USING ENGINEERED INFIELD SOILS

DuraEdge Engineered Infield Soils have revolutionized the industry with a manufacturing process that relies on testing and computer-controlled blending. Scientifically selected soil materials are carefully metered out and mechanically combined to allow for specific infield soils.

New infield skin construction.

Existing infield skin renovation.

When designing and building a new ballfield, the most critical decision you

The development of engineered infield soils has paved the way for many

need to make is the infield soil you will specify and install. To answer that

underperforming infields to be rescued while avoiding the cost of total

question, you’ll need to answer these two questions first.

replacement. This innovative process is based on science and math using a

What are your field maintenance resources with regards to labor, equipment, maintenance practices and frequency?

four-step process for renovation known as “TACS” — Test, Analyze, Compare,

Do you have access to an adequate water supply?

DuraEdge engineered soils come in seven different blends. All FieldSaver

Answers to those questions will guide you in accurately classifying your field. A four-inch profile of infield soil is recommended for all new infield skin construction. See page 27 for more info and page 30 to estimate soil amounts.

INFIELD SOILS

New Versus Existing Infields |

and Solve.

products contain 50% or less sand content. DuraEdge infield soils contain 60% or more sand content. A Beacon Athletics or DuraEdge infield soils consultant can help you decide which soil product(s) should be blended into your existing soil for peak performance.

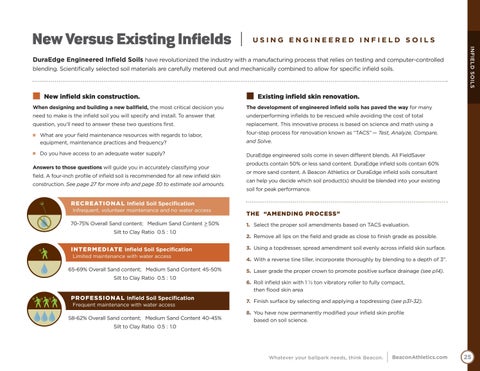

R ECREATIO NAL Infield Soil Specification

Infrequent, volunteer maintenance and no water access

70-75% Overall Sand content; Medium Sand Content _ > 50% Silt to Clay Ratio 0.5 : 1.0

I N TERMED IATE Infield Soil Specification Limited maintenance with water access

65-69% Overall Sand content; Medium Sand Content 45-50% Silt to Clay Ratio 0.5 : 1.0

P R O FESS IO NAL Infield Soil Specification Frequent maintenance with water access

58-62% Overall Sand content; Medium Sand Content 40-45%

THE “AMENDING PROCESS” 1. Select the proper soil amendments based on TACS evaluation. 2. Remove all lips on the field and grade as close to finish grade as possible. 3. Using a topdresser, spread amendment soil evenly across infield skin surface. 4. With a reverse tine tiller, incorporate thoroughly by blending to a depth of 3". 5. Laser grade the proper crown to promote positive surface drainage (see p14). 6. Roll infield skin with 1 ½ ton vibratory roller to fully compact, then flood skin area 7. Finish surface by selecting and applying a topdressing (see p31-32). 8. You have now permanently modified your infield skin profile based on soil science.

Silt to Clay Ratio 0.5 : 1.0

Whatever your ballpark needs, think Beacon.

|

BeaconAthletics.com

25