Food processing is the process of transforming raw ingredients into food. The process takes clean crops or animal products and uses them to produce long shelf life products that are highly marketable.Food processing has been in existence since pre-historic days. Slaughtering, fermenting and preserving foods with salt were the common methods used until canning began. Modern food processing emerged in the late nineteenth century. Canning, freeze drying, artificial sweeteners and preservatives were introduced. In the twentieth century, convenience foods became popular. Frozen foods such as TV dinners became available in all supermarkets. There are many benefits associated with food processing. The removal of toxins, preservation of perishable foods that are transported from long distances and the removal of pathogenic micro-organisms are just a few examples. Today’s supermarkets would not be feasible without modern food processing methods and military campaigns would be near impossible to execute.

The India food processing market size reached INR 28,027.5 billion in 2023. The market is projected to reach INR 61,327.5 billion by 2032, exhibiting a growth rate (CAGR) of 9.1% during 2023-2032. Rapid urbanization, the rising consumer preference for processed foods, favorable government initiatives, ongoing technological advancements in food processing, and an evolving retail landscape promoting convenient RTE food products are among the key factors driving the market growth.

Food processing is the systematic transformation of raw ingredients into edible or marketable food products. This process involves various techniques such as cleaning, sorting, cooking, canning, freezing, and packaging to enhance food safety, shelf life, and consumer convenience. During food processing, additives and preservatives may be used to maintain quality and freshness. Additionally, advanced technologies such as pasteurization, dehydration, and extrusion play vital roles. The food processing industry helps meet the global food demand, ensuring food availability, reducing food waste, and providing diverse food options to consumers across the world.

India's large and diverse population, coupled with rising disposable incomes and changing lifestyles, is fueling the demand for processed and convenience foods, which, in turn, is primarily driving the market growth. Moreover, increased urbanization and a shift towards more hectic work schedules have led to a surge in the preference for packaged and readyto-eat (RTE) meals, creating a favorable outlook for market expansion. Concurrent with this, the government's supportive policies and initiatives, such as the Make in India campaign and the establishment of food parks and processing units, are attracting investments and contributing to the market's growth. Additionally, significant advancements in technology and innovation are enabling efficient food processing methods that improve product quality and reduce post-harvest losses, which is presenting remunerative growth opportunities for the market. Furthermore, the escalating awareness of food safety and quality standards among consumers is encouraging manufacturers to maintain high production standards and comply with regulations, thus propelling the market forward.

Editor Sarvjit Singh

Managing Editor Amrita

China Correspondent & Reporters

Ying Wei-Beijing

Bao Tian Tian - Shanghai

Xing Guang Li - Guangzhou

Assistant Editor/Correspondent Elena

Marketing Director Elisha Kanda

Circulation Surekha Gogna

Production, Design & Degital Media Rakesh Sharma

Marketing & Sales Lina

Catherine Amy Lan

Anna Mi

Technical Advisors

Alex Van Bienen/Lily - Nederlands

Public Relations Director (UK) Mike Steele

International Director Richmond Kanwar

Brampton, ON Canada

International Advisor (Australia)

Andrew S. McCourt

Germany Representatives

Julia Rittershofer

Steffen Schnaderbeck

India

Food 4 Future - Expo Foodtech will host the European Foodtech Nations forum, which brings together pioneering European regions in food technology to share their innovation and digitalization strategies.

The event will be attended by a delegation of 40 representatives from the United Kingdom, the guest country at Food 4 Future 2024, with the support of ICEX Madrid, March 22nd, 2024 –In a globalized world, sharing and learning from the experiences of other countries is of great value to evolve and improve any productive sector.

To achieve this goal in the food industry, Food 4 Future - Expo Foodtech 2024, which will be held from 16 to 18 April in Bilbao, Spain, will once again host the European Foodtech Nations Summit to present innovative ecosystems of the European food industry.

Three days to give visibility to all the initiatives in the foodtech field that are being carried out in other enclaves such as the Netherlands, the United Kingdom -as guest country of this fourth edition-, or Japan, which repeats after its great experience in the last edition and returns to Bilbao to present its latest innovations to the European market. More than 40 international representatives will come together at the European Foodtech Nations Summit, which gathers pioneering European regions in food technology to share their innovation and digitization strategies. Among

them, a delegation of entrepreneurs from the food and beverage industry of the United Kingdom, the event’s guest country in 2024, with the support of ICEX Trade and Investments, will gather in Bilbao. The delegation will include international relevant profiles in foodtech, such as Roberta Re, Director of Cambridge Food Science; Caroline Saunders, Senior Director of Health and Wellbeing at Pladis Global, and Paul Gateley, an expert professor from Leeds Beckett University. They will present the current ecosystem of the United Kingdom in this field, but they will also learn about Spanish strategies and innovations through the Spain Foodtech Nation session organized by ICEX, providing them with a unique perspective on Spain's position as an innovation hub in foodtech. It will be a meeting point to foster dialogue and collaboration among all participants to drive the food technology sector forward and to offer a comprehensive exploration of the innovations and opportunities presented in our country's current ecosystem.

On the other hand, representatives from the Netherlands, such as Kees de Gooijer, CIO of TKI Agri & Food, will present the innovations and strategies implemented in the Netherlands in the fields of circular economy, agrifood, and agrotechnology. Additionally, they will address some of the main challenges facing Dutch society in agriculture, food, and technology. To do this, they will break down the

main objectives set in the 2024-2027 agenda in this area, which include addressing the resilience of the delta nature and the North Sea, sustainability in agriculture and horticulture, rural areas, climate impact, and the creation of healthy, accessible, and safe food. Following their significant experience in the previous edition as the guest country, Japan will participate again in 2024 to showcase its latest innovations in Foodtech to the European market.

More than 110 representatives from Japanese companies, startups, investors, consulting firms, etc., will gather in Bilbao during F4F2024. Companies like UnlocX & Co, Ajinomoto, Wired, or Mitsubishi UFJ Bank will address one of the major challenges facing the food sector today in this edition: providing sufficient quantity and quality food to all inhabitants of the planet and doing so in a healthy and sustainable manner through technological advancements such as genetics, Artificial Intelligence, robotics, etc. They will present solutions related to food fermentation or alternative proteins.

Likewise, the FoodTech innovation ecosystem of Euskadi will also present its advancements, led by Juanan Gutiérrez, Director of Consulting and Analysis at HAZI, and Juan de los Ángeles, a professor at the University of Navarra and expert advisor at HAZI. They will discuss how the food chain is transforming amid an economic crisis and uncertainties about the future. They will highlight how technology is crucial in achieving the goal of being more sustainable through tools such as precision agriculture, supply chain traceability, and innovations aiming for greater efficiency while ensuring food safety.

Food 4 Future 2024 will also feature spaces dedicated to companies from the Desafía Foodtech community, an immersion program by ICEX aimed at the internationalization of such ventures, where participating companies will showcase their solutions and new products. According to María Naranjo, Director of Food Industry at ICEX, "from ICEX Trade and Investment, we support this event from its first edition to reinforce its international character, thus contributing to Spain's external projection as a leading nation in science and technology applied to the entire value chain of the food industry."

Foodtech, which will be held from 16 to 18 April in Bilbao, Spain, will analyse and present all those new ingredients and foods that are emerging as alternative protein sources Representatives from companies such as NaturAll, Fruselva, Ingredalia, BeAmaz, and Noga Plus will be among the participants at the Food 4 Future R&D Summit Madrid/Bilbao, March 26th, 2024 - It is a reality that science, research, and development (R&D) are fundamental in shaping the future of our diets.

Laboratory research is revolutionizing the creation of foods with new ingredients aimed at addressing challenges such as food safety, the growing demand for proteins, or consumers' new preferences. All of this will be analyzed and debated at the R&D Summit to be held within the framework of Food 4 FutureExpo Foodtech 2024, from April 16th to 18th at the BEC in Bilbao.

Among the topics for discussion are the challenges associated with the growing demand for proteins and the innovative solutions emerging in response. In this context, the Food 4 Future World Summit congress will present the latest alternative protein sources, including options for plant-based, cultivated, and sustainable proteins, featuring Abert Tseng, Co-founder of Dao Foods and representative of China at ICEX; Rodrigo Sanchez, CEO of NaturAll; and Beatriz

Jacoste, Director of KM ZERO Food Innovation.

