3 minute read

ROLL-OVER PROTECTIVE STRUCTURE

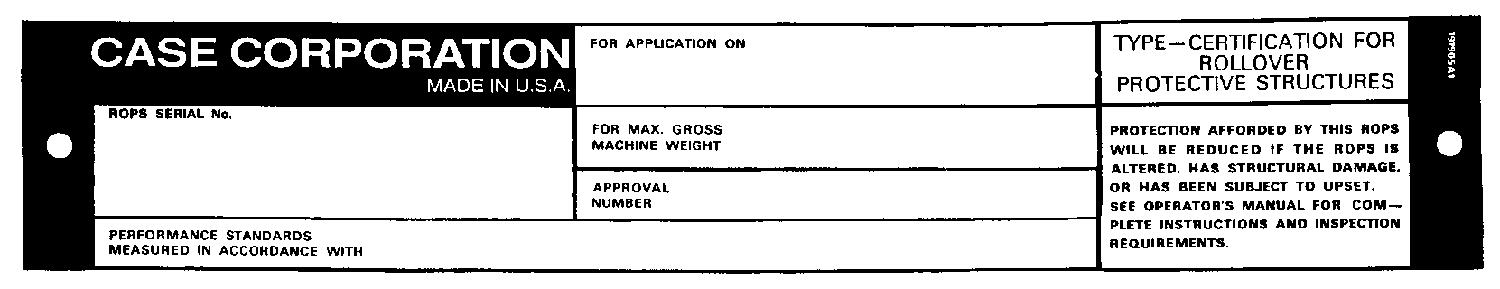

Your machine has a roll-over protective structure (ROPS) which is also certified for falling object protection (FOPS). A ROPS label is fastened to the structure. The ROPS label shows the serial number of the ROPS, gross weight, approval, regulation, and model numbers of the machine.

ROPS Canopy Label

NOTE: For location of ROPS label, see page 6 in this manual.

