4 minute read

DIESEL FUEL SYSTEM

Diesel Fuel

Use No. 2 diesel fuel in the engine of this machine. The use of other fuels can cause the loss of engine power and high fuel consumption.

In very cold temperatures, a mixture of No. 1 and No. 2 diesel fuels is temporarily permitted. See the following Note.

NOTE: See your fuel dealer for winter fuel requirements in your area. If the temperature of the fuel lowers below the cloud point (wax appearance point), wax crystals in the fuel will cause the engine to lose power or not start.

The diesel fuel used in this machine must meet Specification D975-81 of the American Society for Testing and Materials.

Fuel Storage

If you keep fuel in storage for a period of time, you can get foreign material or water in the fuel storage tank. Many engine problems are caused by water in the fuel.

Keep the fuel storage tank outside and keep the fuel as cool as possible. Remove water from the storage container at regular periods of time.

Fill the fuel tank at the end of the daily operating period to prevent condensation in the fuel tank.

WARNING: Engine fuel is flammable and can cause a fire or an explosion. Do not fill the fuel tank or service the fuel system near an open flame, welding, burning cigars, cigarettes, etc. SA022

WARNING: Never refuel the machine when the engine is hot or running. Never smoke while refueling. M139C!

Service Specifications

Fuel Tank Capacity.................................................81.4 litres (17.9 U.K. gallons) Interval for Draining Water From Fuel Filter............................................50 Hours Interval for Replacing Fuel Filter...........................................................500 Hours Interval for Draining Water From the Fuel System..............................1000 Hours

Fuel Tank

Fill the fuel tank at the end of each day or at the end of each shift. This will help prevent condensation of water in the fuel tank. Always keep the area around the fuel cap clean.

1

Fuel Conditioner

Diesel Fuel Conditioner is available from you Case dealer. Follow the instructions on the can. The conditioner will: 1.Clean the fuel injectors, valves and manifold for increased service life. 2.Disperse insoluble gummy deposits that can form in the fuel system. 3.Separate moisture from the fuel 4.Stabilize the fuel in storage.

1.FUEL CAP

H03118A

Draining Water from the Fuel System

Check the fuel filter for water and sediment every 50 hours of operation and check the fuel tank for water every 1000 hours.

To check for water, loosen the water drain valve on the bottom of the fuel filter and drain any water and sediment from the fuel filter.

Draining Water from the Fuel Tank

To drain water and sediment from the fuel tank, place a drain pan under machine able to hold a minimum of 73.8 litres (19.5 gallons) of liquid.

Loosen the fuel tank drain plug to drain water from the tank. After all water is removed, tighten the drain plug.

1

1.WATER DRAIN VALVE

B4053290 1

1.FUEL TANK DRAIN PLUG

B4133688

NOTE: If a large amount of water is removed, check your fuel storage tank or check with your fuel supplier.

Replacing the Fuel Filter

Replace the fuel filter every 500 hours of operation or if you experience a noticeable lose of engine power. 1.Turn the fuel shutoff valve completely clockwise to OFF.

1

1

1.FUEL SHUTOFF VALVE

B4133388

2.Clean the area around the fuel filter. 3.Use a filter wrench and turn the filter counterclockwise to remove.

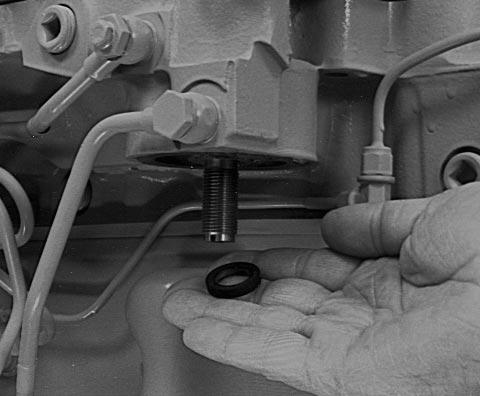

1.RUBBER SEAL

B9079006

5.Use a clean cloth and clean the gasket surfaces of the filter body 6.Apply clean engine oil to the new rubber seal. 7.Install the new rubber seal on the filter head stud. 8.Apply clean engine oil to the gasket of the new fuel filter. Do not fill the new filter with fuel before installation. 9.Turn the filter clockwise onto the filter body until the filter gasket makes contact with the filter body.

Continue to tighten the filter with your hand for 1/2 to 3/4 turn.

1

1.FUEL FILTER

B9079004

4.Remove the rubber seal from the stud on the filter head. IMPORTANT: Do not use a filter wrench to tighten the filter. You can cause a leak if the filter is dented with the wrench. 10.Turn the fuel shutoff valve completely counterclockwise to

ON. 11.Fill the tank with fuel and bleed the air from the fuel system. See

Removing Air from the Fuel

System, page 116

Removing Air from the Fuel System

You must remove air from the fuel system if one or more of the following occurs:

A.The engine runs until the fuel tank is empty.

B.Parts in the fuel system are removed for service.

C.The machine is kept in storage for three months or more. 1.Fill the fuel tank and make sure the shutoff valve at the bottom of the fuel tank is turned completely counterclockwise (open). 1

1.AIR REMOVAL SCREW

B4053290

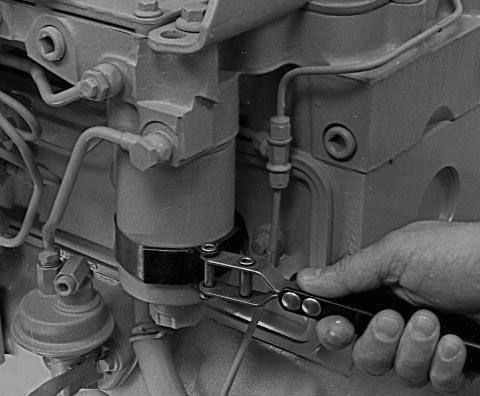

3.Actuate the hand primer pump lever up and down until fuel comes out free of air, then tighten the air removal screw.

1

1

1.FUEL SHUTOFF VALVE

B4133388

2.Loosen the air removal screw on the top of the fuel filter head 2 to 3 turns.

1.HAND PRIMER PUMP

B4053390

4.Start the engine and check for fuel leaks around the filter and lines.