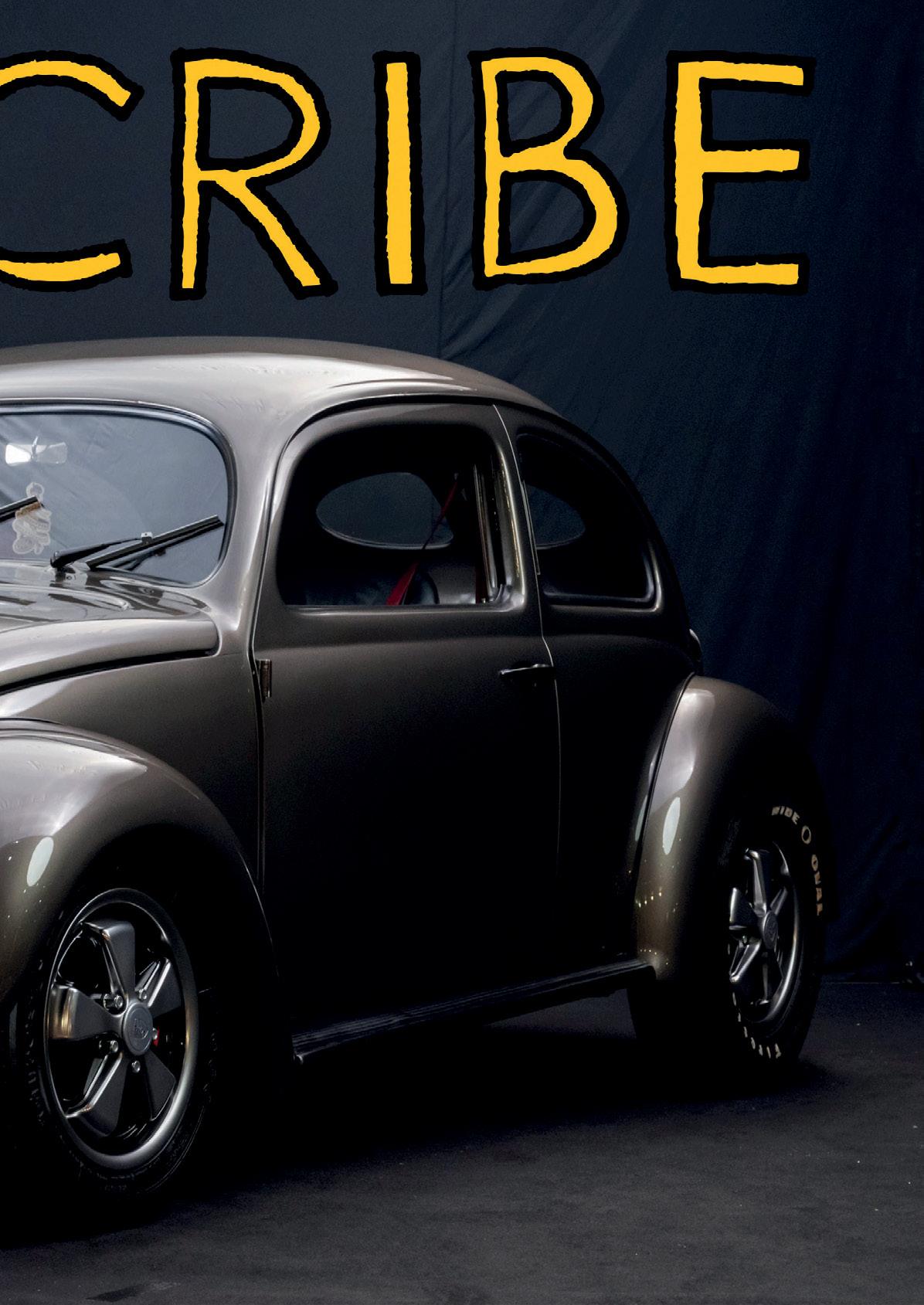

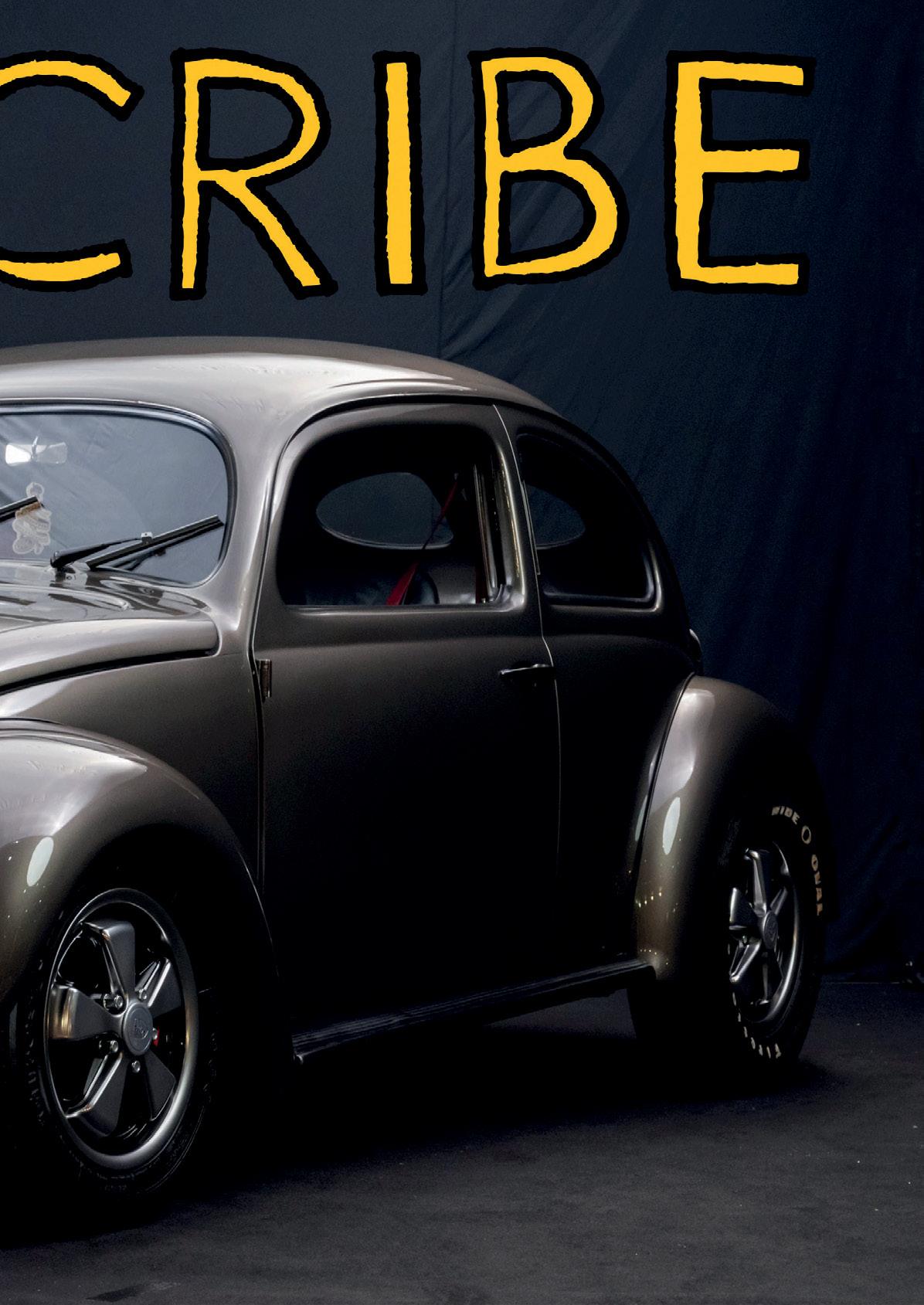

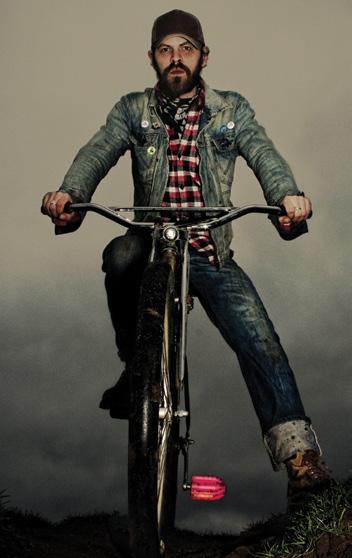

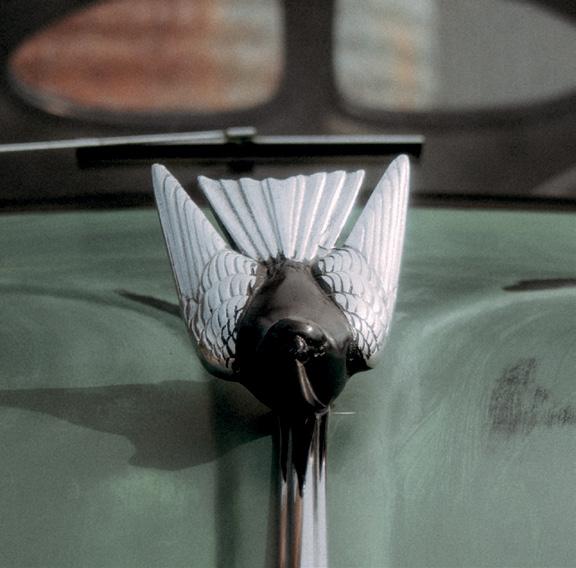

There’s something mythical and wicked about Chris’s ’52 crotch cooler Deluxe known as “Krampus”. But, it isn’t just in the name …

story of one young owner’s journey into the classic Volkswagen world thanks to a chance encounter with a red Karmann Ghia … and finding his dream 1962 Lavender machine.

The resurrection of a Volkswagen –something many of us have dreamed of but few get the chance. Finding your ultimate treasure, a 1964 11-Window Type2 and bringing it back better and stronger than ever before.

On a lonely island in the middle of the Irish Sea lives what many deem to be the holy grail of Volkswagens – a period-modified 1954 Barndoor Type2. Cared for and preserved, this is the true story of a long-forgotten survivor.

Instead of the regular editors letter (which I really don’t want to write anyway) I thought I’d give you a brief rundown of the places car culture has taken me throughout 2022. Ned.

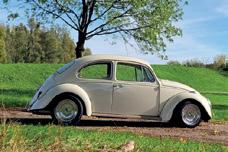

While on the hunt for a classic Beetle, the perfect example fell into Mark and Emma’s hands and they couldn’t pass it up. Turns out, this all original 1961 Volkswagen Beetle came with an incredible story and a small list of owners.

Volkswagen and diesel. Two words that when combined in modern times have spelt controversy and scandal. However, the story of its earliest form in the 1950s had hope, promise and some amazing engineering.

Copyright © 2022 by Hayburner Magazine All rights reserved. This magazine or any portion thereof may not be reproduced or used in

Copyright © 2022 by Hayburner Magazine All rights reserved. This magazine or any portion thereof may not be reproduced or used in

What is building an old air-cooled Beetle without friends and family? Well, Jonny and his closest allies took a forgotten Beetle and turned into a green-laning monster! Here’s Swampy, the ’70/’72 Beetle Class 11 inspired off-roader.