BS99C025

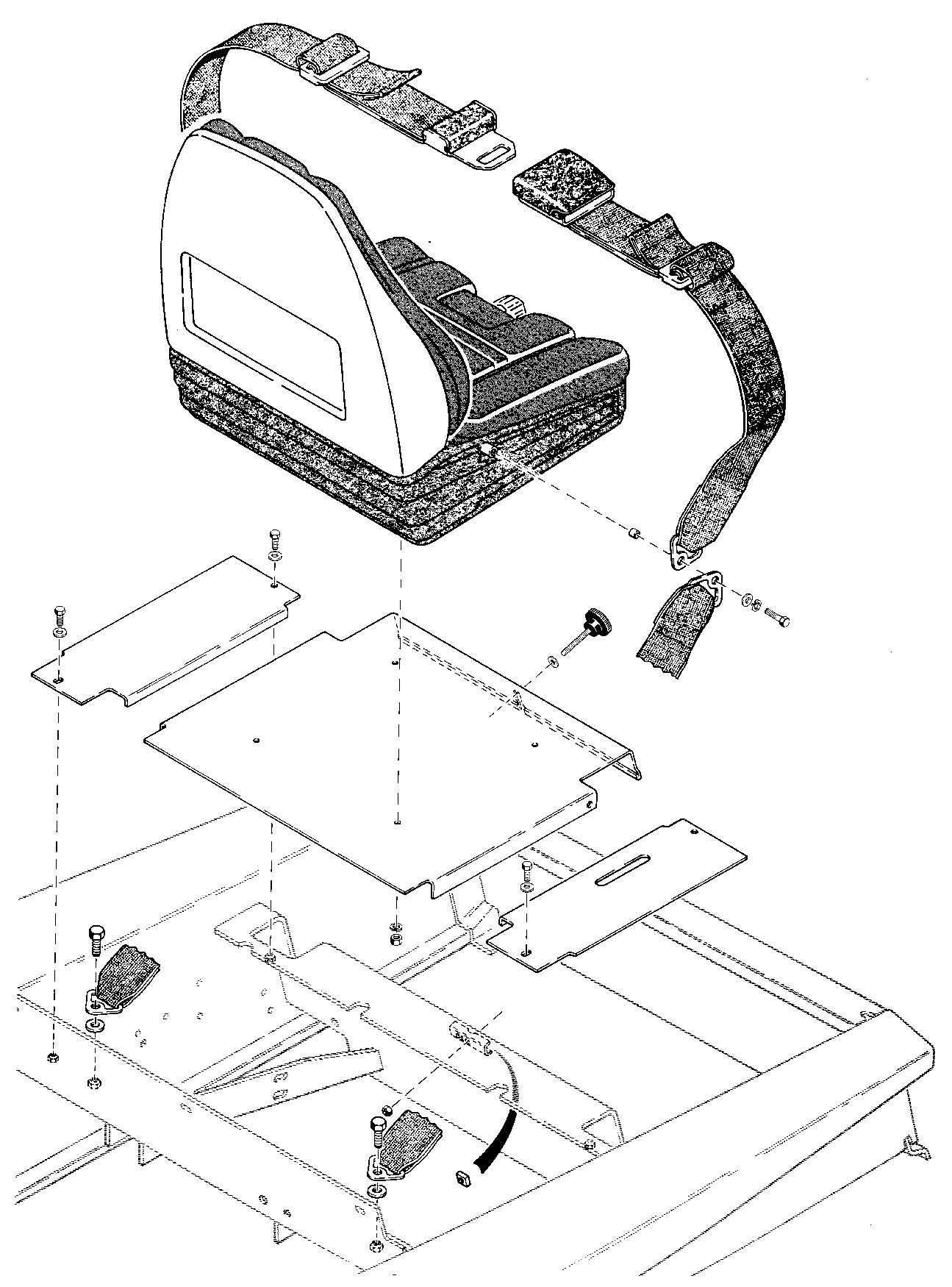

Seat Belt

The seat belt is an important part of your ROPS. You must wear the seat belt at all times when you operate the machine.

Before you operate this machine, always make sure that the ROPS and operators seat belts are correctly installed.