Furthermore, the successful incorporation of next-generation ingredients into various food products will also be addressed through real case studies, providing professionals in the food industry with information on the latest trends and strategies. Clemens Hollah, Managing Director of DIL and representative of Germany at ICEX, and Guillermo Mena, R&D&I Director of Fruselva, will be among those responsible for providing these insights.

The arrival of new foods and additives has brought about a revolution that also entails challenges, a new regulatory framework, and opportunities for innovation, aspects that Miguel Angel Cubero, CEO of Ingredalia; Macarena Baylos de Nárdiz, Director of Exploitation of Results at CNTA; and Thomas Dietrich, Project Manager at Tecnalia Research & Innovation, will discuss.

In the bakery and snacks professionals' realm, Eliana Bejarano, CEO of Be-Amaz; Rina Fainstein, CEO of Noga Plus; and Alejandro de la Brena, Co-founder and CEO of Griyum, will provide a strategic vision of the latest ingredients and flavor concepts, as well as emerging trends in this field and the technical aspects of product development.

Another relevant topic for the industry is food safety in a global-

ized and constantly changing world. John Holah, expert professor at Cardiff University, and Hugo Cunha, Scientific Researcher at AZTI, will analyze issues such as supply chain resilience, regulatory evolution, and technological innovations ensuring food safety. The congress will also showcase the potential of algae in the agri-food sector, a very current topic to be addressed by representatives from AZTI, the University of the Basque Country (EHU-UPV), and the European Algae Biomass Association (EABA). In line with the current situation, citizens are concerned about a diet that favours optimal wellbeing and contributes to improving health. To achieve this goal, probiotics, together with the healthy properties of the lipid fraction of dairy products and the components of coffee, are essential for promoting healthy ageing, as representatives from different CSIC departments will show. This will also be addressed by experts from Eurocat and Northumbria University, who will present the latest advances in research on probiotics and their possible use in the creation of healthy dairy drinks.

From proteins made from plant residues to edible and healthy 'glue' In addition to the congress area, Food 4 Future 2024 will feature an exhibition area where more than 280 firms will showcase their latest solutions. Regarding new ingredients, Moa Foodtech will present sustainable proteins developed from the fermentation of vegetable residues and by-products such as leaves, peels, or fruit skins. On the other hand, the company Nucaps will introduce its alternative to salt, named NuCla, which provides salty flavor without harming the consumer's health. Similarly, the Japanese brand NinjaFoods will exhibit edible and healthy 'glue paste' made from konnyaku food, to bind ingredients for creating healthy snacks.

Other companies that will be present include Maash, with a protein produced by fermenting mushrooms, which has a texture very similar to that of meat, but with a lower environmental impact; or the biotech company Genbioma Aplicaciones, which will be exhibiting its probiotics and postbiotics that help regulate blood sugar in people with diabetes.

Handtmann is a solution provider for end-to-end meat processing from product preparation, handling and processing through to the packaging solution. All process solutions are modular and flexibly configurable. The portfolio includes the production of classics such as clipped bar-shaped products, ham and sausages as well as trend products from the convenience and snacking segments. Handtmann provides technology for the production of such variety, from manual, artisan production as to fully automated, industrial high-performance production.

Product quality starts with the preparation of the product. The extremely gentle mixing technology of the Handtmann Inotec VarioMix is ideal for numerous fields of application in meat processing. The VarioMix allows for both aggressive and gentle mixing. The mixing spirals operate in individually adapted wave patterns and they are independently

adjustable in speed and direction of rotation. The usable volume ranges from 350 to 4,000 litres. The preparation of a large variety of different products can thus be covered with a single machine. During processing, the particularly gentle feed principle of the vane cell feed system in Handtmann vacuum filling machines also ensures firstclass and continuously reproducible product quality as well as long-term stable portioning accuracy. The integration of inline grinding technology provides additional scope for the optimisation of product and cost at the same time, because it is the grinding method, among others, that is decisive for the quality of the products. Grinding the product to its final size during the filling process primarily entails a reduction in the number of process steps. The product is ground to its final grain size and at the same time portioned in a single process step. Handtmann works with the standard feed system for all products, irrespective of the cut size of the

final hole plate in the inline grinding system. It is therefore not necessary to switch feed system parts when the product is changed. The versatile equipment options for cutting set parts guarantee optimum adaptation to the individual product. Digital solutions in the VF 800 vacuum filler additionally ensure quality standards in processing. This includes the continuous, automatic monitoring of crucial process parameters such as filling pressure, temperature and vacuum level. The basic function of this practical solution is to automatically assure quality standards in the production process, thus avoiding rejects.Product quality starts with the preparation of the product. The extremely gentle mixing technology of the Handtmann Inotec VarioMix is ideal for numerous fields of application in meat processing. The VarioMix allows for both aggressive and gentle mixing. The mixing spirals operate in individually adapted wave patterns and they are independently adjustable in speed and direction of

rotation. The usable volume ranges from 350 to 4,000 litres. The preparation of a large variety of different products can thus be covered with a single machine. During processing, the particularly gentle feed principle of the vane cell feed system in Handtmann vacuum filling machines also ensures firstclass and continuously reproducible product quality as well as long-term stable portioning accuracy. The integration of inline grinding technology provides additional scope for the optimisation of product and cost at the same time, because it is the grinding method, among others, that is decisive for the quality of the products. Grinding the product to its final size during the filling process primarily entails a reduction in the number of process steps. The product is ground to its final grain size and at the same time portioned in a single process step. Handtmann works with the standard feed system for all products, irrespective of the cut size of the final hole plate in the inline grinding

system. It is therefore not necessary to switch feed system parts when the product is changed. The versatile equipment options for cutting set parts guarantee optimum adaptation to the individual product. Digital solutions in the VF 800 vacuum filler additionally ensure quality standards in processing. This includes the continuous, automatic monitoring of crucial process parameters such as filling pressure, temperature and vacuum level. The basic function of this practical solution is to automatically assure quality standards in the production process, thus avoiding rejects.

New trend products complementing traditional product range

Meat processing offers enormous potential for high-turnover products, because in addition to the traditional product range, selected classics can be relaunched, new snacks can be created or popular bestsellers varied. Here, Handtmann is not only a supplier of the appropriate production technology, but also a source of inspiration for trend products. Some typical Handtmann concept products are the fried meat

and vegetable sausage, salami snacks with spice coating or filled sticks. These production processes use Handtmann system modules from product preparation and processing technology to downstream product handling. The fried meat and vegetable sausage caters to the health trend with its rich vegetable content, to the sustainability trend by reducing the carbon footprint through reduced meat consumption, and to the culinary trend through unchanging taste and bite despite the high degree of substitution. Originally a classic meat product, but now with a high vegetable content of 40 %, what is decisive here is the substitution of meat with plant components without a noticeable change in the taste of the meat product or with a desired change in taste through the use of other vegetable pastes. The fine fried sausage from pork, vegetable oil and cauliflower paste is filled into natural casing, blanched and can then be grilled. Filled salami sticks belong to the trend category of premium snacking and can be produced in great variety with fillings of the most diverse flavours. The innovation of the product is the

appealing interplay of raw sausage and filling, both in terms of appearance and taste. The dry sausage product is co-extruded in alginate casing with different fillings, linked, cured, matured, smoked and dried. The spicy salami snacks with a variety of spice coatings also fall into the premium snacking category. The continuous production of barshaped salamis with co-extruded spiced alginate paste as a coating is entirely new here. Different spice coatings (e.g. pepper coating, bell pepper coating, etc.) allow for variable flavours. At the same time, the production process offers a high degree of automation, as the dry sausage product with alginatebased spice coating is continuously co-extruded, cured, matured, smoked, dried and sliced.

