5 minute read

sollich

Sollich: tailored to quality

Advertisement

Sollich offers production solutions from a high-quality portfolio of suppliers for the chocolate, confectionery and baked goods industries and pride themselves in their focus on the customer - Head of Sales and Executive Director, Ralf Schäffer spoke to us about his vast experience working for the company

Sollich was originally founded in 1920 as a bakery/cake shop in Ratibor, Poland. What first began with the development of the SOLLKOCH, the world’s first vacuum sugar cooking machine, was continuously expanded over generations, with healthy growth and after World War II, the company relocated and started to work with chocolate - before that, it was more of a sugar, candy processing but after World War II, Above: Ralf Schäffer, Head of Sales and all the focus was on chocolate. Executive Director, Sollich Today, their production ranges from forming, extrusion and cutting systems, fully automatic coating systems and cooling tunnels to chocolate tempering machines and moulding systems Sollich was first founded, it was a Ralf studied electrical for confectionery. small company, but it was a good engineering and began working Head of Sales and Executive provider of technical solutions. for small companies that required Director, Ralf Schäffer, has been But most importantly, it has his skills in a number of varying with Sollich for the last 34 years always valued the relationship roles and soon realised that – taking over commercial as well with the customer and seeing working directly with people was as technical responsibilities and eye to eye with them – meaning his natural calling. He continues: supporting a team together with that we should be understanding “In the early stages of my career, Chairman of the Sollich group, the problems and supporting our electrical software programs Thomas Sollich, based on his vast customers at all times. That, I were being developed and highly knowledge of the market. think, is our main focus and that anticipated, but I wanted to work Ralf told Kennedy’s, “When we hold very dear to us.” with different people, different ideas and different cultures – that’s what interested me more.” “When I applied to work at Sollich, my experience and skill sets matched the criteria they were looking for. In the beginning, I was in charge of various different markets, but in 2002, I became responsible for the whole sales team and have some influence into other departments now as well.” It is not easy to make modern machines for the confectionery industry. There is the know-how of many decades and the quality of the employees within the company. Given the variety of confectionery products, mass Above: The SOLLICH Conbar® line production of the machines is

almost impossible – but this is where Sollich strive to be a little bit different.

“I believe we are important to the confectionery industry when it comes to proficiency, troublefree production and accessibility,” Ralf adds, “we don’t just create standard equipment that produces standard products – we are an experienced and confident partner for developing new products with new processing. We are open to new ideas and designs and can take in all requests and requirements that can helps us find a solution in a well-efficient way, on a high industrial standard but that is still flexible enough to vary between customer preference.”

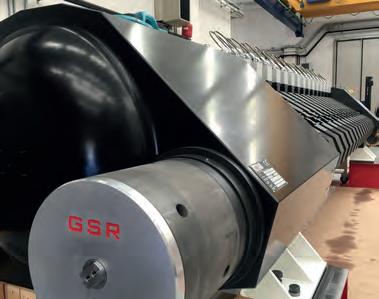

Tempering machines are at the heart of a chocolate processing system as this is where the foundation for a perfect product is laid. Sollich offers the correct machine for every application that result in an optimum shine, long shelf-life, good snap and a heat-resistant product. The company are also widely known for their efficient bar lines – the Sollich Conbar® line, for example, has enormous flexibility to create cereal and candy bars in single layer and multi-layer formats as well as products into rectangles and bars with a variety of different cross-sections.

Ralf continues: “We are very proud of our firm, reliable and efficient tempering chocolate machines which, particularly from a technology point of view, is a key component when you work with real chocolate (with real cocoa butter). Also, the range of products we are producing with our Conbar® line which we call which is a continuous state-ofthe-art platform because it’s not just a typical producer of standard candy bars – I believe the range is really done well because of our experience in the entire process – from initial concept, to the finished product, we are there throughout.”

Regarding Sollich’s future, Ralf concludes: “I think we will do our best to remain the market leader due to our extensive knowledge within tempering, enrobing and bar-forming, but also because of our family-oriented approach. Thomas Sollich’s children are planning to run the company once they have completed their education which will bring in a new, fresh generation to the team. We feel like a big family here at Sollich and I think if we can continue to translate that to the customer, then we have succeeded in our philosophy.”

RAlf Schäffer head of sales & Executive Director, Sollich

THE ONLINE MARKETPLACE FOR CHOCOLATE, CONFECTIONERY AND BAKERY TECHNOLOGY

Once you become a carefully selected Knowledge Partner with Kennedy’s you will have your own platform that will allow you to sell more equipment than ever. View the break-through new website now on kennedysdigital.com

Contact Us Your contacts at Kennedy’s are: Leon Kennedy, Digital Production Editor, leonkennedy@kennedys.co.uk Ben Emery, Sales Manager, benemery@kennedys.co.uk Alex Busby Sales Executive abusby@kennedys.co.uk Tel: (UK) + (44) 01732 752090 Web: www.kennedysdigital.com