2 minute read

Ask the Expert

the Expert

Q: Do you have technical information of saponification temperatures for manufacturing Lithium Greases available?

A:

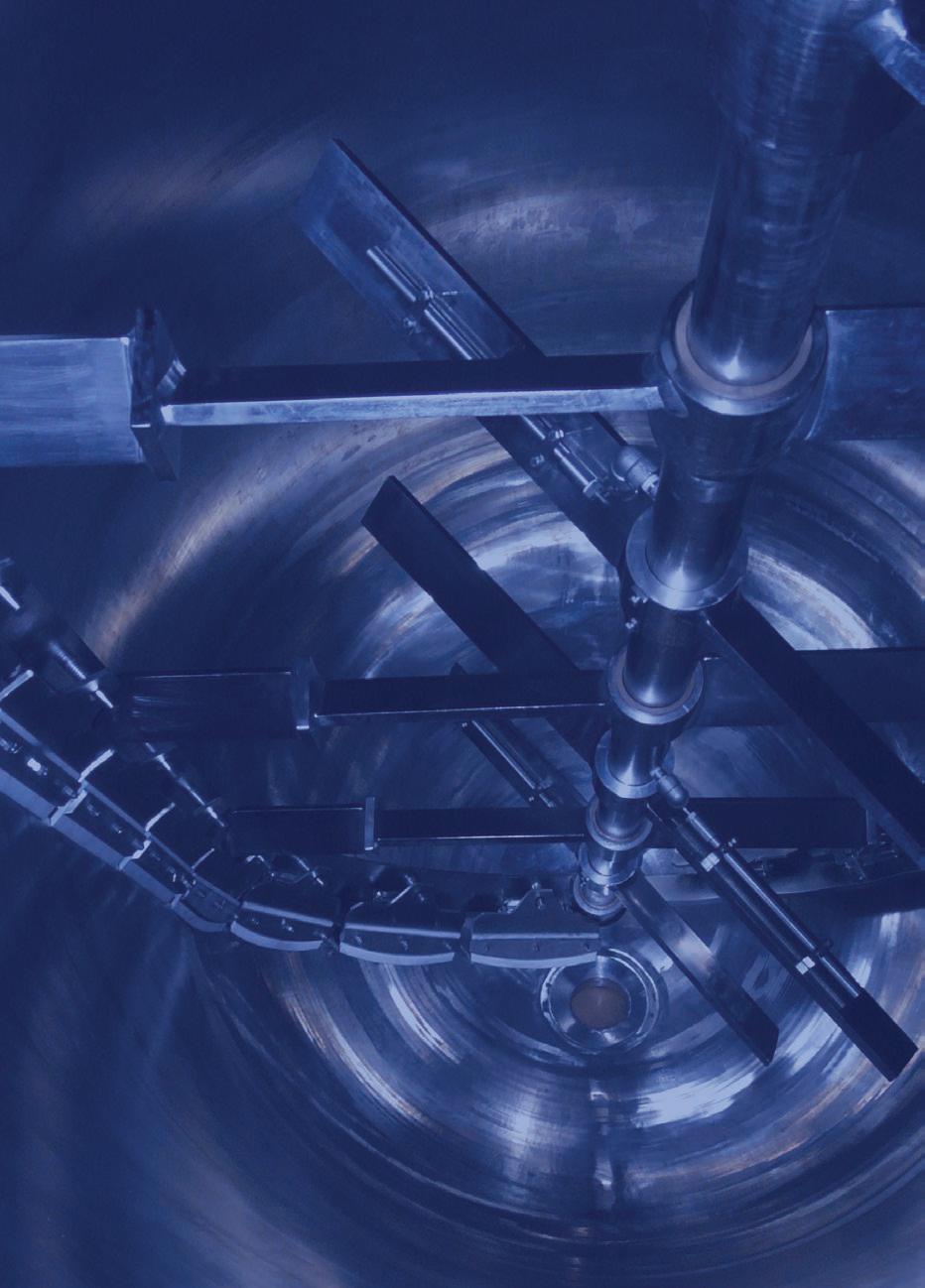

The temperature at which to carry out the saponification reaction for the manufacture of lithium greases is dependent upon the equipment being used for the manufacturing process. In an open kettle, the temperature should be in the range 85 – 95°C, hot enough to drive the reaction while maintaining the water present in liquid form. The time required to carry out the reaction can vary, depending on the amount and concentration of thickener present at that point. In a closed vessel – pressure kettle or Contactor® reactor – the temperature can be higher, since the elevated pressure will elevate the boiling point of water.

Q: Could you please tell me the difference between KP2K and KP2N. Both are in grade NLGI 2.

A:

The KP2K and KP2N designations are from DIN 51825, Type K Lubricating Greases, Classification, requirements and testing. Greases of type KP are designated as containing anti-friction and anti-wear additives and being designed for applications requiring a higher load-carrying capacity (generally referred to as Extreme Pressure or EP greases). The 2 in the designation indicates the NLGI consistency grade. The final character in the designations relates to the recommended maximum operating temperature for the grease and its performance in the presence of water. K indicates a maximum temperature of 120°Cand a performance of 0-90 or 1-90 in DIN 51807-1 (water resistance). N indicates a maximum operating temperature of 140°C, but no requirement regarding water resistance.

NLGI member H. L. Blachford makes metallic stearates and related materials. Their contact information (from the NLGI member directory) is as follows:

H.L. Blachford

Blachford is a manufacturer of specialty metallic stearates and soaps. These include aluminum and calcium stearates as well as our most popular grease pre thickeners, lithium 12-Hydroxystearate and our Calford G-200 (lithium stearate) specifically designed for use in lithium greases.

http://www.blachford.ca/

Aldo Pighin 2323 Royal Windsor Drive Mississauga, Ontario, L5J 1K5 Canada Phone: 905-823-3200 Fax: 905-823-9290 Email: apighin@blachford.ca

They may be able to supply a lithium complex thickener.

Q: Is lube base oil 600N recommended as base fluid to form greases for wheel bearings of light and heavy vehicles?

A:

600 Neutral Oil (600N) refers to a paraffinic base oil with a viscosity of approximately 600 SUS at 100°F. This translates to about 100 - 125 cSt @ 40°C. It is typically either conventionally refined (API Group I) or catalytically refined (API Group II). That type of base oil is generally suitable for use in formulating a grease for automotive and heavy duty wheel bearing applications, but may be too low in viscosity to be used as the only base oil is such a product. Wheel bearing grease typically has a base oil viscosity of about 220 cSt @ 40°C. To obtain that viscosity, the 600 Neutral Oil would need to be blended with a higher viscosity stock to produce the desired viscosity. Of course, the quality of the base oil should be evaluated before selecting it for use in a wheel bearing grease.