Handtmann sausage filling and linking lines are suitable for the production of dry, fresh and boiled sausages in natural, collagen or peeloff casing. The variants of the linking and hanging lines range from systems with manual or semi-

automatic casing spooling to a fullyautomatic solution. The modular concept alternatively includes the option of hanging the sausages directly on a hanging unit or of cutting the sausages in the number of pieces required. An example is the classic sausage production with the PVLH 228 plus linking and hanging line as part of the semiautomatic Handtmann AL systems, i.e. the casing is fed manually, the filling, portioning and linking process is automatic, as is the subsequent hanging of the sausages on the hanging unit. This process allows the production of up to 2,000 portions or sausages per minute. The special feature of the PVLH 228 plus linking and hanging line is a linking unit with revolving head and two nozzles. This enables casing change times of less than two seconds. Parallel voiders ensure extremely gentle linking, which also guarantees a high effective production output, especially when producing sausages in natural casing. Excellent weight accuracy and precise sausage lengths are also guaranteed, even with natural casing products. Another added-value option in modern sausage production are the integrable, digital Handtmann AHE

scales. They can be attached directly to the hanging unit. Give-away is reduced to a minimum thanks to their optimal weight accuracy. Overfilling can thus be reduced by up to 60 %. The scales can function both as portion and smoke stick scales.

Sausages production in alginate casing using coextrusion technology

Handtmann co-extrusion technology (ConPro = continuous process) opens up completely new application options in sausage production. It combines the advantages of an edible alginate casing with the flexible Handtmann vacuum filling and linking technology. The most outstanding feature of the ConPro systems is that sausage skins or casings are no longer used. Alginate is a long-chain carbohydrate, which is extracted from brown algae. Alginate gels can be produced across a wide range of temperatures and pH levels; they are insoluble in water, heat-stable and can therefore be blanched, smoked and dried. They are thus ideal for producing edible casing. With the ConPro system, Handtmann has developed the technical basis needed for this. It facilitates the continuous production of a sausage strand encased in alginate gel. It essentially comprises two vacuum

filling machines which are connected with each other via a coextrusion head. One of the two vacuum fillers, the master machine, pumps the filling product that the sausage strand is produced from. The slave machine transports the alginate paste which subsequently forms the sausage casing. The sausage strand can then either be cut or linked into individual sausages. The sausages produced can be packed as fresh products or transported to downstream process steps, such as maturing and drying or blanching and smoking.

The portfolio of state-of-the-art meat processing companies today includes the production of a wide variety of products from the most diverse raw materials and with different geometries. The single-lane Handtmann FS 525 all-in-one system combines two different forming principles and thus provides unprecedented flexibility for the industrial production of formed products: The hole plate forming technology allows the production of free-formed 3D products with a diameter of 18 to 100 mm. The rotary cutting principle can be used to produce different cross-sections from 15 to 130 mm with a straight cut. The optional use of a flattening

belt with flattening heights of 10 to 50 mm as well as different structuring rollers such as pyramid-, groove-, square-shaped, steak roller or customerspecific, further enhance product design options and the wealth of variants can thus be additionally extended. Different product structures are individually available on request. The forming technology can be quickly changed in under 3 minutes. The FS 525 forming and cutting system can be easily incorporated into integrated processes or be synchronised with automation options. Both individual automated process steps and fully automated solutions all the way down to the packaging unit are possible. An example is the feeding and inserting of the formed products into different tray formats with the new Handtmann transfer system comprising a feeding conveyor, a retracting conveyor and a tray denester. Another option is the integration and synchronisation of the Handtmann WS 910 weighing system in the new advanced version into the filling and forming process. Reducing give-away to a minimum by providing 100 % control through reference weighing of each portion also helps achieve significant cost savings. The use of the Handtmann weighing system further reduces re-work considerably, resulting in savings in packaging, resources and handling. Transparent, sustainable and hence future-proof production is thus ensured.

PRODUCT FEATURES

More Sopisticated

Stainless steel provides high durability suitable for commercial use

Stronger Motor

Equipped with a motor that has more power for excellent performance

One Touch Automatic

Start the automatic blending process with the touch of one button

5 Pre-set Menu Options

Quickly make any order with up to 37 recipes settings

Thomas Wünsche is Industry Director for Food & Beverage Development worldwide at ANDRITZ Separation. As part of the development of the ANDRITZ Turbex, the engineer for beverage technology, mechanical engineering and process engineering worked intensively on the optimisation potential with regard to extraction yield and product quality as well as the identification of market requirements for new applications and extraction applications. He exclusively answers the most important questions about the new technology.

1. What customer requirements led to the development of the ANDRITZ Turbex and on which separation technologies from your portfolio is the development based?

With the Turbex as an extraction application, ANDRITZ Separation is consistently expanding its portfolio alongside dewatering technologies and drying applications. Our customers often require more efficient, upstream extraction and fractionation of the raw materials used.

The Turbex utilises two key technological features:

- Generation and utilisation of cavitation for efficient digestion of natural raw materials in a hydrodynamic environment

- In contrast to conventional batch extraction processes, the Turbex also operates continuously and in a patented counter-current process This achieves an extraction effect that is comparable to a twelve-stage batch process.

2. What challenges had to be overcome before the product was ready for series production and

patenting? In fact, there were a number of challenges to overcome along the way. It was not so much the actual extraction process in the reactor that was affected, but rather the matrix feed into the reactor, for which the fluid properties were underestimated for some products. A quantity of solvent was also initially discharged and lost during solids discharge. This is recovered in the current system and fed back into the solvent.

3. What are the outstanding technical innovations and advantages of the process?

The process is based on the highfrequency interaction of vacuum and high particulate pressure, whereby botanical and organic raw materials are efficiently perforated "from the inside out" and provide a large contact surface for extraction. In a highly turbulent environment, generated by a multi-stage rotorstator arrangement with up to 2,000 revolutions per minute, the mass transfer coefficient is increased almost one hundred-fold compared to conventional extraction. Countercurrent extraction also keeps the gradient between the base material and solvent concentration at a constantly high level. This significantly increases the three decisive factors for mass transfer, i.e. "surface area A", "mass transfer coefficient k" and "concentration difference DC", and greatly accelerates the mass transition. This makes it possible to extract the supplied matrix in less than two minutes. At the same time, the extraction temperature can be kept at a low level - in most cases at 30 to 40°C.

4. Which traditional extraction concepts does counter-current cavitation extraction with the ANDRITZ Turbex compete with?

Comparative studies show significant advantages of the ANDRITZ Turbex over the classic one or two-stage batch process. There are also advantages in terms of extraction time and yield compared to ultrasound-based batch extraction.

Compared to other continuous counter-current extraction processes on the market, the measurable advantage is due to the cavitation effects, which enable a low extraction temperature and keep the active phenol groups of extracted antioxidants at maximum activity in the absence of oxygen.

Compared to other cavitation extractors on the market, the Turbex stands out due to its countercurrent extraction and the high number of cavitation events of up to 150,000 per minute.

Comparison of extraction technologies for extraction of olive leaves

5. What potential savings does the process offer?

In most of the extraction processes tested, the yield in relation to the target molecule could be increased by at least 25 %, and in some cases by up to 80 %. The antioxidant reaction potential (ARP value) can be significantly increased, for example by a factor of five in the case of polyphenols from brewer's spent grains. In simple terms: The Turbex not only extracts significantly more product in less time, the product quality is also measurably better and the energy required for extraction is 30 % less than that of conventional extraction.

6. Which sectors of the food industry can particularly benefit from this innovation? Is the process also suitable for smaller companies?

The Turbex extraction process is aimed at extracting proteins and amino acids, polyphenols and antioxidants as well as fats and oils. The remaining solids, usually roughage and fibres, are of a dietary nature and are characterised by high porosity. In principle, the extraction of leaves, flowers, bark, roots, fruits, seeds and kernels is possible. The material fed in must be adjusted to particle sizes of less than two millimetres. As the amount of product to be processed in terms of dry matter is 200 kg per hour, the Turbex is also suitable for small and medium-sized businesses.

7. How do the respective product requirements for a gentle, valuepreserving extraction process differ? The extraction process offers various parameters that optimise the extraction by individually adjusting it to the selected target molecule. These parameters essentially include the extraction temperature, the selected solvent and the solvent concentration, the cavitation intensity and the cycle time through the reactor. In addition, the extraction medium is divided into a liquid/solid ratio for the matrix preparation and the subsequent counter-current extraction. This increases the extraction of the respective target molecules or substance groups.

8. Are ingredients oxidised or proteins denatured to a small extent or are all properties fully retained?

The short throughput time during extraction, a process temperature of 30 to 40°C, the pressurisation of the process vessels with inert gas and the resulting elimination of excess oxygen help to ensure that the active phenol groups are reduced as little as possible and their activity is maintained at the highest level.

Denaturation of proteins is virtually impossible at the prevailing temperatures.