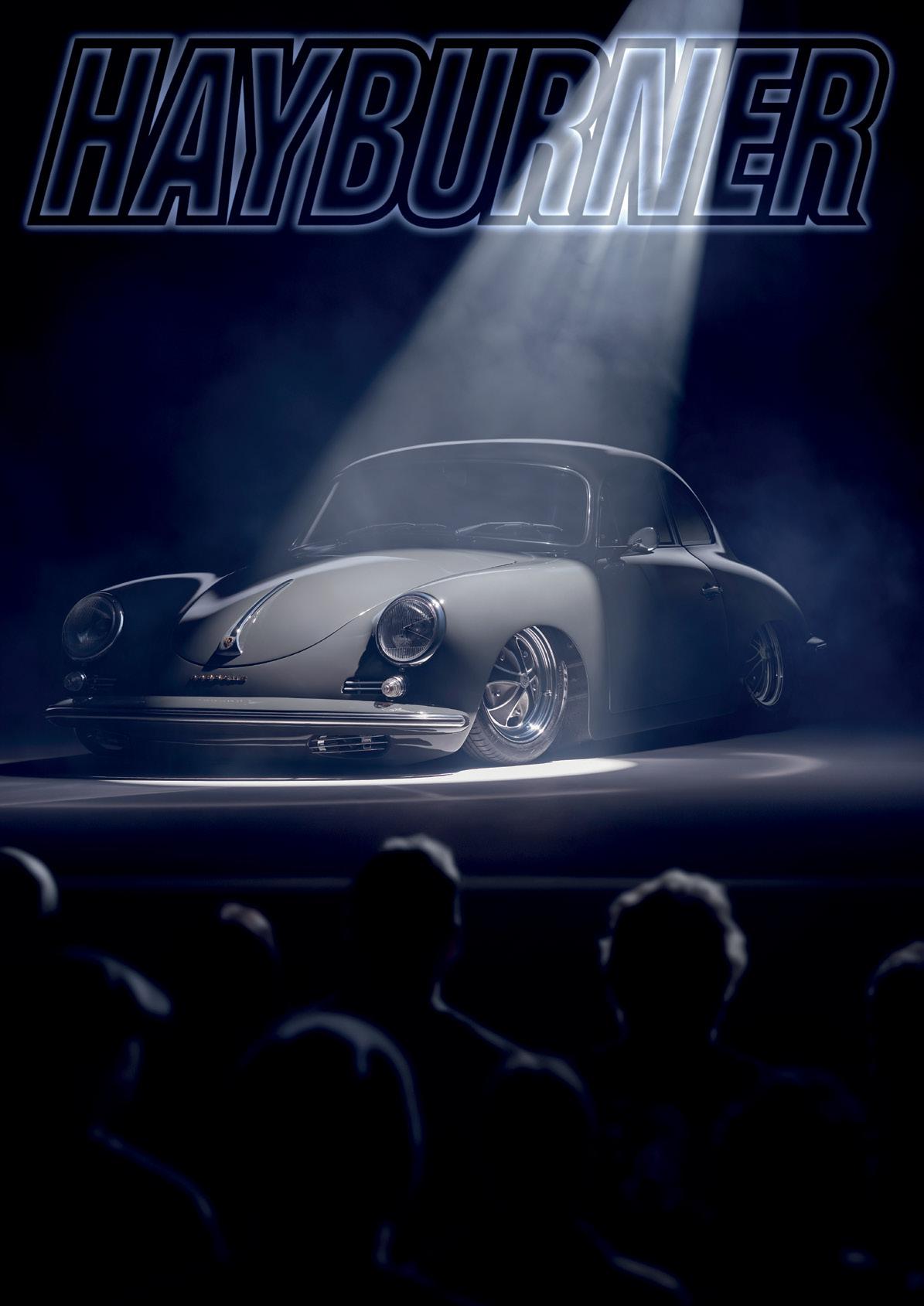

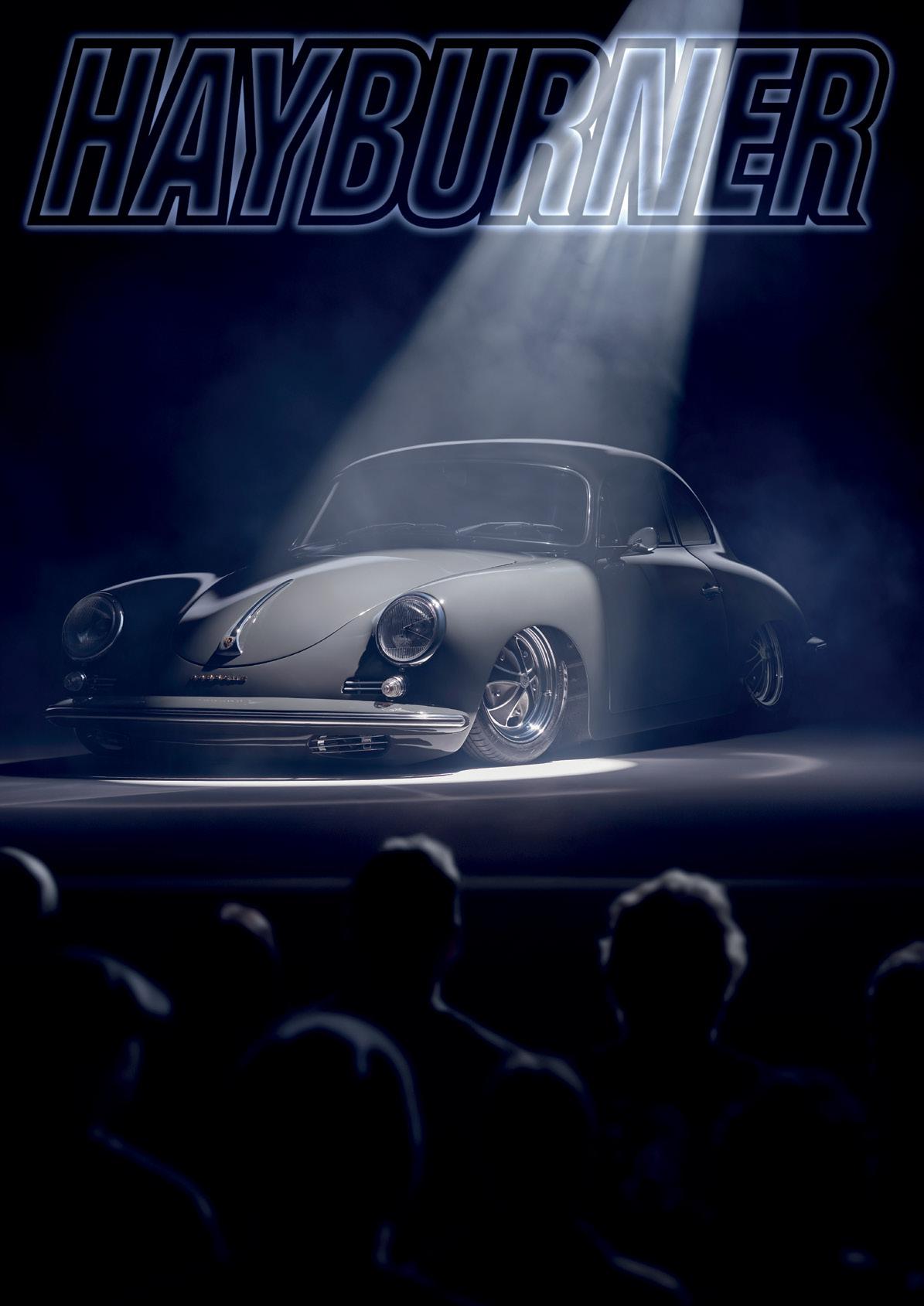

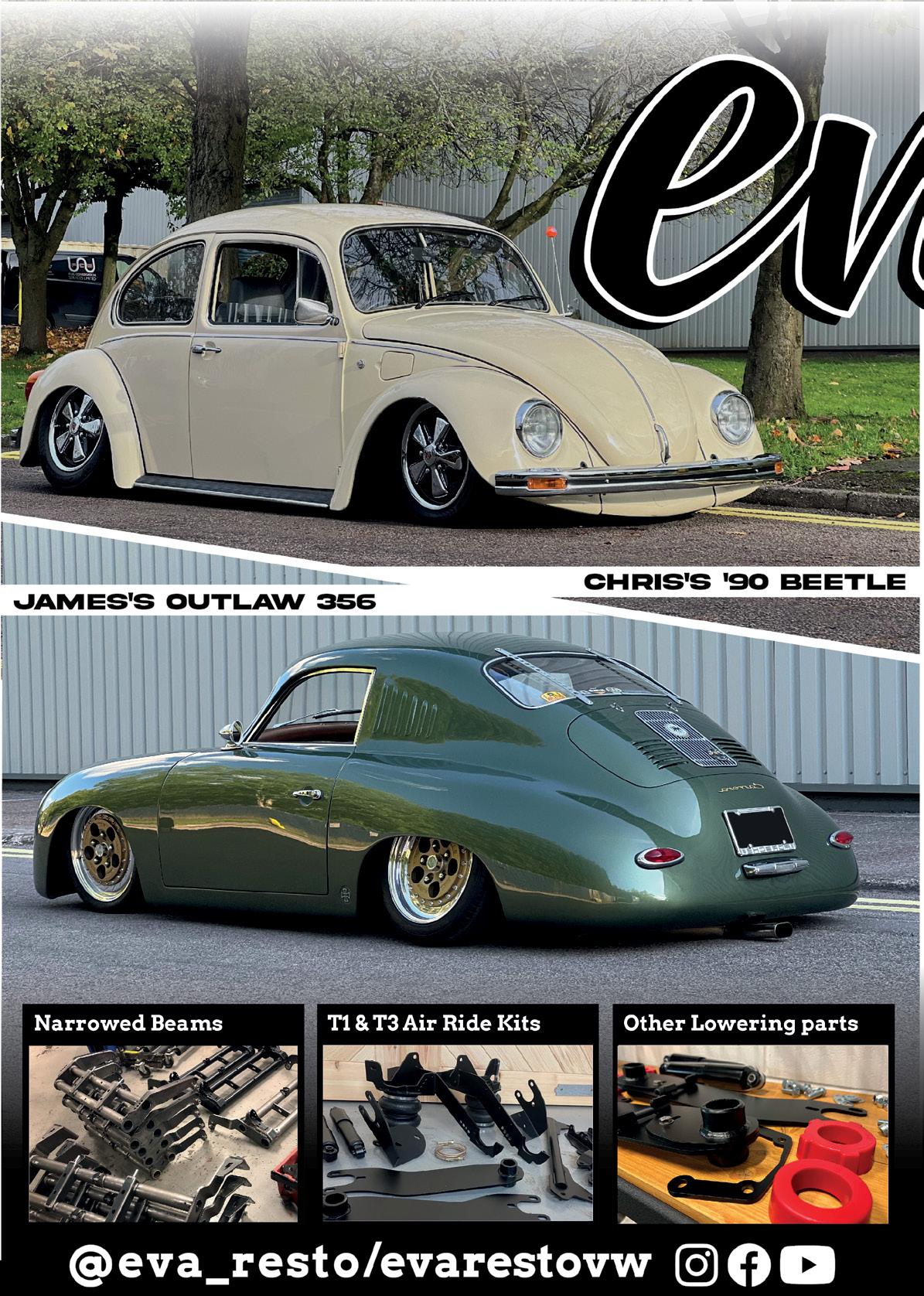

One of the most sought-after silhouettes in the classic car world and lorded over by many. But, what if you took this timeless classic and gave it a whole different attitude? That’s exactly what Ben did with his 1960 Porsche 356 Super90.

OKRASA is a revered name in the Volkswagen world. But imagine finding and owning an original, unrestored OKRASA 1300 Beetle. Feel the envy with Michael Gross’s 1963 OKRASA TSV1300.

The result of years of Volkswagen fascination and an early influence from an Italian comedy show, this is Nicola’s 1953 Jupiter Grey Standard Oval. However, the car and its owners’ story are far from standard.

Before the widely printed “how-to” guides and the wealth of Volkswagen knowledge at your fingertips, you had to go out and find obscure books. Like this one. Here’s a bit from the 1975 printing of “Der KdF Wagen”, the ultimate early VW how-to book.

We all remember Bus Selecta, right? What if you could take what you’d made on the screen and bring it to life? That’s what Mike did with his ’55 Dove Blue Type2.

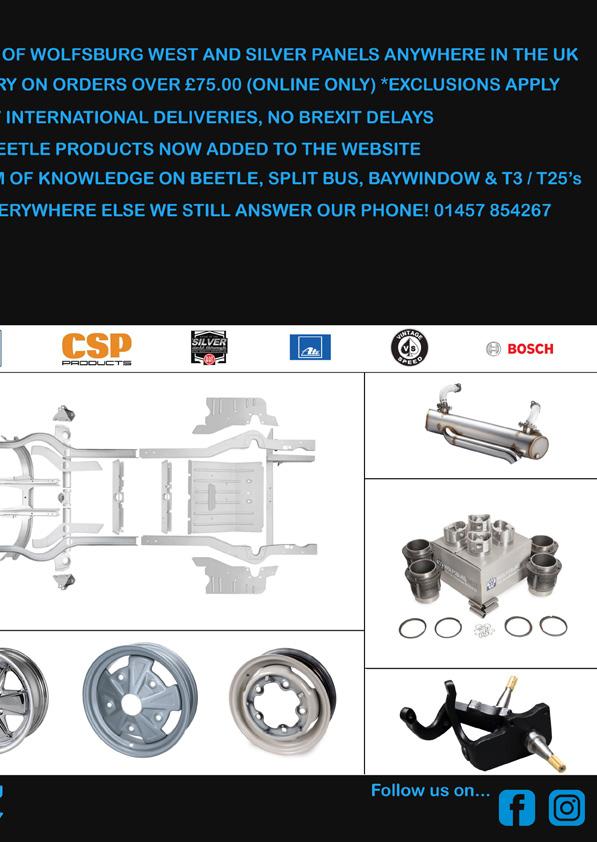

CLAS CAR A S IC PA RT S

CLAS CAR A S IC PA RT S

Wiper switch knobs

New in our assortment are the wiper switch knobs which look identical to the other dashboard knobs but have M4 threads instead of M5. Available in black and ivory.

41940

Self-locking pulley bolt

This bolt has an enlarged compression section that has locking teeth. This pulley bolt is not a reproduction but original Volkswagen.

