Introduction

Forward

Thismanual(CTM170)iswrittenforanexperienced technician.Essentialtoolsrequiredinperforming certainserviceworkareidentifiedinthismanualand arerecommendedforuse.

ThismanualcoversonlyLevel4ElectronicFuel SystemswiththeBoschVP44injectionpump.Itisone offivevolumeson4.5Land6.8Lengines.The followingfourcompanionmanualscoverthebase engineandmechanicalfuelsystemrepair,operation anddiagnostics:

• CTM104—BaseEngine

• CTM207—MechanicalFuelSystems

• CTM220—Level11ElectronicFuelSystemwith DensoHighPressureCommonRail

• CTM331—Level12electronicFuelSystemwith DE10Pump

Othermanualswillbeaddedinthefuturetoprovide additionalinformationonelectronicfuelsystemsas needed.

Livewithsafety:Readthesafetymessagesinthe introductionofthismanualandthecautionspresented throughoutthetextofthemanual.

Thisisthesafety-alertsymbol.Whenyouseethis symbolonthemachineorinthismanual,bealertto thepotentialforpersonalinjury.

Usethiscomponenttechnicalmanualinconjunction withthemachinetechnicalmanual.Anapplication listinginSection01,Group001identifies product-model/componenttype-modelrelationship.See themachinetechnicalmanualforinformationon

componentremovalandinstallation,andgaining accesstothecomponents.

Informationisorganizedinsectionsandgroupsforthe variouscomponentsrequiringserviceinstruction.At thebeginningofeachgrouparesummarylistingsofall applicableessentialtools,serviceequipmentandtools, othermaterialsneededtodothejob,servicepartskits, specifications,weartolerances,andtorquevalues.

Beforebeginningrepaironanengine,cleanthe engine.

ThismanualcontainsSIMetricunitsofmeasure followedimmediatelybytheU.S.customaryunitsof measure.Mosthardwareontheseenginesismetric sized.

Somecomponentsofthisenginemaybeserviced withoutremovingtheenginefromthemachine.Refer tothespecificmachinetechnicalmanualfor informationoncomponentsthatcanbeserviced withoutremovingtheenginefromthemachineandfor engineremovalandinstallationprocedures.

Readeachblockofmaterialcompletelybefore performingservicetocheckfordifferencesin proceduresorspecifications.Followonlythe proceduresthatapplytotheenginemodelnumberyou areworkingon.Ifonlyoneprocedureisgiven,that procedureappliestoalltheenginesinthemanual.

CALIFORNIAPROPOSITION65WARNING

Dieselengineexhaustandsomeofitsconstituentsare knowntotheStateofCaliforniatocausecancer,birth defectsandotherreproductiveharm.

DPSG,OUO1004,2760–19–17JUL01–1/1

SECTION01—General Group000—Safety Group001—EngineIdentification Group002—Fuels

SECTION02—RepairandAdjustments Group090—ElectronicFuelSystemRepairand Adjustments

Group110—ElectricalEngineControlRepairand Adjustment

SECTION03—TheoryofOperation Group130—ElectronicFuelSystemOperation Group140—ElectronicControlSystemOperation

SECTION04—Diagnostics

Group150—ObservableDiagnosticsandTests Group160—TroubleCodeDiagnosticsandTests

SECTION05—ToolsandOtherMaterials Group170—ElectronicFuel/ControlSystemRepair ToolsandOtherMaterials Group180—DiagnosticServiceTools

SECTION06—Specifications Group200—RepairSpecifications Group210—DiagnosticSpecifications

Allinformation,illustrationsandspecificationsinthismanualarebasedon thelatestinformationavailableatthetimeofpublication.Therightis reservedtomakechangesatanytimewithoutnotice.

Group000—Safety

Group001—EngineIdentification

EngineModelDesignation

EngineSerialNumberPlateInformation 01-001-2

OEMEngineOptionCodeLabel 01-001-3

Group002—Fuels

HandleFluidsSafely—AvoidFires

Whenyouworkaroundfuel,donotsmokeorworknear heatersorotherfirehazards.

Storeflammablefluidsawayfromfirehazards.Donot incinerateorpuncturepressurizedcontainers.

Makesuremachineiscleanoftrash,grease,anddebris.

Donotstoreoilyrags;theycanigniteandburn spontaneously.

HandleStartingFluidSafely

Startingfluidishighlyflammable.

Keepallsparksandflameawaywhenusingit.Keep startingfluidawayfrombatteriesandcables.

Topreventaccidentaldischargewhenstoringthe pressurizedcan,keepthecaponthecontainer,andstore inacool,protectedlocation.

Donotincinerateorpunctureastartingfluidcontainer.

ServiceCoolingSystemSafely

Explosivereleaseoffluidsfrompressurizedcooling systemcancauseseriousburns.

Shutoffengine.Onlyremovefillercapwhencoolenough totouchwithbarehands.Slowlyloosencaptofirststop torelievepressurebeforeremovingcompletely.

PreventBatteryExplosions

Keepsparks,lightedmatches,andopenflameawayfrom thetopofbattery.Batterygascanexplode.

Nevercheckbatterychargebyplacingametalobject acrosstheposts.Useavolt-meterorhydrometer.

Donotchargeafrozenbattery;itmayexplode.Warm batteryto16°C(60°F).

PrepareforEmergencies

Bepreparedifafirestarts.

Keepafirstaidkitandfireextinguisherhandy.

Keepemergencynumbersfordoctors,ambulanceservice, hospital,andfiredepartmentnearyourtelephone.