9. How do you ensure hygienic and microbiological stability when recovering and reusing the solvent in the cycle despite low process temperatures?

Various systems are integrated into the Turbex process to directly recover most of the solvents remaining in the solids and return them to the cycle. The resulting increase in the concentration of the solvent is beneficial to the overall material balance. If it makes economic sense, the entire solvent can also be recovered in a vacuum evaporation/drying process.

10. How are the extraction products obtained processed further or passed on?

This task is subject to the respective utilisation characteristics of our customers. The valuable product can be contained in the solids, in the extract obtained or in both process streams. In principle, a concentration-enriched extract can be produced as a product, but drying to powder is also possible. The latter applies to both the liquid and the solid phase.

11. Which cleaning processes are required?

The Turbex can be cleaned with all commercially available cleaning agents. Complete daily cleaning is recommended, but certainly after every product change.

12. Which models for which capacity range does the Turbex series currently comprise?

The Turbex is currently available in two ATEX versions. The first variant is aimed at customers and process requirements that need a complete extraction line. This includes the solids preparation, the reaction vessel, a feed unit on the feed side, as well as solid/liquid and liquid/ solid separation at the corresponding outlets. The entire system is equipped with measurement and control technology so that all processes run fully automatically.

The second system variant is aimed at customers who already have an existing extraction line. This is where the system starts at the existing solids discharge in order to increase the extraction yield or shorten the extraction time without affecting the existing primary product process. This allows the efficiency of the

offline process to be validated and qualified before the processes are combined in an inline process.

The processing quantity of up to 200 kg/h is identical for both processes - in each case in relation to the dry substance in the feed stream.

13. How can a gentle extraction of the ingredients be achieved despite more intensive extraction with energy input through shearing forces, turbulence and cavitation?

The short treatment time in the extraction reactor limits the influence of shear forces.

14. What is the economic comparison between ANDRITZ-Turbex and conventional extraction processes?

The profitability of the investment depends heavily on whether it is a new investment or a process optimisation of existing lines. At the same time, the commercial value of the manufactured product is of considerable importance. Depending on the process yield increase and product value, payback periods of 18 to 48 months are realistic. In the case of new process lines, this period is even shorter. In addition, the ANDRITZ Turbex can help our customers to achieve their ESG (Environmental, Social & Governance) goals, for example by reducing the use of solvents or using less energy in the production process.

15. What preliminary considerations should interested users make before deciding in favour of counter-current cavitation extraction?

The key question is whether a customer sees potential in an increase in process yield or whether the commercial potential lies in better product quality. The higher the yield loss in the discharged solids, the more interesting the use of a Turbex. To evaluate this potential, ANDRITZ offers preliminary analyses and tests at a specially equipped test facility at our site near Gouda in the Netherlands. It is also possible to borrow a transportable pilot system suitable for ATEX and food applications. This allows customers to test and evaluate this new technology without risk. And our experts are on hand with their experience to provide help and advice.

Super fast, super clean crockery: The new ProfiLine generation with a cycle time of only 28 minutes.

Miele Professional. Immer Besser.

While the traditional flavours are still a popular choice, consumers are becoming more adventurous, and are open to experimenting with flavours.

Book a meeting with the IMCD team to discuss the furture of flavouring in the dairy industry.

FLEXI-DISC® Tubular Cable Conveyors gently slide fragile foods and non-foods through smooth stainless steel tubing routed horizontally, vertically or at any angle, over short or long distances, dust-free. Single or multiple inlets and outlets.

FLEXICON® Manual

Dumping Stations allow dust-free dumping of bulk material from bags and other containers. Automatic reversepulse filter cleaning allows continuous, efficient operation. Available with integral bag compactors for total dust containment.

BLOCK-BUSTER® Bulk Bag Conditioners

loosen bulk materials that have solidified during storage and shipment. Variable height turntable positions bag for hydraulic rams with contoured conditioning plates to press bag on all sides at all heights.

Bulk Bag Fillers can fill one bulk bag per week or 20 per hour at the lowest cost per bag. Numerous performance options. Available to industrial or sanitary standards.

BULK-OUT® Bulk Bag Dischargers unload free- and non-free-flowing solids from bulk bags automatically. Allows untying, discharging, retying and collapsing of bulk bags—all dust-free. Available with weigh batching controls.

PNEUMATI-CON®

Pneumatic Conveying Systems move a broad range of bulk materials over short or long distances, between single or multiple inlet and discharge points in low to high capacities. Available as dilute-phase vacuum or positive pressure systems, fully integrated with your process.

TIP-TITE® Container Tippers

dump bulk material from drums (shown), boxes or other containers into vessels up to 3 metres high. Dust-tight (shown) or open chute models improve efficiency and safety of an age-old task.

FLEXICON® Flexible Screw

Conveyors transport free- and non-free-flowing bulk solid materials from large pellets to sub-micron powders, including products that pack, cake or smear, with no separation of blends, dust-free at low cost. No bearings contact material. Easy to clean quickly, thoroughly.

The FLEXICON® Lifetime Performance

Guarantee* assures you of a successful result, whether you purchase one piece of equipment or an engineered, automated plant-wide system. From initial testing in large-scale laboratories, to single-source project management, to after-sale support by a worldwide network of factory experts, you can trust your process— and your reputation— to Flexicon.

With pioneering, award-winning technology, Synergy Grill is revolutionising the hospitality industry. Through high power and low energy consumption, Synergy Grills enable faster food preparation while significantly reducing energy costs when comparing to equivalent grills.

Winner of the 2019 footprint award for sustainable catering equipment, Synergy are the only gas grills that have gained accreditation from the Carbon Trust, a global organisation that is providing solutions for the world’s climate crisis.

Comcater is Australia’s most trusted commercial kitchens expert. We live and love food service, cooking up the kitchens of tomorrow for more than 40 years.

Ammeraal Beltech know the production challenges you face; our belting solutions have been meeting your industry needs for Food Safety, hygiene, durability, performance efficiency and ease of cleaning for more than 60 years. Today, our newest solutions remain your prime choice across all your applications.

Our food-grade range includes unique modular belts built to minimise fissures where bacteria can

hide or knife blades can break. Our synthetic belts feature anti-microbial covers and KleenEdge non-fray properties to eliminate contamination. Our range also features ultra-hygienic homogeneous belts such as our Soliflex Pro positive drive belts, with innovative rounded lugs that cut cleaning time and water waste while also providing excellent power transmission and outstanding self-tracking performance.

Our cloud kitchens – a collective of private and shared commercial-grade kitchens – are designed to help food creators minimise costs, maximise profits and streamline operations.

Until now, adding automation to your production line could be an expensive exercise. But Enmin’s new Generate+ systems changes all that. A range of affordable modular systems that slot easily into an existing line; reducing labour costs, boosting

Designed and built right here in Australia they feature the same quality, reliability and safety that Enmin is renowned for. Plus, they can be added to and extended as your business evolves.

Costacurta conveyor belts are used in food processing as well as in many other industrial processes.

Thanks to the specific experience gained over more than 60 years, Costacurta can assist the client in the selection of the most suitable type of belt for the specific application. Costacurta conveyor belts are suitable for applications with temperatures ranging from -150°C to +1150°C.

Two companies that make catering equipment offer a glimpse of trends and solutions for the restaurants of the future.

Summertime… and the living is ‘trendy’. But what exactly are this summer’s ‘hot’ trends? We asked two companies in the catering equipment business. “Waring’s director of culinary innovation, chef Dustin Selvaggio, says that the hot food trends are fermentation, sustainability, whole product utilization, pizza, noodles of all kinds, Indian Cuisine and Vietnam-

ese Cuisine,” explains Damien Hée, director of sales Europe, Waring Commercial Products Division of Conair Corporation. Senior marketing manager Peter Roffe speaks of the explosion in contactless ordering: “Essentially every restaurant now features these options in some capacity. Along with contactless payments and menus (with QR codes).” Hée predicts “a very busy summer season, as people head out and enjoy a closer return to normal.” But another issue to be addressed is that of labour shortages, which “have really led to an increase in smart restaurant technology. For example, automating online orders through delivery apps that helps to fill up restaurants and reduce ‘downtime’ gaps. The same applies to automating customer communications within the restaurant. This is part of a larger movement towards an omnichannel strategy (bricks&mortar outlets + online) that is helping restaurants to grow and thrive, moving forward.”