17130

A-quality front apron for the VW Beetle

These new front panels replace the original in detail, carefully drill out the spot welds, grind clean and your new front panel can be welded in. With these new A-quality panels we o er equal front aprons to the original, i.e. as your classic car was in the showroom back in the day.

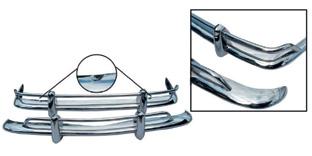

Polished stainless steel Ghia and Type 3 bumpers 10014 / 10015

All models applied to the Karmann Ghia have enhanced our range whether they are bumpers with bumper guards, without bumper guards or the export bumpers tted with protective tubes, we have them all in polished stainless steel. The models after 8.1971 are similar to the VW Type 3, so we have polished stainless steel for this model as well. All bumpers come in sets for both front and rear.

The lock hook is identical to the original, chrome plated and supplied without the threaded plate, bolts and rubbers.

Rear window assembly seal kit

This sealing set not only contains the rubbers for the above mentioned lock hook, but also those of the hinges.

Ghia rear window lock hook 17131 20454

Interior light switch bu er

This stop rubber causes the interior lighting to turn on or o when opening and closing the sliding door.

During his formative years in Italy, a young Nicola Danza had a strong interest in cars. Although his uncle owned a Marathon Beetle, it was a red Puma Dune Buggy featured in the first film he ever saw at the cinema that spiked his interest in VWs. The rest, as they say, is history, and today 50-yearold Nicola is a bona fide car designer, living and working in Germany. I won’t stoop to any national stereotypes, but I will tell you that the film he saw way back as a kid in Italy was a comedy called “Watch Out, We’re Mad!” and the influence went deep. Actually, that film title isn’t a bad metaphor for VW ownership and the incredible levels that so many people go to in the name

of restoration, preservation or the pursuit of a personal dream. Nicola included.

So the day job helps, plus a string of VWs and the odd early Porsche have laid the foundations for a mega build. However, this is Germany – a place where modified VWs don’t generally follow the trends and styles found elsewhere. Home of the Autobahn storming 1303, land of the Porsche cooled Type4 motor, and a place where strict laws govern modifications and parts availability. Actually that’s not entirely accurate. You can buy and fit any part you like to your car, but if it doesn’t come with TUV certification

you can’t drive it – and that’s not a wishy washy UK can’t (well, it will be ok, no-one is that fussed) – that’s a very definite you will be in a whole world of shit! I like to think it’s safety orientated, with unrestricted Autobahn areas being the last place where anyone needs a spurious part to fail, and absolutely nothing to do with Teutonic thoroughness. Either way, it’s safe to say that German builds have a unique feel to them. Damn! The stereotype pledge didn’t last long. Anyway, ignore that and let’s busy ourselves with this superb Jupiter Grey 1953 Standard Oval.

Nicola had been heavily influenced

by traditional Cal Look and Resto Cal styling, so when he stumbled upon the ’53 in the corner of Andreas Wackers’ garage, it was not only love at first sight, but any modern Germanic styling influences were consigned to the bin – cup felgen, nein danke! Andreas had owned the car for many years, and while he was just the third owner, other than knowing it was originally sold in Marburg, the history was like much of the structure – missing!

How much was missing? I hear you ask. Well, the car was complete insofar as the unique Standard model interior,

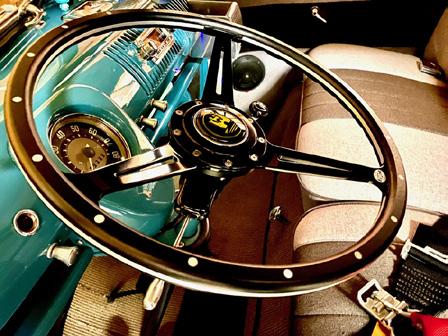

plain painted mirror, door handles, bumpers and threespoke steering wheel were all present. They all needed work, but were there. The rest was in poor condition throughout, but a Standard Oval is a very rare car even in Germany. While the most basic stripped back and Spartan offering from VW hits the spot aesthetically these days, the factory de-chromed look may have predated those DKP boys by decades, but it was very basic and austere. Especially so when compared to the thousands of metallic paint and chrome laden export models being churned out for every Standard ordered.

They were basic, cheap and the passage of time hasn’t been kind to them, which is why they are well worth checking out if you get the chance, even later versions of the Sparkafer as they were known have enough subtle differences to keep a geek busy for a while.

It took a lengthy eight years to complete the full bodyoff restoration, with every single part being redone to meticulous standards, right down to each bolt being of the correct Kamax type. The remit was to retain as much of the original car as possible, and restore to original Standard

model specifications. Tracking down specific 1950s NOS parts added to the time frame (try finding a pair of 1953 Standard doors in a hurry, or paying for them!), and subsequently finding out that the car had been in a significant T bone accident and probably ended up on its roof complicated matters somewhat. It also took a whopping 500+ hours of welding performed by Jens at Kasper Customs in Bad Camberg before the body was ready to receive a fresh coat of the original L22 Jupiter Grey applied by Andrew Duffy.

It’s probably worth noting that as a stock restoration this is about as good as it gets, but it’s not stock. Well it is sort of an amalgamation: a Resto Mod with period power? A Resto Cal without the trinkets? A Vintage Speed Cal Looker? Watch out – it’s sending me mad just trying to pigeonhole the car. Decide for yourselves at the end, as I swiftly move on to the interior which was redone to exacting original specifications by Markus at Wagenmanufactur in Hessisch Oldendorf. Remember, this comprises Standard only materials, short

roof lining, seats held down with wing nut fixings. Even the rubber mats are unique to the poverty spec cars.

At this point it would be easy to have taken a totally stock route, but Nicola, being hands on throughout the project, built the car he’d always wanted. And to be fair, what’s a 2” narrowed beam and some 911 type adjustable spring plates between friends? Easily returned to stock should the mood take him.

The “friends” theme recurs through so many VW stories worldwide, it is no surprise that friend to virtually everyone Tom Gotta was responsible for building the motor. A contemporary period-ish upgrade from the past, made widely available with the Wolfsburg West TSV 1300 Okrasa Kit, it upgrades the original 30hp to around 55hp, but the torque increase when combined with a decent exhaust really wakes up the party. And this particular TSV uses a custom-made exhaust with a party piece of its own, interchangeable tail

pipes from one to four, and why not! Transmission, thanks to Siggy, is the original fully refurbished unit as you would expect, but the big news is the faithful retention of the stock cable braking system. You are probably thinking, hold on, he is talking shite, those are not stock brakes. Well, they are in essence, but I concede the drums are custom items with pressed aluminium cooling rings, a design feature that should also help keep things on the happy side of brake temps.

After all, if your brakes are overheated on a Standard, yanking up the handbrake won’t help you.

We are getting to the point where I should list the wheel and tyre details people like to know, so here goes.

The wheels are 15” TuV approved Maxilite Fuchs replicas in

4.5 and deep 6 configurations, wearing Firestone 135/80s up front and those killer Firestone Wide Oval FR 70s on the rear, further adding to the unique nature of the ’53.

It’s no coincidence that a car designer’s car would have some clever features, but with the nature of the build (rear tyres and stance aside), conceptual originality is key.

The Hella mirror, combination search lamps are wired to act as indicators, the rear light units have one year only US spec egg lenses, and inside a Harmonica folding parcel shelf, Okrasa shifter knob, overhead storage net and coco over mats add a bit of period opulence.

We managed to have a really good look at the car in Hessisch, and the standard (sic) is magnificently high and a real testament to everyone involved over the mammoth

resurrection.

The last words go to Nicola, to whom we asked the usual array of questions, but his reply sort of sums up everything nicely. He is a car designer of course, so should know what he is on about, and it’s saved me the job.

“I love how the car turned out in general. I love the colour combo and the stance with those tyres, and the fact that it doesn’t really follow any particular trend. It is one of a kind.

Standard as VW intended, plus not so standard engine and black wheels and details to keep it more standard look. I wouldn’t change a single thing!”

The “Watch Out, We’re Mad!” friends list includes Andreas, Jens, Tom, Markus, Andrew, Sascha, Lutz, and everyone who Nicola bothered with millions of questions throughout the process and Nook_2m for the photos. It literally couldn’t have been done without them.

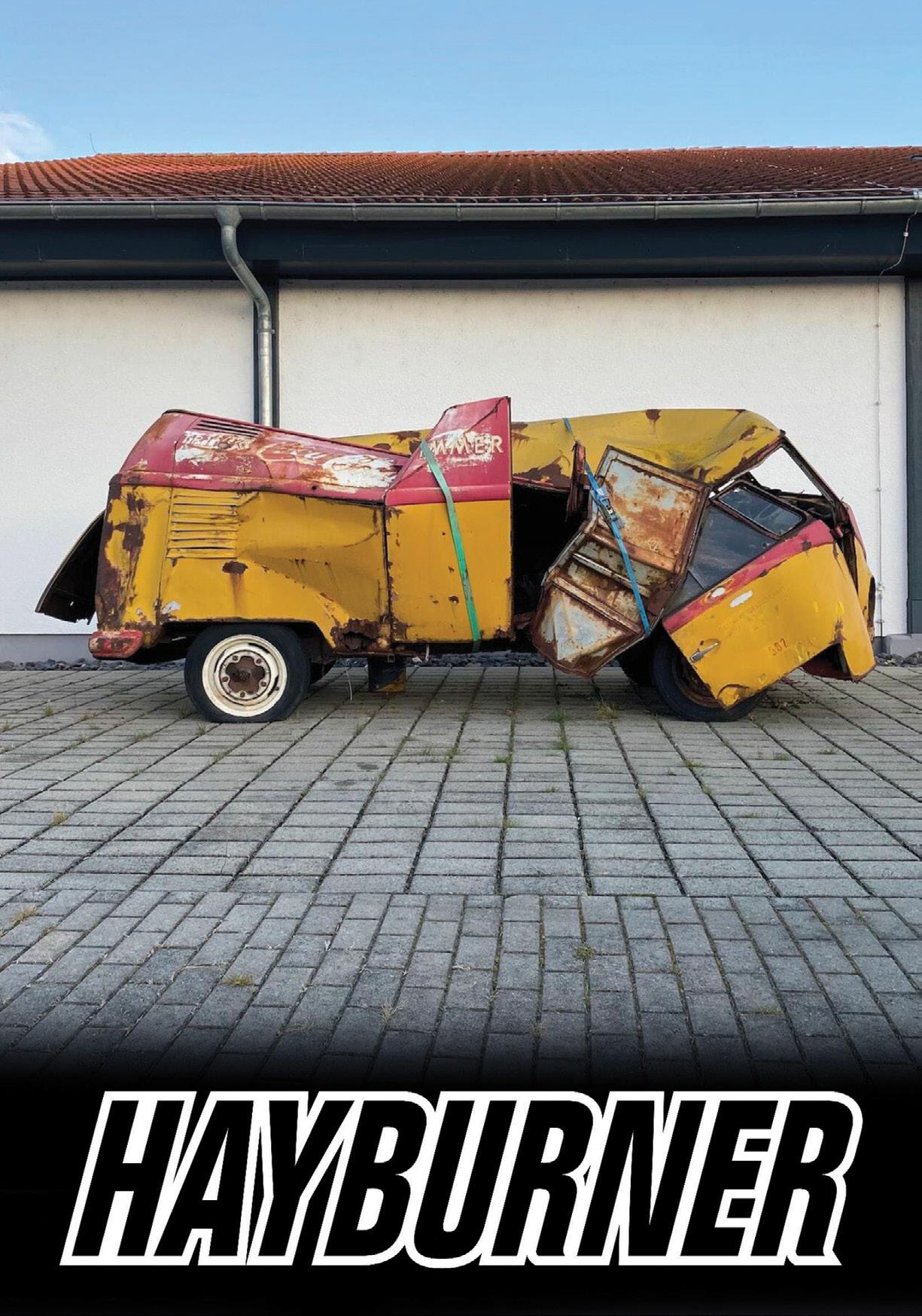

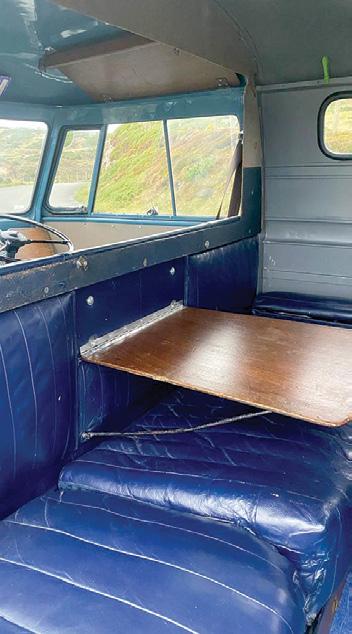

I’m really excited to get this article written. I know it’s going to be a load off. It’s not only the last thing I need to complete and send off to draw a line under Issue 44, which has been a hundred times more work than I ever contemplated, but it will also give me a chance to set this build out on paper and give me some clarity as to where we are at with it. This is the first attempt I’ve ever had at project management, and if I’m completely honest I had no idea just how much work goes into building something for someone else. When you build your own car it’s so different: you do the hours you want; there aren’t any deadlines, or only the deadlines you put upon yourself; the financial aspects are your own so you don’t feel the

need to document and justify every penny; and most of all, the only person you feel like you might let down is yourself. The pressure to make this bus the best it can possibly be is something I never even thought of when I took this job on. It might be a combination of the changes with Hayburner as a business, the current state of the UK economy and juggling family life, but I don’t think I’ve ever been so overwhelmed.

