JANUARY2025

JANUARY2025

www.foodmattersmagazine.in info@foodmattersmagazine.in

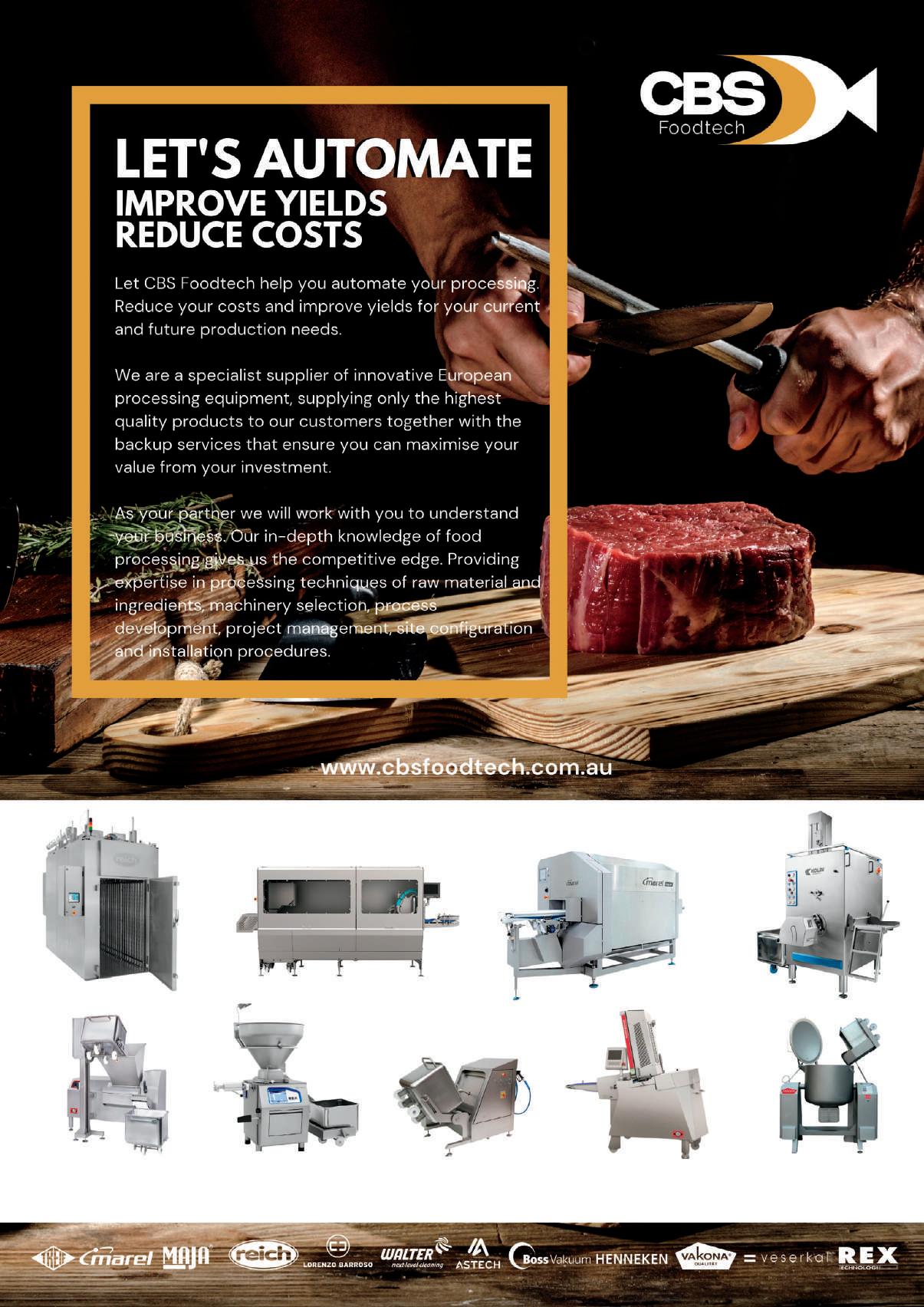

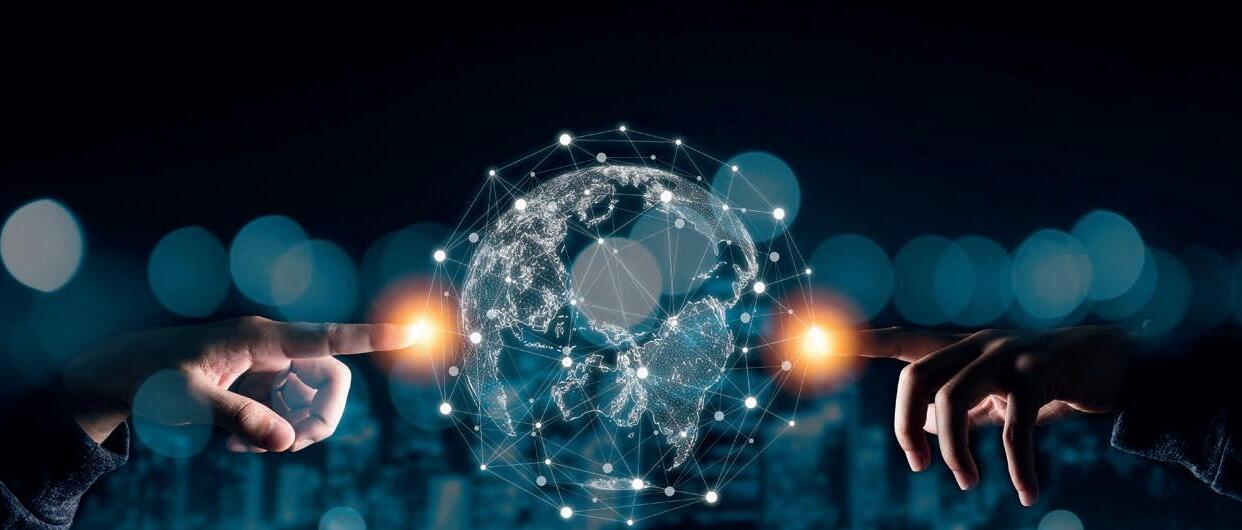

Food Processing Equipment Market is expected to generate a revenue of USD 101.72 Billion by 2031, Globally, at 5.85% CAGR: Verified Market Research® Verified Market Research® is pleased to announce the development and release of our latest market research report, "Food Processing Equipment Market – Global Insights, Trends, and Forecast 2024-2031." designed to equip industry leaders, investors, and stakeholders with actionable insights and strategies to navigate the ever-evolving food processing landscape.