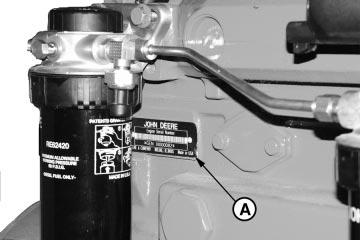

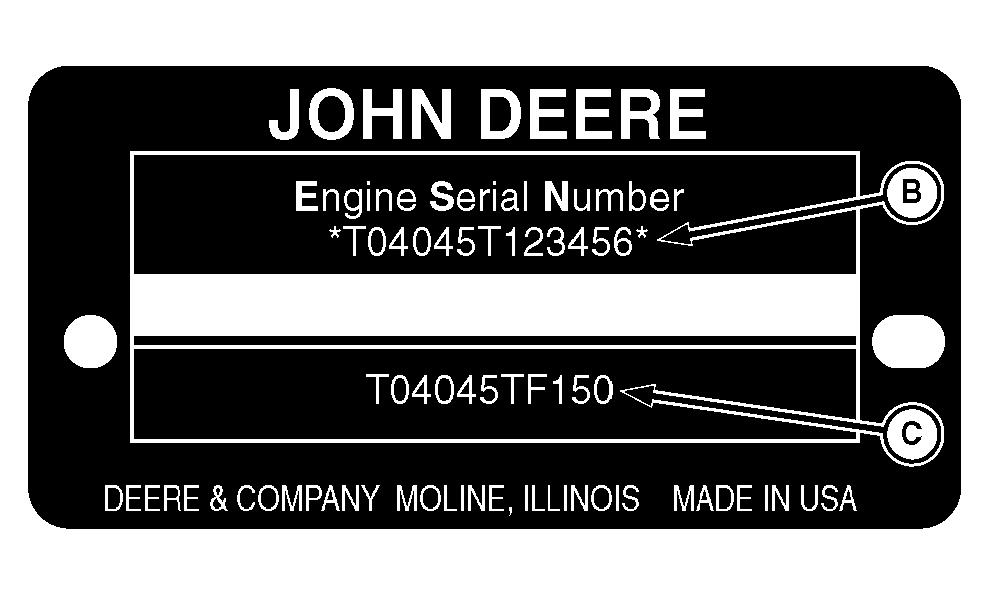

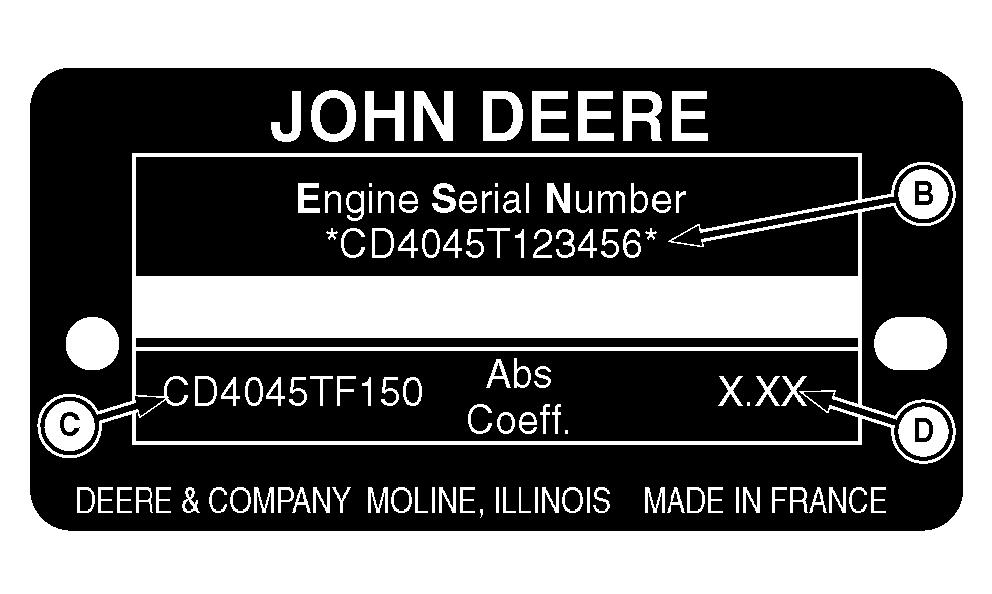

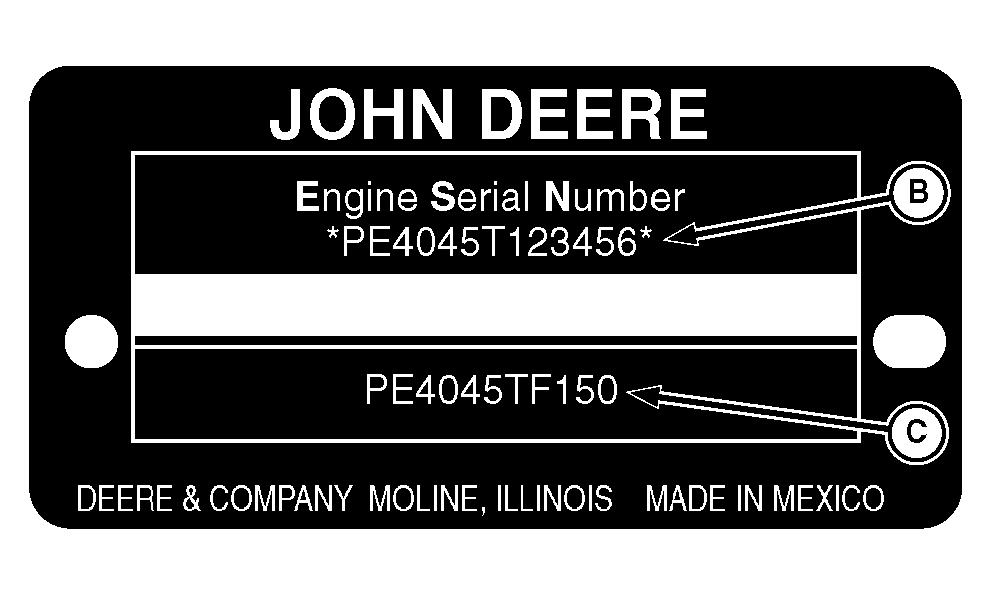

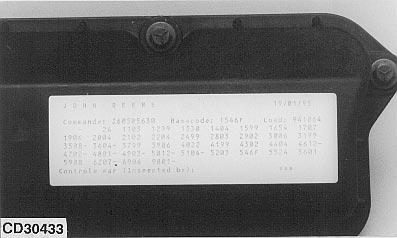

EngineSerialNumberPlateInformation

IMPORTANT:Theengineserialnumberplate(A)can beeasilydestroyed.Before“hottank” cleaningtheblock,removetheplate.

EngineSerialNumber(B)

Eachenginehasa13-digitJohnDeereengineserial numberidentifyingtheproducingfactory,enginemodel designation,anda6-digitsequentialnumber.The followingisanexample:

T04045T000000

T0...........................Factoryproducingengine 4045T.....................Enginemodeldesignation 000000...................Sequentialserialnumber FactoryCode(EngineManufacturer)

T0...........................Dubuque,Iowa CD..........................Saran,France PE..........................Torreon,Mexico EngineModelDesignation 4045T.....................Definitionexplainedpreviously.(SeeENGINE MODELDESIGNATIONearlierinthisgroup. SequentialNumber 000000...................6-digitsequentialserialnumber

EngineApplicationData(C)

Thesecondlineofinformationontheserialnumberplate identifiestheengine/machineorOEMrelationship.See ENGINEAPPLICATIONCHARTlaterinthisgroup.

CoefficientofAbsorption(D)—(Saran-BuiltEngines Only)

ThesecondlineofinformationonSaranserialnumber platealsocontainsthecoefficientofabsorptionvaluefor smokeemissions.