Saying that, I’m so lucky. Ewan is the best person to work for. He constantly tells me not to worry and that there’s no rush. Earlier this week when things got heavy, I dropped him a message to apologise for my radio silence and explained that I have to get this mag out. I worried about this, as I know full well that this project is well behind schedule. Once again, he was cool with it. It makes me wonder if the stress is completely unnecessary. I think I just

want this to be perfect, and so far, although ten times more work than originally anticipated, the work is, well … perfect.

I imagine you’re thinking, “How can the project be ten times more work than first thought?”. It all boils down to how closely we’ve all worked on it. Since the bus went to Lloyd at Deluxe Metalwork, between Lloyd, Ewan, Steve Walker and myself there have been over 2000 photos and videos of the project exchanged, and half of these have been decisions discussed in detail. More often than not, we go with the best possible way to go about the job, whether it’s something major like “do we replace the entire bulkhead?” to “do we mind if this door handle has the correct marking for the year?”. I love that everyone is so involved, but building a perfect patina vehicle can end up harder than fully restoring one. You

have to remember that this was a very rotten bus. It’s not a dry state, change the seals and get the brakes freed off job; it’s a Canadian full restoration. Apart from the exterior paint, this bus has been more extensively worked through than most show cars. But Ewan stated that this is to be a keeper and a bus he could pass down to his children, and that’s exactly what we’re building for him.

Now, to describe every detail would take more pages than are in this magazine, so I am going to have to let these photos do the talking. I guess a brief list of welding works would be that everything 6” up from the floor all round required repair or replacement, and then also localised repairs on the body, doors, front panel, rear corners … I could go on all day! A good example of the extent of getting this just right is the night I got a message from Lloyd saying, “I’ve had to do something. I hope you’re ok with it but it

had to be done.” I nervously awaited a photo, and then discovered that he had removed the entire front end of the bus from the windscreen pillars down. I could see straight away why he had done it. The chassis legs were so bent that it really made sense, but at the same time it’s a daunting photo to see. It looked so drastic that Lloyd didn’t want to put a photo of it on the group until it went back on. However, Ewan is nobody’s fool and mentioned to me in a separate conversation that he could see it had been removed because of

the angle of one of the photos. Once the panel had been refitted, I dropped in to visit Lloyd and I purposely asked someone to point out where they thought the pillars had been cut. They were wrong by a mile. I then pointed out where they had been cut by memory and I was wrong by a mile as well! Now if that’s not testament to Lloyd’s skills I don’t know what is. While Lloyd starts putting the last parts together and begins

blending the paint, I’ve been working on a plan to get this bus put back together. Steve Walker came down for the day and we laid out every component of the bus so we knew it was all there. It wasn’t, not by a long chalk. I don’t know if you’ve ever had to find every single part for a completely disassembled Split bus, but for a basic vehicle there are a hell of a lot of bits required to put one back together, especially finding the best NOS or used parts and the best quality reproduction where required. Every part needs to be the correct age and also aged to suit the bus.

A lot of thought has gone to each component and Steve’s input was priceless. He has put together a complete list of every missing nut and bolt needed – I just need to go and find them.

Spreading out the parts really did highlight what a task we have ahead to get this thing running. The extra time that’s been required for metalwork has pushed the build-up project into my busy period. I was discussing this with Paul Medhurst over at T2D, and he made us a very generous offer to use their ramps and a few of his staff members to get it done and dusted over a weekend. This is extremely tempting, considering that our other option is Steve and myself rolling it around on axle stands in my workshop for

the foreseeable future over the winter months. I think it makes perfect sense. T2D are better equipped for this, it will save everyone a lot of time, effort and expense, and to top it off it sounds like one hell of a fun weekend. I think we’ll video the whole thing for HBTV, so make sure you keep a close eye on our YouTube channel.

Right now the bus is currently a little further on than where I’m going to finish this article, but I’m going to start my next instalment there so I have the space to give it the coverage it deserves. I think you will all be thoroughly impressed.

WANT TO ADVERTISE HERE? PLEASE GET IN TOUCH AT advertising@hayburner.co.uk THANK YOU FOR YOUR SUPPORT.

WANT TO ADVERTISE HERE? PLEASE GET IN TOUCH AT advertising@hayburner.co.uk THANK YOU FOR YOUR SUPPORT.

BY JONNY MARRIAGE

BY JONNY MARRIAGE

A: I work at Thingamies Beetles in West London and work selfemployed at The Volks Cave as a mechanic/welder, well just about everything on air-cooled VWs really. Previous to this I worked on London buses as a diesel mechanical engineer for nine years. When I’m not at work I drag race a Beetle in the Outlaw Flat Four class.

1971 Street legal drag Bug, Miss White

1971 Pru green Bug (sold May 2022)

1972 Marina blue Bug (cut up for parts)

1972 Marina blue Fastback project (ongoing and to sell)

1972 Marina blue Bug, my first Bug (ongoing resto)

1973 Beetle project (ongoing and to sell)

1974 black Beetle (cut up for parts)

1974 Bay Window (sold as project)

1989 T25 scooby powered transporter (my daily vehicle)

Q:Who,orwhat,wouldyousayisyourbiggestinfluenceinthe worldwideVWcommunity?

A: That’s a hard one as all of my cars are different styles and I just build them how I feel and don’t follow a “trend”. Being in the drag racing side of things I’d have to say Clarke Hillyard and Danny Pike but also the rest of the Outlaw Flat Four racers for inspiring me to build my race car.

Q:BestmomentduringclassicVW/Porscheownership?

A: There are two for me that come straight to mind. The first is that because of these VWs I’ve met my now fiancée Harriet Furniss. The second was when I ran my first 11-second ¼ mile in Miss White and became an Outlaw Flat Four member.

Q:WorstmomentduringclassicVW/Porsche ownership?

A: Both in Miss White. The first was a fire and the second was blowing up my engine at the end of 2021 in a dramatic fashion at 7000rpm due to a misfire and the piston disintegrating.

Q:So,whatisitwe’relookingathere(year, specandmodel)?

A: So this is Swampy, my 1970 RHD UKbuilt Class 11 inspired Bug, basically a full bodied Baja. The chassis is originally a LHD (imported from Germany in ’77), being a balljoint beam IRS chassis. The body is actually a ’72.

Q:What’sthestory?Howdidyougethold of it?

A: I had the chassis for a few years from another project but I’d sold the body. I then sold the chassis to a mate for a project but bought it back when he decided to break that car. The body came as a deal for doing some welding work on a mate’s Beetle.

Q:Didthecarcomewithanyhistory?

A: None at all apart from two photos I found online of it with a V6 engine in the back.

Q: Tell us about the condition of the car whenyoufirstgotithome.

A: The chassis needed new pan halves. We had already converted it to RHD for my

mate’s project. The body needed channels and the usual – door posts, rear quarters. It had no rear end and no front bumper mount panels or lower spare wheel well from a radiator install, along with various holes in the body from a badly run water system.

Q:Runusthroughtherestoration/ recommission, and who did the work?

A: I did all the work myself along with some help from my dad Jerry and uncle Steve who paints canal boats for a living. He painted the car using traditional brush painting methods. I also had help from my younger brother Jack and a good mate Adam as I didn’t have a lot of time to get it done. So we fitted new SSP floor pans, new channels, new door

posts and all associated panels, a complete rear end, new front bumper mount panels and wheel well along with some random other pieces that previous owners had cut out on the dash and the firewall. We also added welded on support tubes to the frame head for the front beam as we were using a factory Type181 Trekker beam. We welded in tubing on the rear between the shock towers and to the frame-horns to stiffen up the rear end and remove any wheel hop (coming from my drag racing background). We also welded on brackets for an intermediate gearbox mount. The chassis were then treated to black raptor treatment.

Q:Paintcolour(andcodeifyouknowit)?

A: It’s a Craftmaster coach enamel paint called “Bethnal Green” which was brush painted, and then the roof has a graphite grained vinyl wrap which came already on the car.

Q:Suspensionsetup?

A: The front end is a complete spindle to spindle stock Type181 Trekker beam setup, so it has the “beefed up” factory shock towers and extra supports to bolt to the chassis, along with the Trekker front shocks, then converted to disc brakes.

The rear is factory IRS with twin spring plate setup, slightly notched on the bottoms to allow it to go up and raised about 3 splines or thereabouts (I used an angle finder instead

of going off just splines to dial it in). The angle on the spring plates un-sprung is about 40 degrees! Standard IRS A-arms currently. Porsche 944 drive shafts, stub axles and CVs and 100mm CV flange conversion for the gearbox and also Type3 rear drum brakes making for a great handbrake feel.

Q.Wheelandtyretypeandsizes?

A. Wheels are 15” Centrelines with 195/80/15” Camac 4x4 tyres all round.

Q:Engineandgearbox?

A: Engine is a 1641, 8 dowel VW crank, lightened flywheel, Engle 110 cam, straight cut cam gears, full flowed, slightly ported and polished stock valve twin-port heads,

34 baby ``Dells with CSP Bellcrank linkage. Protected by a factory Trekker bolt on skid plate.

Gearbox is a DC 1500 Type3 box with 100mm CV flanges, supported by German quality rubber mounts, mid mount and heavy duty cradle with strap.

Q:Haveyoureplacedtheelectricalsystem?

A: The loom is mostly original. I have just replaced the light unit wiring and ignition switch and fitted a beefed up starter motor cable and also added a leisure battery system for the radio and accessory lights.

Q:Werethereanypartsthatyoufoundit hardtogetholdof?

A:The Porsche stub axles took a bit of hunting for a good pair. I had most of the bits from collecting over the years. I just

bought them as they popped up, so I already had the Trekker beam for about a year or so before even having the body and starting the project. The rear window louvre took some searching for, too.

Q:Whatisyourgo-toVWpartsshop? A: I used to use Machine7.

Q:Runusthroughtheinterior.

A: There was no interior with the car, so again I went to my parts stash and found a set of US-spec high back seats which my fiancée Harriet of Hatty’s Auto Trimming reupholstered in black vinyl sides and black glitter flake vinyl with matching door cards.

Q: Accessories?

A: In-house built tubular side mirror arms (the only set on the market that you can still

open ¼-light windows with).

Front 7” bumper-mounted spotlights.

Rear LED reverse/work lights.

Rear window Autoplas louvre. Side scoops.

Leather bonnet strap.

Front skid plate and tubular frame added to inside the bumper and braced to the front beam.

Tubular built side bars.

Tubular built folding open rear twin wheel carrier. All the tubular work has been made in house and believe it or not was made from scrap trampoline tubing apart from the mirror arms.

A: There is a stereo, yes, mostly just the radio. I like a bit of classic rock, just need something on in the background or the voices in my head start getting louder!

Q:What’syourfavouritethingaboutthecar, e.g.wheels,paint,detail,tripit’sbeenon, memorywithit,etc.?

A: The fact that we built it in 33 days from start to finish using mostly parts lying around in the stash of parts, meaning it didn’t cost a lot to build too. I also love how anyone can just get in and drive it so easily and comfortably as it handles like a stock Bug if not better and yet 4” higher, and it hasn’t been fazed by anything we’ve thrown it at yet. Also letting my dad have free rein on the paint and letting Harriet have free rein on the interior and it all just working so well together.

Q:What’snextforyouandthecar?

A: A few more little suspension mods including trying to get a bit more height and beefing up the rear A-arms. A safaristyle roof rack with spot lights and roof tent capabilities. A rear engine/gearbox skid plate. When the time comes I’m also going to step up to 215 BF Goodrich tyres. I am currently looking at a front wheel well mounted winch too.

Q:Howoftendoyouusethecar?

A: As much as possible. It’s not my main car but I use it when I don’t need my van. It’s still done 12,000 miles since getting it on the road on last day of 2020. Harriet and my mate Ash have probably done more mileage in it than I have!

Q:What’syournextprojectgoingtobe?

A: I’ve got a few cars to finish up for my wedding next year, including my dad’s Bay and Harriet’s Beetle, but my own personal project is my 1972 Marina blue Bug which was my first car.

Q:Whowouldyouliketothankconnected totheproject?

A: My dad Jerry for the paintwork and all the other general help putting it together. My uncle Steve for his help with painting the car with my dad.

My younger brother Jack for helping with the mechanical work.

My mate Adam Phillips for helping with the welding and refit of the car.