Technological Advancements in Food Processing: The swift advancement of technical innovation in the Food Processing Equipment Market is a significant catalyst. Recent advancements in automation, artificial intelligence, and the Internet of Things are augmenting operating efficiency, decreasing expenses, and elevating product quality. These developments allow enterprises to satisfy increasing consumer needs for enhanced efficiency and improved safety standards, hence driving market growth and providing businesses with a competitive advantage.

Rising Consumer Demand for Processed Foods: The global trend toward convenience and ready-to-eat meals is a major driver of the Food Processing Equipment Market. Urbanization, rising disposable incomes, and changing consumer lifestyles have increased demand for processed and packaged goods, prompting manufacturers to invest in cutting-edge equipment. This surge immediately accelerates market growth by encouraging innovation and production efficiency, generating chances for stakeholders to capitalize on the burgeoning food business.

Focus on Sustainability and Energy Efficiency: As sustainability becomes more important, companies in the Food Processing Equipment Market prioritize environmentally friendly solutions. Equipment developed to decrease energy, water, and trash complies with regulatory requirements and corporate social responsibility objectives. This trend promotes market growth by pushing companies to switch to sustainable technologies, establishing them as industry leaders devoted to environmental stewardship.

High Initial Investment Costs: The considerable initial capital required for sophisticated food processing machinery might provide a significant obstacle for small and medium-sized firms. The elevated expenses may restrict access to cutting-edge technologies, hindering adoption rates and affecting total industry expansion. Businesses must evaluate the long-term advantages against the initial costs to make informed investment decisions.

Stringent Regulatory Compliance: Meeting global food safety regulations is a major problem for the Food Processing Equipment Market. Compliance with changing rules frequently necessitates periodic equipment updates, raising expenses for firms. Furthermore, delays in regulatory clearances can stymie new product releases, causing a bottleneck in market expansion. Companies must commit resources to achieve these criteria, which affects profitability and innovation timetables.

Supply Chain Disruptions and Skilled Labor Shortages: Global supply chain disruptions, such as raw material shortages and logistical restrictions, have impacted the food processing equipment market. Delays in equipment deliveries and growing expenses impede manufacturing timetables, reducing project scalability. Simultaneously, a dearth of experienced staff to operate and maintain modern technology limits adoption rates, creating a substantial impediment to market growth.

Hospitality trends are currently geared towards artisanal taste and practicality, without cutting back on new designs, materials and solutions.

There is a desire for colour, artisan styles, warmth, and lightweight materials that adapt to seasonal menus. Now that hospitality is back

in a big way, it is changing its look and expressing a desire to look positively to the future. And that also involves something that is a litmus test for the sector: the place setting.

“Despite economic uncertainties, the hospitality sector in the Benelux region continues to perform well. We predict that colourful tableware & eccentric shapes will stay very popular in 2024,” says Anne Kemp, marketing assistant of the Luxembourg-based RAK Porcelain Europe, whose main foreign markets are France, Spain, Germany and Italy.

As for the most sought-after trends: “As well as colourful tableware and eccentric shapes, also materials with an artisanal, craft spirit like stoneware. But customers are constantly searching for lighter materials to facilitate the dinner service, so super

lightweight materials such as bone china are very popular.” One of Rak Porcelain’s best-selling product is the coupe plate. “The coupe shape helps clients present and plate their dishes in a tasteful way. It is also very resistant, easy to care for and attractive.” Other popular products include stoneware collections which “exude that beautiful and much sought-after craft feeling.”

There will be a lot of coloured tableware around in 2023, believes Timo Keersmaekers, CEO of the Belgian company Fine Dining & Living. “In the past it was not so much the base material but the design that mattered, so a lot of clients bought stoneware products: very nice, but less durable than porcelain. With today’s developments we can easily combine the reactive glazes with a porcelain base

that is also nice and strong.”

At a time when everything is moving at such a fast pace, another trend is to frequently change not just the menu, which has now become something very seasonal, but also the place setting.

“We see that hospitality owners are buying lower volumes of tableware but combined with the food they have on the menu, so they buy less volume at one time, but they buy more often. We also see that they want to have novelty solutions at all times.”

The best-selling ranges of this company, which mainly exports to France, Spain and the Middle East, include collections that combine nice design with a two-year warranty against chipping.

For over three decades, Gulfood has driven global food commerce — fueling innovation, collaboration, and the future of food. In 2025, it becomes the epicentre of a transforming food landscape. Be where the next era of food begins.

Packaging simply makes sense. It protects goods from damage, contamination and spoiling. We are seeing more and more reusable packaging in the retail market, as an alternative to single use packaging. Supermarket chains offer their customers reusable bottles in reusable crates, reusable bags instead of plastic bags, reusable nets instead of thin plastic bags for fruit and vegetables, reusable lids for yoghurt pots and reusable bowls for takeaway salads.

The companies in the packaging industry are, in principle, open to the trend towards reusable packaging and regularly present innovative solutions that take the desire for more sustainable packaging alternatives into consideration.

However, the comparison between reusable bottles and single use bottles has shown that reusable packaging does not necessarily perform better in ecological balance

analysis. Single use bottles are often lighter and receive a better evaluation for transportation in ecological assessments. For other products, analyses show that energy and water consumption during manufacturing and also in purification can have an influence on the ecological balance. Here, decisions are made on a case-by-case basis in order to find the solution that is the most ecological overall for the relevant application.

In September 2022, the German supermarket chain REWE presented a digital solution for reusable packaging in the retail market. Together with the start-up VYTAL, the retail giant offers its customers in selected REWE supermarkets (primarily) a free reusable system for the salad bar.

These rigid plastic bowls hold 1,250 millilitres, are dishwasher safe and can be microwaved. This rental

system functions entirely without a deposit, unlike the reusable bottle system. Instead, the user registers with the service provider via an app and receives an individual QR code. The customer scans the QR code at the serving station in the suoermarket and can then take the bowl and fill it with salad. The customer has two weeks to return the bowl. If they bring back their bowl within 24 hours, they can give it back unwashed. However, it must be completely closed, completely emptied and have been given a quick clean. If the bowl is rented out for longer period, it must be cleaned with cold water. The process for returning it to the supermarket is similar to the serving process: Scan the code and place the bowl back in the return station. The app users can also hand the reusable packaging back in to other VYTAL partners, including restaurants that offer their guests the reusable bowls for takeaway meals.