Maintenance and Inspection of ROPS

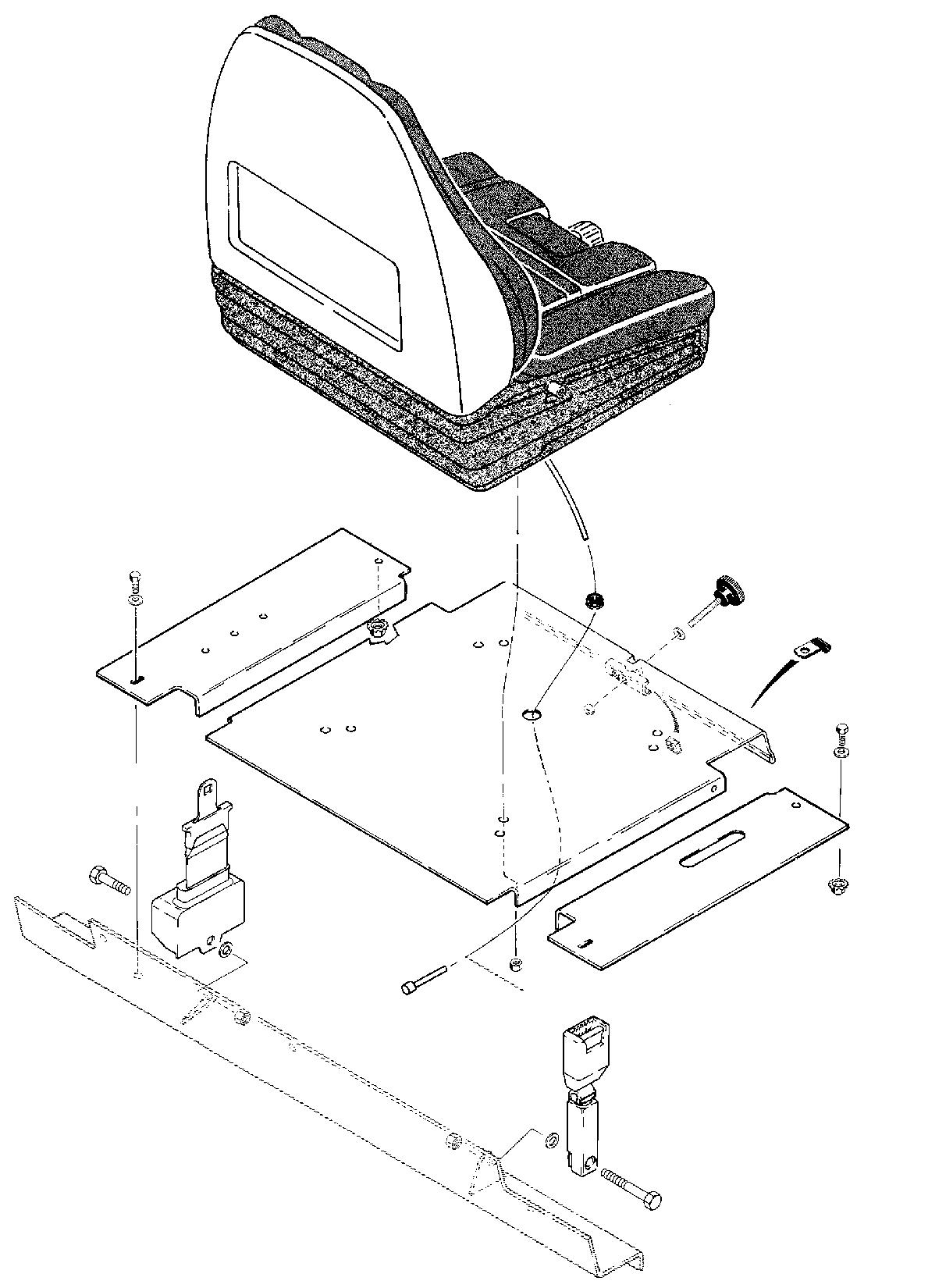

After the first 20 hours of operation and after every 500 hours of operation, do the following: 1.Check the torque of the ROPS mounting bolts. If necessary, tighten the bolts to the correct torque. See Torque Specifications for ROPS, page 139. 2.Check the operators seat and the mounting parts for the seat belt.

Tighten the bolts to the correct torque. See Torque Specifications for Seat, pages 140 and 143.

Replace parts that have wear or damage. 3.Check for cracks, rust, or holes in the ROPS and ROPS parts. Age, weather, and accidents can cause damage to the ROPS and ROPS parts. If you have any doubt about the ROPS system, see your Case dealer.

Damage to the ROPS

If the machine has rolled over or the ROPS has been in some other type of accident (such as hitting an overhead object during transport), you must replace the damaged ROPS component parts.

After an accident, check the following for damage. 1.ROPS canopy and side screens. 2.Operators seat. 3.Seat belt mounting bolts and seat belt.

Before you operate the machine, replace all ROPS components that are damaged.

See your dealer for replaceable components.

DO NOT TRY TO WELD OR STRAIGHTEN THE ROPS.

WARNING: Do not modify ROPS in any manner. Unauthorized modifications such as welding, drilling, cutting or adding attachments can weaken the structure and reduce your protection. Replace ROPS if subjected to roll-over or damage. Do not attempt to repair. SB026

WARNING: If you operate this machine without a ROPS and the machine rolls over, you can be injured or killed. Remove the ROPS only for service or replacement. Do not operate this machine with the ROPS removed.!

SA027

WARNING: Adding additional weight (attachments, etc.). To the machine can cause injury or death. Do not exceed the gross weight printed on the ROPS label. SA028

WARNING: Improper ROPS inspection or maintenance can cause injury or death. Do the recommended ROPS inspection shown in this manual. If you must replace the ROPS, ROPS parts, or ROPS mounting hardware, use only the replacement parts shown in the Case parts catalog for this machine. SA029

WARNING: ALWAYS fasten the seat belt and pull the seat bar down before you start the engine. Make sure the buckle for the seat belt is fastened correctly. SB030

