking last week at the US/NZ Business Summit in Auckland, he says Trump’s approach has prompter other countries to start negotiating trade deals with each other.

“Countries are coming together to try to create certainty for their businesses and try new deals and we’re starting to see that this is a direct result of President Trump’s trade policy.”

“There are more trade deals being negotiated in the world at the moment than I can think of at any time before. Jump forward five or ten years, the world is likely to almost be a more certain place because we’re having more trade agreements.”

Head Office: Lower Ground Floor, 29 Northcroft St, Takapuna, Auckland 0622

Phone 09-307 0399.

Postal Address: PO Box 331100, Takapuna, Auckland 0740

Published by: Rural News Group

Printed by: Inkwise NZ Ltd

Contacts: Editorial: sudeshk@ruralnews.co.nz

Advertising material: beckyw@ruralnews.co.nz

Rural News on-line: www.ruralnews.co.nz

Subscriptions: subsrndn@ruralnews.co.nz

Publisher: Brian Hight ......................Ph 09-307 0399

General Manager: Adam Fricker ...................Ph 021-842 226

Editor: Sudesh Kissun ................Ph 021-963 177

Machinery

Editor: Mark Daniel......................Ph 021-906 723 markd@ruralnews.co.nz

Reporters: Peter Burke.....................Ph 021-224 2184 peterb@ruralnews.co.nz

Subscriptions: Julie Beech ....................Ph 021-190 3144

Production Manager: Becky Williams ..............Ph 021-100 4831

Digital Strategist: Jessica Marshall ..........Ph 021 0232 6446

JUST WHAT falls out of the coalition’s plan to reform local government and environment law is anyone’s guess.

The objective of simplifying the regulations, consenting process and reducing the bureaucracy and rates will strike a chord with most people. At the same time, there is an understandable cautiousness about giving the Government a blanket endorsement for their plans.

Let’s ignore the RMA at this stage as that change has been well signalled.

The idea of getting rid of regional councillors and giving mayors the task of coming up with a new structure for local government is ‘interesting’ to say the least. Why aren’t the chairs of regional councils included with the mayors to at least provide a regional perspective? Former Federated Farmers Waikato president and Waikato Regional Council member Keith Holmes is right when he says the mayors don’t necessarily have all the knowledge and skills, or the time, to take the step up to sorting our regional governance.

He makes the point that the structure of regional councils is basically fine, but it’s the governance that is flawed. That too many councillors lack the skills to control staff who often run their own agendas but who are also hampered by poor, imprecise lawmaking and tasks imposed on them by central government. The same incidentally also applies in Territorial Local Authorities where the governance is often well below par.

Giving the country’s mayors the task of reforming local government is a ‘courageous’ move by ministers Chris Bishop and Simon Watts. Will the well-meaning mayors have the skills and fortitude to override the guidance of another bunch of Sir Humphries who will no doubt be appointed to ‘help’ them in their deliberations? The reality is that the mantra of bureaucrats, councillors and all politicians is self-preservation. Hiring the writers and producers of ‘Yes, Prime Minister’ to undertake the review should not be discounted as an option.

- Peter Burke

AUCKLAND SALES CONTACT: Stephen Pollard .............................................Ph 021-963 166 stephenp@ruralnews.co.nz

WAIKATO & WELLINGTON SALES CONTACT: Lisa Wise ........................................................Ph 027-369 9218 lisaw@ruralnews.co.nz

SOUTH ISLAND SALES REPRESENTATIVE: Kaye Sutherland .........................................Ph 021-221 1994 kayes@ruralnews.co.nz

TRACY BROWN

LAST WEEK marked a major step forward in our work to eradicate Mycoplasma bovis.

Spring bulk tank milk testing across the country has found no sign of M. bovis and no new infections have been detected for two years.

This is a significant milestone and one worth celebrating.

We now enter the very final phase of the eradication programme called ‘confidence of absence.’

with a stronger and more resilient biosecurity system.

DairyNZ stood alongside farmers during this time and established the DairyNZ Beef + Lamb New Zealand Compensation Assistance Team (DBCAT) to help farmers prepare claims and speed up the compensation process.