Another important factor is supply

chain and food supply issues. “Food pricing due to supply and inflation are having a big impact on restaurants. This level of food inflation hasn’t been this high in 40 years. Restaurants will need to balance productivity and pricing to be to be able to migrate some of the inflation. We see this as a major issue that restaurants will continue to deal with throughout this year.” The most popular models include the Food Dehydrator , the 7-litre Stand Mixer and the heavy-duty Juice Extractor. Waring is known for its extensive line of blenders, waffle makers and immersion blenders, which are the brand’s most exported products year after year.

“Everyone is happy to safely return to their favourite restaurants with friends and family again. Dining al fresco took off during the pandemic and it’s here to stay. We expect to see lots of customers sitting outside to enjoy the sunshine and beautiful weather,” says Adriana Desiderio, digital communications manager at Cambro. “We have many products that help support service outdoors, like our CamBars, trays, GoBoxes, and Ice Caddies.”

Events are back in full swing: “A lot of catering and hospitality businesses need ways to safely transport their food and beverages – both hot and cold – and we have a variety of insulated transport units to meet this need. Our GoBoxes are especially popular because they are temperature retentive, but also extremely durable and lightweight,” says Ms Desiderio.

Meanwhile, “food delivery continues to be a popular segment for us. Restaurants need a way to keep their food at safe temperatures during transport and we have the products to make that happen. They make it easy for restaurant owners to feel confident their food and beverages will make it to their customers in the condition they left the kitchen. Keeping food safe can be particularly challenging during the summer, but our products give you peace of mind.”

The global meat processing equipment market size is expected to grow from $9.78 billion in 2021 to $10.43 billion in 2022, according to a report from The Business Research Company.

According to The Business Research Company’s research report on the meat processing equipment market, the increasing consumption of processed meat is expected to propel the growth of the meat processing equipment market going forward. Processed meat provides a number of advantages, including a better taste, a lower risk of meatborne infections, a longer shelf life, and a high degree of portability. For instance, according to Standard Process Inc., a US based food supplement company's report published in 2020, processed

foods account for about 70% of the American diet. Additionally, according to the agricultural and processed food products export development authority, during the fiscal years 2020-21, India exported 774.11 tonnes of processed meat to the world, valued at $1.62 million. Therefore, the increasing consumption of processed meat drives the growth of the processed meat market.

The global meat processing equipment market size is expected to grow from $9.78 billion in 2021 to $10.43 billion in 2022 at a compound annual growth rate (CAGR) of 6.71%. The growth in the market is mainly due to the companies' rearranging their operations and recovering from the COVID-19 impact, which had earlier led to restrictive containment

measures involving social distancing, remote working, and the closure of commercial activities that resulted in operational challenges. As per TBRC’s global meat processing equipment industry growth analysis, the market is expected to reach $13.62 billion in 2026 at a CAGR of 6.89%.

North America was the largest region in the meat processing equipment market in 2021. Asia-Pacific is expected to be the fastest-growing region in the global meat processing equipment market during the forecast period.

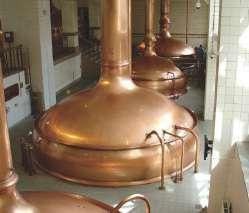

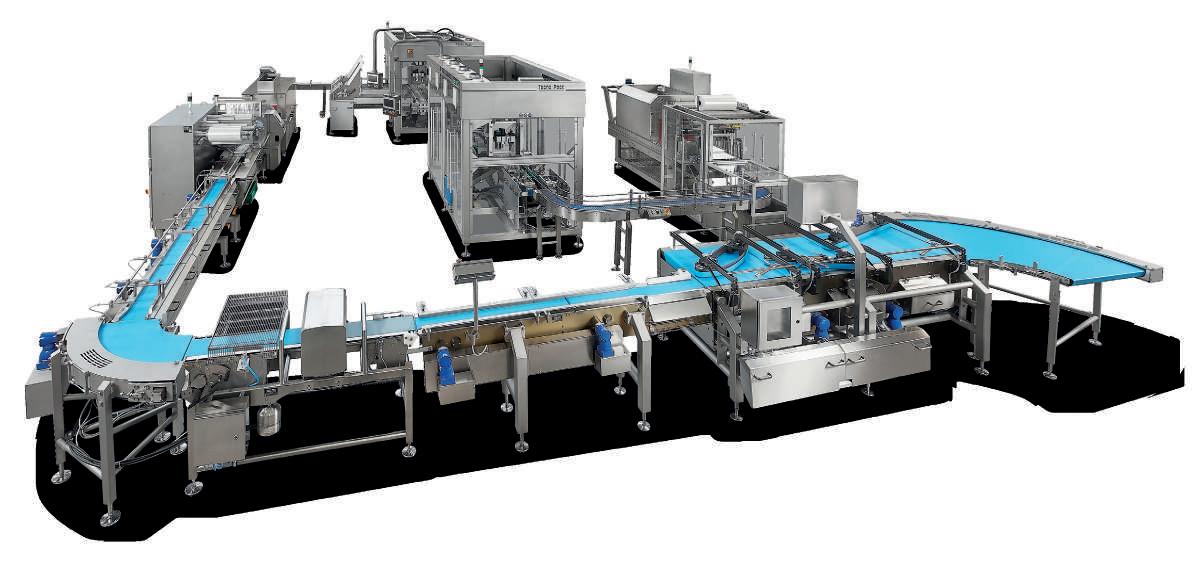

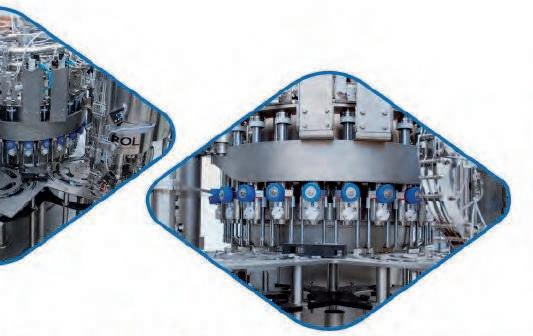

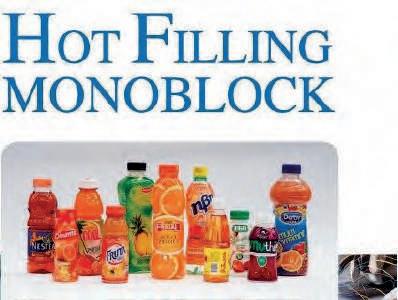

Cip Cleaning Plants

Continuous Sugar Dissolvers

Aseptic Tanks

VERSATILITY: Stores up to 1024 recipes that can be divided into 16 categories based on food types or preparation methods.

STANDARDISATION: Allows operator to add recipes with up to 8 steps each, allowing for consistent preparation results across users.

AGILITY: Ready to complete the recipe with just two touches of the screen.

CONNECTIVITY: Internet of Kitchen (IOK) allows you to stay connected to your Pratica high-speed ovens via Wi-Fi.

Simple maintenance with unique removable catalytic converter. See us at Foodservice Australia 2023 Stand G24.

Mankind is currently facing major challenges that are not leaving the food and beverage industry unscathed either – whether these be climate change, feeding the global population or the responsible use of packaging materials. So it comes as little surprise that future-proof packaging processes will also be forming the focus of Anuga FoodTec 2024, which will be picking up on the industry’s trend towards sustainable solutions with its guiding theme of responsibility. Deciding on the right packaging material is challenging for food manufacturers, because criteria such as product protection, machinability, environmental friendliness, cost effectiveness and consumer expectations all have to be balanced. So it is only logical to reduce the weight of the packaging as far as possible and therefore to save resources and further reduce one’s ecological footprint. But that alone is not sufficient any more, because the latest environmental standards no longer merely demand state-of-the-art technology such as that which will be on display from 19 to 22 Match 2024 at Anuga FoodTec, but also technical updates to existing machines.

One example of this is the European Union Directive ((EU) 2019/904) on single-use plastics (SUP). The specifications formulated in this also concern closures that are firmly connected to the bottle, called tethered caps. Beverage producers are required to modify their production by 3 July 2024 so that PET bottle caps remain attached to the container in open condition. The intention is for the cap to be sent for recycling as well, rather than being put into the residual waste bin separately. What sounds simple on paper is presenting the industry with challenges. “We are seeing a lot of

uncertainty among our customers with respect to tethered caps. What is certain is that there’s no getting around these conversions. The cutoff date is fixed”, says Armin Wille, Head of Service Sales at KHS.