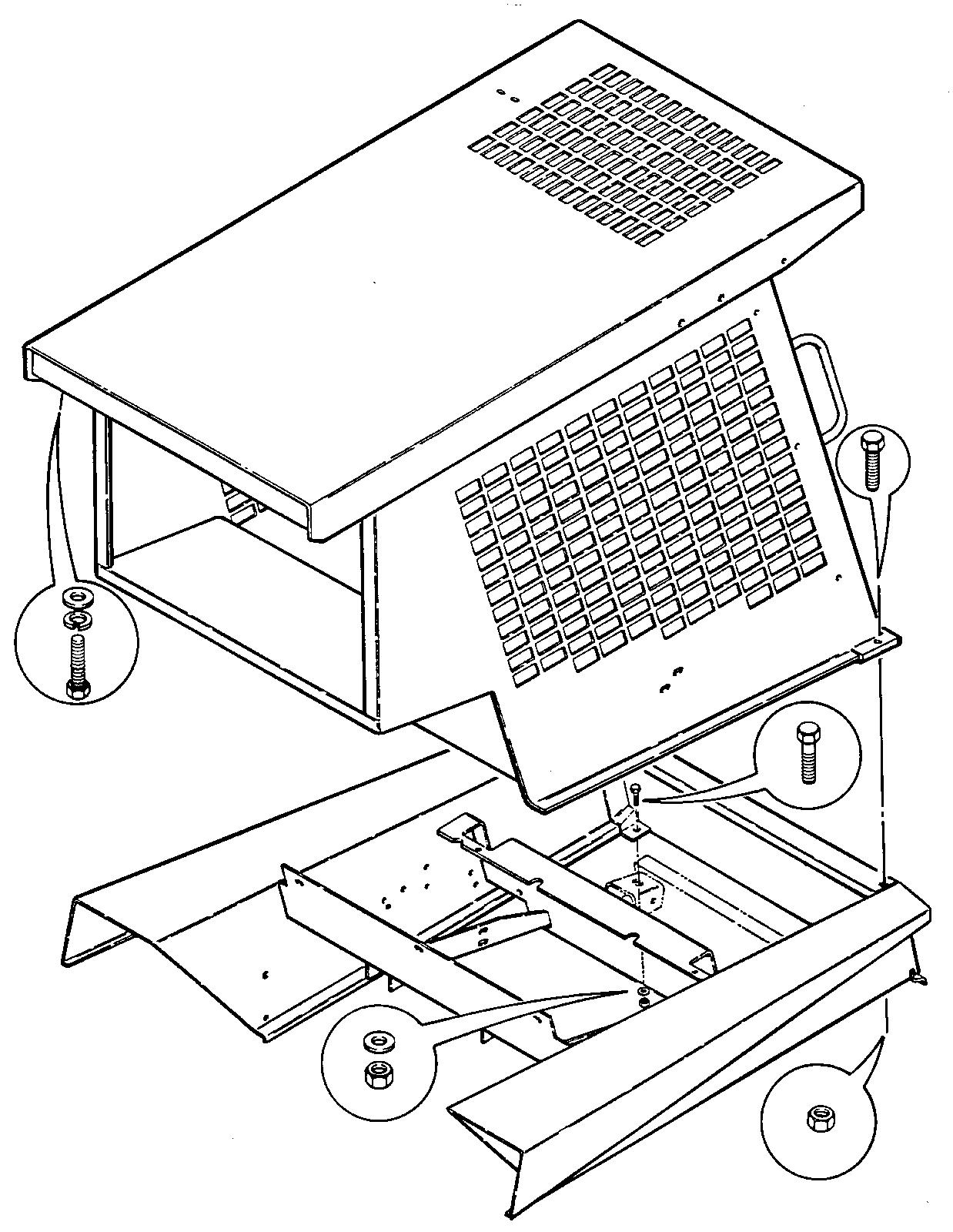

Torque Specifications for ROPS

4

2

3 5 1

1.TORQUE TO 109 TO 130 Nm (80 TO 96 POUND-FEET) 2.TORQUE TO 48 TO 57 Nm (35 TO 42 POUND-FEET) 3.TORQUE TO 54 TO 68 Nm (40 TO 50 POUND-FEET) 4.UPPER ROPS STRUCTURE 5.LOWER ROPS STRUCTURE