During the past seven years, a total of 3,324

DairyNZ Board is proud of, and I know gave a lot of farmers peace of mind during a tough time.

While it’s great to see us move closer to eradication, we’re not there yet.

continue to drop and so will the levies farmers pay.

Letting our guard down now could undo all the hard work and sacrifices made.

Another way farmers can support this work is by keeping their NAIT records up to date.

receiving raw milk keep clear records.

These are just some simple things farmers can do to keep their farms disease-free.

I encourage farmers to continue supporting this important programme – including by enabling testing on farm if required.

It’s vital for stopping disease spread so register your farm, register and tag your animals, and record movements offfarm within 48 hours.

M. bovis can also spread through raw milk so if you’re moving or

The last seven years has been challenging for farmers who have faced significant disruptions to their business and made huge sacrifices to protect the wider sector.

M. bovis claims, with a total value of $290.37 million have been paid in compensation.

Without the collective effort of dairy farmers and other sector stakeholders, we wouldn’t be where we are today-

1370 farmers with more than 2310 claims valuing $161 million have used the free DBCAT service.

That’s something the

It’s important we keep our foot on the pedal. We need another couple of years of testing to be confident M. bovis has gone from the national herd, and to declare eradication.

The new phase will see some small changes for farmers. Movement controls won’t be routinely used when investigating bulk tank milk detect results.

And the cost of the Programme will also

THE MYCOPLASMA bovis eradication programme is a 10-year, $870 million collaboration between the Government and industry partners DairyNZ and Beef + Lamb New Zealand.

Allowing the disease to become endemic would have cost $1.3 billion in lost

Achieving a worldfirst eradication is within reach—and it’s all possible because of our farmers.

• Tracy Brown is chair of DairyNZ.

production in the first ten years alone and continued to burden the sector into the future.

The last transmission of M. bovis in cattle was on 7 September 2023 and the programme remains on track to achieve eradication by June 2028.

ago, as a

Snow

realised he was bucking a trend when he started planting trees to provide shade for his cows, but he knew the animals would appreciate what he was doing.

“Cows suffer heat stress in summer which affects milk yield –sometimes as much as providing four litres less on a very hot day,” says Chubb.

“So, it was just common sense. Whether you’re a human or a dog or a horse or a cow, it’s the same thing. You don’t like to be standing in the paddock in the middle of summer with no shade.”

Snow says the decision paid itself off “in spades”. His cows were producing between 400 and 440 kgMS with a grass-based farming system, with hay silage and a bit of grain in the spring.

“Because my cows always had shade, they used to just waltz through the summer.”

The decision was also a key reason he scooped the inaugural Waikato Environmental Award, the forerunner of today’s Ballance Farm Environment Awards.

The awards were mooted in 1991 by Waikato farmer and chair of the Waikato Conservation Board, the late Gordon Stephenson, as a way to celebrate farmers who were demonstrating excellence in sustainable land management and environmental stewardship. In the first year of the awards, 40 Waikato farmers entered and Snow impressed the judges with his planting of deciduous trees for his 80-strong herd of cows and his awareness of the importance of water quality.

“I’ve always had an appreciation for water. It’s the first building block of everything because without water you’ve got nothing.

“It made sense to me way back then to use

“I’ve always had an appreciation for water. It’s the first building block of everything because without water you’ve got nothing.”

biological-type fertiliser so we weren’t degrading our water quality.”

Snow started sharemilking on his parents’ farm, which he eventually took over from them.

“I was always curious about utilising the land the best way I could. The farm was in terraces so mostly easy farming, but there were gullies that were a natural fit to being planted with natives or production species.”

Snow and his wife Sue planted nearly 3500 trees on the property, a mix of commercial varieties such as pine, blackwoods and

lusicanita, which were planted east to west so they would cast shade on themselves and not the grass, and deciduous trees, which were facing the other direction so in winter when they lost their leaves, it stopped the hard frost from staying on the ground.

“Entering the awards was such a great experience because I was actually relieved to have people say, yep, what you are doing does make sense.

“The neighbours thought I was a bit abnormal, so it was good to get positive reinforcement from all the different judges that I was doing the right thing.”