A—EngineSerialNumberPlate

B—EngineSerialNumber

C—EngineApplicationData

D—CoefficientofAbsorption(SaranEnginesOnly)

EngineIdentification

Tier1vs.Tier2

Thefueltransferpumpislocatedonthefinalfuelfilter headeronTier1applicationsandprimaryfuelfilteron Tier2applications.SomeTier2applicationsusearemote mountedfueltransferpump.FormoreinformationonTier 1vs.Tier2applications,seeENGINEAPPLICATION CHARTinGroup001earlierinthismanual.Thetransfer pumpiselectricallycontrolledbytheElectronicControl Unit(ECU).

AllTier1enginesareequippedwithafuelpressure sensoronthefinalfuelfilter.SomeTier2enginesusea fuelpressuresensorandsomedonot.

Tier1enginesmaybeequippedwithaprimaryfuel filter/waterseparator.AllTier2engineswillhavebotha primaryandfinalfuelfilter.

Tier1enginesmaybeequippedwitheithera30micron or150micronprimaryfilter.AllTier2engineshavea30 micronprimaryfilter.

Allenginesareequippedwitharoundfinalfuelfilter.

Allenginesuse9.5mmpencil-typenozzles.

Fuelsystemoptionsincludefuelheaterandwater separatorbowl.

IMPORTANT:TheBoschVP44InjectionPumpis electronicallycontrolled.Allconnectors onthepumpandtheenginecontrol unit(ECU)mustbedisconnectedbefore anyweldingisaccomplishedonthe engine,ordamagetotheelectrical systemislikelytooccur.

Tier2-FinalFuelfilter

Tier2-PrimaryFuelFilter

LubricantsandCoolant

NOTE:Forinformationonlubricantsandcoolants,refer toSection01,Group002ofCTM104Base EngineManualforinformationonlubricantsand coolants.

DieselFuel-Tier1

NOTE:ForinformationonTier1vs.Tier2 applications,seeENGINEAPPLICATION CHARTinGroup001earlierinthismanual.

Consultyourlocalfueldistributorforpropertiesofthe dieselfuelavailableinyourarea.

Ingeneral,dieselfuelsareblendedtosatisfythelow temperaturerequirementsofthegeographicalareain whichtheyaremarketed.

DieselfuelsspecifiedtoEN590orASTMD975are recommended.

Inallcases,thefuelshallmeetthefollowing properties:

• CetaneNumberof40minimum. Cetanenumber greaterthan50ispreferred,especiallyfor temperaturesbelow—20°C(—4°F)orelevations above1500m(5000ft).

• ColdFilterPluggingPoint(CFPP) belowthe expectedlowtemperatureORCloudPointatleast 5°C(9°F)belowtheexpectedlowtemperature.

• FuelLubricity shouldpassaminimumof3100 gramloadlevelasmeasuredbytheBOCLEscuffing test.

• SulfurContent

–Sulfurcontentshouldnotexceed0.5%.Sulfur contentlessthan0.05%ispreferred.

–Ifdieselfuelwithsulfurcontentgreaterthan0.5% isused,reducetheserviceintervalforengineoil andfilterby50%.

–DONOTusedieselfuelwithsulfurcontent greaterthan1.0%.

Bio-dieselfuelswithpropertiesmeetingDIN51606or equivalentspecificationmaybeused.

DONOTmixusedengineoiloranyothertypeof lubricantwithdieselfuel.

DieselFuel-Tier2

NOTE:ForinformationonTier1vs.Tier2 applications,seeENGINEAPPLICATION CHARTinGroup001earlierinthismanual.

Consultyourlocalfueldistributorforpropertiesofthe dieselfuelavailableinyourarea.

Ingeneral,dieselfuelsareblendedtosatisfythelow temperaturerequirementsofthegeographicalareain whichtheyaremarketed.

DieselfuelsspecifiedtoEN590orASTMD975are recommended.

Requiredfuelproperties

Inallcases,thefuelmustmeetthefollowing properties:

Cetanenumberof45minimum. Cetanenumber greaterthan50ispreferred,especiallyfor temperaturesbelow-20°C(-4°F)orelevationsabove 1500m(5000ft).

ColdFilterPluggingPoint (CFPP)belowthe expectedlowtemperatureOR CloudPoint atleast 5°C(9°F)belowtheexpectedlowtemperature.

Fuellubricity shouldpassaminimumloadlevelof 3100gramsasmeasuredbyASTMD6078or, maximumscardiameterof0.45mmasmeasuredby ASTMD6079.

Sulfurcontent:

• Dieselfuelqualityandfuelsulfurcontentmust complywithallexistingregulationsfortheareain whichtheengineoperates.

• Sulfurcontentlessthan0.05%(500ppm)is preferred.

• Ifdieselfuelwithsulfurcontentgreaterthan0.05% (500ppm)isused,crankcaseoilserviceintervals maybeaffected.(SeerecommendationforDiesel EngineOil.)

• DONOTusedieselfuelwithsulfurcontentgreater than1.0%.

IMPORTANT:DONOTmixusedengineoilorany othertypeoflubricatingoilwith dieselfuel.

RG41221,0000085–19–23OCT02–1/1

Bio-DieselFuel

Consultyourlocalfueldistributorforpropertiesofthe bio-dieselfuelavailableinyourarea.

Bio-dieselfuelsmaybeusedONLYifthebio-diesel fuelpropertiesmeetthelatesteditionofASTMPS121, DIN51606orequivalentspecification.

Ithasbeenfoundthatbio-dieselfuelsmayimprove lubricityinconcentrationsuptoa5%blendin petroleumdieselfuel.

Whenusingablendofbio-dieselfuel,theengineoil levelmustbecheckeddailywhentheairtemperature is-10°C(14°F)orlower.Iftheoilbecomesdilutedwith fuel,shortenoilchangeintervalsaccordingly.

IMPORTANT:RawpressedvegetableoilsareNOT acceptableforuseforfuelinany concentrationinJohnDeere engines.

Theseoilsdonotburncompletely, andwillcauseenginefailureby leavingdepositsoninjectorsandin thecombustionchamber.

Amajorenvironmentalbenefitofbio-dieselfuelisits abilitytobiodegrade.Thismakesproperstorageand handlingofbio-dieselfuelespeciallyimportant.Areas ofconcerninclude:

• Qualityofnewfuel

• Watercontentofthefuel

• Problemsduetoagingofthefuel

Potentialproblemsresultingfromdeficienciesinthe aboveareaswhenusingbio-dieselfuelin concentrationsabove5%mayleadtothefollowing symptoms:

• Powerlossanddeteriorationofperformance

• Fuelleakage

• Corrosionoffuelinjectionequipment

• Cokedand/orblockedinjectornozzles,resultingin enginemisfire

• Filterplugging

• Lacqueringand/orseizureofinternalcomponents

• Sludgeandsediments

• Reducedservicelifeofenginecomponents

RG41183,0000046–19–15NOV01–1/1

DieselscanFuelAnalysis

DIESELSCAN isaJohnDeerefuelsamplingprogramto helpyoumonitorthequalityofyourfuelsource.Itverifies fueltype,cleanliness,watercontent,suitabilityforcold weatheroperation,andiffueliswithinASTM specifications.CheckwithyourJohnDeeredealerfor availabilityofDIESELSCANkits.

