E N T E R >> SPOTLIGHT SPOTLIGHT FOOD & BEVERAGES TECHNOLOGY Government of India | Registeration DELENG19573 www.foodmattersmagazine.in Food Matters food | beverages | packaging & machinery | ho.re.ca.| hospitality Food MattersSpecialEdition APRIL2024

HOTEL HOTELINDUSTRY! INDUSTRY! A CUSTOMISEDA CUSTOMISED ANYTIME! MIXOLOGY! COFFEE PACKAGING! MEAT BARS & what the chef says!

APRIL2024

The Food Service Equipment Market Size was valued at USD 30,489.5 million in 2021. The Food Service Equipment market industry is projected to grow from USD 32,014.0 million in 2022 to USD 45,046.9 million by 2030, exhibiting a compound annual growth rate (CAGR) of 5.0% during the forecast period (2022 - 2030). Food consumption patterns are changing, takeaways are rising, and the hospitality industry is expanding are the key market drivers enhancing market growth for food service equipment. Source: https://www.marketresearchfuture.com/reports/food-service-equipment-market-3776.

Consumers are becoming increasingly aware of energy consumption and eco-friendly initiatives, leading them to adopt energy-efficient appliances, which creates opportunities for the market. To mitigate the impacts of climate change, consumption norms emphasize reducing greenhouse gas emissions (GHG). Restaurants, institutional kitchens, and cafes increasingly prefer appliances displaying the ENERGY STAR symbol, a symbol that signifies a product is energy efficient, saving energy and reducing maintenance costs. A study by the Energy Star program of the U.S. EPA found that food service equipment featuring the ENERGY STAR symbol can save operators USD 5,300 annually or about 340 million BTUs. Further, the market demand has significantly increased due to the emergence of several casual restaurant chains in North America and Europe. According to several regulatory bodies worldwide, companies must sell certified and tested commercial kitchen appliances. By setting these safety standards, restaurant operators and consumers can expect a safe and secure environment. The mission ensure food safety requirements and sanitation protocols are adhered to by the end-user sector, the National Sanitation Foundation (NSF), a non-profit organization that tests, inspects and certifies products, has developed equipment safety standards.

Additionally, with a growing awareness of food safety and smart kitchen appliances, advanced food service machinery will be in high demand in the coming years. Therefore, the introduction of IoT, Big Data, and Industry 4.0 have led to the growth of smart food companies whose equipment is based on technology. In addition to helping restaurants achieve the highest level of food safety, waste reduction, traceability improvement, and cost reduction, this technique can also help to reduce the risks associated with various food serving techniques that are becoming a key trend on the market.

The food service equipment market segmentation, based on product, includes cooking equipment, storage & handling equipment, ware washing equipment, food holding & serving equipment, and others. The cooking food service equipment segment held the majority share in 2021, contributing to around ~38-40% of the Restaurant and Kitchen Equipment market revenue. This is primarily owing to using innovative products in commercial kitchens depending on the kitchen's space and budget. Manufacturers have increased their focus on elements such as the latest technology solutions and exterior appliance designs as the demand for meal preparation appliances increases in open food service kitchens. Source: https://www.marketresearchfuture.com/reports/food-service-equipment-market-3776

Editor Sarvjit Singh Managing Editor Amrita China Correspondent & Reporters Ying Wei-Beijing Bao Tian Tian - Shanghai Xing Guang Li - Guangzhou Assistant Editor/Correspondent Elena Marketing Director Elisha Kanda Circulation Surekha Gogna Production, Design & Degital Media Rakesh Sharma Marketing & Sales Lina Catherine Amy Lan Anna Mi Technical Advisors Alex Van Bienen/Lily - Nederlands Public Relations Director (UK) Mike Steele International Director Richmond Kanwar Brampton, ON Canada International Advisor (Australia) Andrew S. McCourt Germany Representatives Julia Rittershofer Steffen Schnaderbeck India (Head Office) FOOD MATTERS C 2073A, Sushant Lok 1, Cyber City, Gurgaon 122 001 Tel: +91 9999489614 info@foodmattersmagazine.in www.foodmattersmagazine.in Government of India | Registeration DELENG19573 www.foodmattersmagazine.in

Matters food | beverages | packaging & machinery | ho.re.ca.| hospitality

SpecialEdition

Food

Food Matters

Plant-based proteins, algae, or functional probiotic beverages the new foods that will set trends at Food 4 Future

Food 4 Future - Expo Foodtech, which will be held from 16 to 18 April in Bilbao, Spain, will analyse and present all those new ingredients and foods that are emerging as alternative protein sources.

Representatives from companies such as NaturAll, Fruselva, Ingredalia, BeAmaz, and Noga Plus will be among the participants at the Food 4 Future R&D Summit Madrid/Bilbao, March 26th, 2024 - It is a reality that science, research, and development (R&D).

are fundamental in shaping the future of our diets. Laboratory research is revolutionizing the creation of foods with new ingredients aimed at addressing challenges such as food safety, the growing demand for proteins, or consumers' new preferences. All of this will be analyzed and debated at the R&D Summit to be held within the framework of Food 4 Future - Expo Foodtech 2024, from April 16th to 18th at the BEC in Bilbao.

Among the topics for discussion are the challenges associated with the growing demand for proteins and

the innovative solutions emerging in response. In this context, the Food 4 Future World Summit congress will present the latest alternative protein sources, including options for plant-based, cultivated, and sustainable proteins, featuring Abert Tseng, Co-founder of Dao Foods and representative of China at ICEX; Rodrigo Sanchez, CEO of NaturAll; and Beatriz Jacoste, Director of KM ZERO Food Innovation.

Furthermore, the successful incorporation of next-generation ingredients into various food products will also be addressed through real case studies, providing professionals in the food industry with information on the latest trends and strategies. Clemens Hollah, Managing Director of DIL and representative of Germany at ICEX, and Guillermo Mena, R&D&I Director of Fruselva, will be among those responsible for providing these insights.

The arrival of new foods and additives has brought about a revolution that also entails challenges, a new regulatory framework, and opportunities for innovation, aspects that Miguel Angel Cubero,

CEO of Ingredalia; Macarena Baylos de Nárdiz, Director of Exploitation of Results at CNTA; and Thomas Dietrich, Project Manager at Tecnalia Research & Innovation, will discuss.

In the bakery and snacks professionals' realm, Eliana Bejarano, CEO of Be-Amaz; Rina Fainstein, CEO of Noga Plus; and Alejandro de la Brena, Co-founder and CEO of Griyum, will provide a strategic vision of the latest ingredients and flavor concepts, as well as emerging trends in this field and the technical aspects of product development.

Another relevant topic for the industry is food safety in a globalized and constantly changing world. John Holah, expert professor at Cardiff University, and Hugo Cunha, Scientific Researcher at AZTI, will analyze issues such as supply chain resilience, regulatory evolution, and technological innovations ensuring food safety. The congress will also showcase the potential of algae in the agri-food sector, a very current topic to be addressed by representatives from AZTI, the University of the Basque Country (EHU-UPV), and the European Algae Biomass Association (EABA).

In line with the current situation, citizens are concerned about a diet that favours optimal wellbeing and contributes to improving health. To achieve this goal, probiotics, together with the healthy properties of the lipid fraction of dairy products and the components of coffee, are essential for promoting healthy

ageing, as representatives from different CSIC departments will show. This will also be addressed by experts from Eurocat and Northumbria University, who will present the latest advances in research on probiotics and their possible use in the creation of healthy dairy drinks.

From proteins made from plant residues to edible and healthy 'glue'In addition to the congress area, Food 4 Future 2024 will feature an exhibition area where more than 280 firms will showcase their latest solutions. Regarding new ingredients, Moa Foodtech will present sustainable proteins developed from the fermentation of vegetable residues and by-products such as leaves, peels, or fruit skins. On the other hand, the company Nucaps will introduce its alternative to salt, named NuCla, which provides salty flavor without harming the consumer's health. Similarly, the Japanese brand NinjaFoods will exhibit edible and healthy 'glue paste' made from konnyaku food, to bind ingredients for creating healthy snacks.

Other companies that will be present include Maash, with a protein produced by fermenting mushrooms, which has a texture very similar to that of meat, but with a lower environmental impact; or the biotech company Genbioma Aplicaciones, which will be exhibiting its probiotics and postbiotics that help regulate blood sugar in people with diabetes.

