r 02 ea 20 Y n e E tio f th SC c o A Se ct n je lita Pro po ld ro ui et -B M ign es D

DESIGN-BUILD FLASHBACK Why is Halmar the best at Design-Build? We’ve got history

ZEREGA AVENUE BUS MAINTENANCE & TRAINING FACILITY

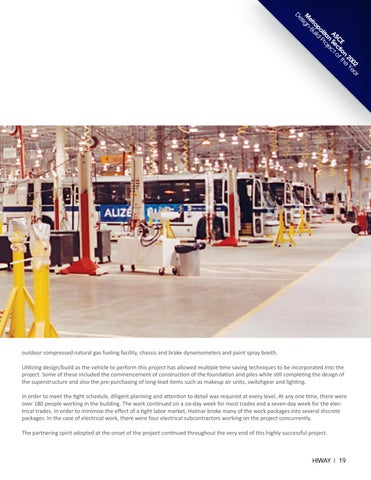

Over the past two decades, New York City Transit has experienced skyrocketing costs based on design standards for a highly specialized, dedicated facility that would last virtually forever. However, on the Zerega project, the ultimate goal was to design and build a maintenance facility with flexibility to meet the requirements of currently emerging technologies. This facility incorporates excellent lighting and ventilation in all work areas and large, open spaces, allowing freedom of bus movement, as well as flexibility to modify work/traffic flows. Our combined objective resulted in the creation of a facility that will maintain its market value for many years to come. The Zerega Facility comprises 180,000 sf of high bay vehicle HIWAY | 18

maintenance area and 60,000 sf of office and classroom space. The facility is New York City Transit’s main bus remanufacturing and mechanical training facility and is the first facility capable of handling CNG powered buses. Refurbishing capabilities at Zerega include, inspection, cleaning, bus-reassembly, dynamometer testing, bodywork and painting. The facility is a concrete framed slab, supported on piles, structural steel frame, masonry and metal panel curtain wall with a standing seam roof. Roof mounted heat recovery units provide a minimum of 8 air changes per hour. Key industrial components of the facility include: compressed air systems, vehicle tailpipe and fume rail exhaust systems, bulk fluid dispensing systems,

outdoor compressed natural gas fueling facility, chassis and brake dynamometers and paint spray booth. Utilizing design/build as the vehicle to perform this project has allowed multiple time saving techniques to be incorporated into the project. Some of these included the commencement of construction of the foundation and piles while still completing the design of the superstructure and also the pre-purchasing of long-lead items such as makeup air units, switchgear and lighting. In order to meet the tight schedule, diligent planning and attention to detail was required at every level. At any one time, there were over 180 people working in the building. The work continued on a six-day week for most trades and a seven-day week for the electrical trades. In order to minimize the effect of a tight labor market, Halmar broke many of the work packages into several discrete packages. In the case of electrical work, there were four electrical subcontractors working on the project concurrently. The partnering spirit adopted at the onset of the project continued throughout the very end of this highly successful project.

HIWAY | 19