DIESELSCANisatrademarkofDeere&Company

DX,FUEL6–19–06DEC00–1/1

LubricityofDieselFuel

Dieselfuelmusthaveadequatelubricitytoensure properoperationanddurabilityoffuelinjectionsystem components.

DieselfuelsforhighwayuseintheUnitedStates, Canada,andtheEuropeanUnionrequiresulfur contentlessthan0.05%.

Experienceshowsthatsomelowsulfurdieselfuels mayhaveinadequatelubricityandtheirusemay reduceperformanceinfuelinjectionsystemsdueto inadequatelubricationofinjectionpumpcomponents. Thelowerconcentrationofaromaticcompoundsin thesefuelsalsoadverselyaffectsinjectionpumpseals andmayresultinleaks.

Useoflowlubricitydieselfuelsmayalsocause acceleratedwear,injectionnozzleerosionorcorrosion, enginespeedinstability,hardstarting,lowpower,and enginesmoke.

Fuellubricityshouldpassaminimumof3100gram loadlevelasmeasuredbytheBOCLEscuffingtest.

ASTMD975andEN590specificationsdonotrequire fuelstopassafuellubricitytest.

Iffuelofloworunknownlubricityisused,addJohn DeerePREMIUMDIESELFUELCONDITIONER(or equivalent)atthespecifiedconcentration.

DX,FUEL5–19–17FEB99–1/1

RemoveandInstallElectronicFuel TransferPump-RemoteMount 02-090-12

ServiceInjectionPumpOverflowValve 02-090-13

BoschVP44InjectionPumpStaticTiming...02-090-14

RemoveBoschVP44FuelInjection Pump

02-090-16

RepairBoschVP44FuelInjectionPump .... 02-090-18

InstallBoschVP44FuelInjectionPump .... 02-090-19

RemoveFuelInjectionNozzles ........... 02-090-22

CleanFuelInjectionNozzleBore 02-090-24

CleanFuelInjectionNozzles 02-090-24

TestFuelInjectionNozzles 02-090-25

DisassembleFuelInjectionNozzles 02-090-30

InspectandCleanFuelInjectionNozzle Body 02-090-33

InspectandCleanValveandValveSeat...02-090-34

InspectValveAdjustingMechanism 02-090-36

AssembleFuelInjectionNozzles .......... 02-090-37

AdjustFuelInjectionNozzles ............ 02-090-38

InstallSealsonFuelInjectionNozzle 02-090-41

InstallFuelInjectionNozzles 02-090-42

Group110—ElectricalEngineControlRepairand Adjustment

EngineControlUnit(ECU) 02-110-1

RemoveandInstallEngineCoolant

02-110-2

ReplaceFuelPressureSensor 02-110-3

ReplacePumpPositionSensor 02-110-4

ReplaceCrankshaftPositionSensor 02-110-4

RemoveandInstallOilPressureSensor ..... 02-110-5

FuelSystem—GeneralInformation

Forstaticlock-pintimingoftheBoschVP44Injection Pump,seeBOSCHVP44INJECTIONPUMPSTATIC TIMINGinthisGroup.

Thefueltransferpumpislocatedonthefinalfuelfilter headeronTier1applicationsandprimaryfuelfilter,or remotemountedonTier2applications.Formore informationonTier1vs.Tier2applications,see ENGINEAPPLICATIONCHARTinGroup001earlier inthismanual.Thetransferpumpiselectrically controlledbytheElectronicControlUnit(ECU).

Tier1enginesmaybeequippedwithaprimaryfuel filter/waterseparator.AllTier2engineswillhaveboth aprimaryandfinalfuelfilter.

Allenginesareequippedwitharoundfinalfuelfilter.

Allenginesuse9.5mmpencil-typenozzles.

Fuelsystemoptionsincludefuelheaterandwater separatorbowl.

IMPORTANT:TheBoschVP44InjectionPumpis electronicallycontrolled.All connectorsonthepumpandthe enginecontrolunit(ECU)mustbe disconnectedbeforeanyweldingis accomplishedontheengine,or damagetotheelectricalsystemis likelytooccur.

RelieveFuelSystemPressure

CAUTION:Escapingdieselfuelunderpressure canhavesufficientforcetopenetratetheskin, causingseriousinjury.Beforedisconnecting lines,besuretorelievepressure.Before applyingpressuretothesystem,besureALL connectionsaretightandlines,pipesand hosesarenotdamaged.Keephandsandbody awayfrompinholesandnozzleswhicheject fluidunderpressure.Useapieceofcardboard orwood,ratherthanhands,tosearchfor suspectedleaks.

IfANYfluidisinjectedintotheskin,itmustbe surgicallyremovedwithinafewhoursbya doctorfamiliarwiththistypeofinjuryor gangrenemayresult.Doctorsunfamiliarwith thistypeofinjurymaycalltheDeere& CompanyMedicalDepartmentinMoline,Illinois, orotherknowledgeablemedicalsource.

Anytimethefuelsystemhasbeenopenedupforservice (linesdisconnectedorfiltersremoved),itwillbenecessary tobleedairfromthesystem.SeeBLEEDTHEFUEL SYSTEMinGroup150laterinthismanual.

RG,35,JW7625–19–20NOV97–1/1

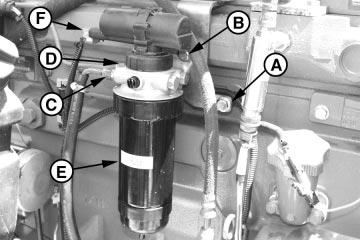

RemoveandInstallPrimaryFuelFilter/Water SeparatorBase-Tier2

NOTE:ForinformationonTier1vs.Tier2applications, seeENGINEAPPLICATIONCHARTinGroup 001earlierinthismanual.

Theprimaryfuelfiltermaybeequippedwithawater separatorbowl.

Theelectronicfueltransferpumpismountedontopofthe filterhead.

1.Thoroughlycleanprimaryfuelfilter/waterseparator assemblyandsurroundingareatokeepfromgetting dirtanddebrisintofuelsystem.

2.Connectafuellinetofilterdrain(ifequipped)on bottomoffilteranddrainallfuelfromthesystem.

3.Removeprimaryfuelfilterelement.

NOTE:Fuellinesmaybeconnectedtodifferentinletand outletportsdependingonengineapplication.

4.Disconnectfuellinesfromfuelinlet(C)andfueloutlet (D).

5.Disconnectfueltransferpumpconnector(F).

6.Removefilterbasecapscrews(B)andprimaryfuel filterbase.