Breakfast and dinner services are doing well but lunches are not, because people are still working from home. And there are changes to what consumers want, with a demand for more “substance”.

The world’s big research organisations have come to the conclusion that the out-of-home eating scenario has changed, at least for the time being. That doesn’t mean that people have stopped going out to eat – quite the reverse is true in fact. And yet many habits have changed, especially as regards when, how and the pace at which people are now working.

Confirmation of this comes from TradeLab. It found that in the month following the reopening of locales in June, as many eight Italians out of ten (38 million people) ate out at least once. However, the times of day when people prefer to go out to eat have changed, shifting particularly to breakfast and dinner

time. Bars have been one of the preferred places to go in this initial phase of recovery, firstly because they can cover most mealtimes and because, at very little cost, they have been able to increase their capacity by using outdoor spaces, and secondly because they are a firm fixture even in small towns and villages, where they have a regular clientele. So the big draw is the traditional breakfast at the bar, followed a little way behind by dinner, which many are using as a way to at last socialise once again after many months in which that was impossible. The early evening aperitif moment seems to be winning back its aficionados, while pre-lunch aperitifs are also becoming popular, and in some cases are preferred to the evening sessions.

The slowest moment of the day right now is lunchtime, to a large extent because so many people are still working from home: over 30% of those interviewed said they haven’t gone back to the office yet.

“While customer numbers are now close to 2019 levels, Italians are going out less, they aren’t spending quite as much, and they have become more selective about when and where they eat out,” says Angela Borghi of TradeLab.

“Spending on dining out in the evening is now more or less back to where it was in 2019, and in some cases is actually doing better than in the past, unlike lunchtime. Other times of the day where trade is now quite brisk is the afternoon break, which has benefited from the fact that kids and adults are at home together, and then also aperitif time.”

Euromonitor, meanwhile, provides a glimpse of what post-Covid consumers actually want when they go out. It identified six trends for the future that look set to influence all sectors. 1) Sustainability extending into a broader eco-aware approach, which brings social, environmental and economic benefits. 2) The growth in Hometainment, in which online experiences need to have the same value as being with people. 3) The growth in digital channels, with a rapid switch to e-commerce and click-and-collect purchases. 4) The redefinition of wellness, with consumers focused on achieving optimal health. 5) “Useful” innovation, i.e. the kind that can satisfy fundamental consumer needs, with product development guided by the efficiency and value they bring. And finally 6) a set of long-term changes the New Normal brings with it: online shopping, remote

living (the increasing popularity of suburban areas and of small communities in and outside the city), a reduction in unnecessary purchases, and more personal care. As for out-of-home eating in the USA, Mintel dares to forecast a return to pre-pandemic sales levels by 2023.

“Dine-in restrictions will shift the focus to off-premise options in the short- and medium-term (end of 2020). In the short term, drivethrough, takeout and delivery options will help mitigate the decline in sales. In the long term (one to two years from now), continued investments in off-premise dining will help operators recoup sales, but foodservice will continue to be challenged in the recession as consumers cut back on discretionary purchases,” says Amanda Topper, associate director of Foodservice at Mintel.

Restaurants with a limited service (fast food, fast casual) will suffer less, not least of all because they were already well equipped on a digital level before the emergency. Restaurants providing a full service will see a 39-42% fall in their business this year, while those offering a limited service will only see a 13-18% drop.

Delicious baked goods begin with baking professionals, like you — people who care about what they do and see change as a chance for growth. �hat�s who you�ll �nd at ����. �rafted by the industry for the industry, this event brings you together with a global community facing your same challenges �like supply chain issues�, as well as opportunities speci�c to your role. From strategies for navigating unpredictable commodity prices to innovative automation solutions, everything you need is here, at your show.

2022. Over 60% of refrigerated and raw meat has, up until now, been packed in rigid plastic packaging. B + P Consultants has stated that currently, manufacturers are trending towards convenience products in recyclable films. Development of machines that package meat as efficiently as possible goes hand-inhand with this growth in innovative materials.

The global demand for meat products takes up almost 19% of the entire food sector with a volume of almost 3 billion Euros, according to the latest report from B + P Consultants, a consulting agency. The demand for packaged fresh meat is also growing here. According to the prognostics from Market Growth Analysis, a market research institute, the market for fresh meat packaging is set to grow at an annual rate of 3.19% in North America and Latin America and in Eastern and Western Europe up until

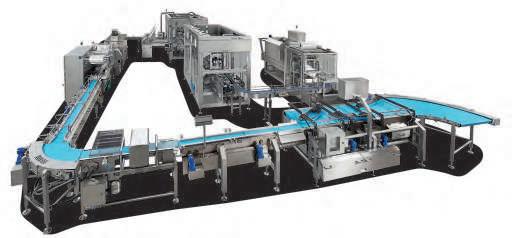

The fully automated packaging line

An innovative application for portioning and packaging fresh meat and other food has been brought out by the packaging company Multivac. The Traysealer TX 730 – the new model in the X-line generation – processes cardboard cutouts to produce multifresh vacuum skin packaging with an inside cut system.

Portioning is executed by a multi-functional, highly flexible portioning system. The fresh meat packaging will be given a full-wrap label by the appropriate conveyor belt labeller. A visual inspection system also ensures quality and marking control, even at top processing speed. Traysealer TX 730 sets itself apart by providing the highest level of process reliability, innovative machine technology and a modern sensor system.

Ulma Packaging presented a new machine for flow packs which was created specifically for packaging fresh meat and poultry. Flow packs are an economic way of packaging raw food. Fresh meat packaging of different sizes and shapes can be produced by the ULMA FM-500 packaging machine. Hygienic design was a prime focal point in development. In order to dispense with time-consuming and extensive cleaning operations to prevent product contamination, the engineers chose to pursue a modern self-supporting machine design that enables easy access to all components in the infeed conveyor, the sealing rollers and the cross-sealing assemblies.