He adds it was equally gratifying to see 150 people turn up to a field

day to see what he was doing after he won the Waikato Farm Awards.

“It was an opportunity to put a positive spin

on farming and build relationships, including with the council.”

Snow went on to become a judge in the

THIRTY TWO years later, Snow Chubb still remembers how exciting it was to actually get to meet Gordon Stephenson.

“It was an awesome experience, and we went on to become good friends,” he says.

Over the following years, Snow and wife Sue strengthened their friendship with Gordon and his wife, Celia, working on several conservation projects in the area. This included building the first 10km of walking tracks, bridges, and boardwalks for the Sanctuary Mountain Maungatautari project, an ambitious plan to ring-fence the 3400ha Waikato mountain to create a mainland conservation ‘island’. The park is New Zealand’s largest fenced eco-sanctuary.

Snow also formed the Pokaiwhenua Stream Care Group and, with the help of

the Hora Hora school teachers and parents, planted 2500 native trees in the catchment. He says his approach was always to take a long-term approach to looking after the land so it would prosper for future generations. “I believe that if you are not improving the land, you are stealing off the next generation.”

From fields to forests, as a young farmer, winning the inaugural Waikato Farm Environment Awards allowed Snow to help shape New Zealand’s farming future. This year, the New Zealand Farm Environment Trust is celebrating 30 years since the Waikato Farm Environment Awards Trust was formed, paving the way for the nationwide Ballance Farm Environment Awards programme we know today.

Agmax Country, we deliver clean lines.

You already know a clean plant keeps grades away and herds humming. What you might not know is that Agmax’s acid and alkali detergents keep your lines hygienically spotless at some of the most competitive prices around. If you’re serious about staying grade-free, stick with Agmax. We’ve been keeping pipes clean for donkey’s years.

EARLY DECEMBER marks a key transition for many dairy farmers, as weaned replacement heifers head offfarm to grazing.

This is a pivotal moment because the growth of these animals will directly influence their future milk production, reproductive performance, and herd longevity. With a continued push for greater on-farm efficiency gains, achieving heifer liveweight targets is essential for highly productive herds.

We typically associate the word “cost” with producing heifer replacements, e.g. grazing, mating, animal health etc. Undoubtedly, rearing replacements is a major cost in terms of money and labour, but they represent the future of your dairy herd, so they should be looked upon as an investment. How well they are grown and their body condition at first calving has a big impact on the return on that investment.

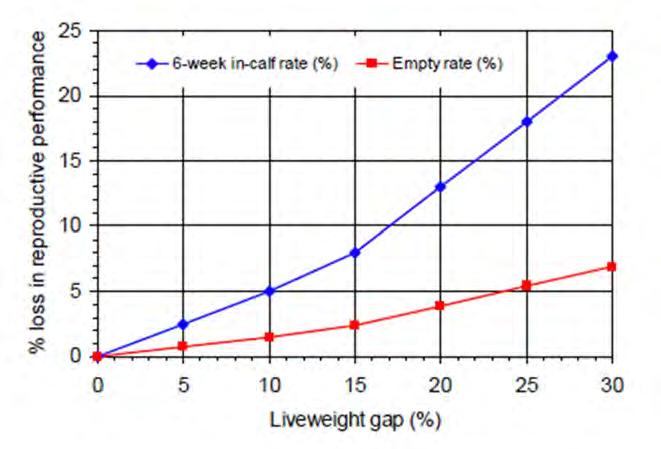

Heifers that reach their target liveweight at first calving, typically 90% of their mature weight, are far more likely to conceive early, enter the herd sooner, and stay productive for longer. Research indicates that a 10% increase in target liveweight contributes an extra 20 kgMS/heifer in

their first lactation and delivers a 5% higher 6-week in-calf rate and a 1.5% lower empty rate (Graph 1) compared to their underweight counterparts.

