3 minute read

Inductor Wiring Harness

The primary circuit pink wire, between the the ignition coil andthe distributor 2 wire plug, contains an inductor to protect boat electronics against Electro-Magnetic Interference (EMI) generated by the ignition system itself.

If the inductor fails (open circuit), then power to the IgnitionModule in the distributor will be lost. The engine will die and will not restart. Check the pink wire for continuity. Occasionally the wire breaks and intermittently opens the circuit, depending on the movement or location of the harness. If this happens, the engine may misfire or shutdown, but may restart.

Ignition Systems: 8.1L

Distributorless Ignition System

(Coil Near Plug, MEFI 4)

8.1 Gi/GXi Ignition Components

DIS DIS

Ignition coils Ignition coils

•One coil per cylinder

•Coil assemblies are interchangeable

The 8.1L engine is the only engine we have at this time that uses the distributorless ignition system.

This systems consists of 8 individual ignition coils, 8 individual ignition control circuits, a camshaft position sensor(CMP) and a crankshaft position sensor (CKP).

There is an IC circuit for each coil, each circuit is connected to the ECM. The ECM triggers each coil and makes all the timing decisions.

The ignition timing is not adjustable, there are no timing markson the balancer or the timing chain cover.

Failure of an IC circuit will set DTC 41.

The 8 ignition coils are individually mounted above each cylinder on the rocker covers, the coils are fired sequentially.

The coils secondary output voltage is very high, more than 40,000 volts.

The assembly is completely interchangeable, coils are identical and wire colors are duplicated.

8.1 L Ignition Components

Crankshaft Position (CKP) Sensor

Reluctor wheel permanently mounted to crankshaft

The 8.1 crankshaft position sensor (CKP) is located on the left rear of the engine block. It is a magneto resistive type sensor. The CKP works in conjunction with a 24x reluctor wheel.

As the crankshaft rotates, the reluctor wheel teeth interrupt amagnetic field produced by a magnet within the sensor. The CKP then outputs a 24x signal to the ECM.

The ECM then uses this signal to accurately measure crankshaft velocity which is a variable used in order to detect misfire, control spark and fuel.

The crankshaft position sensor is installed to contact reluctor wheel and wear to the correct clearance gap.

All CKP signals are output as a digital waveform.

8.1 L Ignition Components

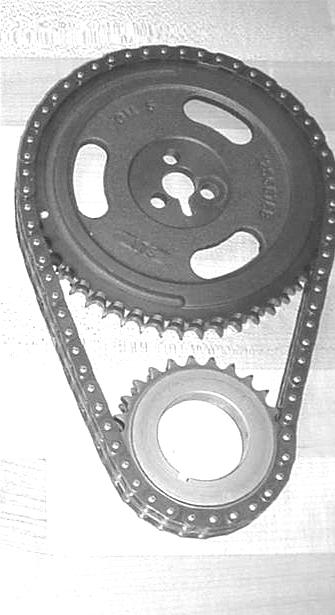

Reluctor Wheel

•Permanently pressed onto crankshaft

•Gives exact position of crank within each 90 degressof its rotation

•Sensor is installed to contact wheel and wear to correct air gap

The 24x reluctor wheel is permanently pressed onto the rear of the crankshaft.

The wheel uses 2 different width notches that are 15 degrees apart. This pulse width encoded pattern allows cylinder position identification within 90 degrees of rotation, in some cases, within 45 degrees. The wheel also has dual track notches that are 180 degrees out of phase, this design allows for quicker starts and accuracy.

If the CMP input is lost before cranking the engine, the engine will still start, but starts in a waste spark mode. This means that 2 ignition coils are fired at one time. The coils will be on companion cylinders. Companion cylinders on the 8.1L are 1 and 6, 8 and 5, 7 and 4, and 2 and 3. One of the 2 cylinders being fired will be on the compression stroke and the other will be on the exhaust stroke. Loss of the CMP input does not affect injector firing.

Camshaft Position (CMP) Sensor

•Reads Cam position each 180 degrees

Cam Gear

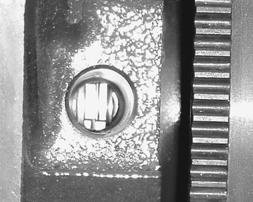

Detects half -moon slots cut in timing gear This is second generation gear

The camshaft position sensor (CMP) is mounted on the front of the engine.

The reluctor wheel has double (redundant) trigger machined into the front of the camshaft gear. The CMP senses the 1-tooth-per-revolution reluctor of the timing gear.

The CMP determines whether #1 cylinder is on the compression stroke or the exhaust stroke. It reads cam position within 180 degrees.

As the camshaft rotates, the reluctor interrupts a magnetic field produced by the sensor. The sensor’s internal circuitry detects this and sends a signal to the ECM.

The ECM uses this 1x signal from the CMP sensor in combination with the 24x signal from the CKP sensor in order to determine crankshaft position and stroke.

As long as the ECM receives the CKP 24x signal, the engine will start.

A failure of this sensor will set a DTC 81, Loss of CMP.

8.1L First Generation Gear

Only one slot