The Mondi Group has stated that they are the world’s leading provider of sustainable paper and packaging solutions, and has produced certified completely recyclable packaging in polypropylene for thermoforming applications to back this claim. In addition, the carbon footprint produced by these types of packaging is 23% smaller than that of its current competitors. The packaging film is perfect for thermoforming processes which use flexible films for modified atmosphere packaging (MAP) and for vacuum packaging. This extends the shelf life of meat and cheese. The packaging material consists of an upper and lower strip with an internal barrier layer that makes up less than 5% of the total structure. This mono-material design ensures that complete recyclability is guaranteed.

Yes, the food has to be good, but better if accompanied by a musical, theatrical or cinematic experience. Because people now want more when they dine out.

Lifestyles, routines, schedules and workplaces are changing and so are people’s priorities... including how they choose their restaurants. For the younger generations experiences matter enormously. And being able to share them on social media will be key for some time to come. It’s priority number one for Millennials, while Gen Z go

online mainly to look for positive reviews. One figure supplied by Global WebIndex is particularly telling: 15% of instagrammers post pictures of what they are about to eat. But something else seems to be carrying more and more weight now, particularly in recent months, and that’s entertainment. The chance to spend an evening enjoying a meal and much more besides could well be one of the secrets to success in the years ahead. Especially in a situation where people are eating out less, because of the recessionary times that will now force large swathes of the population to cut back. Millennials, for example, are 20% more likely than average (10%) to say that the entertainment a restaurant lays on is a decisive factor when choosing where to eat.

This summer there have been picnics – that hugely popular post-

Covid activity – under an oak tree in the countryside or in a meadow in the hills to the accompaniment of a DJ set. Suz Mountfort, co-founder of Gingerline, a London-based company that has been mixing food with experience for the past ten years, explains the success of the concept: “We’re so caught up in the humdrum of our working lives now that we’re all looking for a way to escape the mundane and bring that sense of freedom and experience we enjoy so often as children. That desire for adventure, risk, spontaneity is what is driving the demand for immersive experiences; whether that’s cinema, dining, or theatrics.” So food takes you on a journey with a narrative that holds everything together. Gingerline has managed to overcome the limitations of lockdown with the Picnic Hunters Club project: gourmet hampers for bucolic picnics with friends and family, complete with treasure hunt,

quizzes and puzzles and extra prizes on offer.

Theatre and exhibitions can transform locations used for quite different purposes, like restaurants (which can be considered as places where people satisfy their hunger with food prepared and presented as works of art) into places that offer a more rounded and unique immersive experience. That was the idea behind Tournée da Bar, an Italian concept that brings a revisited Shakespeare to the restaurant or bar.

Meanwhile, cinema was the direction taken by Marennà, the restaurant in Feudi di San Gregorio that set up a cine forum in its extensive outdoor area, serving food, together with still and sparkling wines, gourmet aperitifs, a selection of local cheeses at the restaurant… and of course popcorn.

German food manufacturers FRoSTA and iglo are launching their new frozen foods packaging in 2020. According to statements issued by the companies, they aim to make their packaging even more sustainable and therefore plan to use more paper, save on plastic materials and reduce their carbon footprints in future.

At the beginning of 2020, frozen food manufacturer FRoSTA ushered in a new era of packaging by introducing frozen food packaging made out of paper: From now on, the plastic bags previously used for all of the company’s frozen food products are to be replaced by a bag designed especially for FRoSTA that is made out of 100 percent paper. For three years, experts have honed this unique power paper that protects contents without softening, even once the defrosting process sets in. This new frozen food packaging is neither bleached nor coated and is to gradually replace the current plastic bags from January

2020 onwards – around 40 million per year in total. The greatest challenge the company faced when developing the power paper was ensuring a consistent and high degree of product protection whilst at the same time preventing the paper from softening – no easy feat considering the constant presence of moisture and products that in part contain fats.

The developers achieved this by using a purely physical process on the material mix. A patent has been filed for this unique method of making frozen food bags out of unbleached, FSC-certified paper, including the printing method that exclusively uses water-based colours.

This frozen food packaging made out of paper, which can be recycled along with other waste paper, is not the first step FRoSTA has taken to become more sustainable. In as early as 2013, the company stopped using aluminium and, three years later, was honoured with the German Packaging Award for its then innovative printing technology for

flexible packaging. This technology used water-based colours as well as a 100 percent single-origin and thus recyclable foil made out of the monomaterial PP, which saved around ten percent in plastic compared to conventional bags.

German food company iglo is celebrating its 50th anniversary by exclusively bringing its popular frozen fish to market in a tray that is completely free of PE-composite materials and aluminium. The heat-resistant surface resembles baking parchment and is made out of more than 95 percent cardboard. It can be used to prepare foods in the oven, as usual, as well as in the microwave. In addition, this tray can be disposed of with other waste paper and is completely recyclable, unlike coated versions. According to company statements, switching to these trays means annual savings of around 250 tonnes of aluminium and is the first step in iglo’s sustainability strategy: The company has announced that it aims to ensure that its entire packaging range is based on reusable paper by 2022.