NOTE:Mountingbracketdoesnotneedtoberemoved.

7.Replacepartsasnecessary.

8.Ifremoved,installmountingbracketonengine.Install filterbaseonmountingbracket.Tightencapscrewsto specification.

PrimaryFuelFilterMounting

Specification

Bracket-to-CylinderHeadCap

Screws—Torque74N•m(54.5lb-ft)

PrimaryFuelFilter

Base-to-BracketCapScrews— Torque60N•m(44lb-ft)

PrimaryFuelFilter-Tier2

A—FilterBrackettoEngineMountingCapScrews B—FilterBasetoBracketMountingCapScrews C—FuelInletLine(FromFuelTank) D—FuelOutlet(ToFinalFuelFilter) E—PrimaryFuelFilter F—FuelTransferPumpConnector

9.Installwaterseparatorandprimaryfuelfilterelement. SeeREPLACEFINALFUELFILTERELEMENTlater inthisGroup.

10.Connectfuellinestofuelinlet(C)andfueloutlet(D) andtightentospecification.

Specification

PrimaryFuelFilterInletLine—

Torque30N•m(22lb-ft)

PrimaryFuelFilterOutletLine—

Torque30N•m(22lb-ft)

11.Reconnectfueltransferpumpelectricalconnector.

12.Bleedthefuelsystem.SeeBLEEDTHEFUEL SYSTEMinGroup150laterinthismanual.

RG41221,00000FB–19–17OCT02–2/2

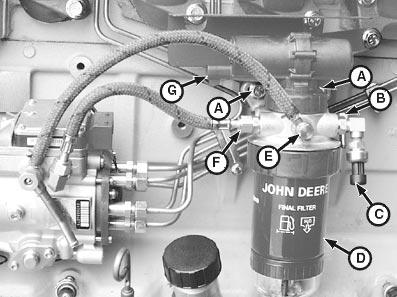

RemoveandInstallFinalFuelFilter/Water SeparatorBase-Tier1

NOTE:ForinformationonTier1vs.Tier2applications, seeENGINEAPPLICATIONCHARTinGroup 001earlierinthismanual.

Finalfuelfiltermaybeequippedwithawaterseparator bowl.

Theelectronicfueltransferpumpismountedontopofthe filterheader.

1.Thoroughlycleanfuelfilter/waterseparatorassembly andsurroundingareatokeepfromgettingdirtand debrisintofuelsystem.

2.Connectafuellinetofilterdrainonbottomoffilterand drainallfuelfromsystem.

3.Removefinalfuelfilterelement.SeeREPLACEFINAL FUELFILTERELEMENT,laterinthisGroup.

NOTE:Fuellinesmaybeconnectedtodifferentfilterinlet andoutletportsdependingonengineapplication.

4.Disconnectfuellinesfromfuelinlet(B),overflowvalve (E),andfueloutlet(F).

5.Disconnectfueltransferpumpconnector(G)andfuel pressuresensorconnector(C)(bothshown disconnected).

6.Removecapscrews(A)andfinalfuelfilterbase.

NOTE:Mountingbracketdoesnotneedtoberemoved.

7.Replacepartsasnecessary.

8.Ifremoved,installfiltermountingbracketonengine. Installfilterbaseonmountingbracket.Tightencap screwstospecifications.

Specification

FinalFuelFilterMounting

Bracket-to-ExhaustManifold— Torque70N•m(52lb-ft)

FinalFuelFilterBase-to-Bracket CapScrews—Torque70N•m(52lb-ft)

FinalFuelFilter-Tier1

A—FilterBaseMountingCapScrews

B—FuelInletLine(FromPrefilter)

C—FuelPressureSensorConnector

D—FinalFuelFilter

E—FuelOverflowLine(ToInjectionPump OverflowValve)

F—FuelOutletLine(ToInjectionPumpInlet)

G—FuelTransferPumpConnector

9.Installwaterseparatorandfuelfilterelement.See REPLACEFINALFUELFILTERELEMENTlaterinthis Group.

10.Connectfuellinestofuelinlet(B),overflowvalve(E), andfueloutlet(F)andtightentospecification.

FinalFuelFilterInletLine—

Specification

Torque30N•m(22lb-ft)

FinalFuelFilterOutletLine—

Torque30N•m(22lb-ft)

11.Reconnectfueltransferpumpandfuelpressure sensorelectricalconnectors.

12.Bleedthefuelsystem.SeeBLEEDTHEFUEL SYSTEMinGroup150laterinthismanual.

RG41221,0000105–19–17OCT02–2/2

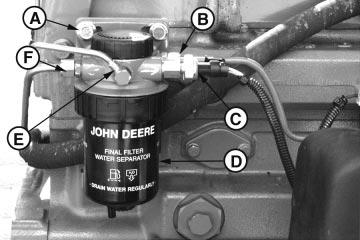

RemoveandInstallFinalFuelFilter/Water SeparatorBase-Tier2

NOTE:ForinformationonTier1vs.Tier2applications, seeENGINEAPPLICATIONCHARTinGroup 001earlierinthismanual.

Finalfuelfiltermaybeequippedwithawaterseparator bowl.

1.Thoroughlycleanfuelfilter/waterseparatorassembly andsurroundingareatokeepfromgettingdirtand debrisintofuelsystem.

2.Connectafuellinetofilterdrainanddrainallfuelfrom system.

3.Removefinalfuelfilterelement.SeeREPLACEFINAL FUELFILTERELEMENTlaterinthisGroup.

NOTE:Fuellinesmaybeconnectedtodifferentfilterinlet andoutletportsdependingonengineapplication.

4.Disconnectfuellinesfromfuelinlet(B),overflowvalve (E),andfueloutlet(F).

5.Disconnectfuelpressuresensorconnector(C).

6.Removecapscrews(A)andfinalfuelfilterbase. Removefinalfilter.

7.Replacepartsasnecessary.

8.Installfilterbaseonenginecylinderhead.Tightencap screwstospecifications.

Specification

FinalFuelFilterBase-to-Cylinder Head—Torque70N•m(52lb-ft)

9.Installwaterseparatorandfuelfilterelement.See REPLACEFINALFUELFILTERELEMENTlaterinthis Group.

10.Connectfuellinestofuelinlet(B),overflowvalve(E), andfueloutlet(F)andtightentospecification.

FinalFuelFilter-Tier2

A—FilterBaseMountingCapScrews

B—FuelInletLine(FromPrefilter)

C—FuelPressureSensorConnector

D—FinalFuelFilter

E—FuelOverflowLine(ToInjectionPump OverflowValve)

F—FuelOutletLine(ToInjectionPumpInlet)

FinalFuelFilterInletLine—

Specification

Torque30N•m(22lb-ft)

FinalFuelFilterOutletLine—

Torque30N•m(22lb-ft)

11.Reconnectthefuelpressureelectricalconnector.