4 | APRIL 2024 | Food Matters

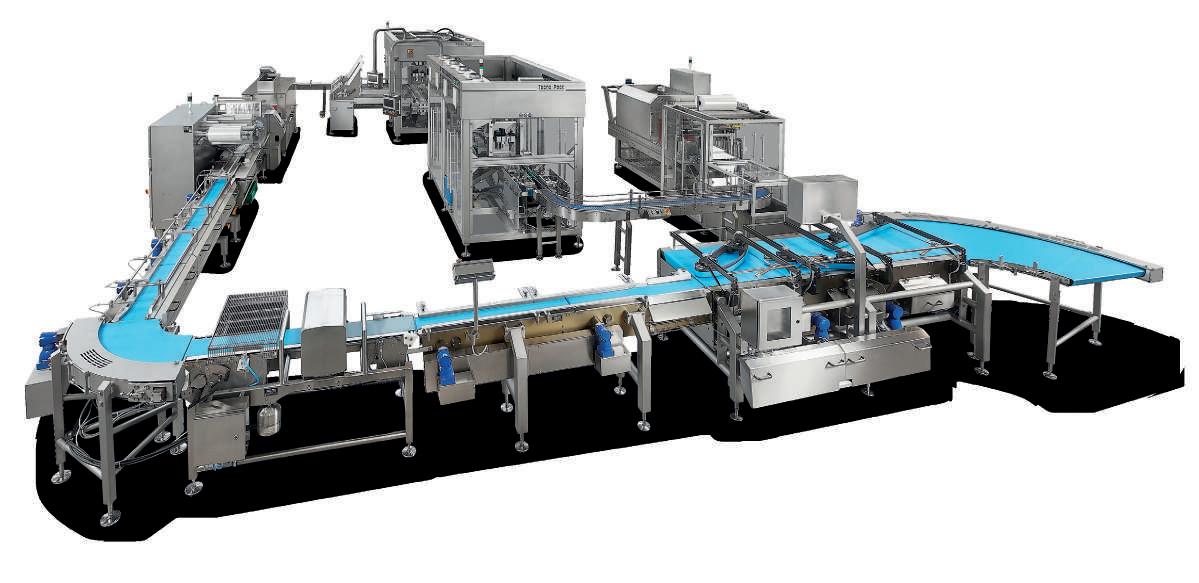

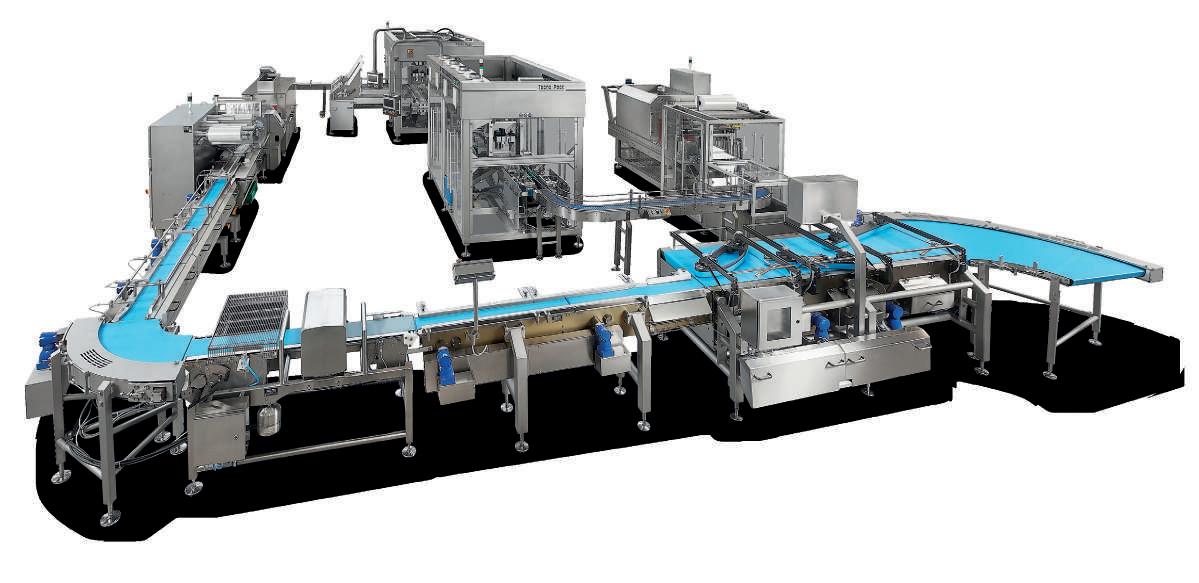

Packaging for all kinds of meat

Multivac: fast product changes and optimised packaging

Nowadays, virtually every process step for packaging meat products can be automated. However, different products require individual solutions. Multivac offers a broad portfolio for enabling cost-effective and sustainable processing and packaging of different foods. These include systems that are suitable for the meat industry as well as for manufacturers of vegan and vegetarian products that are based on alternative proteins.

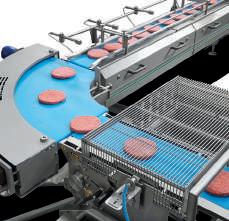

Line solution for burger patties in a protective atmosphere

Multivac’s solutions include a spacesaving, high-performance line for automatically separating, infeeding, packaging and labelling burger patties on a cardboard tray in a tubular bag. A centrifuge separates the patties onto one conveyor while cardboard trays are unstacked on a conveyor running in parallel. A handling module fills the cardboard trays with the burger patties and the filled trays run through a packaging machine in which they are packaged in a protective atmosphere. An inline labeller finally applies a label onto

the upper side of the packs. The flow packing solution is suitable for quick product changes and is characterised by its cost-effectiveness with high performance. The use of thin film and the avoidance of process-related film residues contribute to the solution’s sustainability.

Sliced vegan products reliably portioned

Multivac offers a high-performance thermoforming packaging line for automatically cutting, infeeding, packaging and labelling sliced vegan products. A slicer cuts the product and sprays each slide with a separating agent (liquid interleaving). Thanks to the use of the spray system, no paper or film is required as an interleaver. The thermoforming packaging machine additionally enables optimised packaging material consumption. Each individual portion is placed onto a checkweigher. Portions with incorrect weights are discharged for manual weight correction by means of a rocker. Portions with a correct weight are forwarded by a conveyor belt and grouped appropriate to the

thermoforming packaging machine’s format layout. The portions slide into the packaging trays as they move forwards. Optimum loading results can be achieved due to the flat insertion angle. After packaging in a protective atmosphere, the upper and lower sides of the packs are labelled using cross-web labellers

Automatic packaging for small and medium-sized processors

Multivac is rounding off its portfolio in the entry-level segment with the GMS 400 portioning system. The solution from TVI is aimed at butchers and industrial companies with small lines as well as bulk consumer suppliers that supply restaurants, caterers, canteens, schools or hospitals with portioned meat products. The multifunctional portioner is characterised by flexible 3D forming of the product. The system therefore adapts to the different sizes and shapes of the raw products. The compact system can process virtually any kind of meat and perform diverse portioning tasks – from medallions and schnitzel to roulades, from carpaccio to roast cuts and from on-thebone to boneless pork, lamb or veal.

The GMS 400 portioner

The GMS 400 portioner is characterised by flexible 3D forming of the product. (Photo: © Multivac)

Food Matters | APRIL 2024 | 5

ALL THAT GLITTERS IS NOT GOLD

In four cities that have a particularly lively scene we uncovered the trends of the moment that are transforming the world of cocktails.

All that glitters is not gold, they say, but a cocktail carefully prepared by a well-know bartender in a bar ranked as one of the best in the world surely makes all the difference. In London and New York, obviously, but even more so in cities that until now have not exactly been renowned for their nightlife. So to find out what trends we can expect in the coming months, we chose four cities whose locales embody the big trends of the moment: Athens, Mexico City, Barcelona and Milan.

One of the top trends right now is one that we could call Cocktail Tourism. Remember the times when journeys were planned specifically in order to dine in a particular

restaurant? Well now bars too are becoming destinations worth booking a holiday for. In cities like Athens you can sip a cocktail at Couleur Locale or A for Athens in the shadow of the floodlit Parthenon, or else wander down streets that used to be off limits in the once ill-famed Psyrri district to sample an Aegean Negroni at Clumsies, which is one of the best bars in the world. Not least of all because you spend a lot less money there than in a star-rated restaurant and you socialise more, something we all need more of right now.

As a consequence, new cities have come onto the radar. The pandemic and the opportunities for remote working that came with it have prompted many professionals to move away from the big cities to go and work in more liveable places, where life costs less and things

move at a steadier pace. This might also mean having extended hotel stays, as part of the staycation trend.

So what do these bars have on their menus? So-called Nostalgic Drinks that offer familiar flavours and forgotten combinations, brought back in a way that satisfies the new need for sustainability, using local ingredients and with a healthier, lower alcohol content. An example of this would be the Giostra d’Alcol, a bizarre futurist cocktail, revised and corrected at the 10_11, the bar at the Portrait hotel in Milan.

Alcohol-free cocktails are no longer something people make fun of (the term ‘mocktail’ is going out of fashion in fact). They are now a respected choice, thanks among other things to a plethora of new distillates with zero alcohol or a low ABV (Alcohol by Volume) level. People want fewer calories and less

alcohol, in order to better enjoy ‘the moment’, as well as being able to choose when, where and how to drink. As has already happened in the kitchen, bars are now tending to use local ingredients and spirits to create unique cocktails, ones that say something about the history and culture of the local area. This is something that is happening in Mexico City, as our HostAmbassador tells us in the article The Mexico Mixology Scene Focuses on Identity. Finally, lasers, distillers, driers and sous-vide, i.e. the equipment that has revolutionised haute cuisine, is now also to be found in bars together with advanced processing techniques, as happens at the Paradiso, which recently earned itself the accolade of the world’s best bar. And where is it? For the first time it is not in London or New York, but in Barcelona. In other words, creativity today knows no bounds.

6 | APRIL 2024 | Food Matters

From bars to nursing homes: how companies are helping clients cope in a changed world

Restarting with delivery services, contactless procedures, the creation of new products, coffee supplies and campaigns to get consumers back into bars and restaurants – a whole range of possible approaches.

Relations with customers as lockdown is eased could not be more crucial. After weeks of closure, establishments everywhere are finding it hard to get back to their pre-pandemic rhythm, with customers still scared and reluctant to return, worried about performing gestures that used to be completely natural. Now companies are coming to the r

escue, offering restaurateurs new solutions. The aim: to create a “new”

space, one that will put customers at their ease. “With the Ho.re.ca. sector completely shut down, we have been focusing on four things,” says Marco Rodi, branch manager of Bravilor Italia: coffee-to-go schemes, instant coffee machines suitably adapted to serve automated meals in care homes, the progress of projects and finally the development of a sanitising column developed entirely by us with the same steel used for coffee machines, and which is elegant, versatile and extremely easy and safe to use thanks to the dispenser pedal.”

The coffee-to-go schemes were set up in collaboration with a number of Italian coffee roasters who export to other countries: “in this case both traditional and automatic filter machines were used. We are well aware that Italy is the country of espresso coffee, but right now other consumer trends are emerging that are mainly to do with delivery services, and we will see if they continue once bars reopen.”

Despite the fact that nursing homes are now closed to outside visitors,

activities have of course continued inside, with a new, heightened need to reduce the risk of contamination during the handling of food.

“Thanks to our range of instant coffee machines it is possible to supply breakfast products automatically as well as foodstuffs of just the right consistency, with a wide range of items to choose from: milk and biscuits, tea and biscuits, various flavours of gel water, thickened drinks (hot), starters, main courses, side dishes, fruit mousses and deserts. It is an all-Italian project which we and our distributor are trying to export to other European markets.”

Bravilor also works in the research and development sector: after the summer it will be bringing out a model similar in size to a capsule machine but with its own incorporated coffee grinder, which will require just a click to dispense espresso coffee and can be connected to a refrigerator for cold milk. “It is difficult to say what coffee breaks in companies will be like now, but if social distancing

continues, we will have to have smaller appliances, possibly spread over a wider area. In some countries we are getting a sense that working from home will become an advantage and that companies will start putting home coffee breaks into their welfare packages.”