When reviewing heifer grazing, the value of grazing needs to be compared with the cost. Low-cost grazing is not necessarily good value, just as paying “top dollar” for grazing does not guarantee top results. The two examples in Table 1 demonstrate cost versus value. In this example, paying a higher weekly grazing rate represents better value when assessed on a $/kg liveweight (LWT) gain basis. The ideal is a win-win situation where the dairy farmer receives back from grazing a quality heifer that has met all industry

liveweight targets. The grazier has been well compensated for the heifers they have grown, allowing them to generate a satisfactory margin.

So, what can help deliver a ‘winwin’ outcome?

1. Start with clear communication

Successful grazing arrangements are built on trust and clarity. Farmers should provide graziers with written targets for key liveweight milestones, based on the mature liveweight of their herd. Without these, it’s difficult to assess progress or agree on what success looks like.

2. Know your herd’s mature liveweight

Many farmers are unsure of their herd’s mature liveweight, making it difficult to set realistic targets. This requires weighing 20-50 mature cows (6-8 years old) in condition score 4.5 at 100-200 days in milk. Alternatively, you can reference breed averages or the liveweight breeding value for your herd.

weight on heifers and can be fed in the paddock along a fenceline when ground conditions are dry.

Table 1: Cost vs. value comparison between grazing.

3. Match expectations to feed supply

4. Monitor regularly and intervene early

receive. Heifers sent to grazing at or above their target weaning weights (typically 90–110kg at 12 weeks) and in good health have the best chance of reaching puberty on time and calving at 24 months.

Regular weighing (every eight weeks) allows graziers to track whether heifers are on target. This enables proactive adjustments, such as increasing feed allocation or destocking another stock class to reduce demand. A one-off weigh-in at mating is too late to fix a growth deficit that’s been developing all year.

been well compensated for the heifers theyhavegrown, allowing them to generatea satisfactory margin

So, what can help deliver a win:win” outcome?

Table 1: Cost vs. value comparisonbetween grazing.

Graziers are often tasked with delivering steady growth despite highly variable pasture growth, particularly over summer. When dry spells hit, gains can stall unless there’s a plan in place. Farmers and graziers should work together to ensure a feed budget is in place and supplement options are lined up in advance. Maize silage is an excellent option for putting

1. Start with clear communication

6. Build contingency into the plan

Good graziers don’t wait for a drought to hit before acting. Having flexibility in your grazing system, whether it’s stored supplements or an ability to adjust stocking rate by destocking other stock classes, is key to buffering seasonal volatility.

5. Send well-grown calves Graziers can only build on what they

Successful grazing arrangements are built on trust and clarity. Farmers should provide graziers with written targets for key liveweight milestones, based on the mature liveweight of their herd. Without these, it’s difficult to assess progress or agree on what success looks like.

Grazing costs:

weeks

2. Know your herd's mature liveweight

Many farmers are unsure of their herd's mature liveweight, making it difficult to set realistic targets. This requires weighing 20-50 mature cows (6-8 years old) in condition score 4.5 at 100200 days in milk. Alternatively, you can reference breed averages or the liveweight breeding value for your herd.

Table 1: Cost vs. value comparison between grazing.

So, what can help deliver a win:win” outcome?

1. Start with clear communication

Source: New Zealand Dairy Statistics (2022-23)

Successfulgrazing arrangements arebuilt on trust and clarity.Farmers should provide graziers with written targets for key liveweight milestones, based on the mature liveweight of their herd. Without these, it’s difficult to assess progress or agree on what success looks like.

Growing better heifers is one of the most effective ways to drive greater on-farm productivity, and success is underpinned by proactive communication between farmers and graziers. Clear expectations, documented growth targets, and regular weight checks can keep both parties accountable. Having a contingency plan for poor pasture growth, whether it’s stored supplement, imported feed or alternative grazing, can prevent setbacks.

• Wade Bell is Genetic Technologies farm systems manager. Contact him at wbell@genetic.co.nz

4. Monitor regularly and intervene early

Stacey, are once again reinventing their approach to dairy farming.

ASHBURTON dairy farmers TJ and Mark Stewart are no strangers to adapting and evolving.

With a history of resilience - particularly after the devastating flooding of May 2021, in which their farm was severely impacted - the Stewart brothers, alongside Mark’s wife

Their latest transition sees a move back to spring calving after many years of running a successful winter milking operation – with their free stall barn remaining at the centre of their operation.

