3 minute read

ENGINE COOLING SYSTEM

Service Specifications

Coolant Capacity............................................................17 litres (3.7 U.K. gallons) Reservoir Coolant Level Check Interval.....................Every 10 Hours of Operation Radiator Coolant Level Check Interval.....................Every 250 Hours of Operation Check and Tighten Coolant Hose Clamps...............Every 250 Hours of Operation Coolant System Change Interval...........................Every 2000 Hours of Operation or Once Every Year Thermostat....................................................................83 to 95˚C (181˚ to 203˚F) Radiator Cap.................................................................................103 kPa (15 psi)

WARNING: Hot coolant can spray out if radiator cap is removed. To remove radiator cap: Let system cool, turn to first notch, then wait until all pressure is released. Scalding can result from fast removal of radiator cap. Check and service engine cooling system according to maintenance instructions. SA023

Coolant Solution

A mixture of 50% ethylene glycol and 50% water must be used in this machine. This mixture is used if the lowest ambient temperature is above -37˚C (-34˚F). It is recommended that ethylene glycol and water be used in your machine all year.

NOTE: After you fill the cooling system, mix the ethylene glycol and water completely by running the engine at operating temperature for approximately five minutes. This procedure must be done when the machine is in temperatures below 0˚C (32˚F).

Coolant Levels

Coolant Reservoir Fluid Level

Check the coolant reservoir fluid level every 10 hours of operation when the coolant is cold and the engine is stopped. Open the rear access door. Do not remove the radiator cap during this check. The coolant level must be between the FULL and ADD marks on the reservoir. Add coolant as required to raise the coolant level up to the FULL mark.

Radiator Fluid Level

Check the radiator coolant level every 250 hours of operation when the coolant is cold and the engine is stopped. Open the rear access door and remove the radiator cap. The coolant level must be up to the radiator cap opening.

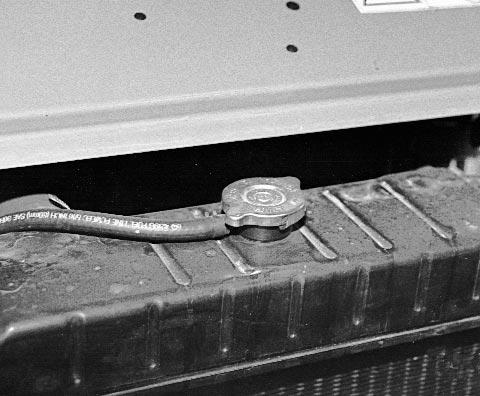

1

1

1.COOLANT RESERVOIR

B4026390

1.RADIATOR CAP

H03114

NOTE: If the radiator coolant level is low and the coolant reservoir level is at the FULL mark, check for air leaks in the hose between the radiator and coolant reservoir.

Coolant System Cleaning

Drain, flush and refill the engine coolant every 2000 hours of operation or once each year, whichever occurs first. Clean the system and replace the coolant if the coolant becomes dirty or rust colored. If possible, drain the cooling system when the coolant is warm. DO NOT remove the radiator cap if the coolant is hot. 1.Open rear access door. Remove the radiator cap. Place a container that will hold a minimum of 17 litres (18 quarts) under the radiator.

Open the radiator drain valve.

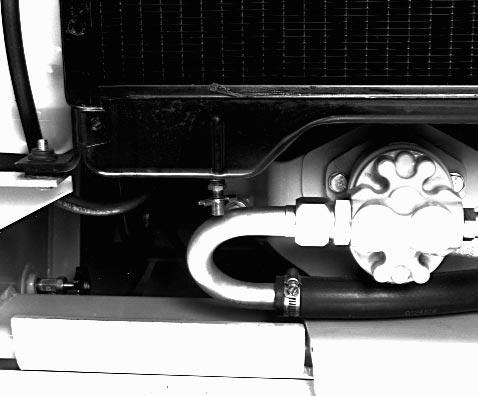

1

2.Close drain valve after all coolant is drained from radiator. 3.Add a cleaning solution to the cooling system and fill the cooling system with clean water. Follow the directions included with the cleaning solution. 4.Drain the cleaning solution and flush with clean water. 5.Close the radiator drain valve. 6.Use compressed air or water to clean the outside of the radiator and hydraulic oil cooler. 7.Fill the cooling system slowly with coolant until the coolant level is up to the bottom of the filler neck of radiator.

1.RADIATOR CAP

1

H03116A NOTE: Allow the venting of entrapped air when filling the cooling system until you have the correct quantity of coolant in the system.

NOTE: Refer to Fluids and Lubricants in this manual for correct coolant specifications. 8.Install the radiator cap. 9.Check that coolant level of reservoir is between FULL and

ADD. 10.Start the engine and run until the engine coolant is at operating temperature. Stop the engine and allow to cool. Check for leaks. 11.Check the coolant level at the coolant reservoir only. Do not remove the radiator cap. If the coolant level is low, add coolant.