Adroit Piping Systems has proudly been servicing a wide range of industries, locations, and applications since the early 1990s.

We are a leading manufacturer, fabricator, importer, and supplier of non-corrosive piping systems. We specialise in High Density Polyethylene (HDPE) products for Pressure, Water, Drainage, and Gas applications.

We operate across a wide and diverse range of industry segments and markets, including Mining and Industrial, Water Utilities, Civil and Infrastructure, Coal Seam Gas, Landfill, Agriculture and Irrigation, and Plumbing and Drainage.

In addition to pipe and fittings we also provide a number of value-added services, including custom and specialised fabrication, pipe butt welding, sales and hire of electrofusion and extrusion pipe welding equipment and machinery. We also provide certified in-house electrofusion welder training.

We have a fully equipped and accredited Service Centre to test, repair, and calibrate all major pipe welding machinery brands to OEM specifications and applicable Australian Standards.

YOUR PARTNER IN PIPING SOLUTIONS

12 Loyalty Road, North Rocks, NSW 2151

•

32 Horne Street, Hoppers Crossing, VIC 3029 •

The “Family” code shown at the top of each page refers to the fitting TYPE, e.g. 2014 for an ElectroFusion Coupler. The next four numbers refer to the SIZE, e.g. 0110 for a 110mm fitting, 1163 for a 110mm x 63mm reducer. A 110mm electrofusion coupler is 2014.0110.

All listed pressure ratings are subject to applicable regulations and standards. For further information, please check with your local regulatory authority. All dimensions shown in this catalogue are intended as a guide only and may change without notice. If exact measurements or items not shown in this catalogue are required, please contact our sales team. We are also able to source and supply a wide range of associated products such as valves and non-standard flanges. 19 DATALOGGER DL7

19 SELF-CENTERING STUB END HOLDER 19 IN-DITCH KITS 20 DECOILING TRAILER

LINETAMER 2-4

98

TABLE D BACKING RINGS AND BLIND FLANGES

100

TABLE E BACKING RINGS AND BLIND FLANGES

102

TABLE F BACKING RINGS AND BLIND FLANGES

104

TABLE H BACKING RINGS AND BLIND FLANGES

106

AS4087 PN16 BACKING RINGS AND BLIND FLANGES

108

AS4087 PN21 BACKING RINGS AND BLIND FLANGES

110

ANSI150 BACKING RINGS AND BLIND FLANGES 114

ANSI300 BACKING RINGS AND BLIND FLANGES

907/W907 HDPE-TO-STEEL

116

ANSI150 REDUCED THICKNESS BACKING RINGS AND BLIND FLANGES

118

AS4087 PN35 BACKING RINGS AND BLIND FLANGES 112

ANSI300 REDUCED THICKNESS BACKING RINGS AND BLIND FLANGES 120

DIN PN10 BACKING RINGS AND BLIND FLANGES

DIN PN16 BACKING RINGS AND BLIND FLANGES

LONG SPIGOT STUB FLANGE

GASKET AND BOLTS

ELECTROFUSION COUPLING

193

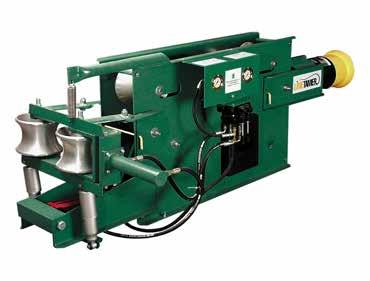

McElroy Service Centre

Adroit has a fully equipped McElroy service and repair centre which is authorised to repair and service McElroy welding equipment and accessories to manufacture’s specifications and Australian standards.

Fusion equipment as dependable as your pipeline

There are plenty of rental fusion machines in the marketplace, but how do you know if your next rental machine is properly maintained and ready to perform?

To secure a premium rental machine, make sure your next rental is from a Certified McElroy Rental equipment fleet.