BS99C026

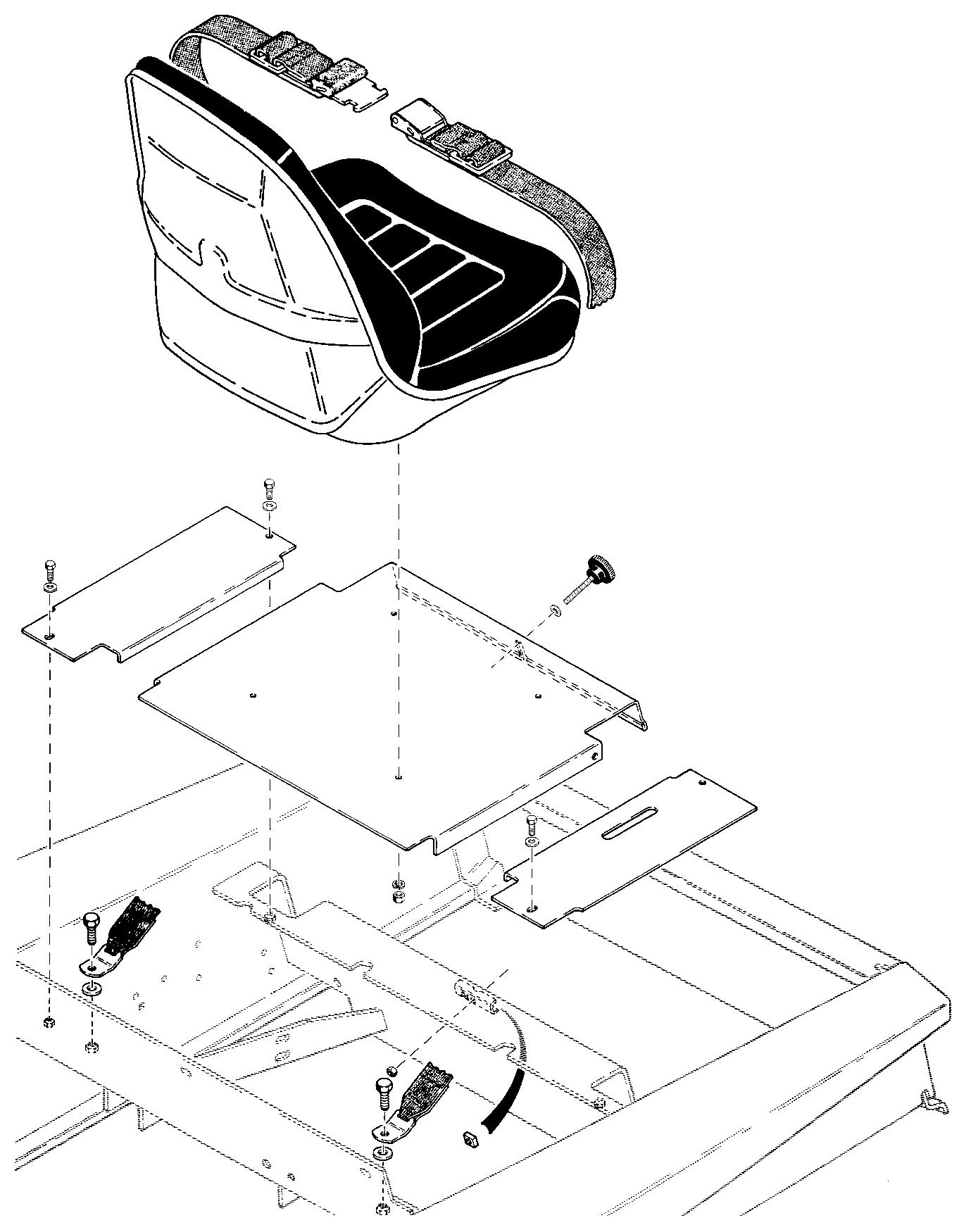

2

1

1.TIGHTEN TO 15.7 TO 28.3 Nm (11 TO 31 POUND-FEET) 2.TIGHTEN TO 69 TO 122 Nm (50 TO 90 POUND-FEET)

