Electrification & Renewables to Displace Fossil Fuel Process Heating

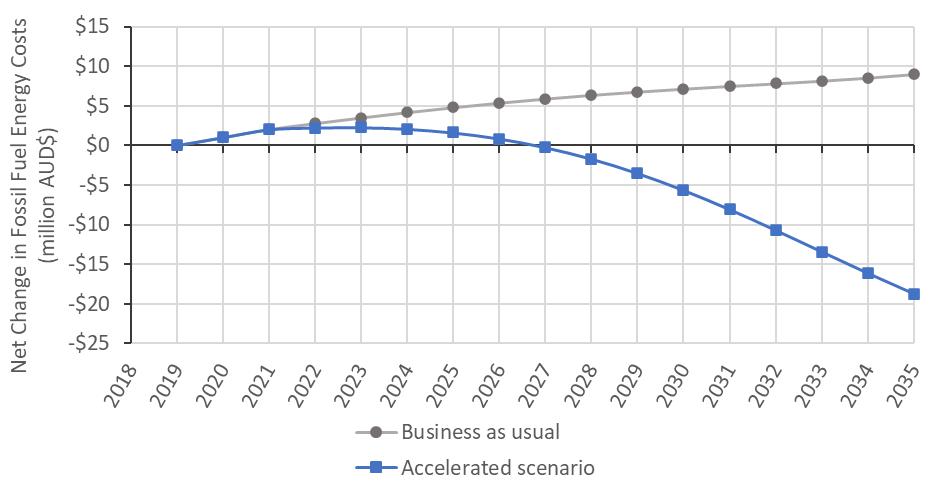

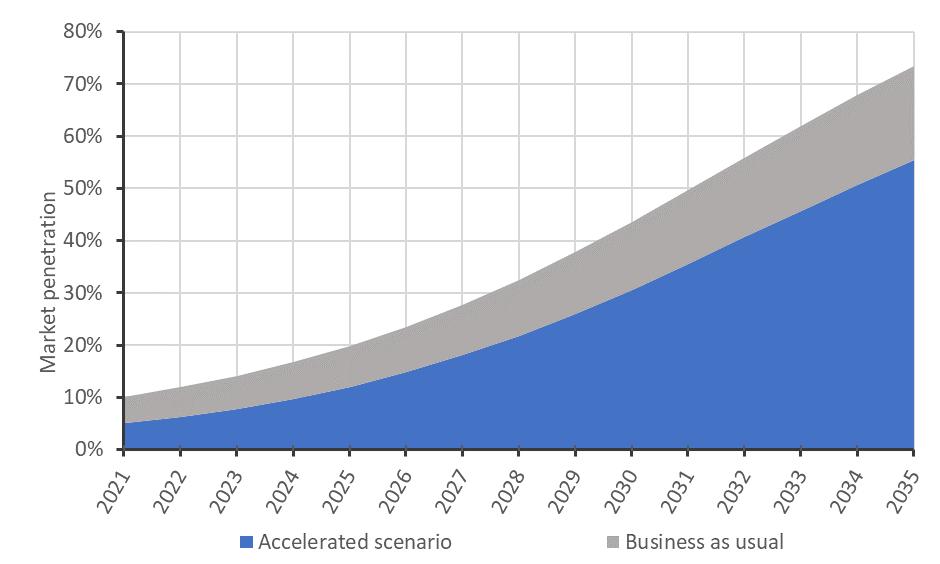

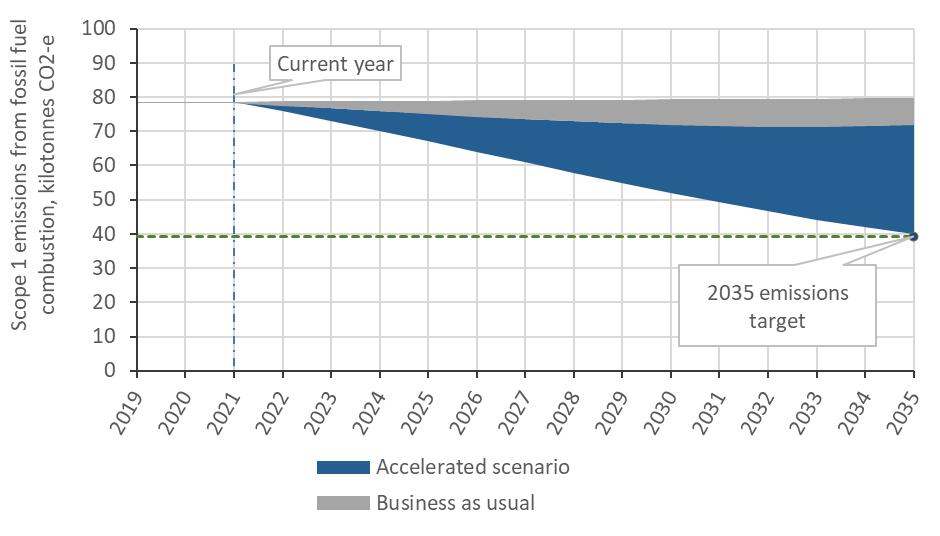

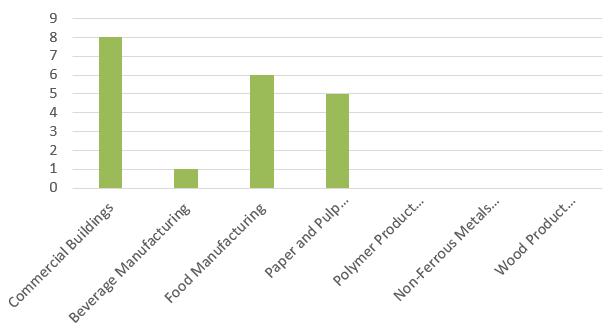

4.4.2 Meat Processing Market potential at a glance In 2019, the Australian meat processing sector consumed 7.48 PJ of energy for thermal processes <150 °C o This resulted in 452 kilotonnes of CO2,eq per annum of greenhouse gas emissions o The cost of fossil fuel consumption for this sector is approximately $55 million per annum o The demand for energy is expected to grow at approximately 2% per year in the near future Based on a logistic model, by 2035: o Under the BaU scenario, the emissions will increase by 66.5 kilotonnes of CO2,eq per annum relative to 2019 levels o Under the accelerated scenario, emissions will reduce by 292.5 kilotonnes of CO2,eq per annum relative to BaU o To achieve the 50% emissions target by 2035, the uptake rate of renewable technologies needs to be increased by a factor of 3.5 compared to the BaU scenario; o Under the ACL scenario, fossil fuel consumption costs will be reduced by $36 million per annum relative to the BaU scenario.