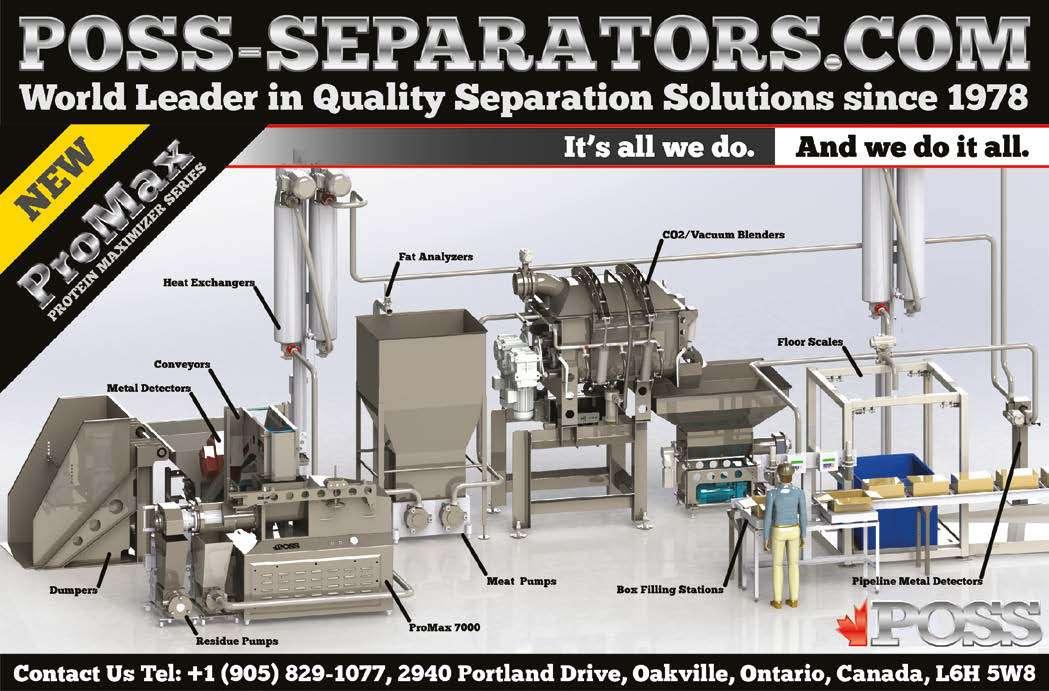

» Removes foreign materials

» Handles a wide range of powders

» Facilitates quick screen changes

» Breaks soft lumps

Ammeraal Beltech know the production challenges you face; our belting solutions have been meeting your industry needs for Food Safety, hygiene, durability, performance efficiency and ease of cleaning for more than 60 years. Today, our newest solutions remain your prime choice across all your applications.

Our food-grade range includes unique modular belts built to minimise fissures where bacteria can

hide or knife blades can break. Our synthetic belts feature anti-microbial covers and KleenEdge non-fray properties to eliminate contamination. Our range also features ultra-hygienic homogeneous belts such as our Soliflex Pro positive drive belts, with innovative rounded lugs that cut cleaning time and water waste while also providing excellent power transmission and outstanding self-tracking performance.

Our cloud kitchens – a collective of private and shared commercial-grade kitchens – are designed to help food creators minimise costs, maximise profits and streamline operations.

IMA FLX HUB, AT THE CENTRE OF YOUR NEXT COMPLETE FLEXIBLE PACKAGING LINE.

Weighing, counting, VFFS vertical bagging, HFFS flow wrapping, net clipping and end-of-line packaging solutions combine with each other to form tailored turnkey lines for the Produce industry.

On show, an IMA Ilapak Vegatronic 6400 ML bagger for cut salad coupled with a WA PRO 16-50 multi-head weigher, and the IP 3000 case packer for the fresh produce.

FRUIT LOGISTICA 2025

BERLIN, GERMANY - 5-7 FEBRUARY 2025

Hall 1.1 | C-10

ima.it/it/flexible-packaging-hub ima.it

From energy saving and air quality to automated washing, up to quality semi-finished products, the sector is experiencing a moment of great revival stimulated by innovation. Once again this year, the macro area dedicated to the Food Service Equipment and Bakery, Pizza, Pasta sectors at Host 2025 represented the beating heart of the event, where exhibitors could showcase technological innovations with a strong focus on sustainability.

This is how Timothy John Fitzgerald, CEO of Middleby, explained it: “We focus on sustainable innovations to save electricity - such as 95% efficient induction - and 'ventless' appliances, in which we are leaders. These are very expensive components with a significant environmental impact, and we can create a completely ventless kitchen”.

People at Rational also agree HostMilano is the most anticipated event to launch innovation. “We exhibit at many trade fairs,” said Federica Padrin, Marketing Director, “but Host remains the most important and international one. We have chosen it to introduce a worldfirst, an automated and integrated washing system for cooking equipment, a significant evolution in

technology.” An environment that looks to the future on an international scale Glauca Vesperini, Marketing Manager at Angelo Po, also agrees on the international level of the event: “It is an opportunity to meet partners from all over the world, and this year there was an even stronger desire to meet in person. Retailers from Europe, Africa, Asia, Russia, and North America, as well as end customers in the Italian market, crowded our booth.”

In addition to modern kitchen equipment, high-quality raw materials are essential. Giulia Alfieri, Marketing & Communication Department at Molino Dalla Giovanna, explained: “It is important for us to be at HostMilano, especially because of the international audience it attracts, the energy it exudes, and the synergies that develop.”

From super-digitized coffee machines to next-generation vending machines, to raw materials reimagined for excellent quality even in the face of climate change, the exhibition is ready for a relaunch.

The Bars, Coffee Machines, Vending sector, together with Coffee, Tea, is

one of the most innovative segments at HostMilano. In this edition, advanced technology played a leading role, from highly digitized machines to high-quality raw materials. “HostMilano is an institution in the coffee industry,” explained Giada Biondi, Communication Manager at La Marzocco, “and we are present to connect with partners and distributors from around the world. We have established contacts in Australia, New Zealand, Southeast Asia, as well as Thailand, China, Singapore, and Korea. There is interest in our coffee machines from every corner of the globe, as they blend design and technology.”

“Just like HostMilano, our company covers the entire coffee world, and it’s natural for us to be here,” added Pascale Capelle, Group Marketing Manager at Bianchi Industry.

“We presented a hybrid OCS range for offices and shops, as well as hotels, small venues, or larger establishments, and launched a machine that will be on the market in 2024. We met with coffee roasters, distributors, restaurateurs, and major chains, many of them from Asia and Eastern Europe, as well as numerous Italians.”

Coffee producers also expressed satisfaction with the international environment, as stated by Simone Favero, Regional Sales Marketing at Julius Meinl: “HostMilano is the most international fair in Italy for coffee, the right place to showcase our coffee with double organic and fair trade certification. We met many foreign visitors, particularly from the Middle East, in addition to our reference markets such as Austria, Eastern Europe, and partly the United States.”

Thanks to its international appeal, HostMilano is also the ideal place to introduce particularly new offerings to the market, such as Costa X, the new B2B concept from Costa Coffee. “We are known for our stores and innovative Costa Express machines,” explained Jazz Berry, Global B2B Marketing Manager. “Today, we are presenting right here a revolutionary innovation for hotel brands, restaurants, or workplace environments.”

Arrivederci to the major players at Host 2025, at Fieramilano in Rho from October 17 to October 21, 2025.

No waste, energy saving, personalisation and the quality of beverages but also data analysis to optimise process will all help define 2025. Quality and sustainability across the production chain, reduction of costs, and digitisation. These are mantras that go across the sectors and apply to the entire hospitality industry. From the cup of coffee to the machine that washes it.