Still on the subject of coffee, Kimbo has decided to give its support to Italian baristas through two initiatives: a series of special free gifts linked to the purchase of coffee beans, and an advertising campaign that aims to help people rediscover the moment of happiness experienced when drinking coffee at a bar.

“At this particularly difficult time, people have changed their behaviour and that includes going without some of those moments that give great pleasure, like enjoying a good cup of coffee at a bar,” the company says.

“We are committed to offering the bar channel our concrete support and we as a firm are making every effort to help kick-start the return to business as usual.”

Food Matters | APRIL 2024 | 7

The hybridisation of bars and mixology: tradition and innovation come together in the world of cocktails

We explore the emerging technologies, consumer trends and innovative products that are redefining the drinking experience in modern bars.

The art of the cocktail and the welcoming atmosphere of bars that offer them have always fascinated enthusiasts. But in recent years the evolution of this art in mixology is leading to a true hybridisation, as traditional bars branch out into new fields. A phenomenon driven by a combination of cutting-edge technologies, new social trends, and an increasingly wide range of innovative products. We take a look at how these elements come together to create a unique and exciting drinking experience.

Technology is playing an increasingly important role in the world of mixology. From automatic cocktailmaking machines to printers that transfer images onto the foam of drinks, technological innovation is allowing bartenders to express their creativity in ways never seen before. The precision and speed offered by these new instruments make it possible to create complex and surprising cocktails, satisfying even the most demanding palates.

Certainly the hybridisation between gelato, mixology, and pastry in the world of bars is something the ever more popular bartenders and mixologists are undertaking. For some years now, new preparations have been developed that are then

supplied to operators. This facilitates the preparation and creation of innovative cocktails and drinks, and offer a unique combination of flavours, textures, and temperatures, in particular thanks to the encounter with gelato.

Other current trends include: more mindful consumption, the search for higher quality products, a veritable explosion in demand for healthier and more sustainable products, and gelato cocktails based on vegetable drinks that are organic, local, and seasonal. Then there is also a greater attention to food allergies and specific dietary preferences being paid in this niche sector. This means that not only restaurants, but now also gelaterias and cocktail bars must be able to offer free-from options, without sacrificing taste, as consumers increasingly favour establishments where they can be sure of finding high-quality products with nice flavours.

So, hybridisation between gelato and mixology represents a fascinating evolution for both worlds, capable of reaching new targets, especially in the cocktail segment.

Thanks to cutting-edge technologies, ever-changing consumption trends and innovative products, modern bars offer unique experiences that are able to satisfy the desires of an increasingly demanding clientele.

8 | APRIL 2024 | Food Matters

PRODUCT FEATURES

DESIGN

More Sopisticated

Stainless steel provides high durability suitable for commercial use

POWER

Stronger Motor

Equipped with a motor that has more power for excellent performance

AUTOMATION

One Touch Automatic

Start the automatic blending process with the touch of one button

QUICK START

5 Pre-set Menu Options

Quickly make any order with up to 37 recipes settings

W W W . K U V I N G S . C O M . A U ( 0 2 ) 9 7 9 8 0 5 8 6

COMMERCIAL BLENDER CB1000

Pastry packaging puts the accent on sustainability

Paying attention to packaging, and carefully making it more sustainable. Sights are very much now set on Europe and overseas countries.

One of the most rapidly evolving specialisations in out-of-home eating, and in the world of gelato and pastry in particular, is that of how products are wrapped and packaged, with a major push towards making things sustainable.

According to a recent analysis by The Business Research Company, in 2022 the global market for recyclable packaging exceeded 28 billion dollars by value, up 7.2% on 2021, a figure that is expected to rise to 34.2 billion dollars in 2026.

New consumer patterns that have been seen recently have led on to new ideas for the segment, as

Alessandro Perli, head of Italian sales at Scotton, explains: “Some of the main trends we have noticed concern ecological issues such as the recyclability of materials. In addition to that, clients want products that are aesthetically pleasing and practical to use, and ones that don’t involve timeconsuming packaging processes.” The technological aspect is also very important:

“When it comes to technologies and concepts, we work in particular on the surface of the cardboard, to produce a special textural effect and we do that in-house. We have a wide range of products, and can use many different colours to enhance individual products.”

Eco-friendly packaging is a central market trend: key features include

being biodegradable, re-usable, non-toxic and made using recycled materials. The use of eco-friendly packaging is encouraged as a way of reducing the carbon footprint and of promoting a greener lifestyle based on saving energy and preventing pollution.

The demand for sustainability as a business opportunity

Efforts to achieve sustainability are increasingly part of the business of matching supply and demand, a key factor at HostMilano, and an extra business opportunity. Perli believes that Scotton’s participation at Host is very important also for this reason:

“For us, this is a physical return to a trade fair in Italy, bringing us into contact with the public, with our operators and with agents. Interaction has to happen if we are

to get a sense of how the market and new products are doing. We also come face to face with the foreign market, where there are many possibilities for development, even though we are already present in 60 countries.

As well as our current clients, we will also be looking for new distributors and users.” Finally, as for the geographical locations of the markets the company will be looking for at HostMilano, Perli says: “Our main market is Europe, because it is close and convenient.

Overseas, we are also interested in Oceania, Australia and North America. We used to be very strong in the Middle East, anddespite the fact that we currently have less penetration there we would also like to re-establish our presence there.”

12 | APRIL 2024 | Food Matters

Tomorrow’s cold storage systems: connected, versatile and barrier free

Constantly-evolving solutions are enabling the sector’s big players – who will be at Host 2023 – to drive the world market towards a record value of 200 billion dollars in 2032.

Upwards of 100 billion dollars. Rising to 200 billion by 2032, thanks to a Compound Annual Growth Rate (CAGR) of 7% a year, according to Global Market Insights data. This is the global value of the professional refrigeration sector, prominent among which are the segments of glass-door appliances, with over 50 million units supplied, and of inverter technology, which accounts for 40% of the market.

This success can be put down to the continued commitment of companies towards innovation. A kind of innovation that has always featured prominently at HostMilano, with all the very latest news ideas about to previewed once again, at fieramilano from 13 to 17 October. But what exactly are the trends that are driving this quest for innovation? One factor must surely be the

growing demand among customers for interconnected devices with more advanced functions that is fuelling the replacement market (the changeover from more obsolete models). One feature very much in demand now is the possibility of connecting appliances to the internet and to manage it remotely from the devices people now use every day, such as smartphones. And if everything is interconnected, then it is possible to operate across different divisions.

Versatility beyond barriers

“The Nice Kitchen group came about precisely in response to the growing tendency to ‘break down the barriers’ between the different segments, for example between foodservice and pastry,” says Angelo Minaudo, head of marketing and communication at The Nice Kitchen. In cold storage in particular, the group operates through the Coldline brand, which designs and produces versatile technologies designed to simplify the daily work of chefs, pastry chefs, bakers, and

pizza and gelato makers. “Simplicity of use lies at the heart of our products, helping users to manage technology designed to be there at its service. And for years, all The Nice Kitchen products have been developed to use just small amounts of energy. Smart software that self-regulate ovens and blast chillers for faster cooking and cooling, avoiding waste.

“The refrigerating gases used across the Coldline range”, Minaudo says finally, “have an environmental impact close to zero – something we are very proud of. At Host we will be previewing a new project that will give our customers the chance to reduce the consumption level of the entire kitchen and to optimise the production process.”

The removal of barriers and the other ongoing improvements that are being made, aimed at anticipating and satisfying ever-changing customer demands, are key to innovation also for a well-established brand like Angelo Po, as Chiara Roncagli, brand manager of Angelo Po Grandi Cucine explains: “To develop the products of the future we start with the ‘voice of the customer’. We recently launched ARI.O, a multi-functional blast chillerfreezer that has one warm and one cold chamber: from -40°C to +85°C. ARI.O is an intuitive, versatile, high-performance appliance: it cooks at a low temperature and freezes automatically, also optimising those moments when the kitchen is not in use.

ARI.O is connected to the free APO.LINK management portal that connects ovens, blast chillers, refrigerators, display cases and dishwashers to a single portal from which to monitor consumption, data history and HACCP parameters, to improve efficiency in the kitchen.”

These are just some examples of the advanced technologies coming to the world of cold storage, which professionals can look forward to seeing for themselves at Host.

Food Matters | APRIL 2024 | 13

Super fast, super clean crockery: The new ProfiLine generation with a cycle time of only 28 minutes. Miele Professional. Immer Besser.

For quotes or enquiries please call on 1300 731 411 www.miele.com.au/professional GlassesPlatesAndCutlery SpotlesslyCleanInOnly28minutes

Indulge the taste buds

Consumers are looking for more sweet and indulgent flavours in dairy products.

While the traditional flavours are still a popular choice, consumers are becoming more adventurous, and are open to experimenting with flavours.

Book a meeting with the IMCD team to discuss the furture of flavouring in the dairy industry.

Scan the QR code for more information

www.imcdgroup.com

FLEXI-DISC® Tubular Cable Conveyors gently slide fragile foods and non-foods through smooth stainless steel tubing routed horizontally, vertically or at any angle, over short or long distances, dust-free. Single or multiple inlets and outlets.

BLOCK-BUSTER® Bulk Bag Conditioners

loosen bulk materials that have solidified during storage and shipment. Variable height turntable positions bag for hydraulic rams with contoured conditioning plates to press bag on all sides at all heights.

FLEXICON® Manual

Dumping Stations allow dust-free dumping of bulk material from bags and other containers. Automatic reversepulse filter cleaning allows continuous, efficient operation. Available with integral bag compactors for total dust containment.

BULK-OUT® Bulk Bag Dischargers unload free- and non-free-flowing solids from bulk bags automatically. Allows untying, discharging, retying and collapsing of bulk bags—all dust-free. Available with weigh batching controls.

PNEUMATI-CON®

Pneumatic Conveying Systems move a broad range of bulk materials over short or long distances, between single or multiple inlet and discharge points in low to high capacities. Available as dilute-phase vacuum or positive pressure systems, fully integrated with your process.

SWING-DOWN®, REAR-POST and TWIN-CENTREPOST™

Bulk Bag Fillers can fill one bulk bag per week or 20 per hour at the lowest cost per bag. Numerous performance options. Available to industrial or sanitary standards.

FLEXICON® Flexible Screw

Conveyors transport free- and non-free-flowing bulk solid materials from large pellets to sub-micron powders, including products that pack, cake or smear, with no separation of blends, dust-free at low cost. No bearings contact material. Easy to clean quickly, thoroughly.