The Stewart farm has been in the family for 70 years. It was originally a sheep and cropping

TODAY THE cows’ diet, designed to maximise production, is comprised of the following: DBC Milk Maker pellets (550kg/cow), PKE (450kg/cow), grass silage (450kg/cow), maize silage (700kg/ cow), lucerne silage (200kg/cow), sunflower and soya protein (150kg/cow) and straw (300kg/cow).

Feed is adjusted seasonally with pellets and PKE fed year-round in the shed, grass silage fed during the shoulders of the season, when required, and maize, lucerne and protein fed in the barn between April and October.

Straw is fed to dry cows, and cows are on grass between October and April.

The cows have proven to do well under this regime, averaging 600 kgMS/cow per season.

The calving season now begins on July 15, with mating starting around October 20. The Stewarts perform four-six weeks of AI to Holstein Friesian sires, then switch to beef genetics through to December.

They prioritise health, fertility, and production traits in their sire selection and are particularly drawn to smaller-framed cows. Bulls like Westcoast Alcove and Walnutlawn Solomon have produced

property before being converted to dairy by TJ and Mark’s parents, David and Maree, in 1982. They began milking 300 cows, laying the foundation for what would become a much larger operation. In 2001 the brothers took the reins, buying the cows and machinery, and steadily expanded the business.

Today, the property supports 600 Holstein Friesian cows on 180ha

effective. While David and Maree have stepped back, they remain an integral part of the family trust, which leases the land to the younger generation.

One of the major turning points in the farm’s development was the construction of a 140m x 70m, 500-bed free stall barn with 40 x 35m straw loafing area in 2013.

“Being autumn calving at the time, we were sick of

progeny the Stewarts are proud to have in their herd.

In 2022, the family adopted Allflex collars for heat detection, allowing them to move to 100% AI breeding and eliminate bulls from the herd. This technology has proven particularly useful for identifying heats in barn-housed cows where visual cues are harder to detect.

The Stewarts have bred some standout cow families, including progeny from the renowned Fairview Goldc Frosty-ET EX line. One of her heifers, Barwell Mercy Frosty-ET, was sold at the 2024 NZ DairyEvent for $8,500.

The family enjoy participating in shows and competitions when time allows and Mark and Stacey’s children Paige, Olivia, and James are involved in calf club.

The family has also had success in the Regional Semex On-Farm Competition: in 2024, they placed second in both the Five-Year-Old Cow category with Barwell Solomon Lilly-ET EX and the Mature Cow category with Barwell Solomon Aimee VG87. Back in 2019, Barwell Wbrook Annie-ET EX2 claimed first place in the National Semex On-Farm

3

mud everywhere,” TJ says.

Competition in the Five-Year-Old Cow category. TJ, Mark and Stacey have a strong appreciation for pedigree cattle and enjoy the aesthetics and performance of Holstein Friesians.

“There’s just something about them,” TJ says. “Their size, their frame, their capacity - you can get a lot of milk out of them. I love looking at good cows.”

Stacey says that while they are transitioning to spring calving, they are maintaining flexibility within the operation.

“We’re figuring out what works best for us in terms of cow numbers, which cows to breed from, and how much to feed under the new system,” she says.

The Stewarts remain focused on balance: between production and animal welfare, and tradition and innovation. Their approach is shaped by a strong understanding of what their land, herd and business need to thrive.

Stacey, originally from Tasmania, sums up the unexpected journey. “I came to New Zealand 18 years ago, planning to stay for one year. Now I’ve got one husband, three kids, and a dairy farm.”

The barn, built in collaboration with Rakaia Engineering, revolutionised their system - offering a warm, dry environment which drastically improved feed utilisation and animal health outcomes.

“The barn gave us options to sustain production and maintain cow comfort,” TJ says. “Benefits include not having milking cows pugging up grass during winter, it is warmer and drier and ensures 99% feed utilisation. Animal health has improved as the cows are not trying to survive wet, cold, miserable weather while making milk.”

An environmental benefit is that effluent is captured and put onto pasture at a suitable time and is not going onto wet paddocks.

