2 minute read

Digital Engine Position Sensor

The DEPS generates a digital signal that is sent back to the ECM.

DEPS stands for "Digital Engine Position Sensor". Two ECM terminals provide a clean power supply (J2-17) and return or ground (J2-18) for digital sensors such as the crankshaft sensor (CKP) and the camshaft sensor (CMP) used on MEFI 4 MPI engines.

DEPS Power is a regulated and filtered +11.5 volt DC supply specifically for digital engine position sensors and is also used to power the cam sensor in a High Voltage Switch distributor on the small block V8’s and the 4.3 V6

Devices other than digital engine sensors should NOT be connected to J2-17 and J2-18 because of the potential to create electrical noise that may interfere with engine operation.

8.1L Crankshaft Position (CKP) Sensor

Tip reads reluctor wheel data

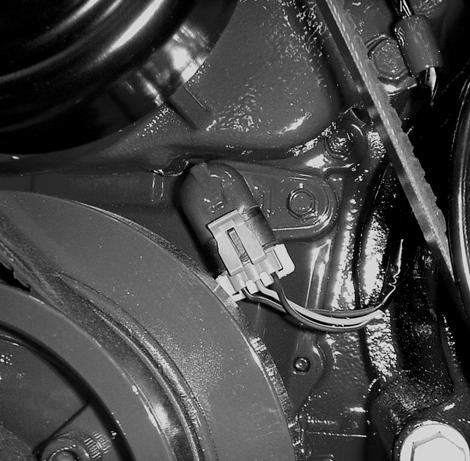

8.1L Crankshaft Position Sensor

The 8.1 crankshaft position sensor (CKP) is located on the left rear of the engine block. It is a magneto resistive type sensor. The CKP works in conjunction with a 24x (teeth) reluctor wheel.

As the crankshaft rotates, the reluctor wheel teeth interrupt amagnetic field produced by a magnet within the sensor. The CKP then outputs a 24x signal to the ECM.

The CKP is used to tell the ECM that a piston is coming to top dead center and how fast it is coming.

The IAFM CKP uses a 4x reluctor which will be discussed in the ignition systems section of this course.

8.1LCamshaft Position (CMP) Sensor

Camshaft Position Sensor

Identifies which piston is at TDC

The 8.1L camshaft position sensor (CMP) is mounted on the front of the engine. It is a magneto resistive type sensor. The cam position sensor detects the half moon “slot”on the camshaft timing gear.

The purpose of the CMP is to tell the ECM which piston is comingto top dead center.

The 8.1L CKP alone provides enough crankshaft information to runthe engine in a waste spark mode if the CMP is lost before cranking. The IAFM engines don’t need CMP input to start or run.

There are 3 different groups of parts for the 8.1L CMP. The earliest was a one groove gear. The later was a 2 groove gear and a sensor with 2 magnets. The 2004 and newer setup uses the 2 groove gear, 2 magnet sensor with a new style connector and a new timing cover that moves the sensor in relation to the cam gear. None of the 3different setups are interchangeable.

4.3, 5.0, 5.7L Crank Sensor (CKP) and Cam Sensor (CMP)

Above are the crank and cam sensors for the 4.3, 5.0, and 5.7L MEFI 4 engines. Just like the 8.1L, the sensors are feed power from the Depspowercircuit and current is returned to the ECM via the DepsLo circuit. Depspowerand DepsLo are shared circuits between the CMP and CKP sensors. Each sensor has it’s own signal wire back to the ECM. All of the CMP and CKP sensors used on the MEFI 4 engines produce an 11.5V square wave pattern on their signal wires in accordance with the number of teeth on each sensor’s reluctor. The IAFM engines use a 4X (4 teeth) CKP reluctor for the 5.0L and 5.7L and a 3x reluctor for the 4.3L. Both the 8.1L and the IAFM engines use a 1X (1 tooth) CMP reluctor. The 8.1L CMP reluctor is milled into the cam gear and the IAFM shutter is in the distributor (as pictured above).