TIP-TITE® Container Tippers

dump bulk material from drums (shown), boxes or other containers into vessels up to 3 metres high. Dust-tight (shown) or open chute models improve efficiency and safety of an age-old task.

The FLEXICON® Lifetime Performance Guarantee* assures you of a successful result, whether you purchase one piece of equipment or an engineered, automated plant-wide system. From initial testing in large-scale laboratories, to single-source project management, to after-sale support by a worldwide network of factory experts, you can trust your process— and your reputation— to Flexicon.

CONVEY SUCCEED

©2023 Flexicon Corporation. Flexicon Corporation has registrations and pending applications for the trademark FLEXICON throughout the world. *See complete Guarantee for details. USA SINGAPORE INDONESIA MALAYSIA SOUTH AFRICA UK SPAIN FRANCE GERMANY +1 610 814 2400 +65 6778 9225 +62 81 1103 2400 +60 10 282 2400 +27 (0)41 453 1871 +44 (0)1227 374710 +34 930 020 509 +33 (0)7 61 36 56 12 +49 173 900 78 76 AUSTRALIA sales@flexicon.com.au 1 300 FLEXICON +61 (0)7 3879 4180 SEE DETAILS

CONVEYDUMPUNLOAD CONDITION FILLCONVEY

TIP

Superior cooking whilst using significantly less energy

With pioneering, award-winning technology, Synergy Grill is revolutionising the hospitality industry. Through high power and low energy consumption, Synergy Grills enable faster food preparation while significantly reducing energy costs when comparing to equivalent grills.

Winner of the 2019 footprint award for sustainable catering equipment, Synergy are the only gas grills that have gained accreditation from the Carbon Trust, a global organisation that is providing solutions for the world’s climate crisis.

Comcater is Australia’s most trusted commercial kitchens expert. We live and love food service, cooking up the kitchens of tomorrow for more than 40 years.

comcater.com.au

Premium advice. Premium equipment.

High Efficiency Sifting

» Removes foreign materials

» Handles a wide range of powders

» Facilitates quick screen changes

» Breaks soft lumps

www.kemutecusa.com 215-788-8013

Information

More

Meat &

Poultry Industry belting

solutions that are a cut above the rest Your One-Stop Belt Shop Thinking Belts & Food Safety? Think Ammeraal Beltech

Ammeraal Beltech know the production challenges you face; our belting solutions have been meeting your industry needs for Food Safety, hygiene, durability, performance efficiency and ease of cleaning for more than 60 years. Today, our newest solutions remain your prime choice across all your applications.

Our food-grade range includes unique modular belts built to minimise fissures where bacteria can

hide or knife blades can break. Our synthetic belts feature anti-microbial covers and KleenEdge non-fray properties to eliminate contamination. Our range also features ultra-hygienic homogeneous belts such as our Soliflex Pro positive drive belts, with innovative rounded lugs that cut cleaning time and water waste while also providing excellent power transmission and outstanding self-tracking performance.

www.ammeraalbeltech.com

We provide the space. You do the cooking.

Our cloud kitchens – a collective of private and shared commercial-grade kitchens – are designed to help food creators minimise costs, maximise profits and streamline operations.

For more information contact Harrison: harrison@tkcollective.co tkcollective.co

AFFORDABLE MODULAR SYSTEMS.

Until now, adding automation to your production line could be an expensive exercise. But Enmin’s new Generate+ systems changes all that. A range of affordable modular systems that slot easily into an existing line; reducing labour costs, boosting

productivity and improving quality.

Designed and built right here in Australia they feature the same quality, reliability and safety that Enmin is renowned for. Plus, they can be added to and extended as your business evolves.

T: +61 3 9800 6777 W: enmin.com.au

food processing industry.

Costacurta conveyor belts are used in food processing as well as in many other industrial processes.

Thanks to the specific experience gained over more than 60 years, Costacurta can assist the client in the selection of the most suitable type of belt for the specific application.

Costacurta conveyor belts are suitable for applications with temperatures ranging from -150°C to +1150°C.

Pantone Pantone Nero Bianco

tcb @ costacurta.it www.costacurta.it

A customised hotel industry

Courtesy items are becoming more eco-friendly and sustainable (plastic free and biodegradable) but also tailored to their target customers, and with references to the local area.

Sustainability, and reducing the environmental impact of products and services. Customisation, to offer guests a unique and distinctive experience, with the creation of product lines tailored to the type of guest, for example products for children. And sensory experiences: these are the guidelines that hotels are following. As Piero Persi, CEO of La Bottega Spa explains.

“For La Bottega innovation means adopting a dual approach: innovating on packaging and innovating on formulae. The company is proud to have been ahead of the game as regards all the main green trends in the sector: it was the first to present dispensers in alternative materials to plastic (for

example ceramic), non-refillable solutions with proprietary patents, solid cosmetics and 100% aluminium single-use tubes. Our cosmetic preparations contain no allergens or harmful substances, they are biodegradable and come in natural, eco-label and organic versions.”

The whole concept of luxury in hotels has changed. “Today, guests are looking for authentic premium experiences that are also sustainable and customised to their personal requirements. And the concept of luxury is evolving towards greater authenticity, also reflecting some aspects of the local area. Guests are keen to make the most of local culture and desire cosmetic products made using traditional ingredients. So hotels need to offer things that are unique and convey a true sense of place.”

ncreasingly, hotels are inclined to offer their guests an all-round

experience that covers all the main touchpoints of their stay. This is why La Bottega suggests offering gift items with retail value in the hotel’s boutique, either for sale or given away as complimentary items, thus extending the guests’ memory of their stay there.

At HostMilano La Bottega will present the main licensed brands and innovative products such as the “Invisibili” dispensers (a patented model), and packaging made of aluminium, ceramic, recycled ocean plastic and glass. The idea of providing useful items that are also unusual and refined is a trend also according to Elisabetta Talpo, branch manager of Giobagnara, a group with various brands that recently also took over the Italian luxury lifestyle brand Riviere.

“Our idea of innovation is about constantly coming up with new ideas for our customers all year round. New articles, new colours, new finishes. In addition, since we are ourselves the producers of our brands, we can customise items to make them truly unique. Depending on the kind of accommodation facility – business, conference, wellbeing – we believe that the true added value lies in being able to put people at their ease. The guest needs to feel special, in a setting that has been thought through right down to the last detail.”

Looking ahead to HostMilano next October: “Our team of designers designer is working continuously on new innovations. We will be bringing our new Tableware and Room Decoration collections, as well as all those other items that embellish hotel spaces. The luxury concept in hotels is more and more about making guests feel ‘at home’, enhancing the establishment with all those comforts that make the place elegant and technologically upto-date, with a welcoming, relaxing atmosphere.”

Food Matters | APRIL 2024 | 27

100 years old and still "cool": How frozen products conquered the hospitality industry

An invention that revolutionised cooking: 100 years after the development of the first freezers, frozen products are still popular in the hospitality industry. We talked to the Managing Director of the German Frozen Food Institute about advantages and trends.

100 years ago, the US naturalist Clarence Birdseye developed the first system for deep freezing, later known as the plate freezer. His investment: 7 dollars, a fan, ice and salt. On 6 March 1930, the first frozen vegetables were sold in the USA. With his invention, the deep-freeze pioneer Birdseye revolutionised the food industry and gave birth to a global industry that is still booming today. The products also enjoy great popularity in the catering industry because of their many advantages. In this interview, Dr Sabine Eichner, Managing Director of the German Frozen Food Institute (Deutsches Tiefkühlinstitut e. V., (dti)), explains the opportunities and advantages of the technology for the hospitality industry:

Which topics will play an important role for the frozen food range of the future?

In 2023, the food industry will continue to face major challenges in terms of inflation and energy crisis. Nevertheless, the key issues of the future, such as sustainability and plant-based nutrition, are gaining enormous importance, to which the frozen food manufacturers have already found numerous promising answers. New frozen products for a more sustainable consumption style will enrich the product ranges. Vegetarian and vegan choices are increasing. The individualisation of nutrition and eating habits is gaining more importance. This also means that convincing

convenience solutions will score even more points with naturalness, freshness, economy and sustainability.

What trends do you see in the gastronomy? How can frozen products help to overcome the enormous challenges of the industry?

The Corona pandemic has further exacerbated the shortage of skilled workers: many restaurants have had to severely restrict menus or opening hours. The guest’s claims have also changed. Needs are becoming more complex, with stagnating expenditure. The trend leads therefore towards system gastronomy which can make attractive offers with convenience products such as frozen goods. The advantages are obvious: the innovative products look like handmade and can be creatively individualised. Frozen food also offers a lot of flexibility in the professional kitchen because the products are durable for a long time, can be portioned well, are not seasonal and can be prepared just in time.

The frozen food industry can look back on a proud past - but the future also holds great tasks: How do you intend to tackle them?

The frozen food industry will continue to lead the way with a pioneering spirit on issues such as innovation and sustainability. We are consistently making progress in further reducing the CO2 footprint. Already in 2012, the Öko-Institut Freiburg calculated climate balances that show that our food has no higher CO2 footprint than other forms of supply. Our industry was recently the first to demonstrate its pioneering role in resource conservation with concrete data in the "Check Food Waste" project: Only very little food waste occurs throughout the entire frozen food chain. With our "Future Workshop" we have also given the starting signal for the frozen food industry's path to climate neutrality in 2022.

