REFRIGERATION

MAINTAINING REFRIGERATION SYSTEM OPERATING EFFICIENCY T

hroughout the lifetime of a refrigeration system there is a need for regular maintenance and repairs. Unfortunately, many systems only receive the attention they need when they break down. There are a number of checks that need to be done regularly to prevent system failure. For this discussion, we will focus on a split system, where there is a condensing unit along with one or more evaporators.

Coil surface Ensure that the condensing and evaporating coils are clean. A dirty evaporator will tend to reduce the suction pressure, while a dirty condenser will tend to increase the discharge pressure. Both conditions contribute to a loss in efficiency. Capacity and efficiency will also drop if the defrost cycle is not working correctly. If necessary, the defrost should be adjusted so all frost is removed from the coil. Additionally, the defrost cycle should allow sufficient drip and drain time to prevent refreezing of the water. Drain pans and drain lines should be cleaned if necessary. Where electric defrost heaters are used, confirm that all defrost and drain line heaters are operating during the defrost cycle.

Compressor oil level and condition Check the compressor oil level and appearance. Generally, the oil level should be at approximately one-half sight glass. If the oil is low, do not add any until it is determined why the level is low. If there are no signs of oil on the external surface of any of the system components or piping, it is quite likely the oill is held up somewhere else within the system. In this case, the refrigerant charge, superheat and subcoolingg values should be checked. In a system with multiple evaporators, it is possible one or more evaporators is starved of refrigerant. In o this case, there may be insufficient liquid available to

Phil Boudreau 94

M e c h a n i c a l

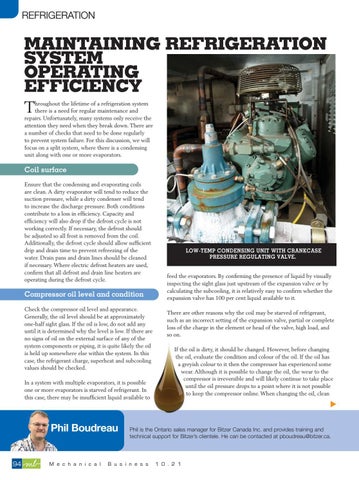

LOW-TEMP CONDENSING UNIT WITH CRANKCASE PRESSURE REGULATING VALVE. feed the evaporators. By confirming the presence of liquid by visually inspecting the sight glass just upstream of the expansion valve or by calculating the subcooling, it is relatively easy to confirm whether the expansion valve has 100 per cent liquid available to it. There are other reasons why the coil may be starved of refrigerant, such as an incorrect setting of the expansion valve, partial or complete loss of the charge in the element or head of the valve, high load, and so on. If the o oil is dirty, it should be changed. However, before changing the oil oil, evaluate the condition and colour of the oil. If the oil has a grey greyish colour to it then the compressor has experienced some wea wear. Although it is possible to change the oil, the wear to the com compressor is irreversible and will likely continue to take place un until the oil pressure drops to a point where it is not possible to keep the compressor online. When changing the oil, clean

Phil is the Ontario sales manager for Bitzer Canada Inc. and provides training and technical support for Bitzer’s clientele. He can be contacted at pboudreau@bitzer.ca.

B u s i n e s s

1 0 . 2 1