“Trends for 2025 in the Netherlands? We continue to see a rise in popularity of coffee to go. A highquality specialty coffee is being offered at more and more locations with low traffic, like barbershops and boutique hotels. Then, socially responsible coffee to ensure that farmers get their fair share, milk alternatives that are less harmful for the environment and the gradual disappearance of single-use cups. Also, new ways to brew cold

coffee. Where cold drip brewing used to be the standard we foresee a rise in immersion brewing as well as Nitro brew solutions,” says Martijn Oostrom, marketing manager of the Dutch company Bravilor, who, in addition to the traditional markets of Scandinavia and Germany, is seeing growth in the UK and the USA.

The sector is currently defined by sustainability (“It used to be important. Nowadays it’s absolutely imperative. With our first refurbishment programme for the Norwegian market we are strengthening our own sustainability ambitions”); by convenience (which “will prove to be an essential element of every product. Convenience of installing new products, as well as personalising beverages”); and finally connectivity and access to data (“we’re noticing steep learning curves at resellers who are using connectivity. They’re analysing the

data and learning where to improve and adapt their organization to operate more efficiently”). One of the most sought-after items is the fully automatic bean-to-cup machine, which customers value and appreciate because of the extraordinary in-cup quality of the espresso beverages and the fresh milk option for the coffee lover that wants nothing but the best. “I also love how easy it is to clean and the low level of preventive maintenance required.”

Art Huisjes, international sales manager for the Dutch company Rendisk, which belongs to the ALI Group, highlights the fact that delivery times are longer than average, and manufacturers have to deal with this: “But also for the endusers, projects are running out of time as construction work is delayed and therefore more difficult to plan. Flexibility on many levels is required.”

The markets its serves include hospitals, large airline catering companies, hotels and resorts, company restaurants and government organisations. The fastestgrowing segments of the Dutch market in 2025 will be convenience, simplicity, health and sustainability. “Sustainability applies not only to equipment, but also to what is on the menu. As for convenience, our customers want a full-support solution.”

The company has embraced a green approach: “We manufacture and supply logistics systems for everything in and around the professional dishwashing areas, and with perfect solutions in the growing amounts of organic kitchen waste is being generated. A process in which waste is no longer a residual product but something valuable. Just think of a fertilizer, compost or biogas.”

Visit our website, scan the QR code!

MELEGARI TECHNOLOGY S.R.L.

Strada Martinella 38/A, Alberi di Vigatto, 43124 (Parma) Italy

Tel. +39.0521 968428

Fax. +39.0521 966721

www.melegaritechnology.com

E-mail: info@melegaritechnology.com

PROMEC s.r.l.

Strada Fornace 4, Bianconese

43010 FONTEVIVO (Parma) Italy

Tel. +39-0521 616611(ISDN)

Fax +39-0521 616620

W eb: www.promec-srl.com

E-mail: sale@promec-srl.com

PROMEC BLOWTEC

Strada Fornace 4, Bianconese

43010 FONTEVIVO (Parma) Italy

Tel. +39-0521 616611(ISDN)

Fax +39-0521 616620

W eb: www.promec-srl.com

E-mail: sale@promec-srl.com

Alook at the global situation reveals a sector that is advancing, and set to reach a value of 43 billion euros in 2025. The USA is the main importer, Brazil the leading producer.

Where is the coffee market heading?

A detailed picture of world trade in one of the most widely marketed products comes from data drawn up by the strategic marketing division of HostMilano and taken from the Export Planning information system.

The good news is that in 2021 world trade in coffee-related products did particularly well: +13.6% in values in euros for espresso coffee machines, so a clear sign that things are recovering, +13.1% for decaffeinated or roasted coffee and +8.8% for nonroasted coffee beans. The overall value of world trade in the three sectors has reached the highest ever recorded level of 34.5 billion euros.

For the 2022-2025 period a

compound annual growth rate (CAGR) of +5.6% in values in euros is forecast for world trade in coffee products, with a total value expected to reach 43 billion euros.

On average in 2021, world trade in non-roasted coffee beans stood at 17.7 billion euros, although this is still lower than the all-time high recorded by the sector at the start of the last decade. A period of moderate expansion is expected for 2022-2025, with a CAGR of +4.6% in values in euros, exceeding the 20 billion-euro threshold for the first time (21 billion euros in 2025).

As for the world market rankings, the United States (22.4 per cent) and Germany (14.2%) were the main destinations in terms of sales in 2021, ahead of Italy (6.4%), Japan (5.1%), Belgium (4.2%) and Switzerland (3.8%).

The sector’s top exporter at a global level in 2021 was once again Brazil (with a 27.6% share), ahead of Colombia (13.9%), Vietnam (9,9%),

Honduras (5.4%), Guatemala (3.6%), Ethiopia and Belgium (each with a share of 3.5%).

Final figures for world trade in decaffeinated or roasted coffee reached a new high of 12.3 billion euros, up 13.1% on 2020. The situation forecast for 2022-2025 is one of continued expansion as has been the case for some time, with a CAGR of +7.1% in values in euros, worth a total of over 16 billion euros.

France was the world’s top importer in this sector in 2021 with a share of 17.6 per cent, ahead of the United States (11.6%), which was some way ahead of Germany (6.2%), the Netherlands (5.5%) and Canada (4.5%).

As for exports, Switzerland held on to pole position with 23.1%, ahead of Germany (15.5%), Italy (13.4%) and France (10.3%).

Stoddart has built on the existing partnership with Giorik to utilise research & development to produce the unique, one of a kind, European styled modular 700 & 900 series cooking equipment to Australian Standards, delivering, efficiency, safety and reliability.

Giorik’s class leading, European design and engineering have been operating in the professional food service equipment industry since 1963.

Meeting the various needs of the global market,

Not just show cooking. Lifelong learning will be at the centre of the wideranging upgrade programme in the food service equipment area with the collaboration of the most authoritative partner associations.

At Host 2023, at fieramilano in Rho from 13 to 17 October, professional development is at the forefront of food service activities. The Smart Food - Smart Chefs - Smart Future events will use an approach involving ingredients, people and sustainability as outlined by APCI (the Professional Association of Italian Chefs).

As it takes visitors on a journey exploring the big topics of the moment – energy, people and sustainability – APCI will set out its manifesto on human, economic and environmental issues. Thanks to synergies with authoritative concerns involved in the various fields, the five-day programme will propose concrete solutions and the star of the show will be APCI Chef Lab, a

project that represents the SMART evolution of the APCI Chef Italia national team, a true hub of human and professional development, for the all-round growth of tomorrow's chefs.