My fiancée Hatty for the awesome one-off interior, carpet and leather bonnet strap.

WANT TO ADVERTISE HERE? PLEASE GET IN TOUCH AT advertising@hayburner.co.uk THANK YOU FOR YOUR SUPPORT.

WANT TO ADVERTISE HERE? PLEASE GET IN TOUCH AT advertising@hayburner.co.uk THANK YOU FOR YOUR SUPPORT.

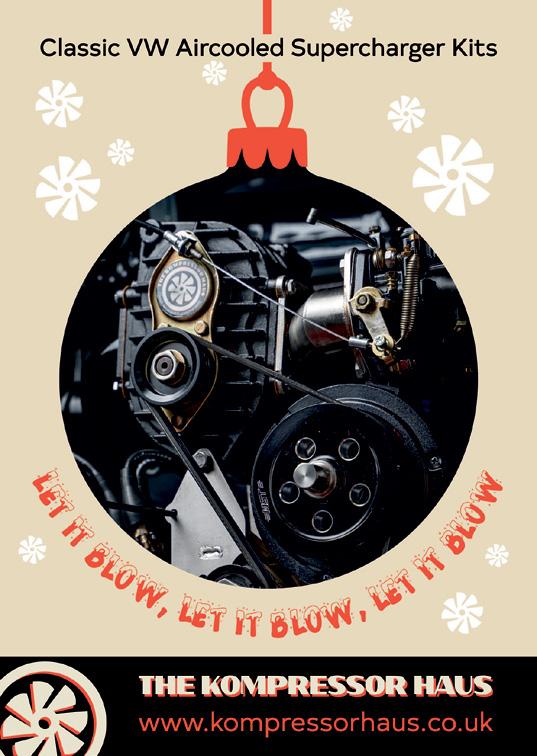

The best of both worlds.

Designed & fabricated in Germany / Hand assembled and shipped from the UK.

Standard Bug/Bus/Race shifters now in stock.

Like to stand out?

Anything goes when it comes to bespoke our builds and we love a challenge, don’t be shy, let us know what you want and we can make it happen. www.bug-tech.de

So it’s very much that time of year again where I usually have a moan about how cold it is in the workshop. Well, I’m sat here writing my article, the sun is out, and I’m in my hoodie and jeans without an electrically warmed set of thermal overalls and woolly hat. It must be said that this suits me down to the ground. I can’t believe we’re at the end of November and I don’t have a massive jet heater blasting horrid fumes into the workshop and consuming diesel like an American V8 drinks petrol. If global warming means I get to skip the early morning frosts and a frozen kettle, then I guess there is a silver lining to every cloud.

Work is busy at the moment, with four newly built engines ready to go out and two winter projects ready to start work on, plus all the usual bits and bobs that come through the door. It’s nice to see that, regardless of the state of the world, things still need fixing and that people still love their classics as much in winter as they do in the summer months. I do tend to tell people during the year, “save that job for when it’s cold and winter”, and then forget how many winter jobs I have potentially booked in. After 11 years I really should have a better organised diary

(or even a diary at all), but I do find that the randomness of the universe deals with this far better than I ever could. Parts get delayed and plans change, so it’s good to be flexible; well, that’s my excuse anyway.

This week in the boulevard of broken engines I have a bit of a head scratcher. Now we see a lot of knackered things that need to be put right, and it’s usually quite obvious what went wrong to cause the failure, but this has had me thinking and researching more than anything I have seen in a while.

So the early Bay Window came into us as a non-runner. We were told that it was a stock engine and that it had done about 1000 miles since the engine was rebuilt by the previous owner and about 200 miles with the new owner. We started with a compression test and the figures were dire, so the only option was to pull it out and investigate. The first thing we found was that one of the inlet valves had dropped its seat out completely and, looking at the mess, had been driven that way for quite a while. Luckily, with the engine having a stock cam and compression, the valve had not hit the piston and the piston tops looked in good condition, brand new if I’m honest, and I could clearly see the size stamped on top. It said 87mm … hmm … 1641 conversion

with very thin barrel walls, something I don’t advise for a heavy Bay Window fully loaded.

We removed the barrels to expose the pistons and realised straight away that every piston had suffered a catastrophic failure. The first things to fall out were the piston rings in several pieces and also the parts of the piston itself that sit between the rings. I’ve not seen such a lot of damage on relatively new pistons. The next thing that struck us was that all four pistons had the skiers smashed off. On one side of the engine the skirts were smashed off at the bottom and on the other side they were smashed off at the top. One of the pistons had cracked all the way from the bottom of the skirt to the top of the crown. Inspecting the barrels, it became clear that at some point they had got very hot. The top of the barrels where they insert into the cylinder head had that iridescent blue/purple tinge about them which does match up with why it dropped a valve seat.

Such a lot of carnage for so few miles and on all cylinders is a very rare situation. Now to split the case and fish out all the broken bits of skirt. The cam shaft had suffered very badly and the lifters were utterly shot – not a great situation for the customer, but things are what they are.

Luckily, the guy does not live that far away and came down to inspect the mess for himself. So what we thought would be a quick job has turned into a far larger project; it’s a good job my diary is flexible.

Of the four engines ready to go out, one is a turbo engine and three are naturally aspirated. One of the naturally aspirated engines is for Adrian Aubry (Orb), who had the 2332 motor in his Samba built by us a while back. He purchased a job lot of new parts that were enough to put together a turnkey 2165. On inspection we decided to use a brand new aluminium Autolinea case as we were not happy with the AS41 that came with the parts. The parts included an Engle 110 cam and 1.25 ratio rockers. The interesting things about the engine are the heads; they have had a lot of porting work done so we then port matched a pair of Big Beef manifolds to make the most of the porting. We could only get hold of fuel injected manifolds, so we machined up bungs for the injector holes and welded them in. There was a lot of material to take out of the manifolds, which meant a lot of hours with the die grinder, but I have to say that we are very pleased with the results. We have gone quite high with the compression ratio, so this should be quite a screamer of an engine. It’s on a pair of 44 HPMX

carbs with hex linkage and an electronic ignition unit. The next step is to install it on the test bed and get it fired up for the first time. I’m not sure what this engine will end up in, as I think Orb plans to sell it when it’s all good to go, but I bet you whatever it ends up in it will be a stack of fun.

One of the things that has made me smile since last time I wrote my article is the arrival of one of my winter projects. I was contacted by a guy called Glen Lucas who lives only down the road from me. He asked me to take a look at his Beetle project that he had in his garage. He told me he had always seen interesting Volkswagens coming in and out of the Souldrop turn on the A6 and had eventually tracked me down.

When he opened the garage doors and moved some boxes, I could see a beautiful 1956 Oval Window Beetle. It’s a UK right hand drive car with a Bedford prefix registration. It was in a fair amount of bits but in really nice condition. Inside the car was an array of spare parts including three partly dismantled engines and spare heads. More digging produced more parts and it quickly became clear that almost everything was there to put the car back together. It’s unusual for so many of the

original parts to still be with a project that was in so many bits.

Glen purchased this little beauty in 2003 from a classified advert in the Beds on Sunday newspaper. It cost £1200 and Glen is the fourth owner on the log book. Shortly after acquiring the car, Glen had three children and all the responsibilities that come with them. The ’56 sat in his garage until November 2022 when we collected it on a recovery truck and installed it on the ramp in the workshop. I was curious as to when it had been taken apart. We looked for a date on the newspapers that some of the parts were wrapped in. It seems that it has been in part restoration since 1994. Glen has never driven the Oval and has real excitement about driving it for the first time. The seats are in his loft and were recovered in the 90s along with door panels and trim.

Glen, being an engineer, has been doing some bits since I saw the car at his in September of this year. All the broken studs have been repaired and the tinware cleaned. He has also obtained a driver’s side quarter light and a few other bits. I’m looking forward to cracking on with this project, as I want to see Glen drive this car after protecting it in its current state for so long. I love a happy story.

If you are old enough to remember the early noughties, and in particular the UK Split Bus scene, you will no doubt recall the internet sensation responsible for countless lost office hours, the go-to website for any excitable boy or girl looking to explore a whole host of new and eye-opening choices. Not Porn Hub, you smutty minded individuals, but the one and only Bus Selecta!

For those who don’t know, the Bus Selecta site allowed

you to build and modify a basic bus template to many specifications of your choice. The brainchild of our very own Rich “Selecta” Whitlock, it was brilliant and basically became a massive hit. You could change body style, stance, wheels, bumpers and colours. You could add roof racks, safaris and exhausts, samba trim, etc. It may sound a bit tame compared to the edgy game realism offered today, but it was addictive, and anyway the internet was crap back then. Most computers were the size of a

small shed, and the noises they made, while mostly not connecting through your pathetic phone line, are the thing of nightmares. Don’t believe me? Google dial-up sounds for a glimpse into purgatory.

Anyway, what has an old bit of UK VW history got to do with Mike Jeff’s ’55 Wolfsburg-built Dove Blue bus? Well, apart from the imminent return of the Bus Selecta towards the end of 2022 (busselecta.com), Mike’s ’55 is pretty much the real-life incarnation of the bus I would regularly build on the plastic AOL shed and keyboard instead of working.

Mike is no stranger to air-cooled VWs, and anyone who cites one of their hobbies as spending the kids’ inheritance

on old VWs and Porsches has the right attitude in my book for sure. This laudable approach has seen an impressive and eclectic collection come and go over the years. In fact I was just about to plough through the list, when I remembered that many of you will be reading this around Christmas, and not every gift is necessarily as requested from the big man himself – I don’t want to be the person reminding you that the nice Oval you wanted manifested as some oversized pants and cat musk deodorant. Let’s just say that the list is impressive, Merry Christmas, and concentrate on the ’55.

Mike purchased the bus from Dave Hall as a rolling project back in 2014. So that’s no floors, no interior, electrics or other useful parts like an engine and gearbox, but still a

great base with awesome patina. We asked Mike about the origins and history of the bus, but he joked that he was still waiting for the history from Dave! Other than it being one of the first post-Barndoor era vans to be produced at Wolfsburg, little is known, but very few of these early models survive and they are highly prized by people looking for a bus built before Type2 production was switched to the purpose-built Hannover plant in April a few months later.

The original idea was to do bits on the bus when work was quiet, only it didn’t really happen quite as planned, with the only real work being done by Mike’s friend Wayne Bates, who managed to get a new floor welded in and to sort out all the door locks (I hope he worked quicker than he drove to HO).

It soon became apparent that fitting the work in as and when really wasn’t working, and with so much effort required to restore one properly the bus was sent up to Lord Irv of Cumbria. Irv had done some work before for Mike, so he had no qualms about handing the ’55 over to someone whom he rates highly and trusts implicitly.

Irv really knows his way round a bus and what does and doesn’t work on the things, which takes some of the stress out of handing over a vehicle. While Irv and the lads did their thing, including fitting up a narrowed Dogback front beam, a built straight axle gearbox and 1776 motor liberated from Mike’s ’57 bus (with some adjustable spring plates thrown in for good measure), Iain Burns aka Autoelec did his, installing a complete new wiring system and full electrical upgrade.

With all the focus going off in Cumbria, Mike managed to knock up his own metal seating section ready to complement a Rusty Lee rock n roll bed unit which was fitted prior to the bus heading down the M6 for upholstery at the Bromsgrove Trimmers. No bonus prizes for guessing where they are located.

We have massively oversimplified the

effort, procedures and parts involved in taking a long-abandoned shell of a van and returning it to even a basic operational state, a process we are currently undertaking ourselves with the build of Ewan’s ’58. But if you fancy a go at mentally deconstructing, like a reverse Bus Selecta, feel free. There is a lot to consider – and I’ll wait.

So fast forward a tad and it’s now up

and running, nice inside, ride height dialled in, wheels we will get to. So that just leaves the patina which, although mostly au naturel, like most things of beauty would benefit from a bit of cosmetic tweaking. Very popular it would seem too, as I recently misread a lift exit and wandered round a whole floor at M&S dedicated entirely to just that.

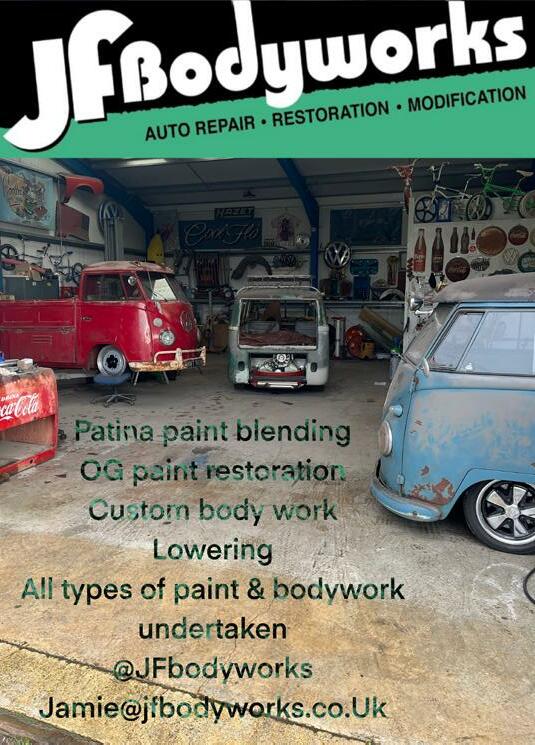

Step forward paint blender to the stars Mr Steve Parsons and his talent for blending and detailing where others fear to tread. Well, fear is the wrong word. I am sure many would have a good go, but if you want your patination correct the first time every time you know what to do.