Frau Dr. Sabine Eichner

Frau Dr. Sabine Eichner

28 | APRIL 2024 | Food Matters

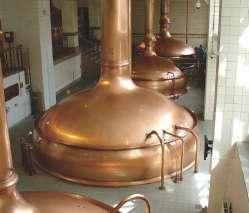

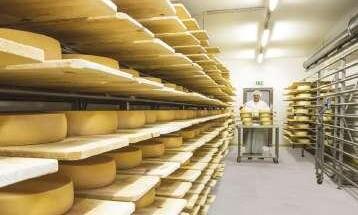

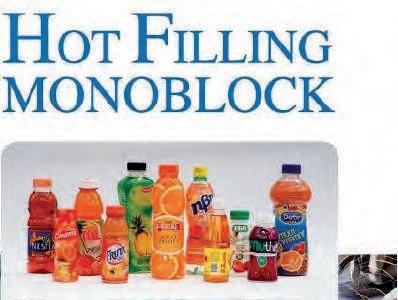

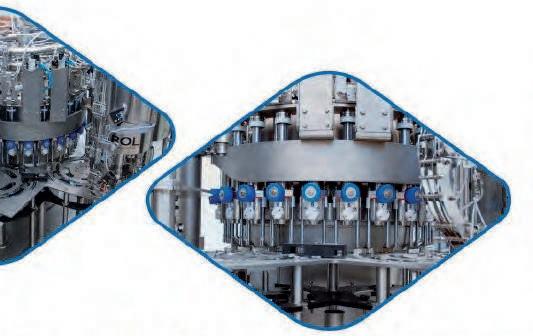

Mixing and Carbonating Units

Cip Cleaning Plants

Pasteurization Plants

Continuous Sugar Dissolvers

Aseptic Tanks

Syrup Rooms

core technologies Milking & Cooling Aseptic Filling Seperators Brewery & Dairy Decanters Compressors Homogenisers Packages & Skids Valves Ice Machines Spray Drying Freezers beverages dairy farmingdairy processing utilities transport food GEA Southern & Eastern Africa 48 Reedbuck Crescent, Corporate Park South, Midrand 1682, RSA Tel. + 27(0)11 392 7114, Fax. +27(0)11 392 7000 info-sea@gea.com

Introducing Pratica FIT Express

VERSATILITY: Stores up to 1024 recipes that can be divided into 16 categories based on food types or preparation methods.

STANDARDISATION: Allows operator to add recipes with up to 8 steps each, allowing for consistent preparation results across users.

AGILITY: Ready to complete the recipe with just two touches of the screen.

CONNECTIVITY: Internet of Kitchen (IOK) allows you to stay connected to your Pratica high-speed ovens via Wi-Fi.

Simple maintenance with unique removable catalytic converter. See us at Foodservice Australia 2023 Stand G24.

1800 777 440

Sydney • Melbourne • Brisbane • Adelaide • Perth • Auckland

• www.jllennard.com.au

Sales, Service and Spare Parts

The new 20x faster, high profit, high speed oven that fits anywhere!

Efficiency at quality’s service, the secret of the ‘new’ food service

At Host, in the Food Service Equipment area, top players and innovative SMEs presented technological solutions that optimize preparation, cooking and conservation.

"Molecular gastronomy" dishes that reinterpret tradition and look forward to a possible future. Ingredients that were once difficult to preserve and use are now giving rise to new recipes, keeping the flavours and aromas unchanged. Cooking and plating methods that preserve the health and nutritional value by combining them with impeccable presentations.

In recent years, haute cuisine has increasingly accustomed us to unusual variations on the theme, which consumers are increasingly appreciating, as confirmed by the data: in Italy alone, in 2022, the added value of restaurant services is estimated to be 43.5 billion euros (data by Confcommercio), up 18% on 2021. But what lies behind this success? A lot of it is thanks to

professional kitchens – places customers rarely get to see – and the secret is called technology. It is helping more and more chefs to give free rein to their creativity by simplifying the most routine operations.

For example, by combining several functions to shorten times, while keeping quality unchanged, as Chiara Roncagli, brand manager of Angelo Po explains: “Our offer is constantly evolving, and starts with us listening to customers. We recently launched new multifunction blast chiller-freezers with programmes that allow you to use a single chamber for both hot and cold processes, also taking advantage of moments when the kitchen is not operational and the possibility of controlling them from an online portal".

Solutions that often, thanks to innovations that have marked a real paradigm shift, have earned the authoritative Smart Label – Host Innovation Award, as happened in the last edition at Unox: “Our

patented system is the first vacuumpacking machine able to seal food that is still hot directly in the pan that was used to cook it,” the company says.

This is a solution that comes in response to two of the most pressing needs in the food service today: fighting waste and supporting delivery. "Together with our 'hot fridge' capable of keeping cooked food at serving temperature for up to 72 hours, the system eliminates waste and waiting times."

And the fight against food waste is part of the broader theme of sustainability, and in particular of energy saving, a point also stressed by Enrico Ferri, CEO of Rational Italia: “Trending topics continue to be linked to energy saving, following the higher costs deriving from price increases and inflation, and the difficulty of finding kitchen staff.

We offer technological solutions that allow staff to work fewer hours but more productively, that make the most of night hours for long

cooking times, and that plan production in advance and delegate activities, with the certainty that the quality of the dishes served will always be the same."

Professional training is a prominent subject among the events dedicated to foodservice. And that involves everything from the interaction between people, ingredients and sustainable methods outlined by APCI (the Professional Italian Chefs Association) with the Smart Food - Smart Chefs - Smart Future events, to the major challenges foodservice faces - such as digital transition, sustainability, skills –discussed during its meetings at FIPE (the Italian Federation of Bars and Catering).

On top of which comes Academy 2023 organised by FIC (the Italian Federation of Chefs), the seminars organized by FCSI - Foodservice Consultants Society International, as well as an actual Food-Technology Lounge organised by ANIMA Confindustria Meccanica Varia with its associations and EFCEM Italia.

34 | APRIL 2024 | Food Matters

PAPER REPLACES PLASTIC IN FROZEN FOOD PACKAGING

German food manufacturers FRoSTA and iglo are launching their new frozen foods packaging in 2023. According to statements issued by the companies, they aim to make their packaging even more sustainable and therefore plan to use more paper, save on plastic materials and reduce their carbon footprints in future.

FROSTA DEVELOPS PAPER BAG

At the beginning of 2023 frozen food manufacturer FRoSTA ushered in a new era of packaging by introducing frozen food packaging made out of paper: From now on, the plastic bags previously used for all of the company’s frozen food products are to be replaced by a bag designed especially for FRoSTA that is made out of 100 percent paper. For three years, experts have honed this unique power paper that protects contents without softening, even once the defrosting process sets in. This new frozen food packaging is neither bleached nor coated and is to gradually replace the current plastic bags from January

2020 onwards – around 40 million per year in total. The greatest challenge the company faced when developing the power paper was ensuring a consistent and high degree of product protection whilst at the same time preventing the paper from softening – no easy feat considering the constant presence of moisture and products that in part contain fats.

The developers achieved this by using a purely physical process on the material mix. A patent has been filed for this unique method of making frozen food bags out of unbleached, FSC-certified paper, including the printing method that exclusively uses water-based colours.

This frozen food packaging made out of paper, which can be recycled along with other waste paper, is not the first step FRoSTA has taken to become more sustainable. In as early as 2013, the company stopped using aluminium and, three years later, was honoured with the German Packaging Award for its then innovative printing technology for

flexible packaging. This technology used water-based colours as well as a 100 percent single-origin and thus recyclable foil made out of the monomaterial PP, which saved around ten percent in plastic compared to conventional bags.

IGLO’S FISH IN SAUCE NOW COME IN HEAT-RESISTANT CARDBOARD TRAYS

German food company iglo is celebrating its 50th anniversary by exclusively bringing its popular frozen fish to market in a tray that is completely free of PE-composite materials and aluminium. The heat-resistant surface resembles baking parchment and is made out of more than 95 percent cardboard. It can be used to prepare foods in the oven, as usual, as well as in the microwave. In addition, this tray can be disposed of with other waste paper and is completely recyclable, unlike coated versions. According to company statements, switching to these trays means annual savings of around 250 tonnes of aluminium and is the first step in iglo’s sustainability strategy: The company has announced that it aims to ensure that its entire packaging range is based on reusable paper by 2024.

Food Matters | APRIL 2024 | 35

MELEGARI TECHNOLOGY S.R.L.

Strada Martinella 38/A, Alberi di Vigatto, 43124 (Parma) Italy

Tel. +39.0521 968428

Fax. +39.0521 966721

www.melegaritechnology.com

E-mail: info@melegaritechnology.com

PROMEC s.r.l.

Strada Fornace 4, Bianconese 43010 FONTEVIVO (Parma) Italy

Tel. +39-0521 616611(ISDN)

Fax +39-0521 616620

W eb: www.promec-srl.com

E-mail: sale@promec-srl.com

PROMEC BLOWTEC

Strada Fornace 4, Bianconese 43010 FONTEVIVO (Parma) Italy

Tel. +39-0521 616611(ISDN)

Fax +39-0521 616620

W eb: www.promec-srl.com

E-mail: sale@promec-srl.com

BAKERY AND PASTRY EQUIPMENT FORNI E ATTREZZATURE PER PANIFICI

realforni.com

a perfect cooking...always

SUSTAINABLE PACKAGING FOR HEALTHY FOOD SHOPPERS

Originally, high-quality food packaging primarily served the purpose of offering protection and ensuring quality for as long as possible. This meant that the packaging material was largely determined by the properties of the food. In the future it will need to live up to quite a few additional criteria –primarily sustainability, tamper protection and whether it's practical.

WHAT IS GOING TO CHANGE IN THE NEW YEAR?

The experts are unanimous. Three market research agencies – Mintel, EcoFocus Trends and Research & Markets – are predicting that 2019 will see a further rise in informed purchasers. For several years now

there has already been a worldwide trend towards healthy eating. At the same time, there has been a rising demand for packaging that reflects the freshness of the food, has been sustainably manufactured and can be reused. Other priorities have been practical packaging formats that are suitable for travelling, and the integration of a tamper-proof seal which shows whether the package has been opened.

Responsible shoppers also base their purchase decisions on the sustainability of the packaging across its entire life cycle. Young shoppers are often particularly keen to use organic packaging materials, i.e. materials which are partly made from renewable resources. Moreover,

there is an increasing demand for recyclable packaging. In 2018, 59 per cent of American shoppers decided to look hard at the package when making purchases – 16 per cent more than in 2013.

Of these shoppers, 30 per cent are more environment-conscious than those outside the group. 38 per cent try to buy paper and cardboard packaging whenever possible.

31 per cent pay attention to the recycling symbol on the packaging. Healthy and safe

Nutraceuticals are said to have a positive impact on our health and are increasingly popular among

millennials. They are food items that have been enriched with additional nutrients. The packaging of such products is therefore seen as an extension of the healthy content, and it is part of the general philosophy of manufacturers that the relevant packaging should be transparent and therefore “clean”. This enables shoppers to take a close look at the product before buying it.