The great challenges facing the food service industry – such as the digital transition, sustainability and skills –will then be discussed at the workshops of FIPE (the Italian Federation of Public Establishments). FIPE will be at HostMilano with this programme to continue the project of accompanying catering companies towards three transitions: digital, energy and professional. The "FIPE laboratory" will present best practices, reports, meetings, workshops and innovative services for the sector that will outline the transitions the future requires. The various items of equipment, stateof-the-art tills, payment systems, apps and digital menus will create a bridge between innovation and tradition and enable companies to develop their business by teaching them more about their customers

and making them easier to reach.

In addition to that, the 2023 Academy organised by FIC (the Italian Federation of Chefs) will offer master classes, training sessions and institutional meetings over the five days of the event. Partners, associated journalists and the merely curious will meet to address the key themes of food service Made in Italy. Meanwhile, visitors will be able to interact with consultants, designers and producers from FCSI (the Foodservice Consultants Society International) in a large professional kitchen, seminar and meeting rooms and a lounge. ANIMA (which represents Italy's mechanical engineering industry) and its various associations, together with EFCEM Italia will also create a FoodTechnology Lounge with a busy calendar of meetings, technical and regulatory updates, business appointments and market trend analyses.

Unibloc-Pump o ers the widest selection of premium sanitary food grade pumps. From our standard clean-in-place design, to our game-changing QuickStrip® technology, Unibloc-Pump travels the unbeaten path to nd better performance and cost-saving technology.

The Ross HSM 100LCI-t Laboratory Mixer delivers POWER, PRECISION and VERSATILITY. Variable speed up to 10,000 rpm, constant torque operation and HMI touchscreen controls ensure optimal results in critical formulations. Record information in 20-second increments with an optional Data Station. Take on virtually any mixing challenge with interchangeable High Shear Rotor/Stator, Disperser, Inline and Micro mixing assemblies.

Batch volumes from 50mL to 15L. Call or buy online. Ask about our Trial/Rental Program.

Bar technologies are becoming increasingly automated and environmentally friendly; the sector is launching solutions that are not only innovative, but also help less experienced operators create high-quality preparations. Digitization, sustainability and awareness are the concepts that in recent years are characterizing the ‘macro-world’ of the public sector, which at HostMilano is found in the sectors of Coffee-Tea and Bar, Coffee Machines, Vending along with Gelato and Pastry. These are increasingly innovative sectors where the bar value chain also integrates important support technologies.

Digitalization Makes Work Easier, Even with Water

Debora Screpanti, Marketing Manager at Blupura, confirm the importance of the most cuttingedge technologies: “IoT integrates devices into professional systems while Artificial Intelligence enables solutions such as remote control of water supply.” Innovation is also sustainability: “We use recycled materials and low-energy production processes”. The Celli Group is

also committed to responsibility: “We define ourselves as a Beyond the Bottle Company, going beyond single-use plastic containers towards more technological and connected delivery plants, for example refrigerators with NFC reader and a QR code reader camera,” explains Sara Marcatelli, Off-Line and Event Marketing Specialist.

WMF will also present its latest innovative machines at Host: “Thanks to the new semi-automatic filter wallet machines, it will be possible to prepare large quantities of highquality product and the cleaning system will be automatic for up to three months,” explains Nina Schmid, International Marketing Manager. “Our goal is to improve energy efficiency over the entire product cycle and their durability.” Finally, Thermoplan also puts sustainability at the heart of its innovation: “We will launch the Environmental Product Report, which will give a vision of the transparent and sustainable environmental impact of our coffee machines,” says Matteo Trachsel, Head of Sustainability. Coffee and hot beverages are experiencing an

exciting moment with specialty coffee, new extraction methods, bubble tea, and cross-cutting innovations. After the great success of 2021, the 'travelling-show' format returns to the Coffee Addition stands with Gianni Cocco, the coffee expert who has two Guinness world records under his belt.

As well as being the first 'travelling show' of its kind, the format presents a series of experts on the various participating stands, with a live approach that promises to make the 'seminar' formula an exciting and engaging professional development experience.

The barista challenges will also feature prominently: in the Grand Prix of the Italian Caffetteria, baristas, bartenders and café staff not only from Italy, but also from AICAF-associated countries Croatia, Morocco and Mexico will battle it out with each other. In a race lasting just 13 minutes, the competitors will be required to prepare two cappuccinos, two espresso coffees and two cold coffee-based drinks that contain an Italian food and wine product. Following several selections carried out around Italy, 15 baristas will compete in the semi-finals at Host and a shortlist of just eight candidates will go through to the final the following day, where the Italian Café Champion 2023 will be declared.

The Moka Challenge, on the other hand, is a competition open to everyone, based on a countdown of just ten minutes. During this time, the drink must be served in the special moka cup with three doses (three cups) provided by the organization and must measure exactly 5 cl in volume per dose, with no additional ingredients allowed. Just ten minutes will be available to prepare and extract the beverage. For the Lags Battle Italy/World Lags Battle ALTOGA will work together with the Latte Art Grading System for the Italian national semi-final and then the world finals of an event involving 50 countries. LAGS (Latte Art Grading System) is one of the world's most important circuits in the sector of latte art competitions, attracting thousands of certified baristas from Central America to Asia. Last year the world championship was held in Dubai.

The Industrial Cutters of K+G Wetter – here the CM 360 (left) and the VCM 200 (right) – all come with the proven Hygienic Secure features. The machines are versatile, durable and economical.

Food processing in industrial scale needs cutters that are economical and versatile as well as easy to use and clean. Industrial bowl cutters from K+G Wetter make efficient food processing on an XXL scale safe and easy, while focusing on hygiene – right down to the smallest detail. With or without vacuum, the durable machines are used by customers worldwide for the processing of all kinds of food: from classic sausage meat to vegan products and all spicy and sweet specialities in between.

All Industrial Cutters from K+G Wetter now have the “Hygienic Secure” standard with innovative and worldwide unique solutions. “I am absolutely convinced of the benefits of Hygienic Secure,” says Niklas Lowis, junior chief at K+G Wetter customer Lowis Butchers, who produces with a VCM 360. “It

wasn’t even on my radar when I was shopping for a machine, but it’s phenomenally easy to clean and really good – for example, because you can remove the knife cover strips. In our experience, Hygienic Secure consistently saves us 20 per cent in terms of cleaning time!”