Crucial to my old Bus Selecta build was the choice of wheel, and as I chose staggered 5 lug sprints I can bask in a degree of virtual smugness at Mike’s equally fine choice – or I could if Mike hadn’t fitted the chromed Lemmertz 5s in place of some South African sprints, which he actually prefers. The vital statistics for tyre lovers are 185/65/15 and 155/55/15. I’ll let you work out which went where, but personally I’ll never really understand the interest in tyre sizes. Saying that, I don’t understand the interest in foot fetishes either but live and let live.

Through a good set of mates and some well-known and trusted businesses, Mike has himself one hell of a good looking and let’s not forget very early and very original bus. You may well see it out and about in the Coventry area, or on a European road trip. You might even see a for sale sign on it, or you might even jump onto the new Bus Selecta and build a look-alike in record time, and if you do that you won’t have to thank the following people afterwards.

Wayne ‘Speedy’ Bates, Irv’s Restos and all the skilled lads that worked on it, Iain Burns, Steve Parsons and anyone inadvertently missed out.

Tailored For :

You & Your Business.

Highest quality service and expertise. Modern insurance tailored for your classic or daily.

Competitors cannot compete when it comes to price!

We had been looking for a Beetle for a while. I wanted an early one and my girlfriend just said “it had to be RHD!” Well, what are the chances that one of my old mates happened across this original 1961 Beetle and in RHD! I didn’t know what to expect when I asked him for the details but in the back of my mind I wanted it to be honest!

The photo came through on my phone. Wow! Perfect faded

blue and looked original. I tried to be cool about it for the negotiation and instantly said that’s a bit of me! We went to see it that week and out of a garage rolled this sweet-looking Beetle covered in a layer of dust. A 1961 and nothing had changed, like time had stood still. A real survivor car! It was love at first sight. I looked at my girlfriend who didn’t look all that impressed (she tells me she was being cool about it). After crawling about on the floor and looking under the

carpets for the usual rust and rot and finding solid car, it was a car that I couldn’t pass by!

We went for a test drive, got lost, and the owner phoned us to check we hadn’t broken down. It just drove so well! I’ve owned a few air-cooled VWs over the years and even had a Chevy truck but this was so nice; maybe this is where we belong. My girlfriend loved the test drive and also started to get excited about owning the Beetle. So we made a deal but had to wait about a week before we could pick it up. We were like kids at Christmas and finally the day came!

The drive back started rather hectic, leaving Farnborough with only 1200cc behind us in the rush hour with over 60 miles ahead

of us. It was a bit worrying with vans and lorries screaming past on the dual carriageway, but we made it out to some quieter roads where we could just cruise back in time. Even the 6 volt radio works – although the channels are mostly talking on medium wave and long wave frequencies.

We have had the Beetle for a couple of weeks now and we’ve been on a few journeys and loved every one of them. We can’t wait to get out to a few shows and get back in the scene after a few years away from the air-cooled world. We have some small plans for the car which you will hopefully see in the future. Nothing too major … as the prices have changed a bit! I can remember picking up old engines for 50 quid and a new full carpet set for £25! Must be getting old …

We’ve also had our deerstalker hats on while carrying a large magnifying glass and have managed to trace the history and previous owners!

Firstly, thanks to Dan. He led us to Michelle who now lives in France but still had a box of history on the car (what are the chances?). So, using that, here’s what we know.

The first owner in 1961 was Roland. He and the car lived in Kent and up until 1970 the service history was exclusively Volkswagen and other garages thereafter. There was a new engine at 53,306 miles on 1/09/72.

It was sold to the next keeper in 2006. So, Roland owned the car

for a whopping 45 years!

The second keeper was a retired chap. He was a classic vehicle enthusiast, although not specifically VW. He was responsible for changing her number. It’s thought that the plate was part of the reason for his purchase. The original registration number (which is still stamped on all the windows) was YJG 111. When Michelle went to his house to purchase the Beetle, her original plate was going on his Porsche. By the look of things, the plate has now been sold on again. It’s a bit of a shame but because the replacement plate was an age-related allocation it wasn’t possible to transfer the old one back.

Michelle purchased the car on 18 May 2011 and became the third

keeper. She found her through a classic car magazine, listed in the classifieds (she was still in Kent at that time). Michelle immediately fell in love, and said she was just immaculate with all her original features and so without a doubt secured her with a £100 deposit!

A few days later, Michelle went back to collect her and at that time she hadn’t ever driven a Bug so was bursting with anticipation and excitement! Michelle had her for seven years. They went to many shows and enjoyable trips away, but couldn’t ever be in a rush. That’s all part of the appeal as far as she is concerned.

There were a few breakdowns along the way, but generally she was a little gem. In 2018 she sadly had to say goodbye. Michelle was moving to Europe and it just wasn’t feasible to do the registration in France (Bug + two campers had to go as part of the move). So, she sold the Beetle to Andy at Farnborough VW and he then sold her on as she was spotted in the foyer at Slough Swap Meet and that was the end of the trail.

Well, this is the bit I know first-hand. We bought her from Robin who had bought her from Andy …

I had sold a 1965 Splitscreen Type2 Camper to Robin around 17 or 18 years ago and what were the chances, our “new” Beetle was in the next garage to my old van!

And that is the story so far!

Its so great to have the history to go with this amazing car and it’s all thanks to the previous keepers for looking after her so well!

We are so happy with this car and it even has a certificate of 100,000k from Wolfsburg!

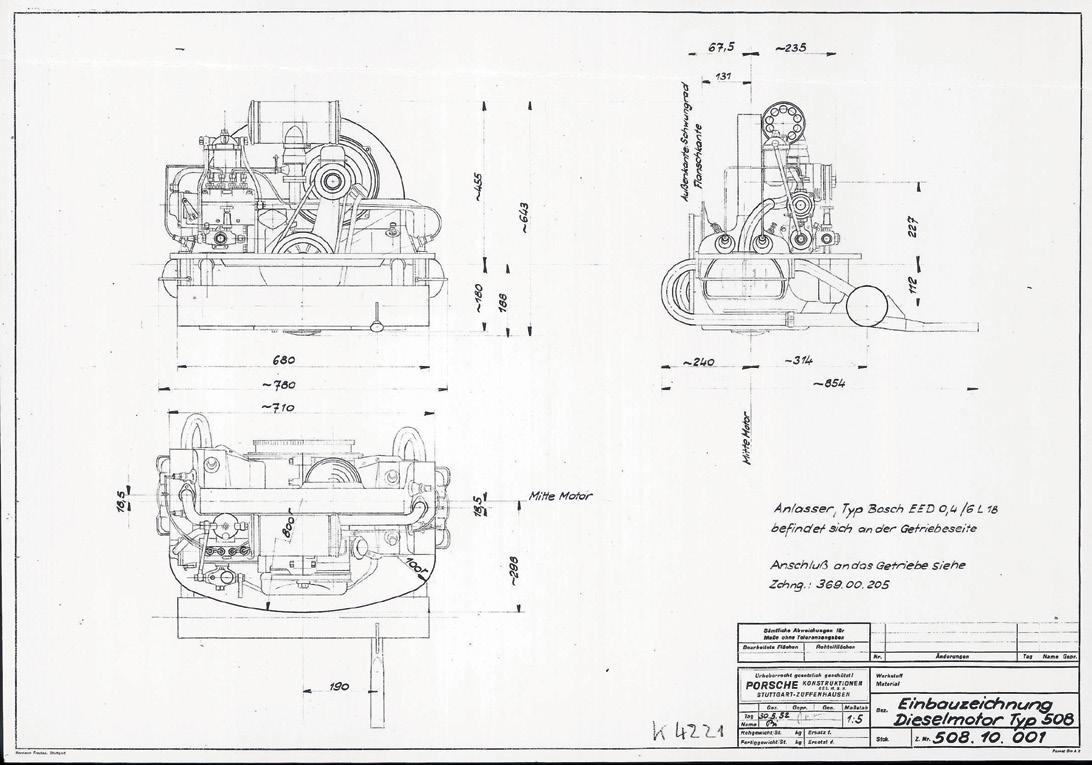

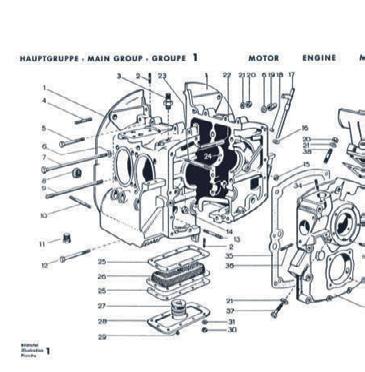

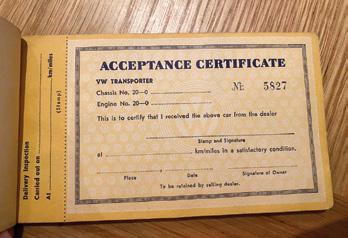

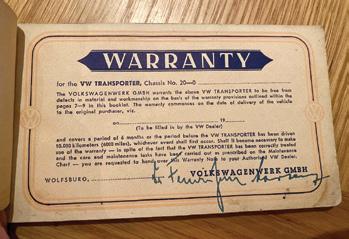

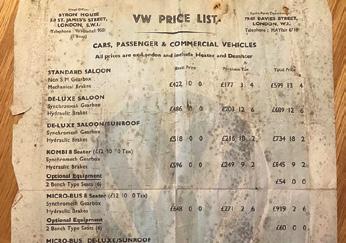

Long before the worlds of “diesel gate” and emissions cheats, Volkswagen had been working on their own early incarnation of a mass-produced diesel car for the people. This is the story of Type 508.

So the story goes – at the beginning of the 1950s, the heads of VW got together to work on expanding the range for their still new Beetle platform. The idea was bandied around the Volkswagen board for about a year before the project’s engine development was handed over to the guys at Porsche. Porsche had been working on their diesel engines (used mainly in their tractors) for several years by that point, but Wolfsburg wanted it to be purely based on the Type 1’s engine platform.

A series of 1200/1300 engines were delivered to Porsche in late 1950/early 1951 to begin development work. These were to be a compression ignition unit to run on the industrial fuel.

Why diesel? Well, at the time diesel was considerably cheaper than regular gasoline on a fuel station forecourt. Nearly a third less than regular petrol and way, way less than the “super” option. So if they could develop this engine then it could open up a whole new market for potential Volkswagen customers wanting cheaper fuel in a country still rebuilding and reeling from World War II.

However, it is interesting to note that this wasn’t their first foray into developing a dieselpowered car. In the 1940s they had worked on creating a prototype Kubelwagen with a diesel engine called the Type 309. But why wasn’t this development programme and everything learnt from it carried forward? According to some sources, the Type 309’s engine was actually a two-stroke diesel pulled from a tractor and transplanted into a Kubelwagen. Nothing is widely known about this car but its existence is documented. So, with that, when it came to the time to start the Type 508 programme, the team had to completely start from scratch.

The job of getting this crazy scheme to work was given to Robert Binder, the man who would

later go on to be part of the team who would develop the Type 2000 (901), which would grow into the fabled 911. Anyway, in 1951 he was asked to create this diesel-powered VW by the bosses.