This is the point at which the Dortmund-based specialist for filling and packaging lines comes into play with its range of services and offers consultation concerning the technical adaptations needed for the lines. This consultation offer has been taken up by Coca-Cola Europacific Partners (CCEP), for example. The KHS machines at locations in Germany, France and Belgium are to be converted by 2024 in order to implement the corresponding solution. The ‘Bottles & Shapes’ programme is an additional consulting module for fostering sustainable production. In this, KHS offers advice from the word go during the development of new container solutions that optimally bring appealing design, functionality, reliable line behaviour, resource-efficient use of material and recyclability into line.

High container quality on use of rPET Environmentally-friendly, sustainable and cost-effective operation at the same time: this was Krones’ objective in further developing the Contiform. Experience has shown that the greatest potential offered by stretch blow moulders lies in reducing the energy they consume to heat the preforms and the compressed air that they consume during bottle production. Opportunities that were grasped by the Krones developers in Neutraubling. Energy consumption has been cut by eleven percent compared to the predecessor generation thanks to shorter distances between the heaters, a more compact heating space and new heaters with parabolic reflectors. Substantial

savings have also been achieved in terms of compressed air. Unlike before, the fourth generation of the stretch blow moulder uses a three-stage compressed air recycling process that reduces compressed air consumption by up to 20 percent.

One additional aspect was also taken into consideration: the use of recycled PET material (rPET), which is increasingly being demanded by consumers. For beverage producers, combining the advantages of PET containers with the

aspect of sustainability means gradually increasing the rPET content in the bottles up to 100 percent. But not all rPET is the same. Above all, high-quality rPET is rare. The quality and composition of the material are crucial – and it is precisely these sometimes fluctuating characteristics that have to be balanced out in the stretch blow moulding process, because the aim is ultimately for each produced container to meet the specified quality requirements.

Krones has developed Contiloop AI to offer support in meeting this challenge. Fully integrated into the stretch blow moulder, the AI-based system measures the degree of light transmission of each produced container at up to 32 measuring points. During production, Contiloop AI reacts to even minimal deviations in material distribution and automatically readjusts the stretch blow moulding process in real time. Additional framework parameters such as the ambient temperature and humidity as well as the preform infeed and outfeed temperature are also taken into consideration in this process. The adjustments that are undertaken are visualised on the HMI to provide the operator with an overview of current process

management.

Is the packaging also available without plastic? Nowadays, the answer to this question determines whether a product will prove successful at the point of sale. Flexibility is therefore particularly important for food manufacturers, especially with regard to the increasing requirements for sustainable packaging. Laminates are increasingly being replaced with recyclable alternatives made of plastic or with cardboard from the outset. Technology providers are actively driving this development forwards. All machines from Syntegon have been able to process sustainable materials for food packaging since the end of 2022. “We’re already looking to the future today: our Kliklok ACE carton erector produces paper trays for biscuits and therefore offers an interesting alternative to conventional plastic trays”, explains Torsten Sauer, Sustainability Project Manager at Syntegon. Thanks to the innovative lock-style technology, the ACE can fold glue-free paper trays and enables manufacturers to replace conventional plastic trays with a more environmentally-friendly alternative. Another example from the Waiblingen/ Stuttgart-based company’s portfolio is the vertical tubular bag machine SVE. In addition to plastics, it is also able to process paper-based materials to produce pillow bags for deep-frozen food or stand up pouches for dry foods, for instance.

Anuga FoodTec 2024 marks a good occasion to rethink your packaging –especially if you are planning to invest in a new line. The conceptual design phase, in particular, offers a great deal of scope for checking product packaging in terms of sustainability and for using more cardboard in packaging development. As a packaging machine manufacturer that has been working mainly with cardboard for 50 years, Schubert can demonstrate a wealth of experience and expertise with this material. The Crailsheimbased packaging machine manufacturer’s lines can switch between conventional and recyclable materials – between plastic and cardboard trays, for example, or between laminates and paper-based films when packaging in tubular bags. Schubert not only offers support in selecting machinable materials, but also develops new cardboard packaging that is optimally tailored to the packaging process. This enables customers’ wishes for material-saving, less costly solutions, other packaging formats, increased marketing space on the packaging or more efficient transport solutions with an increased number of products per secondary packaging to be implemented, for instance.

One thing is certain: sustainable solutions and reducing the amount of plastic have become game-changers within the packaging industry. However, packaging expert Laura Gascho points out the following in all discussions: “We regard eliminating plastic at the expense of shelf life critically at Schubert, because a product’s carbon footprint arises primarily when producing and processing the raw materials. The packaging only accounts for a fraction of it. And it ensures that sensitive foods can withstand transportation without being damaged and also enables them to stay fresh for longer at the consumer’s home”, says the plastics engineer, who is employed in Schubert’s Application Technology department.

It is all the more important to her to be able to offer customers genuinely sustainable solutions in the sense of a recyclable material cycle. Mono materials are the most important trend as far as Gascho is concerned. “They enable complete recycling cycles to be established, for both paper and plastic”, she states with conviction. If plastics were to be segregated and completely recycled, hardly any new plastics would have to be produced using fossil raw materials and no more microplastic would enter the environment. At the same time, the barrier functions that are important to the shelf life of foods could continue to be used without misgivings – a worthwhile objective, but one that is still a long way off.

MELEGARI TECHNOLOGY S.R.L.

Strada Martinella 38/A, Alberi di Vigatto, 43124 (Parma) Italy

Tel. +39.0521 968428

Fax. +39.0521 966721

www.melegaritechnology.com

E-mail: info@melegaritechnology.com

PROMEC s.r.l.

Strada Fornace 4, Bianconese

43010 FONTEVIVO (Parma) Italy

Tel. +39-0521 616611(ISDN)

Fax +39-0521 616620

W eb: www.promec-srl.com

E-mail: sale@promec-srl.com

PROMEC BLOWTEC

Strada Fornace 4, Bianconese

43010 FONTEVIVO (Parma) Italy

Tel. +39-0521 616611(ISDN)

Fax +39-0521 616620

W eb: www.promec-srl.com

E-mail: sale@promec-srl.com

Handling resources responsi bly has never been as important as it is today. With its top theme of responsibility, Anuga FoodTec 2024 will dedicate to this area of innovation that is of importance to the food industry. Attention will be focused on the latest energy and environmental technologies. Minimising the consumption of valuable raw materials and energy has top priority for technology developers at the trade fair. The automated cleaning of lines is also being scrutinised by the development engineers and combined with sensors and cuttingedge software. Water, carbon dioxide, steam, fuels, compressed air or electricity – food manufacturers are increasingly being confronted with the need to reduce their ecological footprint. The products and services on show at Anuga FoodTec will provide food producers with a real-time overview of all aspects of energy and enable them to identify areas requiring optimisation and to improve the efficiency and profitability of their companies.