“It’s been a great add-on to the farm, and we wouldn’t farm without it now.”

during traditionally lowproduction months.

It came in particularly handy in May 2021, when a catastrophic ‘1-in-200year’ flood hit their farm, leaving 14.5 hectares buried under riverbed rubble and a further 20 hectares covered in silt, stones, and debris.

A portion of their herd - dry cows at the grazier - had to be moved, and the family was evacuated. Despite the devastation the Stewart family rallied, aided by community support.

Thanks to strategic planning and the infrastructure already in place, particularly the free stall barn, the farm not only recovered but continued to operate successfully, achieving higher than average production within their pre-flood feed budget.

•Rolls up to 15m wide, therefore fewer joins which means less risk, faster installation and shorter good weather window required.

•

• Design assistance and volume calculations available.

Material warranty from global company - Elevate, a brand of Holcim (formerly Firestone Building Products)

your nearest installation contractor call

021 280 7266

Email: vaughan@cosio.co.nz www.cosio.co.nz

•Nationwide trained and accredited installation contractors.

•Future proof - dependable performance, 50 year life expectancy even when exposed, 20 year material warranty.

•Over 120 million square meters installed worldwide.

•30 years in the NZ lining business.

The barn allowed the Stewarts to transition into a high-input winter milking system, achieving up to 70% autumn calving at one point. This set-up enabled them to secure premium winter milk contracts with Synlait, helping generate a consistent milk flow and strong income even

Despite the success of their winter milking programme, the Stewarts chose to return to spring calving in the 2024/25 season.

“It basically came down to the cost of feed production,” TJ says. “With the rising cost of farm workings, shifting to spring calving made more economic sense.”

Owners: Stewart Family Trust

Leasee: TJ, Mark and Stacey Stewart

Location: Ashburton, Canterbury

THE SWING-OVER herringbone is the most common dairy type in New Zealand, used on 69% of dairy farms.

Simple changes save seconds per cow, and that quickly adds up. There are ways to save time in almost all herringbone milking sheds. The key to improving efficiency is to use a consistent milking routine for all milkers. Shorter milkings have several benefits - improving staff satisfaction, lessening mastitis and reducing lameness.

Making changes is simple and reversible, so you don’t have to wait until the end of the season to assess the impact of changes. If something hasn’t worked, it’s easy to change back at the next milking.

Creating a more efficient milking routine

There are a number of ways to compile an efficient milking routine depending on individual dairy design. However, the following elements have been identified as key elements that good routines have in common.

■ Don’t wait for all the cows to row up – start cupping once the first batch of cows is loaded.

■ Aim to cup first cow in the row within 30

seconds of her being in position and the adjacent cow being finished.

■ Use an efficient cupping technique.

■ Work in batches of 5-10 cows, completing all tasks as you go starting at the exit end of the pit.

■ Avoid leaving cows to come back to or waiting for cows to finish milking.

Implement a MaxT milking strategy.

■ Open the head gate when 50-75% of the cows have had their clusters removed. This gives cows time to start exiting while you finish the rest of the row.

■ Move the backing gate little and often to take up the free space in the yard. By moving it little and often you minimise gaps in cow flow.

■ Don’t leave the pit unless you really need to.

■ Hose under cows with cups on. Hosing as a row is exiting and the next row is loading slows down cow flow by spraying water in cows faces and also risks splashing teats with dirty water prior to milking.

■ if you experience waiting during milking, start with milking duration.

■ if you are removing clusters with no milk visible in the sight glass, or ACRs are coming off before you get to them, start with milking routine.

In summary, many farmers have managed to make significant savings by

■ Ensure meal is fed after the row is loaded.

■ To minimise walking in the pit, consider the location of controls for the backing gate, head gate etc.

• Article - DairyNZ

adopting a routine that:

■ eliminates unnecessary idle (waiting) time from the routine

■ minimises distance walked/steps taken by the milker/s

■ enables the exit gate to be opened at the earliest opportunity.

preparation before milking can involve the cleaning and/or massaging of teats before the cups are attached. As well as ensuring that milk quality is not affected by dirty teats, washing helps the cow produce oxytocin, the milk letdown hormone which creates a better milk flow.