12.Bleedthefuelsystem.SeeBLEEDTHEFUEL SYSTEMinGroup150laterinthismanual.

FinalFuelFilterAssembly-Tier1

NOTE:ForinformationonTier1vs.Tier2applications, seeENGINEAPPLICATIONCHARTinGroup 001earlierinthismanual.

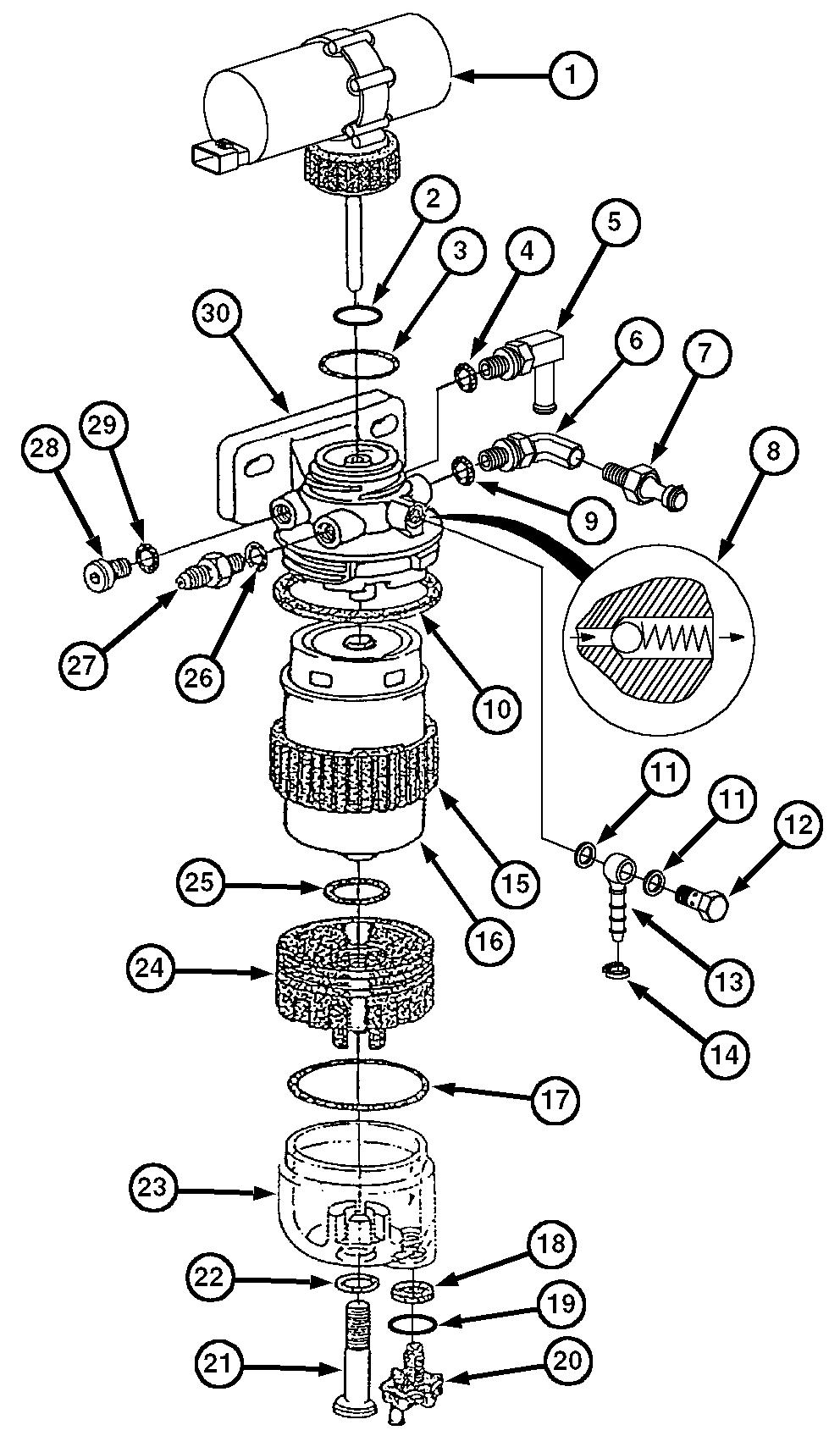

1—FuelTransferPump 2—O-Ring 3—O-Ring 4—O-Ring 5—Fitting 6—Fitting 7—FuelPressureSensor 8—AirBleedSpringandBall(Non-Serviceable) 9—O-Ring 10—DustSeal 11—CopperWasher 12—BanjoBolt 13—BanjoFitting 14—HoseClamp 15—RetainingRing 16—Filter 17—O-Ring 18—Gasket 19—O-Ring 20—DrainAdapter 21—Screw 22—O-Ring 23—WaterSeparatorBowl 24—Adapter 25—O-Ring 26—O-Ring 27—Fitting 28—Plug1 29—O-Ring 30—FilterBase

RG41221,00000FC–19–17OCT02–2/2

1Anoptionalfuelheaterisavailableforinstallationinthisbore.

RG41221,0000106–19–09MAY01–1/1

FinalFuelFilter-Tier1

FinalFuelFilterAssembly-Tier2

NOTE:ForinformationonTier1vs.Tier2applications, seeENGINEAPPLICATIONCHARTinGroup 001earlierinthismanual.