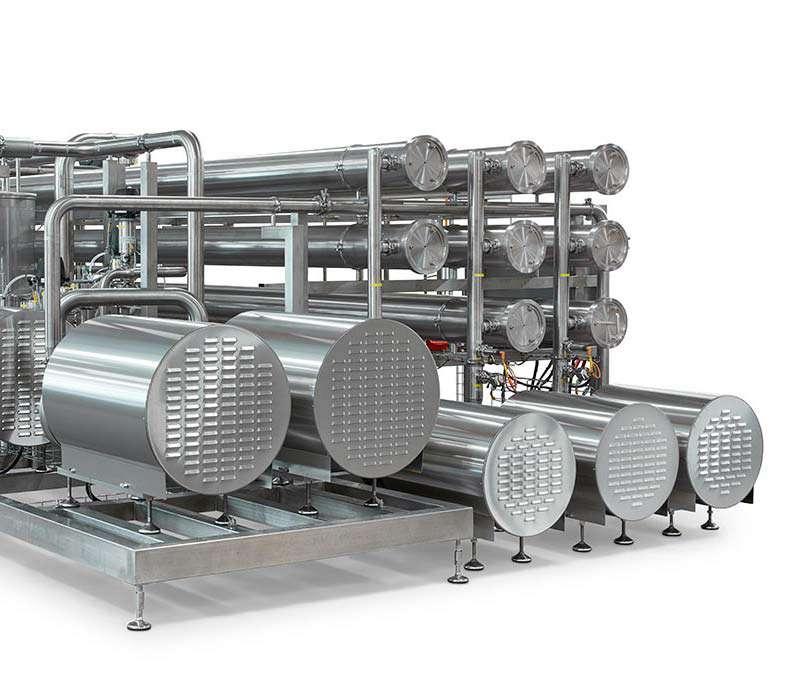

One of the leading suppliers in this sector at the trade fair grounds in Cologne is GEA. Digital solutions that significantly reduce resource consumption during cleaning processes are of particular interest to the machine manufacturer. One example of this is the recently optimised cleaning-in-place (CIP) process in membrane filtration plants that are used mainly in the dairy and new food industries to produce milk protein or fish collagen isolates, for example. The process is used to separate or concentrate substances without thermal stress. Cleaning this plant was previously energy- and

water-intensive: various chemical cleaning agents are dosed into the plant, circulated for a certain length of time using pumps and then flushed out with water. Sensors that constantly measure the permeate quality of the water during flushing are now used in order to reduce water consumption. Instead of setting blanket rinsing intervals and water quantities in advance, the Smart Filtration Flush software stops the process significantly earlier as soon as the required level of hygiene is achieved and the cleaning agents are discharged. This is able to reduce the need for fresh water by up to 50 percent depending on the type and size of the plant and the water properties.

“A typical whey protein concentration process consists of two to four filtration plants connected in series that not infrequently need more than 100 litres of water per cleaning run“, says Nils Mørk, R&D Engineer for membrane filtration at GEA. “Our tests show that we can save up to 50,000 litres of water per cleaning process in such large plants and 500 to 700 litres per CIP process in small plants.” In addition, if less water is input into the process, less effluent also has to be disposed of. “Many manufacturers can only clean their filtration plants successively, because flushing them often exceeds the pipeline capacity. That can lead to a potential safety hazard for staff and cause contamination in the production area. We can eliminate this peak water flow problem with Smart Filtration Flush, because we can significantly reduce pressure fluctuations in the water supply and drain line overflow”, says Mørk.

For producers, CIP solutions are an essential element for cleaning plants and controlling microorganisms and therefore for guaranteeing reliable process results with minimum downtimes. As in numerous other locations, the fact that the best results are achieved by cleaning with

higher energy consumption. GEA is breaking with this practice and ensuring the pulsating operation of filtration plant pumps during the CIP process by means of software. “We are now transferring the process familiar from washing machines –agitating clothes in the drum, stopping at intervals and letting the cleaning agent take effect – to

innovation, large filtration plants require 60 to 100 kilowatt hours less electrical energy per CIP process.

Software in combination with modern sensor technology is an important trend and is regarded as one of the essential solutions of developers. Continuous monitoring by sensors makes the cleaning process more efficient and sustainable. The Fraunhofer Institute for Physical Measurement Techniques IPM is demonstrating this with the F-Fiber sensor. F-Fiber consists of an optical fibre with a diameter of one millimetre that is embedded in a stainless steel sleeve. The end of the fibre is integrated directly into the wall of a food tank or a pipe conducting food. Alternatively, it can be attached to an existing fitting with the aid of a flange. All of the measurement system’s other hardware components are located outside of the plant and are connected to the production plant via the fibre. The tank or pipe content flows around the tip of the fibre on the inner wall of the tank or pipe. Over time, molecules accumulate on the sensor tip and the vessel wall. This leads to the formation of an undesired deposit. During the measurement, the fluorescence of the deposited organic material is excited with UV light via the sensor fibre. The fluorescence emission is fed back via the same fibre to a highly sensitive detector, where it is evaluated. The strength of the fluorescence signal can be used to draw conclusions regarding the extent of fouling, i.e. the deposits. Based on these measured values, the cleaning process can be triggered and adjusted in real time and in various production processes for different foods.

The fact is that food manufacturers want to save energy, water, time and cleaning agents without running the risk of compromising on product safety. However, ensuring the optimum performance of a CIP system poses many of them with a challenge. Not only do the cleaning agent concentrations in the respective cleaning step and in the reprocessing tank have to be known. It is equally important to ensure a turbulent flow, because only then is the desired cleaning effect achieved.

This is where measurement technology suppliers such as Endress+Hauser come into play with a constant array of new inline devices for flow, fill level, pressure and temperature as well as for analytical measurements. Integrated directly into the application, these register data on energy, chemical and water consumption, detect the beginning and end of each cleaning step and thereby enable precise monitoring and control in real time. In this way, the sensors help to reduce the cleaning time, product losses and resources while ensuring complete traceability at the same time. Liquitrend QMW43, for instance, measures whether any deposits are still adhering in tanks or pipelines and their thickness. This multi-parameter device can register the thickness of the coating and the conductivity of the media at the same time. The device’s direct connection to the control system means that the measurement data are available in real time and enables them to be documented automatically. If the sensor no longer indicates any residual coatings, successful cleaning of the critical areas can be concluded.

Stoddart has built on the existing partnership with Giorik to utilise research & development to produce the unique, one of a kind, European styled modular 700 & 900 series cooking equipment to Australian Standards, delivering, efficiency, safety and reliability.

Giorik’s class leading, European design and engineering have been operating in the professional food service equipment industry since 1963.

Meeting the various needs of the global market,

Demand for alternative proteins is higher than ever before. Their use offers a variety of options for new products – such as through the cell-based production of foods or ingredients. GEA is making a mobile test centre available in order to fully exploit this potential. With this, the machine manufacturer is aiming to bridge the gap between laboratory work and demonstration plants for producers. They can use it to test pilot processes for producing new foods on a commercial scale.

Alternative proteins can make an important contribution to securing the food supply for a growing population with fewer resources –“and thereby make our food system more sustainable and viable,” says

Stefan Klebert, CEO of the GEA Group. In order to scale up developments in this sector on an industrial footing, the machine and plant manufacturer presented its mobile test centre at Anuga FoodTec 2022. As a fully-equipped, individually configurable process line, this modular fermenter and bioreactor platform can be used on a pilot scale for cultivating various cell types as well as for fermentation.

As part of the mobile test centre, the GEA UHT pilot plant is a flexible, highly-automated system for the indirect thermal treatment of liquid products such as fermentation solutions or dairy products. (Photo: © GEA)

So far, the leap from testing

innovative foods in the laboratory to validating processes at an industrial level has necessitated significant investment in demonstration plants without any guarantee of success.

With its mobile test centre (MTC), GEA is aiming to achieve a new kind of proof of concept for cellular agriculture. The ingenious part is that customers do not have to invest in a complete pilot plant to support scaling up to commercial cell-based production. Instead, they can rent or buy the MTC or use it at a GEA branch, thereby enabling the growth and behaviour of cell cultures and microorganisms as well as fermentation processes to be studied, recipes to be modified, growth media and ingredients to be varied and process parameters that influence the yield and reproducibility to be influenced.

The MTC offers the option of testing production with the aid of cell cultures and microbial fermentation using bioreactors/fermentation tanks on a pilot scale from 50 to 500 litres and complete process lines. It consists of eight technologies that comply with the food regulations, including GEA’s multifunctional fermenters or bioreactors as well as plants for mixing, heat treatment, homogenisation, separation and filtering. The system offers scope for changing the sequence of the various stages and for adding or repeating process steps in order to test cultivation and fermentation strategies as well as product recovery.

Restarting with delivery services, contactless procedures, the creation of new products, coffee supplies and campaigns to get consumers back into bars and restaurants – a whole range of possible approaches.

Relations with customers as lockdown is eased could not be more crucial. After weeks of closure, establishments everywhere are finding it hard to get back to their pre-pandemic rhythm, with customers still scared and reluctant to return, worried about performing gestures that used to be completely natural. Now companies are coming to the r

escue, offering restaurateurs new solutions. The aim: to create a “new”

space, one that will put customers at their ease. “With the Ho.re.ca. sector completely shut down, we have been focusing on four things,” says Marco Rodi, branch manager of Bravilor Italia: coffee-to-go schemes, instant coffee machines suitably adapted to serve automated meals in care homes, the progress of projects and finally the development of a sanitising column developed entirely by us with the same steel used for coffee machines, and which is elegant, versatile and extremely easy and safe to use thanks to the dispenser pedal.”