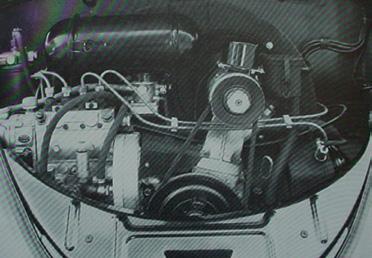

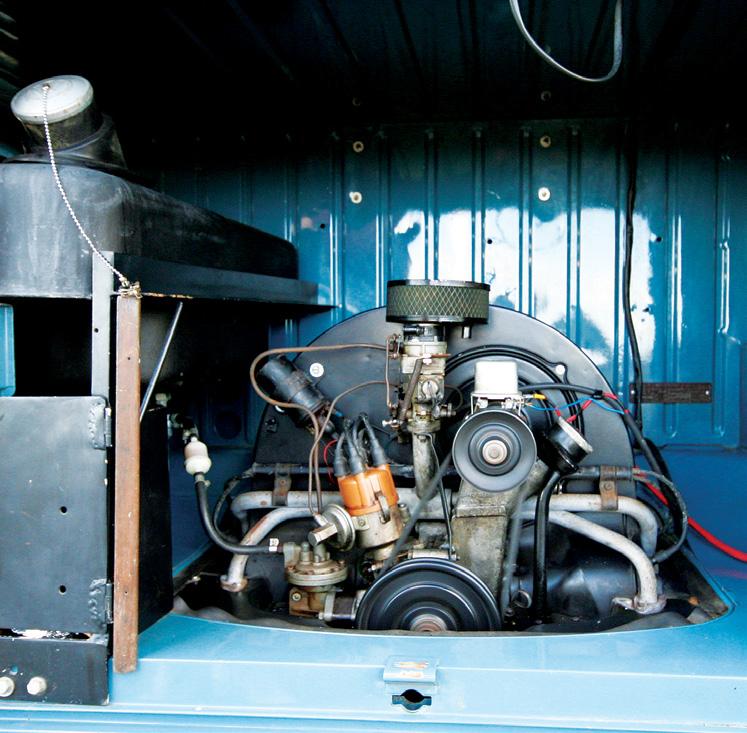

From the very first stages of the engine development, its birth was never going to be easy. Just the sheer space constraints (not only of the engine bay but also between engine components) would make the job harder than any of them could have imagined. In the spring of 1951, the engineers would file their first official report. They noted in their engineering report that the tight fit between the exhaust manifolds and the lower part of the new injector pump was causing them nothing but grief and the small, but dedicated, team were trying to find a way around it. After consulting with their suppliers, namely Bosch, they found the right orientation and fittings to move everything into a position where this might just work … once they figured out how to fit it under the decklid of the prototype car.

The engine itself was an engineering marvel. Rumour has it, it was a bit of a hybrid that

would go on to serve both VW and Porsche later in the 1950s. The original designs for the cylinder heads involved casting pre-chambers and then mating them onto a 1140cc unit for testing to start. Everything had to be uprated for these new diesel engines. Unlike a conventional gasoline engine which uses a spark plug, the diesel engine would use huge pressures and a glow plug to make it go boom. So much so that the compression ratio of the Type 508 engines, the internal codename given to the development programme, was calculated to be around 19:1. There was so much force from the pressure internally that the early Type 508 prototype testbed engines would destroy their drive belts and pulleys due to the intense and harsh vibration. That was a relatively easy fix. From then on, they would all be fitted with much bigger flywheels to counteract it.

On the test stands and in real-world testing, the engines made around 18hp at 3000rpm – not going to set the world on fire but it was a start. The theory worked. After the team had got hold of a 1300, the power would jump to 25bhp after someone on the team managed to get hold of a Scintilla fuel pump, while still achieving between 6 and 6.5 litres per 100km.

The fuel system was all supplied by Bosch. Everything from the injectors, the injection pump, glow plugs and butterfly valves were all supplied by the company. After being tested in the engine department, the two working prototypes were fitted into cars for real-world

testing. Here’s where things get a little bit contested and the story dips and dives through myth, legend and the finer details of VW Beetles.

It was reported that VW wanted to have the engines tested on two separate platforms –one for use in everyday life and the other to be used in a more commercial setting. The cars of choice? A 1951 (or 52/53 depending who you ask or the photo you see) Type 1 Beetle and a very early T2 Splitscreen Panel Van. This is reported by the engineers in their mid-project report in late 1951, where the second engine

is put in what the text calls a “Kombi” and can only be assumed to be a very early T2 and most probably a Panel Van, to be used around the Porsche and Volkswagen factories in Wolfsburg and Stuttgart while also being taken on endurance tests by the engine development team. It is definitely known that the second of the engines was fitted to the Beetle. Original photos show it being fitted to “24 6450” during its real-world tests in the early part of 1952.

At the same time as the two prototypes were being tested and worked on, over in Austria the guys at Palten-Stahlindustrie GmbH were

also hard at work trying to develop what would have been a diesel rival to Porsche/VW’s elusive “Kombi”. Palten had got hold of a very early VW Type2 in order to reverse engineer it to try and get into the automotive manufacturing game through government-backed contracts. To put it simply, the Palten-Wagen was near enough a complete and total rip off of an early VW Type2. Funnily enough, some of the experimental bodies, which involved plans for a camper and pickup along with a panel van, were made by Westfalia. The only things changed were up at the front, with a tweaked design doing away with the characteristic split windscreen and void of the glorious V-shaped pressings in the front panel. It got some straight-up headlights and Palten-Diesel on the front end. Wait, PaltenDiesel? Yep, the Austrians had been working on making their Splitscreen spinoff powered by the cheaper fuel for commercial use.

Now the Palten-Wagens wouldn’t have entirely the same engine configuration as the Type 508s being worked on by VW and Porsche over in Germany. The Palten project made its way down the road (slowly …) by a 1020cc diesel two-stroke, 2-cylinder V-Twin engine making an

earth-shattering 20bhp.

In 1954 there were a reported five copies of the Palten-Wagen in existence to show prospective clients. This diesel-powered copycat would actually go further than the Type 508 “Kombi”, with Spanish company FADISA ordering 2000 of the vans specifically for Iberia in 1956.

What was 24 6450? Well, by the looks of things from historical photos, it was a diesel-powered Beetle. Now, it appeared to be a black rag-top car with a light-coloured interior. Official modern photos, however, believed to be taken from the Porsche Museum in Stuttgart, show its year as a “1950 VW Kafer Diesel”. Now, if you look slightly more closely at the photos you can see that this car does feature a split rear window. However, if you look closely at the dash it has a later dashboard fitted to the car – meaning the car on display is in fact a Zwitter. However, the car on display is not the original. … More on that later.

Porsche took its two prototypes on what can only be described as a real-world torture test.

One engine, the one fitted to the “Kombi”, would cover around 16,000km before being taken out and stripped down for a full assessment. The team didn’t report anything too serious on the “commercial” engine. Meanwhile, in the Beetle, the team had racked up over 25,000km before pulling the experimental flat-four for a full strip down. It was noted on an inspection from earlier in the year that cracks had begun to appear on one of the cylinder heads. However, these guys being engineers, they decided to keep going (the cracks were quickly welded up) until something bad happened and then work backwards. Well, nothing bad actually happened.

But at 25,000km (sometime in mid-late 1953), it was decided that the engine would be removed and some new upgrades fitted which the development team had been working on, trying to improve the engine for everyday use. The team had developed a new all-alloy cylinder head for the car, still with in-cast pre-chambers, but this time with new heat management characteristics as well as much larger valve spacing. This seemed to do the trick as that engine was put back into 24 6450 and sent

back out to be beaten on by the development team.

Except for the fact that they ultimately weren’t.

The board had grown tired of the cost and the slow speed of improvement of the engines. Heinrich Nordhoff, the general director of Volkswagen at the time, gave orders to cut the project off at its knees. He actually said that he saw “no economic success in the combination of Beetle and diesel”. Type 508 was dead in the water. The people on the board saw no appeal or attraction in a louder, more sooty Beetle driving around. But the commercial guys loved it, right? Nope. Albert Prinzing, the commercial director at Porsche (remember, they made tractors), sent out a memo stating that the “final testing of this engine could be completed by the 10th of December 1954” if they really wanted, but he then went on to say that “It is not interesting to continue towing this type of engine in case new developments made it obsolete”. These decisions were apparently made after a trip to the US in 1952 where diesel cars just weren’t a thing, and to this day still remain purely commercial/agricultural.

It wouldn’t be until the introduction of the diesel Golf in late 1976 that Volkswagen would finally conquer the mass-produced, consumer diesel car.

So what happened to the prototype cars? Were they carefully stored away and lorded over in some secret storage facility deep in the heart of Germany, mentioned only in hushed whispers

by those who knew their true intentions? Well, this is where strict scientific engineering reports become myth, folklore and hearsay.

Let’s start with the Beetle.

The Beetle was used for continuous testing for those 18 months. The car was then allegedly stolen at some point, but was apparently so painfully slow to pull away that the would-be thief just got out and walked away. The car would allegedly take a full minute to go from a standstill to 100kph. Ultimately, at the end of the programme, after being cancelled by the bosses, the car was scrapped. However, the engine designs and what was learnt from them were apparently carried forward. The modifications and changes made to both the block and cylinder heads were kept in mind for developing the engines for the early Porsche 356s, allegedly.

The “Kombi” was reportedly scrapped too. Not much is really known about its life during development as opposed to its Type 1 sibling. It was destroyed, though, as both cars were deemed obsolete and essentially useless.

However, the history of this car actually carries on. To mark the 50th anniversary of Porsche in 1981, the bigwigs decided to try out some special projects and get away from their normally motorsport-centred birthday presents. For this, Helmuth Bott (then head of development at Porsche) was thumbing through the archives when he came across the Type 508. He remembered the early “Kombi” diesel

van he had driven around in during his earlier days in the engineering department. That was to become one of the special projects, and thankfully he still had someone on the staff who knew all about it. This is where Robert Binder came back into the story. At this point, he had worked his way up to becoming head of engine development at Weissach. Bott told Binder and his team that he wanted to remake the now long-gone car for display in the museum and to see what it was actually like to drive.

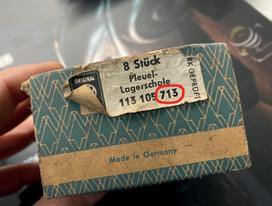

Binder set about trying to get hold of the parts and pieces his team would need to get the job done. So the story goes, Binder found an NOS early 356 three-piece crankcase hidden in the backroom of a dealer – the same engine that had been created using what was learnt from the previous Type 508 study. That was only one piece of the puzzle. Tracking down 50+-year-old diesel components was a job in itself. The team scoured the entire globe trying to get hold of parts that were useable to make the idea work just like it would have back in the day. Binder had to draw on memories and engineering knowhow to get everything working. This included finding an original Bosch injection pump that was fitted to a car on display in the museum, which was very kindly borrowed and fitted into the back of a Beetle. To help out, Mahle even cast a special set of 22:1 pistons to handle the much higher compression ratio.

Thanks to using the Porsche 356 crankcase, and therefore its bigger bearing, the team didn’t have to remake the complicated pre-chamber heads and with that the special gasket needed for them to seal properly.

But what car did it get put into? Originally, we have no idea what year car it was put in. But like we said, guesses would put the prototype car at around 1950/1951. However, when Porsche came to the replica it suddenly became a later car. As we said, the car in the museum appears to be a Zwitter but the sign says “1950”. Maybe that was a mistake or maybe it’s just trying to illustrate that the project dates back to that year and Porsche used a car they had already got in the museum.

It all got put back together in time for the team at Porsche to give it a go. The car rumbled into life, in a haze of smoke and soot. Just like it had back in its original testing phase.

The Porsche bigwigs decided to take turns driving it around Weissach and even allowed some noted journalists to take it out on the Nordschliefe as part of Porsche’s birthday celebrations and also on occasional press days. It apparently was absolutely awful. It was so noisy it was nearly unbearable and was so slow that the team didn’t actually want to drive it on the road as there was no way it could get out of its own way in an emergency.

That is ultimately the story of the Volkswagen Type 508 diesels.

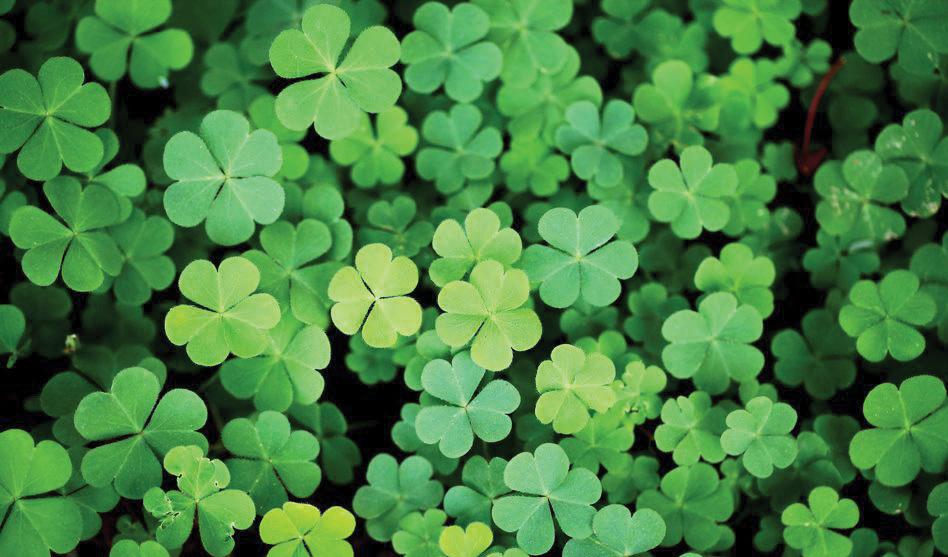

14th 15th 16th July 2023

VW aircooled event & full weekend of camping, show, music, bar, food stalls, tea & coffees & trade stands for the first time in Ireland.