TRACSTAR 500 SERIES 3

160mm-500mm pipe diameter range

TRACSTAR 630 I SERIES

225-630mm pipe diameter range

TRACSTAR 900 I SERIES

315-900mm pipe diameter range

315-900mm pipe diameter range

MEGAMC 1648 SERIES 2

450-1200mm pipe diameter range

1600

500-1600mm pipe diameter range

The DynaMc in 2- and 4-jaw configurations. The low cylinder force machines were designed with a small footprint, allowing fusion operators to take the carriage into small working areas. The 28 EP is powered by the EP1500AD Hydraulic Power Unit (HPU), which is a common HPU for a variety of DynaMc EP fusion machines, such as the Sidewall 28 and Compact 28 Vertical. The HPU uses a hydraulic accumulator to maintain fusion pressures and reduce power consumption.

The manual carriage manifold of the DynaMc 28 EP is powerful enough to tackle thick-walled pipe and is paired with a strong electric facer that can be loaded from either side of the carriage. Capable of 1,500 PSI fusion pressures, the DynaMc EP is compatible with the DataLogger

Whether it is one fusion or 100, the DynaMc 28 EP provides the rugged reliabil ity you expect from a McElroy.

ACROBAT™ 180

63-180mm

ACROBAT™ 250

63-250mm

ACROBAT™ 315

200-315mm

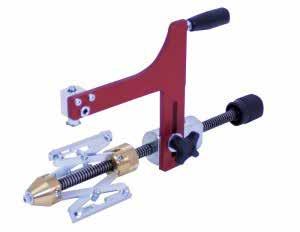

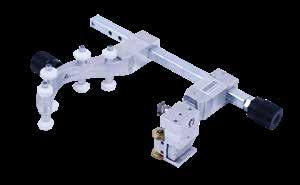

Self-centering stub end holder to hold stub end for butt fusion

PE WELDING EQUIPMENT PURCHASE AND HIRE

CODE: SPRW.SMART

FEATURES: 3M lead

FITTING SIZE: Up to 180mm (sizes above 100mm require cool down time between welds)

WELDS: Plasson only (competitor allowance with App)

CALIBRATION PERIOD: After 200 hours or 12 months

BARCODE READING CAPABILITY: Yes with App

DATA RECORDING: Yes with App

EARTH PIN: 10A

CODE: SPRW.MONO

FEATURES: 5M lead

FITTING SIZE: Up to 355mm

WELDS: Plasson only (competitor allowance with App)

CALIBRATION PERIOD: After 200 hours or 12 months

BARCODE READING CAPABILITY: Yes with App

DATA RECORDING: Yes with App

EARTH PIN: 15A

CODE: SPRW.POLY

FEATURES: 5M lead

FITTING SIZE: Up to 800mm (sizes above 355mm require cool down time between welds)

WELDS: Any EF fittings

CALIBRATION PERIOD: After 200 hours or 12 months

BARCODE READING CAPABILITY: Yes

DATA RECORDING: Yes with App

EARTH PIN: 15A

FEATURES: 10M lead

FITTING SIZE: Almost all sizes. Some sizes between 800 and 1000mm may require a Manut machine. No cool down required when using Polycontrol Plus V2

WELDS: Plasson only (competitor allowance with App)