Shoppers who want to make informed decisions also expect to see clear labels with information about the entire supply chain. Over 30% of all respondents said that they judged the freshness of a food item by its outer appearance and not by the best-before date.

Organic packaging materials: bagasse, palm leaves and bamboo as well as cardboard and paper from sustainably managed forests.

38 | APRIL 2024 | Food Matters

VEGAN WRAP

The vegan movement is spreading ever further and the term vegan is scarcely unfamiliar to anyone. Forgoing all animal products in your nutrition is becoming ever easier thanks to the use of substitute products like soya milk or tofu sausage and vegan restaurants no longer being a rarity. Even in the clothing sector there are now many alternatives to wool or leather and vegan cosmetics are no longer niche products. But what is the situation here as far as packaging goes? When shopping people often only give a thought to this factor later in the day and yet product packaging is obviously also an aspect to be taken into consideration.

VEGAN IS THE TREND

Vegan packaging, zero waste, recycling, sustainability: initially all this sounds very good. But one does not necessarily have anything to do with the other. Not infrequently these terms with a positive connotation among consumers are all thrown into the same pot when it comes to marketing. It is important here that all aspects of the life cycle of a product are taken into consideration. However, this does not mean animal-free packaging is necessarily more sustainable than conventionally produced materials.

The adhesives used for vegan packaging are free of “glutin”, or casein. Both adhesive components are unsuitable for vegan packaging. Photo: © guukaa / fotolia.com

The adhesives used for vegan packaging are free of “glutin” (bone glue made from animal waste products), or casein. Both adhesive components are unsuitable for vegan packaging. Photo: © guukaa /

fotolia.com

VEGAN FOLDING BOXES, PRODUCT CARDS OR BLISTER CARDS

But first things first, let’s go back to the beginning. Anyone opting for this lifestyle can nowadays certainly satisfy this need from head to toe. And this is now also starting to extend to packaging. Even if packaging does not immediately suggest animal products there are still hidden factors you have to watch out for as a vegan.

Organic is not necessarily vegan: with vegan folding boxes, product cards, blister cards or labels all manufacturing stages are scrutinised to ensure the packaging is made without animal products or animalbased ingredients. Photo: © Iraida / fotolia.com

Adhesive, in particular, can come in the form of animal-based gelatine. Often this especially affects the

labelling of the goods. “Glutin” (bone glue from animal waste products) or casein are therefore unsuitable as adhesive components for vegan packaging. The rule here is that all materials like dyes, lacquers, adhesives and additives must be guaranteed free of animal compounds. Vegan labels can be produced using synthetic adhesives; but these must also cause no issues for recycling which would drive the price of the products upwards.

Overall, it can be said that the topic of vegan packaging is being taken seriously by many producers but it has still not found a wide customerbase as yet. However, this may change in the coming years as the topic seems to be in fashion, especially among the target group of Generation Y.

Food Matters | APRIL 2024 | 39

ESSENCE OF EVOLUTION MODULAR SERIES

Stoddart has built on the existing partnership with Giorik to utilise research & development to produce the unique, one of a kind, European styled modular 700 & 900 series cooking equipment to Australian Standards, delivering, efficiency, safety and reliability.

Giorik’s class leading, European design and engineering have been operating in the professional food service equipment industry since 1963.

Meeting the various needs of the global market,

The Worldwide Food Processing & Handling Equipment Industry is Expected to Reach $175.1 Billion by 2026

equipment market is projected to grow from USD 130.6 billion in 2021 to USD 175.1 billion by 2026, recording a compound annual growth rate (CAGR) of 6.0% during the forecast period.

The "Food Processing & Handling Equipment Market by Type (Food Processing, Food Service, Food Packaging), Application (Meat & Poultry, Bakery & Confectionery, Alcoholic, Nonalcoholic Beverages, Dairy), Endproduct Form, and Region - Global Forecast to 2026" report has been added to ResearchAndMarkets.com's offering.

The food processing and handling

The food processing & handling equipment market is exhibiting strong growth, with the rising demand for prepared food products globally, changes in consumer lifestyles, along with a transformative leap forward in technological capabilities and increasing investment opportunities in the food processing industry.

The food processing equipment segment is projected to dominate the food processing and handling equipment market during the forecast period.

The food processing equipment type market has been further segmented into pre-processing and primary processing equipment. One of the key factors driving the food processing equipment market is the growth of the processed food sector, due to the increasing demand for ready-to-eat and readyto-cook products. Further, to provide the highest and consistent quality products, along with keeping the production costs as low as possible, automated processing equipment is increasingly being adopted by food & beverage manufacturers

Asia Pacific is projected to record the highest growth during the forecast period.

The food processing and handling equipment market in the Asia Pacific

is projected to witness the highest growth between 2021 and 2026. The industrial growth in the region over the years, followed by improvements in the food and beverage industry, has created new opportunities for the food processing and handling equipment market.

The growing middle-class population in the region, increasing disposable income among customers, and demand for meat, bakery and dairy items and food items that offer on-the-go consumption are driving the growth of the food processing and handling equipment market. Many food and beverage companies have expanded their manufacturing facilities in these countries, which has also driven the market for food processing and handling equipment.

42 | APRIL 2024 | Food Matters

Kitchen technology: what the chefs say

Three leading figures in Italy’s food service industry talk about their relationship with the machinery that is changing the way work is done, how it is optimising processes and saving energy.

Technology plays a central role in today’s kitchens, it is contributing to its evolution and bringing with it new consumer behaviour and lifestyle patterns. One of the big developments concerns fine dining, which is at the cutting edge of innovation. HostMilano asked three leading figures in Italy’s food service industry for their thoughts on technology and innovation – two key elements at the International Hospitality Exhibition being held at fieraMilano Rho, from 13 to 17 October 2023.

“Technology in the kitchen should not be an end unto itself, but rather should serve to keep energy costs down and reduce cooking times,

which are what cause the most waste,” says Palermo-born chef Filippo La Mantia. “I’m not one who thinks everything should be hi-tech, but prefer a programmed use of technology that makes it possible to respect the way ingredients need to be cooked.” A concrete example would be a dishwasher with two separate wash chambers so that you can wash many more items simultaneously. Fundamental now, though, is the Roner, “which 90% of kitchens now have. But very soon, because I fry a lot, I will be getting a fryer that changes the oil automatically and in no time at all.”

“I’ve been convinced that technology is of fundamental importance for some time,” says Mirko Ronzoni, “Aesthetic Chef” and Food Consultant. “It has made possible a more precise calibration of the many stages in the work of a chef, from preserving and treating the basic ingredients to cooking them and

then preserving the result. It has meant some very basic mistakes can now be avoided and taken a lot of pressure off the cook. For me, though, technology in the kitchen is also about proper ventilation and lighting, the use of things like induction hobs that don’t heat up the room, and water baths for a specific type of cooking.”

Ronzoni says sous vide is what has really revolutionised kitchens in the new millennium: “it ensures constant hygiene and an excellent shelf life, but also a targeted organisation of different cooking processes with different instruments, such as Roners or steam ovens. To say nothing of the fact that preserving food has become so much easier and safer. I find it indispensible for my catering and culinary consultancy services.”

“Technology is important in the kitchen, as everywhere else, making work easier and more efficient. I do, however, think that the thought processes of a chef are the only thing that really matters; it’s what makes all the difference. Technology helps you and optimises your work, but it should never limit manual dexterity, because that would simply cancel out the chef’s personality. Artificial intelligence should be there to give support to creativity, to thought processes, and to the human touch, not take over from them,” believes Daniel Canzian, chef of the like-named restaurant in Milan.

He goes on: “I’m all in favour of using useful instruments to treat and extend the life of ingredients, in a way that is environmentally and economically viable. A blast chiller, for example, is a way of avoiding food waste and improving quality. It doesn’t do the work of the chef, it supplements it, and make what he does smarter. This is the only kind of tool we really need.”

Food Matters | APRIL 2024 | 43

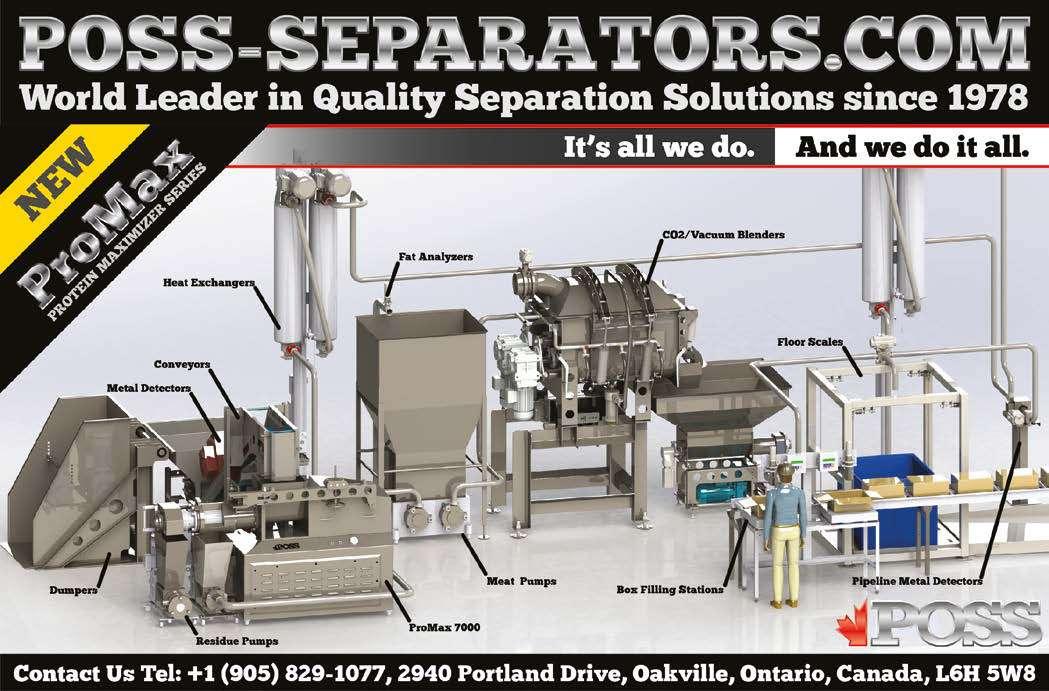

Coffee: trade totalling 34.5 billion euros in 2023

Alook at the global situation reveals a sector that is advancing, and set to reach a value of 43 billion euros in 2025. The USA is the main importer, Brazil the leading producer.