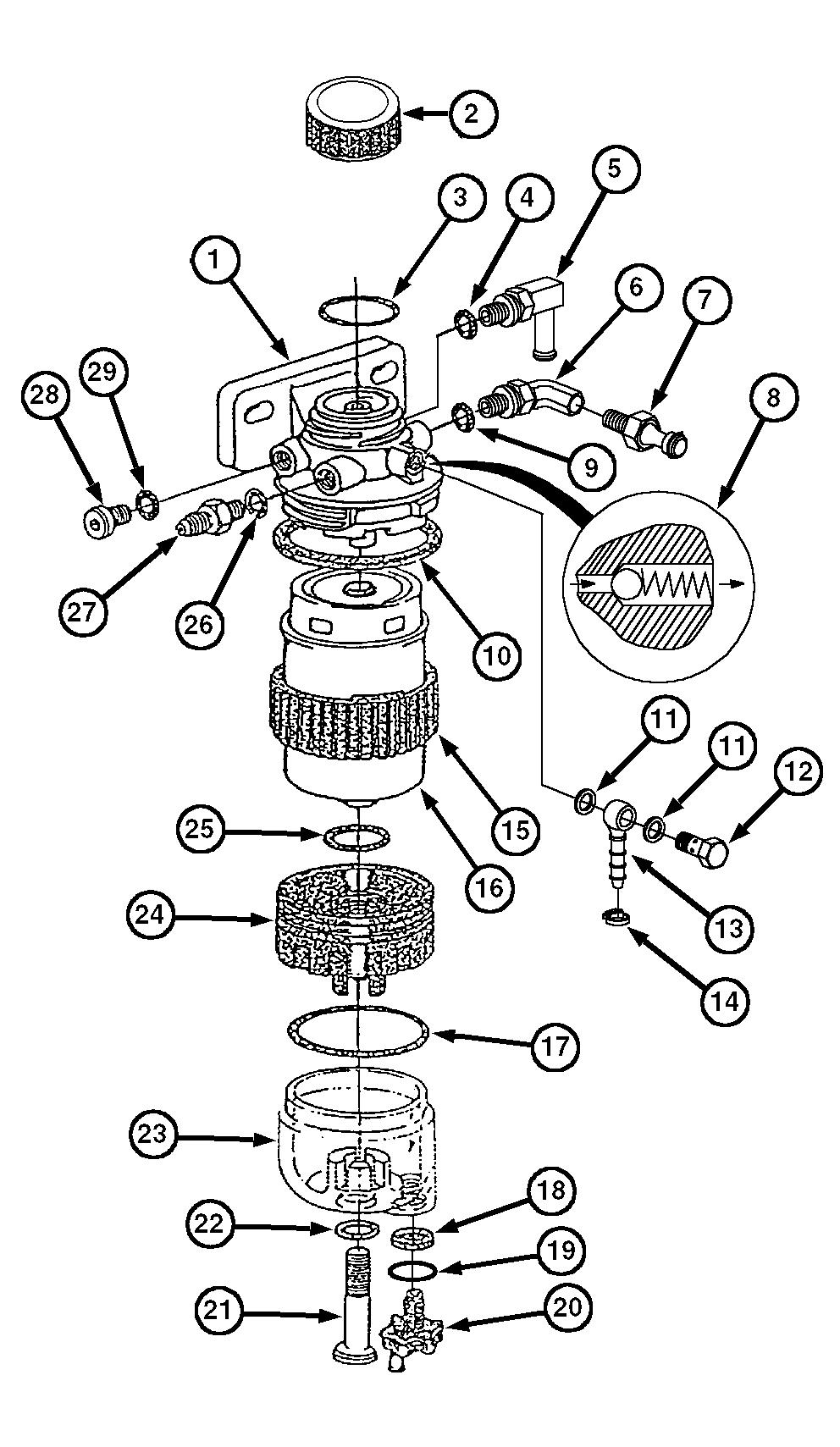

1—FilterBase 2—FinalFuelFilterCover 3—O-Ring 4—O-Ring 5—Fitting 6—Fitting 7—FuelPressureSensor 8—AirBleedSpringandBall(Non-Serviceable) 9—O-Ring 10—DustSeal 11—CopperWasher 12—BanjoBolt 13—BanjoFitting 14—HoseClamp 15—RetainingRing 16—Filter 17—O-Ring 18—Gasket 19—O-Ring 20—DrainAdapter 21—Screw 22—O-Ring 23—WaterSeparatorBowl 24—Adapter 25—O-Ring 26—O-Ring 27—Fitting 28—Plug1 29—O-Ring

FinalFuelFilter-Tier2

1Anoptionalfuelheaterisavailableforinstallationinthisbore.

EngineControlUnitCylinderMisfireTest 04-160-22

ExcavatorTorqueCurveChange Repair 02-110-1

TheoryofOperation............... 03-140-21Test ......................... 04-160-26

Coolant ............................. 01-002-1

TractorTorqueCurveChangeTest...04-160-27

CoolanttemperaturesensorDiagnosticTools 05-180-1

Operation 03-140-8

DiagnosticTroubleCodes

CrankPositionSensorBlinkingCodes 04-160-15 DiagnosticTroubleCodes(DTCs) MeasuringSpeed 03-140-16

CruiseControlOperation 03-140-23

Replace 02-110-4ActiveEngineServiceCodes, Viewing 04-160-13

CylinderCutoutTestActivevs.Inactive 03-140-26 ClearingStoredCodes 03-140-26

EngineTestInstructions 04-160-25

CylinderMisfireTestDiagnosticProcedure ............... 04-160-56

EngineTestInstructions ............. 04-160-22

DisplayFormat .................... 03-140-26

ObservableInstructions .............. 04-150-76ListofSPN/FMI.................... 04-160-52

Listof2-Digit 04-160-54 Listingof 04-160-52 SPN/FMI 04-160-51

DataParameterDescription DiagnosticScanTool 04-160-18000029.04 04-160-119 000084.02 ..................... 04-160-120

ServiceADVISOR .................. 04-160-18

DeratePrograms .................... 03-140-24000091.03 ..................... 04-160-124 000091.04 ..................... 04-160-125 ApplicationSpecifications ............. 06-210-2 DEUTSCHConnectors000091.09 04-160-125

000094.01 04-160-126 Repair 02-110-16

DiagnosticGauge000094.03 04-160-128

ClearingStoredDiagnosticTrouble Codes 04-160-14000094.18 04-160-136

Diagnostics

000094.04 04-160-132

000097.00 04-160-138

ACP-Err/BusEP 04-150-56000097.16 04-160-142

ACP-Err/BusError ................ 04-150-56

000100.01 ..................... 04-160-146

ACP-Err/NoAddr ................. 04-150-56000100.03 ..................... 04-160-150

DoesNotCommunicateWithECU...04-150-56

000100.04 ..................... 04-160-154

EE-error 04-150-56000100.18 04-160-160

EngineConfigurationParameters 04-160-11

000105.00 04-160-162

ViewingActiveDiagnosticTrouble000105.03 04-160-164

000105.04 04-160-168 Codes 04-160-13

ViewingStoredDiagnosticTrouble000105.16 04-160-172

000107.00 04-160-174 Codes 04-160-13

DiagnosticProcedure 04-160-56000110.00 04-160-178

DiagnosticScanTool

000110.03 ..................... 04-160-180

DownloadingPayloadFiles ........... 04-160-29000110.04 ..................... 04-160-184 000110.15 ..................... 04-160-188 ReprogrammingECU ............... 04-160-34

DiagnosticScanTool(DST)000110.16 04-160-190 000111.01 04-160-192 Connectingto 04-160-9

DataParameterDescription 04-160-18000158.17 04-160-196

000174.00 04-160-200 ECUDoesNotCommunicateWith DST........................... 04-150-50000174.15 04-160-204 000174.16 04-160-208 Tests CompressionTest 04-160-24000174.31 04-160-212

000189.00 04-160-214 CylinderCutoutTest 04-160-25

DiagnosticsSelf-Diagnosis 03-140-26

CommunicationProblem

TheoryofOperation 03-140-21

ECUDoesNotCommunicateWithDiagnosticElectricalCircuit Diagnosis ......................... 04-160-2 Gauge ....................... 04-150-56

ECUDoesNotCommunicateWithMalfunctions 04-160-2 Troubleshooting 04-160-5

DST......................... 04-150-50

ECUDoesNotCommunicateWithServiceElectricalConcepts 04-160-1 ElectricalConnectors ADVISOR 04-150-50

ElectricalCircuitMalfunctions

ElectricalCircuitTroubleshooting 04-160-5

FuelSystemSpecifications 06-210-1RepairAMP 02-110-19 RepairDEUTSCH 02-110-16

Fuelsystem,lowpressure

FuelSystem,LowPressure

Excessivefuelconsumption ......... 04-150-37RepairMetri-PackPullType .......... 02-110-11 RepairMetri-PackPushType ......... 02-110-13

Observable Analogthrottle(B)DoesNotElectronicControlSystem AirHeaterOperation

04-150-28

EngineCranks/Won’tStart 04-150-2 EngineDoesNotDevelopFullPumpControlUnit .................