CALIBRATION PERIOD: After 200 hours or 12 months

BARCODE READING CAPABILITY: Yes with App

EARTH PIN: 15A

HDPE DRAINAGE E/F WELDER TO SUIT 40-160

CODE: D40.160

INPUT VOLTAGE RANGE: 190-300V

FREQUENCY: 40-70V

MINIMUM OUTPUT: 18A at 240V - one phase

• Must be able to drive inductive loads

• Must have phase cut control

• Mechanically regulated with brushes is the preferred system

• Synchronised generator

MINIMUM: 6.5kVA - Mechanically Controlled

MINIMUM: 7.5kVA - Electronically Controlled

• Graphic display

• Auto recognition of fittings

• Memory with 350 welding reports

• Report in PDF File

A00 Ø 32 ÷ 160mm All A00+ Ø 200 ÷ 315mm Wavin

A01 Ø 200 ÷ 315mm Akatherm, Valsir

A02 Ø 200 ÷ 315mm Geberit

A04 Ø 200 ÷ 315mm Coes

2006020 Spare Blade for Pipe End Peeler 63-200 (0.2mm peeling depth)

2006029 Spare Blade for Pipe End Peeler 90-315/180-400 (0.3mm peeling depth) 2004002 Pipe Cutter Spare Blade for 63mm (Single Hand) 2004003 Pipe Cutter up to 63mm (Tow Hand Use) Spare Blade

2004003

2004002

Pipe Cutter Spare Blade for 63mm (Single Hand)

Pipe Cutter up to 63mm (Tow Hand Use) Spare Blade

Pipe Cutter Spare Blade for 63mm (Single Hand)

2004003 Pipe Cutter up to 63mm (Tow Hand Use) Spare Blade

CODE

DESCRIPTION

2006035 Drill Powered Pipe end Peeler Incl Bosch Drill and Case

2006058

2006067

2006076

2006059

2006072

2006068

2006060

2006069

2006077

2006061

2006070

2006078

2006062

2006071

Mandrel 32mm SDR11

Mandrel 32mm SDR17

Mandrel 40mm SDR9

Mandrel 40mm SDR11

Mandrel 40mm SDR13.6

Mandrel 40mm SDR17

Mandrel 50mm SDR11

Mandrel 50mm SDR17

Mandrel 63mm SDR7.4

Mandrel 63mm SDR11

Mandrel 63mm SDR17

Mandrel 75mm SDR7.4

Mandrel 75mm SDR11

Mandrel 75mm SDR17

DESCRIPTION

CODE

947777 50/315 HDPE Hand Scraper

947776 50/315 HDPE Hand Scraper blade 2pk

9200.3145

494X.0800

494X.0900

Note:

315-400mm CODE

2008019 Hydraulic Jack (315-400)

2008020 Rounding Shell 315mm (Without jack)

2008021 Rounding Shell 355mm (Without jack)

2008022 Rounding Shell 400mm (Without jack)

2008023 Hydraulic Jack (450-630)

2008024 Rounding Shell 450mm (Without jack)

2008025 Rounding Shell 500mm (Without jack)

2008026 Rounding Shell 560mm (Without jack)

2008027 Rounding Shell 630mm (Without jack)

Note: Used to round pipe after squeezing.

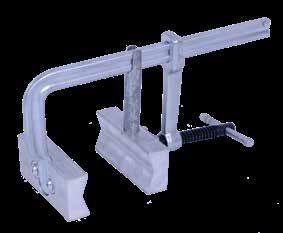

2007001

Pipe Clamp 16-63mm

Infinitely variable grip clamps to suit any combination of sizes, 16-63mm

2007002 Pipe Clamp 32-110mm

Infinitely variable grip clamps to suit any combination of sizes, 32-110mm

2007011 Pipe Clamp 63-225mm

Infinitely variable grip clamps to suit any combination of sizes, 63-225mm

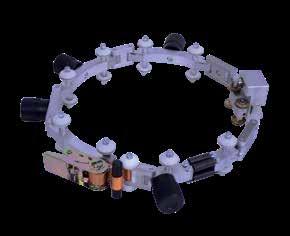

• Adjustable to suit couplers, reducers, 22.5°, 45° and 90° elbows and tees.

• Promotes restraint during the electrofusion process.

• Quick tightening operation, lightweight and easy to use.

2007005 Pipe Clamp 110-560mm

2007006

4 pipe clamps, 2 base bars, angled adaptor 22.5°, 45°, 90° and 180°

Pipe Clamp 250-800mm

With 2 fixed clamps, 2 clamps required

2007007 Pipe Clamp 250-800mm set

Included in set: 2 complete clamps each with a pulling clamp, a fixed clamp and pulling shoes for couplers. Allows you to pull the coupler over the pipe and the opposite pipe into the coupler to complete the insertion.