Teat washing and ensuring the teats are clean before attaching the cups has the following benefits:

■ Can prevent milk quality issues, maintains milk quality.

■ Reduces animal health issues - reduces risk of teat damage, reduces mastitis associated with teat damage or excessive dirt on teats.

■ In New Zealand there are two teat washing practices:

■ universal washing - where every teat is washed.

■ strategic washing - where only those which are visibly dirty are washed. Strategic washing is most commonly practiced in New Zealand. Strategic washing of dirty teats will save time, although there is no opportunity to stimulate the udder through handling/massage to encourage let-down. However, in most cases this is not required.

Drying of teats after washing is essential as it reduces the chance of mastitis, and the risk of milk contamination. Dry teats also interact better with the teat cup liner.

“I can truly say: The Astronaut A5 Next is the best colleague I’ve ever had”

Alessandra Cabrini, herdmanager

“ The Astronaut A5 Next gives me more control, and the cows more comfort.”

When the Lely Astronaut A5 Next takes over the repetitive process of milking, you can allocate your expertise where it is needed most: managing herd health, farm management, and spending time with your family.

Insights from the Lely Horizon app ensure the link between you and your animals by putting the right information at your fingertips.

The new automatic milk filter eliminates the need to replace filters manually - making the process easy, convenient, and less labourintensive. The Astronaut A5 Next also supports the use of Ear Tag ID for basic identification.

Stay ahead of your future Visit our website to learn more about the Astronaut A5 Next.

MARK DANIEL

CASE IH HAS released details of its all-new round balers and redesigns to its large square balers aimed at increasing productivity.

The new variable chamber RB6 series, offered in the RB456 and RB466 models are built to deliver greater reliability, usability in tough conditions, alongside greater connectivity.

An upgraded chain drive system with premium, higher-strength chains is said to help boost performance in heavy crops, while triple-

seal bearings help achieve extended durability by keeping contaminants out and lubricants in.

Extruded rollers now feature a seamless design to increase strength and service life. Reinforced rolls and sealed bearings further enhance resilience and reduce maintenance.

Looking at technology, ISOBUS is standard, making setup easier and offering features such as tractor-baler automation to be unlocked when paired with Case IH tractors. Automated baling steps, such as stopping when the bale is ready, net start and tailgate operation,

improve throughput and reduce fatigue. Functions can be directly controlled from the cab with optional Pro 700 Plus or Pro 1200 displays available for non-ISOBUS tractors.

Optional Case IH connectivity solutions, including Basic and Advanced Telematics, allowing baler data to be brought into FieldOps for access anytime, anywhere, allowing operators to view field totals, bale drop locations and moisture data to improve transport, storage planning.

In addition, Case IH is introducing model year 2026 updates for the

LB436 HD and LB4 XL series large square balers to boost productivity and bale quality for producers.

Each series includes technology and automation upgrades to maximize throughput and produce consistent, highquality bales regardless of operator experience.

Both balers feature updates a new greasing system for automatic chain lubrication instead of oil, said to deliver over four times longer service intervals and requiring only one fluid, while eliminating the oiler pump system for easier maintenance making prefield preparation faster

and easier. A new loadsensing package enables bale ejection and bale ramp activation from the back of the baler as well as from the cab, adding convenience and efficiency.

Baler automation improves capacity,

density, ease of use and overall throughput, especially for less experienced operators.

Soon compatible with Tractor Implement Management (TIM), the system automatically adjusts tractor speed to match crop flow and

density. By monitoring swath consistency and preventing overloads, the baler produces more bales per hour with uniform shape and shape and superior density, while reducing operator fatigue and fuel consumption.

HIGH PERFORMANCE TANK / RESERVOIR VALVE

✔ Adjustable minimum & maximum on/off control

✔ Reduces pump wear with less on/off cycles

✔ Delivers up to 1275 L/min at 12 bar

HEAVY DUTY TANK LEVEL INDICATOR

✔ Shows water level at a glance

✔ Protects system from water loss damage

✔ Fits any tank size or type