I would like to invite all VW clubs to participate for the weekend, feel free to bring your banners etc and let your club colours fly! Please pm me if you’re interested so I have an idea of numbers. There will be a huge swap meet over the weekend. Please bring any parts you would like to sell, pm me for slot availability.

Early bird & family tickets will be on sale on the website from July 2022. Early bird tickets will be limited so keep an eye out on social media for the link to the website in the coming weeks. Tickets and weekend passes also available at the gate.

All aircooled VWs are welcome, we’d love to see your campers, beetles, barndoors karmanns, fastbacks, squarebacks notchbacks etc in one location in the centre of Ireland. If you have a project you’d like to display on the weekend, please pm me for details. Full recovery and mechanic services will be available for any struggleing aircooled vw’s over the weekendyou have no excuse now to not take out your aircooled vehicle ! The event will be held in the Kilbeggan, Co. Westmeath (N91 W6HV).The event will be fully insured. Amenities onsite will include; ample parking for day visitors, camping area, toilets, security, emergency services and much more! - Facebook PM @Mossey Conlon

Some people can only dream of owning a classic car. Not necessarily a vintage Volkswagen, but anything. Whether it be because of a wistful childhood memory involving a role model or a fleeting glance at a piece of history that sits at the back of your mind until the time is right. For Matthew Camilleri, that happened to be a connection to his late father and Sundays spent at car meets and hillclimbs which made up some of his happiest childhood memories shared with his dad.

Those memories of classic cars in the morning Maltese sun with his dad were kept close to Matthew’s heart as the years passed on. Then, one day while walking down the street and minding his own business, he came across something that would reignite that love and curiosity. It was a bright red Karmann Ghia. This low, sleek and stylish coupe stopped him in his tracks. This was the classic he had been waiting to find … so much so that he didn’t actually know what it was. All he knew was that he wanted one.

After doing some research, asking

friends and putting the pieces together against what he could remember in that fleeting glimpse of a classic sports car, Matthew found out it that was in fact a Volkswagen Karmann Ghia.

This was around 2014. After asking around about the best place to find a Karmann Ghia, he was pointed in the direction of thesamba.com after a friend had recommended it as the go-to site for vintage Volkswagens. Looking around and researching just which year he wanted, how much it would cost on average to get the right one for him and all of those bits and pieces, it was time for him to get serious about getting hold of his very

first classic car.

This phase would involve days turning into weeks of refreshing the “newly listed” section of thesamba.com. Then, after one serendipitous click, he stumbled across the car that was right for him and just what he was after.

It was a 1962 RHD Volkswagen Karmann Ghia with a rebuilt 1600cc, a lowered front beam and adjustable spring plates and finished in a stunning shade of Lavender. This was exactly what Matthew wanted and needed. The Sartorelli design spoke to him. He knew that this early Type34 (six months after the car’s redesign was revealed in late 1961)

was the one he was after, as opposed to a later or earlier Ghia. It was right in the sweet spot, and looked like the mythical red Karmann Ghia he’d happened upon on that fateful day.

However, it was a lot of money for him at the time. Remember, he was only 24 and thought his classic car story would begin later in life. So after laying awake for a few nights and going backwards and forwards in his mind over the pros and cons of each variation, he decided to bite the bullet. He took a loan out for the entire asking amount for the car and, with a couple of messages back and forth, the Karmann Ghia was his. Now he just had to get it to

What he did find was a stroke of luck. With the car being over 50 years old, it made it easier to register and transport from the car’s home in the UK (funnily enough with friend of Hayburner, Mike Chare). So, with everything now sorted out, it was time for Matthew to play the waiting game as his first step into the classic car world made its way towards him. It was a month-long wait for him to first set eyes on the car now known as “Karmelina”.

With the car safely in its new sun-bathed home, Matthew got to grips with the new world of classic cars, learning his air-cooled coupe’s personality and secrets. He decided to dig into the car’s history as best he could.

What he found dated back to 1982, with the car being registered in Gloucestershire and wearing the number plate of VTK 647. The car was kept for around 15 years until in early 1997 it was sold to Martyn McGarry at Karmann Ghia Motorworks. While in Martyn’s ownership and using his expertise, it was completely restored. After the restoration was finished, the Ghia made its way over the sea westward to Ireland, apparently owned by a lady called Lisa. She owned the car from 1997 to 2012. Then, its history ramps up a bit. The Lavender Karman Ghia would find its way through four owners within two years, beginning with Graham Lyall back in the UK who passed it onto our friend Mike Chare. Mike would be the one responsible for the car’s second restoration and modifications.

“The Rock”.

“The Rock”.

Then, in 2014, Andy Ward bought the car which is where Matthew found it. Matthew is actually looking for more history on the car to go back further to complete the story of his Karmann Ghia which now has the number plate VKG 062.

But, what do we have here? What has been done to the car? The car was finished in the rare and beautiful colour, Lavender. This made it stand out to Matthew instantly. That delicate look was complemented with a change in attitude thanks to the narrowed front beam and the lowering job done front and back to bring that low, sleek look even further to the ground thanks to addition of

adjustable rear spring plates. For the “go” aspect of the deal, the car had been fitted with a well-rebuilt 1600cc twin-port engine, just enough power and usability for Matthew to enjoy the car. As he says, all he cares about is that every time he walks out and turns the key – it fires into life. With this level of finish and sitting just right thanks to the work of its previous owners, he wanted to put his own stamp on the car for his part in its history.

For this, Matthew chose to make a wheel change, altering the aesthetics to suit his taste and what he felt worked best for the car. That was achieved with a set of Atlas Whitewall

tyres wrapped around 15-inch embellishers to finish off its new Maltese look.

Matthew’s story with Karmelina, a nod to its new Maltese home and its model, is one that reaches back further than most people’s. And this being his first classic car, let alone a classic air-cooled VW, it’s a story he’s not likely to forget and connects him back to the memories of his late father at car meets and hillclimbs, to which Matthew now takes his Ghia. It goes to show that if you look in the right places, something is bound to turn up. It might just be love at first sight.

I’ve done it. I’ve built my bike.

(Audience erupts into rapturous applause.)

Thank you. No really, Stop, You guys … Well, this could take some time …

I see you’ve stopped clapping; shall I just regale the last part of the story to you? You can get everyone else up to speed when they’ve stopped clapping and cheering.

Nice one.

So you know I’ve been building this bike, right? A mid-’50s Phillips, it’s a proper heap but I’ve been building it up like a bicycle hot rod I guess, with all high-end modern components and I’ve done this

just to roll down a hill in France, yeah? Great.

You’ll remember that last time I’d not even started putting it together.

That all changed with a call from Captain Standby at the tail end of September, which brought about a certain sense of urgency when he announced that we would be leaving for France in just over a week. So this was it, time to stop thinking and writing about it, time to break out the spanners and see if all the parts would work with each other.

Apart from very nearly destroying a £200 headset (it turns out that 1950s tolerances differ wildly from 2020s tolerances), the whole process of putting the bike together went remarkably smoothly. The only real issue I couldn’t deal with on my own was the routing of the rear mudguard stay, which wanted to be exactly where the brake calliper now sat. A trip down to 70k Kev’s shed soon had that sorted, with a little bit of grinding, bending and welding … or as I like to call them, The Three Great Ings*.

It’s not actually too surprising that some bicycle parts went on a bicycle and the bicycle worked, but when you have cogitated as long as I have over this, a certain amount of trepidation is, I would suggest, only to be expected. It was therefore a

huge relief when it did all go together with ease, apart from that headset moment, and it was exceedingly satisfying to pull my first skid in the alley upon completion.

The day before departure, the Captain arrived to load up what he termed my “non-essentials”. We were also loading his three-man canoe, which had languished in my garden for a couple of years. Now the Captain has an incredible and special talent when it comes to packing a vehicle, this being his ability to completely fill a van with a Mars bar wrapper and a paper clip. As he pulled up to the shed, looking as though he’d had the Vito lowered, he mentioned that he’d already popped “a few items” in the back. These turned out to be a few hundred bricks, a cement mixer and the “classic” slightly rusty but rarely used gas-fired barbeque, along with an assortment of tools that spilled out as he opened the side door.

I’m not normally precious about my push bikes. I guess that’s mainly down to the fact that none of them have ever cost me more than £150, but the brake levers alone were worth more than that on this one, so I broke out the bubble wrap and a blanket, taped it up and somehow squeezed it into the back.

Then we were there.

More to the point, I was there, in France, in Pleaux, with a load of bricks, a cement mixer, a barbeque and a canoe, but most importantly, my bike, which had remarkably survived the journey.

Can you hear me over all this clapping? Yeah? Okay.

Now before I got to go out and play on my bike I had to earn my keep. There is a slim chance you were wondering why we had taken a load of bricks and a cement mixer on holiday with us. It’s because we were there, as always, to work on the Captain’s house, an ongoing project at the dawn of its second decade.

Although the weather was glorious, we (as the Captain would say) “trusted our instruments” and plumped for the Friday, a week to the day after our arrival, as the optimal day for my descent – a mere flash in the pan given the number of years I’d thought about this.

Pleaux sits at 630 meters above sea level on a plateau in the middle of France. It’s very rural and subsequently pretty quiet traffic-wise. The smooth roads are incredibly well-maintained**, their paths very much dictated by the terrain, which makes for some exciting twists and turns. Even on top of the plateau there are descents of over 100 meters, so during that week when we weren’t working I had plenty of roads with a hairpin or two to roll down, allowing me to acclimatise to the novelty of having brake levers instead of a coaster brake.

On really big hills you have to be pretty sparing with a coaster brake. If you use it too much there is a real risk of overheating and burning out all the grease, which then makes it lock up. I’ve had to douse a coaster on a few occasions, and once at the Clunker Classic we wrapped two rashers of bacon in tin foil around the hub. By the end of the race they were very nearly cooked, over a three mile descent, giving you an indication of how hot they get. I tell you this because my economy of braking went out the window a bit with all the levers, callipers and rotors on the bike. I’d paid for them so I wanted to use them, which at first manifested itself in slower descents than I had imagined on the daily commute from our lodgings to the building site. There is of course a very slight chance it was a confidence issue – I mean, I’ve met me, and I put the bike together.

I soon got over that, though, and I was whizzing along, greeting cows, horses and the ruined castle each morning. Guys! Really! Guys! The cheering, please stop.

Listen, there’s not a lot left to tell. I’ll be as brief as I can so we can both split.

Friday arrives and the road to Egletons is calling. Twelve noon was decided upon as our departure time to optimise my chance of having a traffic-free run down to the Dordogne. Twelve until two is lunchtime, you see, and they take lunchtime very seriously.

I had bits and bobs to be getting on with. The Captain and his brother Barney, on the other hand, were at a loose end, so at 10:30 they went round the corner to the bar on the square, to soak up some of the glorious sunshine and possibly have a coffee.

What follows is an exact recreation of events.

Captain: Well, this is lovely. Would you like a coffee, Barney?

Barney: Isn’t it! Yes, I’d love one. Shall we have an espresso?

Captain: Shall we make it a double?

Barney: Let’s!

Captain orders the double espressos. In due time they arrive and the pair consume them while engaging in pleasant chitchat. After a short period

Barney: Well, that was delicious! Shall we have another?

Captain: Ooh, I’m not sure. You know me and caffeine … ah go on then!

Barney: Excellent decision!

Barney orders another round of double espressos.

By eleven o’clock I have a pair of gibbering idiots trying to chivvy me along because they are off their nuts on caffeine. I draw it out as long as I can while they bounce off the walls because I’d rather not meet any cars on my descent. I manage 40 minutes.

It’s a ten-minute drive to the top of the hill at Maugant, and by the time I’ve unloaded the bike, attached the cameras, made sure they are working and been for a wee in a hedge, it’s basically noon.

So there I am. After at least four years of travelling this road, and the Captain saying to me “It’s about here I drop you off, Willy”, he finally has. I’m no longer going down that hill in a van, daydreaming about what colour metal flake my bike should be; instead I’m sat on my black bike in the middle of the road at 613 meters above sea level, waiting for the van to pull off.

My perspective has changed. I’m no longer a passenger.

As they draw off into the distance, I put three or four pedals in and that’s it. I’m rolling, gently at first through fields. Then, as the road dips to the right, it becomes tree lined. It becomes smoother, steeper and faster, wide open hair pins are rolled around at speed, blind ones flanked by cliff faces I’m more cautious of due to being on the outside edge of massive drops. The trees give me a false sense of security but I’m still wary of the lack of barriers. Speed, although exhilarating, was not necessarily the aim. I was in no rush for it to be over. I was there to savour and enjoy the experience, which I very much did, all the way down.

Thankfully no traffic was met. It was just me and my bike dodging the occasional fall of sweet chestnuts while dropping 343 metres over 4 kilometres, all the way down to the bridge at Spontour that crosses the Dordogne.

Brilliant.