Where is the coffee market heading?

A detailed picture of world trade in one of the most widely marketed products comes from data drawn up by the strategic marketing division of HostMilano and taken from the Export Planning information system.

The good news is that in 2021 world trade in coffee-related products did particularly well: +13.6% in values in euros for espresso coffee machines, so a clear sign that things are recovering, +13.1% for decaffeinated or roasted coffee and +8.8% for nonroasted coffee beans. The overall value of world trade in the three sectors has reached the highest ever recorded level of 34.5 billion euros.

For the 2022-2025 period a

compound annual growth rate (CAGR) of +5.6% in values in euros is forecast for world trade in coffee products, with a total value expected to reach 43 billion euros.

On average in 2021, world trade in non-roasted coffee beans stood at 17.7 billion euros, although this is still lower than the all-time high recorded by the sector at the start of the last decade. A period of moderate expansion is expected for 2022-2025, with a CAGR of +4.6% in values in euros, exceeding the 20 billion-euro threshold for the first time (21 billion euros in 2025).

As for the world market rankings, the United States (22.4 per cent) and Germany (14.2%) were the main destinations in terms of sales in 2021, ahead of Italy (6.4%), Japan (5.1%), Belgium (4.2%) and Switzerland (3.8%).

The sector’s top exporter at a global level in 2021 was once again Brazil (with a 27.6% share), ahead of Colombia (13.9%), Vietnam (9,9%),

Honduras (5.4%), Guatemala (3.6%), Ethiopia and Belgium (each with a share of 3.5%).

Final figures for world trade in decaffeinated or roasted coffee reached a new high of 12.3 billion euros, up 13.1% on 2020. The situation forecast for 2022-2025 is one of continued expansion as has been the case for some time, with a CAGR of +7.1% in values in euros, worth a total of over 16 billion euros.

France was the world’s top importer in this sector in 2021 with a share of 17.6 per cent, ahead of the United States (11.6%), which was some way ahead of Germany (6.2%), the Netherlands (5.5%) and Canada (4.5%).

As for exports, Switzerland held on to pole position with 23.1%, ahead of Germany (15.5%), Italy (13.4%) and France (10.3%).