The coffee-to-go schemes were set up in collaboration with a number of Italian coffee roasters who export to other countries: “in this case both traditional and automatic filter machines were used. We are well aware that Italy is the country of espresso coffee, but right now other consumer trends are emerging that are mainly to do with delivery services, and we will see if they continue once bars reopen.”

Despite the fact that nursing homes are now closed to outside visitors,

activities have of course continued inside, with a new, heightened need to reduce the risk of contamination during the handling of food.

“Thanks to our range of instant coffee machines it is possible to supply breakfast products automatically as well as foodstuffs of just the right consistency, with a wide range of items to choose from: milk and biscuits, tea and biscuits, various flavours of gel water, thickened drinks (hot), starters, main courses, side dishes, fruit mousses and deserts. It is an all-Italian project which we and our distributor are trying to export to other European markets.”

Bravilor also works in the research and development sector: after the summer it will be bringing out a model similar in size to a capsule machine but with its own incorporated coffee grinder, which will require just a click to dispense espresso coffee and can be connected to a refrigerator for cold milk. “It is difficult to say what coffee breaks in companies will be like now, but if social distancing

continues, we will have to have smaller appliances, possibly spread over a wider area. In some countries we are getting a sense that working from home will become an advantage and that companies will start putting home coffee breaks into their welfare packages.”

Still on the subject of coffee, Kimbo has decided to give its support to Italian baristas through two initiatives: a series of special free gifts linked to the purchase of coffee beans, and an advertising campaign that aims to help people rediscover the moment of happiness experienced when drinking coffee at a bar.

“At this particularly difficult time, people have changed their behaviour and that includes going without some of those moments that give great pleasure, like enjoying a good cup of coffee at a bar,” the company says.

“We are committed to offering the bar channel our concrete support and we as a firm are making every effort to help kick-start the return to business as usual.”

PAPACKS is one of Europe's most innovative producers and packaging manufacturers for plastic-free and sustainable packaging solutions made from rapidly renewable raw materials that make single-use plastic obsolete. The company stands for innovative packaging solutions made of moulded pulp or fiber pulp and the development of new production technologies as well as plant-based barrier coatings.

Moulded pulp is a very environmentally friendly material made from waste paper, renewable fibrous materials such as hay, straw, hemp or similar cellulose material. Moulded pulp material can be reused, is recyclable and compostable. A well-known product made of moulded pulp is the egg carton, which circumferentially and safely protects the delicate food product "egg". With the emerging topic of "sustainability", a new focus is being placed on moulded pulp in the

packaging & logistics sector. Further development of moulded pulp

PAPACKS has brought moulded pulp onto the "sustainability stage" with its 3D concepts. Today's moulded pulp can no longer be compared to the egg carton concept. Today's special requirements from the industry were the challenge for PAPACK as a fiber cast manufacturer and fiber cast producer to further develop and optimize the production with the material fiber cast. Fiber forms are now water-resistant, greaserepellent and also fireproof and can therefore be used in a wide range of industries. In the food sector, the portfolio ranges from cups for ice cream and yogurt, coffee capsules, nacho bowls for cinemas and events to bottles and containers for liquid and powdered products.

Molded fiber is the only answer, ecologically and also economically, to packaging and transportation issues. With fiber molding, the

turning point has been reached to banish plastic from the packaging world. In the area of transport and logistics, fiber casts are being processed into transport trays, replacing expanded polystyrene (EPS) or extruded polystyrene (XPS) trays, also known as foams, as well as Styrofoam.

A characteristic feature of the fiber cast material is its versatility. The material itself exhibits high shock absorption. By adding various environmentally friendly substances, the properties of the basic material can be strengthened or even changed. Nevertheless, these fiber moldings are biodegradable or directly compostable, but the most effective way is to reuse them directly through a "green circular system" to shred the packaging after use and use this material to make new molded fiber parts. Beyond the protective function, the fiber molding in PAPACKS' 3D packaging also enables a new, modern design with high recognition value.

The materials come from sustainable forestry and are FSC® certified, with a new tree being planted for every one felled. We also apply the highest quality standards to our raw materials to ensure high product quality.

Plant coating as a unique selling point.

A significant unique selling point regarding the food packaging results from PAPACKS® Plant-Based-Coating. This plastic-free solution, specifically designed for OTR (Oxygen Transmission Rate) and WVTR (Water Vapor Transmission Rate) barriers, offers additional benefits for sensitive products requiring fiber bonding or necessary moisture resistance.

This innovative technology makes it possible to eliminate the use of plastics in packaging while ensuring product quality and shelf life. At the same time, eliminating the use of any plastics allows for reduced disposal and recycling efforts. This opens up new opportunities for sustainable packaging designs and materials that meet the needs of different industries and applications.

Alook at the global situation reveals a sector that is advancing, and set to reach a value of 43 billion euros in 2025.

The USA is the main importer, Brazil the leading producer.

Where is the coffee market heading?

A detailed picture of world trade in one of the most widely marketed products comes from data drawn up by the strategic marketing division of HostMilano and taken from the Export Planning information system.

The good news is that in 2021 world trade in coffee-related products did particularly well: +13.6% in values in euros for espresso coffee machines, so a clear sign that things are recovering, +13.1% for decaffeinated or roasted coffee and +8.8% for nonroasted coffee beans. The overall value of world trade in the three sectors has reached the highest ever recorded level of 34.5 billion euros.

For the 2022-2025 period a

compound annual growth rate (CAGR) of +5.6% in values in euros is forecast for world trade in coffee products, with a total value expected to reach 43 billion euros.

On average in 2021, world trade in non-roasted coffee beans stood at 17.7 billion euros, although this is still lower than the all-time high recorded by the sector at the start of the last decade. A period of moderate expansion is expected for 2022-2025, with a CAGR of +4.6% in values in euros, exceeding the 20 billion-euro threshold for the first time (21 billion euros in 2025).

As for the world market rankings, the United States (22.4 per cent) and Germany (14.2%) were the main destinations in terms of sales in 2021, ahead of Italy (6.4%), Japan (5.1%), Belgium (4.2%) and Switzerland (3.8%).

The sector’s top exporter at a global level in 2021 was once again Brazil (with a 27.6% share), ahead of Colombia (13.9%), Vietnam (9,9%),

Final figures for world trade in decaffeinated or roasted coffee reached a new high of 12.3 billion euros, up 13.1% on 2020. The situation forecast for 2022-2025 is one of continued expansion as has been the case for some time, with a CAGR of +7.1% in values in euros, worth a total of over 16 billion euros.

France was the world’s top importer in this sector in 2021 with a share of 17.6 per cent, ahead of the United States (11.6%), which was some way ahead of Germany (6.2%), the Netherlands (5.5%) and Canada (4.5%).

As for exports, Switzerland held on to pole position with 23.1%, ahead of Germany (15.5%), Italy (13.4%) and France (10.3%).

Honduras (5.4%), Guatemala (3.6%), Ethiopia and Belgium (each with a share of 3.5%).

Honduras (5.4%), Guatemala (3.6%), Ethiopia and Belgium (each with a share of 3.5%).

“Albert Handtmann Maschinenfabrik from Biberach, Germany shows how plastic waste can be avoided when packaging liquid or pasty products in bags. The company relies on natural alginate and won a gold medal at the International FoodTec Award 2024 with its ConProSachet system. Product Manager Andreas Heckenberger explains exclusively what's behind the idea and what potential he sees in his company's innovation.”

Andreas Heckenberger

Mr Heckenberger, what is the ConProSachet system?

The ConProSachet system is a new process for packaging liquid or pasty products in sachets. These can be gels, beverages or even sauces. The casing is made of alginate and is produced in a coextrusion process during filling. Then the product ends are moulded and sealed during the gelling process.

What are the advantages of alginate over conventional packaging systems?

Alginate is obtained from seaweed

and is an ecological and sustainable alternative to existing plastic packaging. It offers the industry completely new possibilities for replacing existing materials. The most significant advantage is that alginate bio-degrades within a few weeks. If you like, you can even eat it without hesitation.

Con Pro sachets seasoning sauce Seasoning sauces packaged with ConProSachet technology

And how is the packaging wrapped around the products?