Biorefinery-Derived Long Chain Dibasic Complexing Agents for Lithium Thickened Lubricating Grease Paul A. Bertin,† and Paul A. Bessette‡ †Elevance Renewable Sciences, Woodridge, IL 60517 USA ‡Triboscience and Engineering, Inc., Fall River, MA 02740 USA

Abstract

Elevance Renewable Sciences, through recent commercialization of Nobel Prize-winning catalytic olefin metathesis of natural oils, can access novel long chain dibasic chemical building blocks from a joint world-scale biorefinery with Wilmar International Limited. In this paper, the authors report the feasibility of using specific long chain dibasic derivatives as complexing agent alternatives to azelaic acid in synthetic lithium complex grease.

Introduction

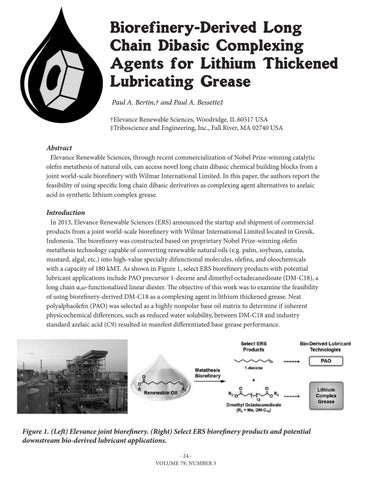

In 2013, Elevance Renewable Sciences (ERS) announced the startup and shipment of commercial products from a joint world-scale biorefinery with Wilmar International Limited located in Gresik, Indonesia. The biorefinery was constructed based on proprietary Nobel Prize-winning olefin metathesis technology capable of converting renewable natural oils (e.g. palm, soybean, canola, mustard, algal, etc.) into high-value specialty difunctional molecules, olefins, and oleochemicals with a capacity of 180 kMT. As shown in Figure 1, select ERS biorefinery products with potential lubricant applications include PAO precursor 1-decene and dimethyl octadecanedioate (DM-C18), a long chain α,ω-functionalized linear diester. The objective of this work was to examine the feasibility of using biorefinery-derived DM-C18 as a complexing agent in lithium thickened grease. Neat polyalphaolefin (PAO) was selected as a highly nonpolar base oil matrix to determine if inherent physicochemical differences, such as reduced water solubility, between DM-C18 and industry standard azelaic acid (C9) resulted in manifest differentiated base grease performance.

Figure 1. (Left) Elevance joint biorefinery. (Right) Select ERS biorefinery products and potential downstream bio-derived lubricant applications. - 24 VOLUME 79, NUMBER 5