....................... 04-150-12

EngineIdlesPoorly ............... 04-150-25TheoryofOperation ................. 03-140-3 WiringDiagram EngineMisfires/RunsIrregularly 04-150-7

EngineWillNotCrank 04-150-25MarineEngines 06-210-18 OEMEngines 06-210-28

EnigneEmitsExcessiveBlackorGrayExhaust Smoke 04-150-22ElectronicEngineControl Tools 05-170-4

EnigneEmitsExcessiveWhiteExhaust Smoke 04-150-18ElectronicEngineControlRepairandAdjustment Specifications 06-200-8

FuelSupplySystemCheck

Tier1 ........................ 04-150-30ElectronicTools ...................... 05-170-4

Tier2 ........................ 04-150-38Emissions

DieselFuel

Tier1vs.Tier2 .................... 01-001-5

Tier1 01-002-1Engine ApplicationChart 01-001-4

Tier2 01-002-2

DigitalMultimeterDeratePrograms 03-140-24 ModelNumber 01-001-1

HowtoUse........................ 04-160-2

DisassembleApplicationSpecific 01-001-4 OptionCodeLabel 01-001-3

InjectionNozzles 02-090-30 DownloadingPayloadFilesSerialNumberPlate 01-001-2 EngineConfigurationParameters ........ 04-160-11

DualStateThrottle

DiagnosticScanTool ............... 04-160-29 ServiceADVISOR .................. 04-160-39EngineControlUnit DiagnosticSoftware

MeasuringThrottlePosition

03-140-12Connectingto 04-160-9 DataParameterDescription 04-160-18 DiagnosticTroubleCodes 04-160-52

Listof2-DigitCodes 04-160-54 E MonitoringParameters 03-140-4 Repair 02-110-1 Reprogramming 04-160-28

ECU Repair 02-110-1Self-Diagnosis 03-140-26

Tier1 04-150-30HarnessConnectors

InchTorqueValues

InjectionNozzles

InstrumentPanel

ClearingStoredDiagnosticTrouble

DiagnosticGauge

ViewingActiveDiagnosticTrouble

ViewingStoredDiagnosticTrouble

04-150-56

ServiceADVISOR

Conectingto 04-160-9

DataParameterDescription .......... 04-160-18 GeneralOEMEngines

DownloadingPayloadFiles ........... 04-160-39

ECUDoesNotCommunicateWithDSTService

ADVISOR 04-150-50 Marine

ReprogrammingECU 04-160-47

CompressionTest 04-160-24

CylinderCutoutTest 04-160-25

CylinderMisfireTest 04-160-22

ExcavatorTorqueCurveChange

TractorTorqueCurveChangeTest...04-160-27

OEMEngines

Test ......................... 04-160-26 GovernorModeSelectionWithOC03034

ServiceCodes

ActiveEngineServiceCodes,

Viewing 04-160-13

Telehandlers Activevs.Inactive 03-140-26

ClearingStoredCodes 03-140-26

SPN/FMI ......................... 04-160-51 TorqueValues

04-160-51

WarningLight 03-140-26

2-Digit 04-160-51

3-Digit 04-160-51

Connectingto 04-160-9

DataParameterDescription 04-160-18

6010Series

...................... 06-210-36

6020Series

ECUDoesNotCommunicate ECUTerminalIdentification ....... 06-210-46

04-150-50

06-210-6

ECUTerminalIdentification 06-210-26 Starting ElectronicEngineControlRepairand EngineCranks/Won’tStart 04-150-2 Adjustment 06-200-8 StaticTiming Excavators InjectionPump 02-090-14

GovernorModeSelection 06-210-10 StoredDiagnosticTroubleCodes Sensors 06-210-8 TorqueCurveSelection 06-210-10ViewonDiagnosticGauge 04-160-13

ThrottleDiagnosticTroubleCodes

T01-Multi-stateThrottleInputHigh 04-160-58

T03-AnalogThrottle(A)InputHigh .... 04-160-66

T11-ExcavatorThrottleReferenceVoltage

T12-ExcavatorThrottleReferenceVoltage

T13-ExcavatorThrottleGroundVoltage

T14-ExcavatorThrottleGroundVoltage

Sensors

TorqueCurveSelection 06-210-39

06-210-36WheelHousePanel WiringDiagram

6020SeriesMarineEngines .................. 06-210-19

ApplicationSpecifications ........... 06-210-2

WhiteExhaustSmoke ................ 04-150-18

SpecificationsWiringDiagram

ECUTerminalIdentification 06-210-46

MarineEngines 06-210-18

GovernorModeSelection 06-210-45FlyBridgePanel 06-210-20

Sensors 06-210-42

StartingCircuit 06-210-19,06-210-20

TorqueCurveSelection 06-210-44WheelHousePanel 06-210-19

7020Series

ApplicationSpecifications

Specifications

OEMEngines 06-210-28

06-210-2InstrumentPanel 06-210-30

StartingCircuit 06-210-30

ECUTerminalIdentification ....... 06-210-52

GovernorModeSelection ......... 06-210-51

Sensor ....................... 06-210-48

TorqueCurveSelection 06-210-50

TractorTorqueCurveChangeTest

EngineTestInstructions 04-160-27

Tri-StateThrottle

MeasuringThrottlePosition 03-140-12

TroubleCodes

ActiveEngineServiceCodes, Viewing ........................ 04-160-13

Activevs.Inactive .................. 03-140-26

ClearingStoredCodes .............. 03-140-26

DiagnosticProcedure 04-160-56

DisplayFormat 03-140-26

ListofSPN/FMI 04-160-52

Troublecodes

Listingof 04-160-52

TroubleCodes

SPN/FMI 04-160-51

StoredEngineServiceCodes,

Viewing ........................ 04-160-13

TheoryofOperation ................ 04-160-51

WarningLight 03-140-26

2-Digit 04-160-51

3-Digit 04-160-51