46 | APRIL 2024 | Food Matters

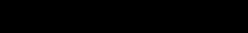

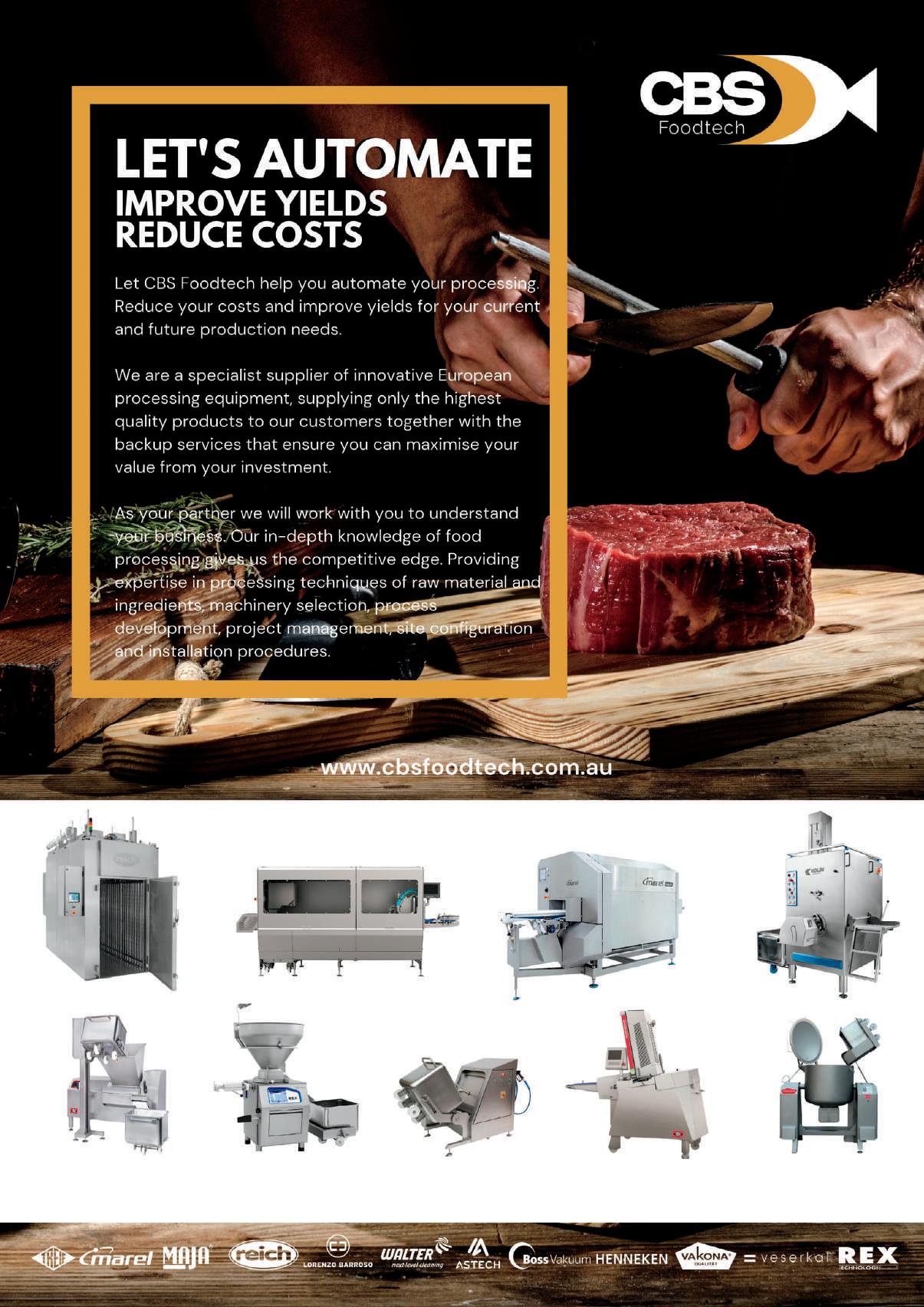

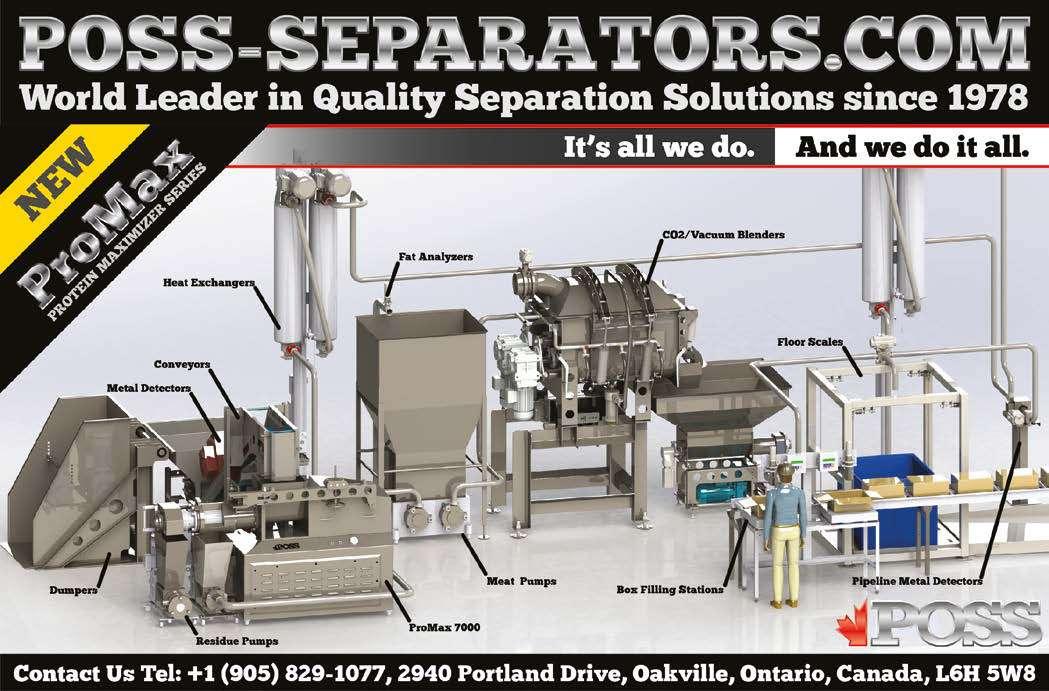

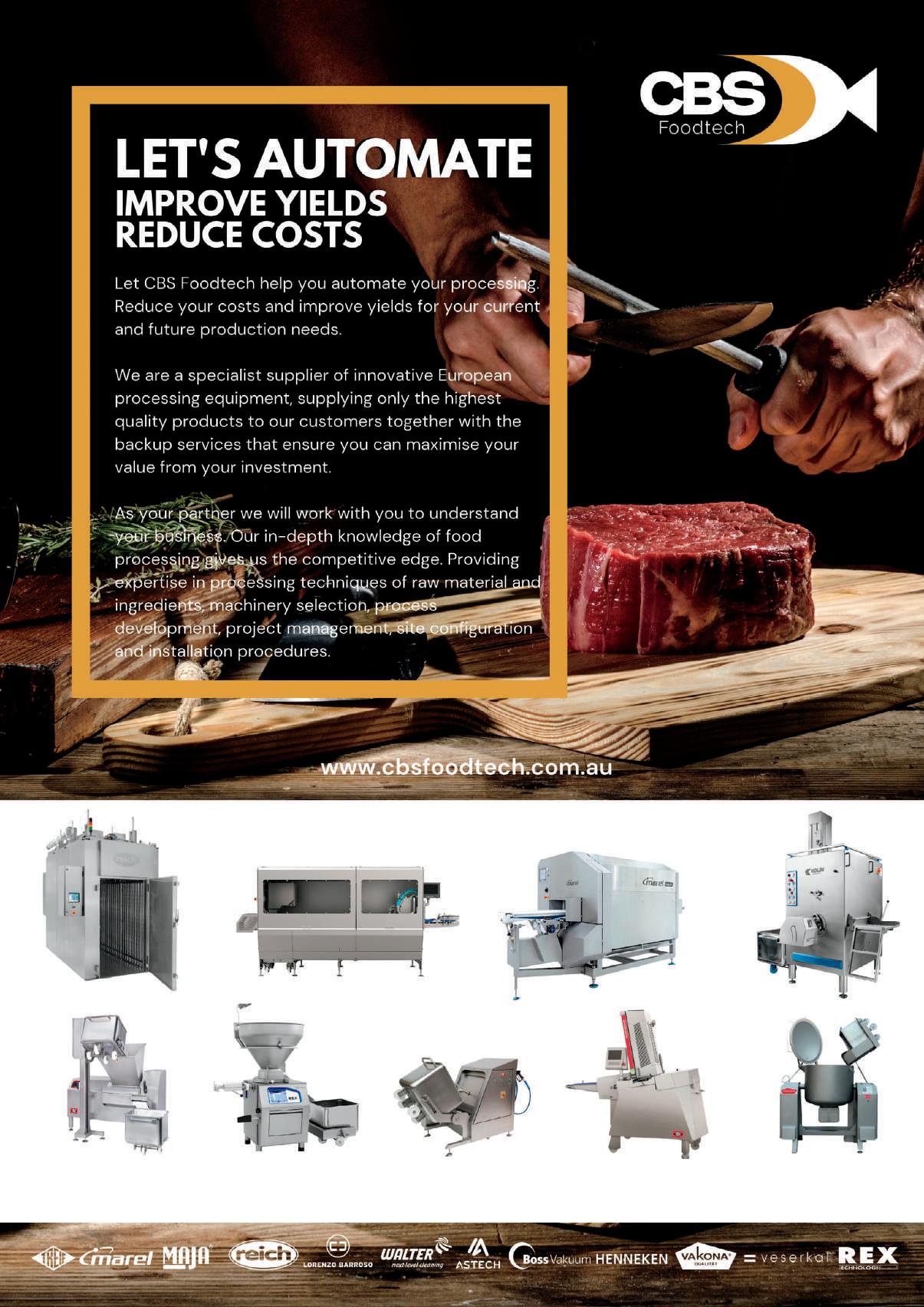

Meat Processing Equipment Market to worth $13 Billion By 2026

The global meat processing equipment market size is expected to grow from $9.78 billion in 2021 to $10.43 billion in 2022, according to a report from The Business Research Company.

According to The Business Research Company’s research report on the meat processing equipment market, the increasing consumption of processed meat is expected to propel the growth of the meat processing equipment market going forward. Processed meat provides a number of advantages, including a better taste, a lower risk of meatborne infections, a longer shelf life, and a high degree of portability. For instance, according to Standard Process Inc., a US based food supplement company's report published in 2020, processed

foods account for about 70% of the American diet. Additionally, according to the agricultural and processed food products export development authority, during the fiscal years 2020-21, India exported 774.11 tonnes of processed meat to the world, valued at $1.62 million. Therefore, the increasing consumption of processed meat drives the growth of the processed meat market.

The global meat processing equipment market size is expected to grow from $9.78 billion in 2021 to $10.43 billion in 2022 at a compound annual growth rate (CAGR) of 6.71%. The growth in the market is mainly due to the companies' rearranging their operations and recovering from the COVID-19 impact, which had earlier led to restrictive containment

measures involving social distancing, remote working, and the closure of commercial activities that resulted in operational challenges. As per TBRC’s global meat processing equipment industry growth analysis, the market is expected to reach $13.62 billion in 2026 at a CAGR of 6.89%.

North America was the largest region in the meat processing equipment market in 2021. Asia-Pacific is expected to be the fastest-growing region in the global meat processing equipment market during the forecast period.

Food Matters | APRIL 2024 | 47

Industrial Bowl Cutters of K+G Wetter: XXL regarding batch size, hygiene and applications

Food processing in industrial scale needs cutters that are economical and versatile as well as easy to use and clean. Industrial bowl cutters from K+G Wetter make efficient food processing on an XXL scale safe and easy, while focusing on hygiene – right down to the smallest detail. With or without vacuum, the durable machines are used by customers worldwide for the processing of all kinds of food: from classic sausage meat to vegan products and all spicy and sweet specialities in between.

All Industrial Cutters from K+G Wetter now have the “Hygienic Secure” standard with innovative and worldwide unique solutions. “I am absolutely convinced of the benefits of Hygienic Secure,” says Niklas Lowis, junior chief at K+G Wetter customer Lowis Butchers, who produces with a VCM 360. “It

wasn’t even on my radar when I was shopping for a machine, but it’s phenomenally easy to clean and really good – for example, because you can remove the knife cover strips. In our experience, Hygienic Secure consistently saves us 20 per cent in terms of cleaning time!”

“A Vacuum Cutter is advantageous for many products, offering greater protein digestion, better bound sausage meat and fewer air inclusions”, says Volker Schlosser, Sales Manager International at K+G Wetter. “And for processing vegetarian and vegan proteins, the vacuum function is in fact indispensable.” Vegetable proteins need to be chopped in the cold range below 40 0C to prevent denaturation, i.e. the irreversible destruction of protein structures. A strong vacuum above 80% has an additional cooling effect and let the

fibres swell, which makes a finer bond with water and oils possible during mincing. The use of vacuum technology also allows longer protein chains to form. That also allows otherwise necessary – and sometimes controversial –additives to be completely or partially dispensed with.

Unique worldwide at K+G Wetter: Applications that demand a cooking function are no longer forced to utilise a vacuum bowl cutter! The K+G Wetter CM 200 and CM 360 Hygienic Secure models now offer a doublewalled cooking bowl as high-quality, energy-saving and efficient cooking system for the open cutters. The closed-system design means that the supplied steam heats the cooking bowl very quickly – and only via the space between the bowl’s dual walls. This delivers considerable savings in terms of time, energy and cost.

Like all machines from K+G Wetter, the Hygienic Secure cutters offer a sound investment for the future, designed for decades of use. One reason: The cast iron body, which K+G Wetter is the only manufacturer worldwide to offer.

"The demonstration already showed us how smoothly, cleanly and quietly the cutter runs”, states Patrick Stephan, Production Manager at Steinemann Holding GmbH & Co. KG. The K+G Wetter Customer owns a new VCM 550 since 2022. “Anyone who has ever stood near such a large bowl cutter knows how it rumbles at 3,000 revolutions or more. The great advantage of this cast-iron stand was immediately apparent to us."

48 | APRIL 2024 | Food Matters

The Industrial Cutters of K+G Wetter – here the CM 360 (left) and the VCM 200 (right) – all come with the proven Hygienic Secure features. The machines are versatile, durable and economical.

Food service equipment is increasingly professional

Not just show cooking. Lifelong learning will be at the centre of the wideranging upgrade programme in the food service equipment area with the collaboration of the most authoritative partner associations.

At Host professional development is at the forefront of food service activities. The Smart Food - Smart Chefs - Smart Future events will use an approach involving ingredients, people and sustainability as outlined by APCI (the Professional Association of Italian Chefs).

As it takes visitors on a journey exploring the big topics of the moment – energy, people and sustainability – APCI will set out its manifesto on human, economic and environmental issues. Thanks to synergies with authoritative concerns involved in the various fields, the five-day programme will propose concrete solutions and the star of the show will be APCI Chef Lab, a project that represents the SMART evolution of the APCI Chef Italia

national team, a true hub of human and professional development, for the all-round growth of tomorrow's chefs.

The great challenges facing the food service industry – such as the digital transition, sustainability and skills –will then be discussed at the workshops of FIPE (the Italian Federation of Public Establishments). FIPE will be at HostMilano with this programme to continue the project of accompanying catering companies towards three transitions: digital, energy and professional. The "FIPE laboratory" will present best practices, reports, meetings, workshops and innovative services for the sector that will outline the transitions the future requires. The various items of equipment, stateof-the-art tills, payment systems, apps and digital menus will create a bridge between innovation and tradition and enable companies to develop their business by teaching them more about their customers and making them easier to reach.

In addition to that, the Academy

organised by FIC (the Italian Federation of Chefs) will offer master classes, training sessions and institutional meetings over the five days of the event. Partners, associated journalists and the merely curious will meet to address the key themes of food service Made in Italy. Meanwhile, visitors will be able to interact with consultants, designers and producers from FCSI (the Foodservice Consultants Society International) in a large professional kitchen, seminar and meeting rooms and a lounge. ANIMA (which represents Italy's mechanical engineering industry) and its various associations, together with EFCEM Italia will also create a Food-Technology Lounge with a busy calendar of meetings, technical and regulatory updates, business appointments and market trend analyses.

Food Matters | APRIL 2024 | 49

Less Waste, Increased Profit

As the Global Leader in Food Cutting Technology, successful processors depend on Urschel’s expertise to deliver optimal cutting solutions for all types of fruits and vegetables.

Urschel cutting equipment delivers a full spectrum of size reduction capabilities. Explore dicing, slicing, or pureeing to achieve your processing goals.

#1 Best selling provider of industrial cutting machinery throughout the world.

®Urschel, Urschel logo symbol, and The Global Leader in Food Cutting Technology are registered trademarks of Urschel Laboratories, Inc. U.S.A.

Global Leader in Food Cutting Technology

Set up a free test-cut of your product. www.urschel.com The

Book a FREE Demo Today! Call (02) 9798 0586 Scan the QR Code kuvings.com.au/commercial

GLOBAL PARTNERS INSTITUTIONAL PARTNERS AN EVENT OF DEPARTAMENTO DE DESARROLLO ECONÓMICO, SOSTENIBILIDAD MEDIO AMBIENTE CANNED +8,000 C-LEVEL ATTENDEES BEVERAGE SEAFOOD OIL MEAT BAKERY D A I R Y A G R I Innovation in foodtech Powering logistics and packaging for the food industry +450 SPEAKERS 5 AUDITORIUMS +150 HOURS OF INSPIRATION C-LEVEL AGENDAS 16-18 APRIL 2024 BILBAO - BEC #PICKPACK2024 www.pickpackexpo.com #F4F2024 www.expofoodtech.com AUTOMATION & ROBOTICS INDUSTRY 4.0 REFRIGERATION & CLIMATE SUSTAINABILITY FOOD LOGISTICS FOOD PROCESSING FOOD PACKAGING FOOD SAFETY AGRITECH FOOD SCIENCE GET YOUR FREE BUSINESS PASS OR REDEEM THE CODE: RM6JV

Frau Dr. Sabine Eichner

Frau Dr. Sabine Eichner