BS99C027

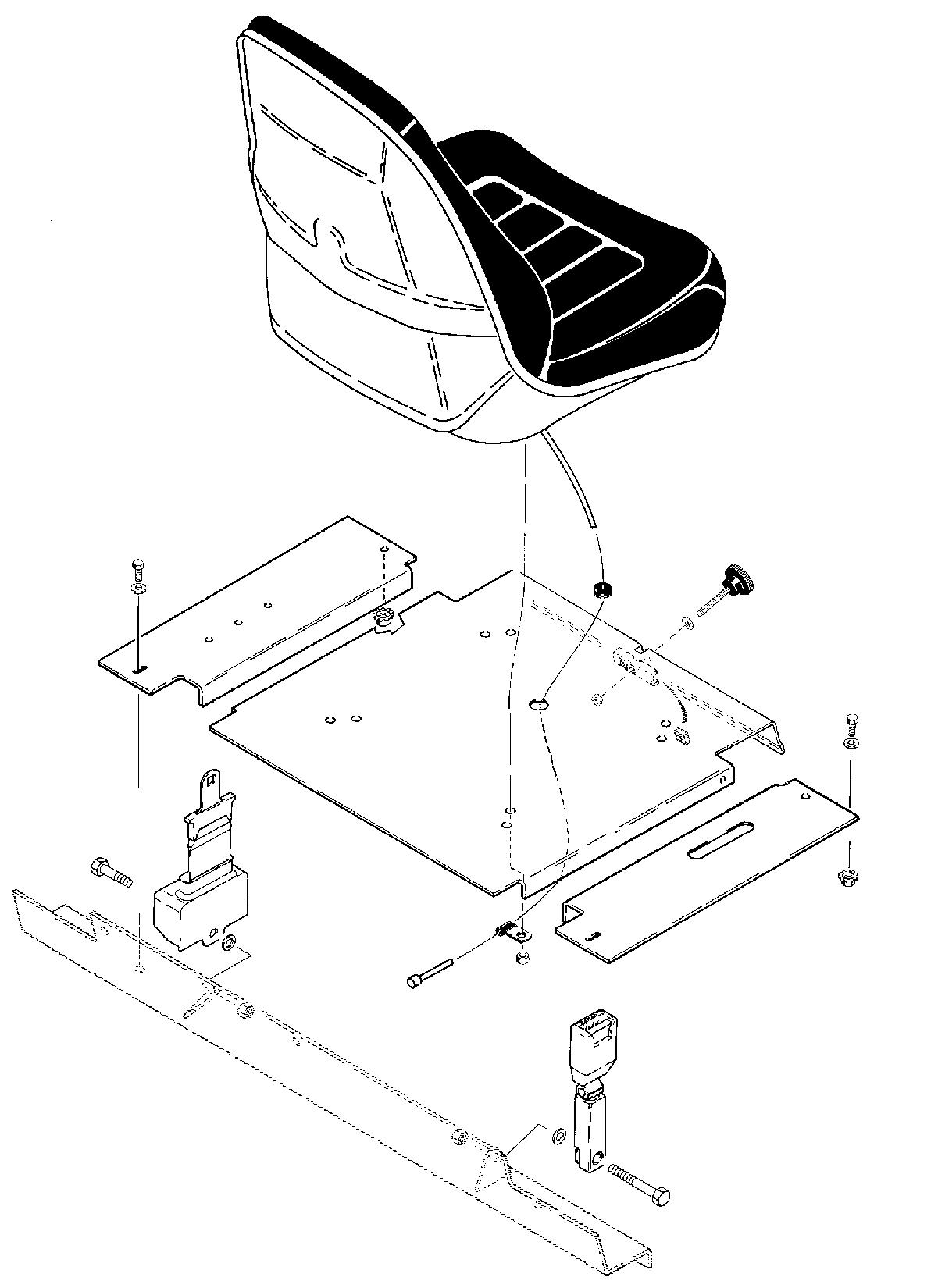

1 2

1.TIGHTEN TO 24.3 TO 44 Nm (17.9 TO 32.3 POUND-FEET) 2.TIGHTEN TO 28 TO 50 Nm (20.6 TO 37 POUND-FEET)

BS99E078

1

3

1.TORQUE TO 15.7 TO 28.3 Nm (11.6 TO 21 POUND-FEET) 2.TORQUE TO 28 TO 50 Nm (20.6 TO 37 POUND-FEET) 3.TORQUE TO 69 TO 122 Nm (50 TO 90 POUND-FEET)

BS99C028

1 2

1.TORQUE TO 24.3 TO 44 Nm (17.9 TO 32.3 POUND-FEET) 2.TORQUE TO 28 TO 50 Nm (20.6 TO 37 POUND-FEET)

BS99E079