2007008 Pipe Support Pipe support to 225mm

DESCRIPTION

2012001 L Saddle outlet 90-160mm

Includes:

- Splitable plates: 90/110 x 125/160mm

- Pressure Test Spigot Removal Tool

- Rounding Ring 250mm

- Transport Case

2012040 XL Saddle outlet 180-200mm

Includes:

- Splitable Plate: 180/200mm

- Reductions 180mm, 200mm and 225mm for Rounding Ring 250mm

- Transport Case

- Tensioning Tool Kit required 2012020

2012018 XL Saddle outlet 225-250mm

Includes:

- Splitable Plate: 225/250mm

- Rounding Ring 250mm

- Reduction 225mm for Rounding Ring 250mm

- Transport Case

- Tensioning Tool Kit required 2012020

2012029 XXL Saddle outlet 280-315mm

Includes:

- Splitable Plate: 280/315mm

- Pressing Tool 280mm

- Pressing Tool 315mm

- Transport Case

- Tensioning Tool Kit required 2012020

2012049 XXXL Saddle outlet 355-400mm

Includes:

- Splitable Plate: 355/400mm

- Pressing Tool 355mm

- Pressing Tool 400mm

- Transport Case

- Tensioning Tool Kit required 2012020

2012020 Straps for clamping all Clamp Kits 180-1200mm

Includes:

- 3 x Straps

- 3 x Ratchets

- Torque wrench

- Torque wrench adapter with fine tooth pitch

- Pressure Test Spigot Removal Tool

- Unlocking tool for ratchets

- Adapter for pressure test pump 1/2"

- Transport Case

To install a Plasson Large Bore Saddle the following are required:

1. A Clamp Kit to suit the outlet size of the saddle.

2. A Strap Kit for outlet sizes 180-400mm.

3. A Core Cutter to core the saddle after welding.

4. A Drill/Motor to operate the Core Cutter.

2012002

2012050

2012037

Saddle Outlet

Includes:

1 x 90mm core cutter, Borehole 71mm*

1 x 110mm core cutter, Borehole 87mm*

1 x 125mm core cutter, Borehole 99mm*

1 x 160mm core cutter, Borehole 127mm*

* Equipped with SDS-Max Adaptor

1 x Centre Drill

1 x Drill chuck connector

1 x Connector for SDS-Plus

1 x Transport Case

Saddle outlet 180mm

Core cutter for 180mm outlet, Borehole 143mm

Includes Drill Adaptor and Case

Saddle outlet 200mm

Core Cutter for 200mm outlet, Borehole 159mm

Includes Drill Adaptor and Case

2012044 Saddle outlet 225mm

2012015

2012051

2012028

2012052

2012022

• Saddles with outlets 90-225mm use a hand operated drill.

• Saddles with 250mm outlets can use a hand operated drill.

A safety arm must be used to stabilise the drill.

• Alternatively, the drill can be operated with the motor mounting clamp.

• Saddles 280mm and above use a motor mounting clamp.

• The same motor can be used on all outlets.

Core Cutter for 225mm outlet, Borehole 179mm

Includes Drill Adaptor and Case

Saddle outlet 250mm

Core Cutter for 280mm outlet, Borehole 233mm

Includes Drill Adaptor and Case

Saddle outlet 280mm

Core Cutter for 280mm outlet, Borehole 233mm

Includes Drill Adaptor and Case

Saddle outlet 315mm

Core Cutter for 315mm outlet, Borehole 251mm

Includes Drill Adaptor and Case

Saddle outlet 355mm

Core Cuter for 355mm outlet, Borehole 283mm

Includes Drill Adaptor and Case

Saddle outlet 400mm

Core Cutter for 400mm outlet, Borehole 319mm Includes Drill Adaptor and Case