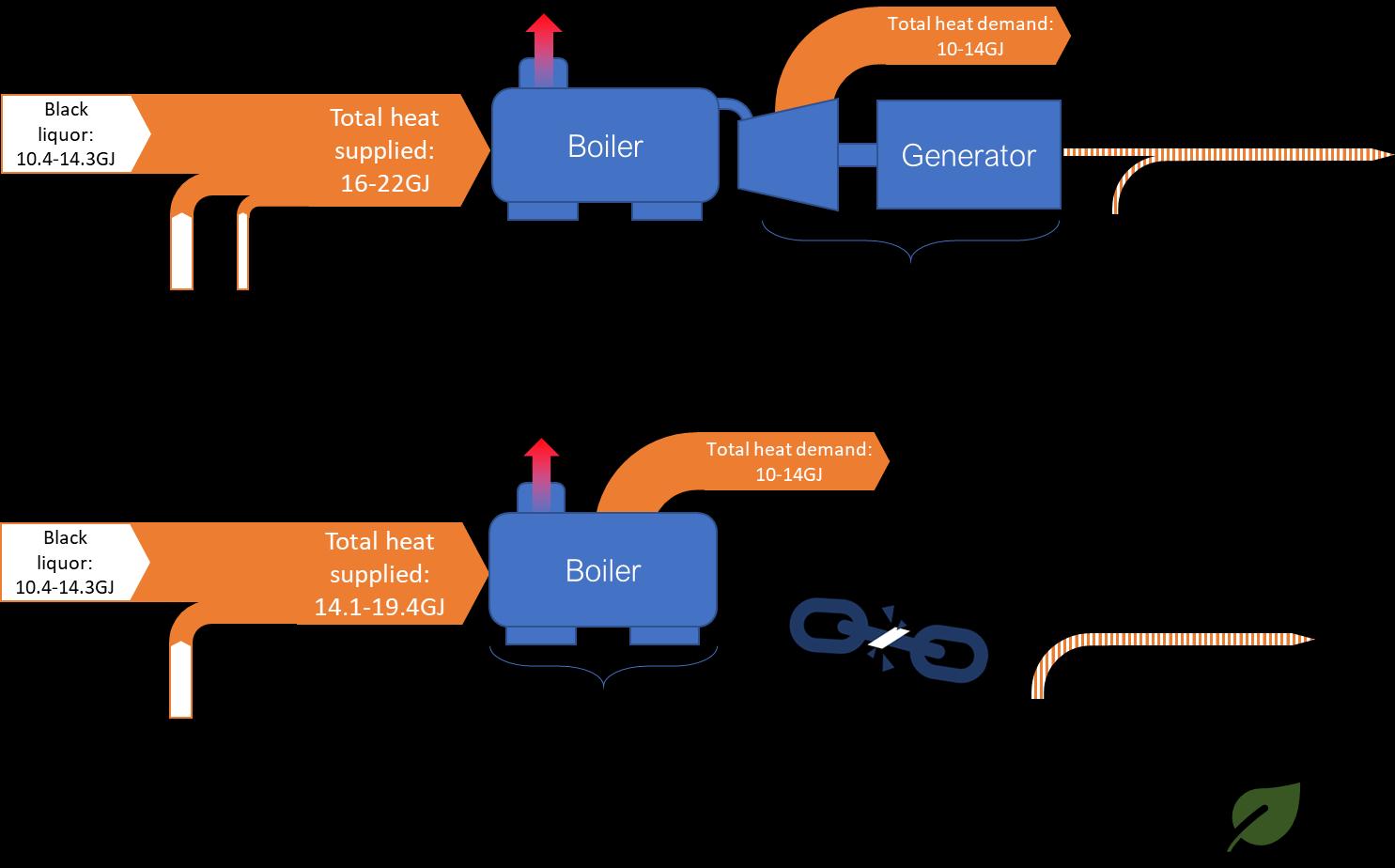

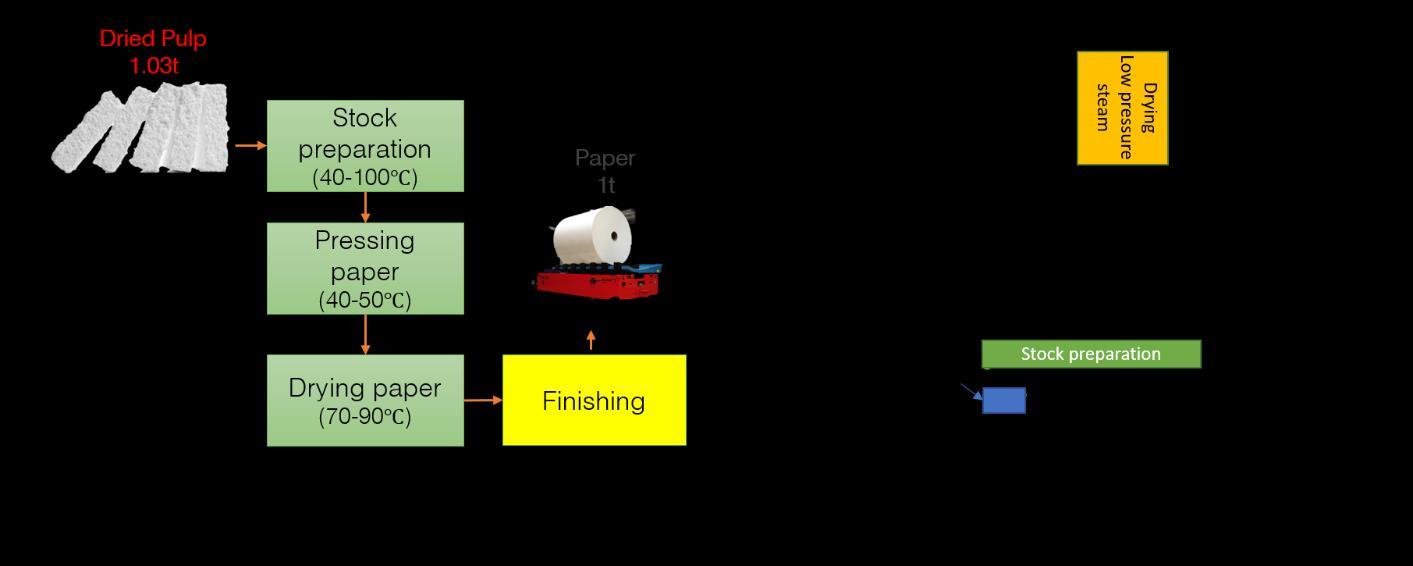

Australia’s red meat and livestock industry contributed significantly to Gross Domestic Product (GDP), i.e. 17.6 billion AUD in 2018-19 equivalent to 1.4% of Australia’s key industry GDP [237]. This industry employed 31,200 people in meat processing, which accounts for 17% of total full-time equivalent employment in the Agriculture, Forestry & Fishing sector [238]. Figure 80 below presents the amount of red meat production in Australia since 2000. Continuously growing from 2016, Australia’s red meat production totalled 3.56 million tonnes Hot Standard Carcase Weight (HSCW) in 2019 [239]. Steam is the main source of heat in the meat processing. A typical process requires approximately 2.1 GJ of heat per tonnes of HSCW on average. Medium pressure steam at temperatures around 180 °C – 185 °C, generated by the central boilers, is used directly in rendering and blood processing, which demands most of heat (≈88%). The waste heat from exhausted steam in the rendering process is recovered and used to supply hot water (82 °C) and warm water (43 °C) for sterilization, slaughter, and evisceration processes. Almost 60-70% of energy needs for hot/warm water comes from the waste heat. Figure 25 provides the meat processing overview and summarizes the energy and temperature demand in each process.

108