“A Vacuum Cutter is advantageous for many products, offering greater protein digestion, better bound sausage meat and fewer air inclusions”, says Volker Schlosser, Sales Manager International at K+G Wetter. “And for processing vegetarian and vegan proteins, the vacuum function is in fact indispensable.” Vegetable proteins need to be chopped in the cold range below 40 0C to prevent denaturation, i.e. the irreversible destruction of protein structures. A strong vacuum above 80% has an additional cooling effect and let the

fibres swell, which makes a finer bond with water and oils possible during mincing. The use of vacuum technology also allows longer protein chains to form. That also allows otherwise necessary – and sometimes controversial –additives to be completely or partially dispensed with.

Unique worldwide at K+G Wetter: Applications that demand a cooking function are no longer forced to utilise a vacuum bowl cutter! The K+G Wetter CM 200 and CM 360 Hygienic Secure models now offer a doublewalled cooking bowl as high-quality, energy-saving and efficient cooking system for the open cutters. The closed-system design means that the supplied steam heats the cooking bowl very quickly – and only via the space between the bowl’s dual walls. This delivers considerable savings in terms of time, energy and cost.

Like all machines from K+G Wetter, the Hygienic Secure cutters offer a sound investment for the future, designed for decades of use. One reason: The cast iron body, which K+G Wetter is the only manufacturer worldwide to offer.

"The demonstration already showed us how smoothly, cleanly and quietly the cutter runs”, states Patrick Stephan, Production Manager at Steinemann Holding GmbH & Co. KG. The K+G Wetter Customer owns a new VCM 550 since 2022. “Anyone who has ever stood near such a large bowl cutter knows how it rumbles at 3,000 revolutions or more. The great advantage of this cast-iron stand was immediately apparent to us."

Recovery is happening, and delivery is helping… with the tools of the trade

Two companies that make catering equipment offer a glimpse of trends and solutions for the restaurants of the future.

Summertime… and the living is ‘trendy’. But what exactly are this summer’s ‘hot’ trends? We asked two companies in the catering equipment business. “Waring’s director of culinary innovation, chef Dustin Selvaggio, says that the hot food trends are fermentation, sustainability, whole product utilization, pizza, noodles of all kinds, Indian Cuisine and Vietnam-

ese Cuisine,” explains Damien Hée, director of sales Europe, Waring Commercial Products Division of Conair Corporation. Senior marketing manager Peter Roffe speaks of the explosion in contactless ordering: “Essentially every restaurant now features these options in some capacity. Along with contactless payments and menus (with QR codes).” Hée predicts “a very busy summer season, as people head out and enjoy a closer return to normal.” But another issue to be addressed is that of labour shortages, which “have really led to an increase in smart restaurant technology. For example, automating online orders through delivery apps that helps to fill up restaurants and reduce ‘downtime’ gaps. The same applies to automating customer communications within the restaurant. This is part of a larger movement towards an omnichannel strategy (bricks&mortar outlets + online) that is helping restaurants to grow and thrive, moving forward.”

Another important factor is supply

chain and food supply issues. “Food pricing due to supply and inflation are having a big impact on restaurants. This level of food inflation hasn’t been this high in 40 years. Restaurants will need to balance productivity and pricing to be to be able to migrate some of the inflation. We see this as a major issue that restaurants will continue to deal with throughout this year.” The most popular models include the Food Dehydrator , the 7-litre Stand Mixer and the heavy-duty Juice Extractor. Waring is known for its extensive line of blenders, waffle makers and immersion blenders, which are the brand’s most exported products year after year.

“Everyone is happy to safely return to their favourite restaurants with friends and family again. Dining al fresco took off during the pandemic and it’s here to stay. We expect to see lots of customers sitting outside to enjoy the sunshine and beautiful weather,” says Adriana Desiderio, digital communications manager at Cambro. “We have many products that help support service outdoors, like our CamBars, trays, GoBoxes, and Ice Caddies.”

Events are back in full swing: “A lot of catering and hospitality businesses need ways to safely transport their food and beverages – both hot and cold – and we have a variety of insulated transport units to meet this need. Our GoBoxes are especially popular because they are temperature retentive, but also extremely durable and lightweight,” says Ms Desiderio.

Meanwhile, “food delivery continues to be a popular segment for us. Restaurants need a way to keep their food at safe temperatures during transport and we have the products to make that happen. They make it easy for restaurant owners to feel confident their food and beverages will make it to their customers in the condition they left the kitchen. Keeping food safe can be particularly challenging during the summer, but our products give you peace of mind.”

With over 30 years of manufacturing experience, our PC-based and touch-screen operated systems are an economical way to transport edible and inedible items, and an aid in keeping your plant clean while reducing labor and water usage.

Count on Cantrell for innovative and reliable equipment, parts, systems and solutions.

The Rotary Separator is constructed with heavy stainless steel and is available with either a perforated or wedge wire drum. Every Separator is custom built to varying length and width requirements and comes standard with a programmable spray bar and backup drive.

The two pictured CMP-36 Modular Pickers are designed to efficiently remove the most hard-to-get feathers, and features ease of maintenance and cleaning.

Heat and Control’s experienced team of engineers has designed the best nut production equipment to increase quality and output for peanuts, almonds, cashews and all other nut based products. From roasting to glazing, seasoning and coatings, frying and cooling, Heat and Control can assist you with complete solutions to add value to our nut based foods.

With manufacturing facilities and sales offices worldwide, Heat and Control supports manufacturers with experience, expertise and resources to develop the most value driven and efficient solutions for any food production challenge.

Put our innovation to action in your plant today!

As the Global Leader in Food Cutting Technology, successful processors depend on Urschel’s expertise to deliver optimal cutting solutions for all types of fruits and vegetables.

Urschel cutting equipment delivers a full spectrum of size reduction capabilities. Explore dicing, slicing, or pureeing to achieve your processing goals.

By Hillewaert

Hillewaert bv ‘t Walletje 74, 8300 Knokke-Heist, België +32 (0)50 55 12 51- info@fksbenelux.com

Mertens Horecamachines Luikersteenweg 365, B-3500 Hasselt +32 (0)11 27 03 36 - info@mertens-faema.be

Hillewaert Nederland bv Marconiweg 17, 3899 BR Zeewolde, Nederland +31 (0)85 902 16 00 - info.nl@fksbenelux.com